Three-Dimensional Pulse-Based Modelling of Femtosecond Laser Ablation of Metals: Validation with Grooves

Abstract

1. Introduction

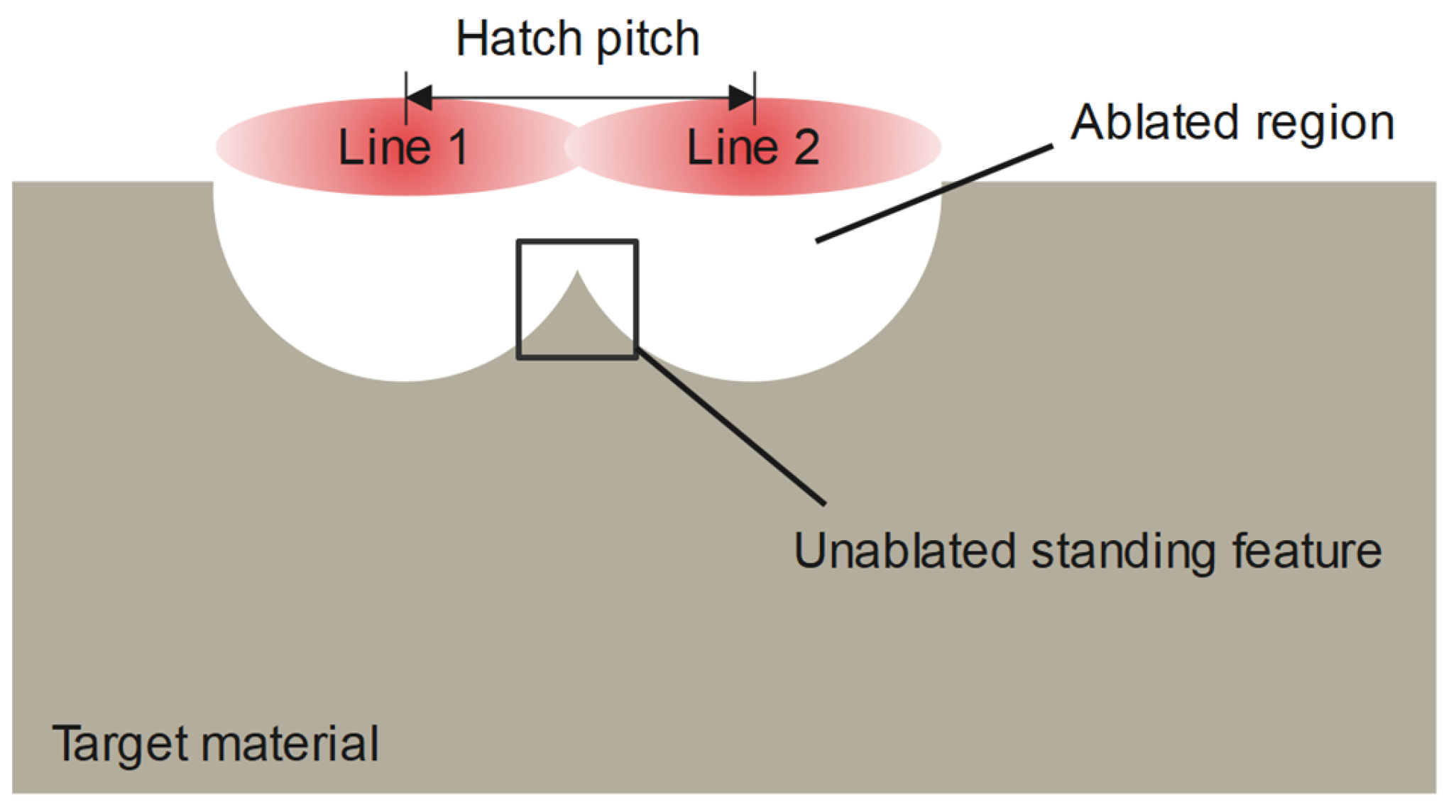

2. Temperature Influence in Parallel Line Scanning

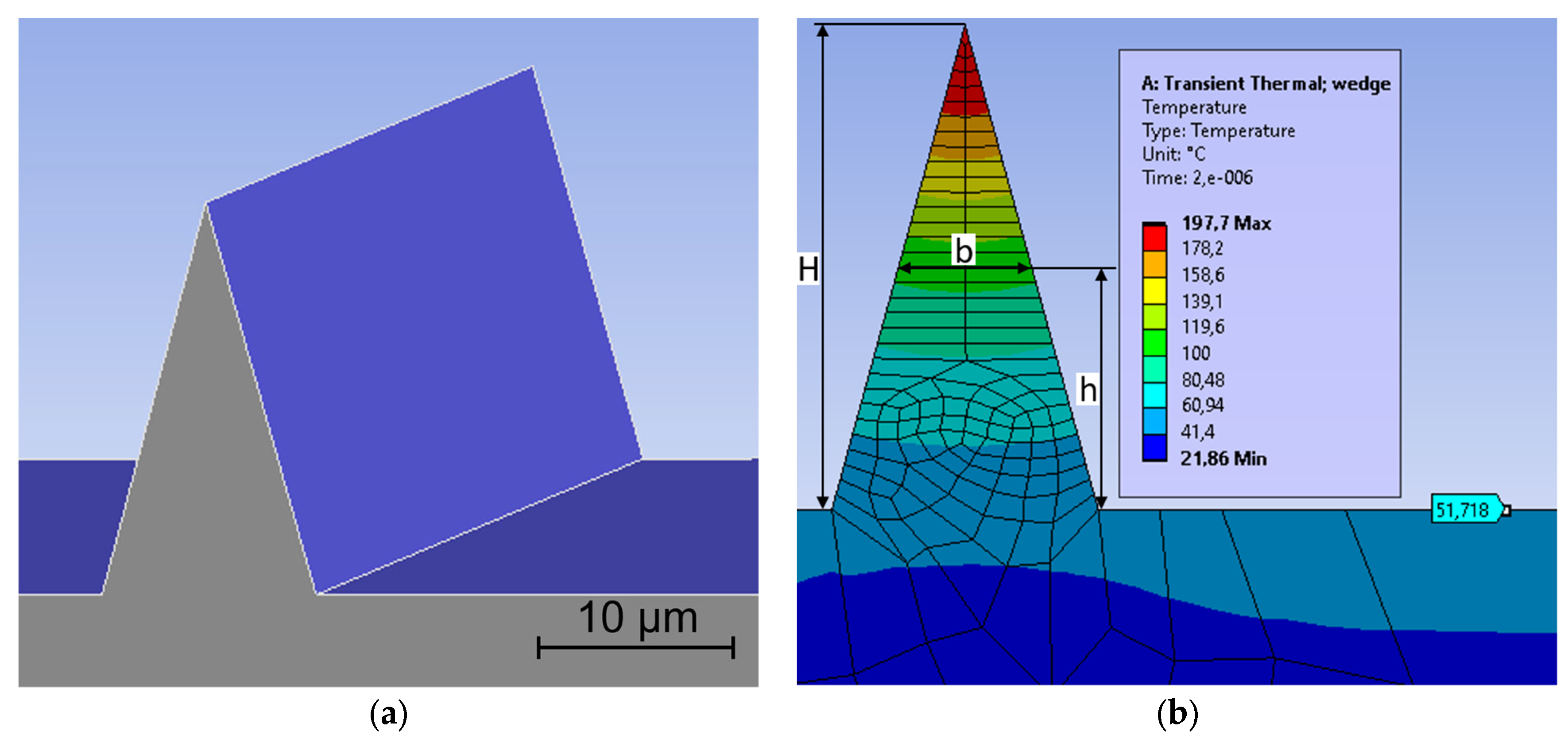

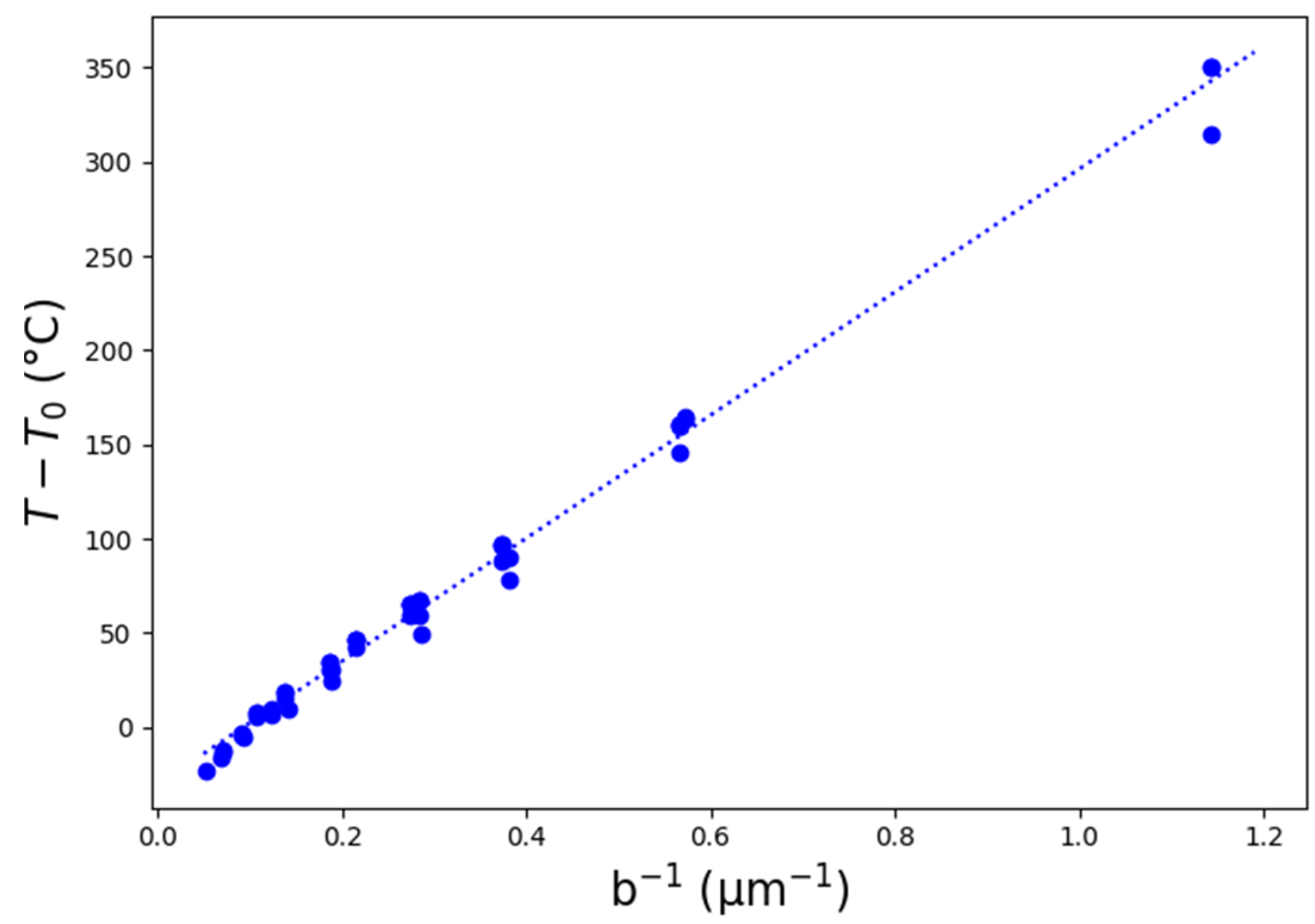

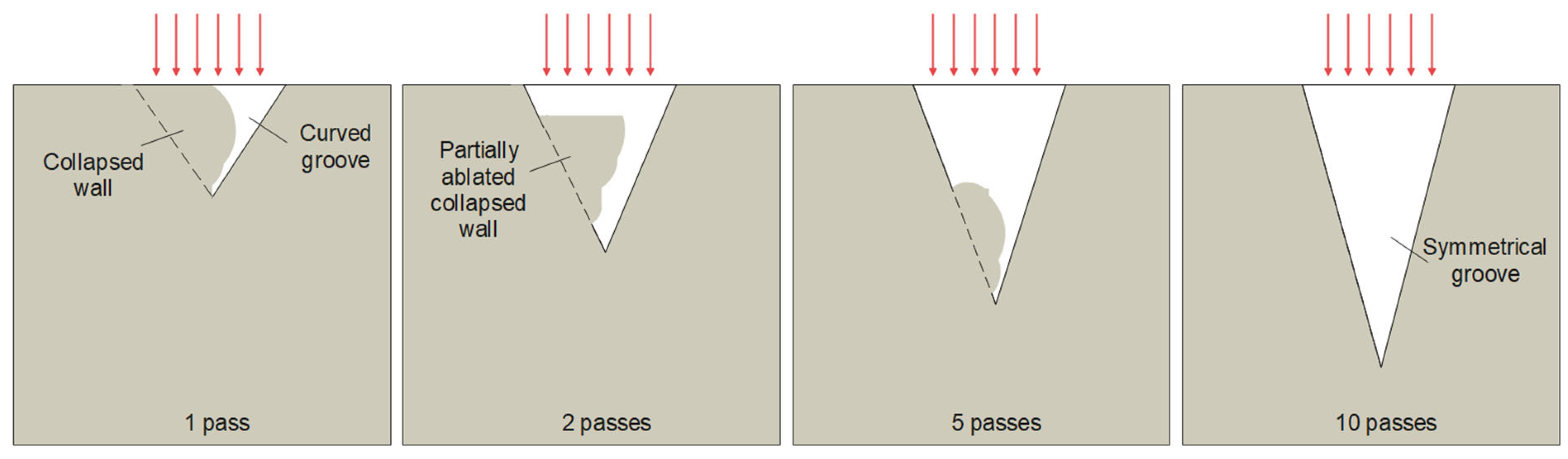

The Relationship between the Temperature Gradient and the Feature Geometry

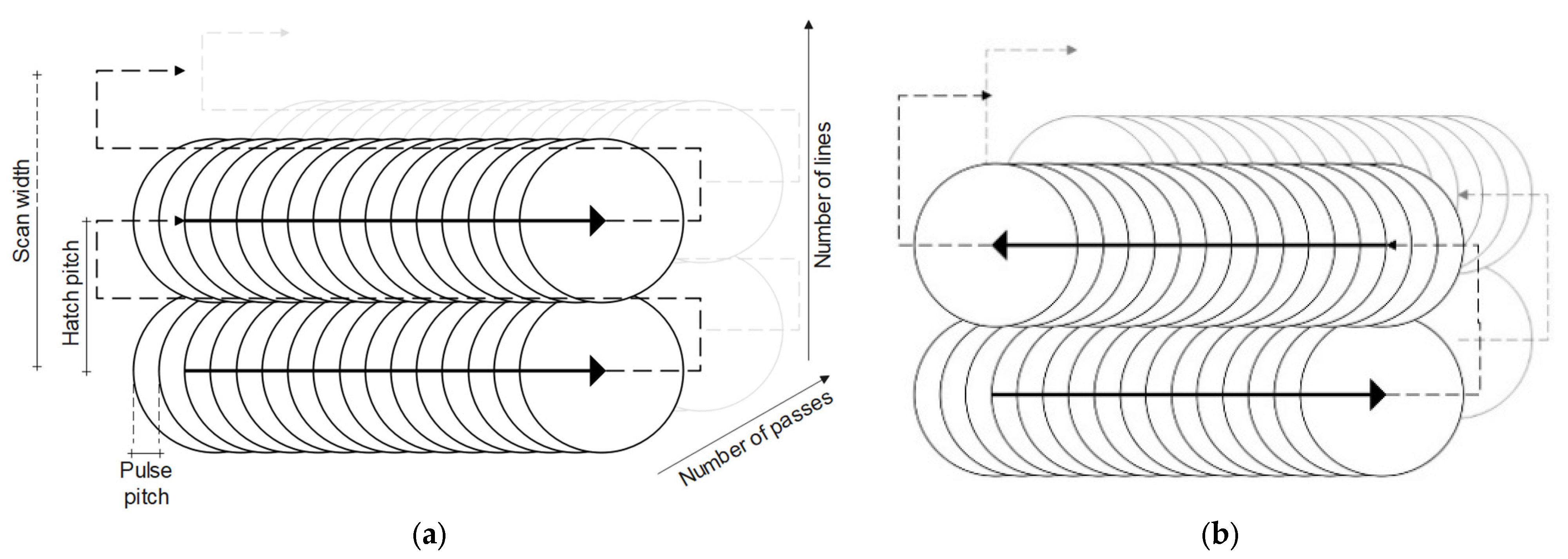

