Fabrication of High Aspect Ratio Nano-Channels by Thermal Nano-Imprinting and Parylene Deposition

Abstract

1. Introduction

2. Experiments

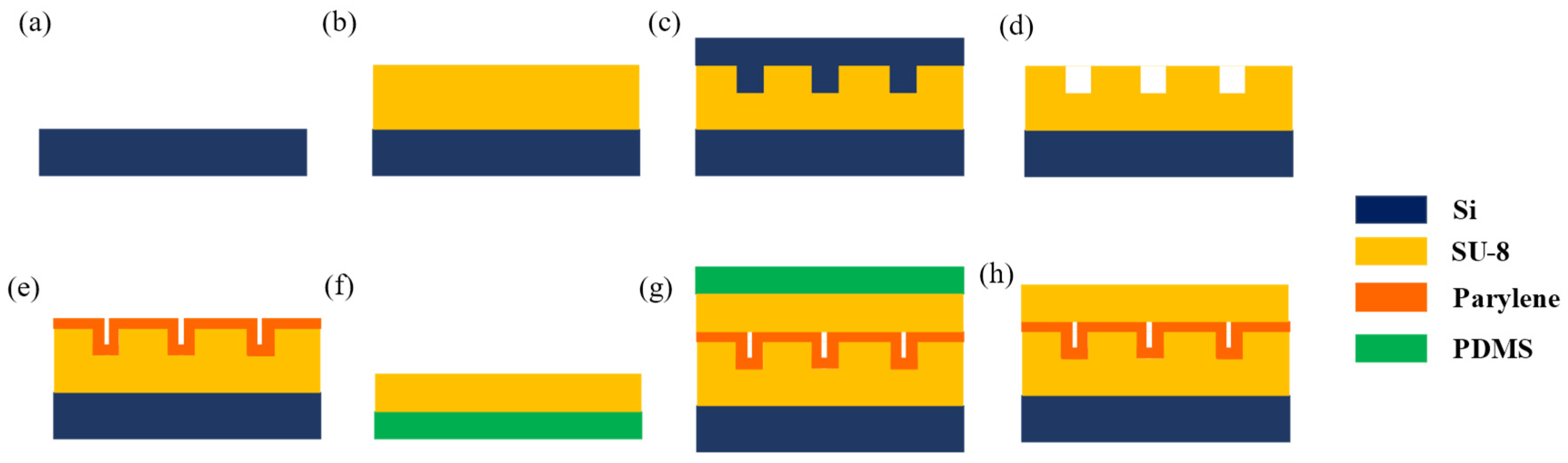

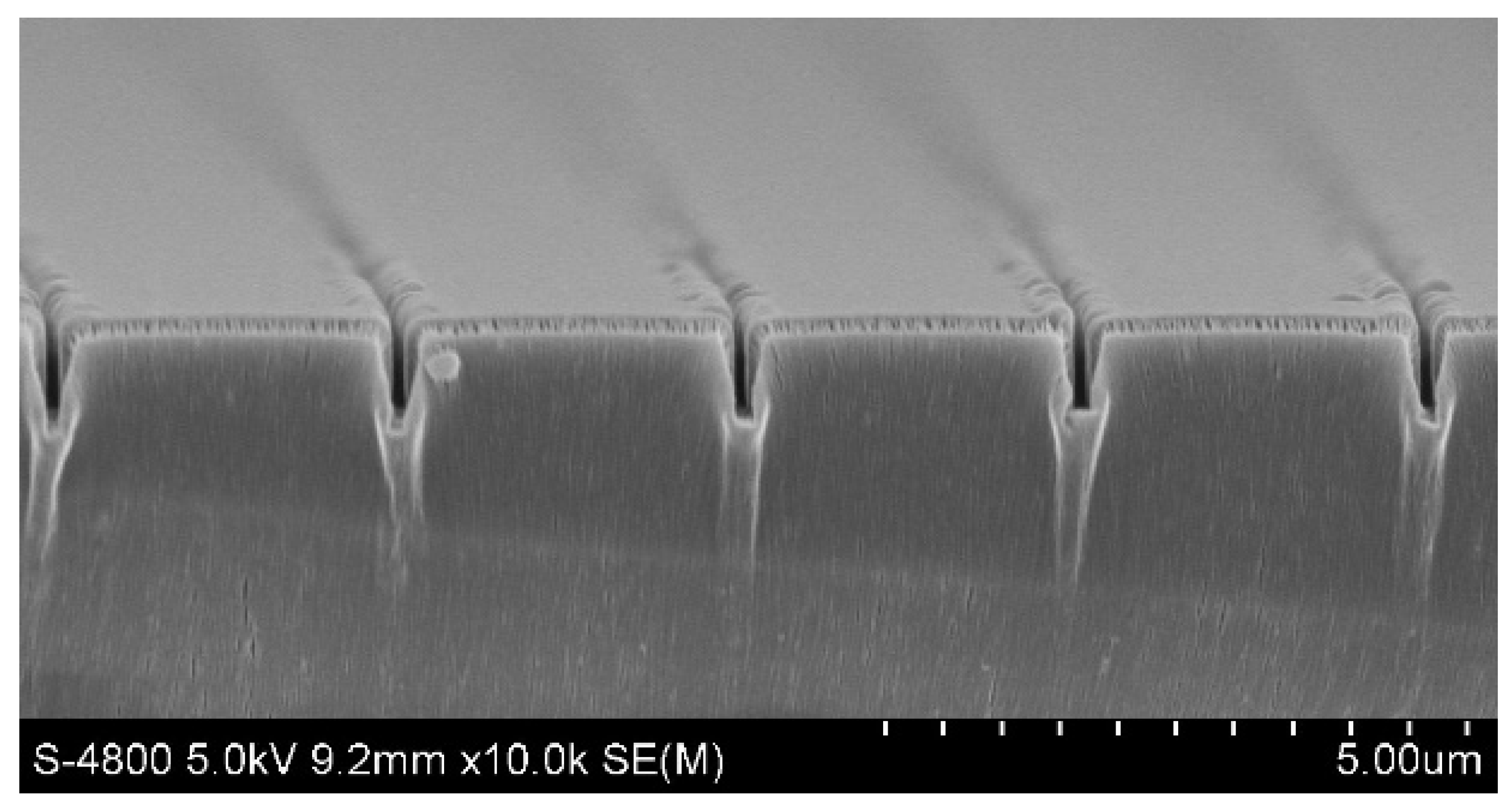

2.1. Fabrication Process of Nano-Channels

2.2. Parylene Deposition

3. Results

