Thin Glass Micro Force Plate Supported by Planar Spiral Springs for Measuring Minute Forces

Abstract

1. Introduction

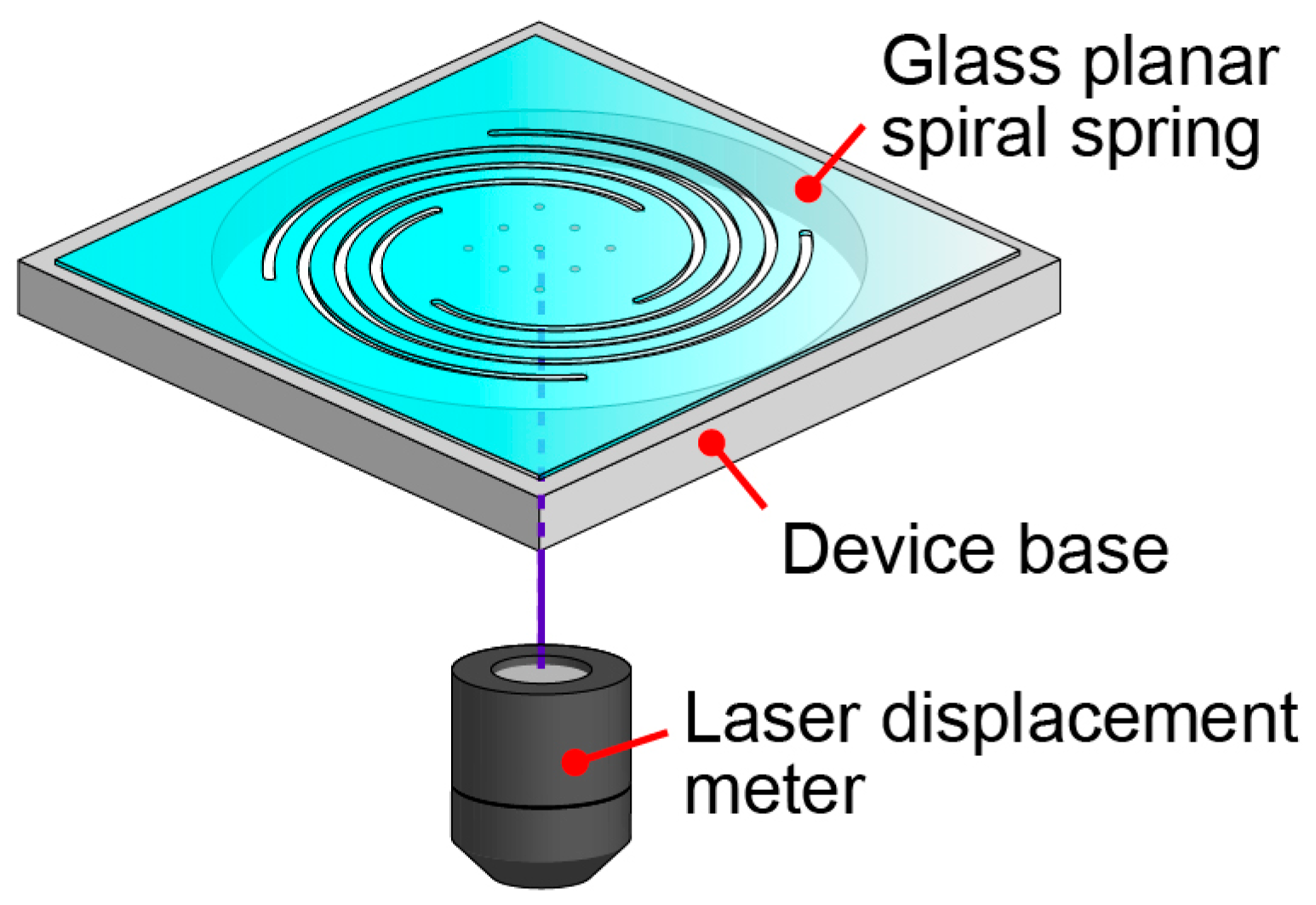

