1. Introduction

Compared to traditional RF technology, free-space optical communication offers significant advantages in data rate performance, cost-effectiveness, and increased security [

1]. As such, it plays an important role in space-ground integrated networks. At the same time, CubeSat satellites are becoming increasingly popular in low Earth orbit networks due to their low cost, quick response times, potential for constellation formation, and ability to perform tasks that a single large satellite cannot [

2,

3]. Since the German Aerospace Center began to focus on the research and development of small satellite optical communication terminals more than 10 years ago, this field has attracted more and more attention from major research institutions: NASA, the Jet Propulsion Laboratory, European Space Agency, and National Institute of Information and Communication Technology of Japan [

4,

5].

In 2008, the German TerraSAR-X and the United States NFIRE satellites marked a new phase in space laser communication by successfully establishing the first coherent link over a distance of more than 5000 km at a rate of 5.6 Gbit/s [

6,

7]. The TerraSAR-X satellite is equipped with the LCT135 laser terminal developed by DLR and has become the standard configuration of the European Data Relay Satellite System (EDRS). LCT135 has made significant contributions to the establishment of high-orbit backbone satellite networks and low-orbit satellite constellations. After more than 30 years of research and technological accumulation, TESAT has developed a range of new laser communication terminal (LCT) products [

8,

9].

However, establishing optical communication links between CubeSats is a daunting task. The laser transmission link requires very strict beam pointing stability because the system is extremely susceptible to interference from the mechanical vibration of the loading platform. Severe jitter will cause the laser beam to deviate from the field of view of the target receiving system, resulting in pointing errors that increase the probability of signal interruption and information loss. Precise pointing, acquisition, and tracking (PAT) of incident light to establish a communication link often requires complex optical and hardware systems to account for the relative movement between terminals. For small satellites with strict size, weight and power (SWaP) requirements, the PAT system also increases the system burden. Therefore, it is vital that the miniaturized laser communication precise pointing transceiver system be studied.

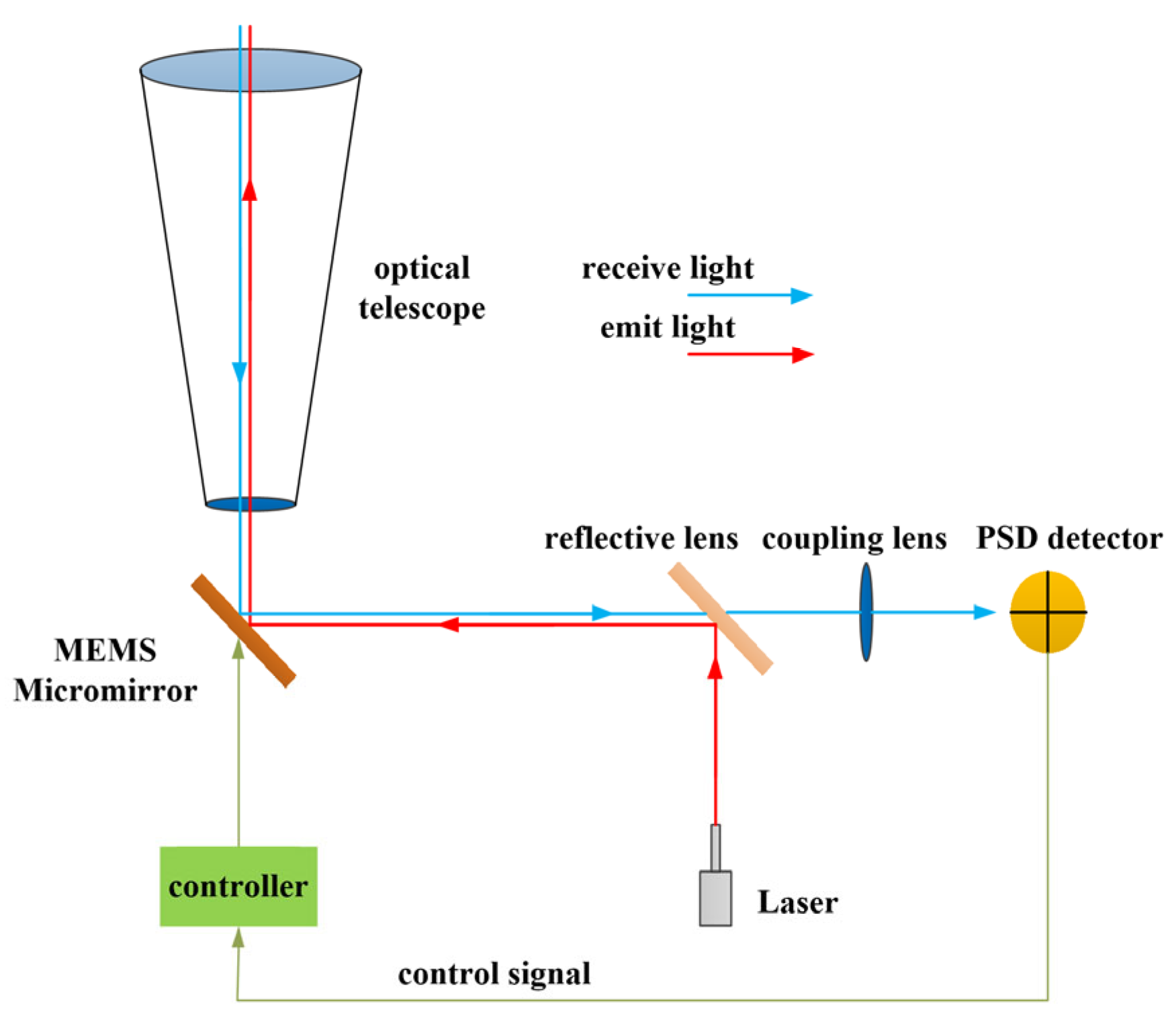

Mirror-based PAT systems use reflective mirrors as actuators to achieve beam stabilization, pointing, and tracking. The reflector mirrors deflect the incident laser beam onto the receiving sensor, but unlike traditional gimbal-based PAT mechanisms, mirror-based PAT systems are lightweight, have high response speeds, and provide fine pointing resolution. Feedback control systems are typically used to detect errors in the trajectory or phase of the reflected beam and to fine-tune the deflection angle of the reflector mirror.

