Review of Intelligence for Additive and Subtractive Manufacturing: Current Status and Future Prospects

Abstract

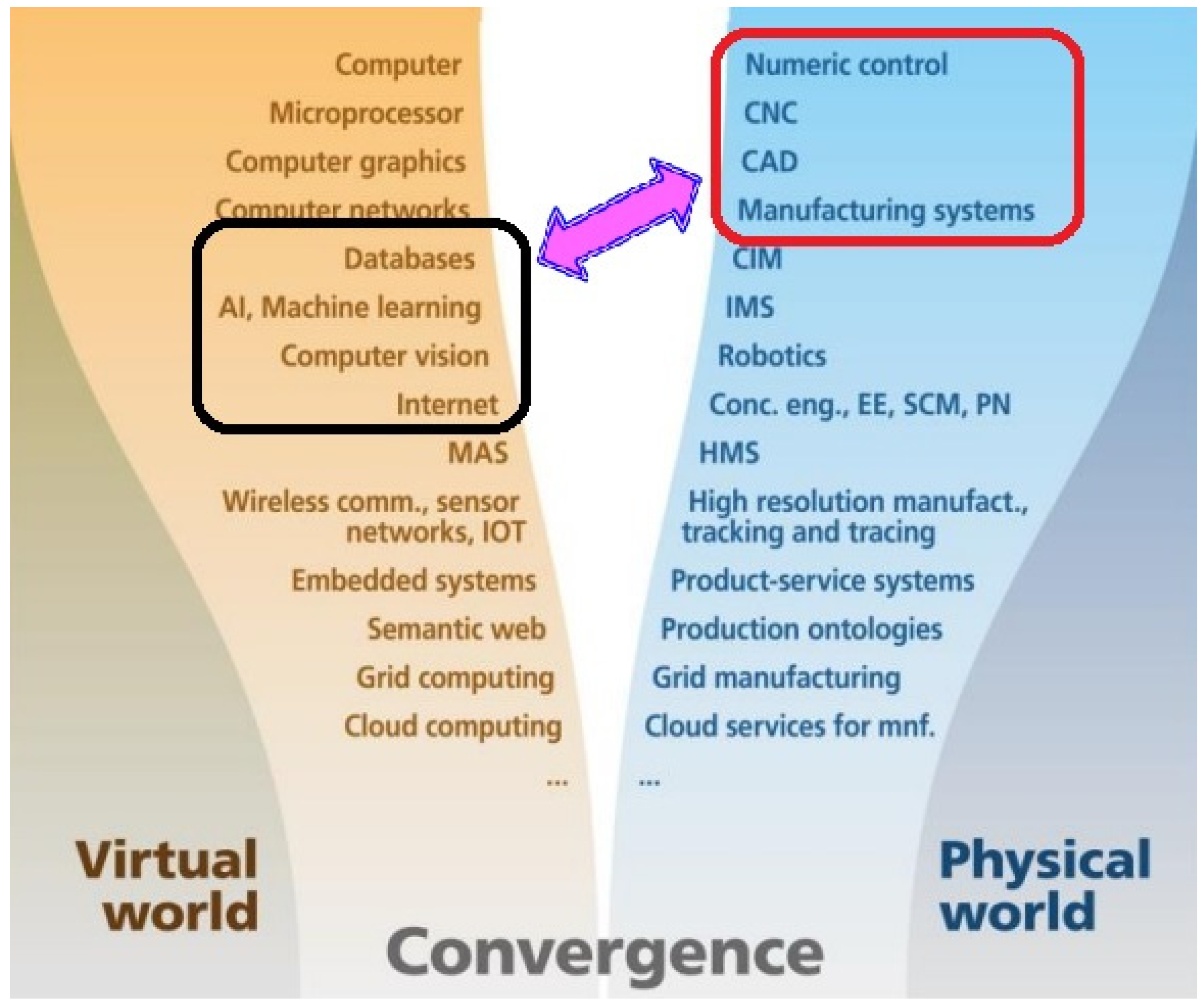

1. Introduction

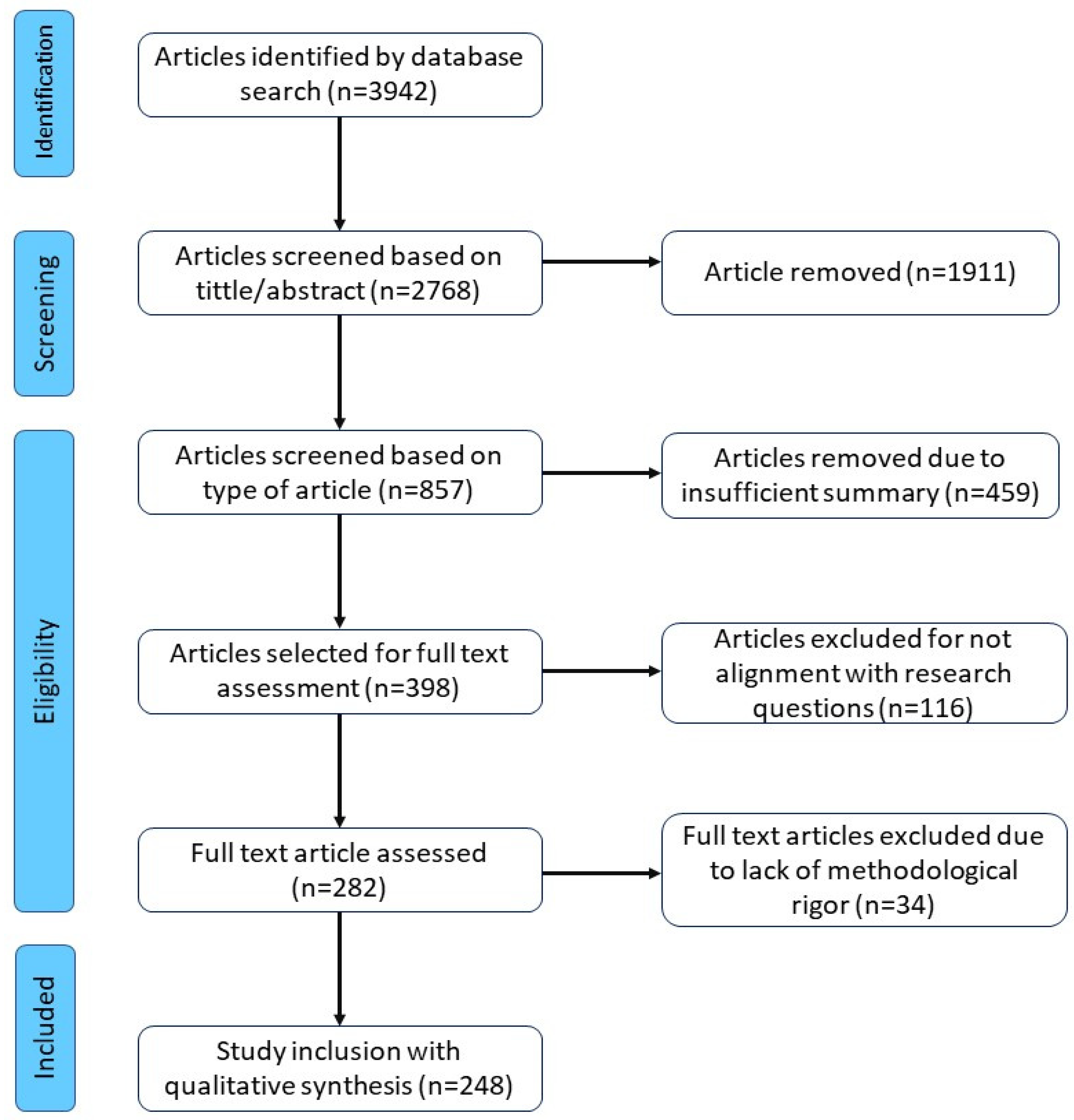

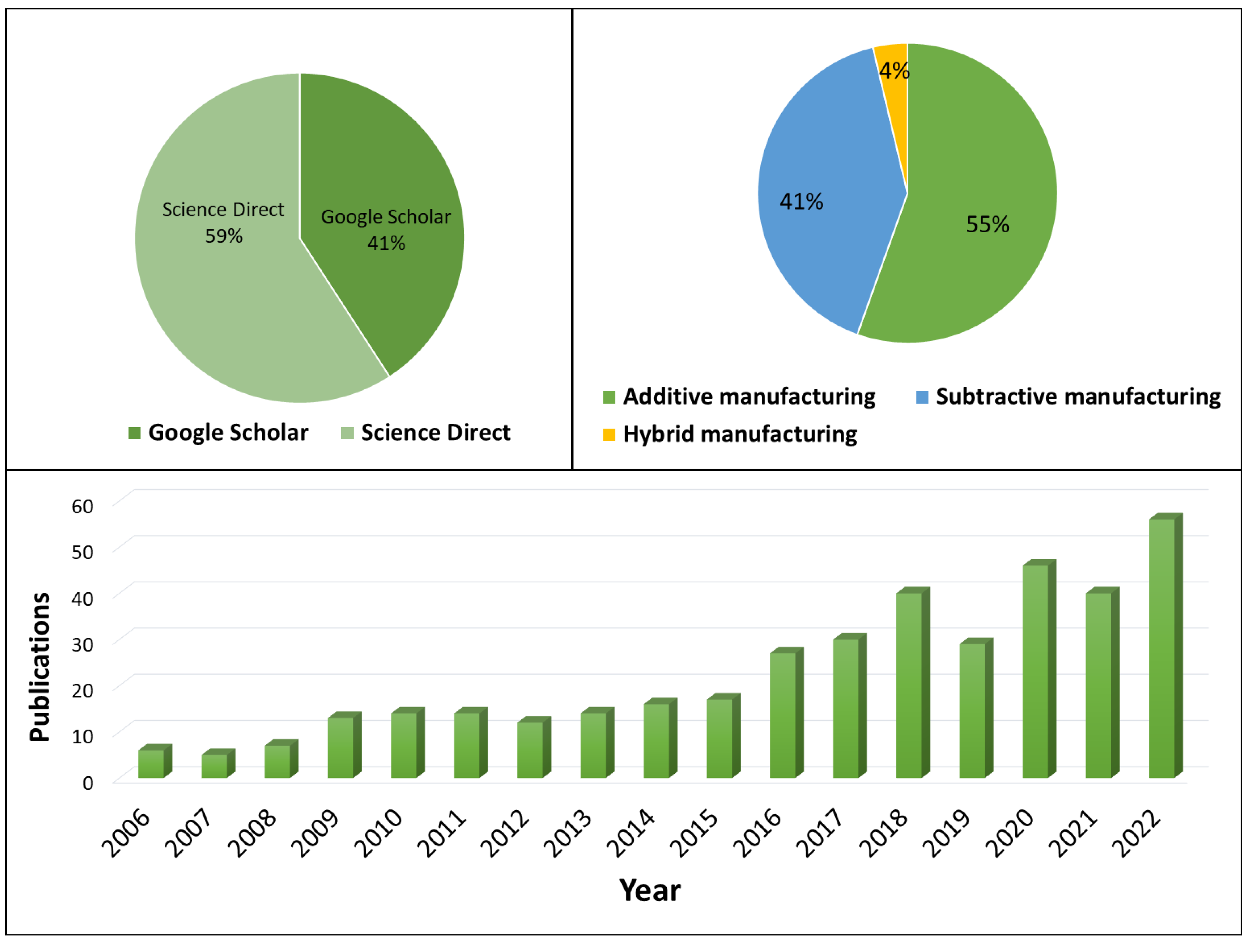

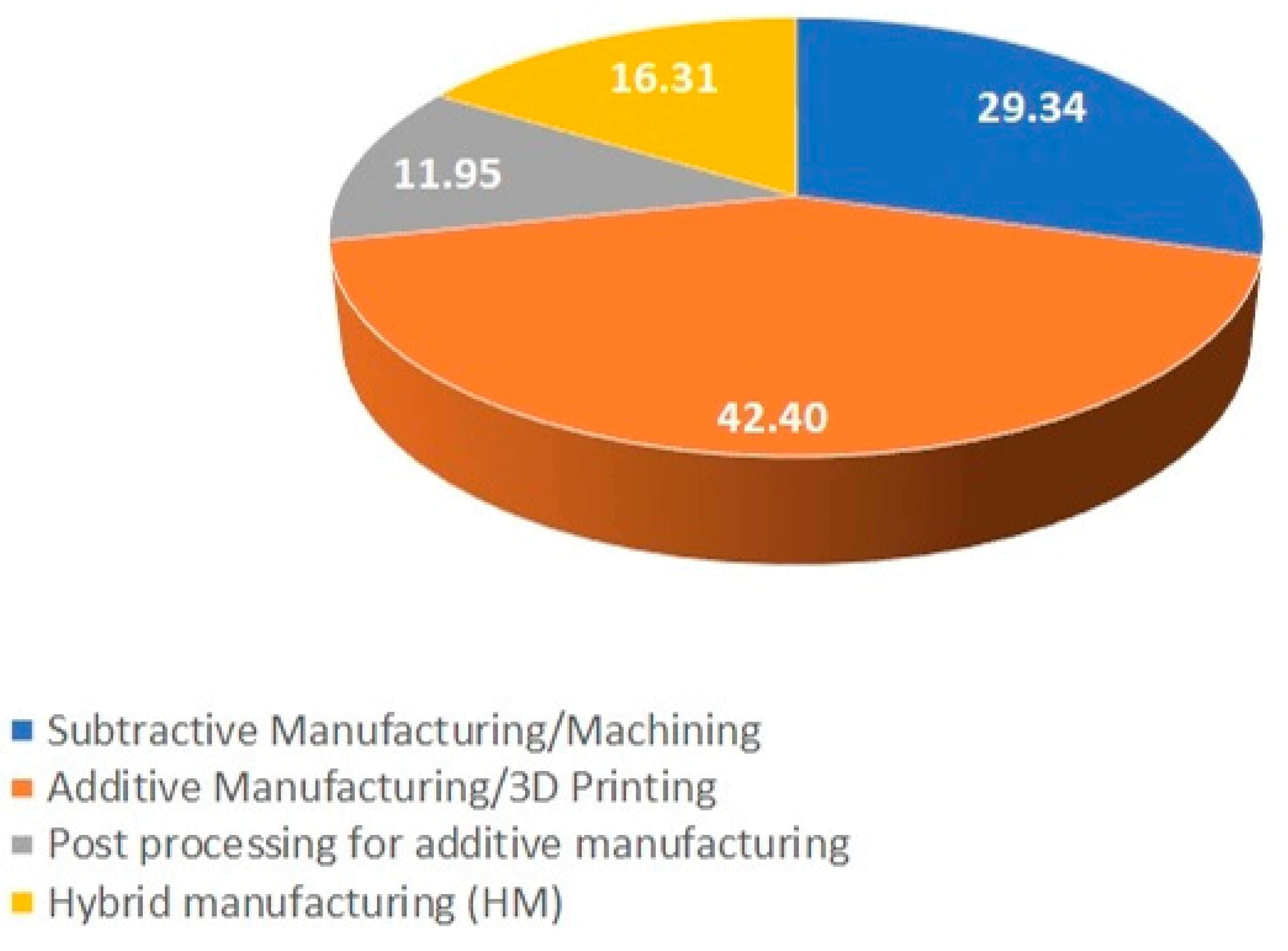

2. Review Methodology

- RQ1.

- What is the role of intelligence in additive and subtractive manufacturing?

- RQ2.

- What are the major challenges of intelligence in additive and subtractive manufacturing?

- RQ3.

- What are the present trends of intelligence in additive and subtractive manufacturing?

- RQ4.

- How to prepare the present intelligence of additive and subtractive manufacturing for the future?

- RQ5.

- What future directions need to be followed from the status of intelligent additive and subtractive manufacturing?

