Research on Configuration Design Optimization and Trajectory Planning of Manipulators for Precision Machining and Inspection of Large-Curvature and Large-Area Curved Surfaces

Abstract

1. Introduction

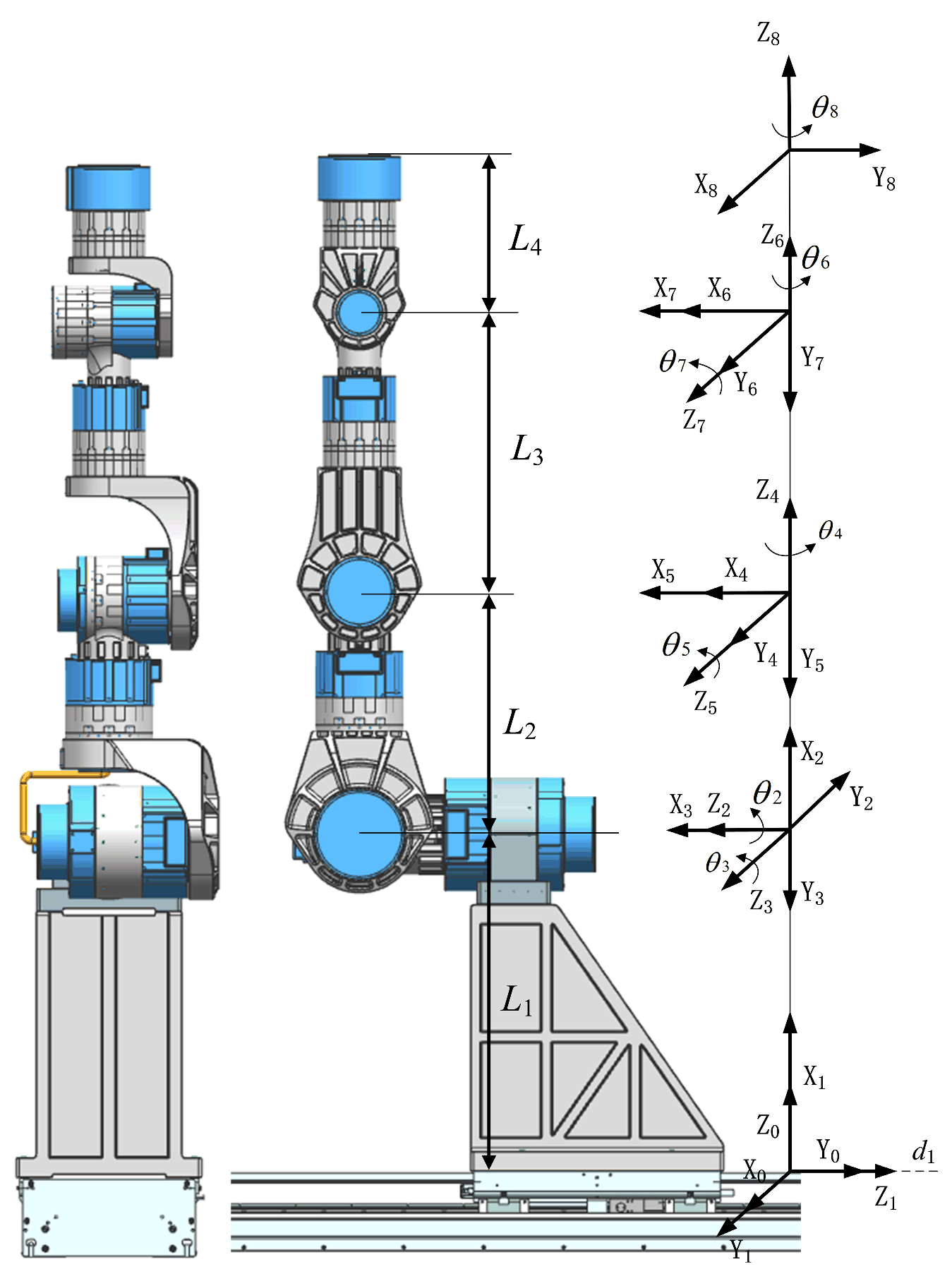

2. Configuration Design and Optimization

2.1. Configuration Design

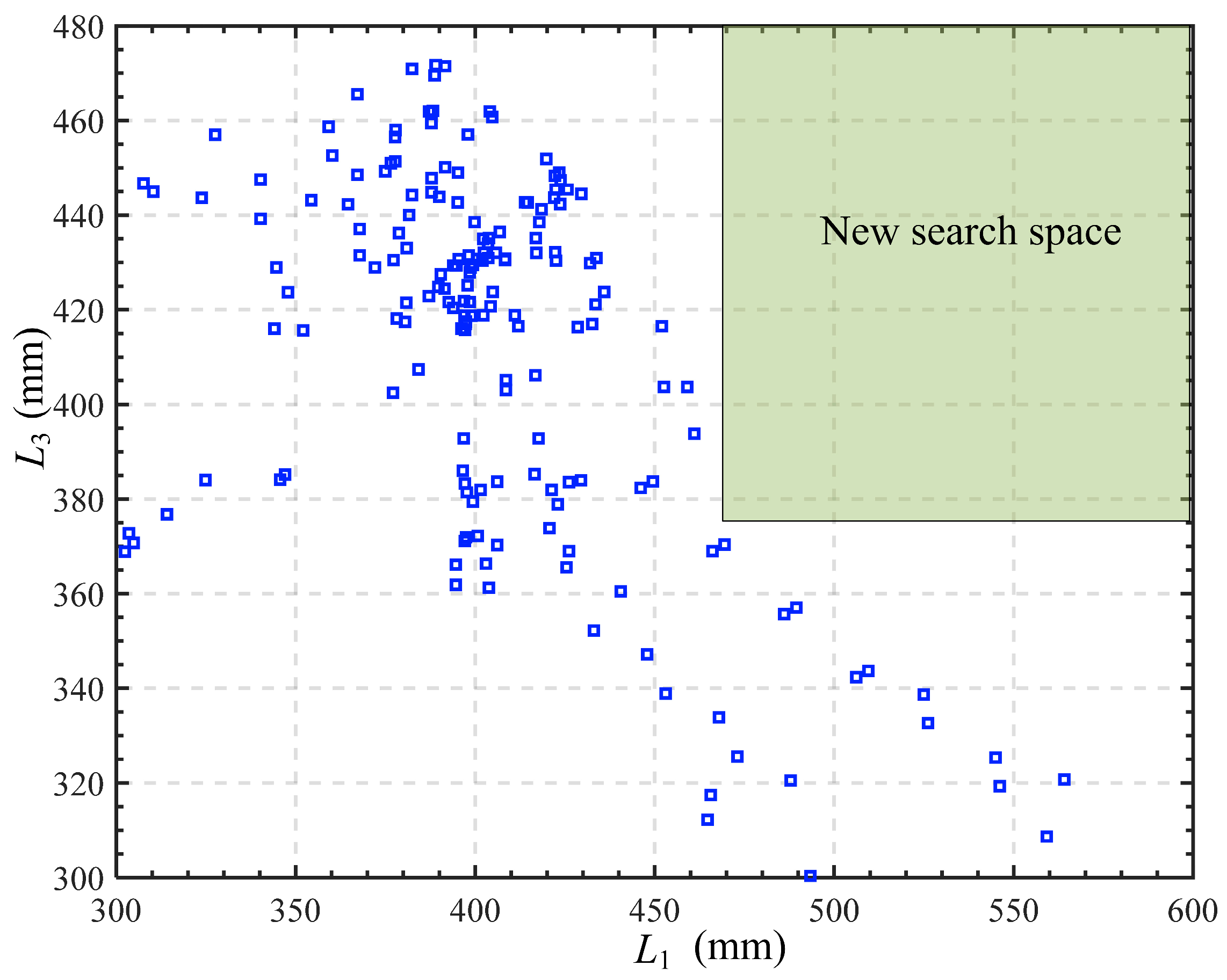

2.2. Configuration Optimization

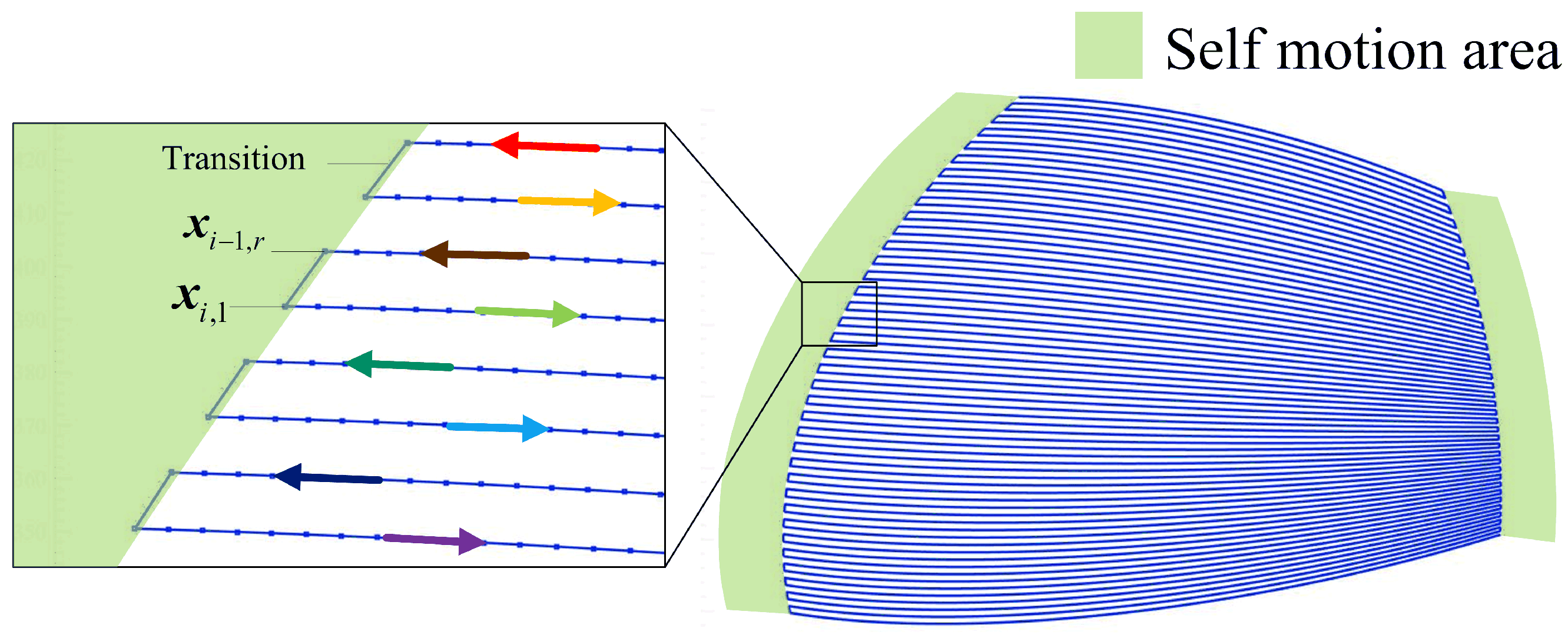

