Study on the Targeted Improvement Mechanism of the Carrier Concentration and Mobility of BiCuSeO Ceramics

Abstract

1. Introduction

2. Experimental Part

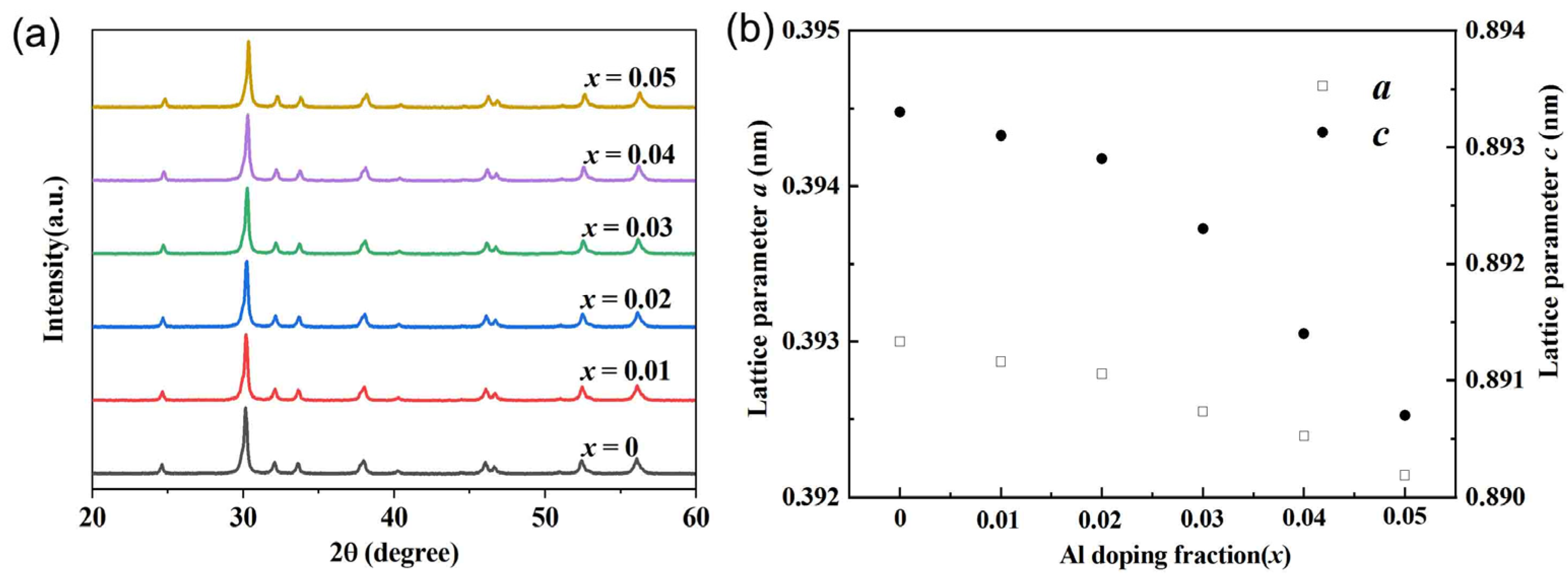

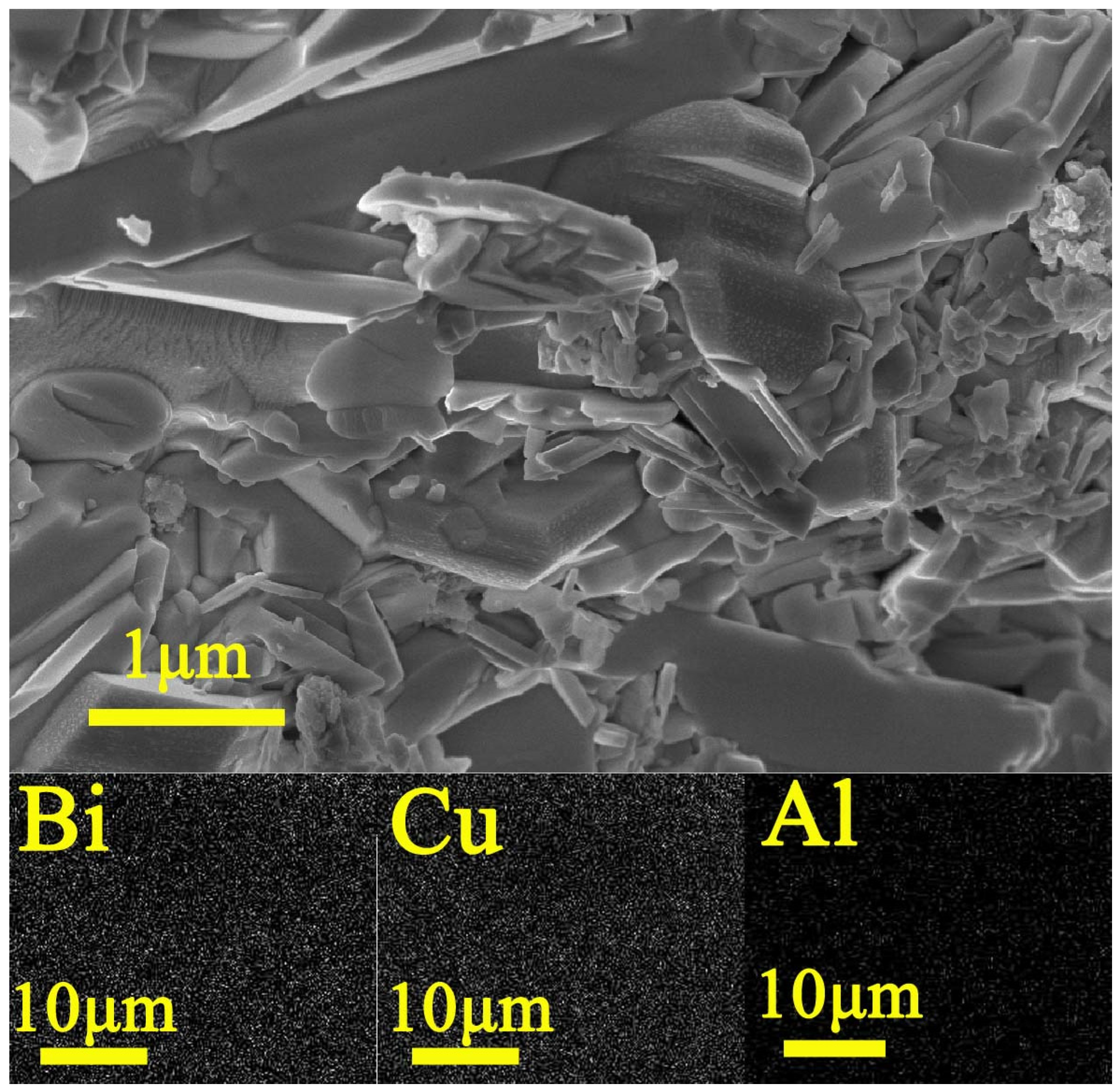

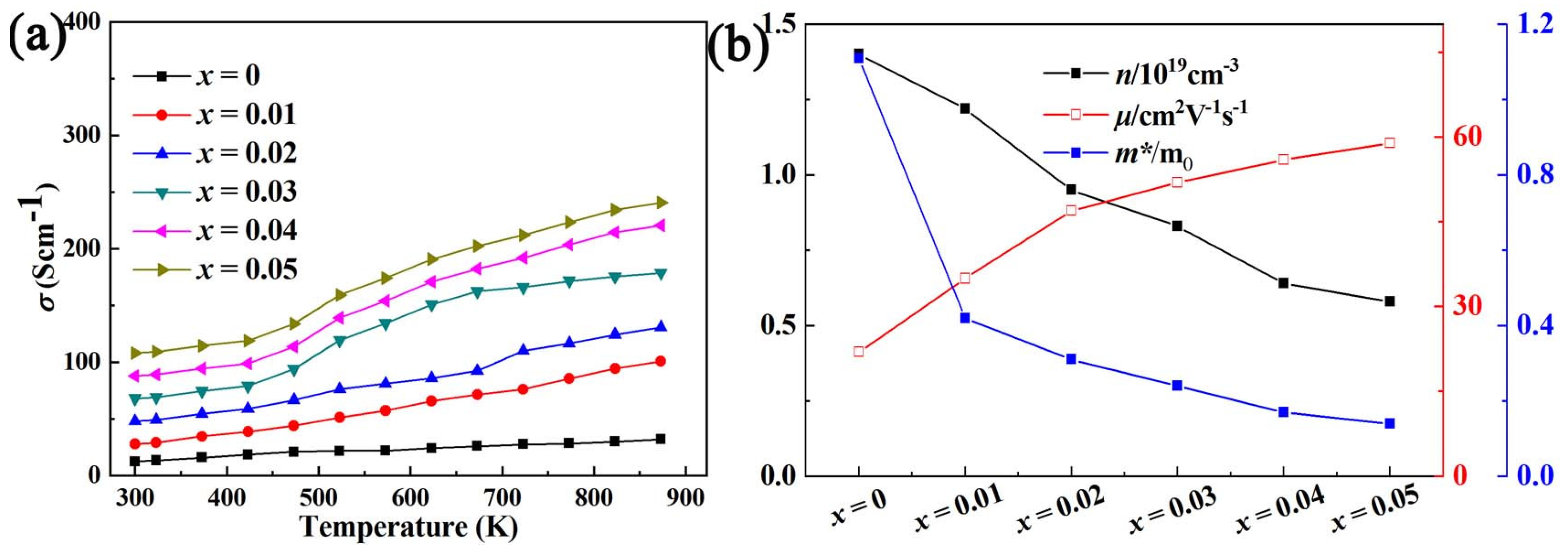

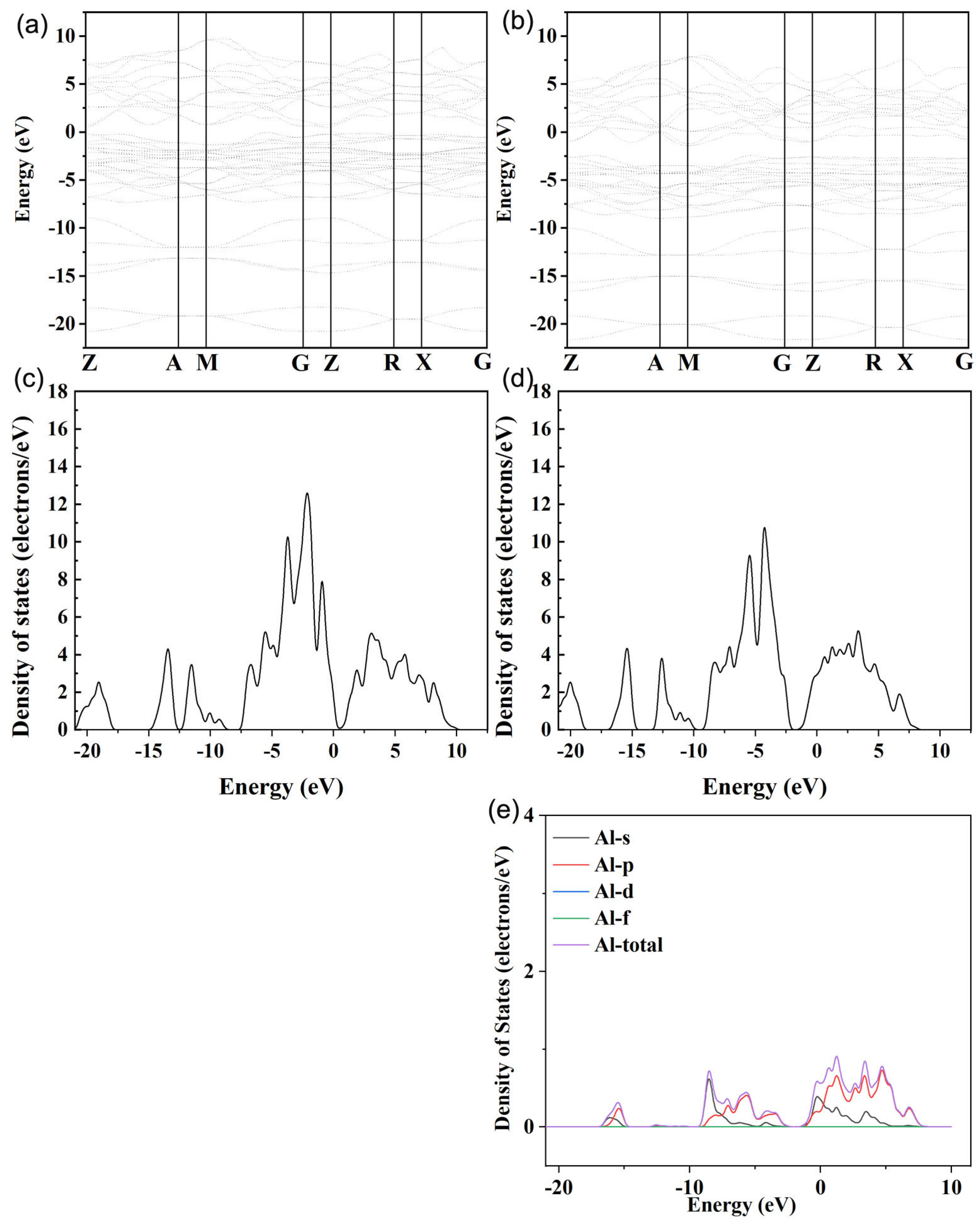