Micro-electromechanical Systems (MEMS) is a cutting-edge technology based on micro/nanotechnology [

10]. It enables various micro-actuators, sensors, and signal processing circuits to be integrated into a microscale/nanoscale chip. Because of its advantages—small size, ultra-low power consumption, low cost, high integration density, and stable reliability—MEMS is increasingly important for the entire semiconductor ecosystem. It has been widely used in defense, high-speed optical communication, the aerospace and automotive industries, medical equipment, and smart terminal devices [

11,

12,

13].

2. MEMS Micromirror Optical Scanning Model

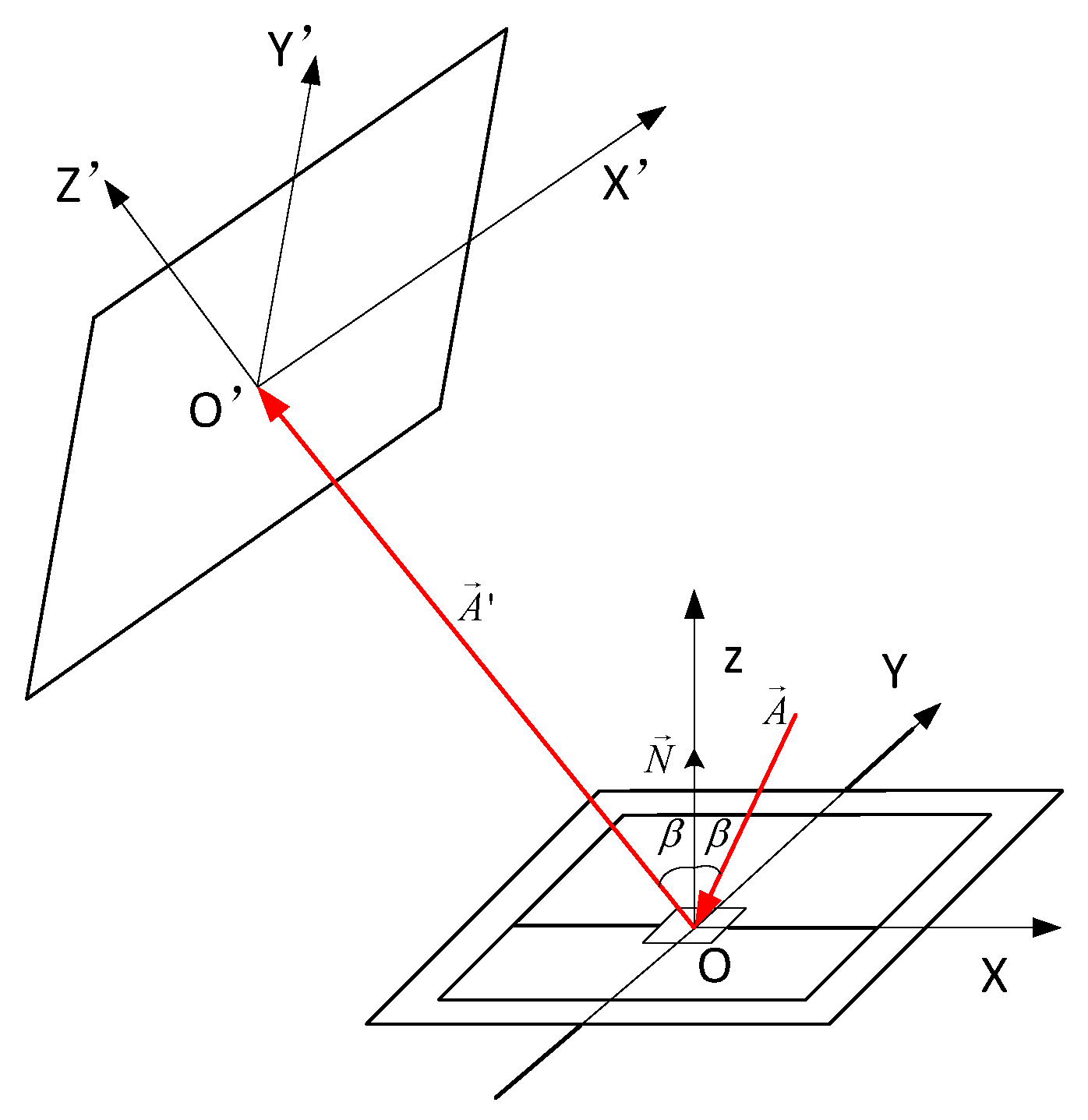

To investigate the relationship between the deflection angle and planar scanning of the 2D MEMS micromirror, a spatial rectangular coordinate system was established (

Figure 1). In the initial state, where it did not deflect, the micromirror coincided with the

plane, and

was the normal unit vector of the

plane coincident with the

Z axis. The incident light

formed an angle

with the normal of the MEMS reflection plane on the

plane. The reflected light

was reflected by the MEMS reflective plane, entered the

plane, and was coplanar with it. The distance between

O and

O’ was L, the unit normal vector was

, and the output light was

. The surface of the MEMS reflective mirror continuously changes as the 2D MEMS mirror vibrates in the horizontal and vertical directions, and this relationship can be derived using the method of matrix optics [

12,

14].