3. Materials and Methods

3.1. Experiments

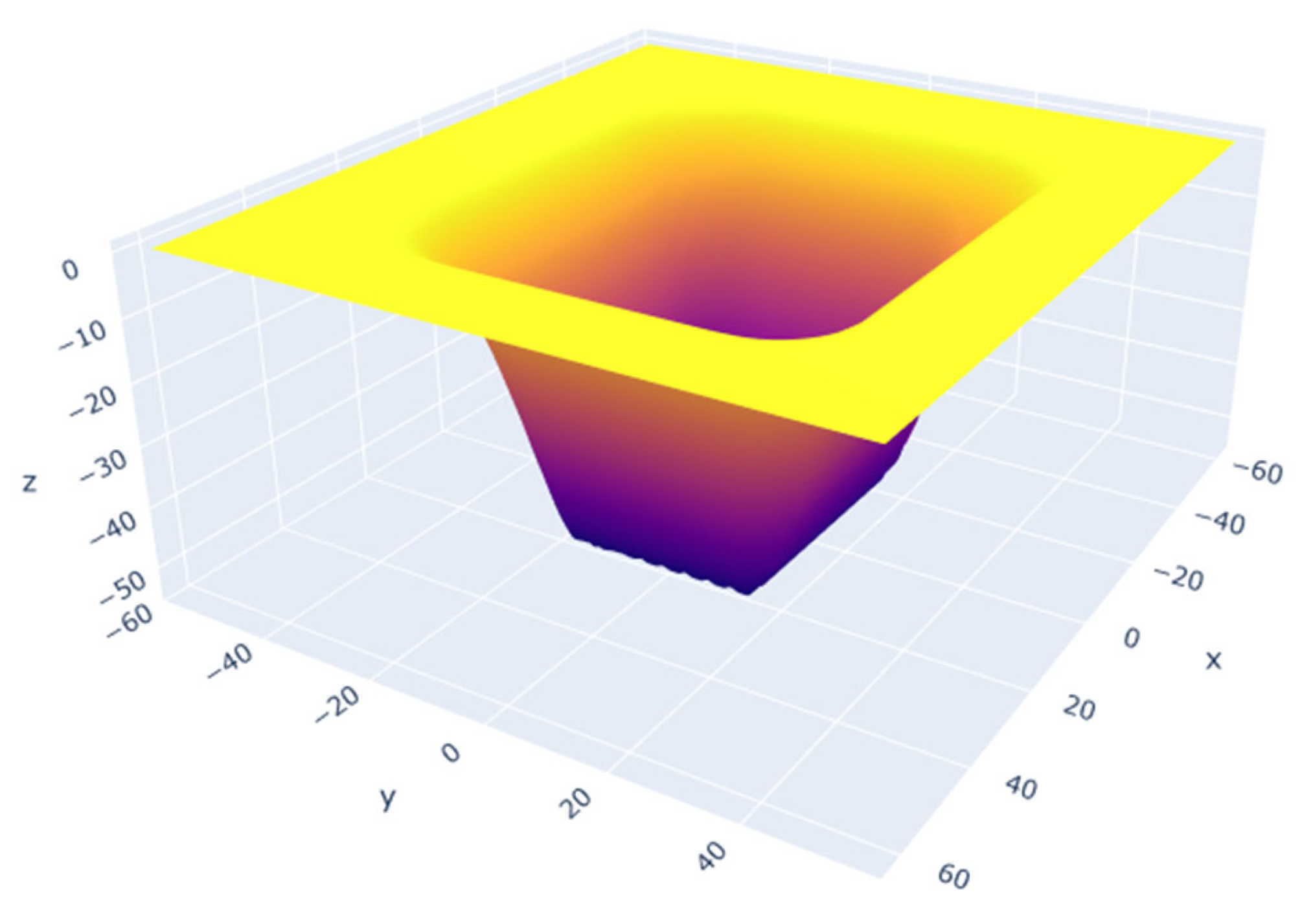

3.2. Simulations

- The position of the center of the pulse is calculated;

- For each mesh point, the inclination of the surface (based on the least squares plane through the 8 mesh points around it) is calculated;

- For each mesh point, the feature width perpendicular to the scanning direction is found, and the temperature-dependent threshold fluence and reflectivity are calculated;

- For each mesh point, the absorbed fluence, dependent on the inclination, distance from the pulse center, feature width, and vertical distance to focus height, is calculated;

- For each mesh point, the ablation depth parallel to the laser beam propagation direction generated by the pulse is calculated;

- The ablation depths are subtracted from the current geometry;

- The above steps are repeated until all pulses are calculated.