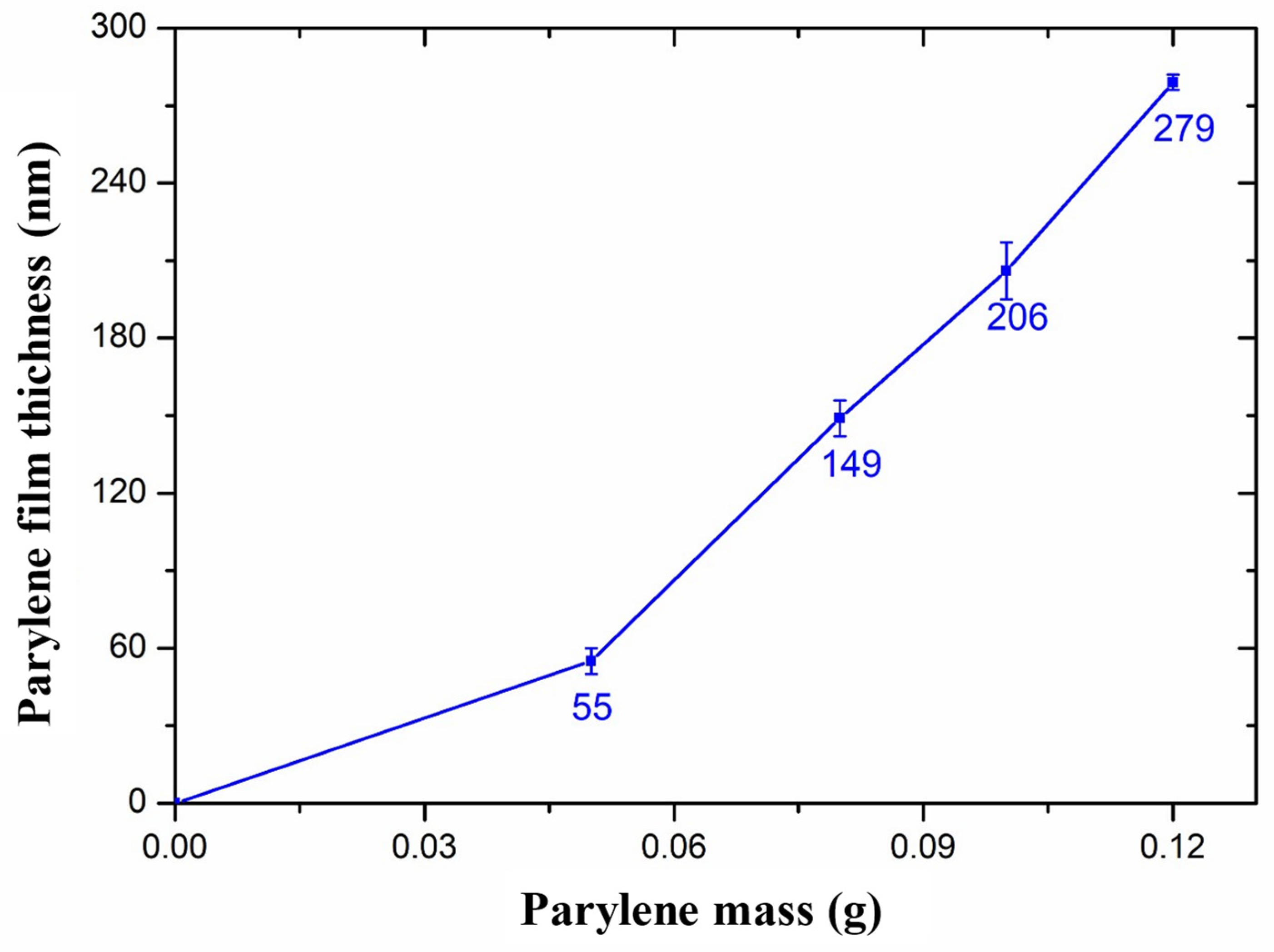

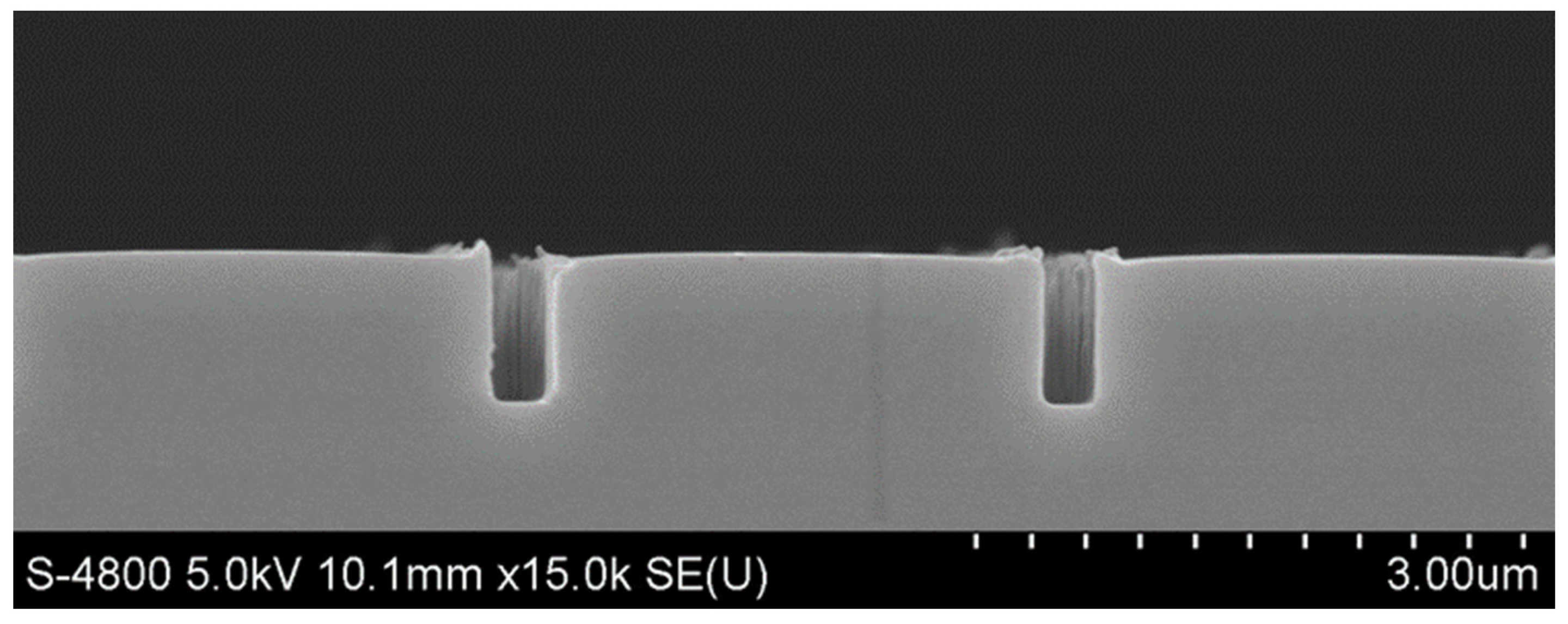

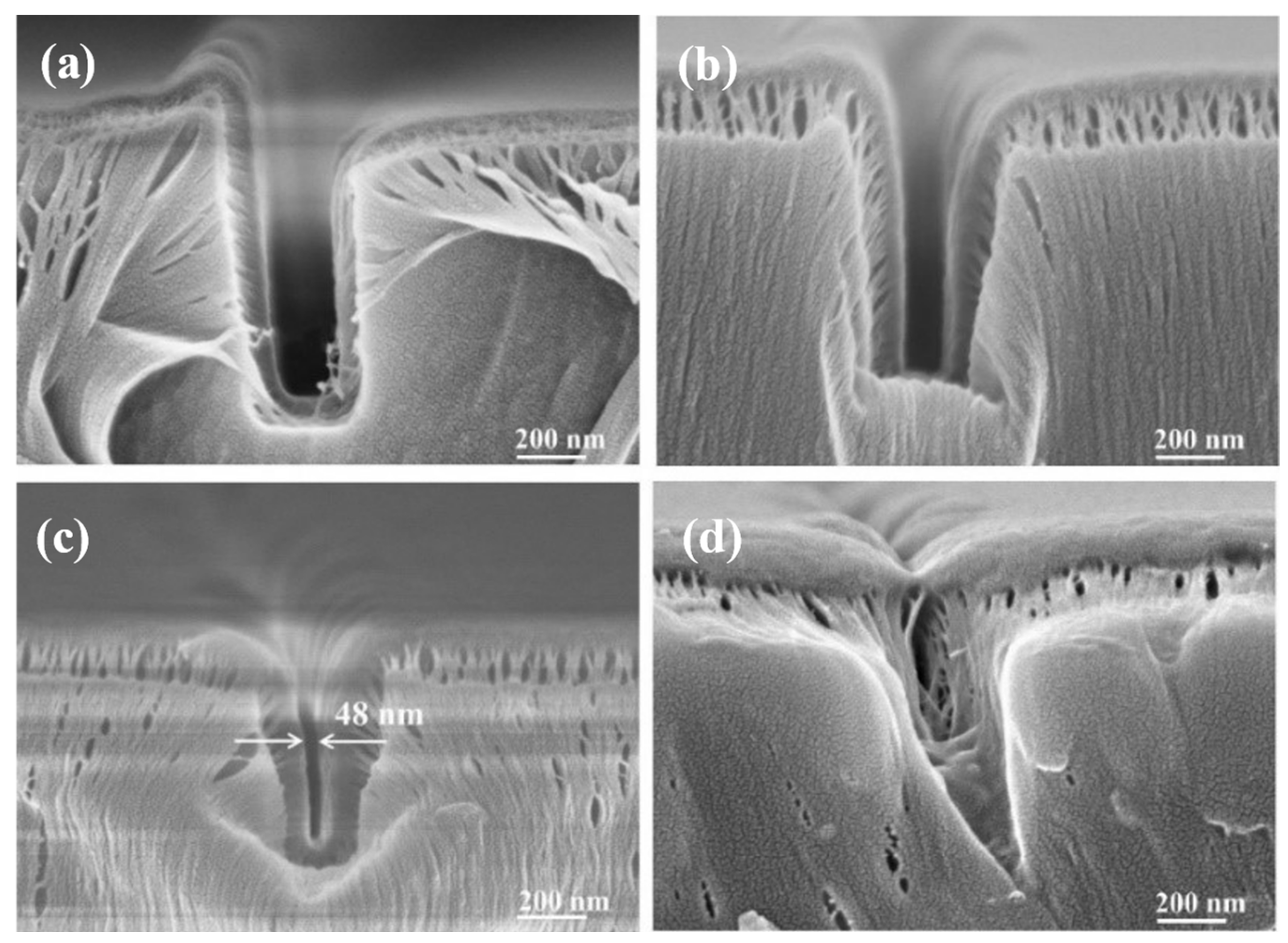

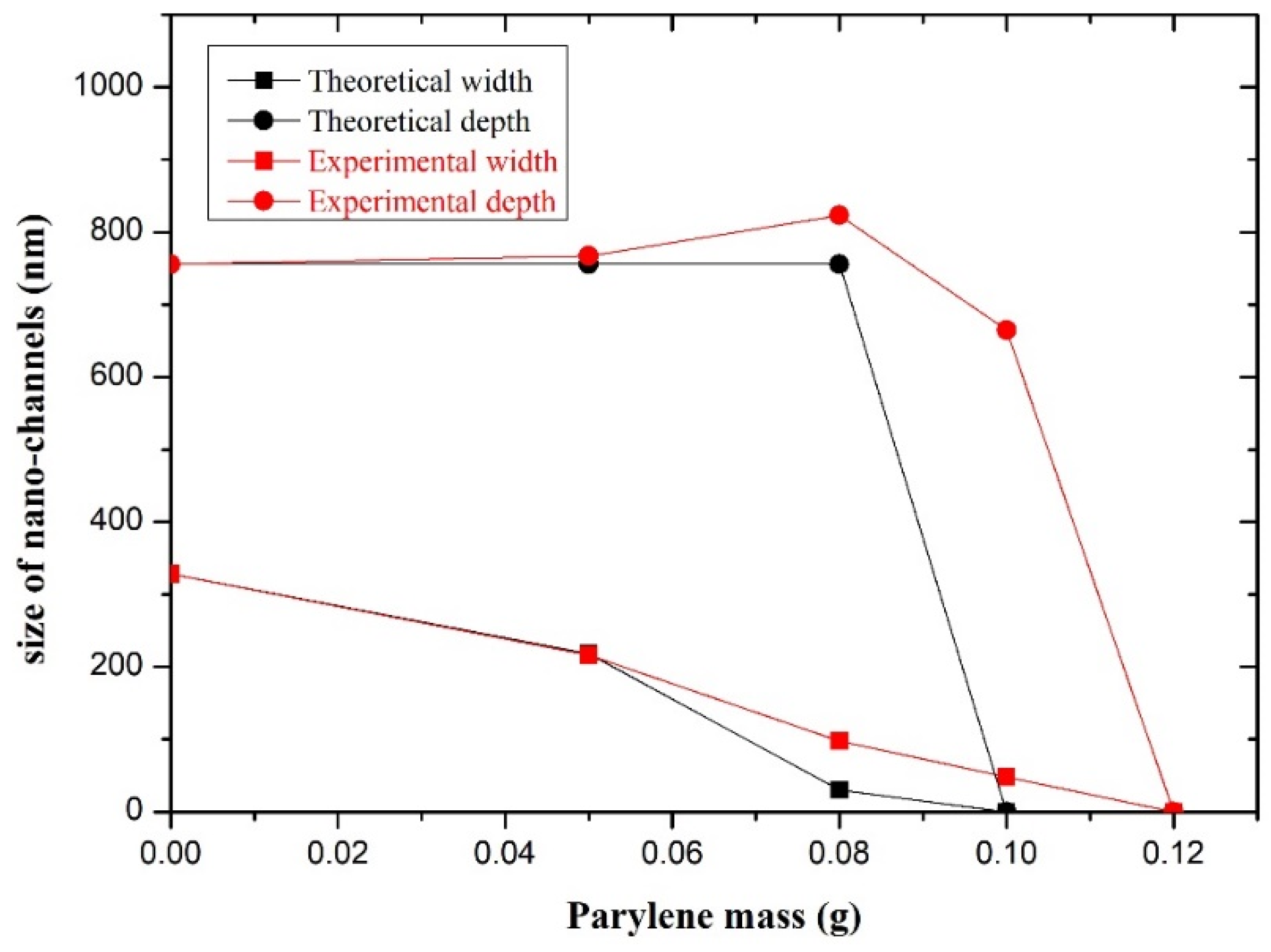