2. Design, Principle, and Development

2.1. Design and Principle

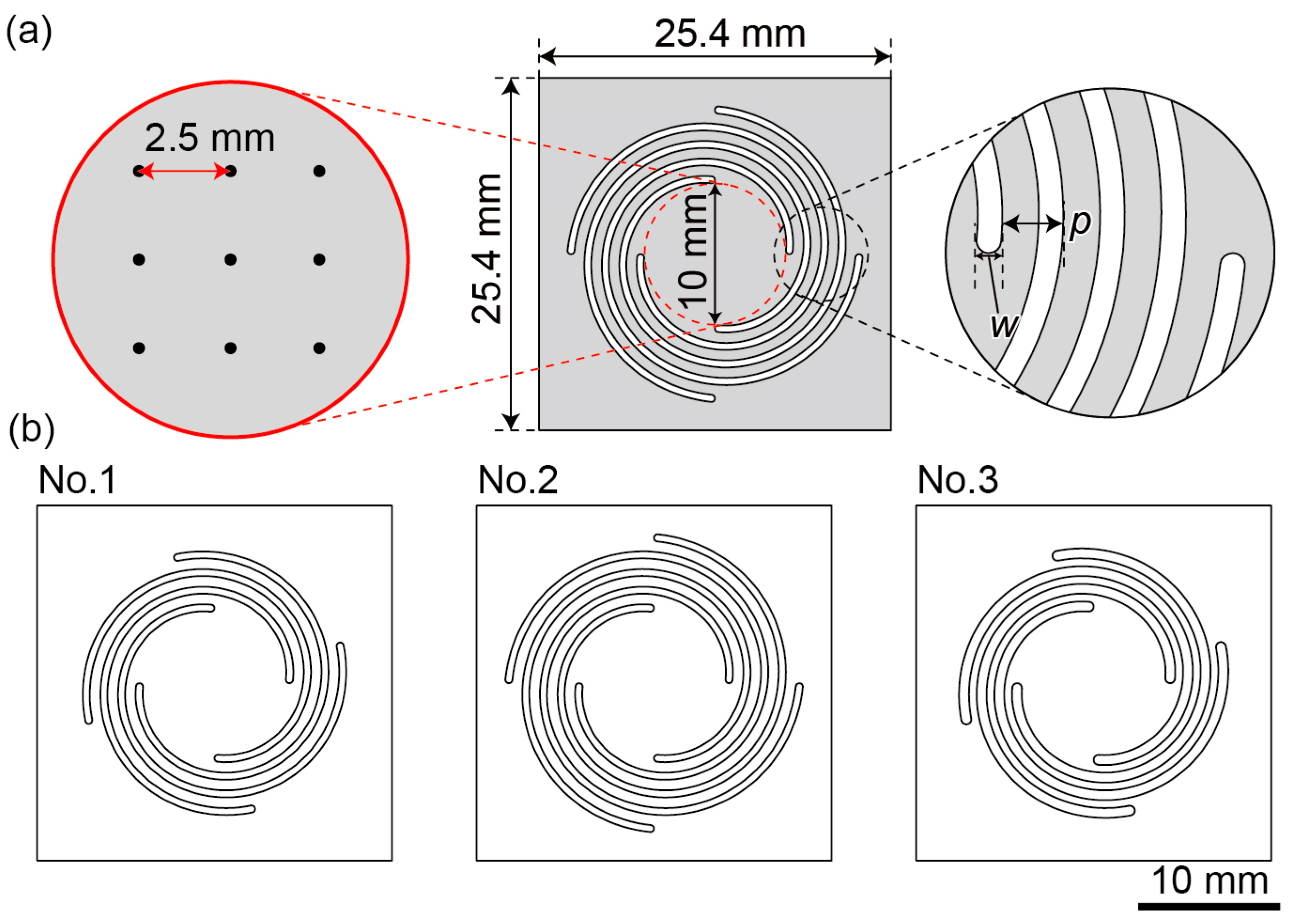

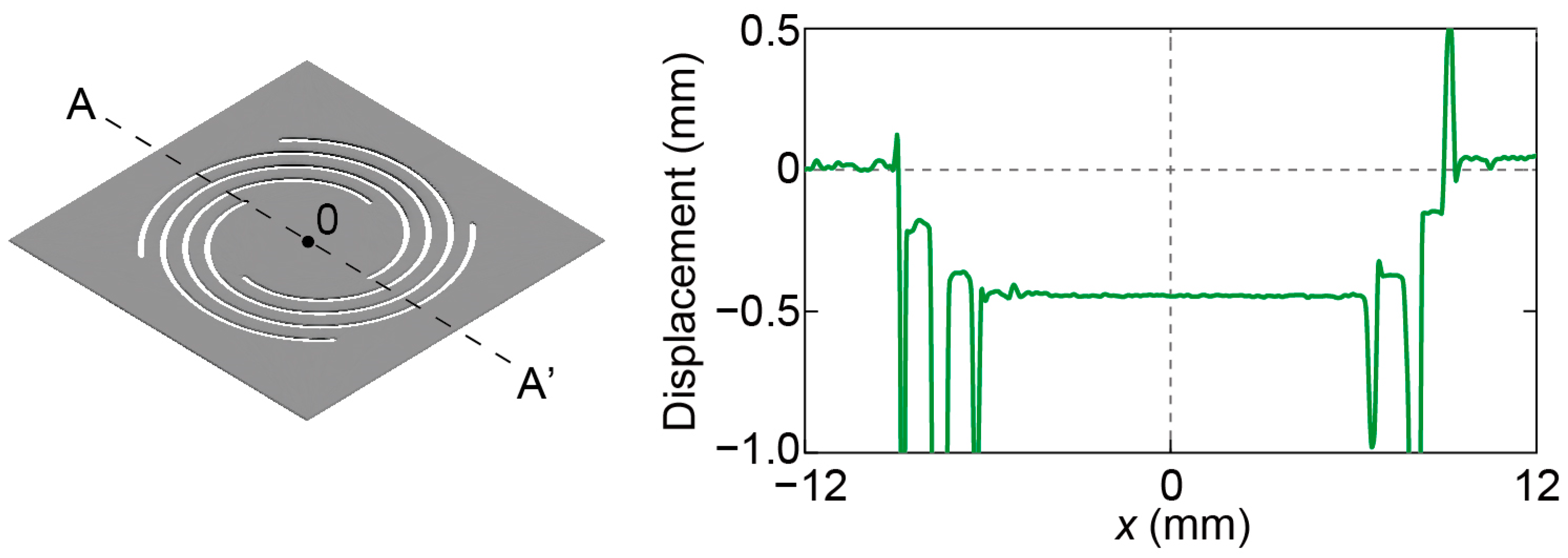

