A New Elementary Method for Determining the Tip Radius and Young’s Modulus in AFM Spherical Indentations

Abstract

:1. Introduction

2. Materials and Methods

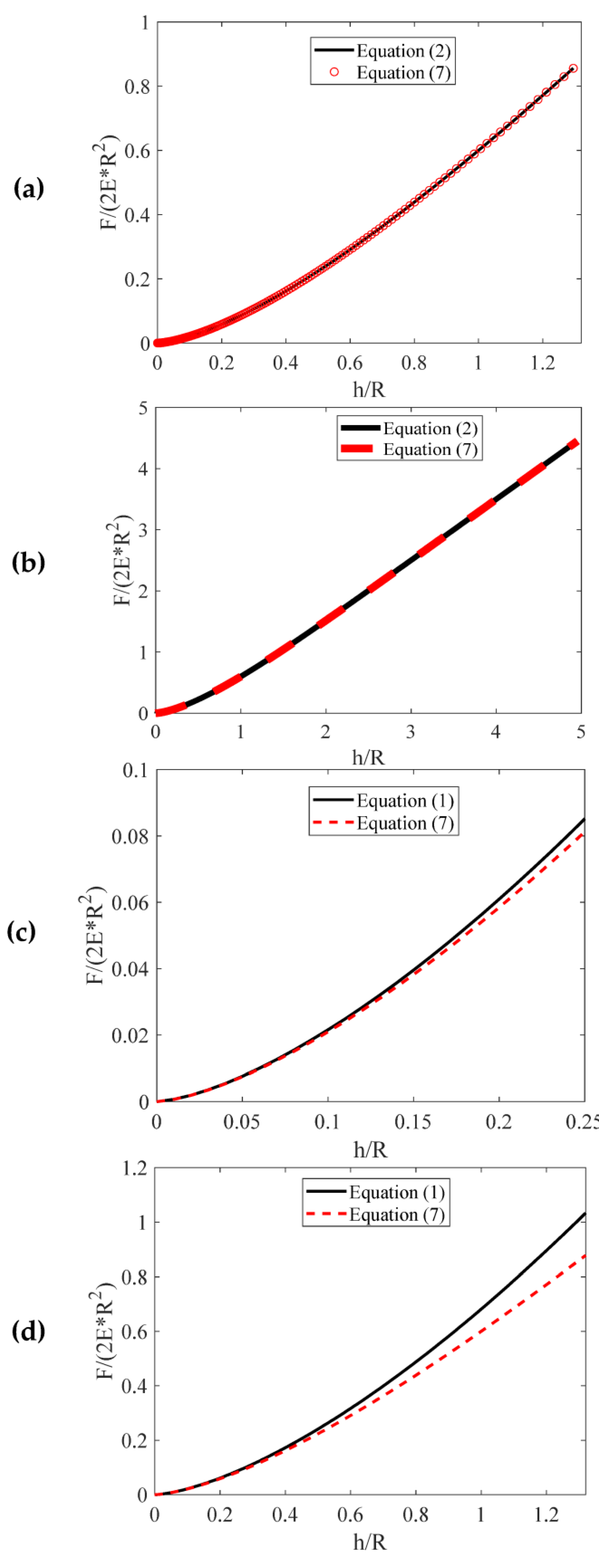