3. Trajectory Planning

3.1. Trajectory Planning Method

3.2. An Improved Trajectory Planning Strategy

3.2.1. Pre-Processing Motion Path

3.2.2. Trajectory Planning Strategy

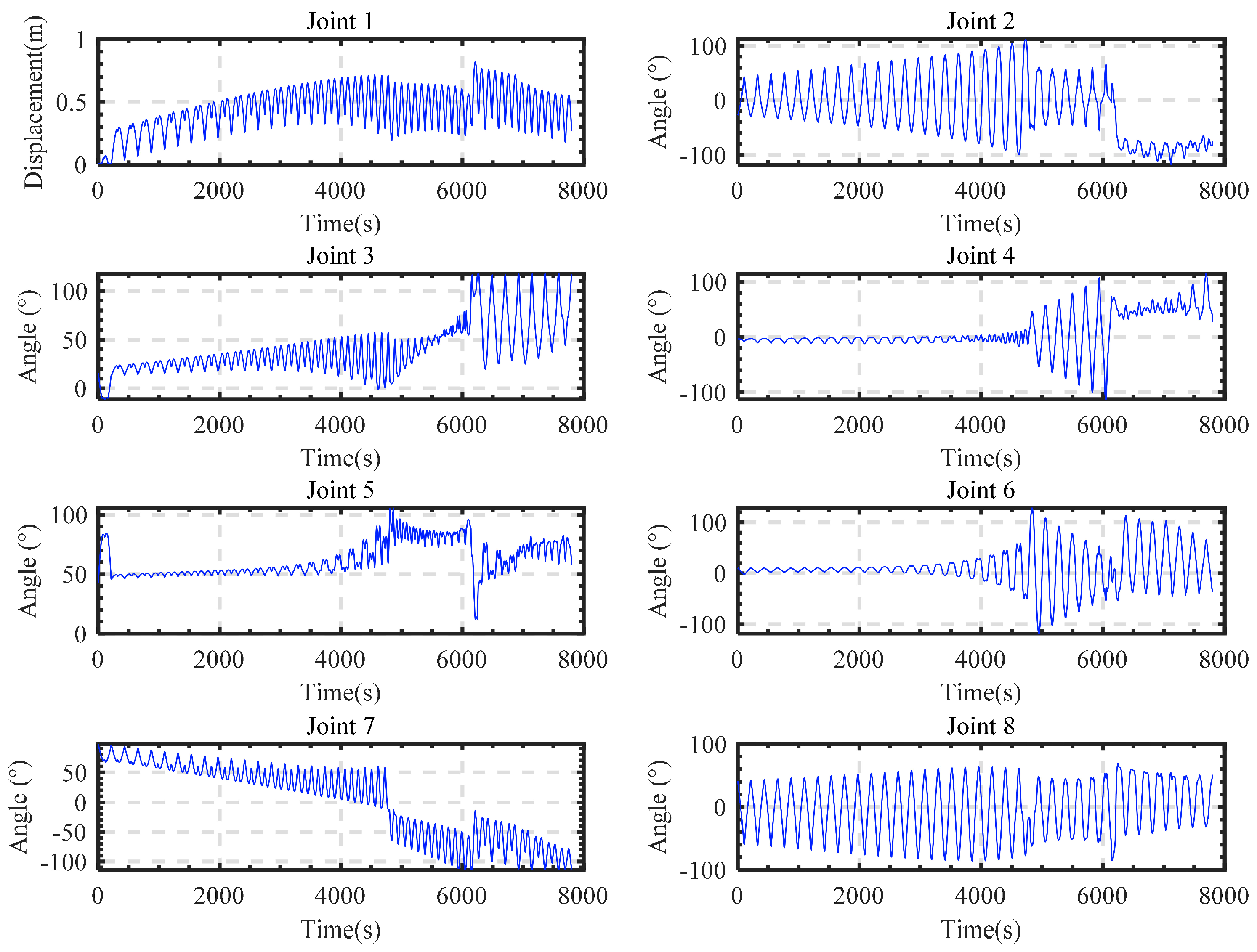