2.2. Plate Design

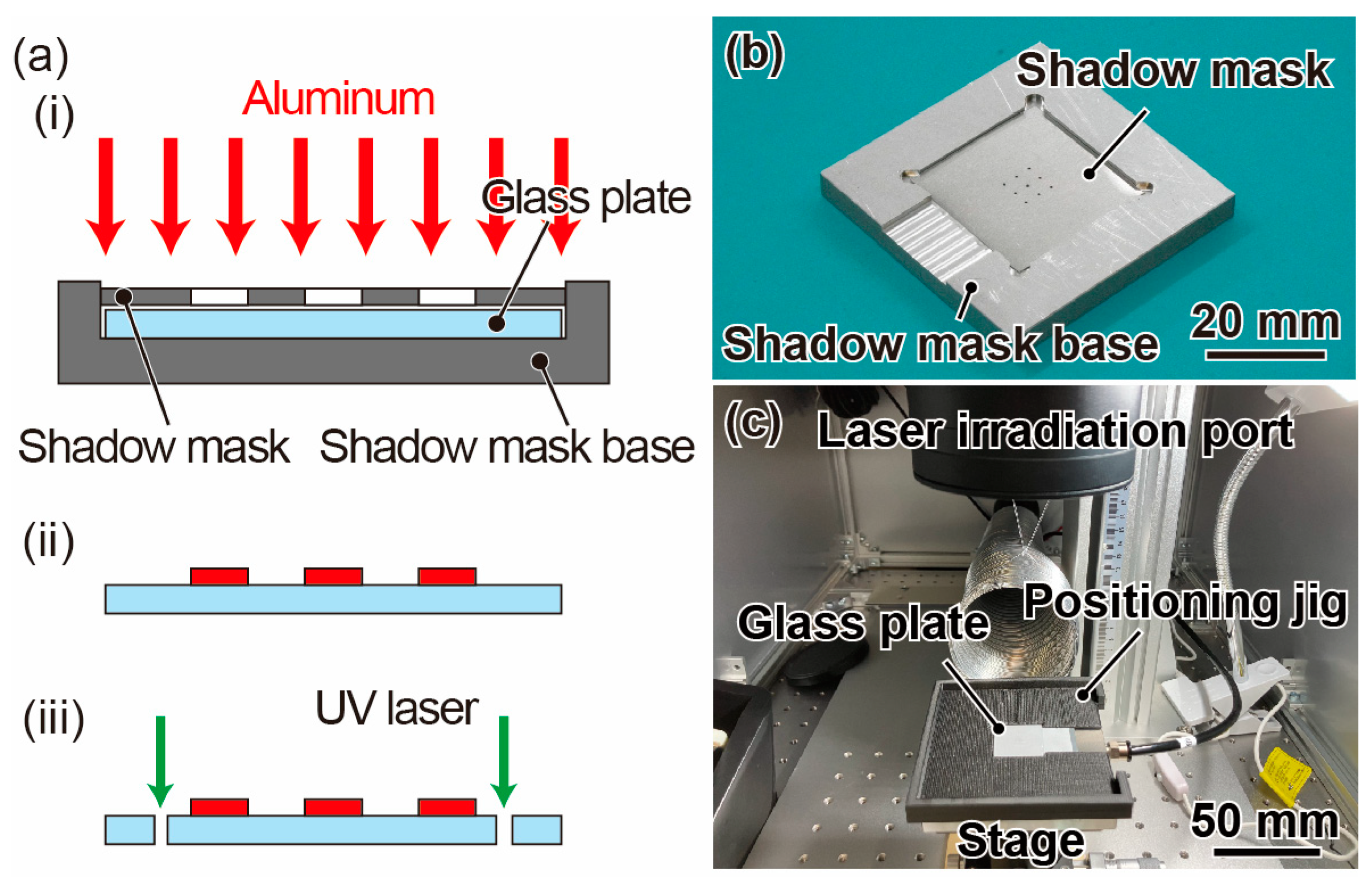

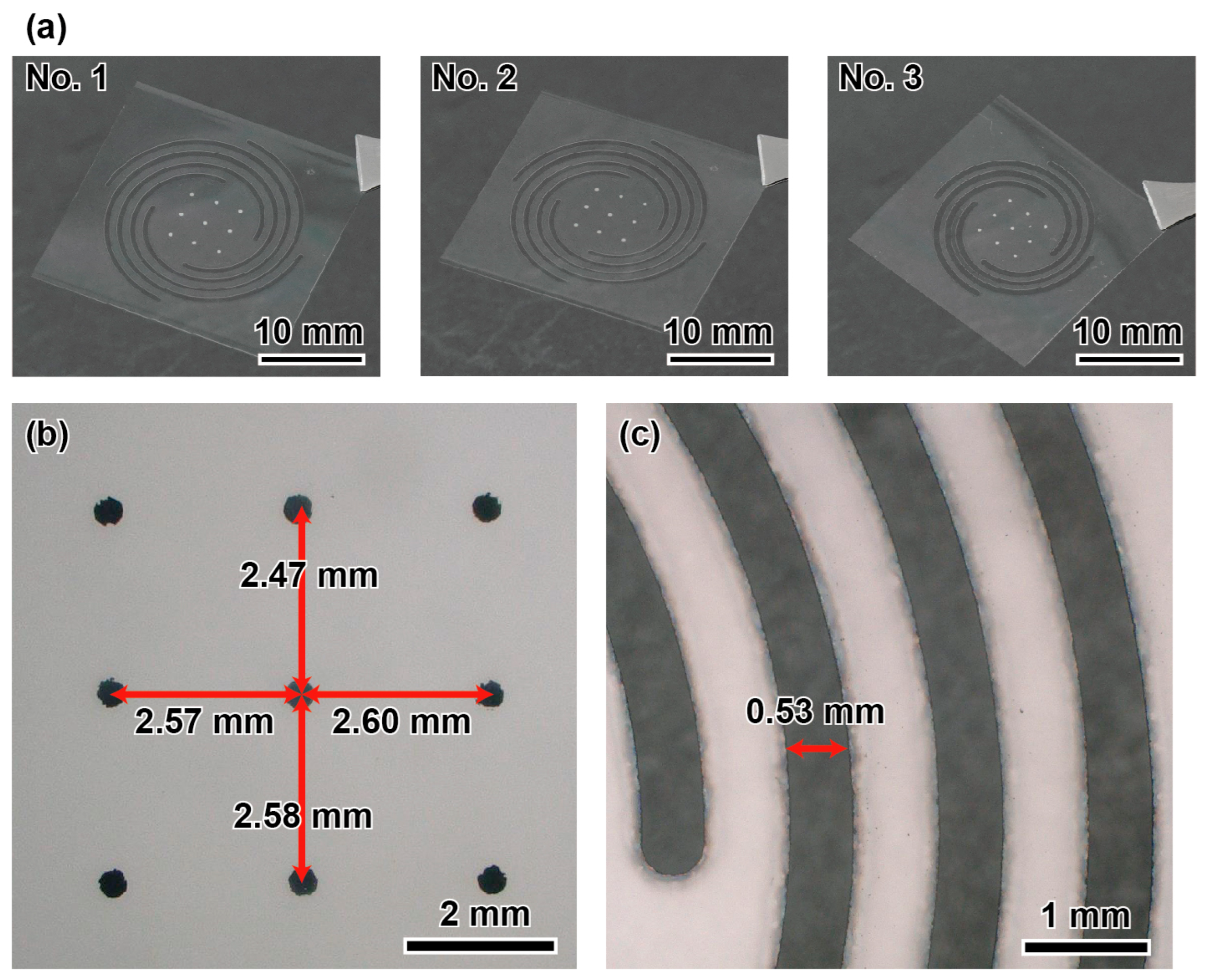

2.3. Fabrication