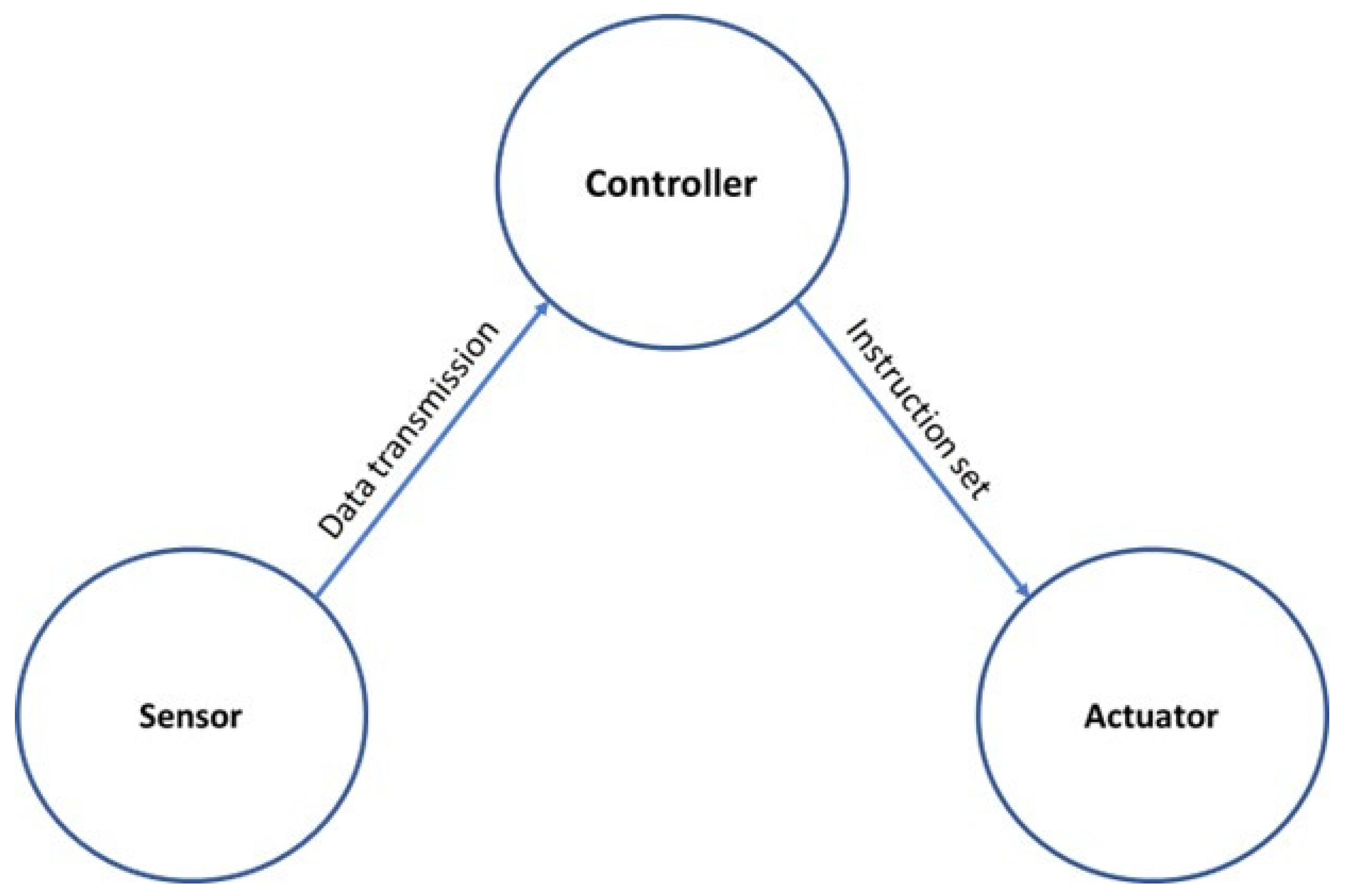

3. Intelligent/Smart Systems- Definition, Principle, Prerequisites

4. Intelligence in State-of-the-Art Manufacturing Technology: Monitoring, Feedback, Controlling, and Machine Learning

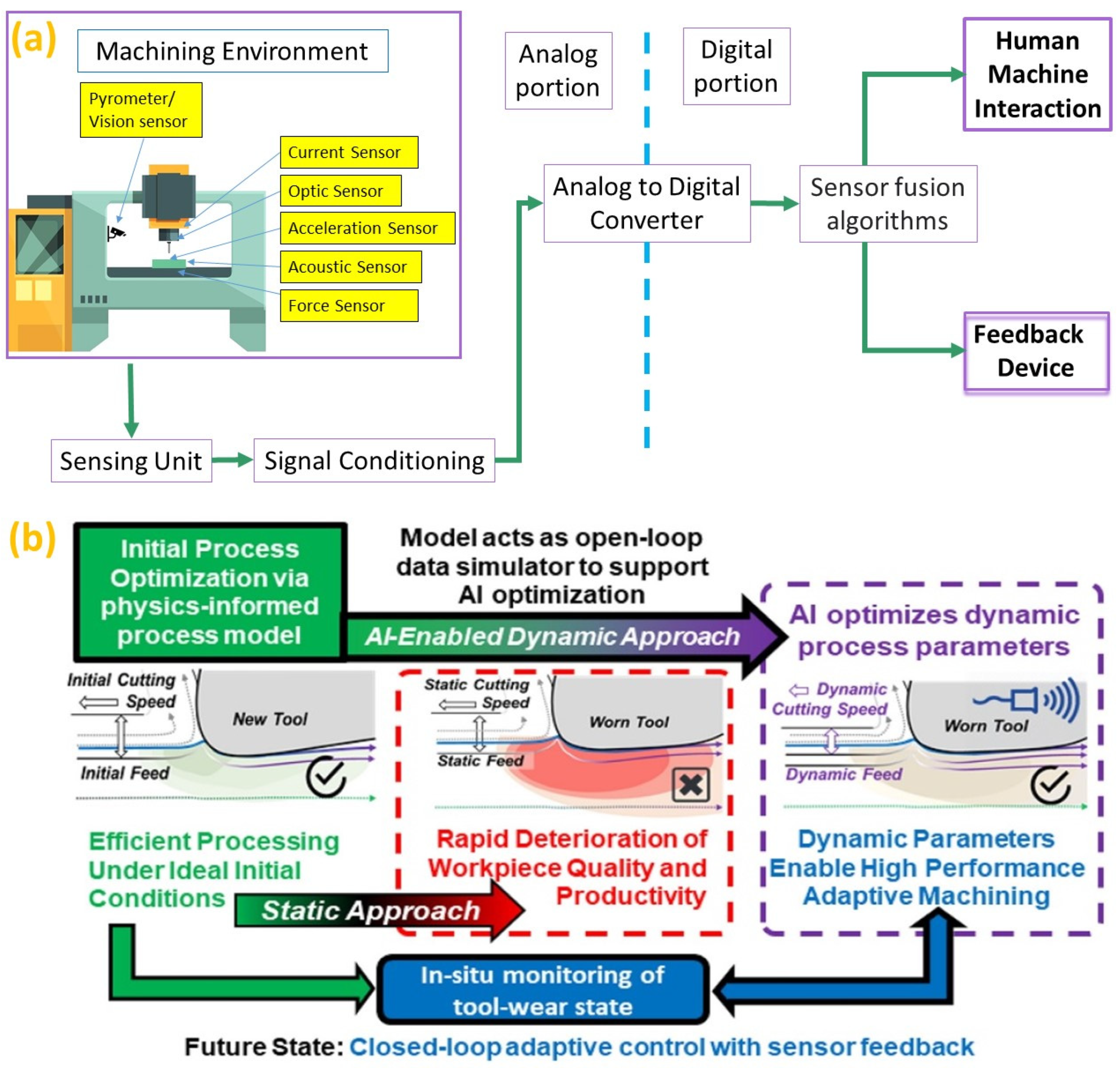

4.1. Subtractive Manufacturing/Machining

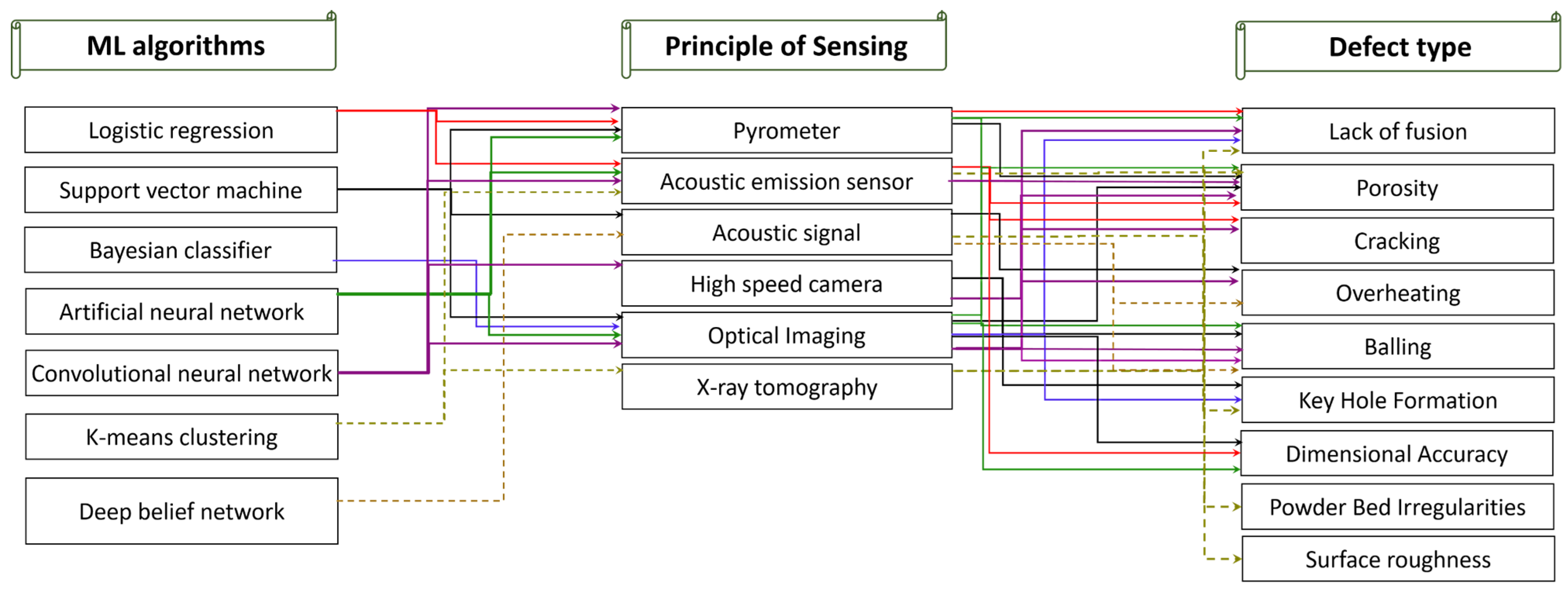

4.2. Additive Manufacturing/3D Printing

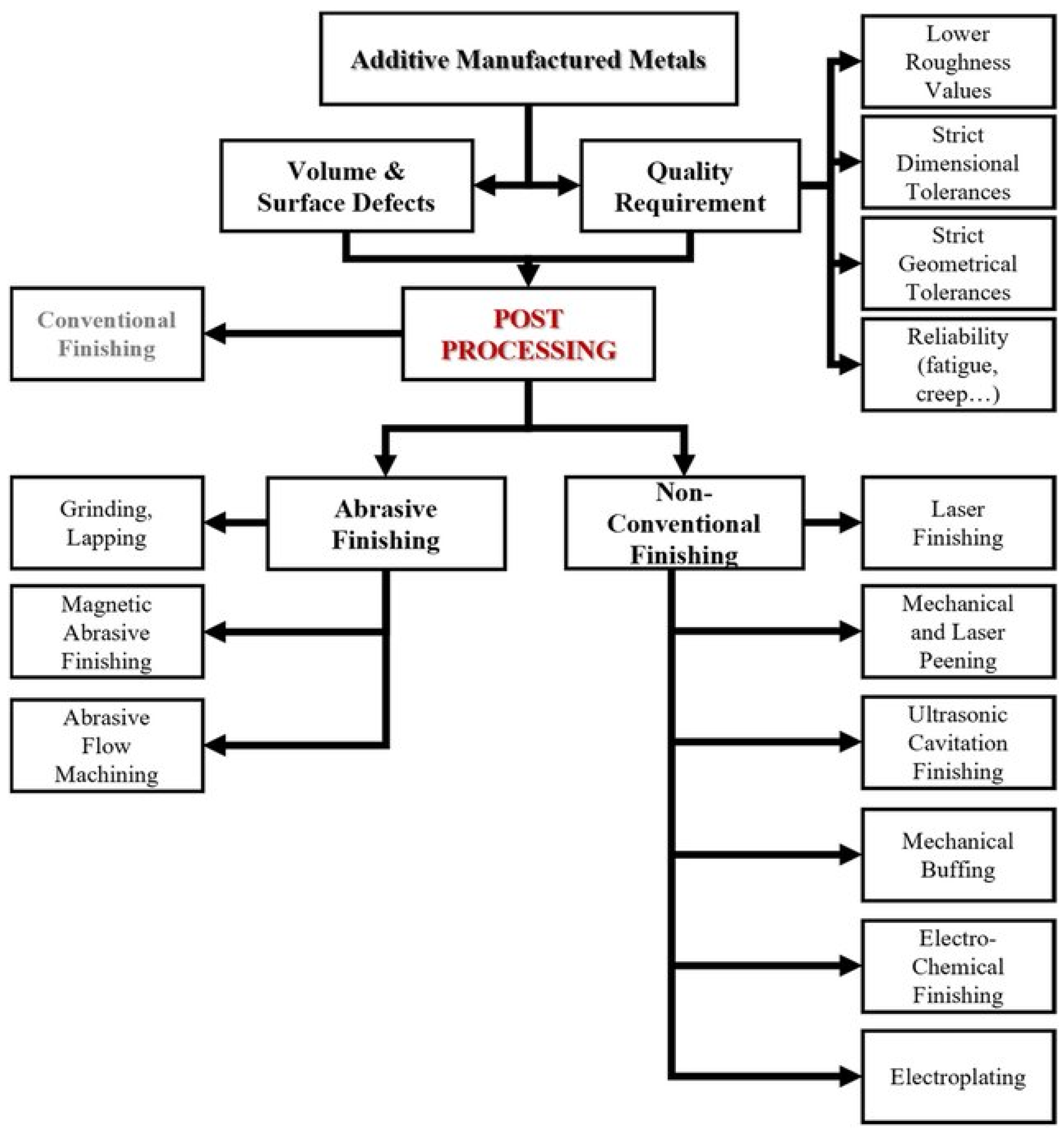

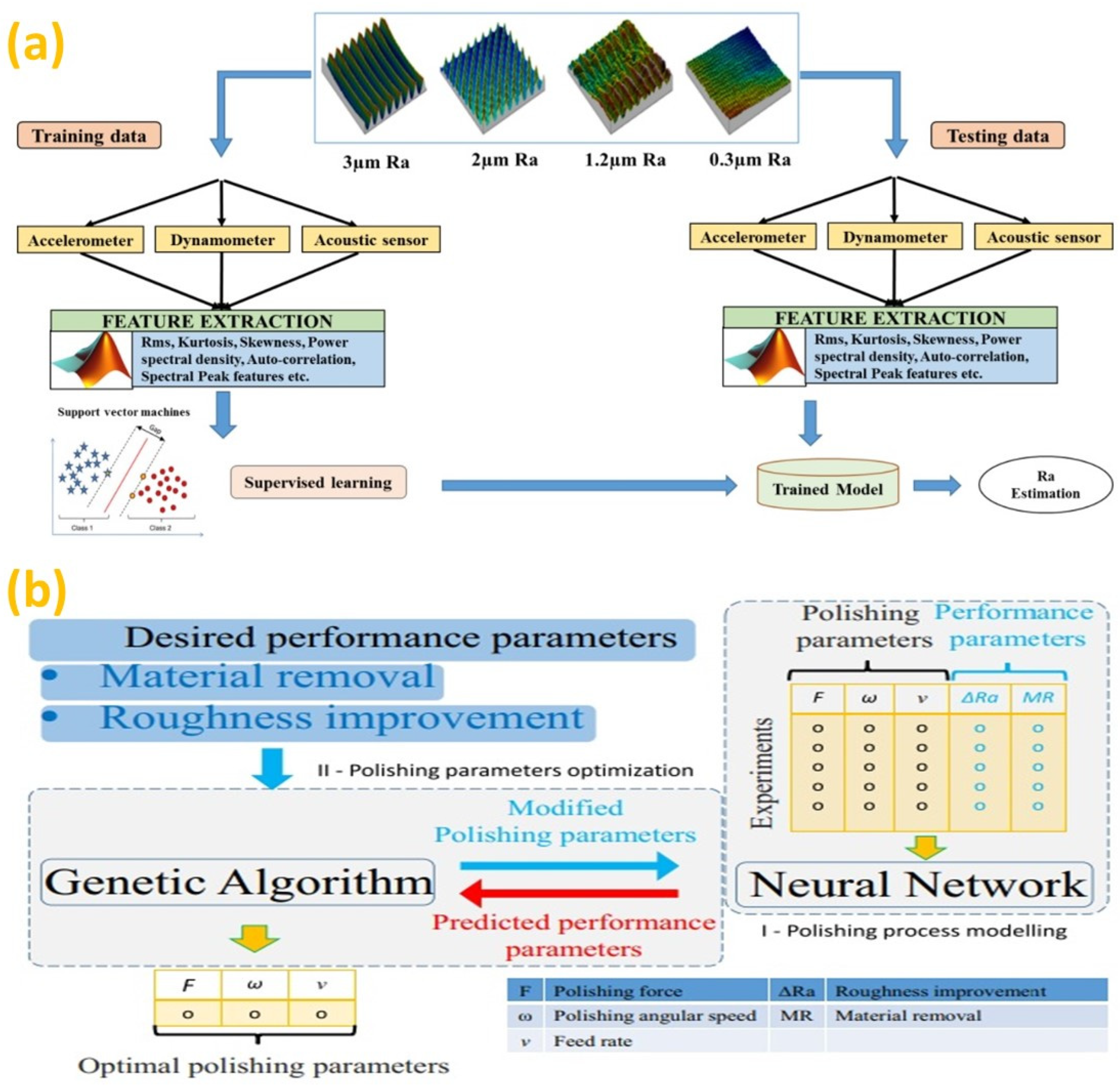

4.3. Post Processing for Additive Manufacturing

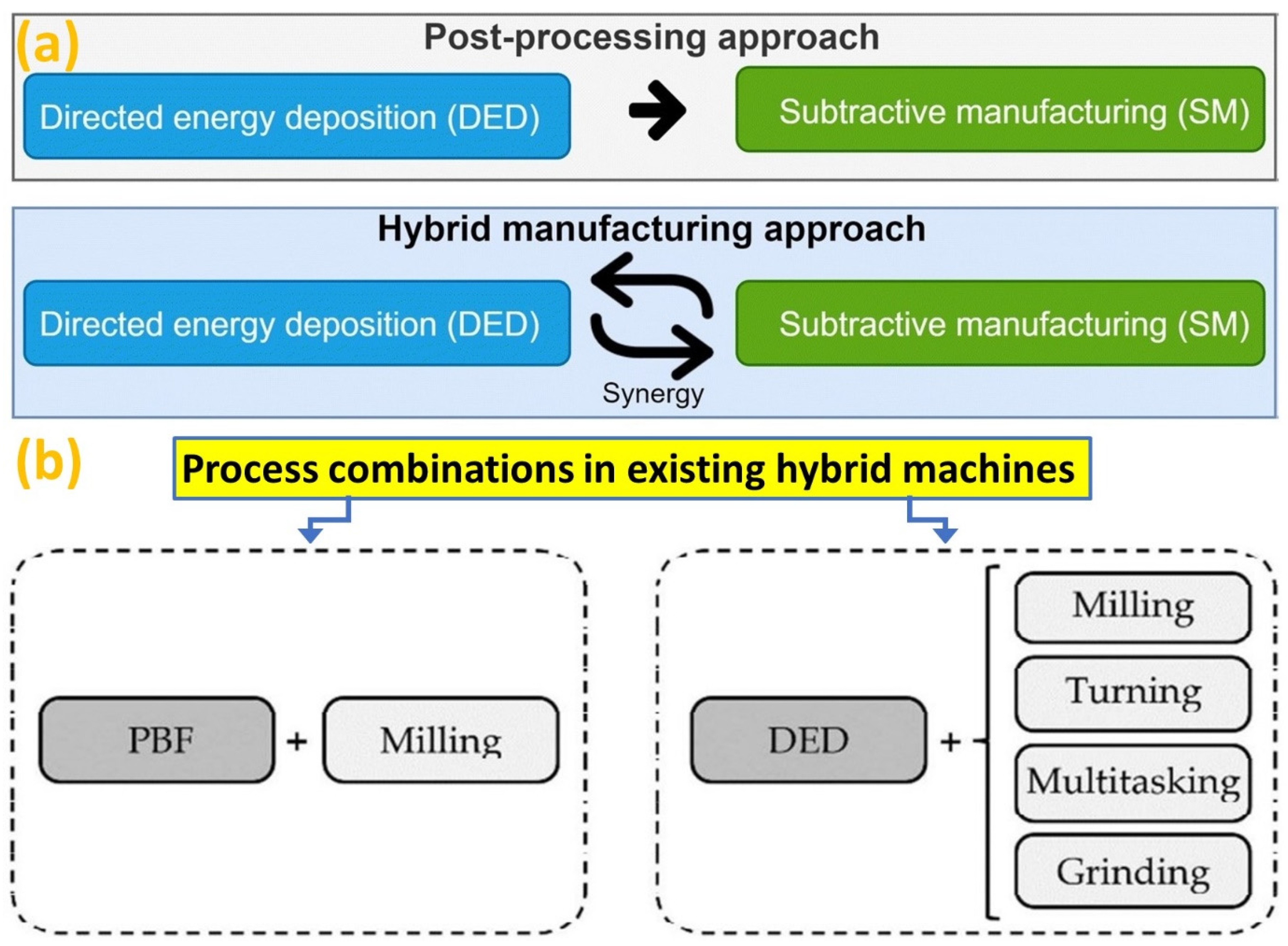

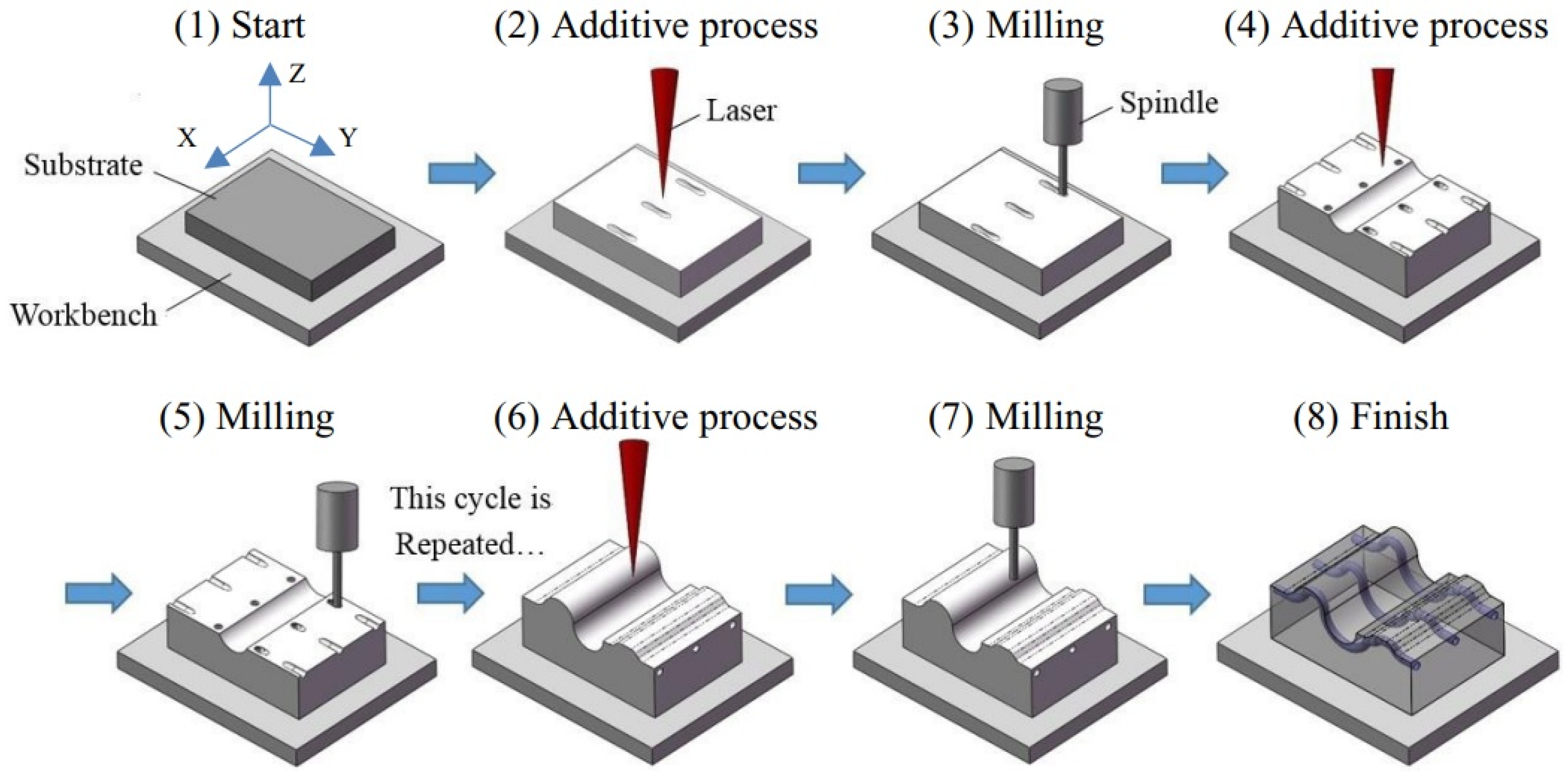

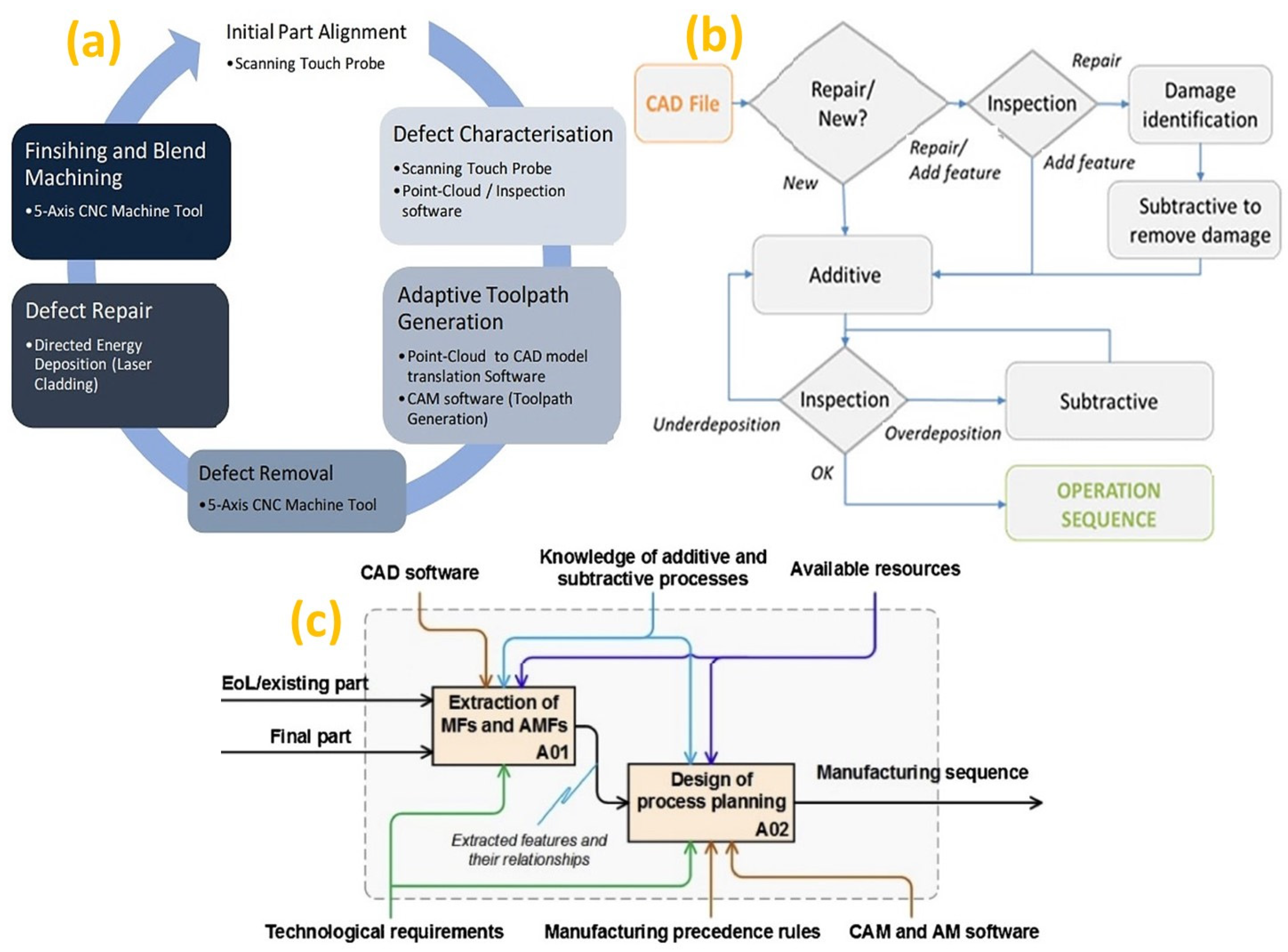

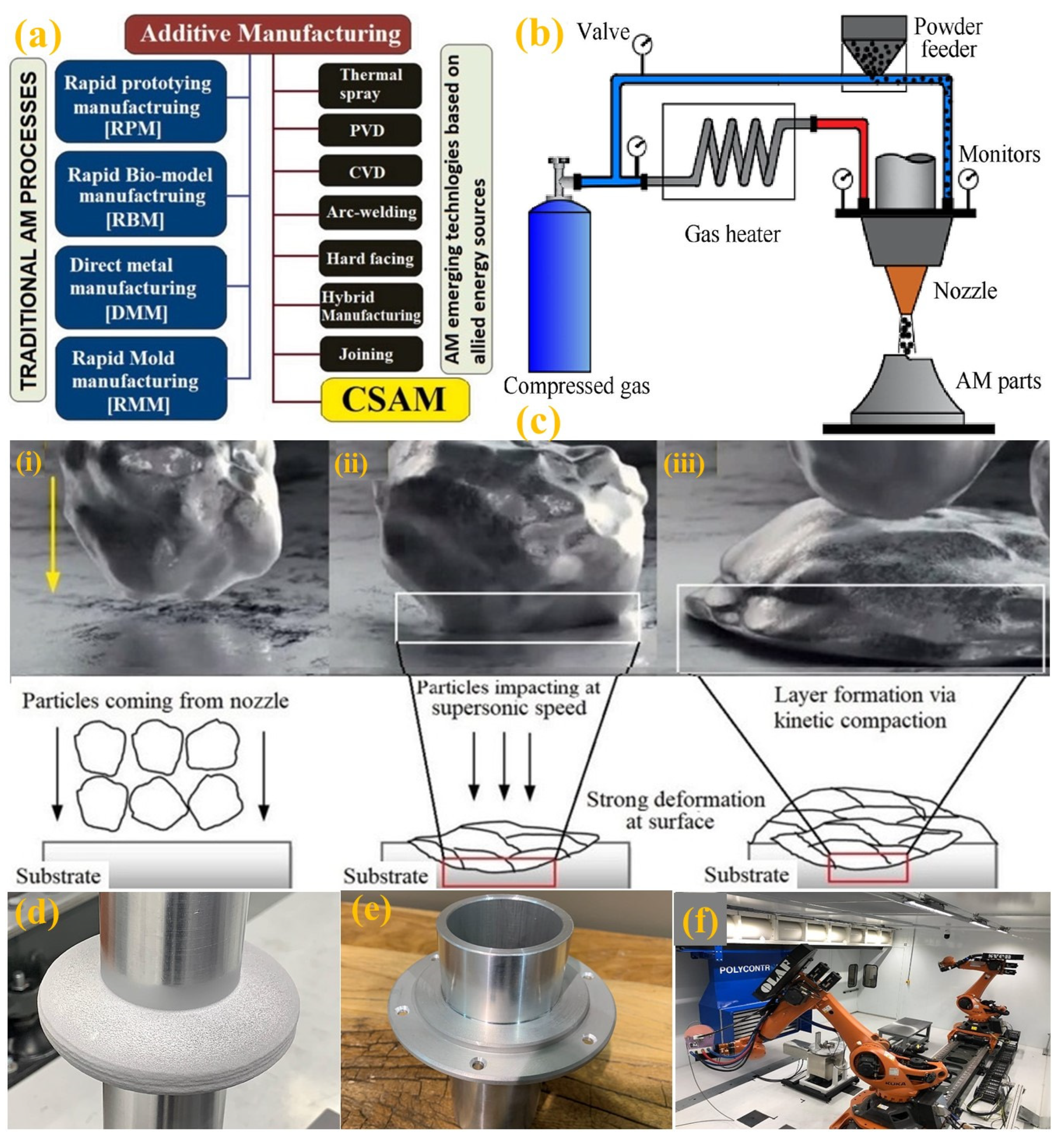

4.4. Hybrid Manufacturing (HM)

5. Critical Analysis and Challenges in Intelligent Manufacturing

6. Future Prospect

6.1. Smart Sensors and Applications