4. Results and Discussion

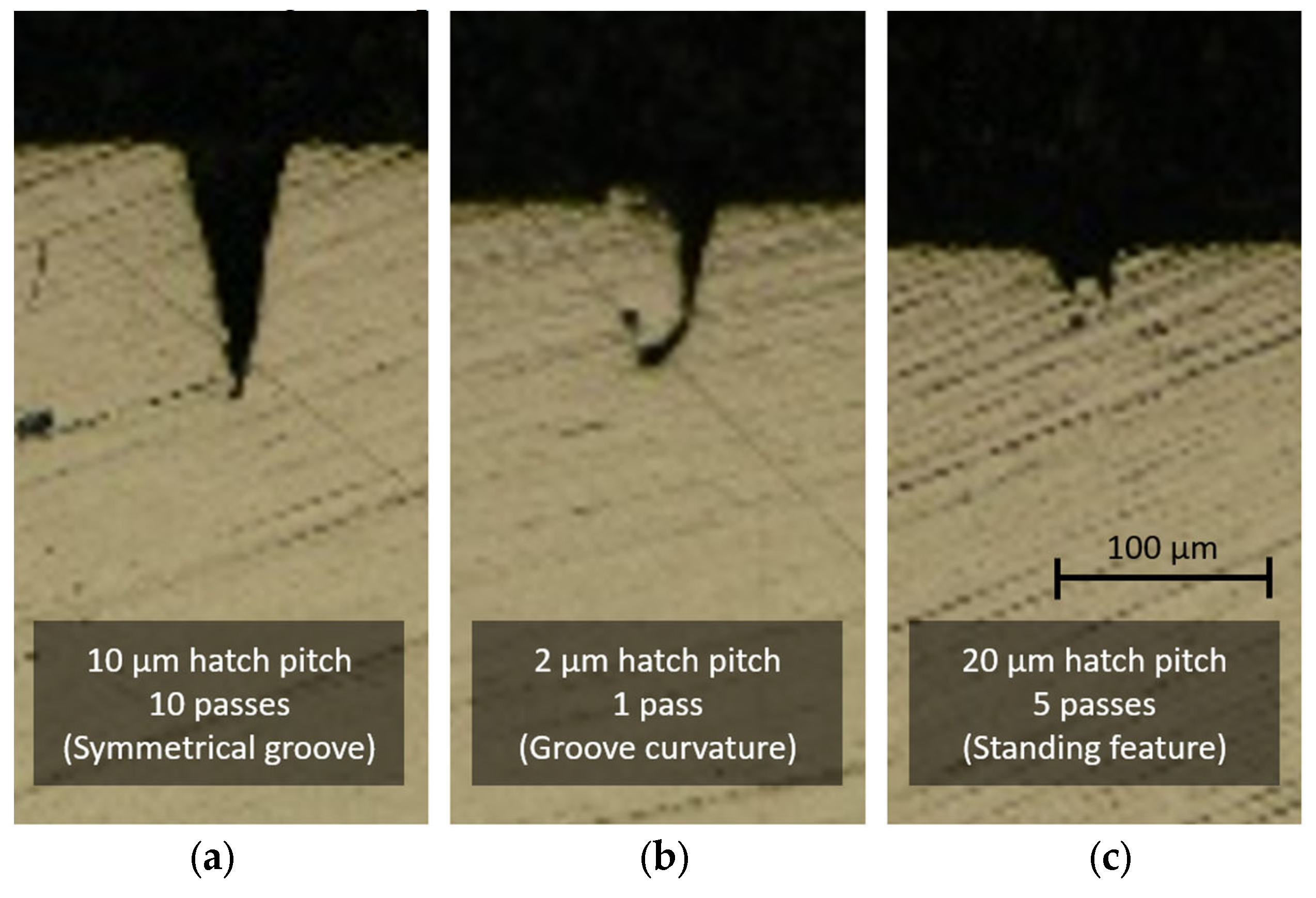

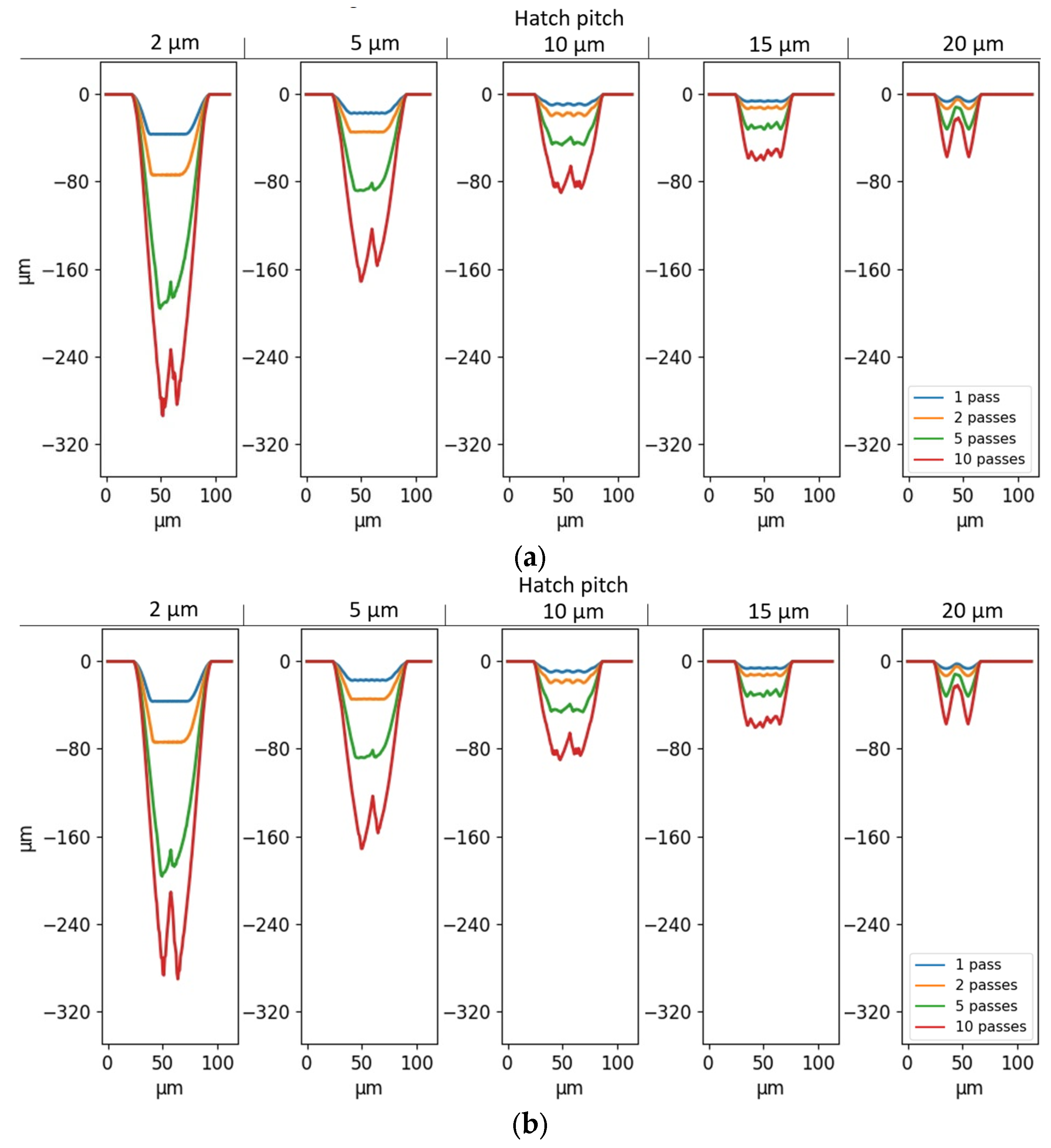

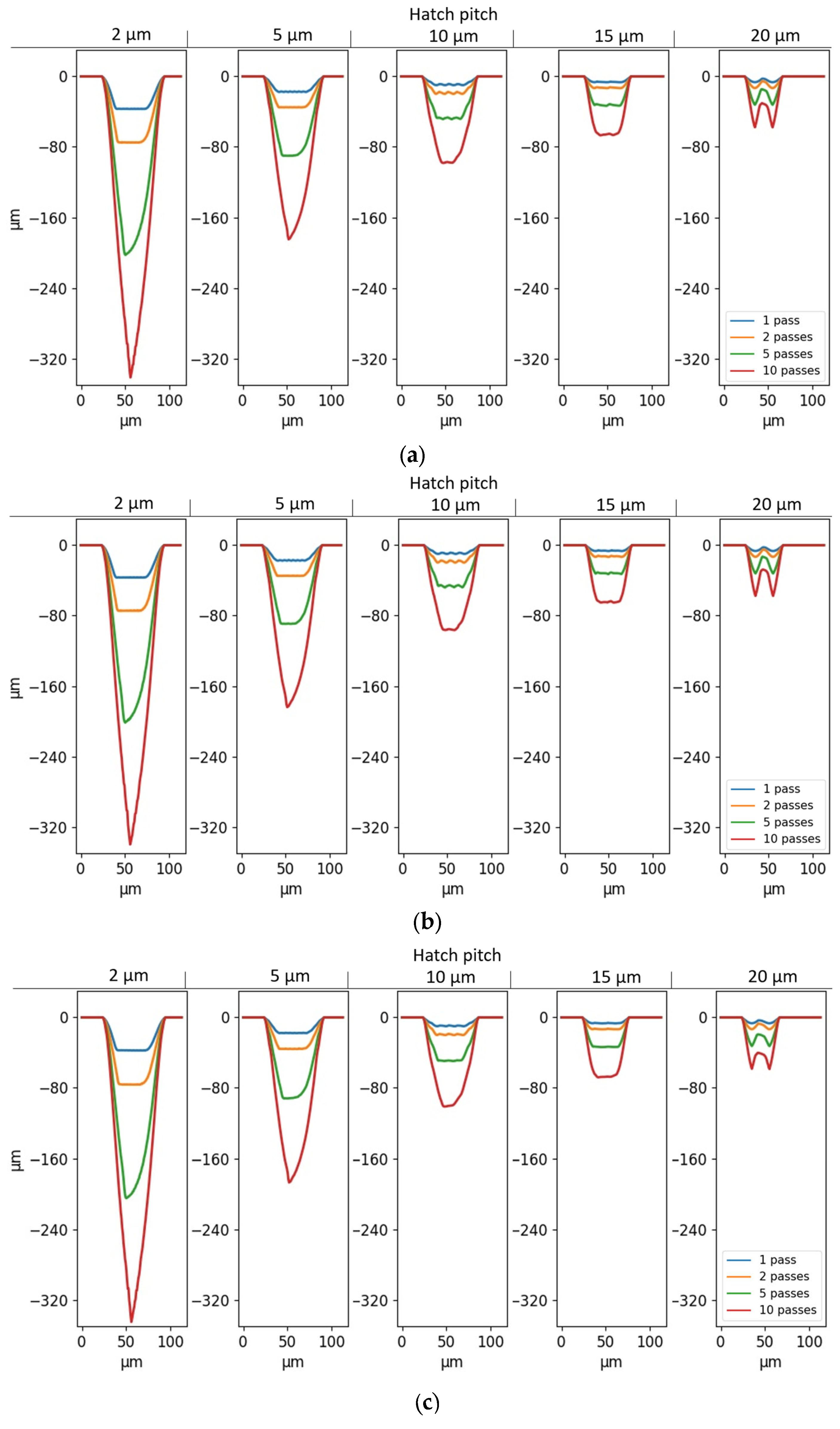

4.1. Experiments