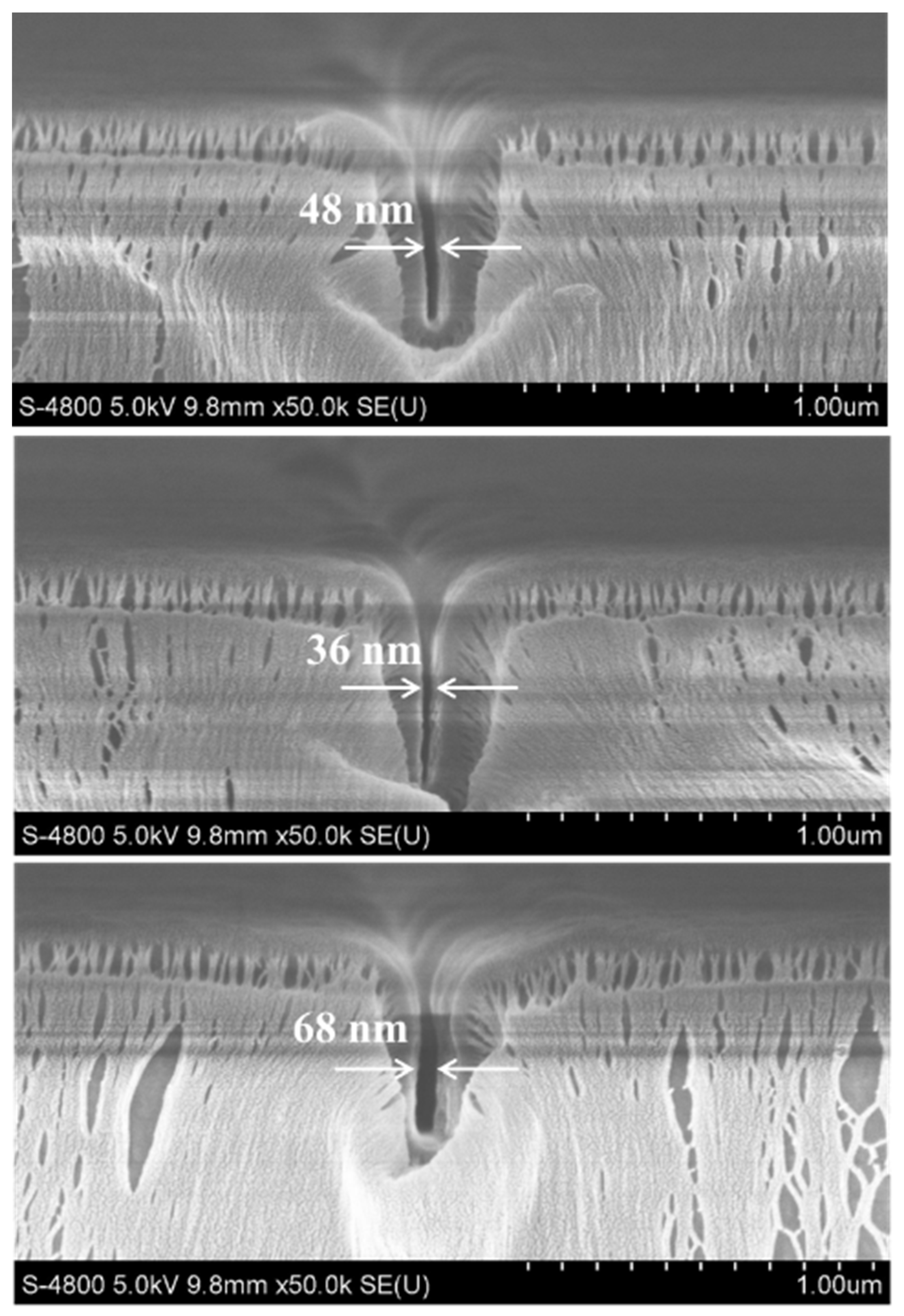

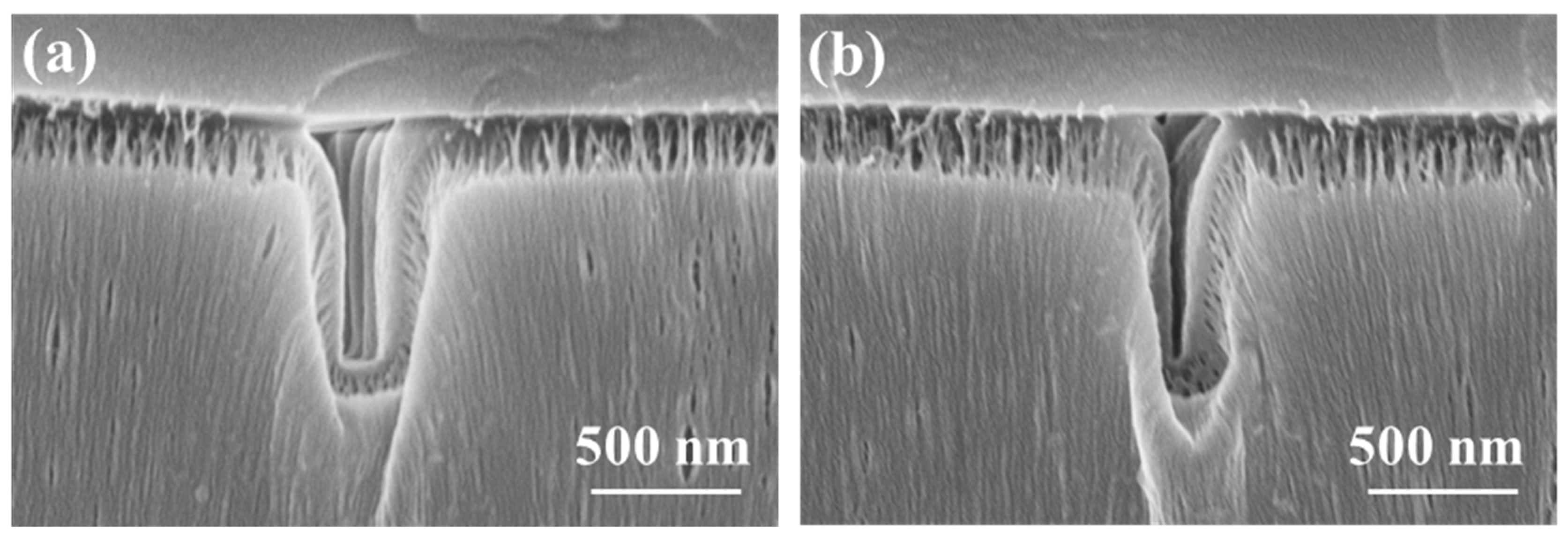

3.1. Influence of Parylene Mass on Nano-Channel Size