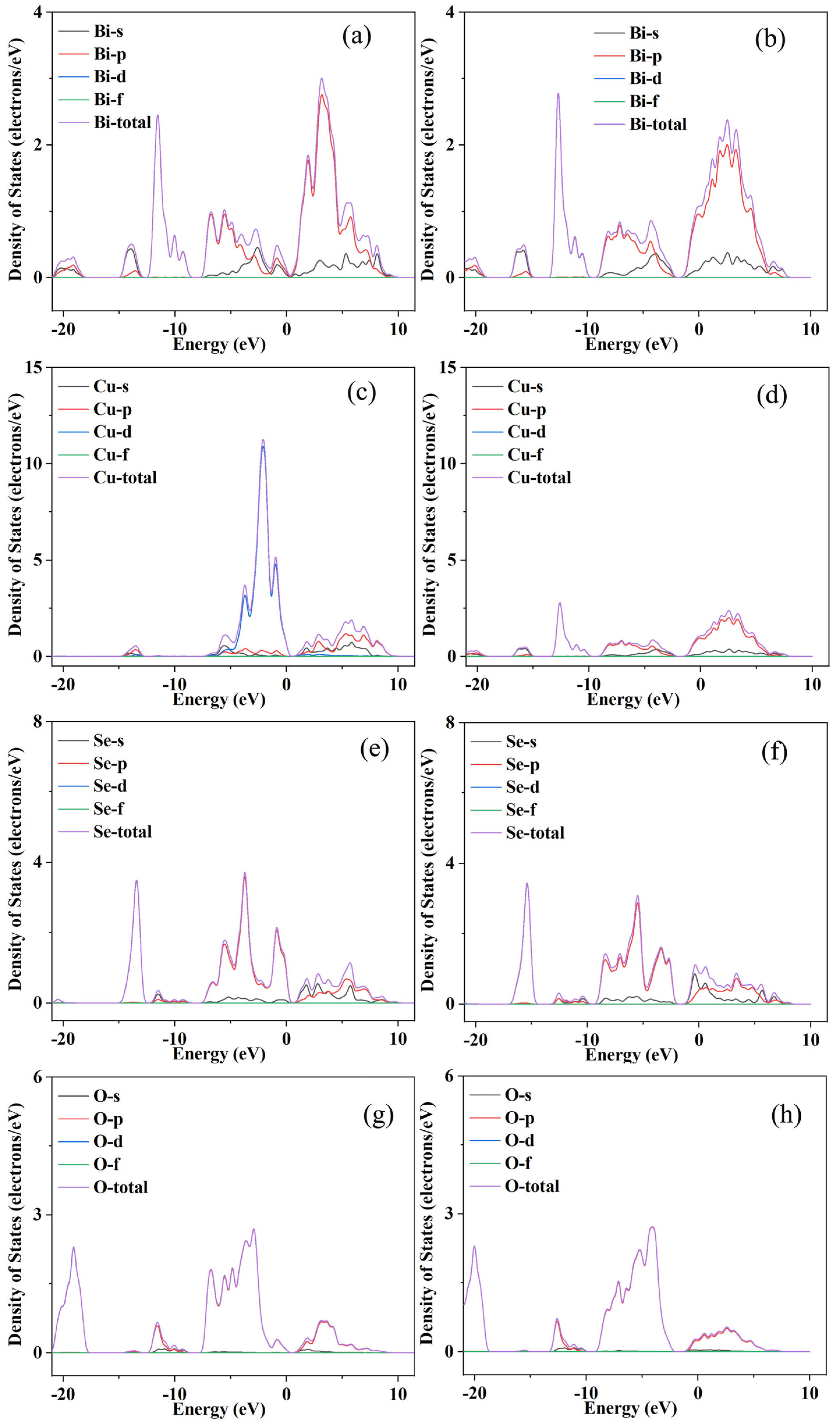

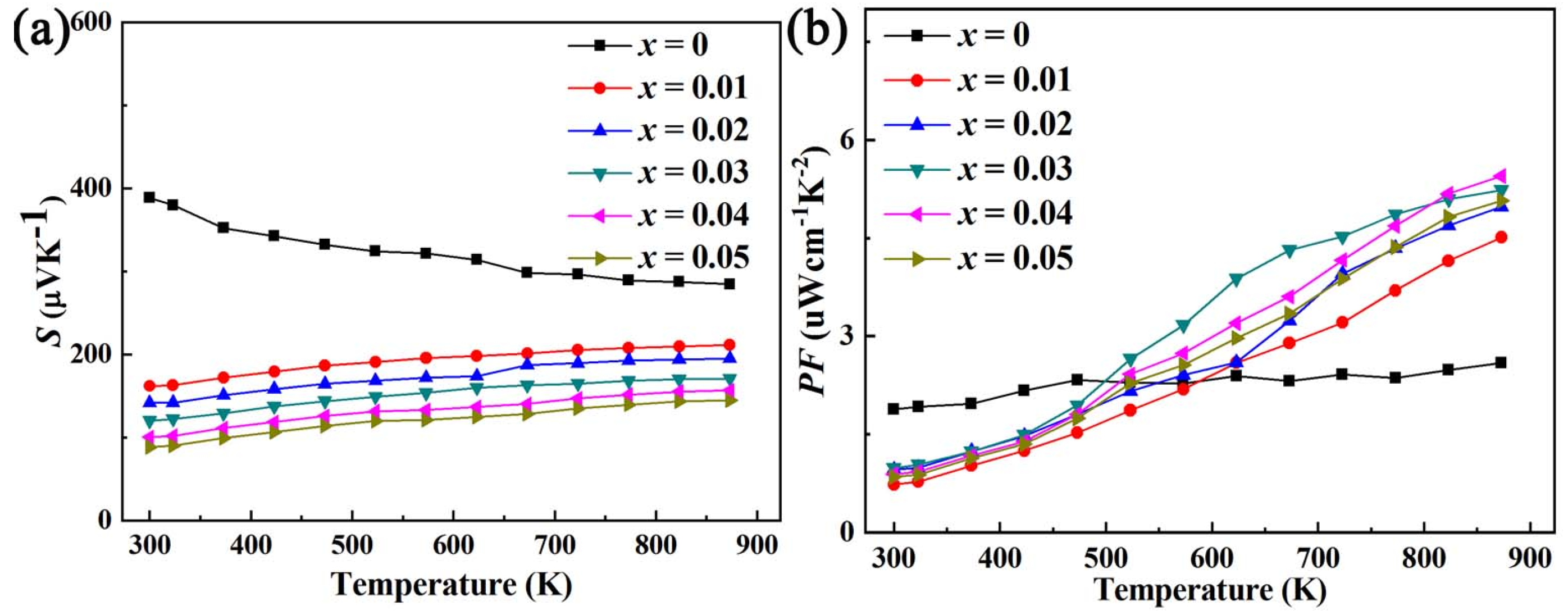

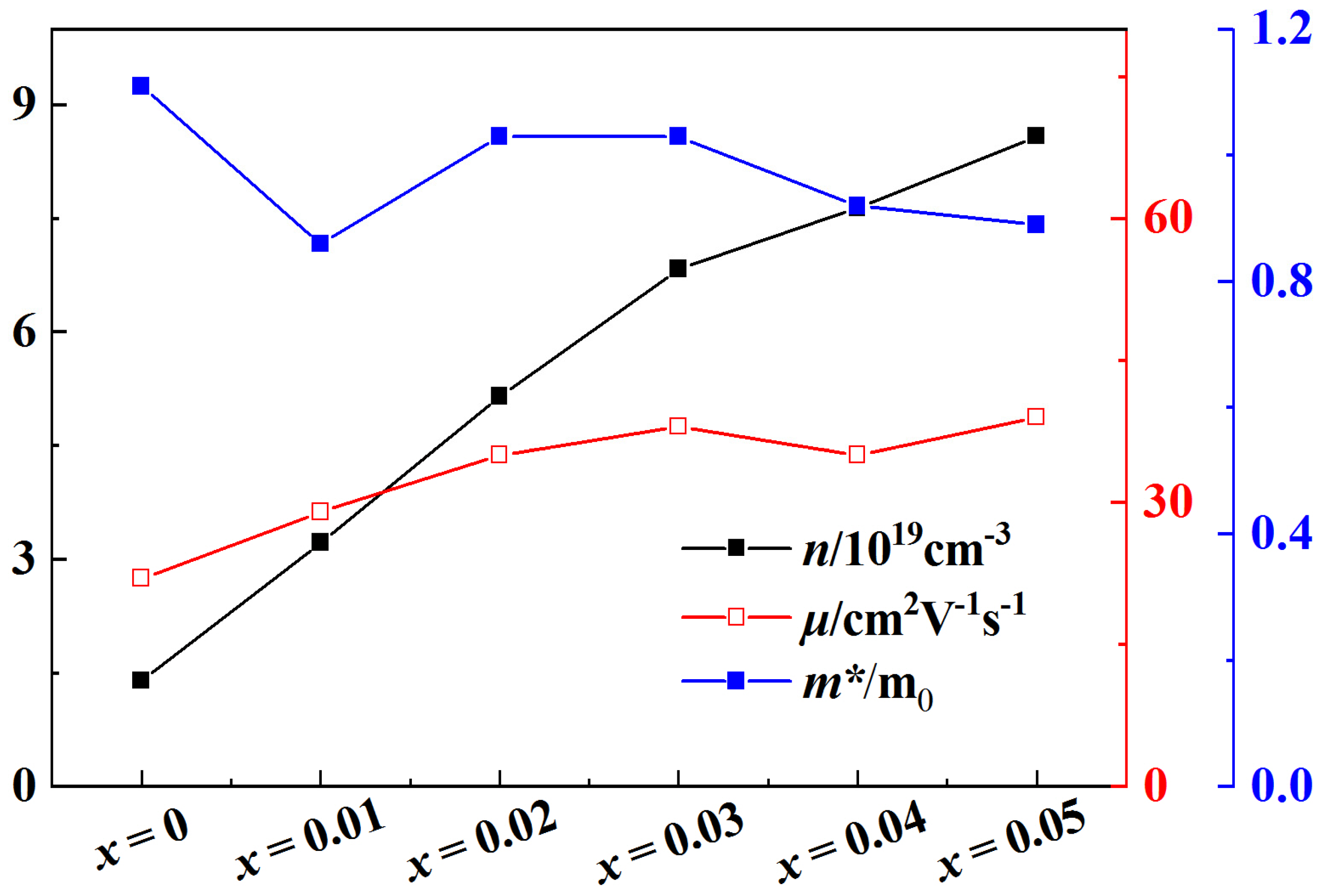

3. Experimental Test Results and Analysis

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Conflicts of Interest

References

- Liu, B.T.; Chien, K.H.; Wang, C.C. Effect of working fluids on organic