The vector form of its reflection law can be expressed in matrix optics by Equation (1).

where

is the incident light unit vector;

is the normal direction unit vector; and

is the outgoing light unit vector. Transforming the vector form of the reflection law in Equation (1) into a matrix expression, establishes a 3D rectangular coordinate system

x,

y,

z where

i,

j,

k represent the directions of the three-dimensional components in the vector analysis, respectively.

The outgoing light

, the incident light

and the reflection matrix

can be expressed as Equation (5).

According to the above description, the expression of the reflection matrix can be obtained as Equation (6).

The expression of the reflection matrix

is only related to the component of the normal unit vector

of the reflection surface in each direction, and the reflection matrix is determined by the spatial position of the reflection surface. When the MEMS micromirror did not vibrate in the initial state using

as the principal coordinate system, the following relationship was obtained:

Thus, the reflection matrix in the initial state can be obtained as Equation (9).

Equation (9) confirms that the intersection point of

and the

plane in the initial state is the origin

, and the outgoing light overlaps with the

axis. When the MEMS mirror undergoes vibrations and deflections in the 2D space, the aforementioned theory will be used to calculate the intersection coordinates of the projection line and the

plane as well as the deflection angle of the

axis. Assuming that the horizontal deflection angle of the MEMS micromirror is

, the vertical deflection angle is

. This is equivalent to the

plane in

Figure 1: first rotating

counterclockwise with the

y-axis as the axis of rotation and then rotating

clockwise with the

x-axis as the axis of rotation. The new normal unit vector corresponding to the reflective surface of the MEMS micromirror can be expressed as Equation (10).

After calculation and simplification, the output light in the deflected state of the mirror was obtained:

Regardless of the deviation of the reflecting mirror, the starting point of the output light was always

. Therefore, the linear equation of the output light was

The coordinates of the intersection point between the incident light and the

plane was obtained as follows:

It can be seen from Equation (13) that when , the MEMS micromirror was deflected only in the horizontal direction, and was obtained, indicating that the new reflected line was deflected at an angle of to the original reflected line. This meant that the optical reflection angle in the horizontal direction was twice the mechanical deflection angle of the micromirror. On the other hand, when the relationship was not satisfied in the vertical direction. Since the condition for this conclusion is that the initial incident light was horizontally incident, it lay in the horizontal plane. When , indicating that the deviation angle of the MEMS mirror was extremely small, we approximated , which implied . The equation showed that when the mechanical deflection angle was small, the ratio of the vertical scan length to the horizontal scan length of the reflector was approximately the cosine of the incident light angle; that is, the scanning effect of the MEMS micromirror was related to the incident angle of the initial incident light.

From Equation (13), it is clear that for various horizontal mechanical deflection angles

and vertical mechanical deflection angles

of the MEMS micromirrors as well as the different initial light incident angles, the relationship between the horizontal and the vertical deflection angles of the initial output light vector could be expressed as Equation (14):

3. Scanning Range of MEMS Micromirrors

As scanning devices in laser communication, MEMS micromirrors have the significant advantages of being small and giving excellent performance [

15]. However, their mechanical deflection angle is relatively limited, and currently available rapid-scanning 2D scanning mirrors typically have mechanical deflection angles of around ±5°, rendering them unsuitable for large-field scanning. In view of this, the expansion angle optical system for the MEMS micromirror is designed to increase the scanning angle. By adjusting the distance between the lens and the micromirror, the optical system expands or reduces the optical scanning range [

16].