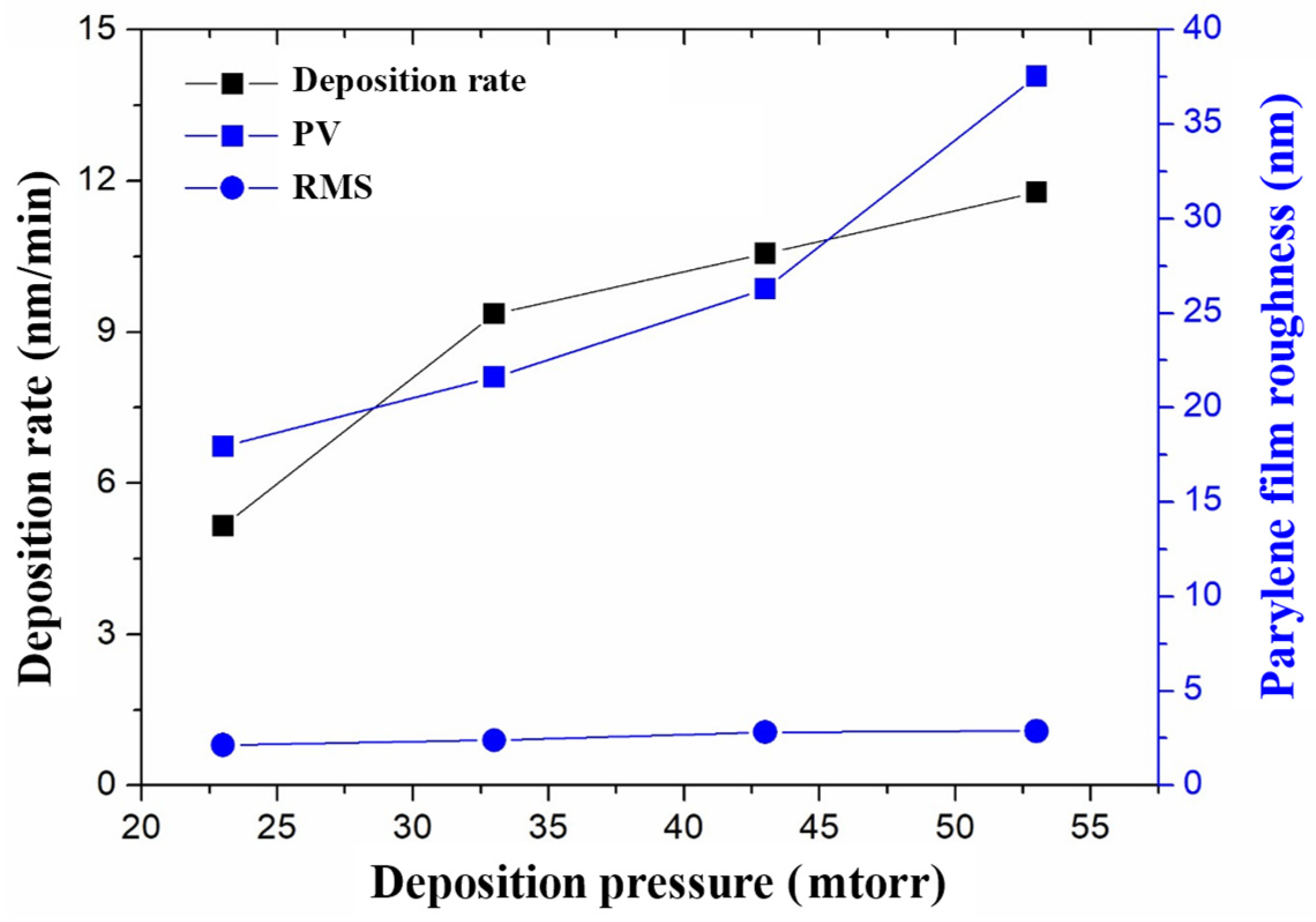

3.2. Influence of Deposition Pressure on Deposition Rate and Film Roughness

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Nouri, R.; Guan, W. Nanofluidic charged-coupled devices for controlled DNA transport and separation. Nanotechnology 2021, 32, 345501. [Google Scholar] [CrossRef]