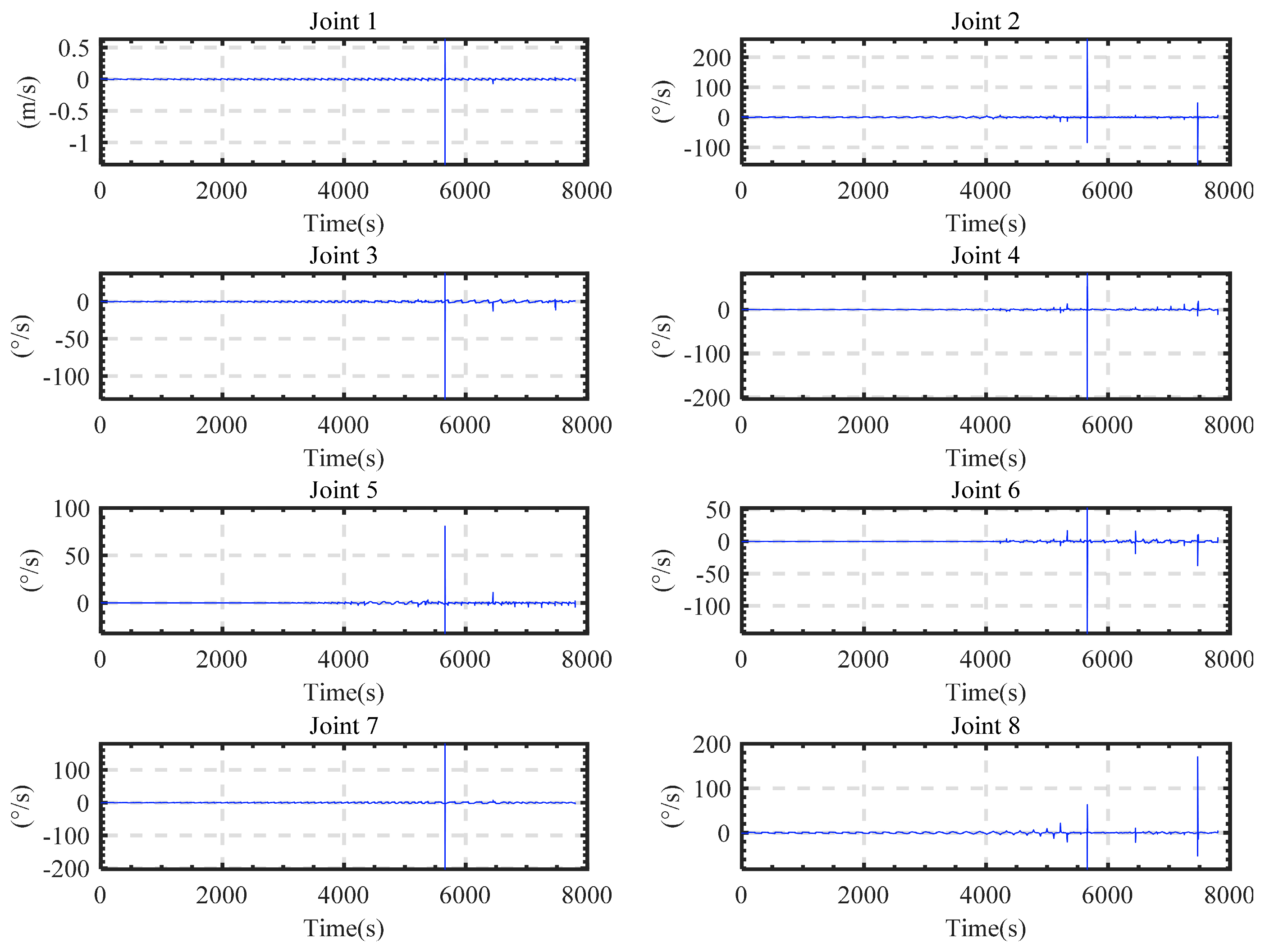

4. Simulation and Experimentation

5. Discussion

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Solanes, J.E.; Gracia, L.; Muoz-Benavent, P.; Esparza, A.; Miro, J.V.; Tornero, J. Adaptive robust control and admittance control for contact-driven robotic surface conditioning. Robot. Comput.-Integr. Manuf. 2018, 54, 115–132. [Google Scholar] [CrossRef]