3. Experiments and Results

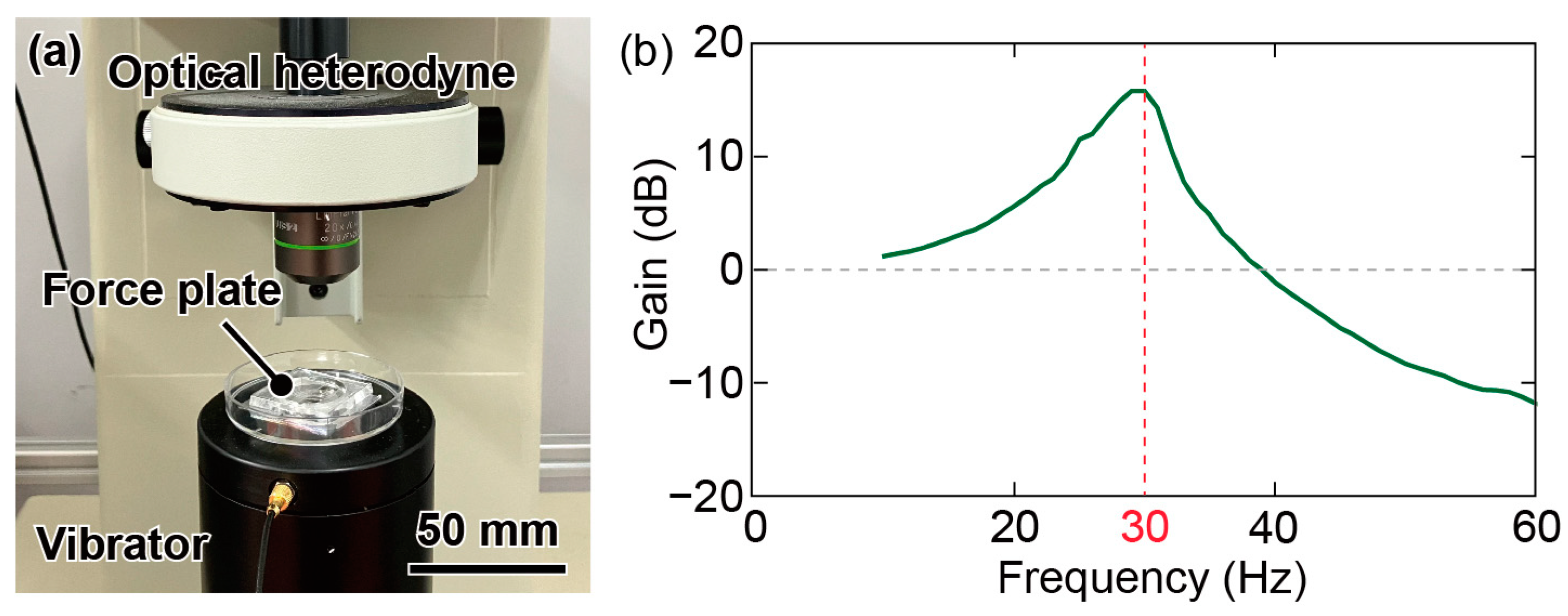

3.1. Resonant Frequency

3.2. Experimental Setup

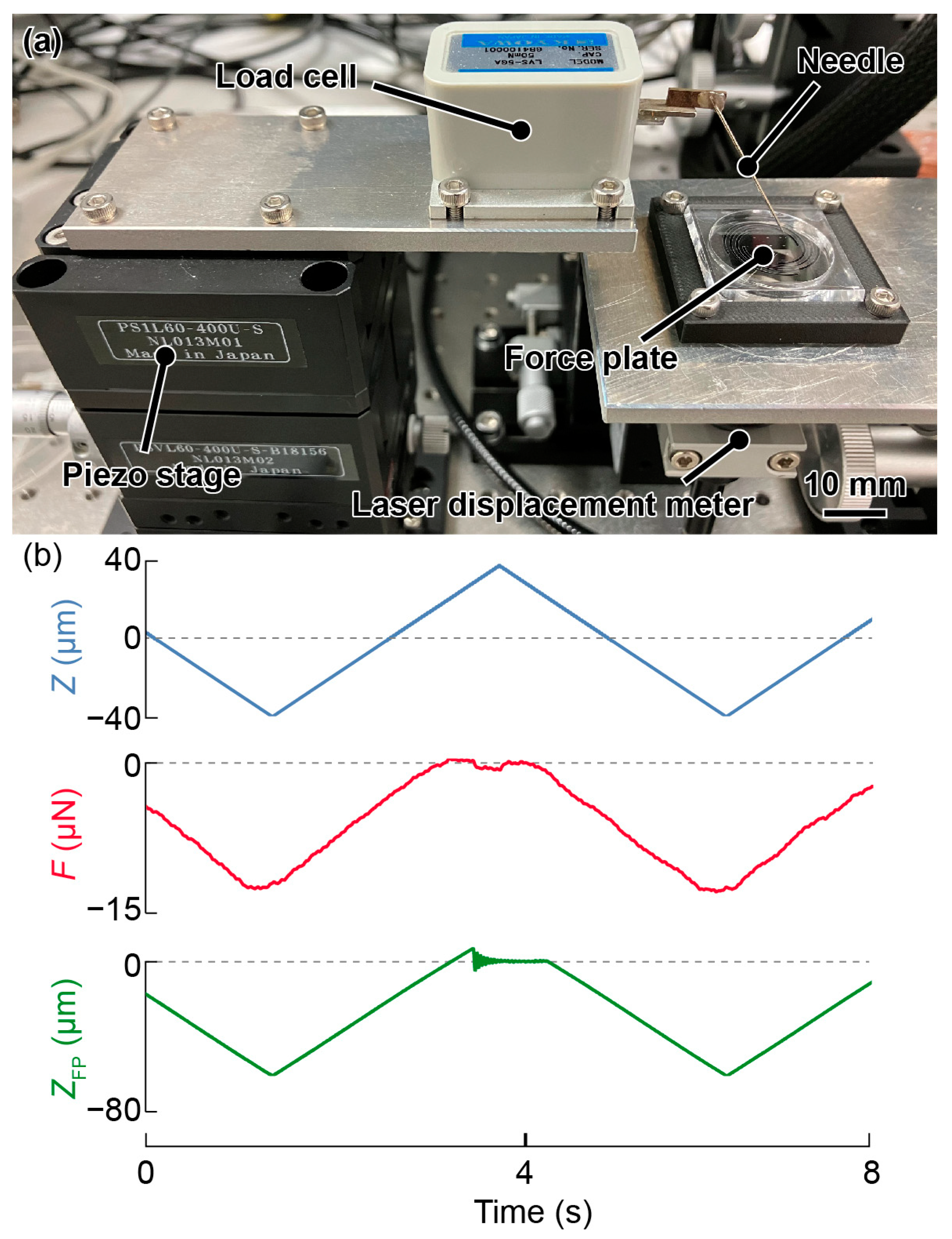

3.3. Sensitivity Evaluation

4. Discussion

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Liang, Q.; Zhang, D.; Coppola, G.; Wang, Y.; Wei, S.; Ge, Y. Multi-Dimensional MEMS/Micro Sensor for Force and Moment Sensing: A Review. IEEE Sens. J. 2014, 14, 2643–2657. [Google Scholar] [CrossRef]