Rankine cycle for waste heat recovery. Energy 2004, 29, 1207–1217. [Google Scholar] [CrossRef]

- Yin, Y.; Tudu, B.; Tiwari, A. Recent advances in oxide thermoelectric materials and modules. Vacuum 2017, 146, 356–374. [Google Scholar] [CrossRef]

- Moon, J.W.; Masuda, Y.; Seo, W.S.; Koumoto, K. Ca-doped HoCoO3 as p-type oxide thermoelectric material. Mater. Lett. 2001, 48, 225–229. [Google Scholar] [CrossRef]

- Feng, B.; Li, G.; Pan, Z.; Hu, X.; Liu, P.; Li, Y.; He, Z.; Fan, X. Enhanced thermoelectric performances in BiCuSeO oxyselenides via Er and 3D modulation doping. Ceram. Int. 2019, 45, 4493–4498. [Google Scholar] [CrossRef]

- Wu, H.J.; Zhao, L.D.; Zheng, F.S.; Wu, D.; Pei, Y.L.; Tong, X.; Kanatzidis, M.G.; He, J.Q. Broad temperature plateau for thermoelectric figure of merit ZT > 2 in phase-separated PbTe0.7S0.3. Nat. Commun. 2014, 5, 4515. [Google Scholar] [CrossRef]

- Lan, J.L.; Deng, C.; Ma, W.; Ren, G.-K.; Lin, Y.-H.; Yang, X. Ultra-fast synthesis and high thermoelectric properties of heavy sodium doped BiCuSeO. J. Alloys Compd. 2017, 708, 955–960. [Google Scholar] [CrossRef]

- Liu, Y.-C.; Zheng, Y.-H.; Zhan, B.; Chen, K.; Butt, S.; Zhang, B.; Lin, Y.-H. Influence of Ag doping on thermoelectric properties of BiCuSeO. J. Eur. Ceram. Soc. 2015, 35, 845–849. [Google Scholar] [CrossRef]