- Gracia, L.; Solanes, J.E.; Muoz-Benavent, P.; Miro, J.V.; Perez-Vidal, C.; Tornero, J. Adaptive Sliding Mode Control for Robotic Surface Treatment Using Force Feedback. Mechatronics 2018, 52, 102–118. [Google Scholar] [CrossRef]

- Walker, D.; Dunn, C.; Yu, G.Y.; Bibby, M.; Zheng, X.; Wu, H.Y.; Li, H.; Lu, C. The role of robotics in computer controlled polishing of large and small optics. Optical Manufacturing and Testing Xi. Int. Soc. Opt. Photonics 2015, 9575, 50–58. [Google Scholar]

- Liu, H.T.; Wan, Y.J.; Zeng, Z.G.; Xu, L.C.; Fang, K. Freeform surface grinding and polishing by CCOS based on industrial robot. 8th International Symposium on Advanced Optical Manufacturing and Testing Technologies: Advanced Optical Manufacturing Technologies. SPIE 2016, 9683, 587–593. [Google Scholar]

- Klein, A. CAD-based off-line programming of painting robots. Robotica 1987, 5, 267–271. [Google Scholar] [CrossRef]

- Antonio, J.K. Optimal trajectory planning for spray coating. In Proceedings of the 1994 IEEE International Conference on Robotics and Automation, San Diego, CA, USA, 8–13 May 1994; pp. 2570–2577. [Google Scholar]

- Hertling, P.; Hog, L.; Larsen, R. Task curve planning for painting robots. I. Process modeling and calibration. IEEE Trans. Robot. Autom. 1996, 12, 324–330. [Google Scholar] [CrossRef]

- Omodei, A.; Legnani, G.; Adamini, R. Three methodologies for the calibration of industrial manipulators: Experimental results on a SCARA robot. J. Robot. Syst. 2000, 17, 291–307. [Google Scholar] [CrossRef]

- Nubiola, A.; Bonev, I.A. Absolute calibration of an ABB IRB 1600 robot using a laser tracker. Robot. Comput.-Integr. Manuf. 2013, 29, 236–245. [Google Scholar] [CrossRef]

- Hasirden; Zeng, Z.; Liu, H.; Zhao, H. Measurement and analysis on positioning accuracy for optical processing robots. Opto-Electron. Eng. 2017, 44, 558. [Google Scholar]

- Fang, H.R.; Zhu, T.; Zhang, H.Q.; Yang, H.; Jiang, B.S. Design and analysis of a novel hybrid processing robot mechanism. Int. J. Autom. Comput. 2020, 17, 403–416. [Google Scholar] [CrossRef]

- Gao, Z.; Zhang, D. Performance analysis, mapping, and multiobjective optimization of a hybrid robotic machine tool. IEEE Trans. Ind. Electron. 2014, 62, 423–433. [Google Scholar] [CrossRef]

- Gao, F.; Peng, B.; Zhao, H.; Li, W. A novel 5-DOF fully parallel kinematic machine tool. Int. J. Adv. Manuf. Technol. 2006, 31, 201–207. [Google Scholar] [CrossRef]

- Kucuk, S. Dexterous workspace optimization for a new hybrid parallel robot manipulator. J. Mech. Robot. 2018, 10, 064503. [Google Scholar] [CrossRef]

- Tanev, T.K. Kinematics of a hybrid (parallel–serial) robot manipulator. Mech. Mach. Theory 2000, 35, 1183–1196. [Google Scholar] [CrossRef]

- Coppola, G.; Zhang, D.; Liu, K. A 6-DOF reconfigurable hybrid parallel manipulator. Robot. Comput.-Integr. Manuf. 2014, 30, 99–106. [Google Scholar] [CrossRef]