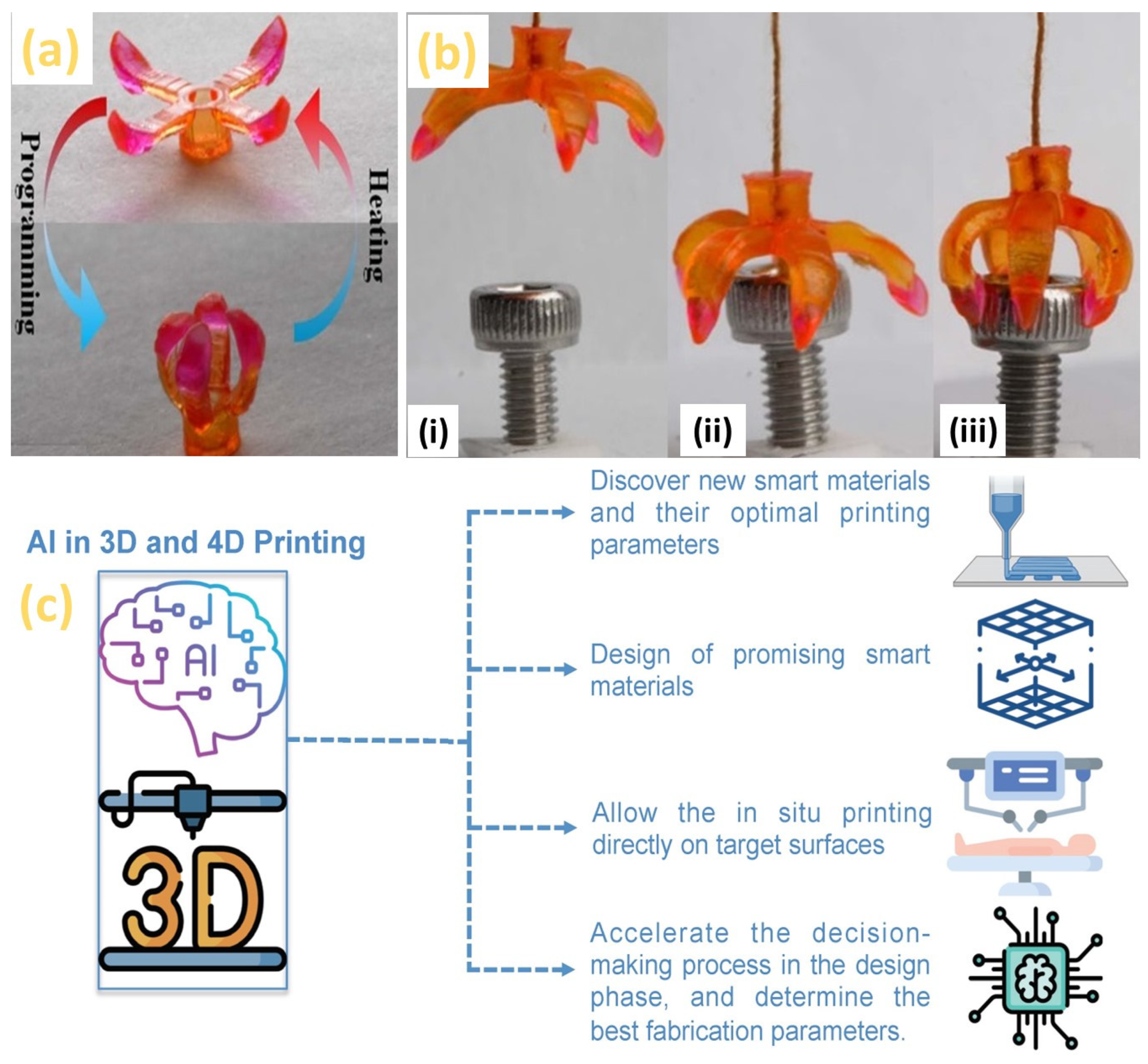

6.2. Intelligent 4D Printing

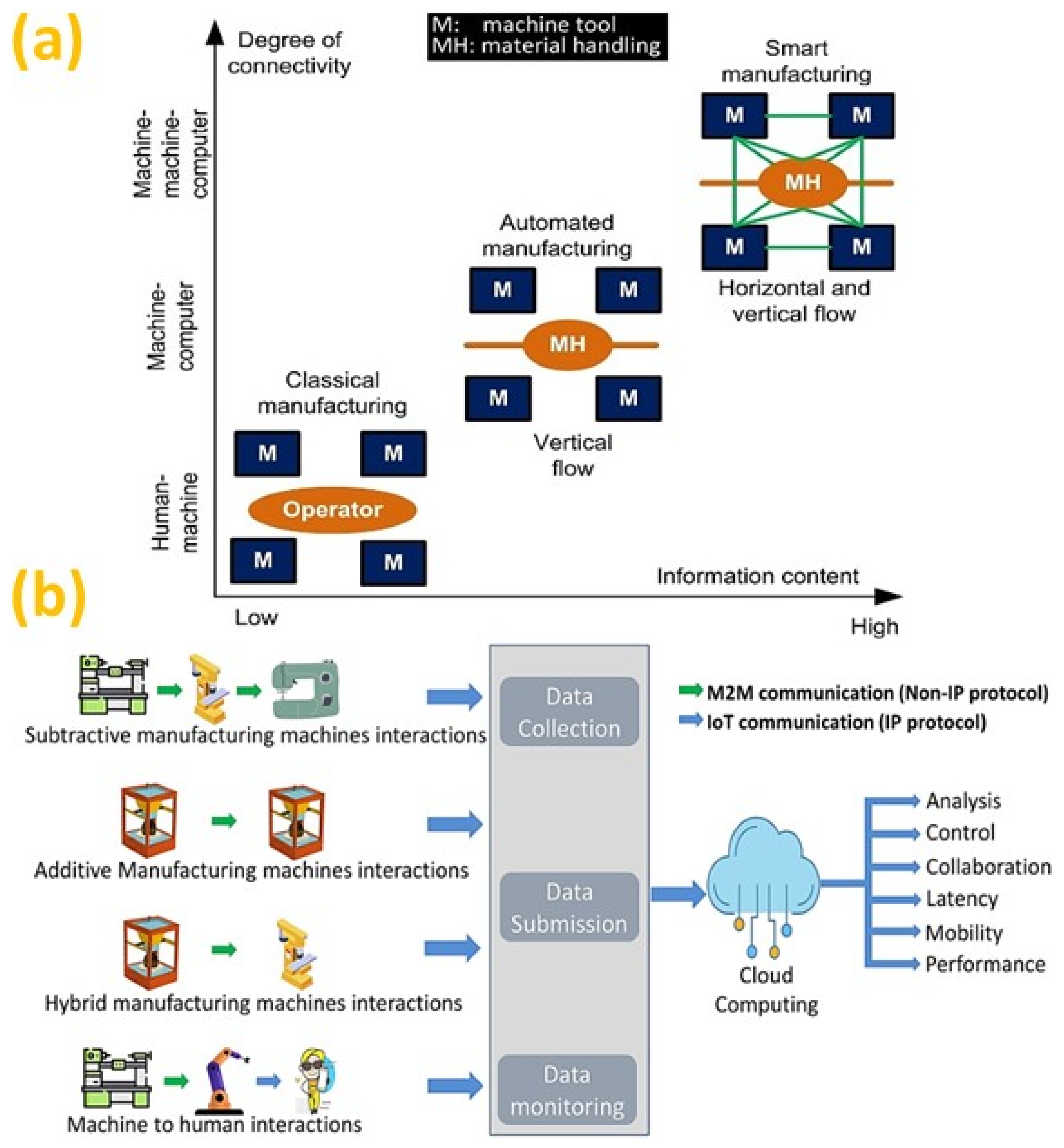

6.3. Machine to Machine (M2M) Communication and Machine to Human (M2H) Interaction

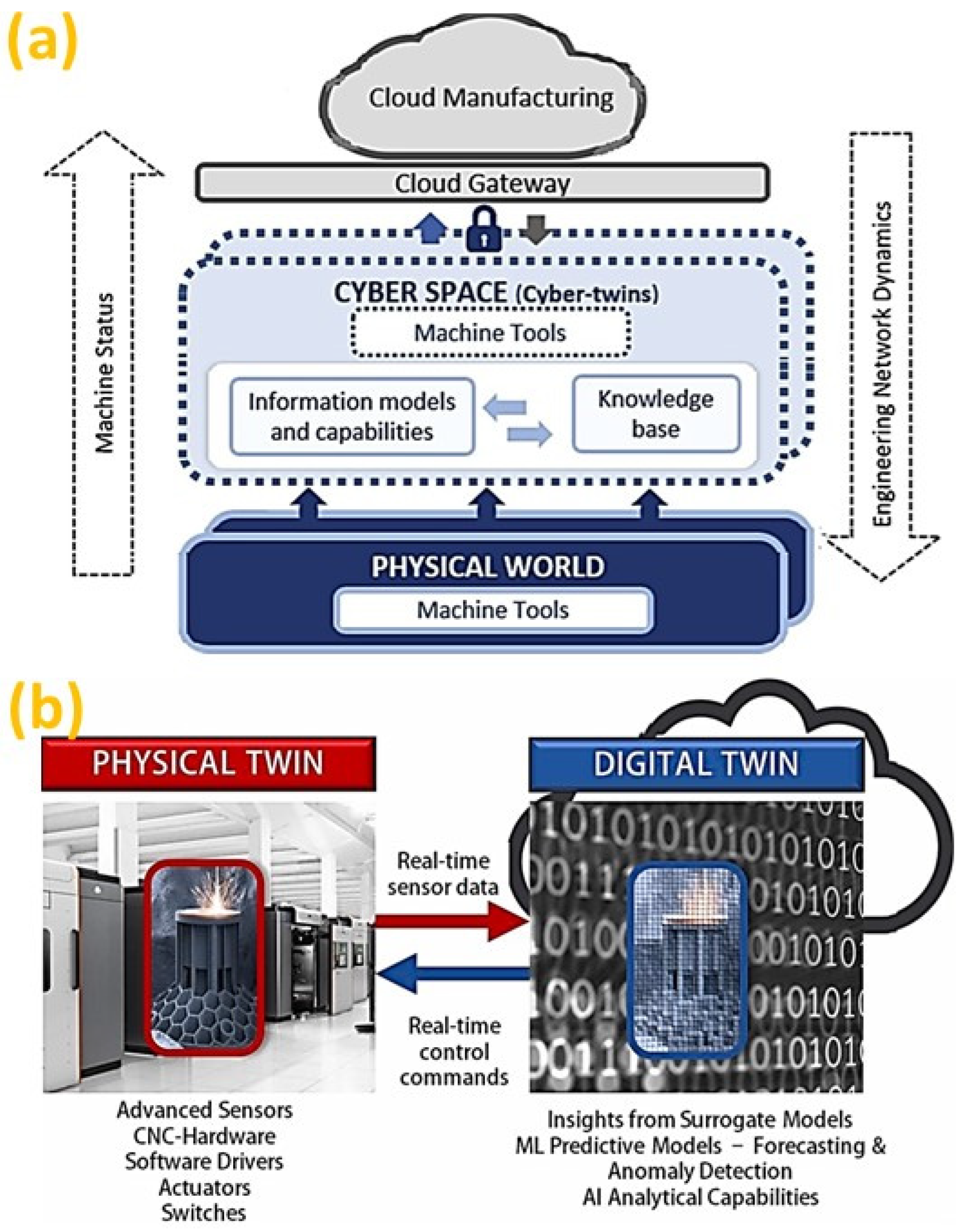

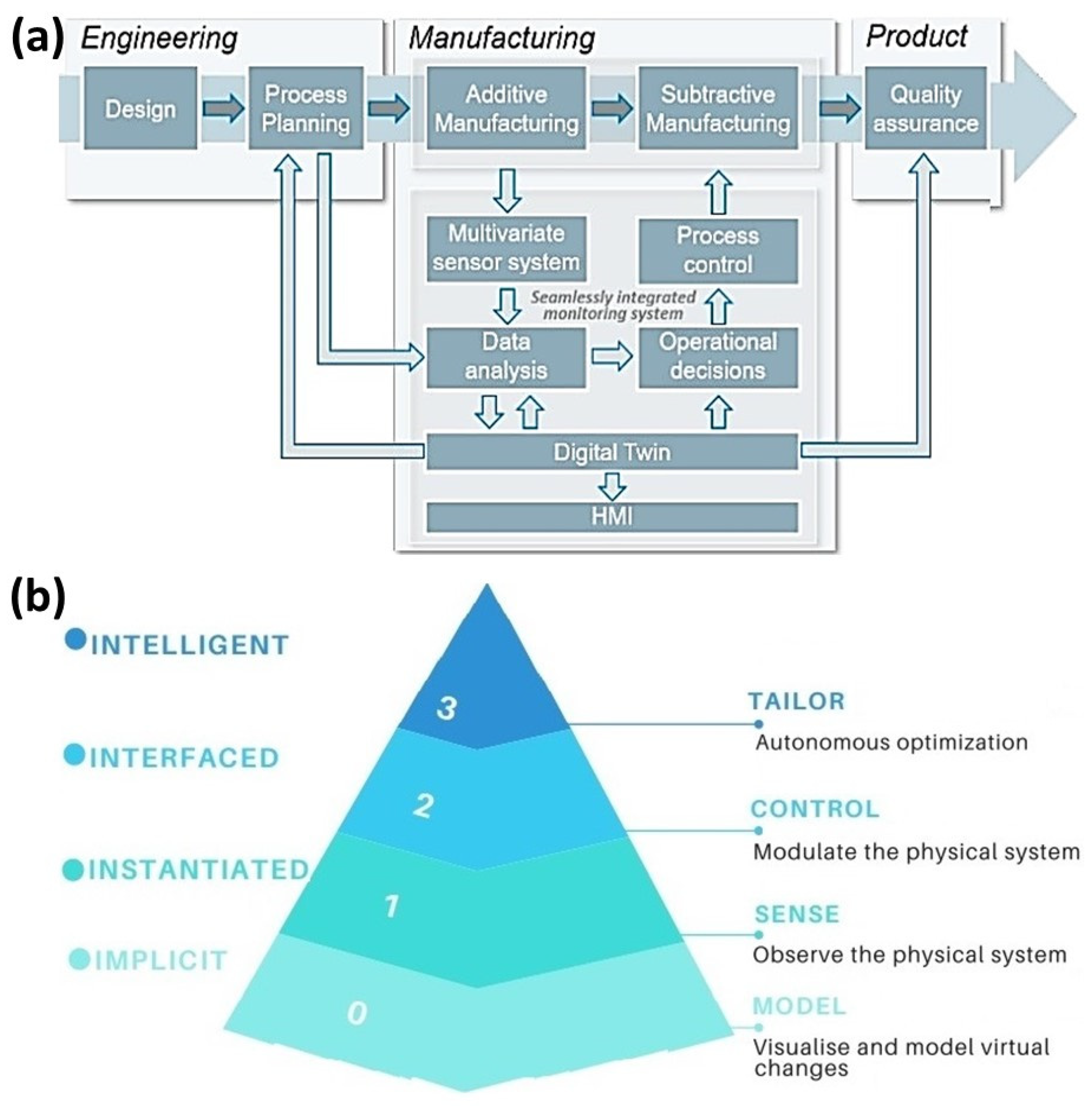

6.4. Cyber Physical System (CPS) and Digital Twin (DT) Driven Manufacturing

6.5. Embracing the Digitalization and Intelligence

7. Conclusions

7.1. Current Status

- The integration of artificial intelligence (AI) into machines and software are widely recognized as a key enabler of process automation. However, for AI to fully realize its potential to improve subtractive and additive manufacturing technologies, it is critical that significant advances should be made in the areas of connectivity, sensing, data collection and transmission;