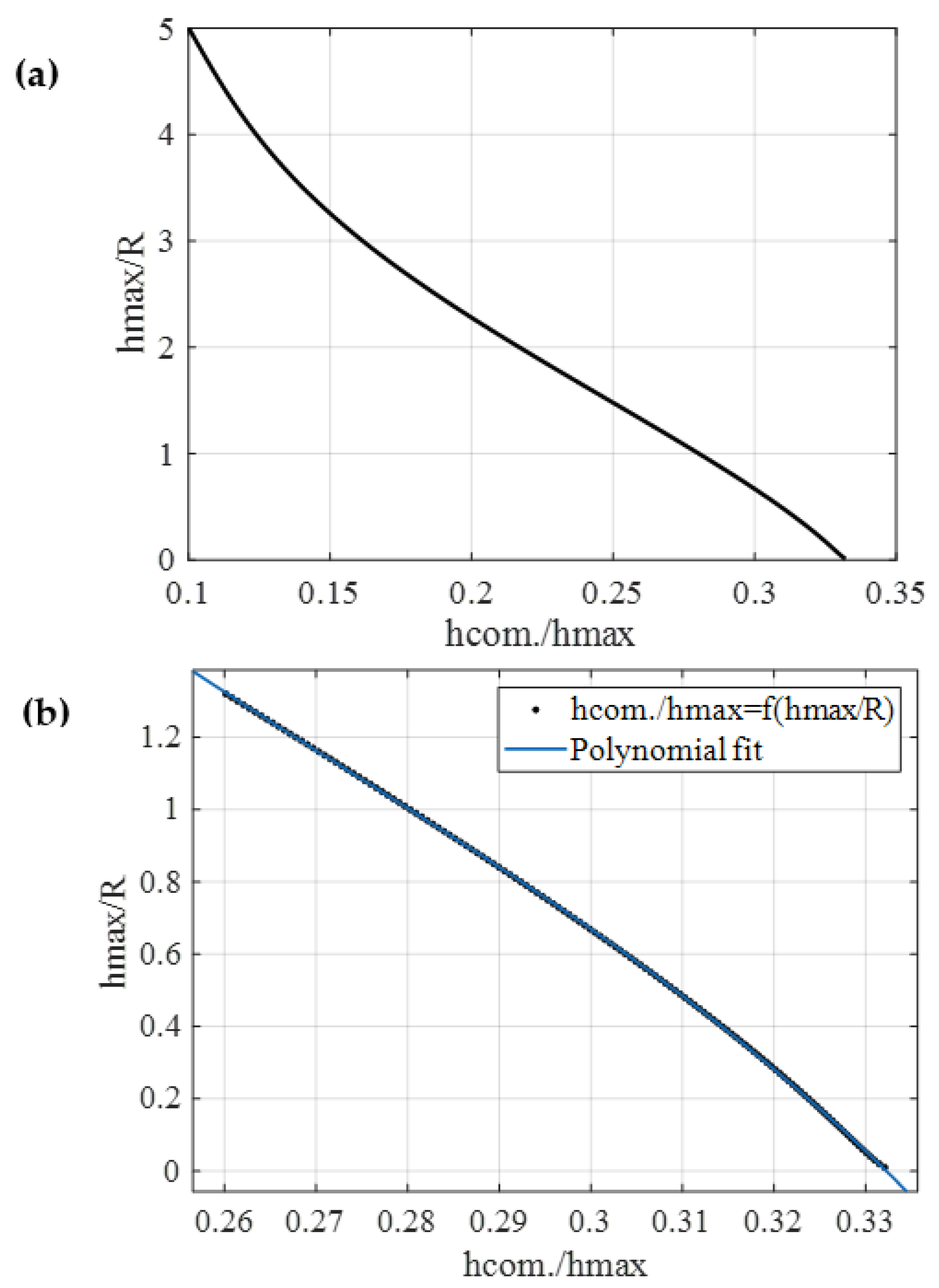

2.1. A New Model for Processing Force—Indentation Curves

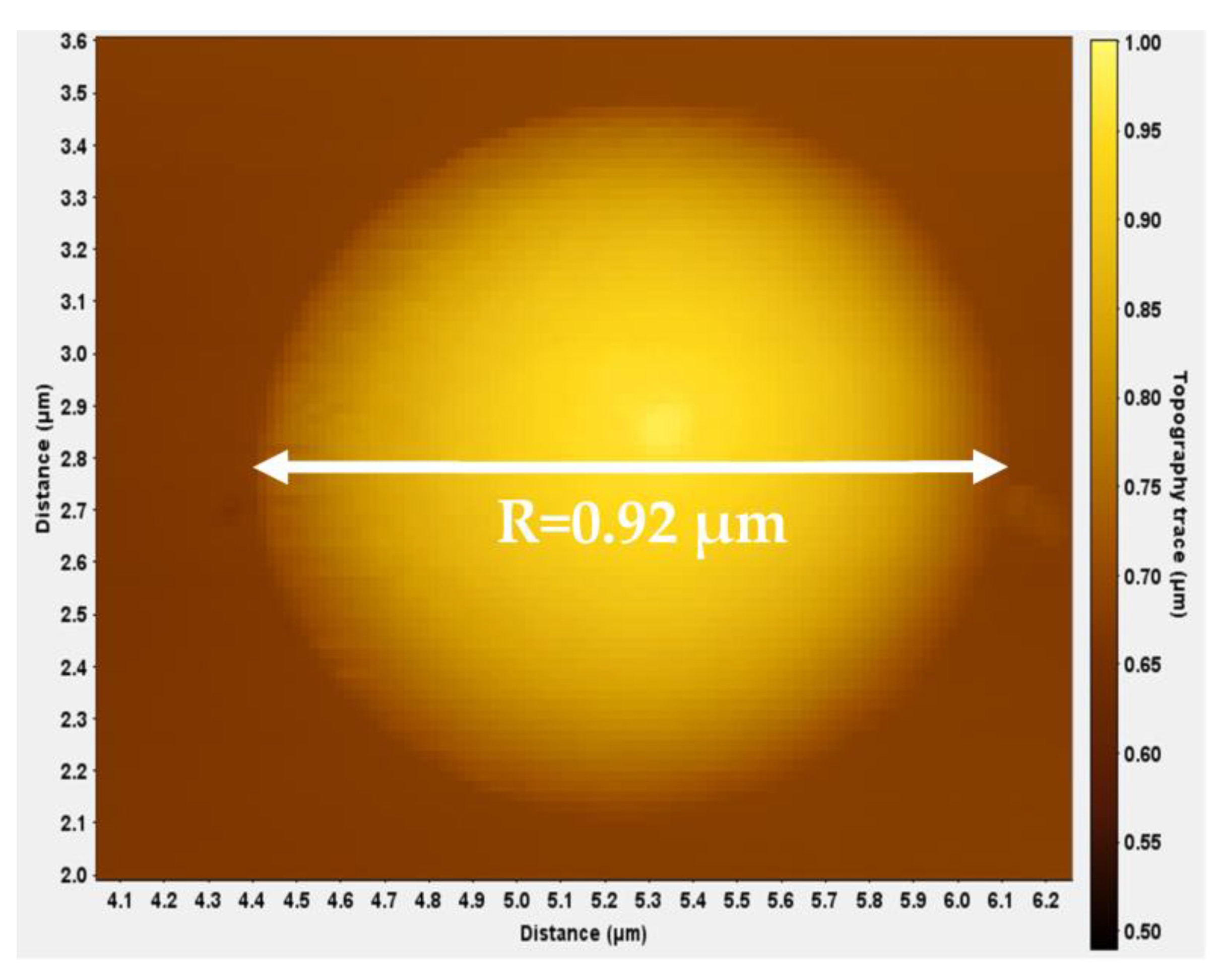

2.2. AFM Indentation Experiments on an Agarose Gel