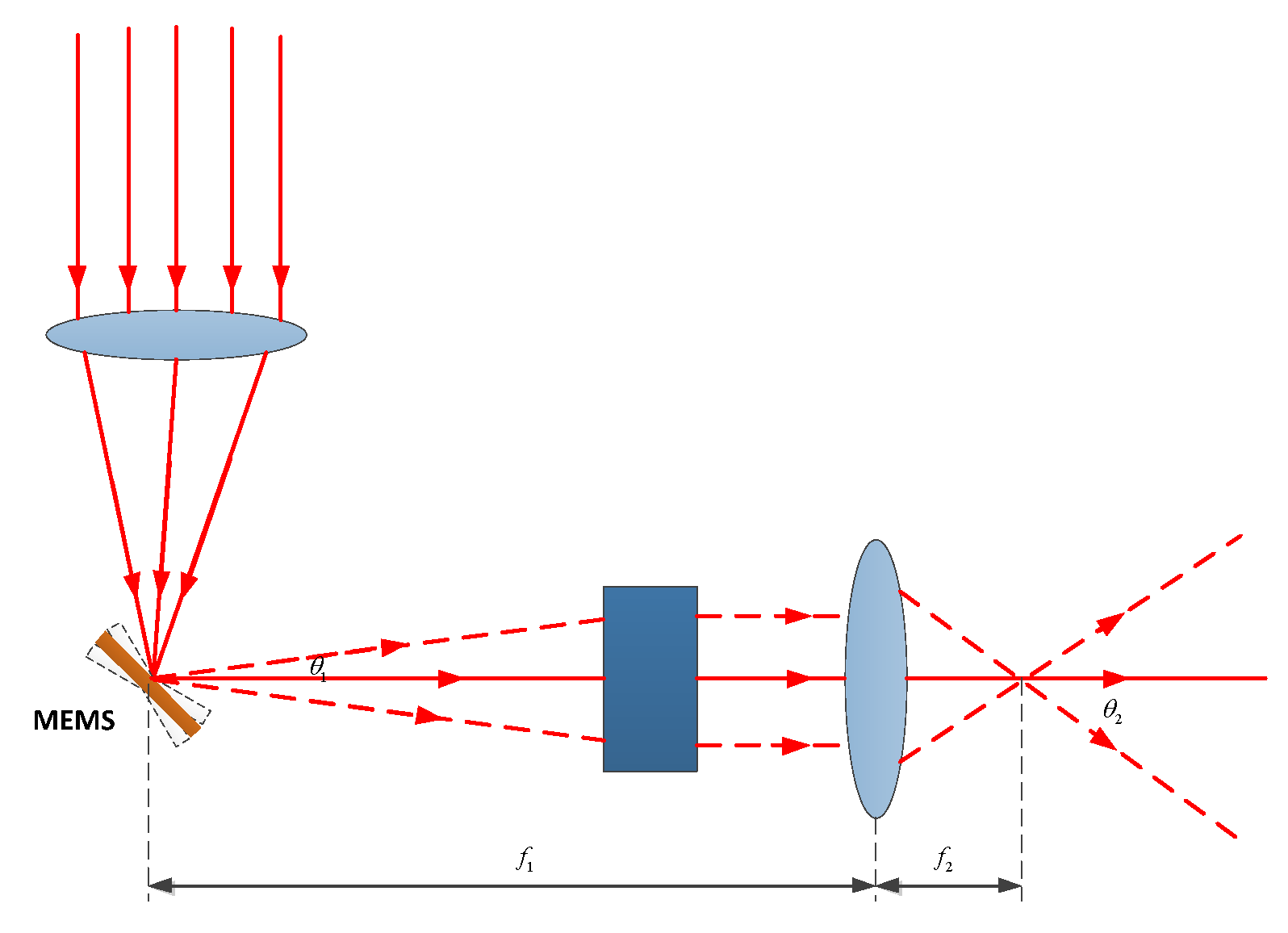

By designing an optical beam expanding system as shown in

Figure 2, the laser beam is emitted and then collimated before being focused onto the reflective surface of a MEMS mirror by a preceding focusing lens. The mechanical deflection angle of the MEMS mirror is relatively small. After passing through an

lens, a light spot corresponding to a certain field of view for the rear lens is obtained. In this case, the field-of-view angle is designed to be 60°.

The maximum image height

on the image plane of the

lens can be expressed as:

where

is the focal length of the

lens, and

is 2 times the maximum mechanical deflection angle of the MEMS. Finally, through a positive lens, its field of view

satisfies Equation (16):

where

is the effective image square focal length of the angle-expanding lens, and

is the field-of-view angle after beam expansion. Therefore, Equation (17) can be obtained:

Obviously, to expand the scanning-angle range of the MEMS micromirror, must be smaller than , which is a key condition of the optical beam expander system. Moreover, when the light emitted by the short-focus positive lens is parallel or close to parallel beams, the laser spot can be made smaller when projected from a longer distance.

5. Scan Capture Simulation Experiment

Due to the small divergence angle of the communication light that MEMS micromirrors use for laser communication scanning and capturing, the beam jitter impact is significant. Moreover, the system operates in an open-loop state during scanning, without error correction, which can cause the scanning beam to deviate from its intended trajectory, leading to excessive overlap or missed scanning spots. Ultimately, this results in decreased coverage of the scanning beam over the uncertain area.

Line-of-sight (LOS) jitter is caused mainly by the vibration of the platform. Therefore, this paper proposes mitigating the effect of optical axis jitter by introducing an additional overlap factor during scanning. In general, LOS jitter follows a Rayleigh distribution in the radial direction, and its probability density function can be expressed as

During scanning,

is the angular deviation of the scanning-beam jitter

is the standard deviation of the beam. When the angular deviation

of the jitter exceeds a certain threshold in the azimuth and elevation directions, there is a gap between the scanning spots, resulting in an uncovered scanning area. This phenomenon is known as “missed scanning”. Let’s designate the threshold angle for missed scanning as

and the probability of missed scanning as

. The expression for

is

Therefore, the coverage

of the scanning beam of the communication light on the capture uncertainty region is shown by Equation (28).

From this, the expression of the missed scan-limit angle

can be deduced as

To eliminate the missed scan and meet the scanning beam coverage requirements

of the uncertain region, an additional overlap factor

was introduced, as shown in Equation (30):

To further analyze and validate the impact of factors such as beam divergence angle, overlap factor, size of the uncertain region and possible microvibrations on the performance of laser communication scanning capture, experimental studies were conducted using computer simulations. For this purpose, a GUI experimental interface was designed as shown in

Figure 6. This software program allows the flexible adjustment of parameters such as beam divergence angle, overlap factor, detector response time, size of the uncertain region, and standard deviation of microvibrations. By changing the values of these parameters, the scanning trajectory of the spot and its coverage of the uncertain region can be observed in the interface, enabling simulation-based calculations of the time required to complete the scanning of the uncertain region.

