Experimental Research of High-Quality Drilling Based on Ultrasonic Vibration-Assisted Machining

Abstract

1. Introduction

- (1)

- Drilling holes is one of most commonly used hole-machining methods in the field of machining, with its simple implementation, high machining efficiency, good dimensional accuracy, and low machining cost [8,9]. For holes with large diameters, small, deep diameters, and low accuracy requirements, drilling machining methods can generally meet machining requirements [10]. However, the drill bit is in a semi-closed state during the drilling process, which makes chip removal very difficult and prone to chip clogging. In addition, when the drill rotates fast, the machining gap is small, and the machining depth is large, the cooling medium does not easily enter the machining area, and it is difficult to cool and lubricate the drill, which increases the temperature of the drilling area and causes serious wear of drill, resulting in poor machining accuracy and easy damage to drill [11,12,13]. For hospital stainless steel, titanium alloy, and/or high hardness materials below 0.5 high-precision, small-hole machining is limited by drill strength, tool diameter, table drill speed requirements and/or conditions, and no effective drilling machining means to achieve rapid machining of micro-hole.

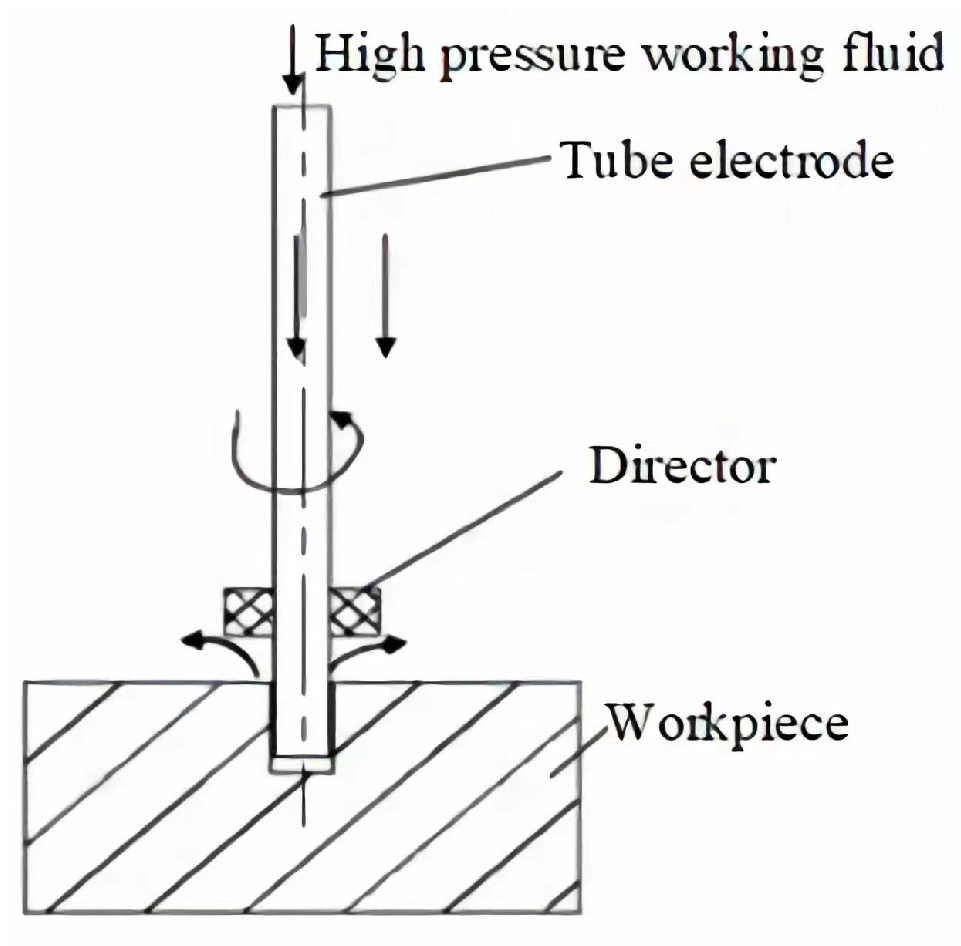

- (2)

- EDM perforation is the main machining method for machining large depth-to-diameter ratio deep small holes, which can process any conductive materials, such as titanium alloys, nickel-based high-temperature alloys, and/or difficult-to-machine materials, and has a wide range of applications in aerospace manufacturing [14,15,16,17]. EDM perforation mainly uses tubular electrodes that can perform high-pressure punching, and timely renewal and rapid discharge of galvanic corrosion products from the machining area, which enables efficient batch production of deep and small holes. A schematic diagram of EDM perforation is shown in Figure 1. However, in EDM deep small hole machining, the tool electrode cross-sectional area is small and under the influence of high-pressure punching fluid, irregular vibration is easily generated during the machining process; with an increase of hole machining depth, there are also problems such as heat dissipation, chip removal, and guiding difficulties, poor stability, high roughness, poor straightness, and low-dimensional accuracy [18,19,20,21]. At the same time, due to high-temperature melt removal material, hole walls often have re-microcracks, heat-affected zones, and recast layers [22], which cannot meet micro-hole quality requirements for high-temperature and high-pressure harsh environment work and require or means to improve machining surface quality and remove recast layers.

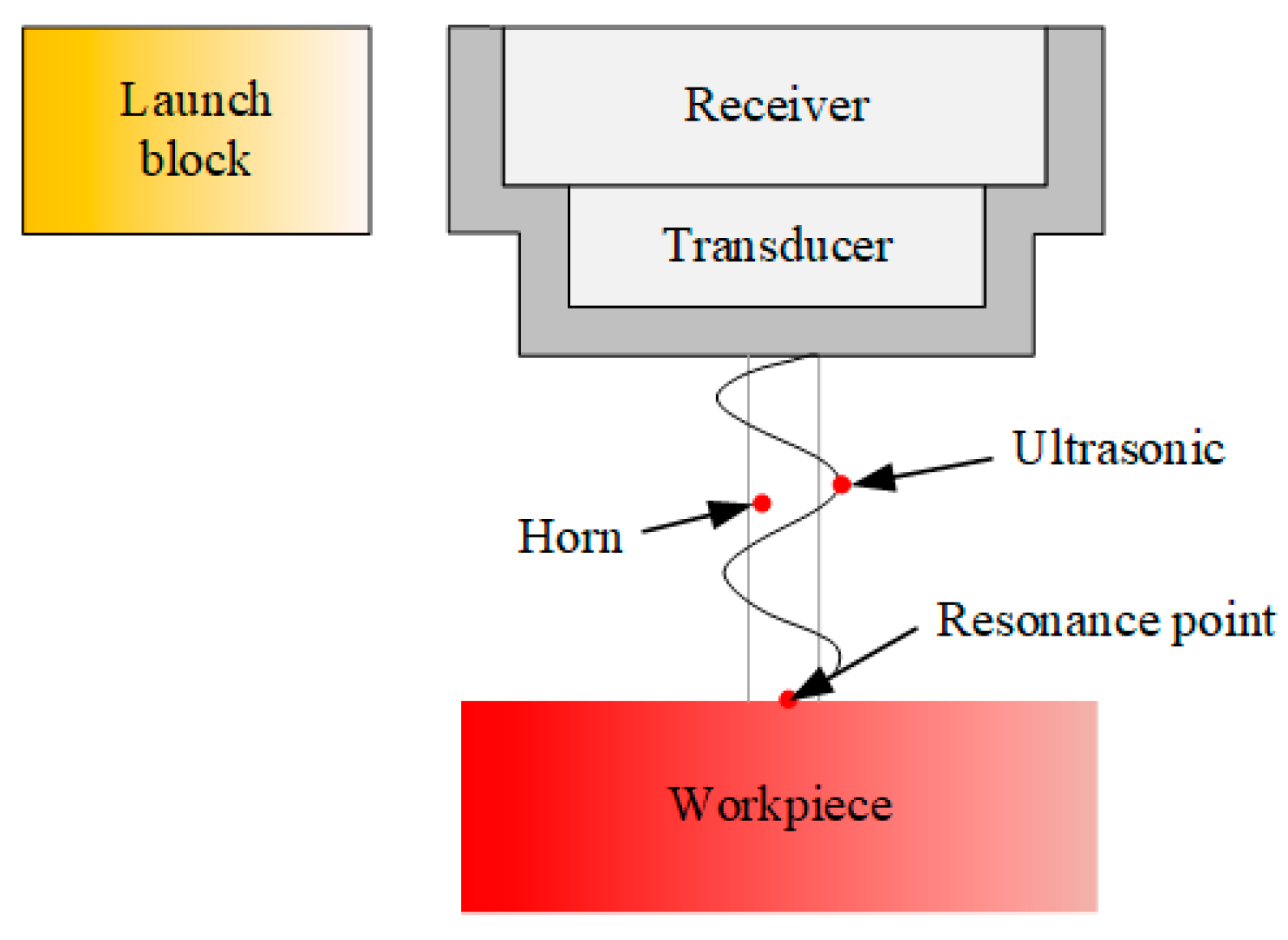

2. Ultrasonic Cutting Technology

2.1. Ultrasonic Machining Principle

- (a)

- Kinetic energy: E = 1/2 mv2 (speed between 104~105 m/s);

- (b)

- Amplitude: 1~20 μm (small amplitude, will not affect machining accuracy);

- (c)

- Frequency: 20 kHz~50 kHz (High-frequency impact material, break material first, and remove it);

- (d)

- Cavitation: After contacting the tool, coolant forms a local negative pressure zone under the action of ultrasonic waves, causing rapid expansion of liquid interface and rupture, resulting in micro-excitation waves (5 × 107 Pa high pressure, 4 KM jet stream).