- Wei, Y.Z.; Xu, Q.S. An overview of micro-force sensing techniques. Sens. Actuators A Phys. 2015, 234, 359–374. [Google Scholar] [CrossRef]

- Polacheck, W.J.; Chen, C.S. Measuring cell-generated forces: A guide to the available tools. Nat. Meth. 2016, 13, 415–423. [Google Scholar] [CrossRef] [PubMed]

- Yang, Y.; Zhao, M.R.; Huang, Y.G.; Zhang, H.; Guo, N.; Zheng, Y.L. Micro-force sensing techniques and traceable reference forces: A review. Meas. Sci. Technol. 2022, 33, 114010. [Google Scholar] [CrossRef]

- Agarwal, K.; Hwang, S.; Bartnik, A.; Buchele, N.; Mishra, A.; Cho, J.-H. Small-Scale Biological and Artificial Multidimensional Sensors for 3D Sensing. Small 2018, 14, 1801145. [Google Scholar] [CrossRef] [PubMed]

- Takahashi, H. MEMS-Based Micro Sensors for Measuring the Tiny Forces Acting on Insects. Sensors 2022, 22, 8018. [Google Scholar] [CrossRef] [PubMed]

- Takahashi, H.; Thanh-Vinh, N.; Jung, U.G.; Matsumoto, K.; Shimoyama, I. MEMS two-axis force plate array used to measure the ground reaction forces during the running motion of an ant. J. Micromech. Microeng. 2014, 24, 065014. [Google Scholar] [CrossRef]

- Reinhardt, L.; Blickhan, R. Ultra-miniature force plate for measuring triaxial forces in the micronewton range. J. Exp. Biol. 2014, 217, 704–710. [Google Scholar] [PubMed]

- Endlein, T.; Federle, W. On Heels and Toes: How Ants Climb with Adhesive Pads and Tarsal Friction Hair Arrays. PLoS ONE 2015, 10, e0141269. [Google Scholar] [CrossRef] [PubMed]

- Furuya, R.; Takahashi, H.; Thanh-Vinh, N.; Yano, T.; Ito, K.; Takahata, T.; Matsumoto, K.; Shimoyama, I. Measurement of jumping force of a fruit fly using a mesa structured force plate. In Proceedings of the 29th IEEE International Conference on Micro Electro Mechanical Systems (MEMS2016), Shanghai, China, 24–28 January 2016; pp. 165–168. [Google Scholar]

- Mouterde, T.; Nguyen, T.-V.; Takahashi, H.; Clanet, C.; Shimoyama, I.; Quéré, D. How merging droplets jump off a superhydrophobic surface: Measurements and model. Phys. Rev. Fluids 2017, 2, 112001. [Google Scholar] [CrossRef]

- Full, R.J.; Tu, M.S. Mechanics of six-legged runners. J. Exp. Biol. 1990, 148, 129–146. [Google Scholar] [CrossRef] [PubMed]

- Bartsch, M.S.; Federle, W.; Full, R.J.; Kenny, T.W. A Multiaxis Force Sensor for the Study of Insect Biomechanics. J. Microelectromech. Syst. 2007, 16, 709–718. [Google Scholar] [CrossRef]

- Lin, H.-T.; Trimmer, B.A. A new bi-axial cantilever beam design for biomechanics force measurements. J. Biomech. 2012, 45, 2310–2314. [Google Scholar] [CrossRef] [PubMed]

- Takahashi, H.; Furuya, R.; Yano, T.; Ito, K.; Takahata, T.; Matsumoto, K.; Shimoyama, I. Maximum force capacity of legs of a fruit fly during landing motion. In Proceedings of the 19th International Conference on Solid-State Sensors, Actuators and Microsystems (TRANSDUCERS2017), Kaohsiung, Taiwan, 18–22 June 2017; pp. 1061–1064. [Google Scholar]

- Kohyama, S.; Takahashi, H.; Takahata, T.; Shimoyama, I. High sensitive and large area force plate for ground reaction force measurement of ant running. In Proceedings of the 31st IEEE International Conference on Micro Electro Mechanical Systems (MEMS2018), Belfast, UK, 21–25 January 2018; pp. 874–877. [Google Scholar]

- Sugimoto, T.; Kawasaki, Y.; Toda, H.; Takahashi, H. Measurement method of a microspring-supported force plate with an external laser displacement meter. Meas. Sci. Technol. 2022, 33, 105118. [Google Scholar] [CrossRef]