- Fang, Y.; Hu, J.; Liu, W.; Shao, Q.; Qi, J.; Peng, Y. Smooth and time-optimal S-curve trajectory planning for automated robots and machines. Mech. Mach. Theory 2019, 137, 127–153. [Google Scholar] [CrossRef]

- Božek, P.; Trnka, K. Path planning with motion optimization for car body-in-white industrial robot applications. Adv. Mater. Res. 2013, 605, 1595–1599. [Google Scholar] [CrossRef]

- Chembuly, V.S.; Voruganti, H.K. Trajectory planning of redundant manipulators moving along constrained path and avoiding obstacles. Procedia Comput. Sci. 2018, 133, 627–634. [Google Scholar] [CrossRef]

- Zhang, P.; Gong, J.; Zeng, Y.; Li, C. Optimizing Trajectory of Painting Robot’s Spray Gun for Large Curvature Surface. Mechanical Sci. Technol. Aerospace Eng. 2015, 34, 1670–1674. [Google Scholar]

- Zhang, P.; Gong, J.; Ning, H.; Zeng, Y.; Liu, Y.; Wei, L. Study on Trajectory Combination and Connection Problems of Spray- painting Robot for Large Curvature Combination Surfaces. J. Sichuan Univ. (Eng. Sci. Ed.) 2016, 48, 217–222. [Google Scholar] [CrossRef]

- Shao, J.Y.; Zhang, C.Q.; Chen, Y.; Chen, K. Trajectory planning for redundant robots for internal surface spraying. J. Tsinghua Univ. 2014, 54, 799–804. [Google Scholar]

- Lamikiz, A.; López de Lacalle, L.N.; Ocerin, O.; Díez, D.; Maidagan, E. The Denavit and Hartenberg approach applied to evaluate the consequences in the tool tip position of geometrical errors in five-axis milling centres. Int. J. Adv. Manuf. Technol. 2008, 37, 122–139. [Google Scholar] [CrossRef]

- Katoch, S.; Chauhan, S.S.; Kumar, V. A review on genetic algorithm: Past, present, and future. Multimed. Tools Appl. 2021, 80, 8091–8126. [Google Scholar] [CrossRef] [PubMed]

- Dorigo, M.; Stützle, T. Ant Colony Optimization: Overview and Recent Advances. In Handbook of Metaheuristics; Springer Nature: Basel, Switzerland, 2019; pp. 311–351. [Google Scholar]

- Ding, S.; Su, C.; Yu, J. An optimizing BP neural network algorithm based on genetic algorithm. Artif. Intell. Rev. 2011, 36, 153–162. [Google Scholar] [CrossRef]

- Wang, D.; Tan, D.; Liu, L. Particle swarm optimization algorithm: An overview. Soft Comput. 2018, 22, 387–408. [Google Scholar] [CrossRef]

- Bai, Q. Analysis of particle swarm optimization algorithm. Computer Inform. Sci. 2010, 3, 180. [Google Scholar] [CrossRef]

- Jiang, Y.; Hu, T.S.; Huang, C.; Wu, X.N. An improved particle swarm optimization algorithm. Appl. Math. Comput. 2007, 193, 231–239. [Google Scholar] [CrossRef]

- Chen, C.Y.; Ye, F. Particle swarm optimization algorithm and its application to clustering analysis. In Proceedings of the 2012 Proceedings of 17th Conference on Electrical Power Distribution, Tehran, Iran, 2–3 May 2012; pp. 789–794. [Google Scholar]

- Coello, C.A.C.; Pulido, G.T.; Lechuga, M.S. Handling multiple objectives with particle swarm optimization. IEEE Trans. Evol. Comput. 2004, 8, 256–279. [Google Scholar] [CrossRef]