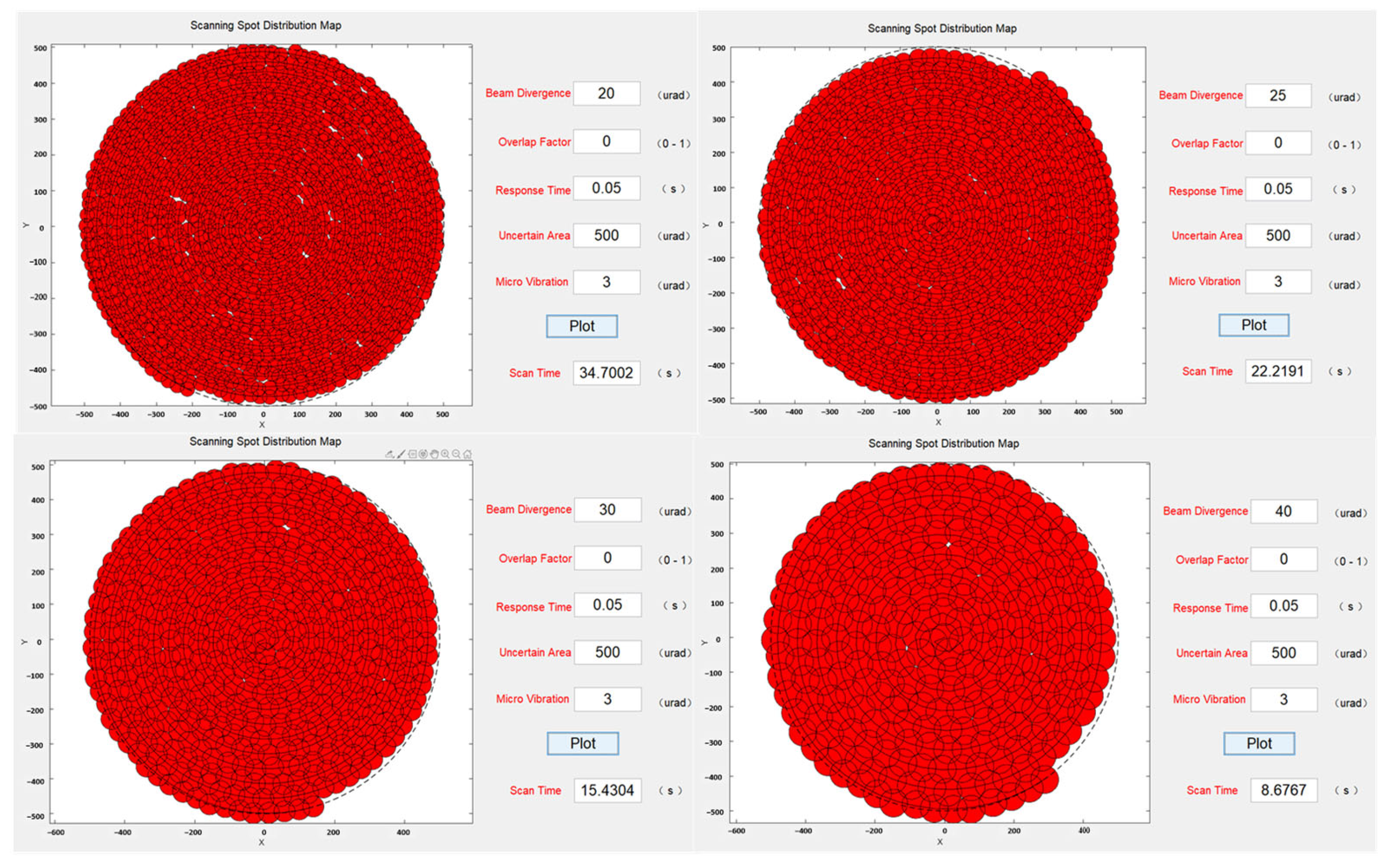

First, the simulation program analyzed the scanning coverage of the same uncertain region for different beam divergence angles. The results, shown in

Figure 7, indicated that when the system was affected by microvibrations to some extent, certain areas exhibited missed scanning. This observation was consistent with the previous analysis. As the beam divergence angle increased, the time required to scan the entire uncertain region gradually decreased. It was observed that while the microvibrations were kept constant, a larger beam divergence angle led to a smaller area of missed scanning, suggesting that increasing the beam divergence angle had a certain effect on reducing the impact of microvibrations.