- Shimazaki, K.; Sugimoto, T.; Toda, H.; Takahashi, H. A Polyimide Film-Based Simple Force Plate for Measuring the Body Mass of Tiny Insects. Sensors 2022, 22, 8352. [Google Scholar] [CrossRef] [PubMed]

- Kawasaki, Y.; Takahashi, H. Spiral Spring-Supported Force Plate with an External Eddy Current Displacement Sensor. Actuators 2023, 12, 16. [Google Scholar] [CrossRef]

- Suzuki, M.; Takahashi, T.; Aoyagi, S. A Distributed 3D Force Sensor for Detecting Insect Motion by Optically Evaluating Deformation of Microscale Grid Pattern Inscribed on A Flexible Hydrogel Sheet. In Proceedings of the 2019 20th International Conference on Solid-State Sensors, Actuators and Microsystems & Eurosensors XXXIII (TRANSDUCERS & EUROSENSORS XXXIII), Berlin, Germany, 23–27 June 2019; pp. 2504–2507. [Google Scholar]

- Zheng, Y.; Yin, W.; Lu, H.; Tian, Y. Revealing stepping forces in sub-mg tiny insect walking. Chin. Phys. B 2020, 29, 124703. [Google Scholar] [CrossRef]

- Gong, Y.; Gong, Z. Laser-based micro/nano-processing techniques for microscale LEDs and full-color displays. Adv. Mater. Technol. 2023, 8, 2200949. [Google Scholar] [CrossRef]

- Zhao, L.; Liu, Z.; Chen, D.; Liu, F.; Yang, Z.; Li, X.; Yu, H.; Liu, H.; Zhou, W. Laser synthesis and microfabrication of micro/nanostructured materials toward energy conversion and storage. Nano-Micro Lett. 2021, 13, 49. [Google Scholar] [CrossRef]

- Mendes, C.S.; Bartos, I.; Akay, T.; Márka, S.; Mann, R.S. Quantification of gait parameters in freely walking wild type and sensory deprived Drosophila melanogaster. eLife 2013, 2, e00231. [Google Scholar] [CrossRef] [PubMed]

| w (mm) | p (mm) | N (—) | |

|---|---|---|---|

| No. 1 | 0.5 | 1.25 | 1.6 |

| No. 2 | 0.5 | 1.25 | 2.0 |

| No. 3 | 0.7 | 1.25 | 1.6 |

| Resonant Frequency (Hz) | Spring Constant (N/m) | Position Error (%) | |

|---|---|---|---|

| No. 1 | 39.5 | 0.460 | 0.62 |

| No. 2 | 26.6 | 0.231 | 0.92 |

| No. 3 | 34.2 | 0.326 | 0.87 |

| Mark Loop | Speed | Power | Frequency | Point Dist. |

|---|---|---|---|---|

| 160 | 5000 mm/s | 100% | 10 kHz | 0.5 mm |

| Resonant Frequency (Hz) | Spring Constant (N/m) | Position Error (%) | |

|---|---|---|---|

| No. 1 | 30 | 0.319 | 8.5 |

| No. 2 | 25 | 0.224 | 6.0 |

| No. 3 | 27 | 0.260 | 8.3 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kiriyama, T.; Shimazaki, K.; Nakashima, R.; Takahashi, H. Thin Glass Micro Force Plate Supported by Planar Spiral Springs for Measuring Minute Forces. Micromachines 2023, 14, 1056. https://doi.org/10.3390/mi14051056

Kiriyama T, Shimazaki K, Nakashima R, Takahashi H. Thin Glass Micro Force Plate Supported by Planar Spiral Springs for Measuring Minute Forces. Micromachines. 2023; 14(5):1056. https://doi.org/10.3390/mi14051056

Chicago/Turabian StyleKiriyama, Taisei, Kenichiro Shimazaki, Rihachiro Nakashima, and Hidetoshi Takahashi. 2023. "Thin Glass Micro Force Plate Supported by Planar Spiral Springs for Measuring Minute Forces" Micromachines 14, no. 5: 1056. https://doi.org/10.3390/mi14051056

APA StyleKiriyama, T., Shimazaki, K., Nakashima, R., & Takahashi, H. (2023). Thin Glass Micro Force Plate Supported by Planar Spiral Springs for Measuring Minute Forces. Micromachines, 14(5), 1056. https://doi.org/10.3390/mi14051056