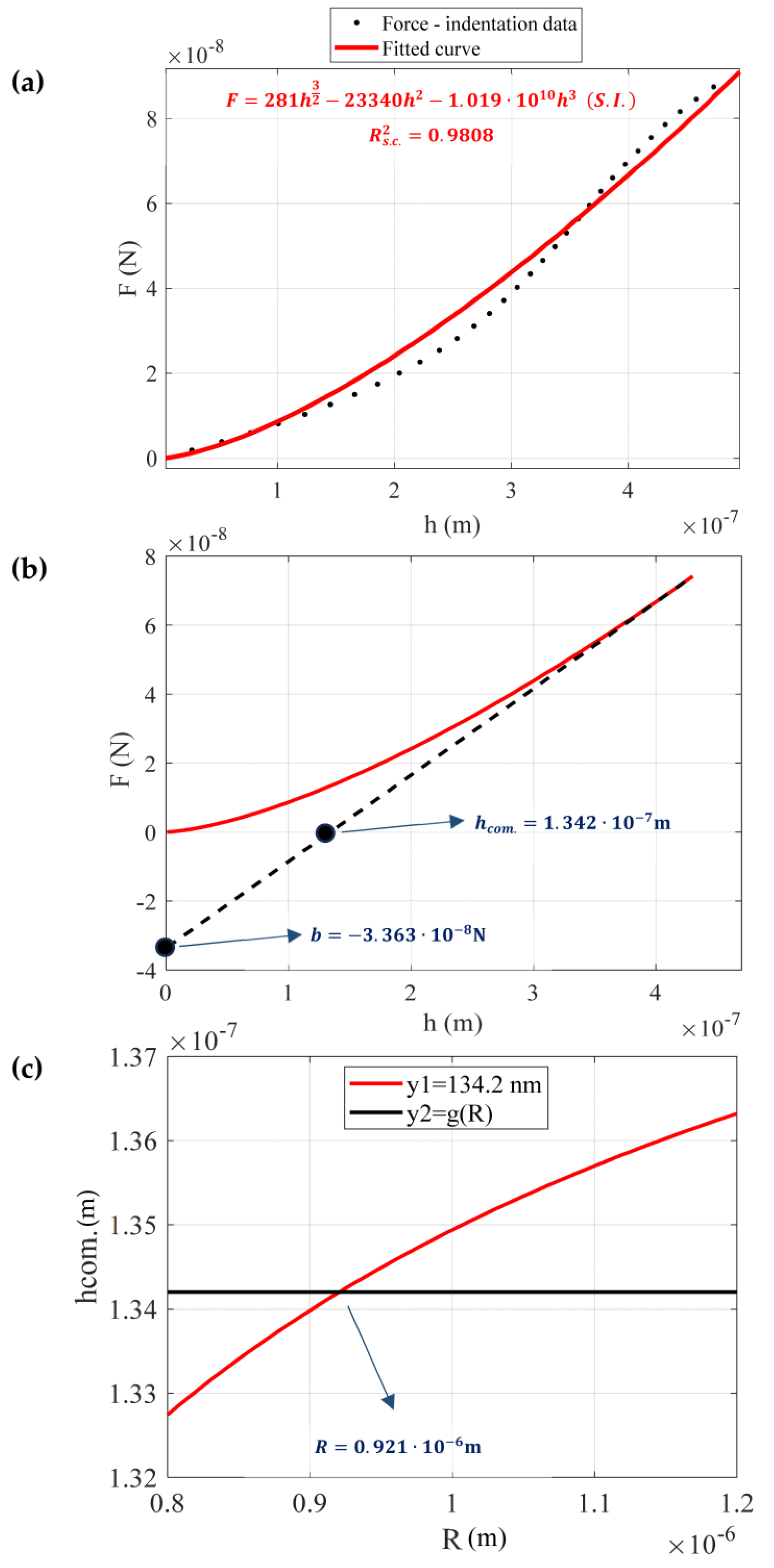

2.2.1. Contact Point Determination

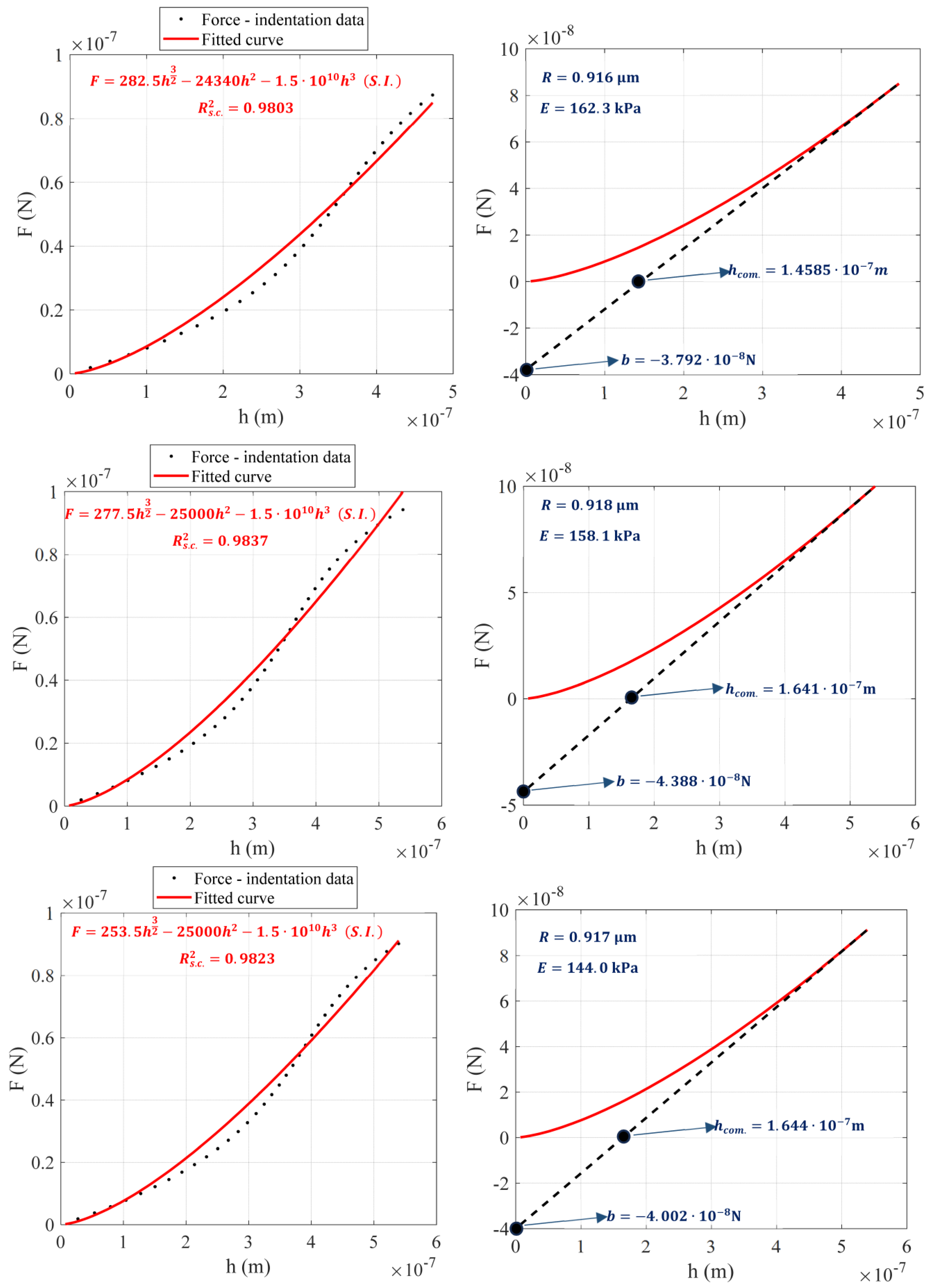

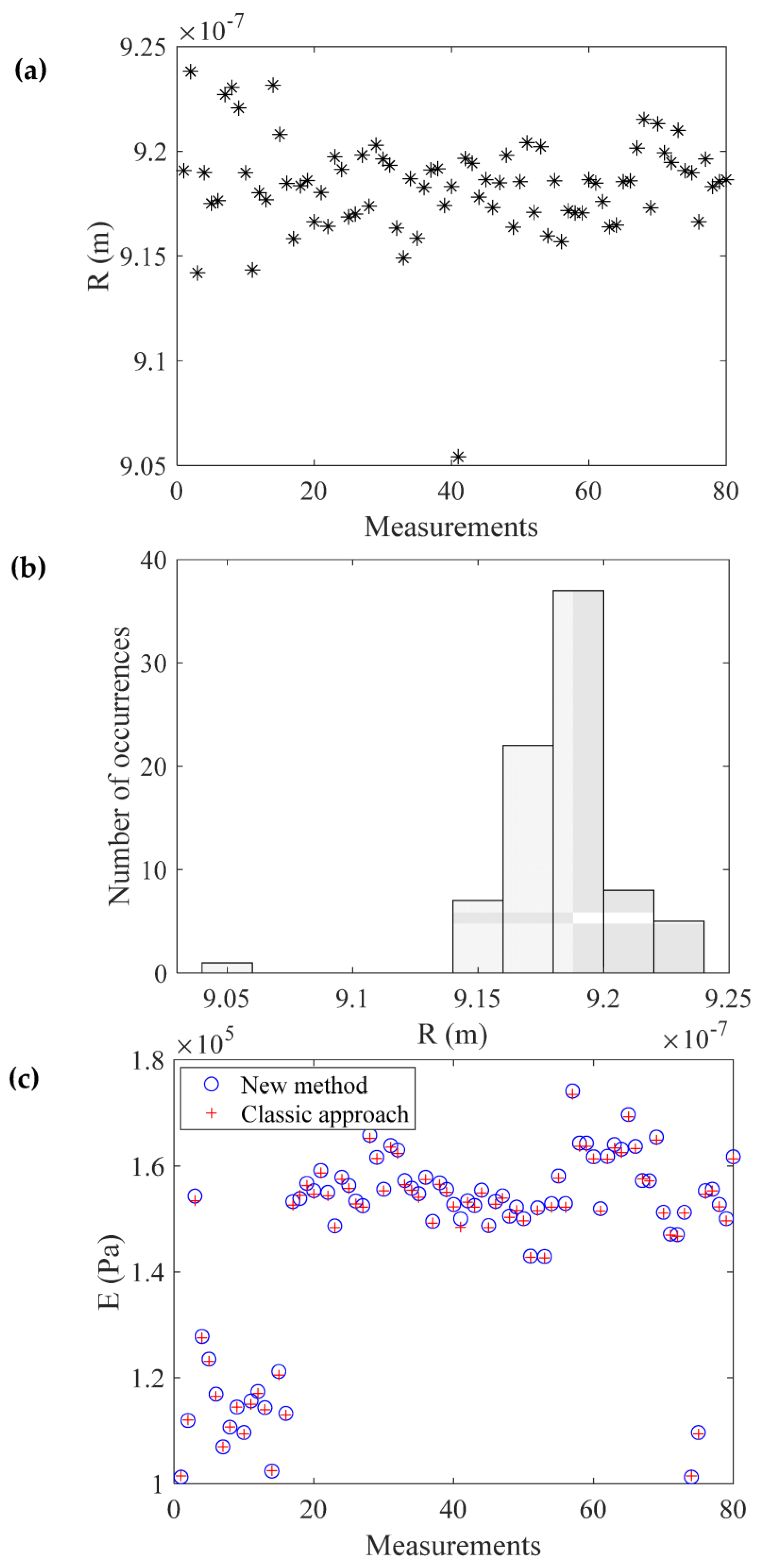

2.2.2. Measurements

3. Results

4. Discussion

5. Conclusions

- Fit the force–indentation data to Equation (17).

- Plot the tangent line of the fitted curve at the maximum indentation depth.

- To calculate the Young’s modulus at the tested point, identify the intersection point between the tangent line and the force axis, and solve either Equations (14) or (20).