- An on-machine measurement system is imperative for the implementation of automatic compensation during tool path generation, which can be achieved through the implementation of feedback control of the process parameters in intelligent machining. Moreover, the integration of smart technology is crucial for the in-situ evaluation of defects and quality control of additive manufactured (AM) parts;

- The generalization capability of most machine learning (ML) algorithms is well-known. However, it is also widely acknowledged that the variability in the manufacturing process can undermine the effectiveness of these algorithms. Moreover, AI-based predictions are regarded as black-box style indications where the end user has limited access on the decision-making rationale of the model. The lack of clarity due to the complex computing architecture has reduced the trustworthiness of AI predictions, especially when the process chains are dependent on inputs from various operations;

- The post-processing method of additively manufactured parts provides opportunities for improvement in surface quality though the method is deeply integrated with the application and the primary processing techniques. Moreover, conventional finishing methods may prove inadequate in complex structures. To address this challenge, a hybrid process that considers the thermal history of the part is necessary to create a digital thread in the tool path planning for intermediate and final machining operations. Furthermore, it is difficult to capture the intrinsic structure-process–property performance relationship through intelligent techniques. Thus, most of the current intelligent predictive models are material-dependent and may not work for a different material;

- Hybrid or convergent manufacturing is the next-generation manufacturing process, offering infinite possibilities of creating complex-shaped parts with desired dimensional accuracy and surface finish, that are otherwise difficult to obtain by either subtractive or additive manufacturing. However, the current commercial hybrid machines are expensive, and the amortization period is long due to limited use cases. Integration of intelligent and smart manufacturing tools, i.e., in-situ monitoring, sensing, and control and application of ML and AI will be the near future direction of hybrid manufacturing research;

- Digitalization of traditional manufacturing equipment and processes are the path to keep up with the trend of automation and Industry 4.0. Small and medium size industries can be benefit from the digital manufacturing technologies, which will allow control of all the equipment in a factory by monitoring and controlling them from a web cloud. However, there are challenges associated with the implication of digital and smart manufacturing tools. A large number of sensors need to be installed on the machine tool for data collection and storage, which may not be cost-effective for small to medium-scale manufacturing industries. In addition to data collection, the accurate data analysis is challenging;

- The advancement in 3D printing technology has opened new avenues in the field of bioprinting, with 4D printing being at the forefront of this revolution. The ability to create personalized bio-printing solutions through 4D printing applications has generated significant interest in recent times.

7.2. Future Prospects

- To overcome the challenges mentioned above and fully realize the potential of intelligent subtractive and additive manufacturing, continued research is required in these areas, including advances in the collection and analysis of process data, and the development of sophisticated and platform independent M2M communication systems that can effectively transmit data in real-time. Moreover, to address limited availability of training data for AI and ML models, future research should focus on revealing the physics of the process and then use the physics-based findings to train the model using ML techniques so that manufacturing science can be revealed with the change of new operating conditions or input data;

- The integration of various smart sensors into real-time monitoring and feedback control systems will offer an in-depth understanding of the hybrid machining process. This allows for a more complete evaluation of the process by dynamically incorporating thermal, acoustic and electromagnetic signals or even other information that was ignored from a machining perspective. Therefore, a complex and innovative algorithm will be needed to process such a data matrix that will ultimately enable the implementation of high-performance adaptive and hybrid manufacturing techniques beyond current perception;

- Future manufacturing trends will not only focus on combining additive and subtractive manufacturing in a single platform but also will incorporate smart sensing technology into the convergent manufacturing system to create an intelligent smart convergent manufacturing system. In comparison to other manufacturing processes, the hybrid systems needed to fabricate complete parts are still low. Thus, the rapid expansion of hybrid processes is needed with adaptive learning, digital metrology, in situ monitoring, and 3D model synchronization for smart factory applications;

- With rapidly evolved cloud manufacturing into an integrated cyber-physical system (CPS) leveraging cloud services, virtualized resources and intelligent decision-making capabilities enable the development of virtual machine tool, which can act as building block for digital twin to facilitate cyber-physical manufacturing. However, to be truly effective, the cloud manufacturing requires the provision of smart machine tools with built-in computation and intelligence to support the optimal decision-making through real-time monitoring of processes. Hence, a cyber-physical machine tool (CPMT) will have a digital space with computing and networking capabilities to provide real-time monitoring and feedback control, for example: edge computing;

- Four-dimensional printing requires a further leap forward in terms of technological sophistication. However, in biomedical applications, such as personalized organ printing, there is a mismatch between the printed part and the target surface due to limited real-time knowledge of the target geometry. To address this challenge, AI-based intelligent 3D and 4D printing can be used to predict the most likely behavior of the printing process and help to develop personalized anatomical models. However, collecting a large enough dataset for training the AI algorithms remains a critical challenge in this field;

- Managing an end-to-end hybrid process requires experienced engineers, designers and operators who are not always available. This creates bottlenecks in scaling up these processes for industrial applications. The future research, thus, will be focused on reducing the barriers for expert users through software and process automation algorithms. In this respect, more emphasis will be needed on digital twin (DT) technology which has created a lot of significant advances in AM and SM processes for evaluating the virtual representation. However, both spaces differ from each other. Therefore, the DT to overcome the divergence for the seamless inclusion of a product’s mechanical and microstructural behavior to precisely obtain physical attributes before the production process;

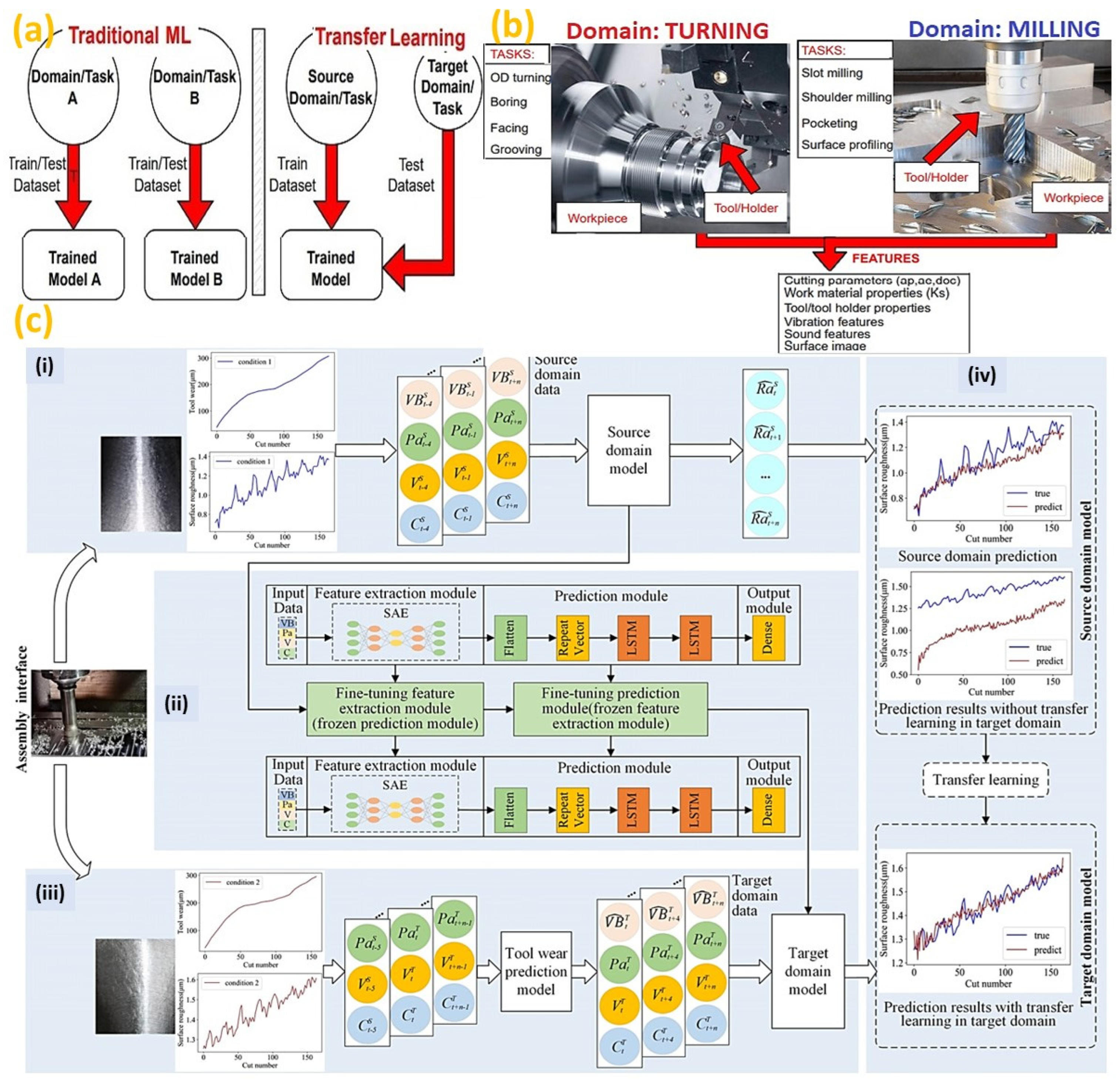

- Over the past decade, ML algorithms have been widely studied and adopted in various manufacturing-related fields. However, the variability in manufacturing processes can limit the effectiveness of these ML algorithms. To address this challenge, transfer learning (TL) has emerged as a solution, allowing for transferring knowledge acquired from one process variation to another. Despite current limitations in transmission speed and data storage sizes, advancements in AI tools, such as ChatGPT by OpenAI and Bard by Google offer a glimpse into a future where cross-disciplinary topics can be understood in a more integrated manner.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Arinez, J.F.; Chang, Q.; Gao, R.X.; Xu, C.; Zhang, J. Artificial Intelligence in Advanced Manufacturing: Current Status and Future Outlook. J. Manuf. Sci. Eng. 2020, 142, 110804. [Google Scholar] [CrossRef]

- Monostori, L.; Kádár, B.; Bauernhansl, T.; Kondoh, S.; Kumara, S.; Reinhart, G.; Sauer, O.; Schuh, G.; Sihn, W.; Ueda, K. Cyber-Physical Systems in Manufacturing. CIRP Ann. 2016, 65, 621–641. [Google Scholar] [CrossRef]

- Lim, M.K.; Xiong, W.; Lei, Z. Theory, Supporting Technology and Application Analysis of Cloud Manufacturing: A Systematic and Comprehensive Literature Review. Ind. Manag. Data Syst. 2020, 120, 1585–1614. [Google Scholar] [CrossRef]

- Volpe, G.; Mangini, A.M.; Fanti, M.P. An Architecture for Digital Processes in Manufacturing with Blockchain, Docker and Cloud Storage. In Proceedings of the 2021 IEEE 17th International Conference on Automation Science and Engineering (CASE), Lyon, France, 23–27 August 2021; pp. 39–44. [Google Scholar] [CrossRef]

- Liu, C.; Vengayil, H.; Lu, Y.; Xu, X. A Cyber-Physical Machine Tools Platform Using OPC UA and MTConnect. J. Manuf. Syst. 2019, 51, 61–74. [Google Scholar] [CrossRef]

- Cho, J.; Kang, S.; Kim, K. Real-Time Precise Object Segmentation Using a Pixel-Wise Coarse-Fine Method with Deep Learning for Automated Manufacturing. J. Manuf. Syst. 2022, 62, 114–123. [Google Scholar] [CrossRef]

- Boccella, A.R.; Centobelli, P.; Cerchione, R.; Murino, T.; Riedel, R. Evaluating Centralized and Heterarchical Control of Smart Manufacturing Systems in the Era of Industry 4.0. Appl. Sci. 2020, 10, 755. [Google Scholar] [CrossRef]

- Wang, S.; Wan, J.; Li, D.; Zhang, C. Implementing Smart Factory of Industrie 4.0: An Outlook. Int. J. Distrib. Sens. Netw. 2016, 12, 3159805. [Google Scholar] [CrossRef]

- Zhang, Y.; Qian, C.; Lv, J.; Liu, Y. Agent and Cyber-Physical System Based Self-Organizing and Self-Adaptive Intelligent Shopfloor. IEEE Trans. Ind. Inf. 2017, 13, 737–747. [Google Scholar] [CrossRef]

- Sari, T.; Gules, H.K.; Yigitol, B. Awareness and Readiness of Industry 4.0: The Case of Turkish Manufacturing Industry. Adv. Prod. Eng. Manag. 2020, 15, 57–68. [Google Scholar] [CrossRef]

- Thames, L.; Schaefer, D. Industry 4.0: An Overview of Key Benefits, Technologies, and Challenges. In Cybersecurity for Industry 4.0; Thames, L., Schaefer, D., Eds.; Springer International Publishing: Cham, Switzerland, 2017; pp. 1–33. ISBN 978-3-319-50659-3 978-3-319-50660-9. [Google Scholar] [CrossRef]

- Yuan, C.; Li, G.; Kamarthi, S.; Jin, X.; Moghaddam, M. Trends in Intelligent Manufacturing Research: A Keyword Co-Occurrence Network Based Review. J. Intell. Manuf. 2022, 33, 425–439. [Google Scholar] [CrossRef]

- Sarker, I.H. AI-Based Modeling: Techniques, Applications and Research Issues Towards Automation, Intelligent and Smart Systems. SN Comput. Sci. 2022, 3, 158. [Google Scholar] [CrossRef]

- Gajsek, B.; Marolt, J.; Rupnik, B.; Lerher, T.; Sternad, M. Using Maturity Model and Discrete-Event Simulation for Industry 4.0 Implementation. Int. J. Simul. Model. 2019, 18, 488–499. [Google Scholar] [CrossRef]

- Caggiano, A. Cloud-Based Manufacturing Process Monitoring for Smart Diagnosis Services. Int. J. Comput. Integr. Manuf. 2018, 31, 612–623. [Google Scholar] [CrossRef]

- Cheng, K.; Niu, Z.-C.; Wang, R.C.; Rakowski, R.; Bateman, R. Smart Cutting Tools and Smart Machining: Development Approaches, and Their Implementation and Application Perspectives. Chin. J. Mech. Eng. 2017, 30, 1162–1176. [Google Scholar] [CrossRef]

- Ong, P.; Lee, W.K.; Lau, R.J.H. Tool Condition Monitoring in CNC End Milling Using Wavelet Neural Network Based on Machine Vision. Int. J. Adv. Manuf. Technol. 2019, 104, 1369–1379. [Google Scholar] [CrossRef]

- Liu, L.; Zhang, X.; Wan, X.; Zhou, S.; Gao, Z. Digital Twin-Driven Surface Roughness Prediction and Process Parameter Adaptive Optimization. Adv. Eng. Inform. 2022, 51, 101470. [Google Scholar] [CrossRef]

- Chuo, Y.S.; Lee, J.W.; Mun, C.H.; Noh, I.W.; Rezvani, S.; Kim, D.C.; Lee, J.; Lee, S.W.; Park, S.S. Artificial Intelligence Enabled Smart Machining and Machine Tools. J. Mech. Sci. Technol. 2022, 36, 1–23. [Google Scholar] [CrossRef]

- Araújo, N.; Pacheco, V.; Costa, L. Smart Additive Manufacturing: The Path to the Digital Value Chain. Technologies 2021, 9, 88. [Google Scholar] [CrossRef]

- Brown, K.A.; Gu, G.X. Dimensions of Smart Additive Manufacturing. Adv. Intell. Syst. 2021, 3, 2100240. [Google Scholar] [CrossRef]

- Kim, D.B.; Witherell, P.; Lipman, R.; Feng, S.C. Streamlining the Additive Manufacturing Digital Spectrum: A Systems Approach. Addit. Manuf. 2015, 5, 20–30. [Google Scholar] [CrossRef]

- Kunovjanek, M.; Knofius, N.; Reiner, G. Additive Manufacturing and Supply Chains—A Systematic Review. Prod. Plan. Control. 2022, 33, 1231–1251. [Google Scholar] [CrossRef]

- Wang, C.; Tan, X.P.; Tor, S.B.; Lim, C.S. Machine Learning in Additive Manufacturing: State-of-the-Art and Perspectives. Addit. Manuf. 2020, 36, 101538. [Google Scholar] [CrossRef]

- Oleff, A.; Küster, B.; Stonis, M.; Overmeyer, L. Process Monitoring for Material Extrusion Additive Manufacturing: A State-of-the-Art Review. Prog. Addit. Manuf. 2021, 6, 705–730. [Google Scholar] [CrossRef]

- Du, W.; Bai, Q.; Zhang, B. A Novel Method for Additive/Subtractive Hybrid Manufacturing of Metallic Parts. Procedia Manuf. 2016, 5, 1018–1030. [Google Scholar] [CrossRef]

- Bhaduri, D.; Penchev, P.; Batal, A.; Dimov, S.; Soo, S.L.; Sten, S.; Harrysson, U.; Zhang, Z.; Dong, H. Laser Polishing of 3D Printed Mesoscale Components. Appl. Surf. Sci. 2017, 405, 29–46. [Google Scholar] [CrossRef]

- Boban, J.; Ahmed, A.; Jithinraj, E.K.; Rahman, M.A.; Rahman, M. Polishing of Additive Manufactured Metallic Components: Retrospect on Existing Methods and Future Prospects. Int. J. Adv. Manuf. Technol. 2022, 121, 83–125. [Google Scholar] [CrossRef]

- Manogharan, G.; Wysk, R.; Harrysson, O.; Aman, R. AIMS—A Metal Additive-Hybrid Manufacturing System: System Architecture and Attributes. Procedia Manuf. 2015, 1, 273–286. [Google Scholar] [CrossRef]

- Kerbrat, O.; Mognol, P.; Hascoët, J.-Y. A New DFM Approach to Combine Machining and Additive Manufacturing. Comput. Ind. 2011, 62, 684–692. [Google Scholar] [CrossRef]

- Dilberoglu, U.M.; Gharehpapagh, B.; Yaman, U.; Dolen, M. The Role of Additive Manufacturing in the Era of Industry 4.0. Procedia Manuf. 2017, 11, 545–554. [Google Scholar] [CrossRef]

- Pragana, J.P.M.; Sampaio, R.F.V.; Bragança, I.M.F.; Silva, C.M.A.; Martins, P.A.F. Hybrid Metal Additive Manufacturing: A State–of–the-Art Review. Adv. Ind. Manuf. Eng. 2021, 2, 100032. [Google Scholar] [CrossRef]

- Grzesik, W. Hybrid Additive and Subtractive Manufacturing Processes and Systems: A Review. J. Mach. Eng. 2018, 18, 5–24. [Google Scholar] [CrossRef]

- Behandish, M.; Nelaturi, S.; de Kleer, J. Automated Process Planning for Hybrid Manufacturing. Comput. -Aided Des. 2018, 102, 115–127. [Google Scholar] [CrossRef]

- Abdulhameed, O.; Al-Ahmari, A.M.; Ameen, W.; Mian, S.H. Novel Dynamic CAPP System for Hybrid Additive–Subtractive–Inspection Process. Rapid Prototyp. J. 2018, 24, 988–1002. [Google Scholar] [CrossRef]

- Dávila, J.L.; Neto, P.I.; Noritomi, P.Y.; Coelho, R.T.; da Silva, J.V.L. Hybrid Manufacturing: A Review of the Synergy between Directed Energy Deposition and Subtractive Processes. Int. J. Adv. Manuf. Technol. 2020, 110, 3377–3390. [Google Scholar] [CrossRef]