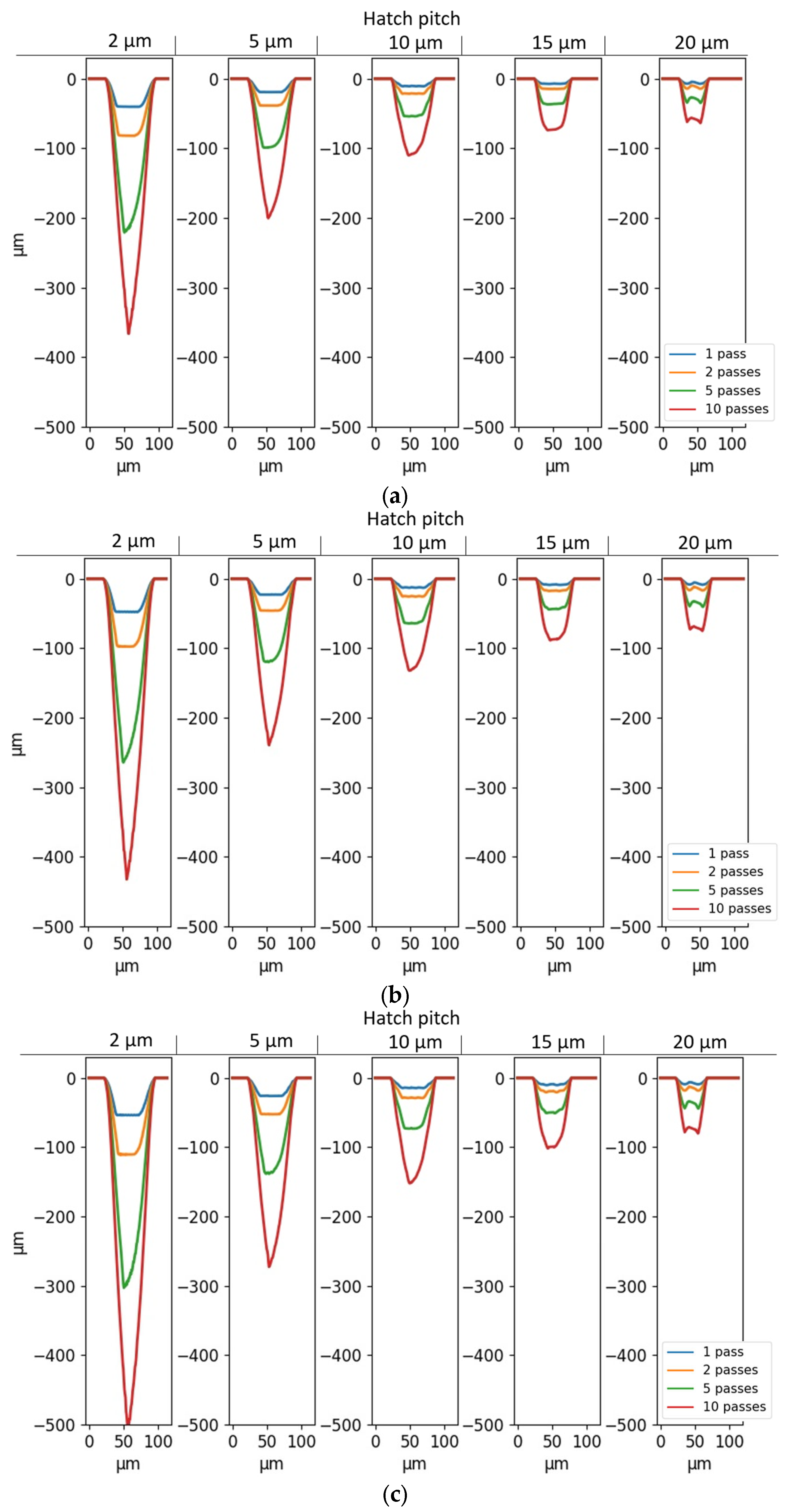

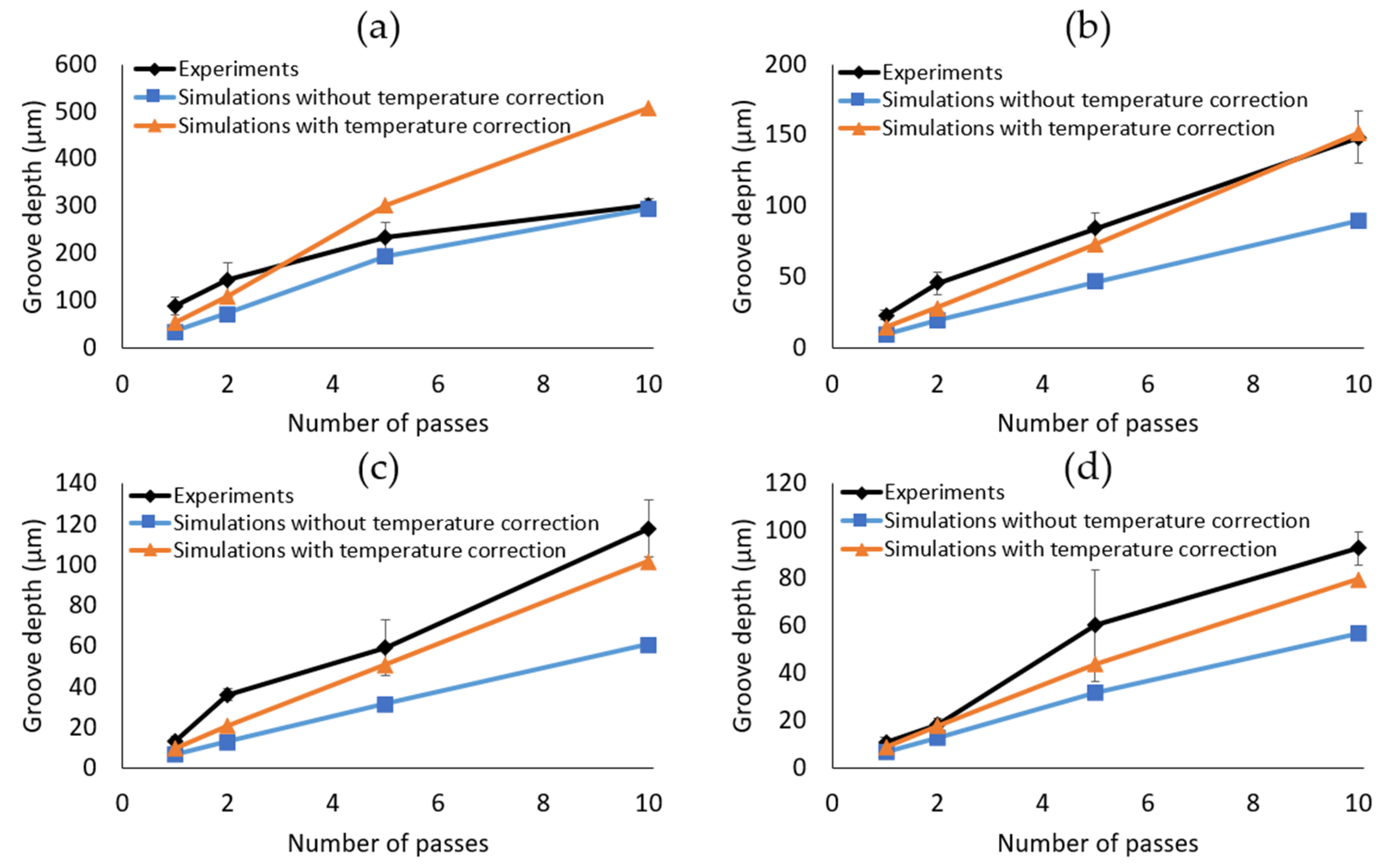

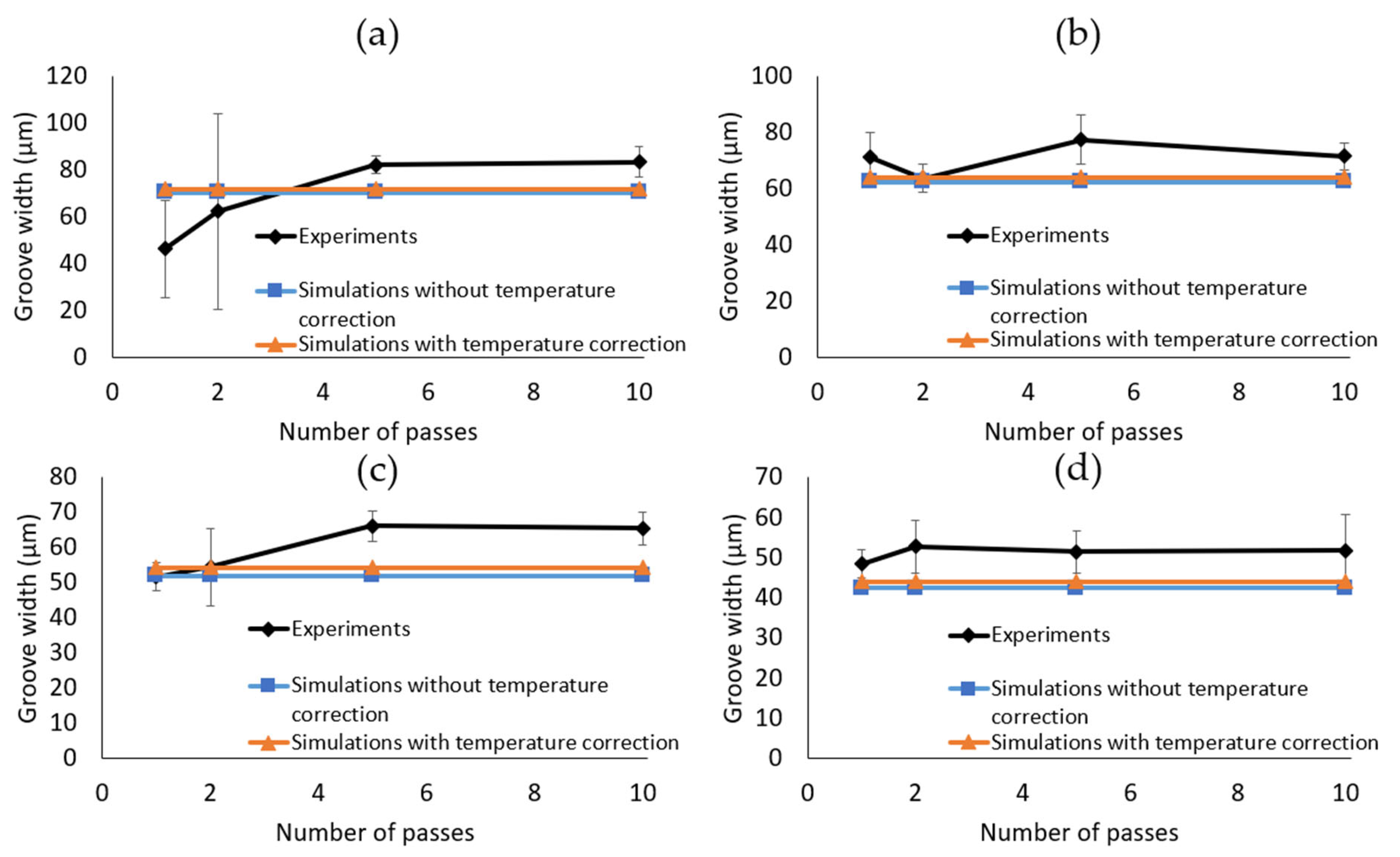

4.2. Simulations without Geometry-Dependent Fth and R

4.3. Fitting of the Geometry-Dependent Fth and R

4.4. Discussion on the Modelling Deviations

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Leitz, K.-H.; Redlingshöfer, B.; Reg, Y.; Otto, A.; Schmidt, M. Metal Ablation with Short and Ultrashort Laser Pulses. Phys. Procedia 2011, 12, 230–238. [Google Scholar] [CrossRef]