- Uba, F.I.; Pullagurla, S.R.; Sirasunthorn, N.; Wu, J.; Park, S.; Chantiwas, R.; Cho, Y.K.; Shin, H.; Soper, S.A. Surface charge, electroosmotic flow and DNA extension in chemically modified thermoplastic nanoslits andnano-channels. Analyst 2015, 140, 113–126. [Google Scholar] [CrossRef]

- Wang, Y.; Sadar, J.; Tsao, C.W.; Mukherjee, S.; Qing, Q. Nanopore chip with self-aligned transverse tunneling junction for DNA detection. Biosens. Bioelectron. 2021, 193, 113552. [Google Scholar] [CrossRef]

- Zrehen, A.; Huttner, D.; Meller, A. On-Chip stretching, sorting, and electro-optical nanopore sensing of ultralong human genomic DNA. ACS Nano 2019, 13, 14388–14398. [Google Scholar] [CrossRef]

- Chen, Y.-Y.; Chiu, P.-H.; Weng, C.-H.; Yang, R.-J. Preconcentration of diluted mixed-species samples following separation and collection in a micro–nanofluidic device. Biomicrofluidics 2016, 10, 014119. [Google Scholar] [CrossRef] [PubMed]

- Chen, X.; Miller, A.; Cao, S.; Gan, Y.; Zhang, J.; He, Q.; Wang, R.Q.; Yong, X.; Qin, P.; Lapizco-Encinas, B.H.; et al. Rapid Escherichia coli Trapping and Retrieval from Bodily Fluids via a Three-Dimensional Bead-Stacked Nanodevice. ACS Appl. Mater. Interfaces 2020, 12, 7888–7896. [Google Scholar] [CrossRef]

- Weerakoon-Ratnayake, K.M.; Uba, F.I.; Oliver-Calixte, N.J.; Soper, S.A. Electrophoretic Separation of Single Particles Using Nanoscale Thermoplastic Columns. Anal. Chem. 2016, 88, 3569–3577. [Google Scholar] [CrossRef] [PubMed]

- Geninatti, T.; Hood, R.L.; Bruno, G.; Jain, P.; Nicolov, E.; Ziemys, A.; Grattoni, A. Sustained Administration of Hormones Exploiting Nanoconfined Diffusion throughnano-channel Membranes. Materials 2015, 8, 5276–5288. [Google Scholar] [CrossRef]

- Di Trani, N.; Silvestri, A.; Bruno, G.; Geninatti, T.; Chua, C.Y.X.; Gilbert, A.; Rizzo, G.; Filgueira, C.S.; Demarchi, D.; Grattoni, A. Remotely controlled nanofluidic implantable platform for tunable drug delivery. Lab Chip 2019, 19, 2192–2204. [Google Scholar] [CrossRef]

- Van der Heyden, F.H.J.; Bonthuis, D.J.; Stein, D.; Meyer, C.; Dekker, C. Electrokinetic Energy Conversion Efficiency in Nanofluidic Channels. Nano Lett. 2006, 6, 2232–2237. [Google Scholar] [CrossRef] [PubMed]

- Van der Heyden, F.H.J.; Bonthuis, D.J.; Stein, D.; Meyer, C.; Dekker, C. Power Generation by Pressure-Driven Transport of Ions in Nanofluidic Channels. Nano Lett. 2007, 7, 1022–1025. [Google Scholar] [CrossRef]

- Daiguji, H.; Oka, Y.; Adachi, T.; Shirono, K. Theoretical study on the efficiency of nanofluidic batteries. Electrochem. Commun. 2006, 8, 1796–1800. [Google Scholar] [CrossRef]

- Dewanda, F.; Ahsan, S.; Lee, M.S. Fabrication of micro/nano-fluidic channels by single-beam direct femtosecond laser writing. Int. Soc. Opt. Photonics 2013, 8615, 76–82. [Google Scholar]

- Liao, Y.; Cheng, Y.; Liu, C.; Song, J.; He, F.; Shen, Y.; Chen, D.; Xu, Z.; Fan, Z.; Wei, X.; et al. Direct laser writing of sub-50 nm nanofluidic channels buried in glass for three-dimensional micro-nanofluidic integration. Lab Chip 2013, 13, 1626–1631. [Google Scholar] [CrossRef] [PubMed]

- Morikawa, K.; Kazoe, Y.; Takagi, Y.; Tsuyama, Y.; Pihosh, Y.; Tsukahara, T.; Kitamori, T. Advanced Top-Down Fabrication for a Fused Silica Nanofluidic Device. Micromachines 2020, 11, 995. [Google Scholar] [CrossRef] [PubMed]