2.2. Principle of Ultrasonic Machining System

2.3. Ultrasonic Vibration-Assisted Drilling Motion Trajectory Model

3. Ultrasonic Experimental Platform

3.1. Experimental Systems

3.2. Experimental Equipment

4. Micro-Hole Machining Test Analysis

4.1. Experimental Parameters

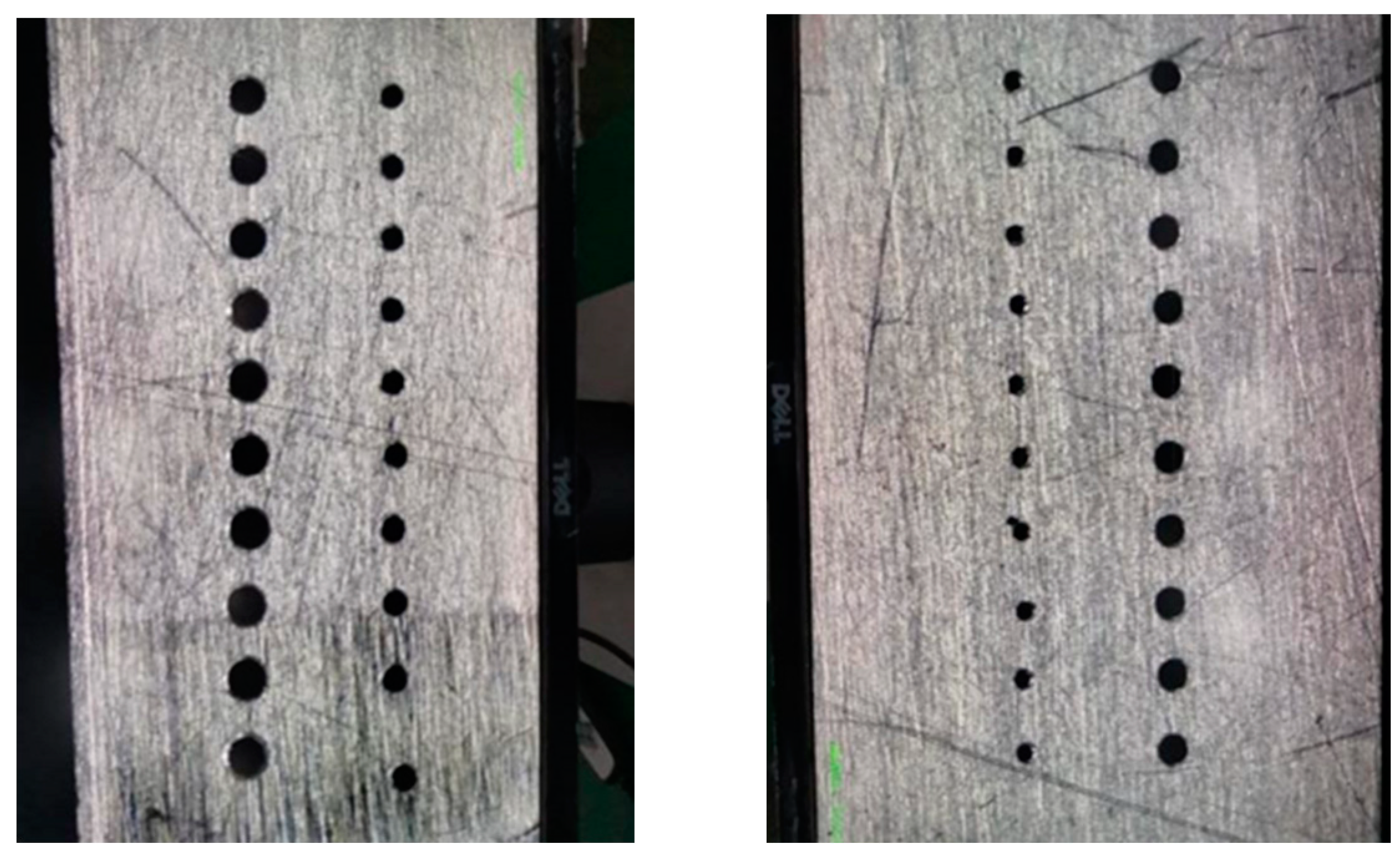

4.2. GH4169 Experimental Analysis of Plate Aperture Machining

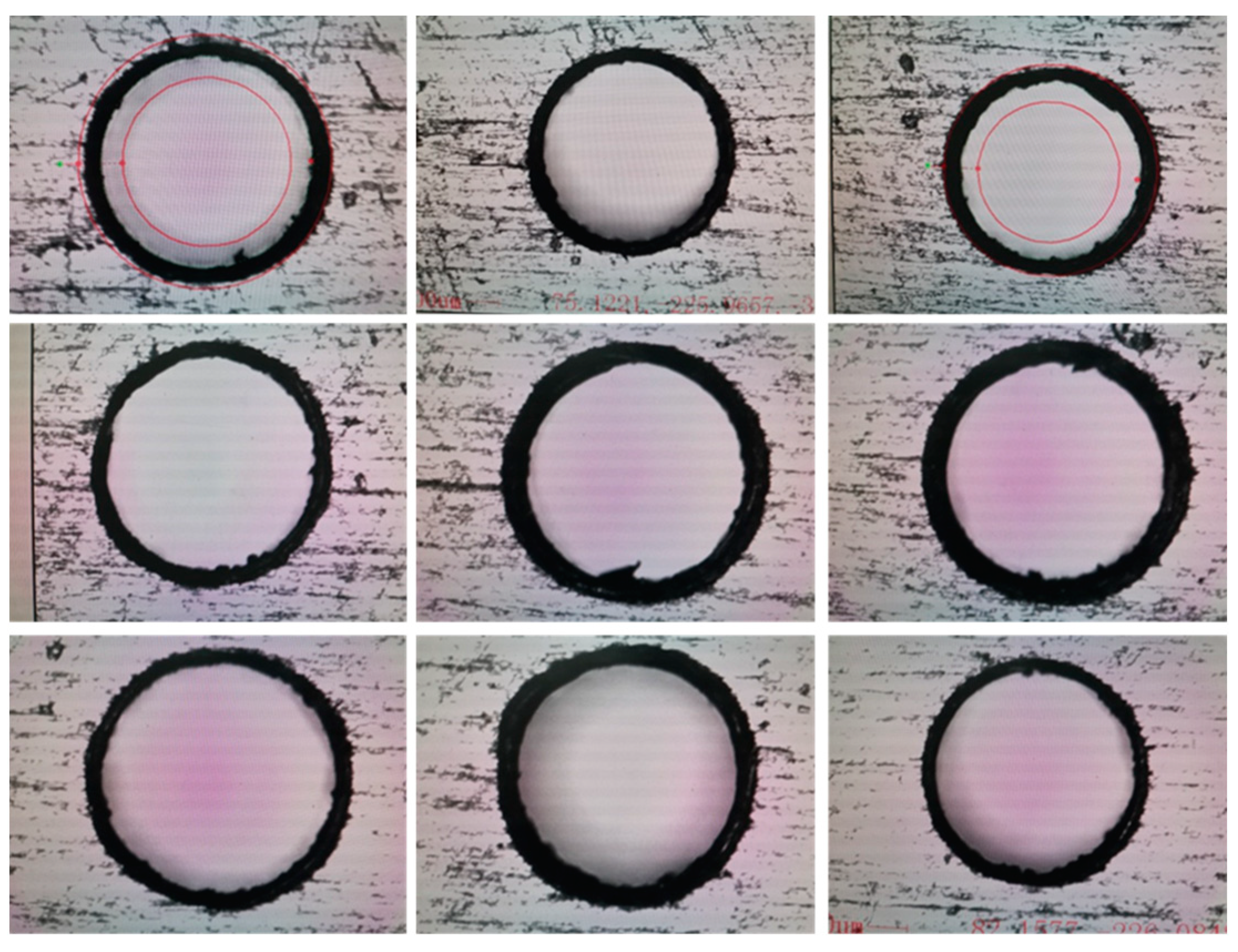

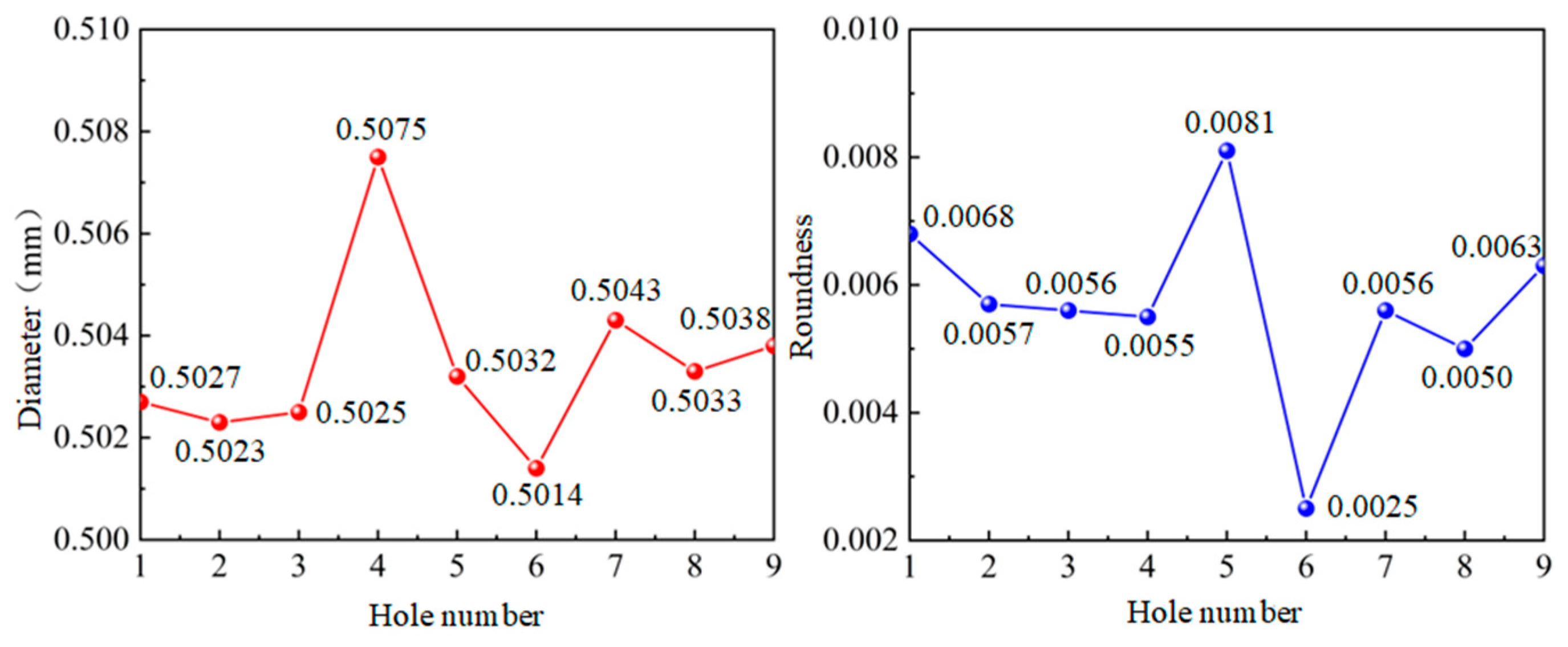

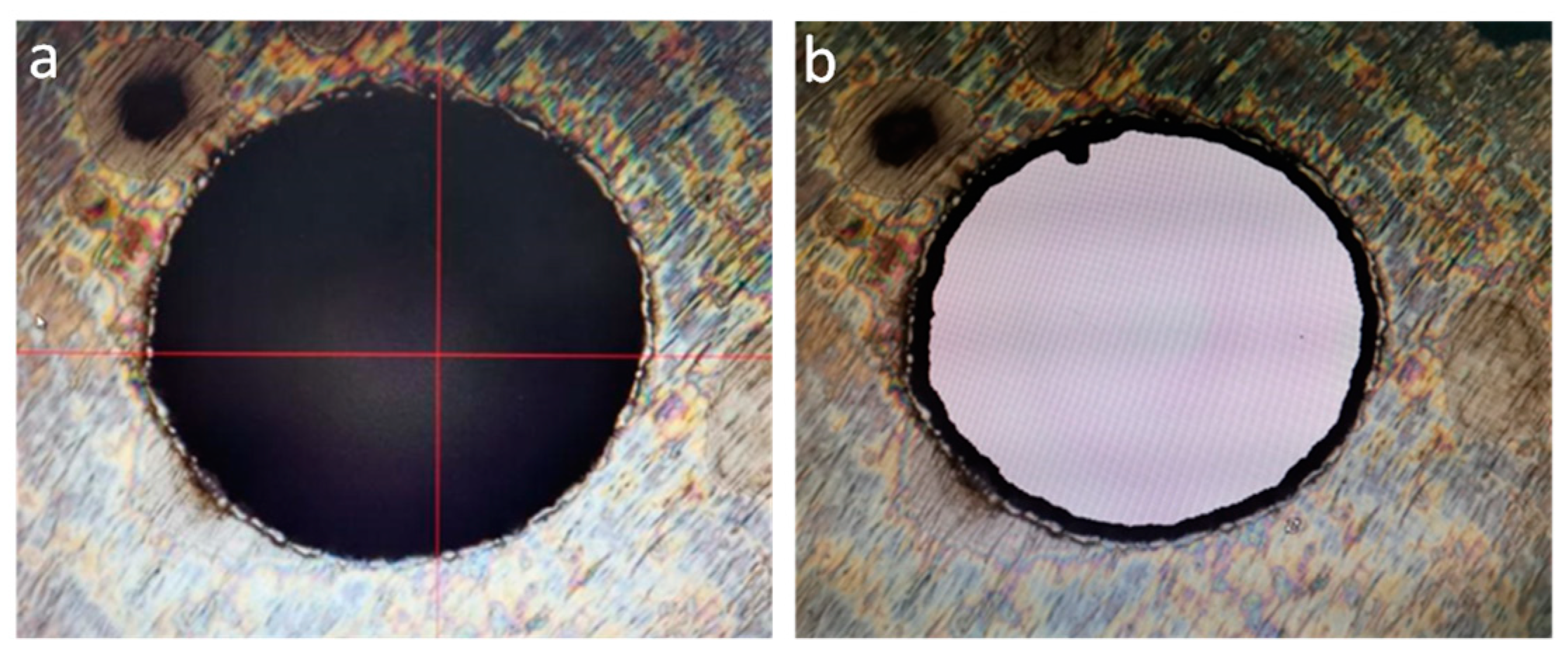