- Achour, A.; Chen, K.; Reece, M.J.; Huang, Z. Enhanced thermoelectric performance of Cs doped BiCuSeO prepared through eco-friendly flux synthesis. J. Alloys Compd. 2018, 735, 861–869. [Google Scholar] [CrossRef]

- Li, J.; Sui, J.; Barreteau, C.; Berardan, D.; Dragoe, N.; Cai, W.; Pei, Y.; Zhao, L.-D. Thermoelectric properties of Mg doped p-type BiCuSeO oxyselenides. J. Alloys Compd. 2013, 551, 649–653. [Google Scholar] [CrossRef]

- Li, F.; Wei, T.-R.; Kang, F.; Li, J.-F. Enhanced thermoelectric performance of Ca-doped BiCuSeO in a wide temperature range. J. Mater. Chem. A 2013, 1, 11942–11949. [Google Scholar] [CrossRef]

- Barreteau, C.; Bérardan, D.; Amzallag, E.; Zhao, L.; Dragoe, N. Structural and electronic transport properties in Sr-doped BiCuSeO. Chem. Mater. 2012, 24, 3168–3178. [Google Scholar] [CrossRef]

- Li, J.; Sui, J.; Pei, Y.; Barreteau, C.; Berardan, D.; Dragoe, N.; Cai, W.; He, J.; Zhao, L.-D. A high thermoelectric figure of merit ZT > 1 in Ba heavily doped BiCuSeO oxyselenides. Energy Environ. Sci. 2012, 5, 8543–8547. [Google Scholar] [CrossRef]

- Liu, Y.-C.; Lan, J.-L.; Zhan, B.; Ding, J.; Liu, Y.; Lin, Y.-H.; Zhang, B.; Nan, C.-W. Thermoelectric Properties of Pb-Doped BiCuSeO Ceramics. J. Am. Ceram. Soc. 2013, 96, 2710–2713. [Google Scholar] [CrossRef]

- Ren, G.K.; Wang, S.; Zhou, Z.; Li, X.; Yang, J.; Zhang, W.; Lin, Y.-H.; Yang, J.; Nan, C.-W. Complex electronic structure and compositing effect in high performance thermoelectric BiCuSeO. Nat. Commun. 2019, 10, 2814. [Google Scholar] [CrossRef]

- Liu, Y.; Zhao, L.D.; Zhu, Y.; Liu, Y.; Li, F.; Yu, M.; Liu, D.-B.; Xu, W.; Lin, Y.-H.; Nan, C.-W. Synergistically optimizing electrical and thermal transport properties of BiCuSeO via a dual-doping approach. Adv. Energ. Mater. 2016, 6, 1502423. [Google Scholar] [CrossRef]

- Ren, G.K.; Wang, S.Y.; Zhu, Y.C.; Ventura, K.J.; Tan, X.; Xu, W.; Lin, Y.-H.; Yang, J.; Nan, C.-W. Enhancing thermoelectric performance in hierarchically structured BiCuSeO by increasing bond covalency and weakening carrier–phonon coupling. Energy Environ. Sci. 2017, 10, 1590–1599. [Google Scholar] [CrossRef]

- Gu, Y.; Shi, X.; Pan, L.; Liu, W.; Sun, Q.; Tang, X.; Kou, L.; Liu, Q.; Wang, Y.; Chen, Z. Rational electronic and structural designs advance BiCuSeO thermoelectrics. Adv. Funct. Mater. 2021, 31, 2101289. [Google Scholar] [CrossRef]

- De Lyon, T.J.; Woodall, J.M.; Goorsky, M.S.; Kirchner, P.D. Lattice contraction due to carbon doping of GaAs grown by metalorganic molecular beam epitaxy. Appl. Phys. Lett. 1990, 56, 1040–1042. [Google Scholar] [CrossRef][Green Version]

- Feng, B.; Li, G.; Hou, Y.; Zhang, C.; Jiang, C.; Hu, J.; Xiang, Q.; Li, Y.; He, Z.; Fan, X. Enhanced thermoelectric properties of Sb-doped BiCuSeO due to decreased band gap. J. Alloy Compd. 2017, 712, 386–393. [Google Scholar] [CrossRef]

- Liu, Y.; Ding, J.; Xu, B.; Lan, J.; Zheng, Y.; Zhan, B.; Zhang, B.; Lin, Y.; Nan, C. Enhanced thermoelectric performance of La-doped BiCuSeO by tuning band structure. Appl. Phys. Lett. 2015, 106, 233903. [Google Scholar] [CrossRef]