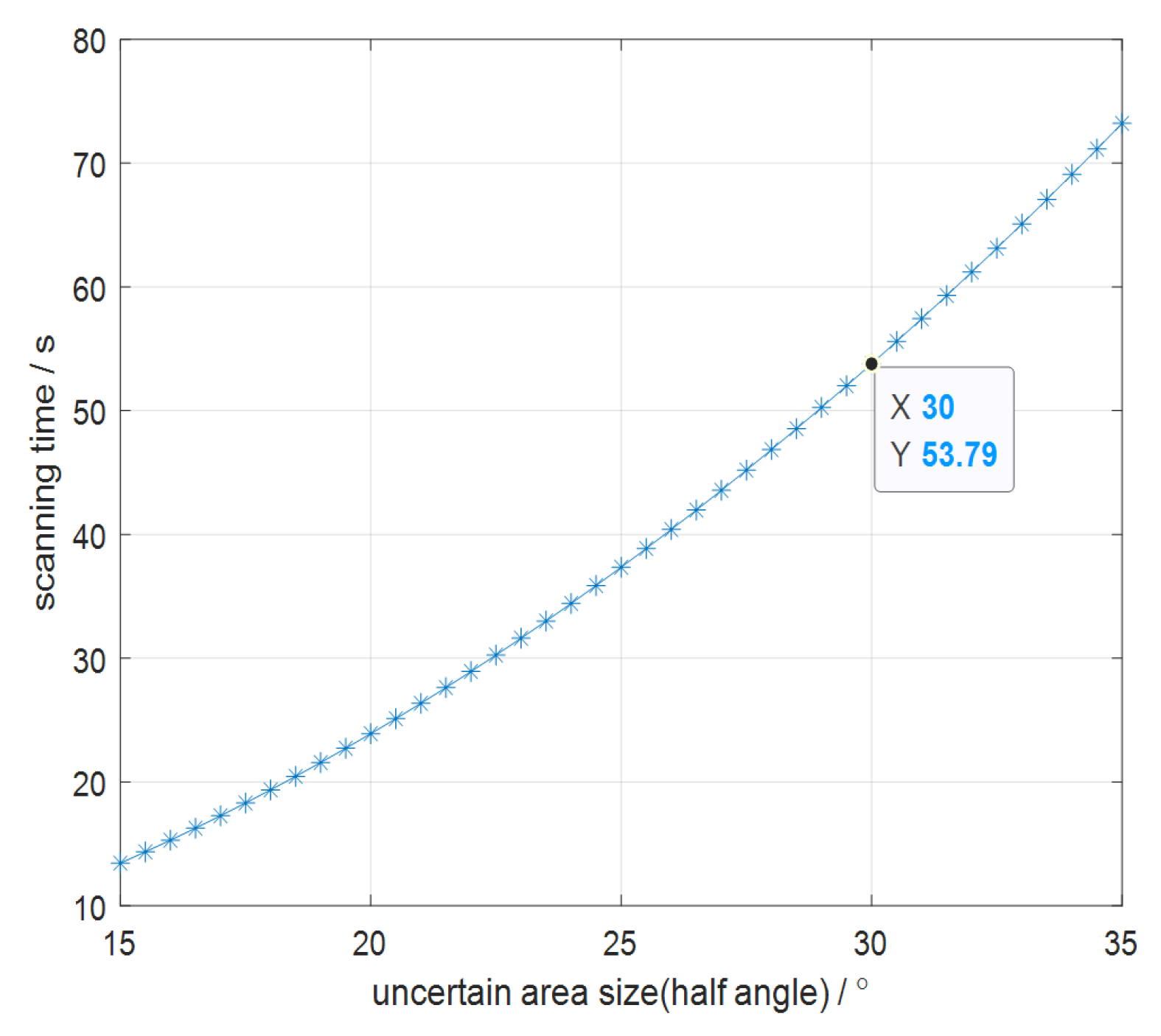

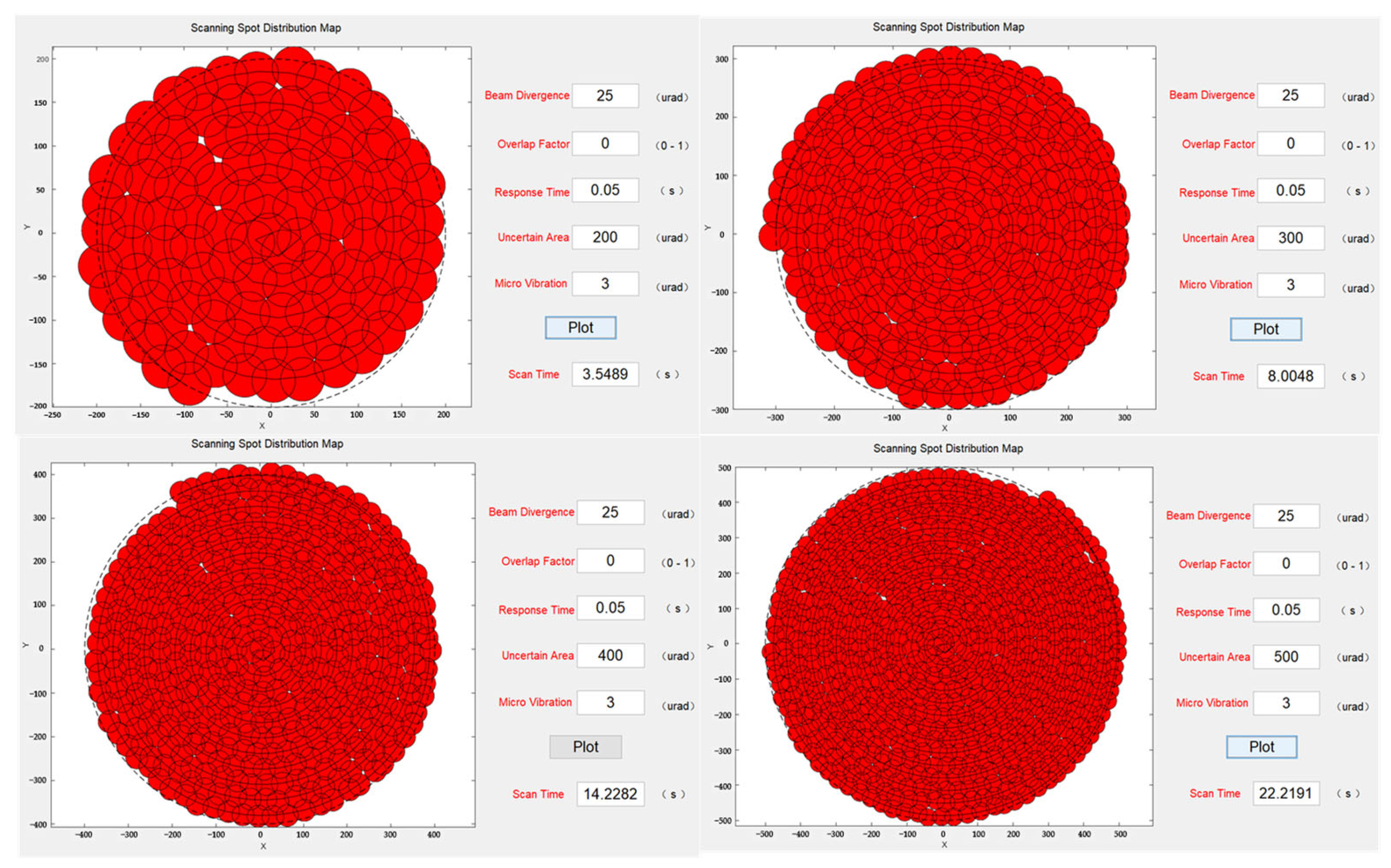

Next, while keeping the beam divergence angle constant, the scanning coverage for different sizes of uncertain regions was analyzed. The simulation results, shown in