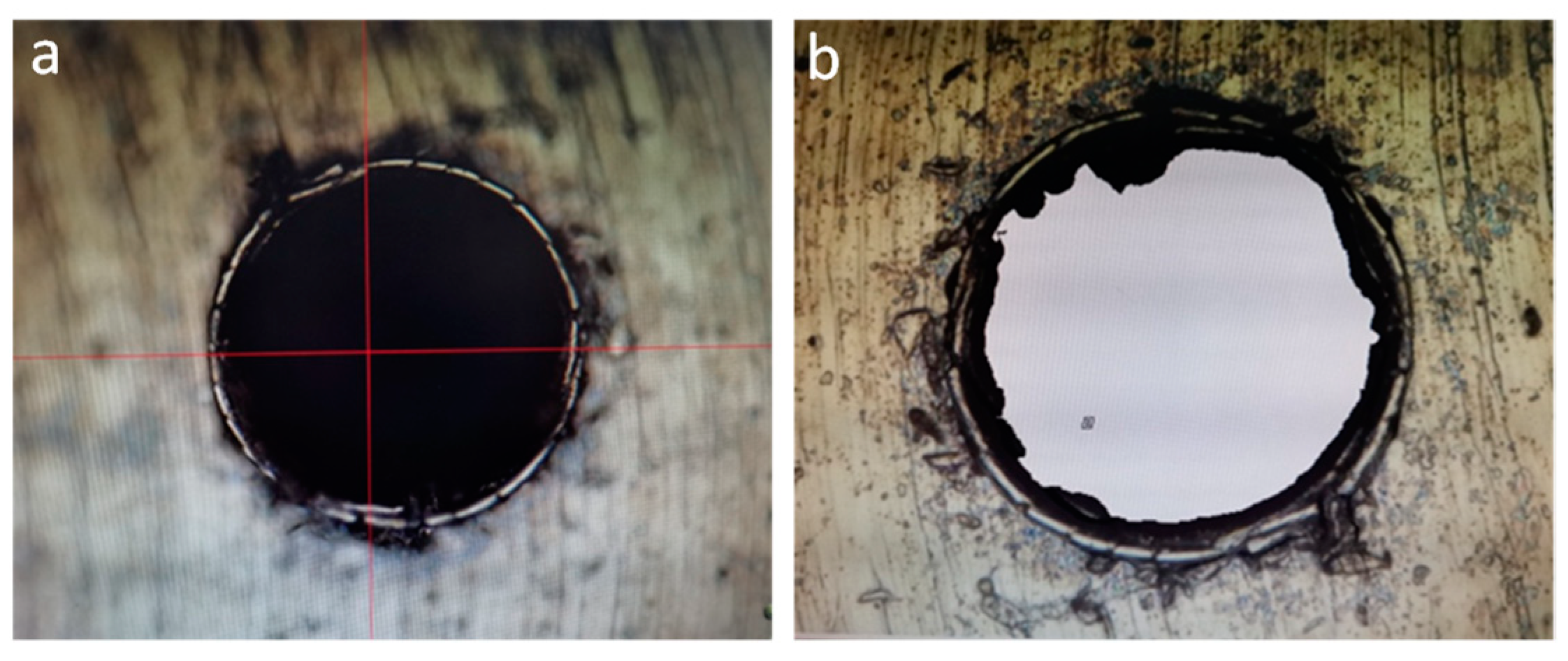

4.2.1. Ultrasonic Machining Results of 0.5 mm Micro-Hole on GH4169 Plate and Analysis

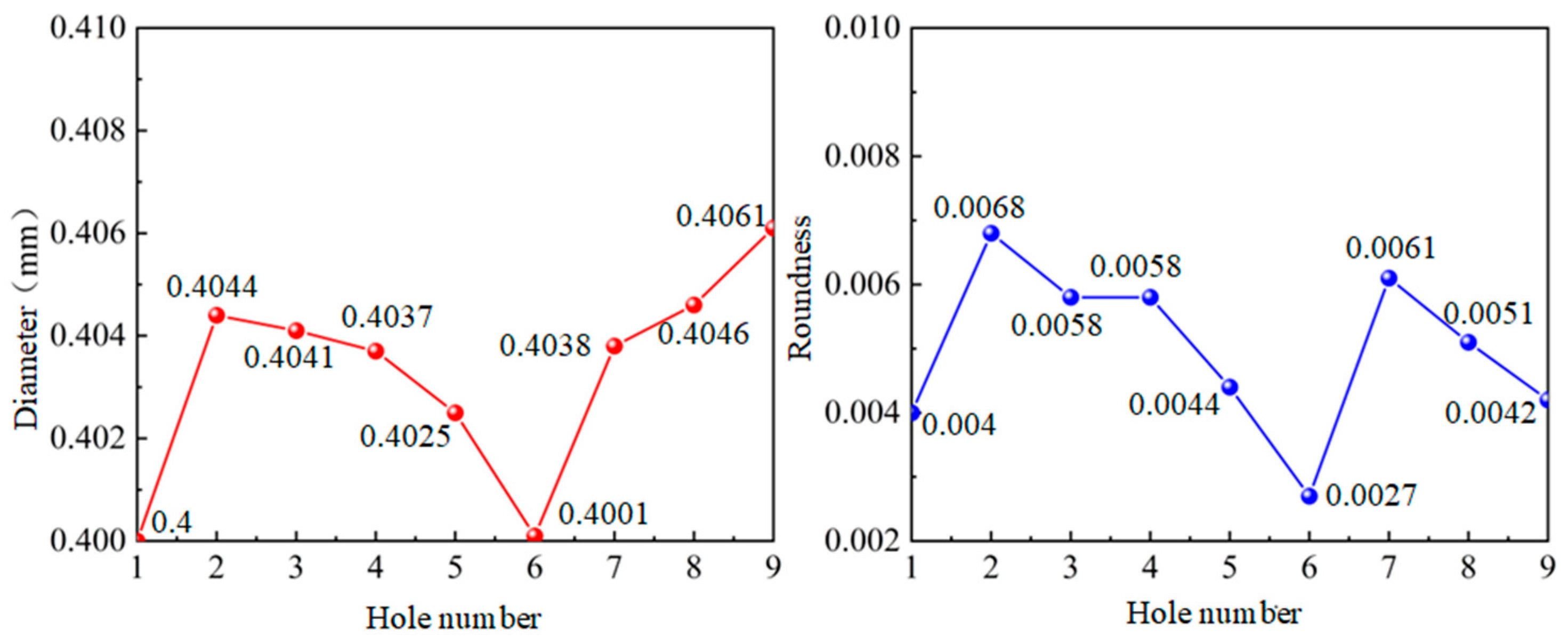

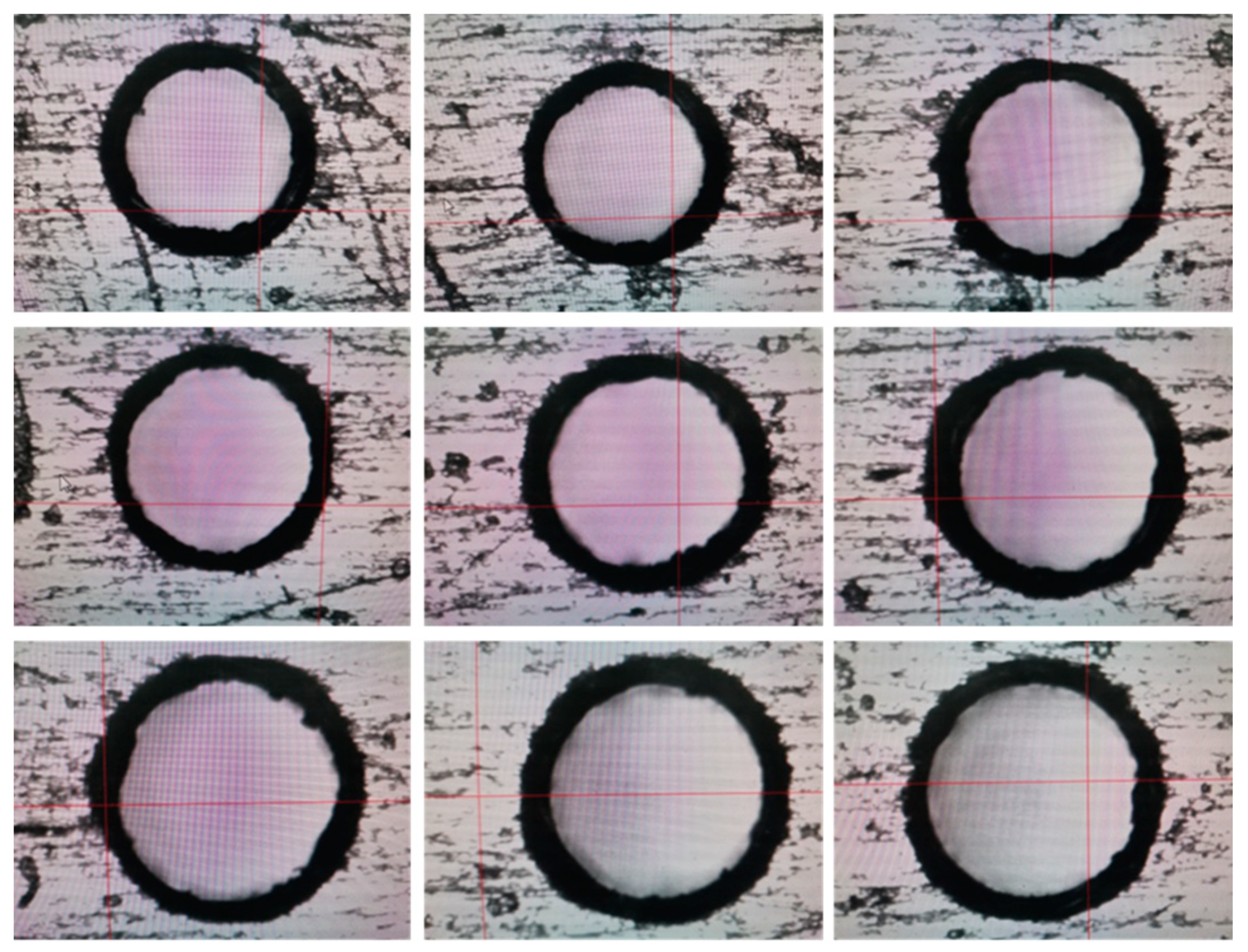

4.2.2. Ultrasonic Machining Results of 0.4 mm Micro-Hole on GH4169 Plate and Analysis

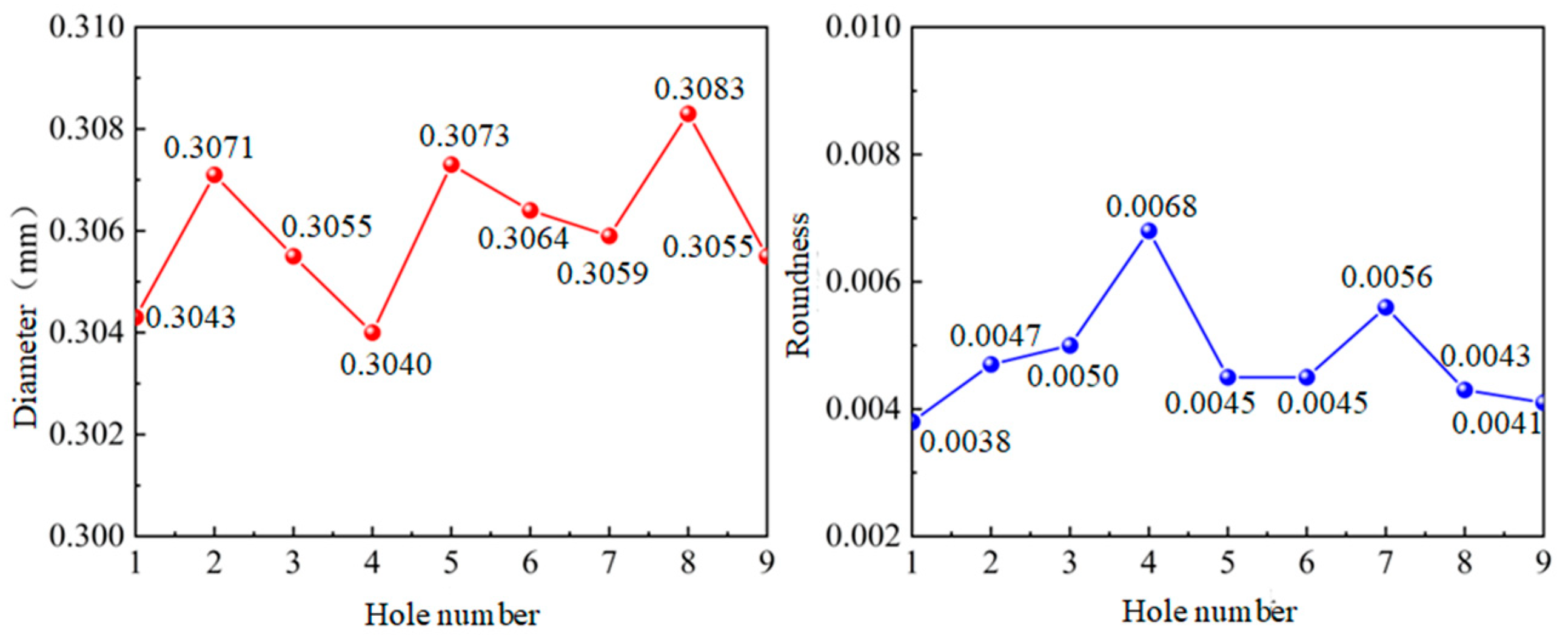

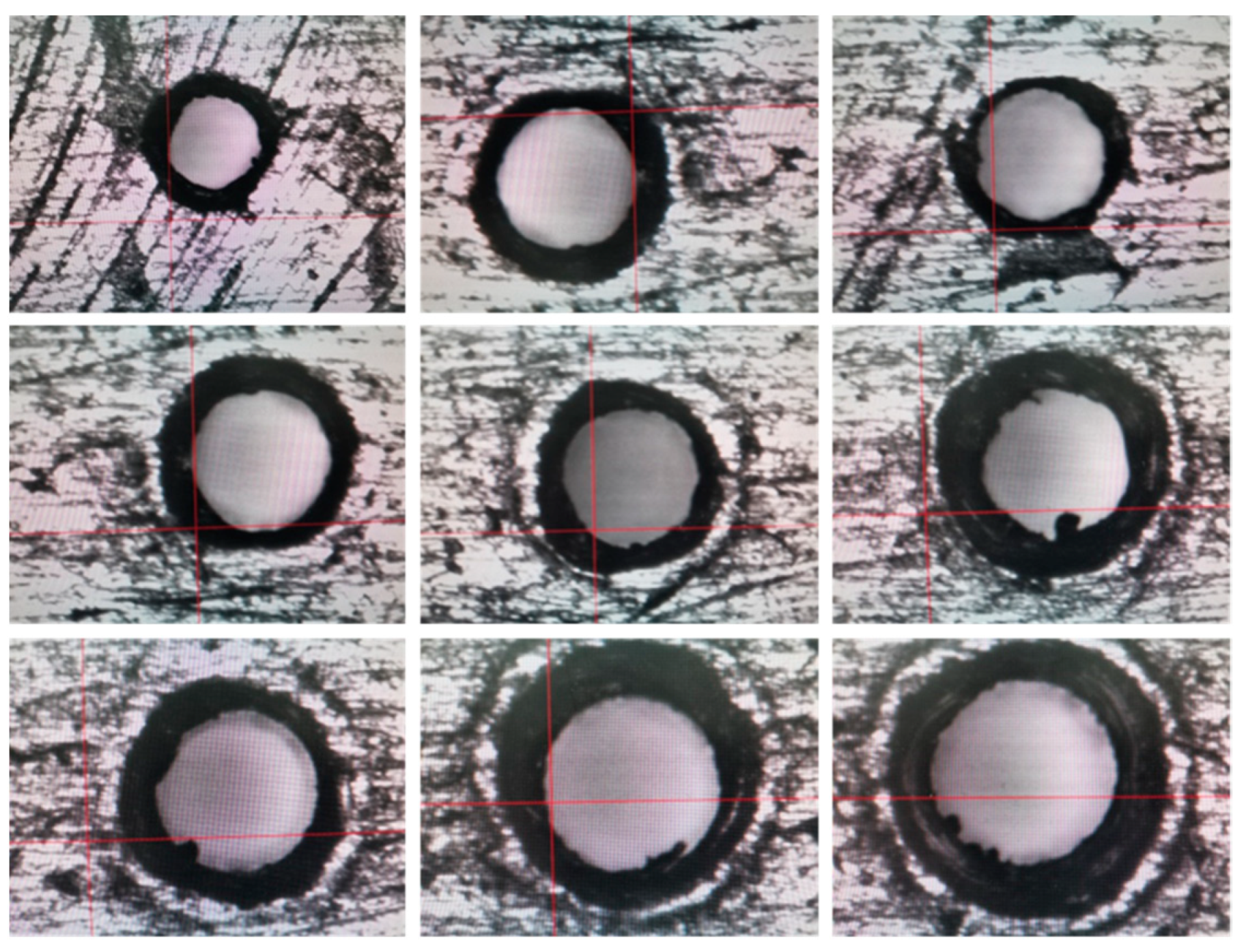

4.2.3. Ultrasonic Machining Results of 0.3 mm Micro-Hole on GH4169 Plate and Analysis