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Amabili, M.; Asgari, M.; Breslavsky, I.D.; Franchini, G.; Giovanniello, F.; Holzapfel, G.A. Microstructural and mechanical characterization of the layers of human descending thoracic aortas. Acta Biomater. 2021, 134, 401–421. [Google Scholar] [PubMed]

- Stylianou, A.; Kontomaris, S.V.; Grant, C.; Alexandratou, E. Atomic Force Microscopy on Biological Materials Related to Pathological Conditions. Scanning 2019, 2019, 8452851. [Google Scholar] [CrossRef] [PubMed]

- Stylianou, A.; Lekka, M.; Stylianopoulos, T. AFM assessing of nanomechanical fingerprints for cancer early diagnosis and classification: From single cell to tissue level. Nanoscale 2018, 10, 20930–20945. [Google Scholar] [PubMed]

- Lekka, M. Discrimination between Normal and Cancerous Cells Using AFM. BioNanoScience 2016, 6, 65–80. [Google Scholar]

- Plodinec, M.; Loparic, M.; Monnier, C.A.; Obermann, E.C.; Zanetti-Dallenbach, R.; Oertle, P.; Hyotyla, J.T.; Aebi, U.; Bentires-Alj, M.; Lim, R.Y.; et al. The nanomechanical signature of breast cancer. Nat. Nanotechnol. 2012, 7, 757–765. [Google Scholar] [CrossRef]

- Najera, J.; Rosenberger, M.R.; Datta, M. Atomic Force Microscopy Methods to Measure Tumor Mechanical Properties. Cancers 2023, 15, 3285. [Google Scholar] [CrossRef]

- Stolz, M.; Gottardi, R.; Raiteri, R.; Miot, S.; Martin, I.; Imer, R.; Staufer, U.; Raducanu, A.; Dueggelin, M.; Baschong, W.; et al. Early detection of aging cartilage and osteoarthritis in mice and patient samples using atomic force microscopy. Nat. Nanotechnol. 2009, 4, 186–192. [Google Scholar] [CrossRef]

- Asgari, M.; Latifi, N.; Giovanniello, F.; Espinosa, H.D.; Amabili, M. Revealing Layer-Specific Ultrastructure and Nanomechanics of Fibrillar Collagen in Human Aorta via Atomic Force Microscopy Testing: Implications on Tissue Mechanics at Macroscopic Scale. Adv. NanoBiomed Res. 2022, 2, 2100159. [Google Scholar] [CrossRef]

- Andriotis, O.G.; Manuyakorn, W.; Zekonyte, J.; Katsamenis, O.L.; Fabri, S.; Howarth, P.H.; Davies, D.E.; Thurner, P.J. Nanomechanical assessment of human and murine collagen fibrils via atomic force microscopy cantilever-based nanoindentation. J. Mech. Behav. Biomed. Mater. 2014, 39, 9–26. [Google Scholar]

- Ramalho, R.; Rankovic, S.; Zhou, J.; Aiken, C.; Rousso, I. Analysis of the mechanical properties of wild type and hyperstable mutants of the HIV-1 capsid. Retrovirology 2016, 13, 17. [Google Scholar] [CrossRef]

- Deng, X.; Xiong, F.; Li, X.; Xiang, B.; Li, Z.; Wu, X.; Guo, C.; Li, X.; Li, Y.; Li, G.; et al. Application of atomic force microscopy in cancer research. J. Nanobiotechnol. 2018, 16, 102. [Google Scholar]

- Krieg, M.; Fläschner, G.; Alsteens, D.; Gaub, B.M.; Roos, W.H.; Wuite, G.J.L.; Gaub, H.E.; Gerber, C.; Dufrêne, Y.F.; Müller, D.J. Atomic force microscopy-based mechanobiology. Nat. Rev. Phys. 2019, 1, 41–57. [Google Scholar]

- Puricelli, L.; Galluzzi, M.; Schulte, C.; Podestàa, A.; Milani, P. Nanomechanical and topographical imaging of living cells by atomic force microscopy with colloidal probes. Rev. Sci. Instrum. 2015, 86, 033705. [Google Scholar] [PubMed]

- Wenger, M.P.E.; Bozec, L.; Horton, M.A.; Mesquidaz, P. Mechanical properties of collagen fibrils. Biophys. J. 2007, 93, 1255–1263. [Google Scholar] [CrossRef] [PubMed]

- Kontomaris, S.V.; Malamou, A. A novel approximate method to calculate the force applied on an elastic half space by a rigid sphere. Eur. J. Phys. 2021, 42, 025010. [Google Scholar] [CrossRef]

- Pharr, G.M.; Oliver, W.C.; Brotzen, F.R. On the generality of the relationship among contact stiffness, contact area, and elastic modulus during indentation. J. Mater. Res. 1992, 7, 613–617. [Google Scholar] [CrossRef]

- Nguyen, Q.D.; Chung, K.H. Effect of tip shape on nanomechanical properties measurements using AFM. Ultramicroscopy 2019, 202, 1–9. [Google Scholar]

- Korkmaz, S.; Vahdat, A.S.; Trotsenko, O.; Minko, S.; Babu, S.V. AFM-based study of the interaction forces between ceria, silicon dioxide and polyurethane pad during non-Prestonian polishing of silicon dioxide films. ECS J. Solid State Sci. Technol. 2015, 4, 5016–5020. [Google Scholar] [CrossRef]