Figure 8, revealed that when the system was affected by microvibrations, changing the size of the uncertain region without altering the beam divergence angle and coverage factor did not reduce missed scans. Moreover, under the same parameter settings, larger uncertain regions required a longer time to complete the scanning. Furthermore, to mitigate missed scanning at the same beam divergence angle, it was necessary to increase the coverage factor, which further increased the scanning duration.

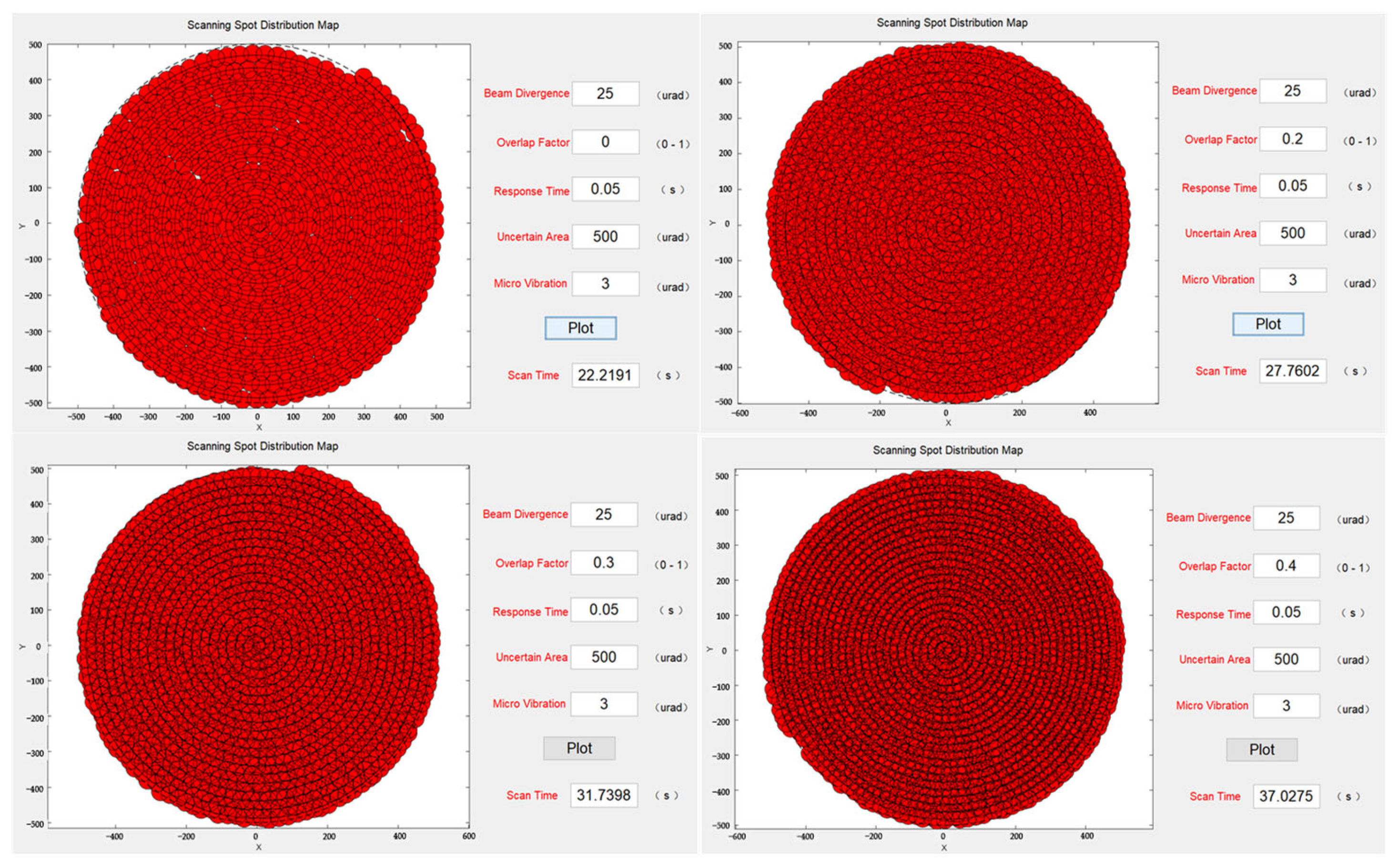

To verify the reduction in missed scanning caused by microvibrations, the overlap factor was gradually increased from 0 to 0.4 while keeping other system parameters constant. The simulation results, shown in

Figure 9, indicated that when the system was affected by microvibrations, severe missed scanning occurred if no overlap factor had been introduced. However, when it was introduced and gradually increased to 0.3, there was a noticeable reduction in microvibrations with a standard deviation of 5 µrad. Until the overlap factor reached 0.4, there were no missed scans. However, it is important to note that as the overlap factor increased, scanning time also increased, which should not be ignored. At an overlap factor of 0.4, the time required for the system to scan the entire uncertain region increased by 68% compared to no overlap factor. In practical applications, it is necessary to consider both the scanning time and coverage rate to select optimal parameters.