4.2.4. Ultrasonic Machining Results of 0.2 mm Micro-Hole on GH4169 Plate and Analysis

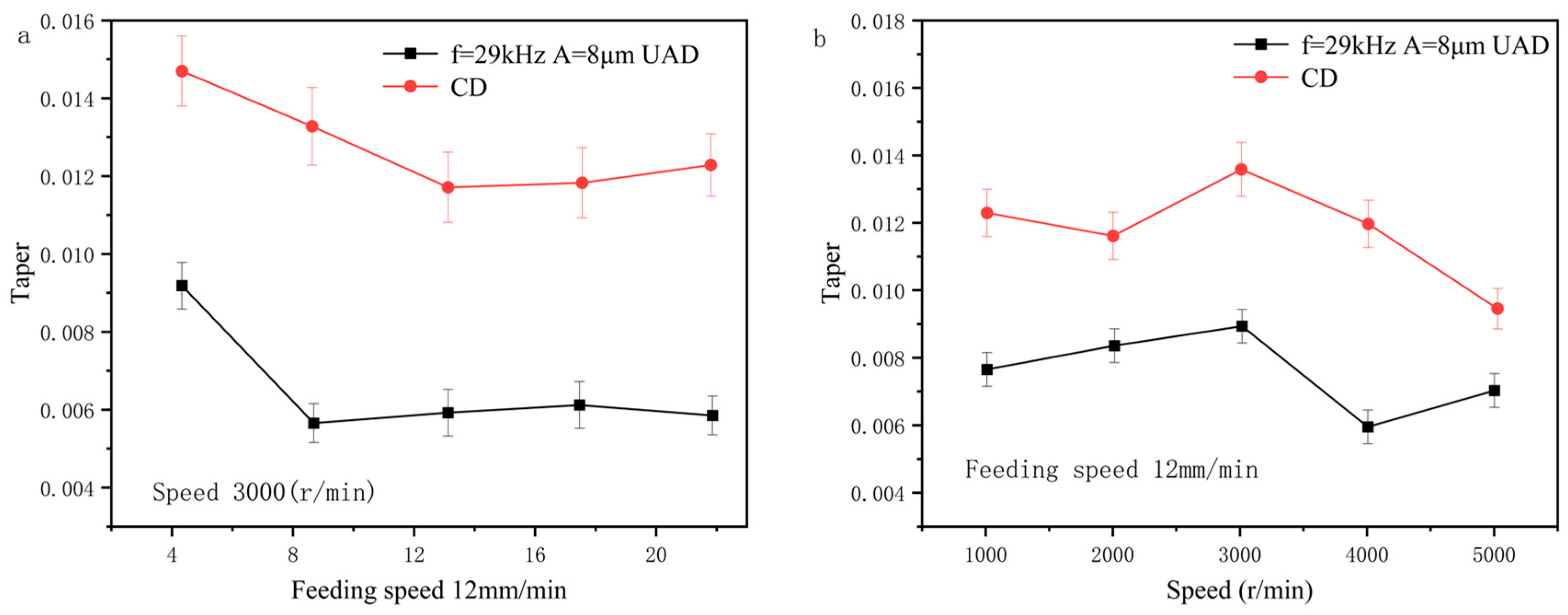

4.3. Microporous Taper Analysis

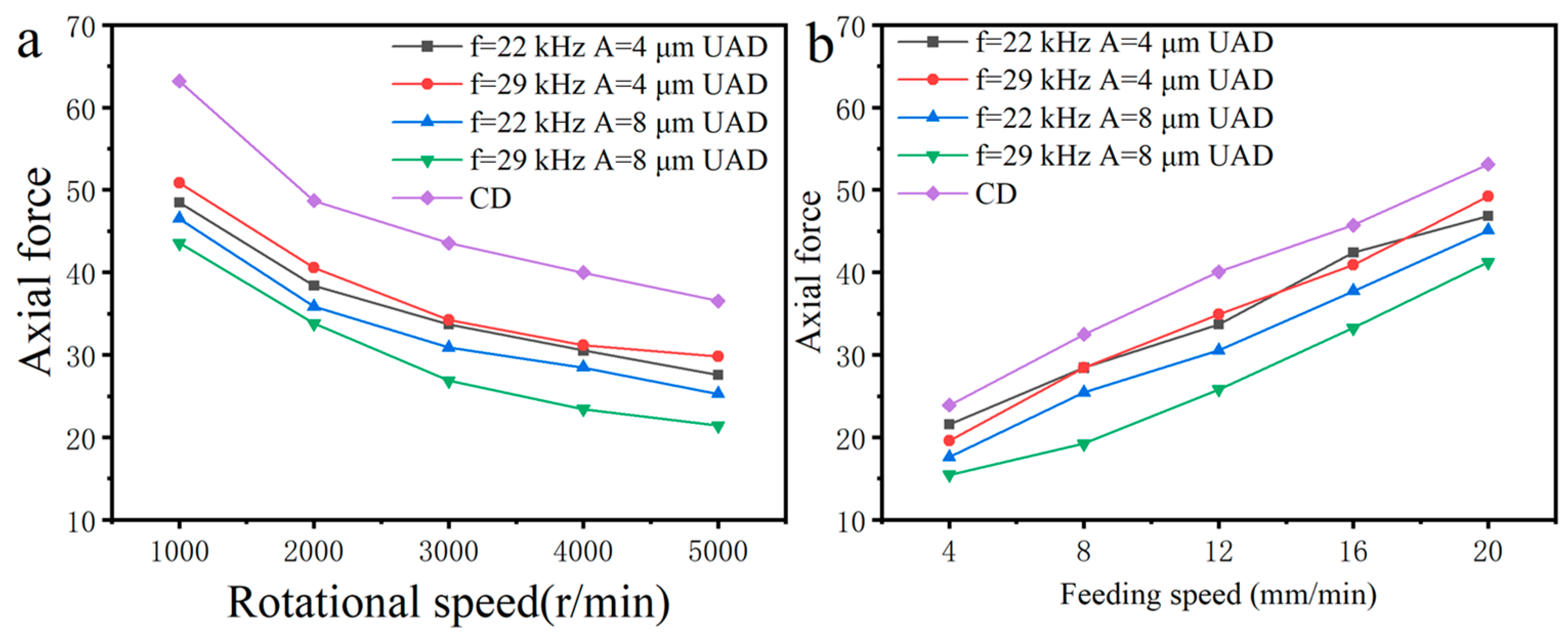

4.4. Cutting Force Analysis

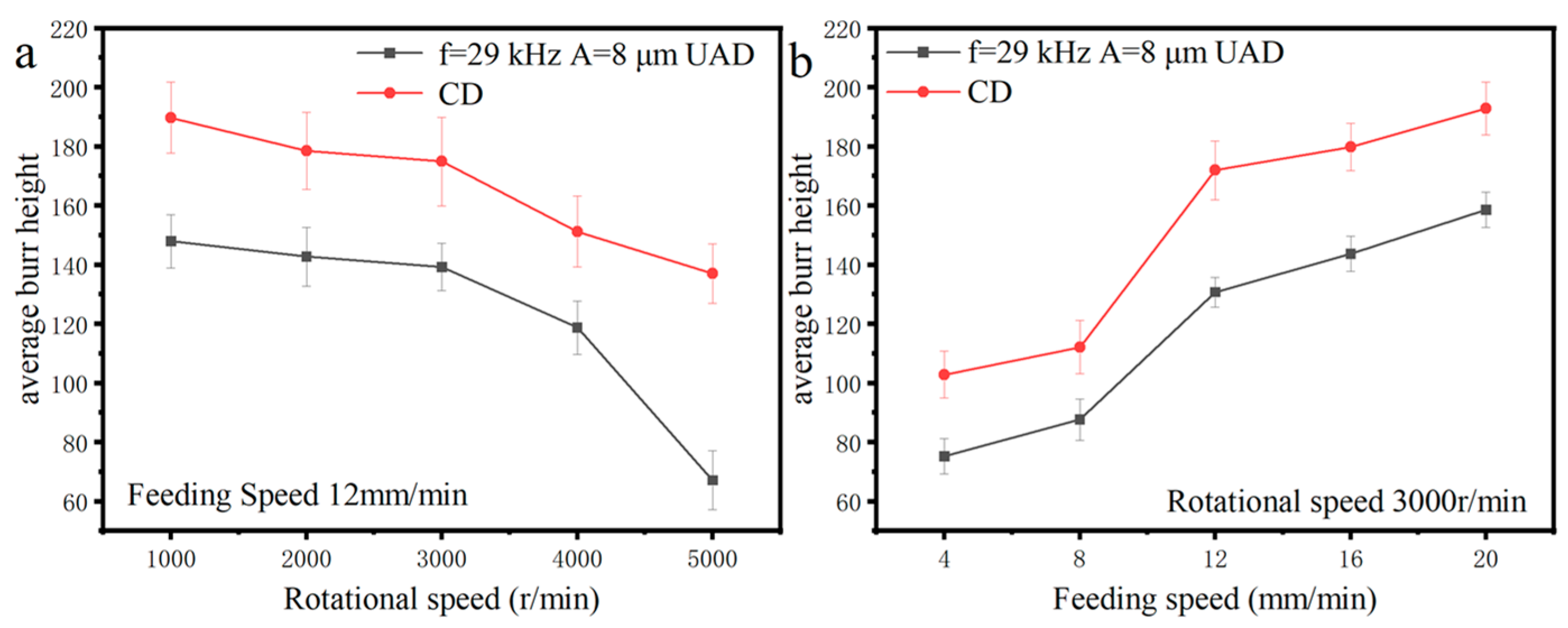

4.5. Analysis of Cutting Burrs

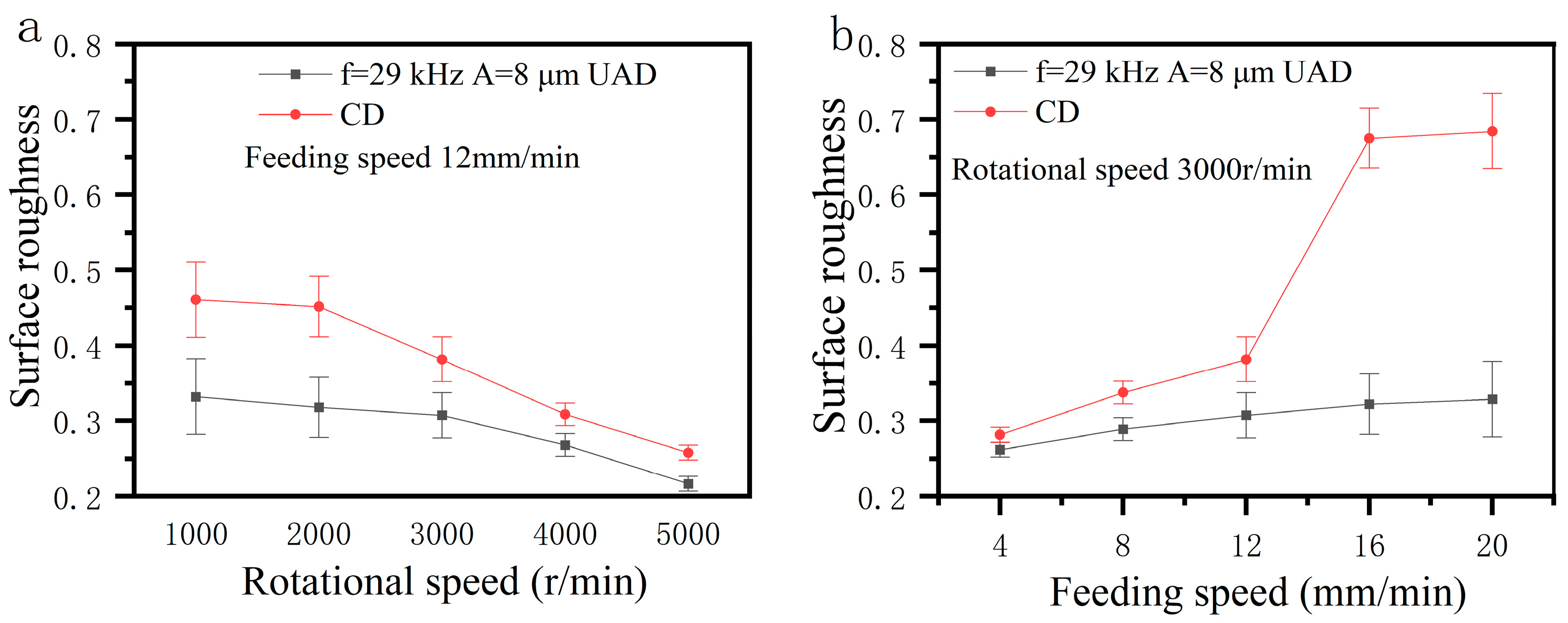

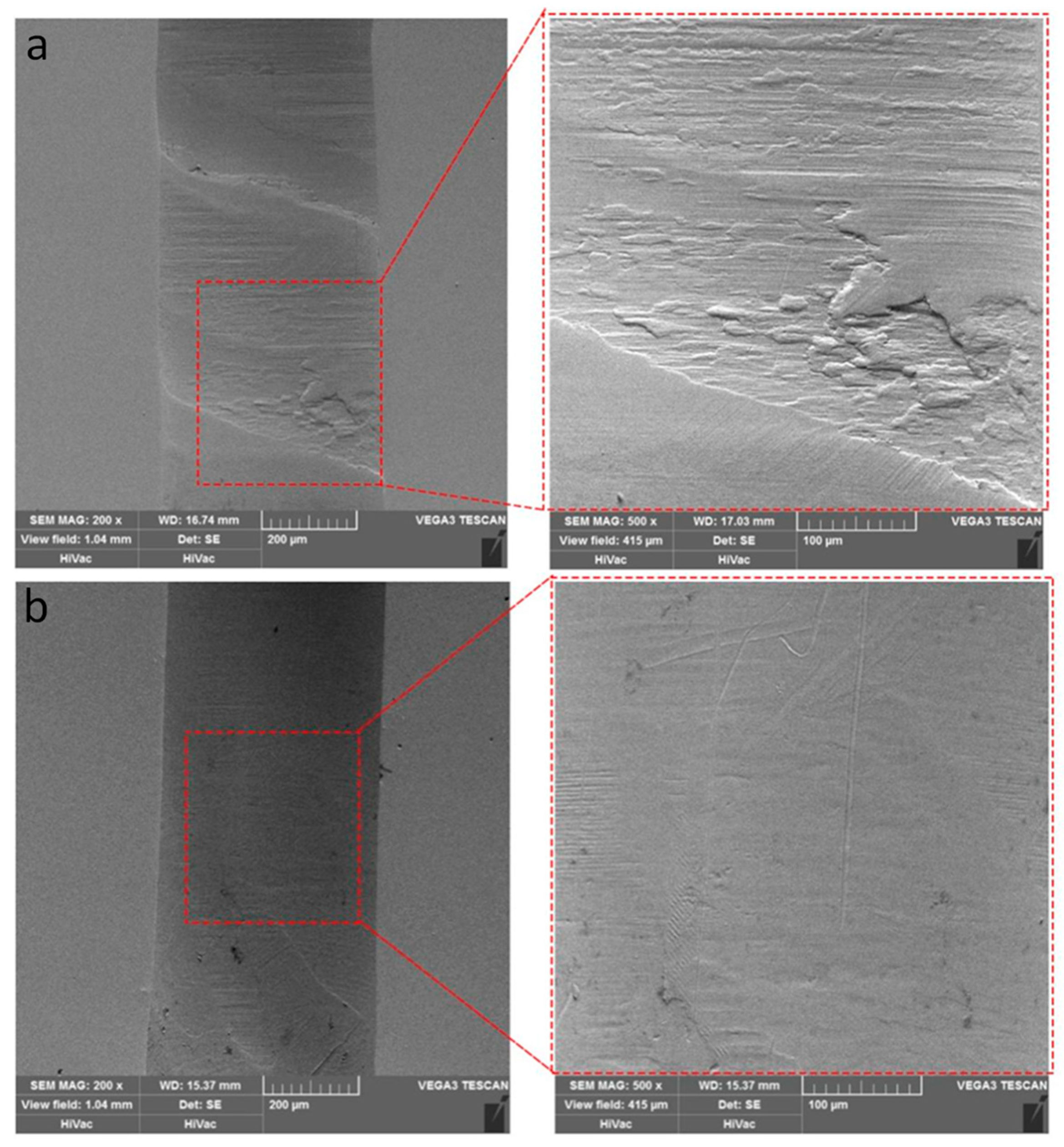

4.6. Analysis of Surface Quality

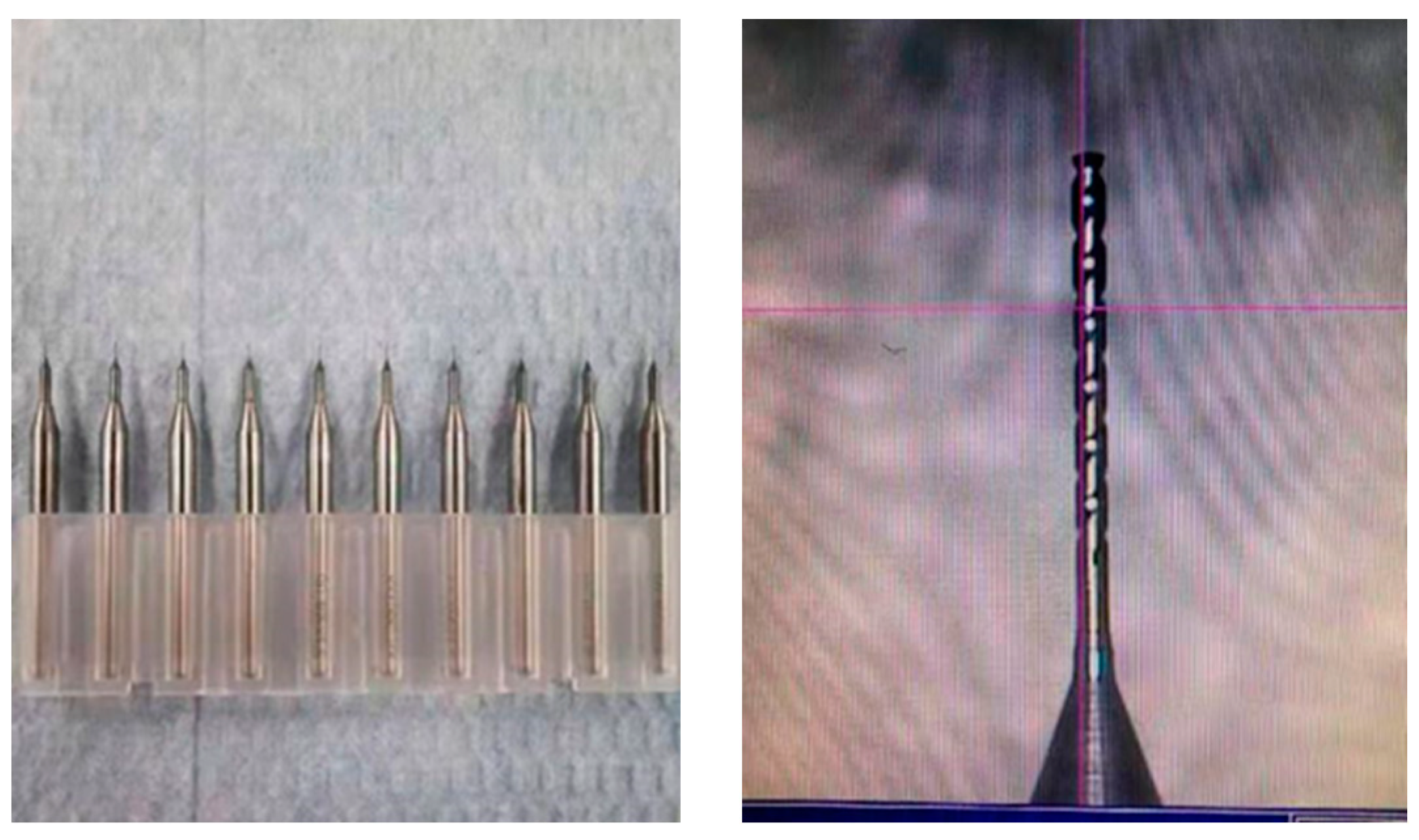

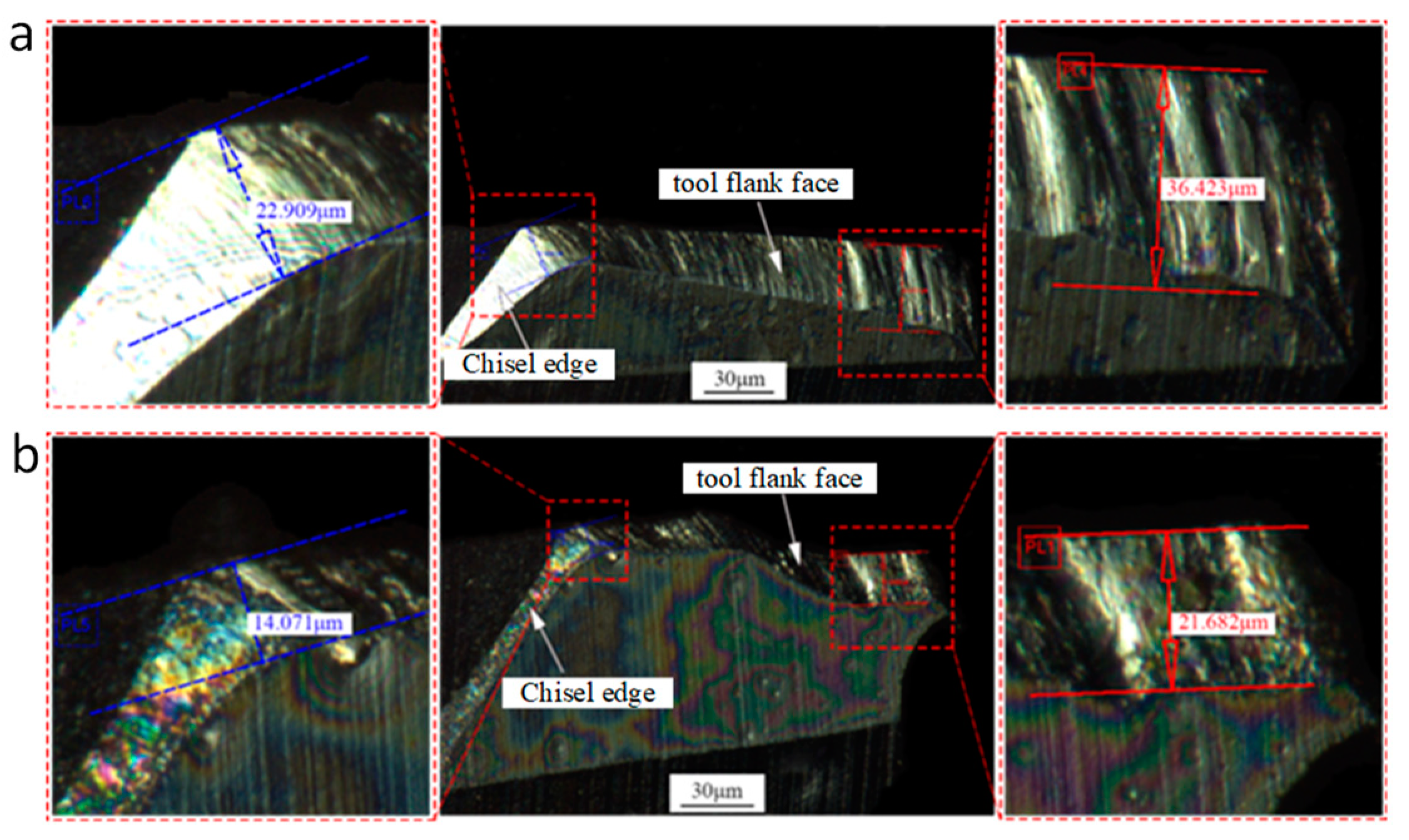

4.7. Tool Wear Analysis

5. Experimental Validation Analysis

6. Conclusions

- (1)

- Ultrasonic-assisted machining as a new special machining method, especially UAD in micro-hole machining has unique advantages, can solve the problem of micro-hole machining traditional drilling can not be processed or machining instability, while machining using general-purpose machine tools and tools to increase number of auxiliary ultrasonic machining system to achieve machining process, machining process of different hardness materials, good adaptability, especially in micro-hole machining of super-hard materials advantages are outstanding in micro-hole machining of difficult-to-cut materials.

- (2)

- After experimental analysis of UAD machining of micro-hole below 0.5 compared with traditional drilling machining, because of its machining process for high-frequency pulse intermittent cutting, machining diameter changes steadily, shape tolerance roundness and cylindricity, and/or parameters of good stability, cutting process cutting force is small, tool wear is small, micro-hole wall surface roughness is small.

- (3)

- Relative to EDM, UAD machining efficiency, machining diameter and shape tolerance roundness and or parameters of good stability, but UAD is still tool and part material contact metal cutting process, drill in the micro-hole machining process of the metal plastic deformation process, relative to EDM electrode discharge metal high-temperature melting process, hole burr height condition is worse than EDM machining.