- Hermanowicz, P.; Sarna, M.; Burda, K.; Gabryś, H. An open source software for analysis of force curves. Rev. Sci. Instrum. 2014, 85, 063703. [Google Scholar] [CrossRef]

- Stylianou, A.; Gkretsi, V.; Patrickios, C.S.; Stylianopoulos, T. Exploring the Nano-Surface of Collagenous and Other Fibrotic Tissues with AFM. In Fibrosis: Methods and Protocols; Rittié, L., Ed.; Springer: New York, NY, USA, 2017; pp. 453–489. [Google Scholar]

- Hang, J.-T.; Kang, Y.; Xu, G.-K.; Gao, H. A hierarchical cellular structural model to unravel the universal power-law rheological behavior of living cells. Nat. Commun. 2021, 12, 6067. [Google Scholar] [CrossRef]

- Efremov, Y.M.; Wang, W.-H.; Hardy, S.D.; Geahlen, R.L.; Raman, A. Measuring nanoscale viscoelastic parameters of cells directly from AFM force-displacement curves. Sci. Rep. 2017, 7, 1541. [Google Scholar] [PubMed]

- Hang, J.T.; Xu, G.K. Stiffening and softening in the power-law rheological behaviors of cells. J. Mech. Phys. Solids 2022, 167, 104989. [Google Scholar]

- Fernández, P.; Ott, A. Single Cell Mechanics: Stress Stiffening and Kinematic Hardening. Phys. Rev. Lett. 2008, 100, 238102. [Google Scholar] [CrossRef] [PubMed]