- Jena, M.C.; Mishra, S.K.; Moharana, H.S. Application of Industry 4.0 to Enhance Sustainable Manufacturing. Environ. Prog. Sustain. Energy 2020, 39, 13360. [Google Scholar] [CrossRef]

- Smith, C.S.; Wright, P.K. CyberCut: A World Wide Web Based Design-to-Fabrication Tool. J. Manuf. Syst. 1996, 15, 432–442. [Google Scholar] [CrossRef]

- Chand, R.; Sharma, V.S.; Trehan, R.; Gupta, M.K.; Sarikaya, M. Investigating the Dimensional Accuracy and Surface Roughness for 3D Printed Parts Using a Multi-Jet Printer. J. Mater. Eng. Perform. 2022, 1–15. [Google Scholar] [CrossRef]

- Ngo, T.D.; Kashani, A.; Imbalzano, G.; Nguyen, K.T.Q.; Hui, D. Additive Manufacturing (3D Printing): A Review of Materials, Methods, Applications and Challenges. Compos. B Eng. 2018, 143, 172–196. [Google Scholar] [CrossRef]

- DIng, D.; Zhao, Z.; Huang, R.; Dai, C.; Zhang, X.; Xu, T.; Fu, Y. Error Modeling and Path Planning for Freeform Surfaces by Laser Triangulation On-Machine Measurement. IEEE Trans. Instrum. Meas. 2021, 70. [Google Scholar] [CrossRef]

- Sathish, K.; Kumar, S.S.; Magal, R.T.; Selvaraj, V.; Narasimharaj, V.; Karthikeyan, R.; Sabarinathan, G.; Tiwari, M.; Kassa, A.E. A Comparative Study on Subtractive Manufacturing and Additive Manufacturing. Adv. Mater. Sci. Eng. 2022, 2022, 6892641. [Google Scholar] [CrossRef]

- Yusuf, S.M.; Cutler, S.; Gao, N. Review: The Impact of Metal Additive Manufacturing on the Aerospace Industry. Metals 2019, 9, 1286. [Google Scholar] [CrossRef]

- Korpela, M.; Riikonen, N.; Piili, H.; Salminen, A.; Nyrhilä, O. Additive Manufacturing—Past, Present, and the Future. Tech. Econ. Soc. Eff. Manuf. 4.0 2020, 17–41. [Google Scholar] [CrossRef]

- Pereira, T.; Kennedy, J.V.; Potgieter, J. A Comparison of Traditional Manufacturing vs Additive Manufacturing, the Best Method for the Job. Procedia Manuf. 2019, 30, 11–18. [Google Scholar] [CrossRef]

- Paris, H.; Mokhtarian, H.; Coatanéa, E.; Museau, M.; Ituarte, I.F. Comparative Environmental Impacts of Additive and Subtractive Manufacturing Technologies. CIRP Ann. 2016, 65, 29–32. [Google Scholar] [CrossRef]

- Boban, J.; Ahmed, A. Electric Discharge Assisted Post-Processing Performance of High Strength-to-Weight Ratio Alloys Fabricated Using Metal Additive Manufacturing. CIRP J. Manuf. Sci. Technol. 2022, 39, 159–174. [Google Scholar] [CrossRef]

- Ingarao, G.; Priarone, P.C. A Comparative Assessment of Energy Demand and Life Cycle Costs for Additive- and Subtractive-Based Manufacturing Approaches. J. Manuf. Process. 2020, 56, 1219–1229. [Google Scholar] [CrossRef]

- Sdvizhenskii, P.A.; Lednev, V.N.; Asyutin, R.D.; Grishin, M.Y.; Tretyakov, R.S.; Pershin, S.M. Online Laser-Induced Breakdown Spectroscopy for Metal-Particle Powder Flow Analysis during Additive Manufacturing. J. Anal. At. Spectrom. 2020, 35, 246–253. [Google Scholar] [CrossRef]

- Xia, C.; Pan, Z.; Polden, J.; Li, H.; Xu, Y.; Chen, S.; Zhang, Y. A Review on Wire Arc Additive Manufacturing: Monitoring, Control and a Framework of Automated System. J. Manuf. Syst. 2020, 57, 31–45. [Google Scholar] [CrossRef]

- Chabot, A.; Laroche, N.; Carcreff, E.; Rauch, M.; Hascoët, J.Y. Towards Defect Monitoring for Metallic Additive Manufacturing Components Using Phased Array Ultrasonic Testing. J. Intell. Manuf. 2020, 31, 1191–1201. [Google Scholar] [CrossRef]

- Cao, L.; Li, J.; Hu, J.; Liu, H.; Wu, Y.; Zhou, Q. Optimization of Surface Roughness and Dimensional Accuracy in LPBF Additive Manufacturing. Opt. Laser Technol. 2021, 142, 107246. [Google Scholar] [CrossRef]

- Boban, J.; Ahmed, A.; Rahman, M.A.; Rahman, M. Wire Electrical Discharge Polishing of Additive Manufactured Metallic Components. Procedia CIRP 2020, 87, 321–326. [Google Scholar] [CrossRef]

- Abdulhameed, O.; Al-Ahmari, A.; Ameen, W.; Mian, S.H. Additive Manufacturing: Challenges, Trends, and Applications. Adv. Mech. Eng. 2019, 11, 1687814018822880. [Google Scholar] [CrossRef]

- Bourell, D.; Kruth, J.P.; Leu, M.; Levy, G.; Rosen, D.; Beese, A.M.; Clare, A. Materials for Additive Manufacturing. CIRP Ann. 2017, 66, 659–681. [Google Scholar] [CrossRef]

- Kok, Y.; Tan, X.P.; Wang, P.; Nai, M.L.S.; Loh, N.H.; Liu, E.; Tor, S.B. Anisotropy and Heterogeneity of Microstructure and Mechanical Properties in Metal Additive Manufacturing: A Critical Review. Mater. Des. 2018, 139, 565–586. [Google Scholar] [CrossRef]

- Arias-González, F.; Barro, O.; del Val, J.; Lusquiños, F.; Fernández-Arias, M.; Comesaña, R.; Riveiro, A.; Pou, J. Laser-Directed Energy Deposition: Principles and Applications. Addit. Manuf. 2021, 121–157. [Google Scholar] [CrossRef]

- Atzeni, E.; Salmi, A. Economics of Additive Manufacturing for End-Usable Metal Parts. Int. J. Adv. Manuf. Technol. 2012, 62, 1147–1155. [Google Scholar] [CrossRef]

- Yakout, M.; Phillips, I.; Elbestawi, M.A.; Fang, Q. In-Situ Monitoring and Detection of Spatter Agglomeration and Delamination during Laser-Based Powder Bed Fusion of Invar 36. Opt. Laser Technol. 2021, 136, 106741. [Google Scholar] [CrossRef]

- Lalegani Dezaki, M.; Serjouei, A.; Zolfagharian, A.; Fotouhi, M.; Moradi, M.; Ariffin, M.K.A.; Bodaghi, M. A Review on Additive/Subtractive Hybrid Manufacturing of Directed Energy Deposition (DED) Process. Adv. Powder Mater. 2022, 1, 100054. [Google Scholar] [CrossRef]

- Newman, S.T.; Zhu, Z.; Dhokia, V.; Shokrani, A. Process Planning for Additive and Subtractive Manufacturing Technologies. CIRP Ann. 2015, 64, 467–470. [Google Scholar] [CrossRef]

- Liu, C.; Yan, D.; Tan, J.; Mai, Z.; Cai, Z.; Dai, Y.; Jiang, M.; Wang, P.; Liu, Z.; Li, C.C.; et al. Development and Experimental Validation of a Hybrid Selective Laser Melting and CNC Milling System. Addit. Manuf. 2020, 36, 101550. [Google Scholar] [CrossRef]

- Chen, N.; Frank, M. Process Planning for Hybrid Additive and Subtractive Manufacturing to Integrate Machining and Directed Energy Deposition. Procedia Manuf. 2019, 34, 205–213. [Google Scholar] [CrossRef]

- Xu, K.; Li, Y.; Liu, C.; Liu, X.; Hao, X.; Gao, J.; Maropoulos, P.G. Advanced Data Collection and Analysis in Data-Driven Manufacturing Process. Chin. J. Mech. Eng. 2020, 33, 1–21. [Google Scholar] [CrossRef]

- Amanullah, A.N.M.; Murshiduzzaman; Saleh, T.; Khan, R. Design and Development of a Hybrid Machine Combining Rapid Prototyping and CNC Milling Operation. Procedia Eng. 2017, 184, 163–170. [Google Scholar] [CrossRef]

- Boban, J.; Ahmed, A. Improving the Surface Integrity and Mechanical Properties of Additive Manufactured Stainless Steel Components by Wire Electrical Discharge Polishing. J. Mater. Process. Technol. 2021, 291, 117013. [Google Scholar] [CrossRef]

- Krakhmalev, P.; Sebbe, N.P.V.; Fernandes, F.; Sousa, V.F.C.; Silva, F.J.G. Hybrid Manufacturing Processes Used in the Production of Complex Parts: A Comprehensive Review. Metals 2022, 12, 1874. [Google Scholar] [CrossRef]

- Li, L.; Haghighi, A.; Yang, Y. A Novel 6-Axis Hybrid Additive-Subtractive Manufacturing Process: Design and Case Studies. J. Manuf. Process. 2018, 33, 150–160. [Google Scholar] [CrossRef]

- Cortina, M.; Arrizubieta, J.; Ruiz, J.; Ukar, E.; Lamikiz, A. Latest Developments in Industrial Hybrid Machine Tools That Combine Additive and Subtractive Operations. Materials 2018, 11, 2583. [Google Scholar] [CrossRef]

- Wang, L. From intelligence science to intelligent manufacturing. Engineering 2019, 5, 615–618. [Google Scholar] [CrossRef]

- Iqbal, A.; Zhao, G.; Suhaimi, H.; He, N.; Hussain, G.; Zhao, W. Readiness of Subtractive and Additive Manufacturing and Their Sustainable Amalgamation from the Perspective of Industry 4.0: A Comprehensive Review. Int. J. Adv. Manuf. Technol. 2020, 111, 2475–2498. [Google Scholar] [CrossRef]

- Aggour, K.S.; Gupta, V.K.; Ruscitto, D.; Ajdelsztajn, L.; Bian, X.; Brosnan, K.H.; Chennimalai Kumar, N.; Dheeradhada, V.; Hanlon, T.; Iyer, N.; et al. Artificial Intelligence/Machine Learning in Manufacturing and Inspection: A GE Perspective. MRS Bull. 2019, 44, 545–558. [Google Scholar] [CrossRef]

- Caggiano, A.; Zhang, J.; Alfieri, V.; Caiazzo, F.; Gao, R.; Teti, R. Machine Learning-Based Image Processing for on-Line Defect Recognition in Additive Manufacturing. CIRP Ann. 2019, 68, 451–454. [Google Scholar] [CrossRef]

- Poole, D.L.; Mackworth, A.K.; Goebel, R. Computational Intelligence: A Logical Approach; Oxford University Press: New York, NY, USA, 1998; ISBN 978-0-19-510270-3. [Google Scholar]

- Kim, D.-H.; Song, J.-Y. Knowledge-Evolutionary Intelligent Machine-Tools —Part 1: Design of Dialogue Agent Based on Standard Platform. J. Mech. Sci. Technol. 2006, 20, 1863–1872. [Google Scholar] [CrossRef]

- Kim, D.-H.; Song, J.-Y.; Lee, J.-H.; Cha, S.-K. Development and Evaluation of Intelligent Machine Tools Based on Knowledge Evolution in M2M Environment. J. Mech. Sci. Technol. 2009, 23, 2807–2813. [Google Scholar] [CrossRef]

- Lee, S.W.; Lee, H.K. Rule-Based Cutting Condition Recommendation System for Intelligent Machine Tools. J. Mech. Sci. Technol. 2009, 23, 1202–1210. [Google Scholar] [CrossRef]

- Reisch, R.; Hauser, T.; Kamps, T.; Knoll, A. Robot Based Wire Arc Additive Manufacturing System with Context-Sensitive Multivariate Monitoring Framework. Procedia Manuf. 2020, 51, 732–739. [Google Scholar] [CrossRef]

- Verl, A.; Lechler, A.; Schlechtendahl, J. Glocalized Cyber Physical Production Systems. Prod. Eng. Res. Devel. 2012, 6, 643–649. [Google Scholar] [CrossRef]

- Stentoft, J.; Olhager, J.; Heikkilä, J.; Thoms, L. Manufacturing Backshoring: A Systematic Literature Review. Oper. Manag. Res. 2016, 9, 53–61. [Google Scholar] [CrossRef]

- Tranfield, D.; Denyer, D.; Smart, P. Towards a Methodology for Developing Evidence-Informed Management Knowledge by Means of Systematic Review. Br. J. Manag. 2003, 14, 207–222. [Google Scholar] [CrossRef]

- Akhras, G. Smart materials and smart systems for the future. Can. Mil. J. 2000, 1, 25–31. [Google Scholar]

- Ricquebourg, V.; Menga, D.; Durand, D.; Marhic, B.; Delahoche, L.; Loge, C. The Smart Home Concept: Our Immediate Future. In Proceedings of the 2006 1ST IEEE International Conference on E-Learning in Industrial Electronics, Hammamet, Tunisia, 1–20 December 2006; pp. 23–28. [Google Scholar] [CrossRef]

- Kusiak, A. Smart Manufacturing. Int. J. Prod. Res. 2018, 56, 508–517. [Google Scholar] [CrossRef]

- Deshayes, L.; Welsch, L.; Donmez, A.; Ivester, R.; Gilsinn, D.; Rhorer, R.; Whitenton, E.; Potra, F. Smart Machining Systems: Issues and Research Trends. In Innovation in Life Cycle Engineering and Sustainable Development; Brissaud, D., Tichkiewitch, S., Zwolinski, P., Eds.; Springer: Dordrecht, The Netherlands, 2006; pp. 363–380. ISBN 978-1-4020-4601-8. [Google Scholar] [CrossRef]

- Imad, M.; Hosseini, A.; Kishawy, H.A. Optimization Methodologies in Intelligent Machining Systems—A Review. IFAC-PapersOnLine 2019, 52, 282–287. [Google Scholar] [CrossRef]

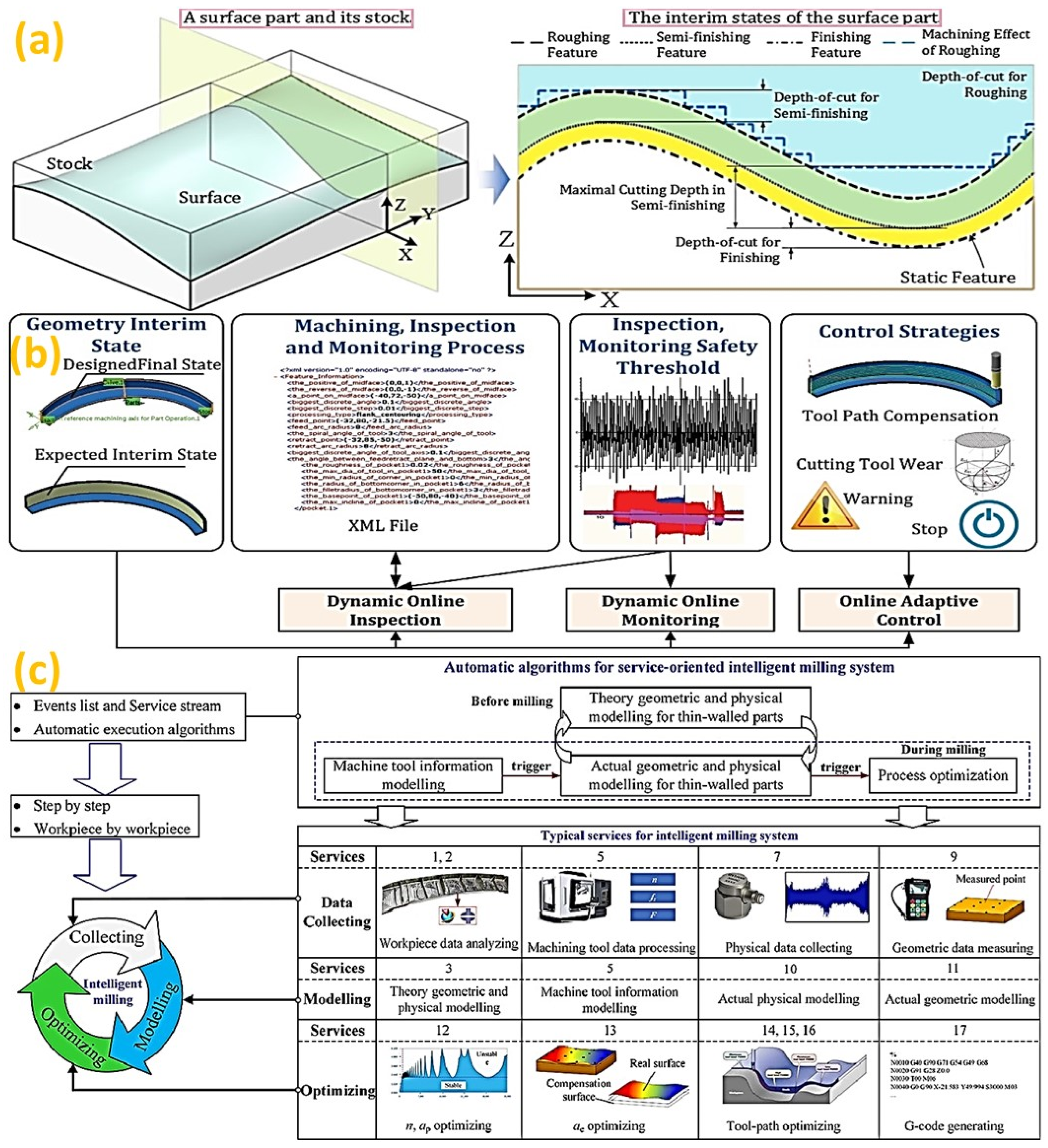

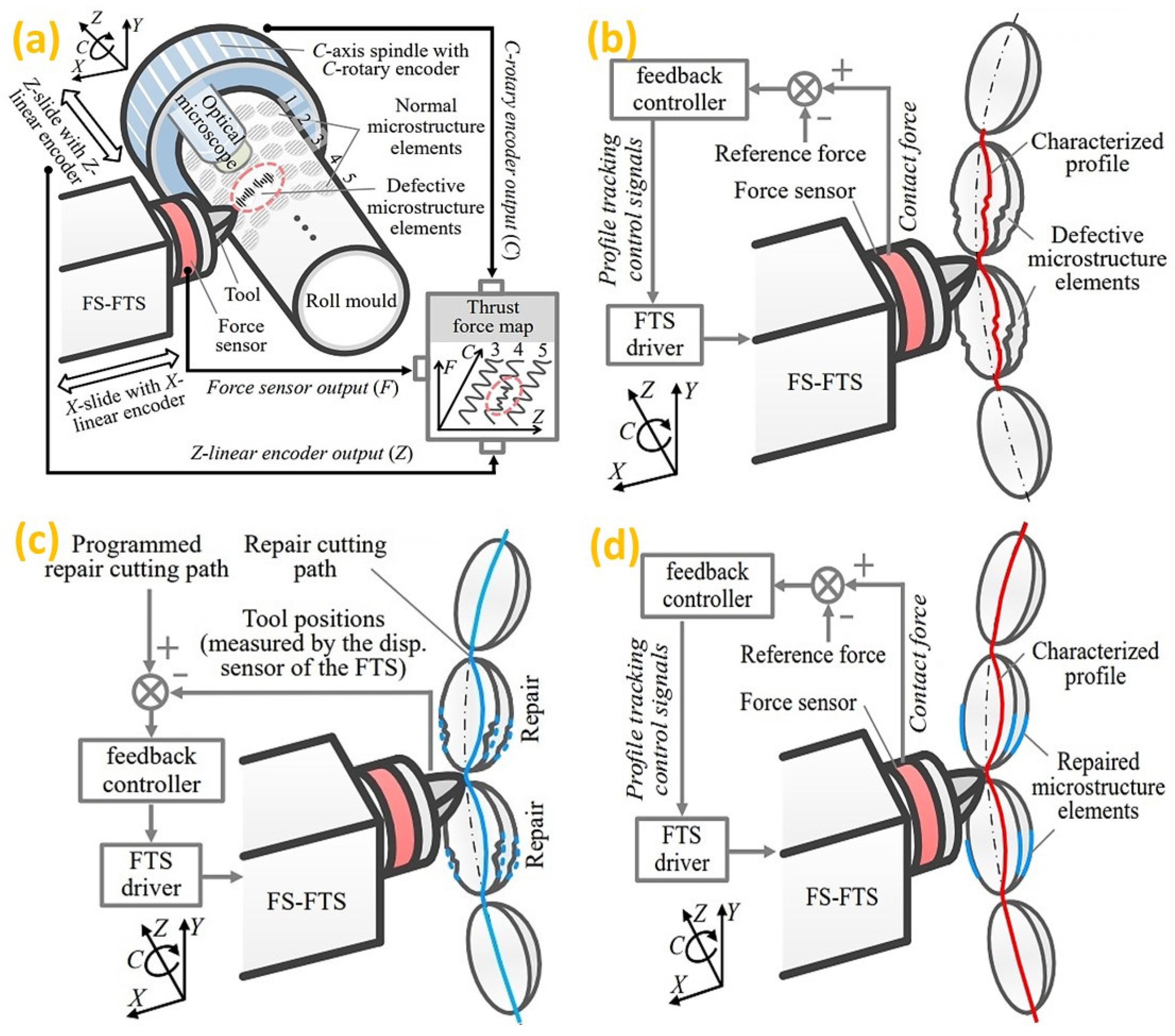

- Chen, M.; Wang, C.; An, Q.; Ming, W. Tool Path Strategy and Cutting Process Monitoring in Intelligent Machining. Front. Mech. Eng. 2018, 13, 232–242. [Google Scholar] [CrossRef]