- (4)

- A comprehensive analysis of UAD can be used as an alternative technical solution for the machining of small holes in non-special requirements of metal materials in hospitals, with stable batch production technical feasibility.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Marimuthu, S.; Antar, M.; Dunleavey, J. Characteristics of micro-hole formation during fibre laser drilling of aerospace superalloy. Precis. Eng.-J. Int. Soc. Precis. Eng. Nanotechnol. 2019, 55, 339–348. [Google Scholar] [CrossRef]

- Feng, Y.X.; Hsu, F.C.; Lu, Y.T.; Lin, Y.F.; Lin, C.T.; Lin, C.F.; Lu, Y.C.; Liang, S.Y. Force prediction in ultrasonic vibration-assisted milling. Mach. Sci. Technol. 2021, 25, 307–330. [Google Scholar] [CrossRef]

- Alao, A.R. A fundamental study of vibration assisted machining. Adv. Mater. Res. 2011, 264–265, 1702–1707. [Google Scholar]

- Xu, W.X.; Zhang, L.C. Ultrasonic vibration-assisted machining: Principle, design and application. Adv. Manuf. 2015, 3, 173–192. [Google Scholar] [CrossRef]

- Mochimaru, Y.; Ota, M.; Yamaguchi, K. Micro Hole Machining Using Electro-Chemical Discharge Machining. J. Adv. Mech. Des. Syst. Manuf. 2012, 6, 949–957. [Google Scholar] [CrossRef]

- Zhang, Q.H.; Zhang, J.H.; Du, R.X.; Ai, X. Present research status and development trends of EDM. China Mech. Eng. 2005, 16, 1586–1592. [Google Scholar]

- Qin, X.D.; Chen, S.M.; Liu, W.C.; Ni, W.Y.; Liu, Y.X. Development and application of hole helical milling technology in aviation manufacturing assembly industry. Aeronaut. Manuf. Technol. 2009, 6, 58–60. [Google Scholar]

- Zhang, Y.; Kang, R.K.; Liu, J.T.; Zhang, Y.; Zheng, W.; Dong, Z. Review of Ultrasonic Vibration Assisted Drilling. J. Mech. Eng. 2017, 53, 33–44. [Google Scholar] [CrossRef]

- Liao, Y.S.; Chen, Y.C.; Lin, H.M. Feasibility study of the ultrasonic vibration assisted drilling of Inconel superalloy. Int. J. Mach. Tools Manuf. 2007, 47, 1988–1996. [Google Scholar] [CrossRef]

- Liu, Z.F.; Liu, Y.S.; Han, X.L.; Zheng, W. Study on super-long deep-hole drilling of titanium alloy. J. Appl. Biomater. Funct. Mater. 2018, 16, 150–156. [Google Scholar] [CrossRef]

- Heinemann, R.; Hinduja, S.; Barrow, G. Use of process signals for tool wear progression sensing in drilling small deep holes. Int. J. Adv. Manuf. Technol. 2007, 33, 243–250. [Google Scholar] [CrossRef]

- Chen, S.; Zou, P.; Wu, H.; Kang, D.; Wang, W. Mechanism of chip formation in ultrasonic vibration drilling and experimental research. Proc. Inst. Mech. Eng. Part C J. Mech. Eng. Sci. 2019, 233, 5214–5226. [Google Scholar] [CrossRef]

- Tian, Y.J.; Zou, P.; Kang, D.; Fan, F. Study on tool wear in longitudinal-torsional composite ultrasonic vibration-assisted drilling of Ti-6Al-4V alloy. Int. J. Adv. Manuf. Technol. 2021, 113, 1989–2002. [Google Scholar] [CrossRef]

- Yu, Z.Q.; Tong, H.; Li, Y.; Chai, Y.; Wang, Z.; Li, C. Vibration amplitude characteristics of tubular electrode in EDM drilling. J. Beijing Univ. Aeronaut. Astronaut. 2016, 42, 2516–2523. [Google Scholar]

- Tanjilul, M.; Ahmed, A.; Kumar, A.S.; Rahman, M. A study on EDM debris particle size and flushing mechanism for efficient debris removal in EDM-drilling of Inconel 718. J. Mater. Mach. Technol. 2018, 255, 263–274. [Google Scholar] [CrossRef]

- Maity, K.P.; Choubey, M. A review on vibration-assisted EDM; micro-EDM and WEDM. Surf. Rev. Lett. 2019, 26, 1830008. [Google Scholar] [CrossRef]

- Kumar, L.; Kumar, K.; Chhabra, D. Experimental investigations of electrical discharge micro-drilling for Mg-alloy and multi-response optimization using MOGA-ANN. CIRP J. Manuf. Sci. Technol. 2022, 38, 774–786. [Google Scholar] [CrossRef]

- Tamang, S.K.; Natarajan, N.; Chandrasekaran, M. Optimization of EDM process in machining micro holes for improvement of hole quality. J. Braz. Soc. Mech. Sci. Eng. 2017, 39, 1277–1287. [Google Scholar] [CrossRef]

- Azad, M.S.; Puri, A.B. Simultaneous optimisation of multiple performance characteristics in micro-EDM drilling of titanium alloy. Int. J. Adv. Manuf. Technol. 2012, 61, 1231–1239. [Google Scholar] [CrossRef]

- Lauwers, B.; Oosterling, H.; Vanderauwera, W. Development of an operations evaluation system for sinking EDM. CIRP Ann. Manuf. Technol. 2010, 59, 223–226. [Google Scholar] [CrossRef]

- Hou, S.J.; Bai, J.C.; Tian, B.Y. Experimental investigation to improve the efficiency and surface integrity of deep micro-hole machined by micro-EDM. Int. J. Adv. Manuf. Technol. 2022, 123, 2249–2259. [Google Scholar] [CrossRef]

- Zhang, Y.; Xu, Z.Y.; Zhu, D.; Qu, N.; Zhu, Y. Drilling of film cooling holes by a EDM/ECM in situ combined process using internal and side flushing of tubular electrode. Int. J. Adv. Manuf. Technol. 2016, 83, 505–517. [Google Scholar] [CrossRef]

- Yang, Z.C.; Zhu, L.D.; Zhang, G.X.; Ni, C.; Lin, B. Review of ultrasonic vibration-assisted machining in advanced materials. Int. J. Mach. Tools Manuf. 2020, 156, 103594. [Google Scholar] [CrossRef]

- Sabyrov, N.; Jahan, M.P.; Bilal, A.; Perveen, A. Ultrasonic Vibration Assisted Electro-Discharge Machining (EDM)—An Overview. Materials 2019, 12, 522. [Google Scholar] [CrossRef]

- Ning, F.D.; Cong, W.L. Ultrasonic vibration-assisted (UV-A) manufacturing processes: State of the art and future perspectives. J. Manuf. Process. 2020, 51, 174–190. [Google Scholar] [CrossRef]

| Traditional Method | Non-Traditional Methods |

|---|---|

| Drilling, reaming, water jet machining, abrasive jet machining, punching, boring, end milling, honing, milling inner cavity, grinding, hinge | EDM perforation, electrolytic machining, chemical machining, electropolishing machining laser machining, photochemical machining, ion beam machining, ultrasonic machining |

| Drill Diameter | Spindle Speed | Feed Speed |

|---|---|---|

| Φ0.2 mm, Φ0.3 mm, Φ0.4 mm, Φ0.5 mm | 10,000 rpm | 15–30 mm/min |

| Hole Serial Number | 1# | 2# | 3# | 4# | 5# | 6# | 7# | 8# | 9# |

|---|---|---|---|---|---|---|---|---|---|

| Diameter (mm) | 0.5027 | 0.5023 | 0.5025 | 0.5075 | 0.5032 | 0.5014 | 0.5043 | 0.5033 | 0.5038 |

| Roundness | 0.0068 | 0.0057 | 0.0056 | 0.0055 | 0.0081 | 0.0025 | 0.0056 | 0.0050 | 0.0063 |

| Hole Serial Number | 1# | 2# | 3# | 4# | 5# | 6# | 7# | 8# | 9# |

|---|---|---|---|---|---|---|---|---|---|

| Diameter (mm) | 0.4000 | 0.4044 | 0.4041 | 0.4037 | 0.4025 | 0.4001 | 0.4038 | 0.4046 | 0.4061 |

| Roundness | 0.0040 | 0.0068 | 0.0058 | 0.0058 | 0.0044 | 0.0027 | 0.0061 | 0.0051 | 0.0042 |

| Hole Serial Number | 1# | 2# | 3# | 4# | 5# | 6# | 7# | 8# | 9# |

|---|---|---|---|---|---|---|---|---|---|

| Diameter (mm) | 0.3043 | 0.3071 | 0.3055 | 0.3040 | 0.3073 | 0.3064 | 0.3059 | 0.3083 | 0.3055 |

| Roundness | 0.0038 | 0.0047 | 0.0050 | 0.0068 | 0.0045 | 0.0045 | 0.0056 | 0.0043 | 0.0041 |

| Hole Serial Number | 1# | 2# | 3# | 4# | 5# | 6# | 7# | 8# | 9# |

|---|---|---|---|---|---|---|---|---|---|

| Diameter (mm) | 0.2066 | 0.2027 | 0.2004 | 0.2074 | 0.2021 | 0.2028 | 0.2082 | 0.2075 | 0.2064 |

| Roundness | 0.0067 | 0.0082 | 0.0088 | 0.0058 | 0.0085 | 0.0086 | 0.0062 | 0.0041 | 0.0045 |

| Ultrasonic Toolholder System | Ultrasound Frequency | Drill Diameter | Spindle Speed | Feeding Speed |

|---|---|---|---|---|

| CKN-XH | 30 ± 1 kHZ | Φ0.1 | 10,000 rpm | 15–30 mm/min |

| Category | UAD | Drill Diameter |

|---|---|---|

| Diameter (mm) | 1.006 | 1.012 |

| Roundness (mm) | 0.006 | 0.014 |

| Burr height (mm) | 0.035 | 0.011 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Deng, S.; Guo, Y.; Lu, S. Experimental Research of High-Quality Drilling Based on Ultrasonic Vibration-Assisted Machining. Micromachines 2023, 14, 1579. https://doi.org/10.3390/mi14081579

Deng S, Guo Y, Lu S. Experimental Research of High-Quality Drilling Based on Ultrasonic Vibration-Assisted Machining. Micromachines. 2023; 14(8):1579. https://doi.org/10.3390/mi14081579

Chicago/Turabian StyleDeng, Shuang, Yu Guo, and Songsong Lu. 2023. "Experimental Research of High-Quality Drilling Based on Ultrasonic Vibration-Assisted Machining" Micromachines 14, no. 8: 1579. https://doi.org/10.3390/mi14081579

APA StyleDeng, S., Guo, Y., & Lu, S. (2023). Experimental Research of High-Quality Drilling Based on Ultrasonic Vibration-Assisted Machining. Micromachines, 14(8), 1579. https://doi.org/10.3390/mi14081579