| 0.01 | 0.3321 | 0.35 | 0.3168 | 0.68 | 0.2993 |

| 0.02 | 0.3315 | 0.36 | 0.3163 | 0.69 | 0.2987 |

| 0.03 | 0.3310 | 0.37 | 0.3159 | 0.70 | 0.2982 |

| 0.04 | 0.3305 | 0.38 | 0.3154 | 0.71 | 0.2976 |

| 0.05 | 0.3301 | 0.39 | 0.3149 | 0.72 | 0.2970 |

| 0.06 | 0.3297 | 0.40 | 0.3144 | 0.73 | 0.2964 |

| 0.07 | 0.3292 | 0.41 | 0.3139 | 0.74 | 0.2959 |

| 0.08 | 0.3288 | 0.42 | 0.3134 | 0.75 | 0.2953 |

| 0.09 | 0.3284 | 0.43 | 0.3128 | 0.76 | 0.2947 |

| 0.10 | 0.3280 | 0.44 | 0.3123 | 0.77 | 0.2941 |

| 0.11 | 0.3276 | 0.45 | 0.3118 | 0.78 | 0.2935 |

| 0.12 | 0.3272 | 0.46 | 0.3113 | 0.79 | 0.2929 |

| 0.13 | 0.3268 | 0.47 | 0.3108 | 0.80 | 0.2924 |

| 0.14 | 0.3263 | 0.48 | 0.3103 | 0.81 | 0.2918 |

| 0.15 | 0.3259 | 0.49 | 0.3097 | 0.82 | 0.2912 |

| 0.16 | 0.3255 | 0.50 | 0.3092 | 0.83 | 0.2906 |

| 0.17 | 0.3251 | 0.51 | 0.3087 | 0.84 | 0.2900 |

| 0.18 | 0.3246 | 0.52 | 0.3081 | 0.85 | 0.2894 |

| 0.19 | 0.3242 | 0.53 | 0.3076 | 0.86 | 0.2888 |

| 0.20 | 0.3238 | 0.54 | 0.3071 | 0.87 | 0.2882 |

| 0.21 | 0.3233 | 0.55 | 0.3065 | 0.88 | 0.2876 |

| 0.22 | 0.3229 | 0.56 | 0.3060 | 0.80 | 0.2870 |

| 0.23 | 0.3225 | 0.57 | 0.3054 | 0.90 | 0.2864 |

| 0.24 | 0.3220 | 0.58 | 0.3049 | 0.91 | 0.2858 |

| 0.25 | 0.3215 | 0.59 | 0.3043 | 0.92 | 0.2852 |

| 0.26 | 0.3211 | 0.60 | 0.3038 | 0.93 | 0.2846 |

| 0.27 | 0.3206 | 0.61 | 0.3032 | 0.94 | 0.2840 |

| 0.28 | 0.3202 | 0.62 | 0.3027 | 0.95 | 0.2834 |

| 0.29 | 0.3197 | 0.63 | 0.3021 | 0.96 | 0.2827 |

| 0.30 | 0.3192 | 0.64 | 0.3016 | 0.97 | 0.2821 |

| 0.31 | 0.3188 | 0.65 | 0.3010 | 0.98 | 0.2815 |

| 0.32 | 0.3183 | 0.66 | 0.3004 | 0.99 | 0.2809 |

| 0.33 | 0.3178 | 0.67 | 0.2999 | 1.00 | 0.2802 |

| 0.34 | 0.3173 |

| 0.05 | 0.3301 | 1.75 | 0.2326 | 3.40 | 0.1443 |

| 0.10 | 0.3280 | 1.80 | 0.2294 | 3.45 | 0.1424 |

| 0.15 | 0.3259 | 1.85 | 0.2263 | 3.50 | 0.1405 |

| 0.20 | 0.3238 | 1.90 | 0.2231 | 3.55 | 0.1386 |

| 0.25 | 0.3216 | 1.95 | 0.2200 | 3.60 | 0.1368 |

| 0.30 | 0.3192 | 2.00 | 0.2169 | 3.65 | 0.1351 |

| 0.35 | 0.3168 | 2.05 | 0.2138 | 3.70 | 0.1334 |

| 0.40 | 0.3144 | 2.10 | 0.2107 | 3.75 | 0.1317 |

| 0.45 | 0.3118 | 2.15 | 0.2077 | 3.80 | 0.1301 |

| 0.50 | 0.3092 | 2.20 | 0.2047 | 3.85 | 0.1285 |

| 0.55 | 0.3065 | 2.25 | 0.2017 | 3.90 | 0.1269 |

| 0.60 | 0.3039 | 2.30 | 0.1988 | 3.95 | 0.1254 |

| 0.65 | 0.3010 | 2.35 | 0.1959 | 4.00 | 0.1240 |

| 0.70 | 0.2982 | 2.40 | 0.1930 | 4.05 | 0.1225 |

| 0.75 | 0.2953 | 2.45 | 0.1901 | 4.10 | 0.1211 |

| 0.80 | 0.2924 | 2.50 | 0.1873 | 4.15 | 0.1198 |

| 0.85 | 0.2894 | 2.55 | 0.1845 | 4.20 | 0.1185 |

| 0.90 | 0.2864 | 2.60 | 0.1818 | 4.25 | 0.1172 |

| 0.95 | 0.2834 | 2.65 | 0.1791 | 4.30 | 0.1159 |

| 1.00 | 0.2803 | 2.70 | 0.1765 | 4.35 | 0.1147 |

| 1.05 | 0.2772 | 2.75 | 0.1739 | 4.40 | 0.1134 |

| 1.10 | 0.2741 | 2.80 | 0.1713 | 4.45 | 0.1122 |

| 1.15 | 0.2709 | 2.85 | 0.1688 | 4.50 | 0.1111 |

| 1.20 | 0.2678 | 2.90 | 0.1663 | 4.55 | 0.1099 |

| 1.25 | 0.2646 | 2.95 | 0.1639 | 4.60 | 0.1088 |

| 1.30 | 0.2614 | 3.00 | 0.1616 | 4.65 | 0.1077 |

| 1.35 | 0.2582 | 3.05 | 0.1592 | 4.70 | 0.1066 |

| 1.40 | 0.2550 | 3.10 | 0.1570 | 4.75 | 0.1055 |

| 1.45 | 0.2518 | 3.15 | 0.1547 | 4.80 | 0.1044 |

| 1.50 | 0.2486 | 3.20 | 0.1525 | 4.85 | 0.1033 |

| 1.55 | 0.2454 | 3.25 | 0.1504 | 4.90 | 0.1023 |

| 1.60 | 0.2422 | 3.30 | 0.1483 | 4.95 | 0.1012 |

| 1.65 | 0.2390 | 3.35 | 0.1463 | 5.00 | 0.1002 |

| 1.70 | 0.2358 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kontomaris, S.V.; Stylianou, A.; Chliveros, G.; Malamou, A. A New Elementary Method for Determining the Tip Radius and Young’s Modulus in AFM Spherical Indentations. Micromachines 2023, 14, 1716. https://doi.org/10.3390/mi14091716

Kontomaris SV, Stylianou A, Chliveros G, Malamou A. A New Elementary Method for Determining the Tip Radius and Young’s Modulus in AFM Spherical Indentations. Micromachines. 2023; 14(9):1716. https://doi.org/10.3390/mi14091716

Chicago/Turabian StyleKontomaris, Stylianos Vasileios, Andreas Stylianou, Georgios Chliveros, and Anna Malamou. 2023. "A New Elementary Method for Determining the Tip Radius and Young’s Modulus in AFM Spherical Indentations" Micromachines 14, no. 9: 1716. https://doi.org/10.3390/mi14091716

APA StyleKontomaris, S. V., Stylianou, A., Chliveros, G., & Malamou, A. (2023). A New Elementary Method for Determining the Tip Radius and Young’s Modulus in AFM Spherical Indentations. Micromachines, 14(9), 1716. https://doi.org/10.3390/mi14091716