- Chichkov, B.N.; Momma, C.; Nolte, S.; Alvensleben, F.; Tünnermann, A. Femtosecond, picosecond and nanosecond laser ablation of solids. Appl. Phys. A 1996, 63, 109–115. [Google Scholar] [CrossRef]

- Vanwersch, P.; Schildermans, S.; Nagarajan, B.; Van Bael, A.; Castagne, S. Three-Dimensional Modelling of Femtosecond Laser Ablation of Metals. Lasers Manuf. Mater. Process. 2022, 9, 515–531. [Google Scholar] [CrossRef]

- Audouard, E.; Mottay, E. Engineering model for ultrafast laser microprocessing. Front. Ultrafast Opt. Biomed. Sci. Ind. Appl. XVI 2016, 9740, 974016. [Google Scholar]

- Zhidkov, M.V.; Vershinina, T.N.; Golosova, O.A.; Kudryashov, S.I.; Ionin, A.A. Surface texturing of steel by femtosecond laser and accompanying structure/phase transformations. Opt. Laser Technol. 2020, 131, 106370. [Google Scholar] [CrossRef]

- Jee, Y.; Becker, M.F.; Walser, R.M. Laser-induced damage on single-crystal metal surfaces. JOSA B 1988, 5, 648. [Google Scholar] [CrossRef]

- Neuenschwander, B.; Jaeggi, B.; Schmid, M.; Dommann, A.; Neels, A.; Bandi, T.; Hennig, G. Factors controlling the incubation in the application of ps laser pulses on copper and iron surfaces. In Laser Applications in Microelectronic and Optoelectronic Manufacturing (LAMOM) XVIII; SPIE: Bellingham, WA, USA, 2013; Volume 8607, pp. 26–35. [Google Scholar]

- Di Niso, F.; Gaudiuso, C.; Sibillano, T.; Mezzapesa, F.P.; Ancona, A.; Lugarà, P.M. Role of heat accumulation on the incubation effect in multi-shot laser ablation of stainless steel at high repetition rates. Opt. Express 2014, 22, 12200. [Google Scholar] [CrossRef] [PubMed]

- Ahmmed, K.M.T.; Grambow, C.; Kietzig, A.-M. Fabrication of Micro/Nano Structures on Metals by Femtosecond Laser Micromachining. Micromachines 2014, 5, 1219–1253. [Google Scholar] [CrossRef]

- Cangueiro, L.; Audouard, E.; Martin, P.E.; Mottay, E.; Ramos-de-Campos, J.A.; Kupisiewicz, A.; Bruneel, D. Model Ultrafast Laser Micromachining. Laser-Based Micro-Nanoprocessing XII 2018, 10520, 38. [Google Scholar]

- Heinigk, C.; Barthels, T.; Nießen, M.; Schulz, W. A multi-scale model for ultra short pulsed parallel laser structuring—Part I. Micro-Scale Model JLMN 2021, 16, 1–6. [Google Scholar]

- Paquin, R.A. Properties of Metals in Handbook of Optics: Devices, Measurements, and Properties; van Stryland, E.W., Optical Society of America, Eds.; McGraw-Hill: New York, NY, USA, 1995; pp. 4.1–4.74. [Google Scholar]

- Ward, M.R. Electrical Engineering Science; McGraw-Hill: Montreal, QC, Canada, 1971; pp. 36–40. [Google Scholar]

- Steen, W.M.; Mazumder, J. Laser Material Processing, 4th ed.; Springer: London, UK, 2010; Volume 20. [Google Scholar]

- Han, J.; Malek, O.; Vleugels, J.; Braem, A.; Castagne, S. Ultrashort pulsed laser ablation of zirconia-alumina composites for implant applications. J. Mater. Process. Technol. 2022, 299, 117335. [Google Scholar] [CrossRef]

- Zhao, W.; Wang, L.; Yu, Z.; Chen, J.; Yang, J. A processing technology of grooves by picosecond ultrashort pulse laser in Ni alloy: Enhancing efficiency and quality. Opt. Laser Technol. 2019, 111, 214–221. [Google Scholar] [CrossRef]

| Feature height H [µm] | 5; 10; 15; 20; 25 |

| Feature angle [°] | 10; 20; 30; 40; 50 |

| Measurement height h [µm] | 5; 10; 15; 20 |

| [4] | 0.1001 J/cm² |

| [4] | 0.055 J/cm² |

| [14] | 4.49 |

| [14] | 3.81 |

| [4] | 32.77 nm |

| [4] | 18.00 nm |

| [8] | 0.8 |

| Pulse energy | 15.4 µJ |

| Repetition rate | 500,000 Hz |

| Scanning speed | 100 mm/s |

| Scan width | ~50 µm |

| Number of passes | 1; 2; 5; 10 |

| Hatch pitch | 2; 5; 10; 15; 20 µm |

| Direction |  (unidirectional) (bidirectional) |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Vanwersch, P.; Nagarajan, B.; Van Bael, A.; Castagne, S. Three-Dimensional Pulse-Based Modelling of Femtosecond Laser Ablation of Metals: Validation with Grooves. Micromachines 2023, 14, 593. https://doi.org/10.3390/mi14030593

Vanwersch P, Nagarajan B, Van Bael A, Castagne S. Three-Dimensional Pulse-Based Modelling of Femtosecond Laser Ablation of Metals: Validation with Grooves. Micromachines. 2023; 14(3):593. https://doi.org/10.3390/mi14030593

Chicago/Turabian StyleVanwersch, Pol, Balasubramanian Nagarajan, Albert Van Bael, and Sylvie Castagne. 2023. "Three-Dimensional Pulse-Based Modelling of Femtosecond Laser Ablation of Metals: Validation with Grooves" Micromachines 14, no. 3: 593. https://doi.org/10.3390/mi14030593

APA StyleVanwersch, P., Nagarajan, B., Van Bael, A., & Castagne, S. (2023). Three-Dimensional Pulse-Based Modelling of Femtosecond Laser Ablation of Metals: Validation with Grooves. Micromachines, 14(3), 593. https://doi.org/10.3390/mi14030593