- Zhang, J.; Starly, B.; Cai, Y.; Cohen, P.H.; Lee, Y.-S. Particle Learning in Online Tool Wear Diagnosis and Prognosis. J. Manuf. Process. 2017, 28, 457–463. [Google Scholar] [CrossRef]

- Wang, J.; Li, Y.; Zhao, R.; Gao, R.X. Physics Guided Neural Network for Machining Tool Wear Prediction. J. Manuf. Syst. 2020, 57, 298–310. [Google Scholar] [CrossRef]

- Li, Z.; Liu, R.; Wu, D. Data-Driven Smart Manufacturing: Tool Wear Monitoring with Audio Signals and Machine Learning. J. Manuf. Process. 2019, 48, 66–76. [Google Scholar] [CrossRef]

- Gomes, M.C.; Brito, L.C.; da Silva, M.; Viana Duarte, M.A. Tool Wear Monitoring in Micromilling Using Support Vector Machine with Vibration and Sound Sensors. Precis. Eng. 2021, 67, 137–151. [Google Scholar] [CrossRef]

- Li, Y.; Liu, X.; Gao, J.X.; Maropoulos, P.G. A Dynamic Feature Information Model for Integrated Manufacturing Planning and Optimization. CIRP Ann. 2012, 61, 167–170. [Google Scholar] [CrossRef]

- Liu, X.; Li, Y.; Gao, J. A Multi-Perspective Dynamic Feature Concept in Adaptive NC Machining of Complex Freeform Surfaces. Int. J. Adv. Manuf. Technol. 2016, 82, 1259–1268. [Google Scholar] [CrossRef]

- Li, Y.; Liu, C.; Gao, J.X.; Shen, W. An Integrated Feature-Based Dynamic Control System for on-Line Machining, Inspection and Monitoring. Integr. Comput. Aided Eng. 2015, 22, 187–200. [Google Scholar] [CrossRef]

- Zhao, X.; Zheng, L.; Wang, Y.; Zhang, Y. Services-Oriented Intelligent Milling for Thin-Walled Parts Based on Time-Varying Information Model of Machining System. Int. J. Mech. Sci. 2022, 219, 107125. [Google Scholar] [CrossRef]

- Cheung, C.F.; Kong, L.B.; Lee, W.B.; To, S. Modelling and Simulation of Freeform Surface Generation in Ultra-Precision Raster Milling. Proc. Inst. Mech. Eng. Part B J. Eng. Manuf. 2006, 220, 1787–1801. [Google Scholar] [CrossRef]

- Chen, Y.-L.; Wang, S.; Shimizu, Y.; Ito, S.; Gao, W.; Ju, B.-F. An In-Process Measurement Method for Repair of Defective Microstructures by Using a Fast Tool Servo with a Force Sensor. Precis. Eng. 2015, 39, 134–142. [Google Scholar] [CrossRef]

- Gao, W.; Haitjema, H.; Fang, F.Z.; Leach, R.K.; Cheung, C.F.; Savio, E.; Linares, J.M. On-Machine and in-Process Surface Metrology for Precision Manufacturing. CIRP Ann. 2019, 68, 843–866. [Google Scholar] [CrossRef]

- Noor, W.I.; Saleh, T.; Rashid, M.A.N.; Mohd Ibrahim, A.; Ali, M.S.M. Dual-Stage Artificial Neural Network (ANN) Model for Sequential LBMM-ΜEDM-Based Micro-Drilling. Int. J. Adv. Manuf. Technol. 2021, 117, 3343–3365. [Google Scholar] [CrossRef]

- Rahman, M.A.; Ahmed, A.; Mia, M. Trends in Electrical Discharge Machining of Ti- and Ni-Based Superalloys: Macro-Micro-Compound Arc/Spark/Melt Process. In Micro Electro-Fabrication; Elsevier: Amsterdam, The Netherlands, 2021; pp. 63–87. ISBN 978-0-12-820049-0. [Google Scholar] [CrossRef]

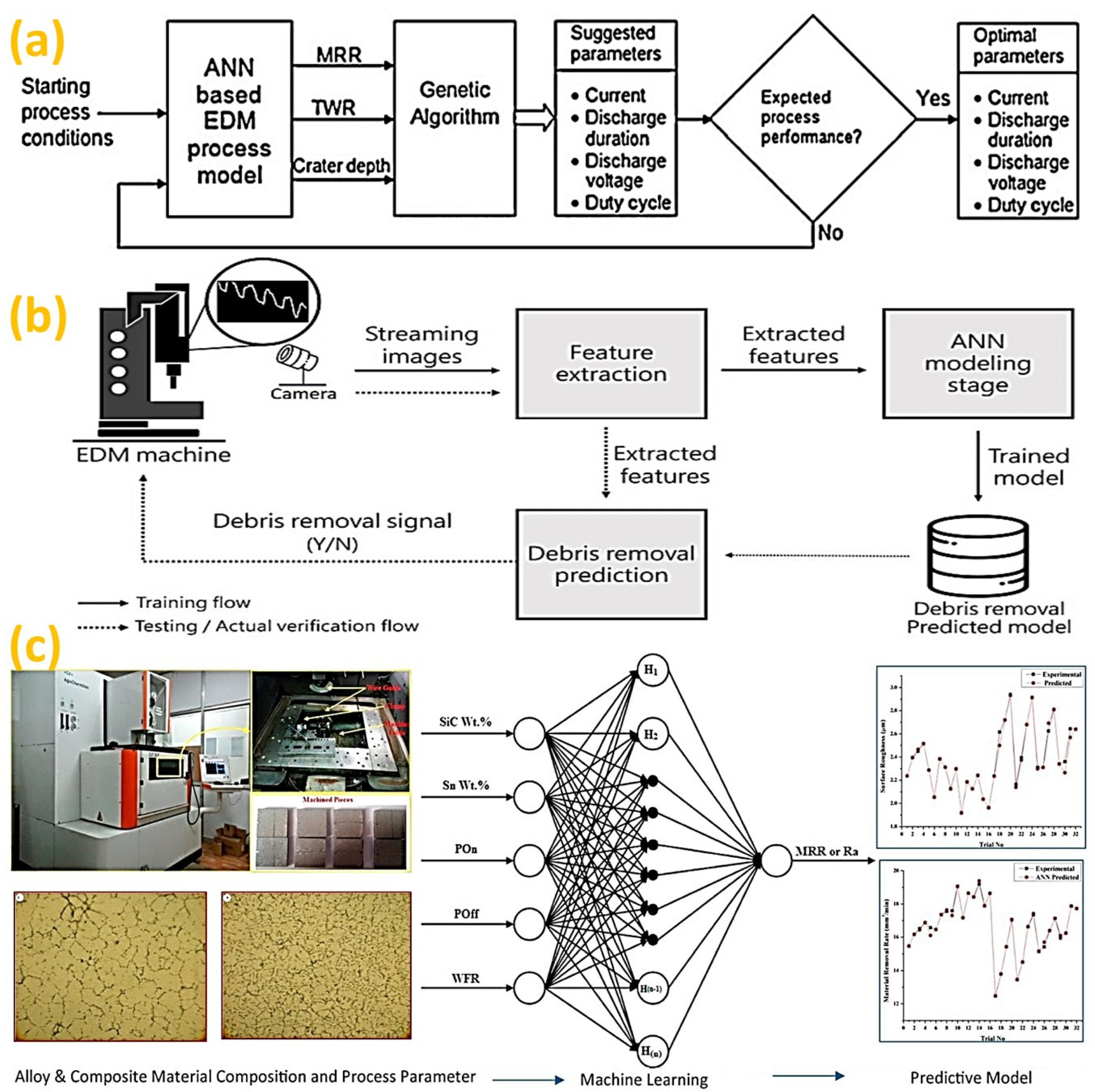

- Joshi, S.N.; Pande, S.S. Intelligent Process Modeling and Optimization of Die-Sinking Electric Discharge Machining. Appl. Soft Comput. 2011, 11, 2743–2755. [Google Scholar] [CrossRef]

- Kao, J.Y.; Tarng, Y.S. A Neutral-Network Approach for the on-Line Monitoring of the Electrical Discharge Machining Process. J. Mater. Process. Technol. 1997, 69, 112–119. [Google Scholar] [CrossRef]

- Ahmed, A.; Fardin, A.; Tanjilul, M.; Wong, Y.S.; Rahman, M.; Senthil Kumar, A. A Comparative Study on the Modelling of EDM and Hybrid Electrical Discharge and Arc Machining Considering Latent Heat and Temperature-Dependent Properties of Inconel 718. Int. J. Adv. Manuf. Technol. 2018, 94, 2729–2737. [Google Scholar] [CrossRef]

- Zhang, X.; Liu, Y.; Wu, X.; Niu, Z. Intelligent Pulse Analysis of High-Speed Electrical Discharge Machining Using Different RNNs. J. Intell. Manuf. 2020, 31, 937–951. [Google Scholar] [CrossRef]

- Lee, C.H.; Lai, T.S. An Intelligent System for Improving Electric Discharge Machining Efficiency Using Artificial Neural Network and Adaptive Control of Debris Removal Operations. IEEE Access 2021, 9, 75302–75312. [Google Scholar] [CrossRef]

- Jarin, S.; Saleh, T. Artificial Neural Network Modelling and Analysis of Carbon Nanopowder Mixed Micro Wire Electro Discharge Machining of Gold Coated Doped Silicon. Int. J. Mater. Eng. Innov. 2019, 10, 346. [Google Scholar] [CrossRef]

- Thankachan, T.; Soorya Prakash, K.; Malini, R.; Ramu, S.; Sundararaj, P.; Rajandran, S.; Rammasamy, D.; Jothi, S. Prediction of Surface Roughness and Material Removal Rate in Wire Electrical Discharge Machining on Aluminum Based Alloys/Composites Using Taguchi Coupled Grey Relational Analysis and Artificial Neural Networks. Appl. Surf. Sci. 2019, 472, 22–35. [Google Scholar] [CrossRef]

- Wuest, T.; Weimer, D.; Irgens, C.; Thoben, K.D. Machine Learning in Manufacturing: Advantages, Challenges, and Applications. Prod. Manuf. Res. 2016, 4, 23–45. [Google Scholar] [CrossRef]

- Patange, A.D.; Jegadeeshwaran, R. A Machine Learning Approach for Vibration-Based Multipoint Tool Insert Health Prediction on Vertical Machining Centre (VMC). Measurement 2021, 173, 108649. [Google Scholar] [CrossRef]

- Zacharia, K.; Krishnakumar, P. Chatter Prediction in High Speed Machining of Titanium Alloy (Ti-6Al-4V) Using Machine Learning Techniques. Mater. Today Proc. 2020, 24, 350–358. [Google Scholar] [CrossRef]

- Oleaga, I.; Pardo, C.; Zulaika, J.J.; Bustillo, A. A Machine-Learning Based Solution for Chatter Prediction in Heavy-Duty Milling Machines. Measurement 2018, 128, 34–44. [Google Scholar] [CrossRef]

- Unver, H.O.; Sener, B. Exploring the Potential of Transfer Learning for Chatter Detection. Procedia Comput. Sci. 2022, 200, 151–159. [Google Scholar] [CrossRef]

- Wang, Y.; Wang, Y.; Zheng, L.; Zhou, J. Online Surface Roughness Prediction for Assembly Interfaces of Vertical Tail Integrating Tool Wear under Variable Cutting Parameters. Sensors 2022, 22, 1991. [Google Scholar] [CrossRef]

- Standard Terminology for Additive Manufacturing—General Principles—Terminology. Available online: https://www.astm.org/f3177-15.html (accessed on 27 January 2023).

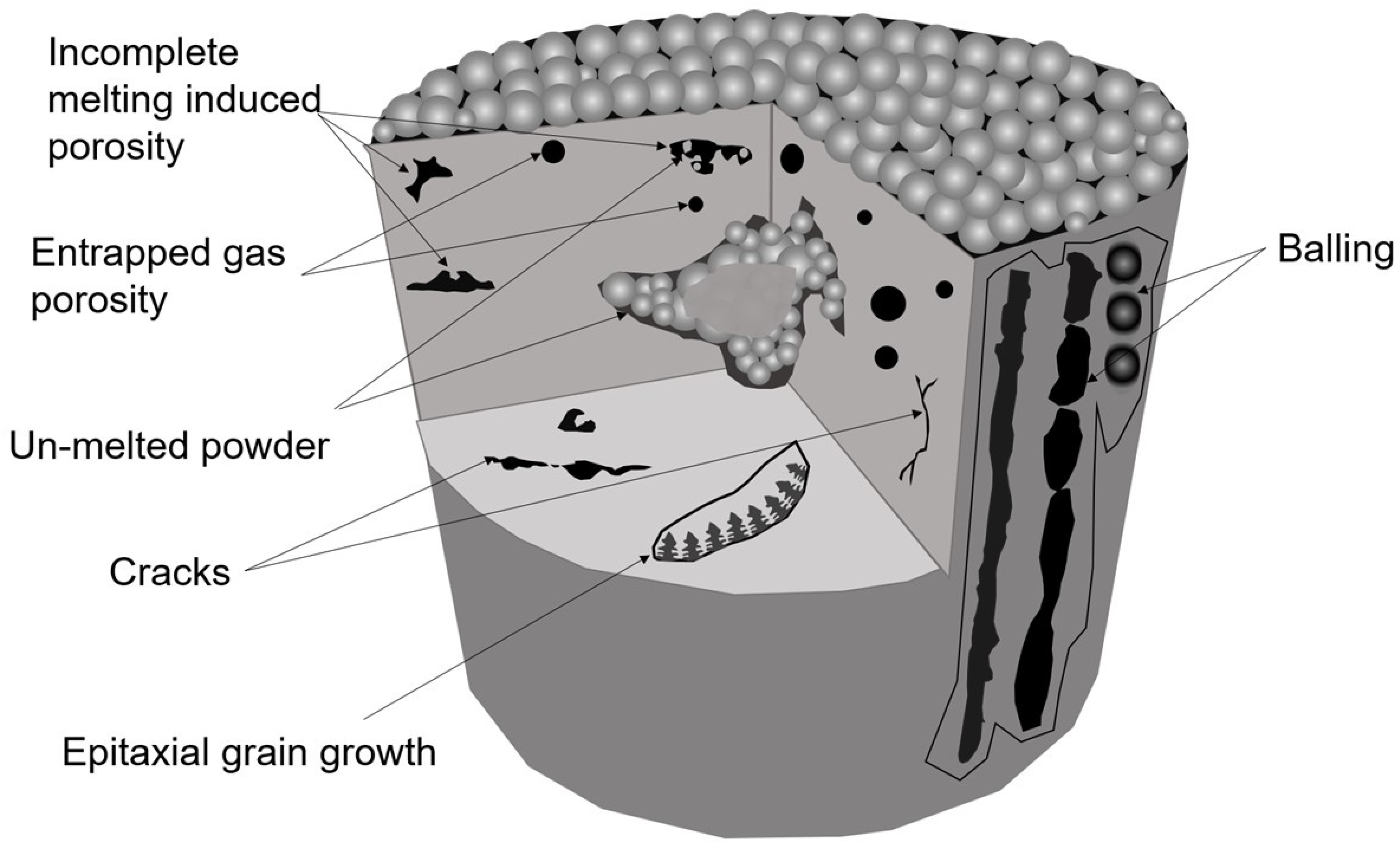

- Bidare, P.; Jiménez, A.; Hassanin, H.; Essa, K. Porosity, Cracks, and Mechanical Properties of Additively Manufactured Tooling Alloys: A Review. Adv. Manuf. 2022, 10, 175–204. [Google Scholar] [CrossRef]

- Cunningham, R.W. Defect Formation Mechanisms in Powder-Bed Metal Additive Manufacturing. Ph.D. Thesis, Carnegie Mellon University, Pittsburgh, PA, USA, 2018. [Google Scholar] [CrossRef]

- Svetlizky, D.; Das, M.; Zheng, B.; Vyatskikh, A.L.; Bose, S.; Bandyopadhyay, A.; Schoenung, J.M.; Lavernia, E.J.; Eliaz, N. Directed Energy Deposition (DED) Additive Manufacturing: Physical Characteristics, Defects, Challenges and Applications. Mater. Today 2021, 49, 271–295. [Google Scholar] [CrossRef]

- Bidare, P.; Bitharas, I.; Ward, R.M.; Attallah, M.M.; Moore, A.J. Laser Powder Bed Fusion in High-Pressure Atmospheres. Int. J. Adv. Manuf. Technol. 2018, 99, 543–555. [Google Scholar] [CrossRef]

- Ferrar, B.; Mullen, L.; Jones, E.; Stamp, R.; Sutcliffe, C.J. Gas Flow Effects on Selective Laser Melting (SLM) Manufacturing Performance. J. Mater. Process. Technol. 2012, 212, 355–364. [Google Scholar] [CrossRef]

- Talib Mohammed, M. Mechanical Properties of SLM-Titanium Materials for Biomedical Applications: A Review. Mater. Today Proc. 2018, 5, 17906–17913. [Google Scholar] [CrossRef]

- Bax, B.; Rajput, R.; Kellet, R.; Reisacher, M. Systematic Evaluation of Process Parameter Maps for Laser Cladding and Directed Energy Deposition. Addit. Manuf. 2018, 21, 487–494. [Google Scholar] [CrossRef]

- Ng, G.K.L.; Jarfors, A.E.W.; Bi, G.; Zheng, H.Y. Porosity Formation and Gas Bubble Retention in Laser Metal Deposition. Appl. Phys. A 2009, 97, 641–649. [Google Scholar] [CrossRef]