- Chan, T.F.; Dubey, R.V. A weighted least-norm solution based scheme for avoiding joint limits for redundant joint manipulators. IEEE Trans. Robot. Autom. 1995, 11, 286–292. [Google Scholar] [CrossRef]

- Phuoc, L.M.; Martinet, P.; Lee, S.; Kim, H. Damped least square based genetic algorithm with Ggaussian distribution of damping factor for singularity-robust inverse kinematics. J. Mech. Sci. Technol. 2008, 22, 1330–1338. [Google Scholar] [CrossRef]

- Huang, S.H.; Peng, Y.G.; Wei, W.; Xiang, J. Clamping weighted least-norm method for the manipulator kinematic control with constraints. Int. J. Control 2016, 89, 2240–2249. [Google Scholar] [CrossRef]

- Rodríguez, A.; González, M.; Pereira, O.; López de Lacalle, L.N.; Esparta, M. Edge finishing of large turbine casings using defined multi-edge and abrasive tools in automated cells. Int. J. Adv. Manuf. Technol. 2021, 124, 3149–3159. [Google Scholar] [CrossRef]

- Bustillo, A.; Urbikain, G.; Perez, J.M.; Pereira, O.M.; López de Lacalle, L.N. Smart optimization of a friction-drilling process based on boosting ensembles. J. Manuf. Syst. 2018, 48, 108–121. [Google Scholar] [CrossRef]

- He, Z.; Zhang, S.; Zheng, L.; Liu, Z.; Zhang, G.; Wu, H.; Wang, G. Si-Based NIR Tunneling Heterojunction Photodetector With Interfacial Engineering and 3D-Graphene Integration. IEEE Electron Device Lett. 2022, 43, 1818–1821. [Google Scholar] [CrossRef]

- Zhou, W.; Zheng, L.; Ning, Z.; Cheng, X.; Wang, F.; Xu, K.; Yu, Y. Silicon: Quantum dot photovoltage triodes. Nat. Commun. 2021, 12, 6696. [Google Scholar] [CrossRef]

| Joint i | αi−1/(°) | ai−1/mm | di/mm | θi/(°) |

|---|---|---|---|---|

| 1 | −90 | 0 | d1 | −90 |

| 2 | 180 | L1 | 0 | θ2 |

| 3 | 90 | 0 | 0 | θ3 + 90 |

| 4 | 90 | 0 | L2 | θ4 |

| 5 | −90 | 0 | 0 | θ5 |

| 6 | 90 | 0 | L3 | θ6 |

| 7 | −90 | 0 | 0 | θ7 |

| 8 | 90 | 0 | L4 | θ8 + 90 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Sun, X.; He, S.; Xu, Z.; Zhang, E.; Li, Y. Research on Configuration Design Optimization and Trajectory Planning of Manipulators for Precision Machining and Inspection of Large-Curvature and Large-Area Curved Surfaces. Micromachines 2023, 14, 886. https://doi.org/10.3390/mi14040886

Sun X, He S, Xu Z, Zhang E, Li Y. Research on Configuration Design Optimization and Trajectory Planning of Manipulators for Precision Machining and Inspection of Large-Curvature and Large-Area Curved Surfaces. Micromachines. 2023; 14(4):886. https://doi.org/10.3390/mi14040886

Chicago/Turabian StyleSun, Xiangyang, Shuai He, Zhenbang Xu, Enyang Zhang, and Yanhui Li. 2023. "Research on Configuration Design Optimization and Trajectory Planning of Manipulators for Precision Machining and Inspection of Large-Curvature and Large-Area Curved Surfaces" Micromachines 14, no. 4: 886. https://doi.org/10.3390/mi14040886

APA StyleSun, X., He, S., Xu, Z., Zhang, E., & Li, Y. (2023). Research on Configuration Design Optimization and Trajectory Planning of Manipulators for Precision Machining and Inspection of Large-Curvature and Large-Area Curved Surfaces. Micromachines, 14(4), 886. https://doi.org/10.3390/mi14040886