- Zhou, J. Controllable fabrication of enclosed micro/nanochannels via polymethyl methacrylate pattern as sacrificial template and capillary effect. J. Micro/Nanolithography MEMS MOEMS 2011, 10, 049701. [Google Scholar] [CrossRef]

- Scaiola, D.; Stassi, S.; Calmo, R.; Maillard, D.; Varricchio, S.S.; De Pastina, A.; Villanueva, G.; Renaud, P.; Ricciardi, C. Fabrication of clamped-clamped beam resonators with embedded fluidicnano-channel. Microelectron. Eng. 2020, 231, 111395. [Google Scholar] [CrossRef]

- Xia, L.; Zhang, M.; Yang, Z.; Cui, H.; Yin, S.; Hu, S.; Du, C. Nano-channel fabrication by imprinting-induced cracks. Appl. Phys. Lett. 2014, 104, 073104. [Google Scholar] [CrossRef]

- Wang, J.; Yin, Z. SU-8 nano-nozzle fabrication for electrohydrodynamic jet printing using UV photolithography. Mater. Sci. Semicond. Process. 2018, 84, 144–150. [Google Scholar] [CrossRef]

- Mills, K.L.; Huh, D.; Takayama, S.; Thouless, M.D. Instantaneous fabrication of arrays of normally closed, adjustable, and reversible nanochannels by tunnel cracking. Lab Chip 2010, 10, 1627–1630. [Google Scholar] [CrossRef]

- Chung, S.; Lee, J.H.; Moon, M.W.; Han, J.; Kamm, R.D. Non-lithographic wrinklenano-channels for protein preconcentration. Adv. Mater. 2008, 20, 3011–3016. [Google Scholar] [CrossRef]

- Cho, S.Y.; Jang, D.; Kang, H.; Koh, H.J.; Choi, J.; Jung, H.T. Ten nanometer scale WO3/CuO heterojunctionnano-channel for an ultrasensitive chemical Sensor. Anal. Chem. 2019, 91, 6850–6858. [Google Scholar] [CrossRef] [PubMed]

- Liu, M.L.; Huang, M.; Tian, L.Y.; Zhao, L.H.; Ding, B.; Kong, D.B.; Yang, Q.H.; Shao, J.J. Two-Dimensionalnano-channel arrays based on flexible montmorillonite membranes. ACS Appl. Mater. Interfaces 2018, 10, 44915–44923. [Google Scholar] [CrossRef]

- Cheng, H.; Zhou, Y.; Feng, Y.; Geng, W.; Liu, Q.; Guo, W.; Jiang, L. Electrokinetic Energy Conversion in Self-Assembled 2D Nanofluidic Channels with Janus Nanobuilding Blocks. Adv. Mater. 2017, 29, 1700177. [Google Scholar] [CrossRef]

- Zhang, R.; Huang, D.; Fan, Y.; Liu, X.; Liu, Z.; Chu, J. Integrated fabrication of micro/nano-fluidic chip based on nano-imprint lithography and bonding. J. Micromech. Microeng. 2021, 31, 085008. [Google Scholar] [CrossRef]

- Guo, R.; Qi, L.; Xu, L.; Liu, L.; Sun, L.; Yin, Z.; Li, K.; Zou, H. Fabrication of 2D silicon nano-mold by side etch lift-off method. Nanotechnology 2021, 32, 285301. [Google Scholar] [CrossRef] [PubMed]

- Kwon, S.; Kim, Y.-J.; Lim, H.; Kim, J.; Choi, K.-B.; Lee, J.; Kim, G. Fabrication of a Metal Roller Mold with Nanoimprinted Pattern Using Thermal Nanoimprint Lithography. Sci. Adv. Mater. 2020, 12, 481–485. [Google Scholar] [CrossRef]

- Han, J.; Xu, A. Parylene Coating Material and Its Application. Mater. Devices 2011, 36, 430–433. [Google Scholar]

| Deposition Temperature | Chamber Vacuum | Deposition Pressure |

|---|---|---|

| 650 °C | 8 mTorr | 23 mTorr, 33 mTorr, 43 mTorr, 53 mTorr |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Yang, K.; Yin, Z.; Sun, L. Fabrication of High Aspect Ratio Nano-Channels by Thermal Nano-Imprinting and Parylene Deposition. Micromachines 2023, 14, 1430. https://doi.org/10.3390/mi14071430

Yang K, Yin Z, Sun L. Fabrication of High Aspect Ratio Nano-Channels by Thermal Nano-Imprinting and Parylene Deposition. Micromachines. 2023; 14(7):1430. https://doi.org/10.3390/mi14071430

Chicago/Turabian StyleYang, Kun, Zhifu Yin, and Lei Sun. 2023. "Fabrication of High Aspect Ratio Nano-Channels by Thermal Nano-Imprinting and Parylene Deposition" Micromachines 14, no. 7: 1430. https://doi.org/10.3390/mi14071430

APA StyleYang, K., Yin, Z., & Sun, L. (2023). Fabrication of High Aspect Ratio Nano-Channels by Thermal Nano-Imprinting and Parylene Deposition. Micromachines, 14(7), 1430. https://doi.org/10.3390/mi14071430