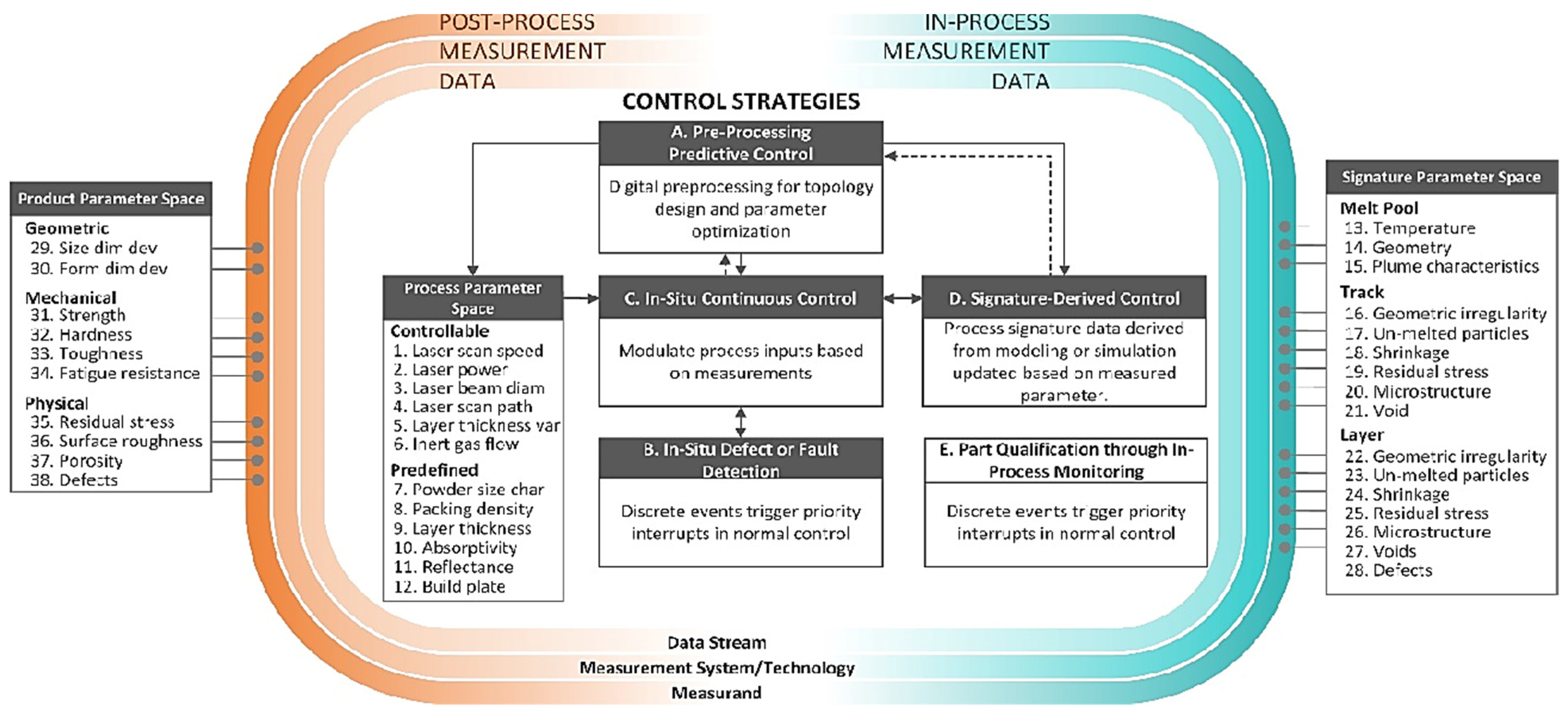

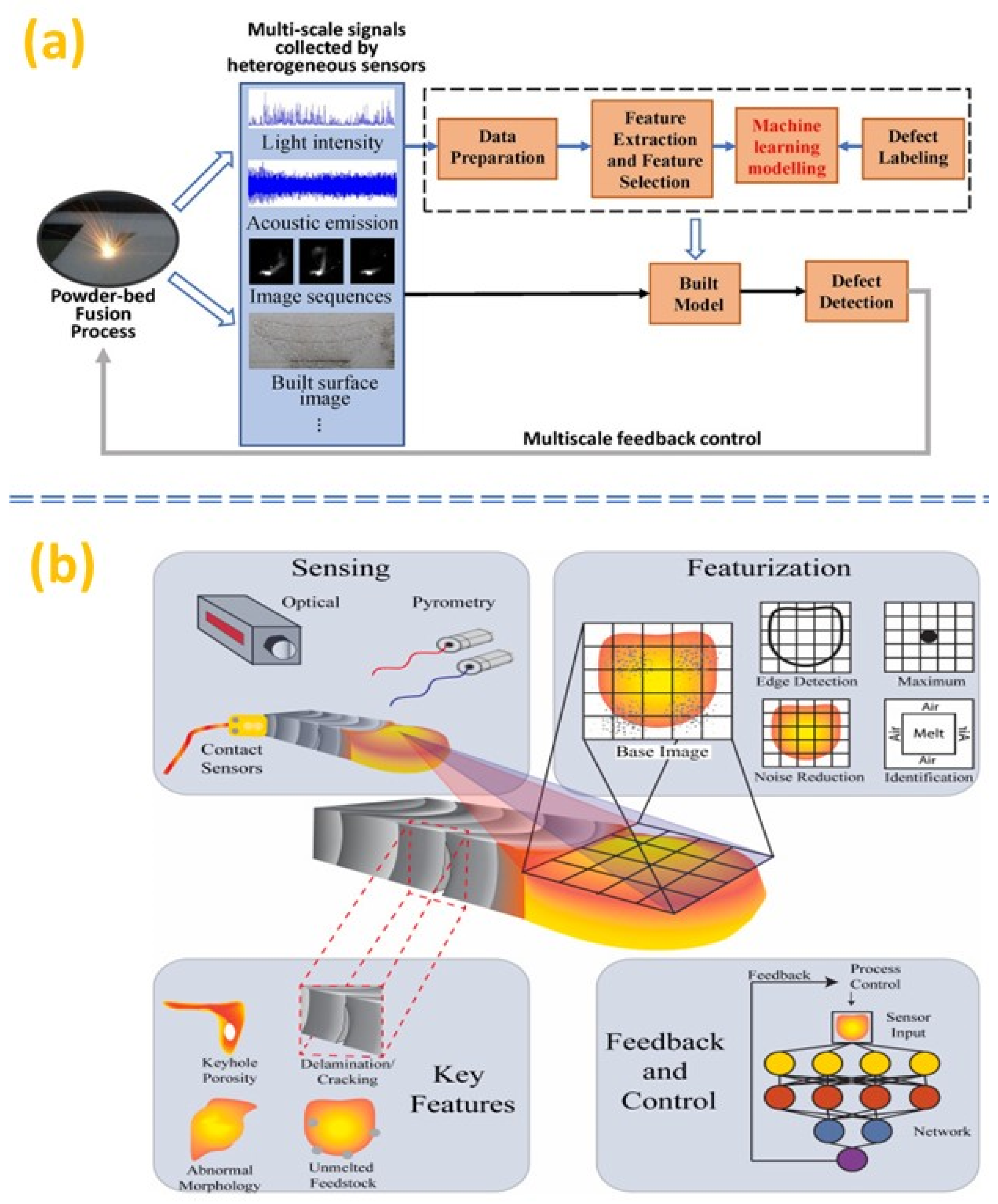

- McCann, R.; Obeidi, M.A.; Hughes, C.; McCarthy, É.; Egan, D.S.; Vijayaraghavan, R.K.; Joshi, A.M.; Acinas Garzon, V.; Dowling, D.P.; McNally, P.J.; et al. In-Situ Sensing, Process Monitoring and Machine Control in Laser Powder Bed Fusion: A Review. Addit. Manuf. 2021, 45, 102058. [Google Scholar] [CrossRef]

- Rieder, H.; Spies, M.; Bamberg, J.; Henkel, B. On- and Offline Ultrasonic Characterization of Components Built by SLM Additive Manufacturing. In AIP Conference Proceedings; AIP Publishing LLC: Melville, NY, USA, 2016; p. 130002. [Google Scholar] [CrossRef]

- Rieder, H.; Dillhöfer, A.; Spies, M.; Bamberg, J.; Hess, T. Ultrasonic Online Monitoring of Additive Manufacturing Processes Based on Selective Laser Melting. In AIP Conference Proceedings; American Institute of Physics: College Park, MD, USA, 2015; pp. 184–191. [Google Scholar] [CrossRef]

- Honarvar, F.; Varvani-Farahani, A. A Review of Ultrasonic Testing Applications in Additive Manufacturing: Defect Evaluation, Material Characterization, and Process Control. Ultrasonics 2020, 108, 106227. [Google Scholar] [CrossRef]

- Wasmer, K.; Le-Quang, T.; Meylan, B.; Shevchik, S.A. In Situ Quality Monitoring in AM Using Acoustic Emission: A Reinforcement Learning Approach. J. Mater. Eng. Perform. 2019, 28, 666–672. [Google Scholar] [CrossRef]

- Ye, D.; Hong, G.S.; Zhang, Y.; Zhu, K.; Fuh, J.Y.H. Defect Detection in Selective Laser Melting Technology by Acoustic Signals with Deep Belief Networks. Int. J. Adv. Manuf. Technol. 2018, 96, 2791–2801. [Google Scholar] [CrossRef]

- Shevchik, S.A.; Kenel, C.; Leinenbach, C.; Wasmer, K. Acoustic Emission for in Situ Quality Monitoring in Additive Manufacturing Using Spectral Convolutional Neural Networks. Addit. Manuf. 2018, 21, 598–604. [Google Scholar] [CrossRef]

- Smith, R.J.; Hirsch, M.; Patel, R.; Li, W.; Clare, A.T.; Sharples, S.D. Spatially Resolved Acoustic Spectroscopy for Selective Laser Melting. J. Mater. Process. Technol. 2016, 236, 93–102. [Google Scholar] [CrossRef]

- Yadroitsev, I.; Krakhmalev, P.; Yadroitsava, I. Selective Laser Melting of Ti6Al4V Alloy for Biomedical Applications: Temperature Monitoring and Microstructural Evolution. J. Alloy. Compd. 2014, 583, 404–409. [Google Scholar] [CrossRef]

- Craeghs, T.; Clijsters, S.; Yasa, E.; Kruth, J.-P. Online Quality Control of Selective Laser Melting. In 2011 International Solid Freeform Fabrication Symposium; University of Texas at Austin: Austin, TX, USA, 2011. [Google Scholar] [CrossRef]

- Nassar, A.R.; Spurgeon, T.J.; Reutzel, E.W. Sensing Defects during Directed-Energy Additive Manufacturing of Metal Parts Using Optical Emissions Spectroscopy. In 2014 International Solid Freeform Fabrication Symposium; University of Texas at Austin: Austin, TX, USA, 2014. [Google Scholar] [CrossRef]

- Dunbar, A.J.; Nassar, A.R.; Reutzel, E.W.; Blecher, J.J. A real-time communication architecture for metal powder bed fusion additive manufacturing. In 2016 International Solid Freeform Fabrication Symposium; University of Texas at Austin: Austin, TX, USA, 2015. [Google Scholar]

- Mohr, G.; Altenburg, S.J.; Ulbricht, A.; Heinrich, P.; Baum, D.; Maierhofer, C.; Hilgenberg, K. In-Situ Defect Detection in Laser Powder Bed Fusion by Using Thermography and Optical Tomography—Comparison to Computed Tomography. Metals 2020, 10, 103. [Google Scholar] [CrossRef]

- Zenzinger, G.; Bamberg, J.; Ladewig, A.; Hess, T.; Henkel, B.; Satzger, W. Process Monitoring of Additive Manufacturing by Using Optical Tomography. In AIP Conference Proceedings; American Institute of Physics: College Park, MD, USA, 2015; pp. 164–170. [Google Scholar] [CrossRef]

- du Plessis, A.; Yadroitsev, I.; Yadroitsava, I.; le Roux, S.G. X-ray Microcomputed Tomography in Additive Manufacturing: A Review of the Current Technology and Applications. 3D Print Addit. Manuf. 2018, 5, 227–247. [Google Scholar] [CrossRef]

- du Plessis, A.; Yadroitsava, I.; Yadroitsev, I. Effects of Defects on Mechanical Properties in Metal Additive Manufacturing: A Review Focusing on X-ray Tomography Insights. Mater. Des. 2020, 187, 108385. [Google Scholar] [CrossRef]

- Kanko, J.A.; Sibley, A.P.; Fraser, J.M. In Situ Morphology-Based Defect Detection of Selective Laser Melting through Inline Coherent Imaging. J. Mater. Process. Technol. 2016, 231, 488–500. [Google Scholar] [CrossRef]

- Mahato, V.; Obeidi, M.A.; Brabazon, D.; Cunningham, P. An Evaluation of Classification Methods for 3D Printing Time-Series Data. IFAC-PapersOnLine 2020, 53, 8211–8216. [Google Scholar] [CrossRef]

- Berumen, S.; Bechmann, F.; Lindner, S.; Kruth, J.-P.; Craeghs, T. Quality Control of Laser and Powder Bed-Based Additive Manufacturing (AM) Technologies. Phys. Procedia 2010, 5, 617–622. [Google Scholar] [CrossRef]

- Zhao, C.; Fezzaa, K.; Cunningham, R.W.; Wen, H.; de Carlo, F.; Chen, L.; Rollett, A.D.; Sun, T. Real-Time Monitoring of Laser Powder Bed Fusion Process Using High-Speed X-ray Imaging and Diffraction. Sci. Rep. 2017, 7, 3602. [Google Scholar] [CrossRef]

- Mani, M.; Feng, S.; Brandon, L.; Donmez, A.; Moylan, S.; Fesperman, R. Measurement science needs for real-time control of additive manufacturing powder-bed fusion processes. In Additive Manufacturing Handbook; CRC Press: Boca Raton, FL, USA, 2015; pp. 629–652. [Google Scholar] [CrossRef]

- Vlasea, M.L.; Lane, B.; Lopez, F.; Mekhontsev, S.; Donmez, A. Development of powder bed fusion additive manufacturing test bed for enhanced real-time process control. In 2015 International Solid Freeform Fabrication Symposium; University of Texas at Austin: Austin, TX, USA, 2015. [Google Scholar]

- Kruth, J.-P.; Mercelis, P.; Van Vaerenbergh, J.; Craeghs, T. Feedback Control of Selective Laser Melting, 1st ed.; CRC Press: Boca Raton, FL, USA, 2007; Volume 1, pp. 521–528. ISBN 978-0-429-22420-1. [Google Scholar] [CrossRef]

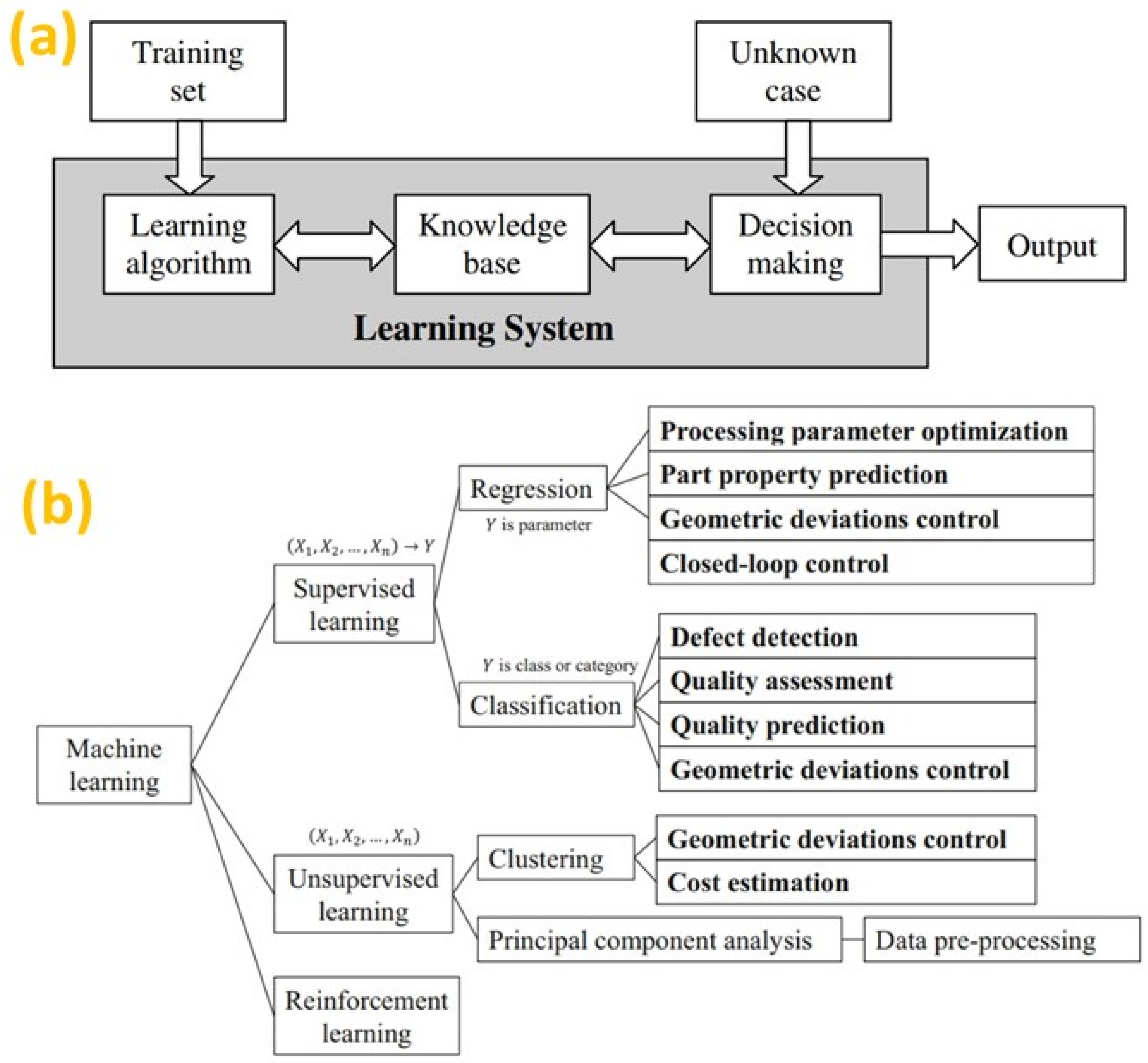

- Razvi, S.S.; Feng, S.; Narayanan, A.; Lee, Y.-T.T.; Witherell, P. A Review of Machine Learning Applications in Additive Manufacturing; American Society of Mechanical Engineers Digital Collection: Anaheim, CA, USA, 2019. [Google Scholar] [CrossRef]

- Du, C.-J.; Sun, D.-W. Learning Techniques Used in Computer Vision for Food Quality Evaluation: A Review. J. Food Eng. 2006, 72, 39–55. [Google Scholar] [CrossRef]

- Meng, L.; McWilliams, B.; Jarosinski, W.; Park, H.-Y.; Jung, Y.-G.; Lee, J.; Zhang, J. Machine Learning in Additive Manufacturing: A Review. JOM 2020, 72, 2363–2377. [Google Scholar] [CrossRef]

- Yao, X.; Moon, S.K.; Bi, G. A Hybrid Machine Learning Approach for Additive Manufacturing Design Feature Recommendation. Rapid Prototyp. J. 2017, 23, 983–997. [Google Scholar] [CrossRef]

- Chen, D.; Wang, P.; Pan, R.; Zha, C.; Fan, J.; Kong, S.; Li, N.; Li, J.; Zeng, Z. Research on in Situ Monitoring of Selective Laser Melting: A State of the Art Review. Int. J. Adv. Manuf. Technol. 2021, 113, 3121–3138. [Google Scholar] [CrossRef]

- Zhang, Y.; Yan, W. Applications of Machine Learning in Metal Powder-Bed Fusion in-Process Monitoring and Control: Status and Challenges. J. Intell. Manuf. 2022. [CrossRef]

- Johnson, N.S.; Vulimiri, P.S.; To, A.C.; Zhang, X.; Brice, C.A.; Kappes, B.B.; Stebner, A.P. Invited Review: Machine Learning for Materials Developments in Metals Additive Manufacturing. Addit. Manuf. 2020, 36, 101641. [Google Scholar] [CrossRef]

- Zhang, B.; Liu, S.; Shin, Y.C. In-Process Monitoring of Porosity during Laser Additive Manufacturing Process. Addit. Manuf. 2019, 28, 497–505. [Google Scholar] [CrossRef]

- de la Yedra, A.; Pfleger, M.; Aramendi, B.; Cabeza, M.; Zubiri, F.; Mitter, T.; Reitinger, B.; Scherleitner, E. Online Cracking Detection by Means of Optical Techniques in Laser-Cladding Process. Struct. Control Health Monit. 2019, 26, e2291. [Google Scholar] [CrossRef]

- Scime, L.; Beuth, J. Using Machine Learning to Identify In-Situ Melt Pool Signatures Indicative of Flaw Formation in a Laser Powder Bed Fusion Additive Manufacturing Process. Addit. Manuf. 2019, 25, 151–165. [Google Scholar] [CrossRef]

- de Oliveira, D.; Gomes, M.C.; dos Santos, A.G.; Ribeiro, K.S.B.; Vasques, I.J.; Coelho, R.T.; da Silva, M.B.; Hung, N.W. Abrasive and Non-Conventional Post-Processing Techniques to Improve Surface Finish of Additively Manufactured Metals: A Review. Prog. Addit. Manuf. 2022, 1–8. [Google Scholar] [CrossRef]

- Sibanda, P.S.; Carr, P.; Ryan, M.; Bigot, S. State of the Art in Surface Finish of Metal Additive Manufactured Parts. Adv. Transdiscipl. Eng. 2019, 9, 221–225. [Google Scholar] [CrossRef]

- Petri, K.L.; Billo, R.E.; Bidanda, B. A Neural Network Process Model for Abrasive Flow Machining Operations. J. Manuf. Syst. 1998, 17, 52–64. [Google Scholar] [CrossRef]

- Markopoulos, A.; Vaxevanidis, N.M.; Petropoulos, G.; Manolakos, D.E. Artificial Neural Networks Modeling of Surface Finish in Electro-Discharge Machining of Tool Steels. In Proceedings of the Volume 4: Fatigue and Fracture, Heat Transfer, Internal Combustion Engines, Manufacturing, and Technology and Society; ASMEDC: Torino, Italy, 2006; pp. 847–854. [Google Scholar] [CrossRef]

- Oh, J.H.; Lee, S.H. Prediction of Surface Roughness in Magnetic Abrasive Finishing Using Acoustic Emission and Force Sensor Data Fusion. Proc. Inst. Mech. Eng. Part B J. Eng. Manuf. 2011, 225, 853–865. [Google Scholar] [CrossRef]

- Kanish, T.C.; Kuppan, P.; Narayanan, S.; Ashok, S.D. A Fuzzy Logic Based Model to Predict the Improvement in Surface Roughness in Magnetic Field Assisted Abrasive Finishing. Procedia Eng. 2014, 97, 1948–1956. [Google Scholar] [CrossRef]

- Pandiyan, V.; Tjahjowidodo, T.; Samy, M.P. In-Process Surface Roughness Estimation Model for Compliant Abrasive Belt Machining Process. Procedia CIRP 2016, 46, 254–257. [Google Scholar] [CrossRef]

- Khalick Mohammad, A.; Hong, J.; Wang, D. Polishing of Uneven Surfaces Using Industrial Robots Based on Neural Network and Genetic Algorithm. Int. J. Adv. Manuf. Technol. 2017, 93, 1463–1471. [Google Scholar] [CrossRef]

- Wang, R.; Cheng, M.N.; Loh, Y.M.; Wang, C.; Fai Cheung, C. Ensemble Learning with a Genetic Algorithm for Surface Roughness Prediction in Multi-Jet Polishing. Expert Syst. Appl. 2022, 207, 118024. [Google Scholar] [CrossRef]

- Fountas, N.A.; Vaxevanidis, N.M. Optimization of Abrasive Flow Nano-Finishing Processes by Adopting Artificial Viral Intelligence. J. Manuf. Mater. Process. 2021, 5, 22. [Google Scholar] [CrossRef]

- Caggiano, A.; Teti, R.; Alfieri, V.; Caiazzo, F. Automated Laser Polishing for Surface Finish Enhancement of Additive Manufactured Components for the Automotive Industry. Prod. Eng. Res. Devel. 2021, 15, 109–117. [Google Scholar] [CrossRef]

- Speidel, A.; Sélo, R.; Bisterov, I.; Mitchell-Smith, J.; Clare, A.T. Post Processing of Additively Manufactured Parts Using Electrochemical Jet Machining. Mater. Lett. 2021, 292, 129671. [Google Scholar] [CrossRef]

- Sealy, M.P.; Madireddy, G.; Williams, R.E.; Rao, P.; Toursangsaraki, M. Hybrid Processes in Additive Manufacturing. J. Manuf. Sci. Eng. 2018, 140, 60801. [Google Scholar] [CrossRef]

- Motallebi, R.; Savaedi, Z.; Mirzadeh, H. Post-Processing Heat Treatment of Lightweight Magnesium Alloys Fabricated by Additive Manufacturing: A Review. J. Mater. Res. Technol. 2022, 20, 1873–1892. [Google Scholar] [CrossRef]

- Merklein, M.; Junker, D.; Schaub, A.; Neubauer, F. Hybrid Additive Manufacturing Technologies—An Analysis Regarding Potentials and Applications. Phys. Procedia 2016, 83, 549–559. [Google Scholar] [CrossRef]

- Flynn, J.M.; Shokrani, A.; Newman, S.T.; Dhokia, V. Hybrid Additive and Subtractive Machine Tools—Research and Industrial Developments. Int. J. Mach. Tools Manuf. 2016, 101, 79–101. [Google Scholar] [CrossRef]

- LENS 860 Machine Tool Systems—Optomec. Available online: https://optomec.com/3d-printed-metals/lens-printers/additive-and-hybrid-manufacturing-860-printer/ (accessed on 27 January 2023).