- Ong, K.P.; Singh, D.J.; Wu, P. Analysis of the thermoelectric properties of n-type ZnO. Phys. Rev. B 2011, 83, 115110. [Google Scholar] [CrossRef]

- Xiao, Y.; Wu, H.; Cui, J.; Wang, D.; Fu, L.; Zhang, Y.; Chen, Y.; He, J.; Pennycook, S.J.; Zhao, L.-D. Realizing high performance n-type PbTe by synergistically optimizing effective mass and carrier mobility and suppressing bipolar thermal conductivity. Energy Environ. Sci. 2018, 11, 2486–2495. [Google Scholar] [CrossRef]

- Zhao, L.D.; He, J.; Berardan, D.; Lin, Y.; Li, J.F.; Nan, C.W.; Dragoe, N. BiCuSeO oxyselenides: New promising thermoelectric materials. Energy Environ. Sci. 2014, 7, 2900–2924. [Google Scholar] [CrossRef]

- Ge, Z.H.; Song, D.; Chong, X.; Zheng, F.; Jin, L.; Qian, X.; Zheng, L.; Dunin-Borkowski, R.E.; Qin, P.; Feng, J.; et al. Boosting the thermoelectric performance of (Na, K)-codoped polycrystalline SnSe by synergistic tailoring of the band structure and atomic-scale defect phonon scattering. J. Am. Chem. Soc. 2017, 139, 9714–9720. [Google Scholar] [CrossRef]

- Yang, L.; Chen, Z.-G.; Hong, M.; Wang, L.; Kong, D.; Huang, L.; Han, G.; Zou, Y.; Dargusch, M.; Zou, J. n-type Bi-doped PbTe nanocubes with enhanced thermoelectric performance. Nano Energy 2017, 31, 105–112. [Google Scholar] [CrossRef]

- Lan, J.L.; Liu, Y.C.; Zhan, B.; Lin, Y.-H.; Zhang, B.; Yuan, X.; Zhang, W.; Xu, W.; Nan, C.-W. Enhanced thermoelectric properties of Pb-doped BiCuSeO ceramics. Adv. Mater. 2013, 25, 5086–5090. [Google Scholar] [CrossRef] [PubMed]

- Ren, G.K.; Butt, S.; Ventura, K.J.; Lin, Y.H.; Nan, C.W. Enhanced thermoelectric properties in Pb-doped BiCuSeO oxyselenides prepared by ultrafast synthesis. RSC Adv. 2015, 5, 69878–69885. [Google Scholar] [CrossRef]

- Tang, W.; Ma, W.; Yu, P.; Zhou, Z.; Lan, J.; Lin, Y.-H.; Yang, X. Synergistically Optimized Electron and Phonon Transport of p-type BiCuSeO oxyselenides via Pb dopant and Te composite. Mater. Today Phys. 2022, 28, 100898. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wang, Z.; Zhao, H.; Luo, X.; Han, W.; Wang, H.; Meng, L.; She, X.; Quan, A.; Peng, Y.; Cai, G.; et al. Study on the Targeted Improvement Mechanism of the Carrier Concentration and Mobility of BiCuSeO Ceramics. Micromachines 2023, 14, 1757. https://doi.org/10.3390/mi14091757

Wang Z, Zhao H, Luo X, Han W, Wang H, Meng L, She X, Quan A, Peng Y, Cai G, et al. Study on the Targeted Improvement Mechanism of the Carrier Concentration and Mobility of BiCuSeO Ceramics. Micromachines. 2023; 14(9):1757. https://doi.org/10.3390/mi14091757

Chicago/Turabian StyleWang, Zhibin, Hong Zhao, Xinyu Luo, Wenyuan Han, Hao Wang, Linghao Meng, Xinqi She, Anlong Quan, Yixin Peng, Guoji Cai, and et al. 2023. "Study on the Targeted Improvement Mechanism of the Carrier Concentration and Mobility of BiCuSeO Ceramics" Micromachines 14, no. 9: 1757. https://doi.org/10.3390/mi14091757

APA StyleWang, Z., Zhao, H., Luo, X., Han, W., Wang, H., Meng, L., She, X., Quan, A., Peng, Y., Cai, G., Liu, Y., Tang, Y., & Feng, B. (2023). Study on the Targeted Improvement Mechanism of the Carrier Concentration and Mobility of BiCuSeO Ceramics. Micromachines, 14(9), 1757. https://doi.org/10.3390/mi14091757