Finally, to verify the effect of microvibrations on the system visually, standard deviations of 3, 5, 10, and 20 µrad were introduced under the same beam divergence angle, overlap factor, and uncertain region size. The scanning simulation results in

Figure 10 revealed that as the effect of microvibrations gradually increased, the occurrences of missed scanning became more severe.

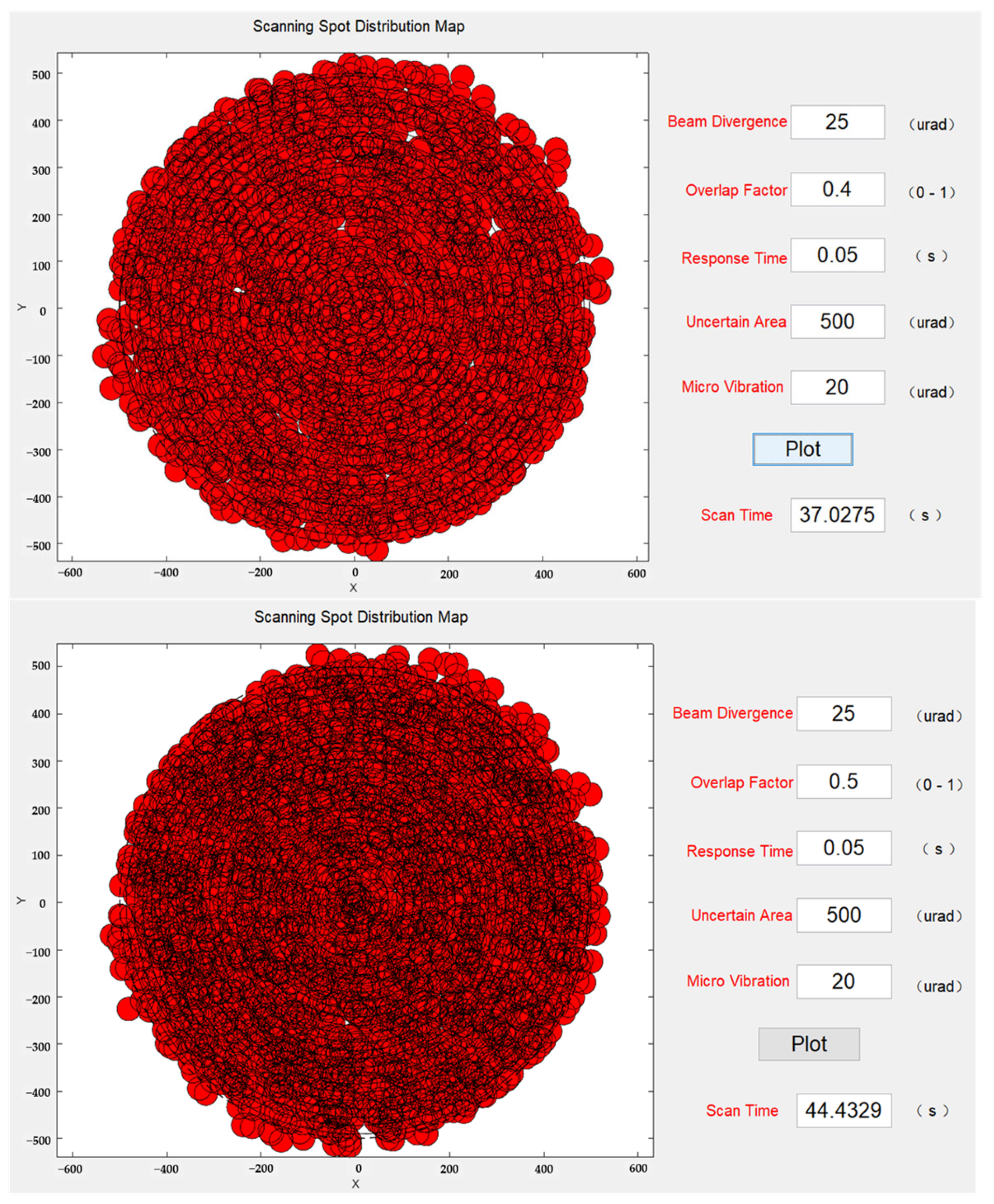

As mentioned earlier, to mitigate the effect of microvibrations, increasing the size of the overlap factor was considered. Building upon the previous set of simulation experiments, the overlap factor was gradually increased up to 0.5 while the microvibration standard deviation remained at 20 µrad. The scanning simulation results at this stage are shown in

Figure 11. With an overlap factor of 0.4, there were still some instances of missed scanning, but the beams had already covered the majority of the uncertain region. When the overlap factor reached 0.5, there were no missed scans. However, the scanning time of the system reached 44 s, representing a 95% increase compared to the 0.2 overlap factor.

Based on the above analysis, it is evident that the system inevitably experiences some level of micro-vibration effects. These micro-vibrations introduce missed scanning occurrences during the scanning process, which adversely impact the scanning capture probability. To overcome the detrimental effects of micro-vibrations in equidistant and equilinear velocity spiral scanning, the introduction of an overlap factor is necessary. However, increasing the overlap factor also increases the system scanning time. Therefore, in practical applications, a comprehensive consideration of the overlap factor, balancing capture probability and scanning time, is required. Through simulation analysis, the optimal system parameters can be determined.