- LASERTEC 65 DED Hybrid—ADDITIVE MANUFACTURING Machines by DMG MORI. Available online: https://en.dmgmori.com/products/machines/additive-manufacturing/powder-nozzle/lasertec-65-ded-hybrid (accessed on 27 January 2023).

- AM—Additive Manufacturing. Available online: https://english.mazak.jp/machines/technology/hybrid-multi-tasking-machine/am/#am-l (accessed on 27 January 2023).

- K.G.& Co.K. Maschinenfabrik Berthold Hermle AG—Hermle MPA Technology—Additive Manufacturing, Milling at Its Best. 2023. Available online: https://www.hermle.de/en/services/additive_manufacturing (accessed on 27 January 2023).

- Hybrid Additive Manufacturing Archives | Fabrisonic. Available online: https://fabrisonic.com/tag/hybrid-additive-manufacturing// (accessed on 27 January 2023).

- Hybrid Wire Arc Additive Manufacturing (H-WAAM) | Additive Manufacturing | 3D Metalforge | 3D Metalforge Pte Ltd.—News. Available online: https://3dmetalforge.com/news/?limit=20&limitstart=20 (accessed on 27 January 2023).

- Products | Hybrid Manufacturing Technologies. Available online: https://hybridmanutech.com/products/ (accessed on 27 January 2023).

- 3D HYBRID: AM FOR CNC—Home. Available online: https://www.3dhybridsolutions.com/ (accessed on 27 January 2023).

- Ren, L.; Padathu, A.P.; Ruan, J.; Sparks, T.; Liou, F. Three Dimensional Die Repair Using a Hybrid Manufacturing System. In Proceedings of the 17th Annual Solid Freeform Fabrication Symposium, Austin, TX, USA, 16 August 2006; pp. 51–59. [Google Scholar]

- Jones, J.; McNutt, P.; Tosi, R.; Perry, C.; Wimpenny, D. Remanufacture of Turbine Blades by Laser Cladding, Machining and In-Process Scanning in a Single Machine; University of Texas at Austin: Austin, TX, USA, 2012. [Google Scholar]

- Stavropoulos, P.; Bikas, H.; Avram, O.; Valente, A.; Chryssolouris, G. Hybrid Subtractive–Additive Manufacturing Processes for High Value-Added Metal Components. Int. J. Adv. Manuf. Technol. 2020, 111, 645–655. [Google Scholar] [CrossRef]

- Le, V.T.; Paris, H.; Mandil, G. The Development of a Strategy for Direct Part Reuse Using Additive and Subtractive Manufacturing Technologies. Addit. Manuf. 2018, 22, 687–699. [Google Scholar] [CrossRef]

- Feldhausen, T.; Heinrich, L.; Saleeby, K.; Burl, A.; Post, B.; MacDonald, E.; Saldana, C.; Love, L. Review of Computer-Aided Manufacturing (CAM) Strategies for Hybrid Directed Energy Deposition. Addit. Manuf. 2022, 56, 102900. [Google Scholar] [CrossRef]

- Feldhausen, T.; Saleeby, K.; Kurfess, T. Spinning the Digital Thread with Hybrid Manufacturing. Manuf. Lett. 2021, 29, 15–18. [Google Scholar] [CrossRef]

- Lynn, R.; Louhichi, W.; Parto, M.; Wescoat, E.; Kurfess, T. Rapidly Deployable MTConnect-Based Machine Tool Monitoring Systems. In Proceedings of the Volume 3: Manufacturing Equipment and Systems; American Society of Mechanical Engineers: Los Angeles, CA, USA, 2017; p. V003T04A046. [Google Scholar] [CrossRef]

- Akin, S.; Lee, S.; Jo, S.; Ruzgar, D.G.; Subramaniam, K.; Tsai, J.-T.; Jun, M.B.-G. Cold Spray-Based Rapid and Scalable Production of Printed Flexible Electronics. Addit. Manuf. 2022, 60, 103244. [Google Scholar] [CrossRef]

- Prashar, G.; Vasudev, H. A Comprehensive Review on Sustainable Cold Spray Additive Manufacturing: State of the Art, Challenges and Future Challenges. J. Clean Prod. 2021, 310, 127606. [Google Scholar] [CrossRef]

- Yu, T.; Chen, M.; Wu, Z. Experimental and Numerical Study of Deposition Mechanisms for Cold Spray Additive Manufacturing Process. Chin. J. Aeronaut. 2022, 35, 276–290. [Google Scholar] [CrossRef]

- Cold Spray Additive Manufacturing | Call Us Today 514 865-5763. Available online: https://polycontrols.com/polycsam/ (accessed on 19 December 2022).

- Stavropoulos, P.; Foteinopoulos, P.; Stavridis, J.; Bikas, H. Increasing the Industrial Uptake of Additive Manufacturing Processes: A Training Framework. Adv. Ind. Manuf. Eng. 2023, 6, 100110. [Google Scholar] [CrossRef]

- Ahuett-Garza, H.; Kurfess, T. A Brief Discussion on the Trends of Habilitating Technologies for Industry 4.0 and Smart Manufacturing. Manuf. Lett. 2018, 15, 60–63. [Google Scholar] [CrossRef]

- Blakey-Milner, B.; Gradl, P.; Snedden, G.; Brooks, M.; Pitot, J.; Lopez, E.; Leary, M.; Berto, F.; du Plessis, A. Metal Additive Manufacturing in Aerospace: A Review. Mater. Des. 2021, 209, 110008. [Google Scholar] [CrossRef]

- Debnath, B.; Shakur, M.S.; Tanjum, F.; Rahman, M.A.; Adnan, Z.H. Impact of Additive Manufacturing on the Supply Chain of Aerospace Spare Parts Industry—A Review. Logistics 2022, 6, 28. [Google Scholar] [CrossRef]

- Schweiger, J.; Bomze, D.; Schwentenwein, M. 3D Printing of Zirconia–What Is the Future? Curr. Oral Health Rep. 2019, 6, 339–343. [Google Scholar] [CrossRef]

- Eyers, D.; Dotchev, K. Technology Review for Mass Customisation Using Rapid Manufacturing. Assem. Autom. 2010, 30, 39–46. [Google Scholar] [CrossRef]

- Gardner, L.; Kyvelou, P.; Herbert, G.; Buchanan, C. Testing and Initial Verification of the World’s First Metal 3D Printed Bridge. J. Constr. Steel Res. 2020, 172, 106233. [Google Scholar] [CrossRef]

- Selema, A.; Ibrahim, M.N.; Sergeant, P. Electrical Machines Winding Technology: Latest Advancements for Transportation Electrification. Machines 2022, 10, 563. [Google Scholar] [CrossRef]

- Jankovics, D.; Barari, A. Customization of Automotive Structural Components Using Additive Manufacturing and Topology Optimization. IFAC-PapersOnLine 2019, 52, 212–217. [Google Scholar] [CrossRef]

- Jeng, J.Y.; Lin, M.C. Mold Fabrication and Modification Using Hybrid Processes of Selective Laser Cladding and Milling. J. Mater. Process. Technol. 2001, 110, 98–103. [Google Scholar] [CrossRef]

- Binder, M.; Illgner, M.; Anstaett, C.; Kindermann, P.; Kirchbichler, L.; Seidel, C. Automated Manufacturing of Sensor-Monitored Parts. Laser Tech. J. 2018, 15, 36–39. [Google Scholar] [CrossRef]

- Korkmaz, M.E.; Waqar, S.; Garcia-Collado, A.; Gupta, M.K.; Krolczyk, G.M. A Technical Overview of Metallic Parts in Hybrid Additive Manufacturing Industry. J. Mater. Res. Technol. 2022, 18, 384–395. [Google Scholar] [CrossRef]

- Yasir, M.; Danish, M.; Mia, M.; Gupta, M.K.; Sarikaya, M. Investigation into the Surface Quality and Stress Corrosion Cracking Resistance of AISI 316L Stainless Steel via Precision End-Milling Operation. Int. J. Adv. Manuf. Technol. 2021, 112, 1065–1076. [Google Scholar] [CrossRef]

- Prathipati, R.; Dora, S.P.; Chanamala, R. Wear Behavior of Wire Electric Discharge Machined Surface of 316L Stainless Steel. SN Appl. Sci. 2020, 2, 412. [Google Scholar] [CrossRef]

- Larimian, T.; AlMangour, B.; Grzesiak, D.; Walunj, G.; Borkar, T. Effect of Laser Spot Size, Scanning Strategy, Scanning Speed, and Laser Power on Microstructure and Mechanical Behavior of 316L Stainless Steel Fabricated via Selective Laser Melting. J. Mater. Eng. Perform. 2021, 31, 2205–2224. [Google Scholar] [CrossRef]

- Marya, M.; Singh, V.; Marya, S.; Hascoet, J.Y. Microstructural Development and Technical Challenges in Laser Additive Manufacturing: Case Study with a 316L Industrial Part. Metall. Mater. Trans. B Process Metall. Mater. Process. Sci. 2015, 46, 1654–1665. [Google Scholar] [CrossRef]

- Wang, L.; Xue, J.; Wang, Q. Correlation between Arc Mode, Microstructure, and Mechanical Properties during Wire Arc Additive Manufacturing of 316L Stainless Steel. Mater. Sci. Eng. A 2019, 751, 183–190. [Google Scholar] [CrossRef]

- Rännar, L.E.; Koptyug, A.; Olsén, J.; Saeidi, K.; Shen, Z. Hierarchical Structures of Stainless Steel 316L Manufactured by Electron Beam Melting. Addit. Manuf. 2017, 17, 106–112. [Google Scholar] [CrossRef]

- Pacheco, J.T.; Meura, V.H.; Bloemer, P.R.A.; Veiga, M.T.; de Moura Filho, O.C.; Cunha, A.; Teixeira, M.F. Laser Directed Energy Deposition of AISI 316L Stainless Steel: The Effect of Build Direction on Mechanical Properties in as-Built and Heat-Treated Conditions. Adv. Ind. Manuf. Eng. 2022, 4, 100079. [Google Scholar] [CrossRef]

- Sadaf, M.; Bragaglia, M.; Nanni, F. A Simple Route for Additive Manufacturing of 316L Stainless Steel via Fused Filament Fabrication. J. Manuf. Process. 2021, 67, 141–150. [Google Scholar] [CrossRef]

- Yang, Y.; Gong, Y.; Qu, S.; Xin, B.; Xu, Y.; Qi, Y. Additive/Subtractive Hybrid Manufacturing of 316L Stainless Steel Powder: Densification, Microhardness and Residual Stress. J. Mech. Sci. Technol. 2019, 33, 5797–5807. [Google Scholar] [CrossRef]

- Kaynak, Y.; Kitay, O. Porosity, Surface Quality, Microhardness and Microstructure of Selective Laser Melted 316L Stainless Steel Resulting from Finish Machining. J. Manuf. Mater. Process. 2018, 2, 36. [Google Scholar] [CrossRef]

- Lynn, R.; Helu, M.; Sati, M.; Tucker, T.; Kurfess, T. The State of Integrated Computer-Aided Manufacturing/Computer Numerical Control: Prior Development and the Path Toward a Smarter Computer Numerical Controller. Smart Sustain. Manuf. Syst. 2020, 4, 20190046. [Google Scholar] [CrossRef]

- Xu, X.W.; Newman, S.T. Making CNC Machine Tools More Open, Interoperable and Intelligent—A Review of the Technologies. Comput. Ind. 2006, 57, 141–152. [Google Scholar] [CrossRef]

- Latif, K.; Adam, A.; Yusof, Y.; Kadir, A.Z.A. A Review of G Code, STEP, STEP-NC, and Open Architecture Control Technologies Based Embedded CNC Systems. Int. J. Adv. Manuf. Technol. 2021, 114, 2549–2566. [Google Scholar] [CrossRef]

- Wang, R.; Gu, C.; He, S.; Shi, Z.; Meng, W. An Interoperable and Flat Industrial Internet of Things Architecture for Low Latency Data Collection in Manufacturing Systems. J. Syst. Archit. 2022, 129, 102631. [Google Scholar] [CrossRef]

- Möhring, H.-C.; Wiederkehr, P.; Erkorkmaz, K.; Kakinuma, Y. Self-Optimizing Machining Systems. CIRP Ann. 2020, 69, 740–763. [Google Scholar] [CrossRef]

- Everton, S.K.; Hirsch, M.; Stravroulakis, P.; Leach, R.K.; Clare, A.T. Review of In-Situ Process Monitoring and in-Situ Metrology for Metal Additive Manufacturing. Mater. Des. 2016, 95, 431–445. [Google Scholar] [CrossRef]

- Usha, S. In Situ Monitoring of Metal Additive Manufacturing Process: A Review. In Additive Manufacturing; Elsevier: Amsterdam, The Netherlands, 2021; pp. 275–299. ISBN 978-0-12-822056-6. [Google Scholar] [CrossRef]

- Goh, G.D.; Sing, S.L.; Yeong, W.Y. A Review on Machine Learning in 3D Printing: Applications, Potential, and Challenges. Artif. Intell. Rev. 2021, 54, 63–94. [Google Scholar] [CrossRef]

- AbouelNour, Y.; Gupta, N. In-Situ Monitoring of Sub-Surface and Internal Defects in Additive Manufacturing: A Review. Mater. Des. 2022, 222, 111063. [Google Scholar] [CrossRef]

- De Baere, D.; Strantza, M.; Hinderdael, M.; Devesse, W.; Guillaume, P. Effective Structural Health Monitoring with Additive Manufacturing. In Proceedings of the EWSHM-7th European Workshop on Structural Health Monitoring, Nantes, France, 8–11 July 2014. [Google Scholar]

- Park, S.-H.; Choi, S.; Song, D.-G.; Jhang, K.-Y. Microstructural Characterization of Additively Manufactured Metal Components Using Linear and Nonlinear Ultrasonic Techniques. Materials 2022, 15, 3876. [Google Scholar] [CrossRef]

- Qi, X.; Chen, G.; Li, Y.; Cheng, X.; Li, C. Applying Neural- Network- Based Machine Learning to Additive Manufacturing: Current Applications, Challenges, and Future Perspectives. Engineering 2019, 5, 721–729. [Google Scholar] [CrossRef]

- Jithinraj, E.K.; Ahmed, A.; Boban, J. Improving the Surface Integrity of Additively Manufactured Curved and Inclined Metallic Surfaces Using Thermo-Electric Energy Assisted Polishing. Surf. Coat Technol. 2022, 446, 128803. [Google Scholar] [CrossRef]

- Xu, P.; Cheung, C.F.; Wang, C.; Zhao, C. Novel Hybrid Robot and Its Processes for Precision Polishing of Freeform Surfaces. Precis. Eng. 2020, 64, 53–62. [Google Scholar] [CrossRef]

- Bonnard, R.; Hascoët, J.-Y.; Mognol, P.; Stroud, I. STEP-NC Digital Thread for Additive Manufacturing: Data Model, Implementation and Validation. Int. J. Comput. Integr. Manuf. 2018, 31, 1141–1160. [Google Scholar] [CrossRef]

- Pasi, B.N.; Mahajan, S.K.; Rane, S.B. Development of Innovation Ecosystem Framework for Successful Adoption of Industry 4.0 Enabling Technologies in Indian Manufacturing Industries. J. Sci. Technol. Policy Manag. 2022, 13, 154–185. [Google Scholar] [CrossRef]

- Tuloup, C.; Harizi, W.; Aboura, Z.; Meyer, Y.; Khellil, K.; Lachat, R. On the Use of In-Situ Piezoelectric Sensors for the Manufacturing and Structural Health Monitoring of Polymer-Matrix Composites: A Literature Review. Compos. Struct. 2019, 215, 127–149. [Google Scholar] [CrossRef]

- Nasir, V.; Sassani, F. A Review on Deep Learning in Machining and Tool Monitoring: Methods, Opportunities, and Challenges. Int. J. Adv. Manuf. Technol. 2021, 115, 2683–2709. [Google Scholar] [CrossRef]

- Liu, J.; Zhou, H.; Liu, X.; Tian, G.; Wu, M.; Cao, L.; Wang, W. Dynamic Evaluation Method of Machining Process Planning Based on Digital Twin. IEEE Access 2019, 7, 19312–19323. [Google Scholar] [CrossRef]

- Schoop, J.; Poonawala, H.A.; Adeniji, D.; Clark, B. AI-Enabled Dynamic Finish Machining Optimization for Sustained Surface Integrity. Manuf. Lett. 2021, 29, 42–46. [Google Scholar] [CrossRef]

- Shen, B.; Erol, O.; Fang, L.; Kang, S.H. Programming the Time into 3D Printing: Current Advances and Future Directions in 4D Printing. Multifunct. Mater. 2020, 3, 012001. [Google Scholar] [CrossRef]

- Shin, D.G.; Kim, T.H.; Kim, D.E. Review of 4D Printing Materials and Their Properties. Int. J. Precis. Eng. Manuf. -Green Technol. 2017 4:3 2017, 4, 349–357. [Google Scholar] [CrossRef]

- Ge, Q.; Sakhaei, A.H.; Lee, H.; Dunn, C.K.; Fang, N.X.; Dunn, M.L. Multimaterial 4D Printing with Tailorable Shape Memory Polymers. Sci. Rep. 2016, 6, 1–11. [Google Scholar] [CrossRef]

- Momeni, F.; M. Mehdi Hassani, N.S.; Liu, X.; Ni, J. A Review of 4D Printing. Mater. Des. 2017, 122, 42–79. [Google Scholar] [CrossRef]

- Pugliese, R.; Regondi, S. Artificial Intelligence-Empowered 3D and 4D Printing Technologies toward Smarter Biomedical Materials and Approaches. Polymers 2022, 14, 2794. [Google Scholar] [CrossRef] [PubMed]

- Pugliese, R.; Regondi, S.; Marini, R. Machine Learning-Based Approach: Global Trends, Research Directions, and Regulatory Standpoints. Data Sci. Manag. 2021, 4, 19–29. [Google Scholar] [CrossRef]

- Huff, T.J.; Ludwig, P.E.; Zuniga, J.M. The Potential for Machine Learning Algorithms to Improve and Reduce the Cost of 3-Dimensional Printing for Surgical Planning. Expert Rev. Med. Devices 2018, 15, 349–356. [Google Scholar] [CrossRef]

- Quanjin, M.; Rejab, M.R.M.; Idris, M.S.; Kumar, N.M.; Abdullah, M.H.; Reddy, G.R. Recent 3D and 4D Intelligent Printing Technologies: A Comparative Review and Future Perspective. Procedia Comput. Sci. 2020, 167, 1210–1219. [Google Scholar] [CrossRef]

- Kusiak, A. Fundamentals of Smart Manufacturing: A Multi-Thread Perspective. Annu. Rev. Control 2019, 47, 214–220. [Google Scholar] [CrossRef]

- Rahman, M.A.; Shakur, M.S.; Ahamed, S.; Hasan, S.; Rashid, A.A.; Islam, M.A.; Haque, S.S.; Ahmed, A. A Cloud-Based Cyber-Physical System with Industry 4.0: Remote and Digitized Additive Manufacturing. Automation 2022, 3, 400–425. [Google Scholar] [CrossRef]

- Tripathi, S.; Gupta, M. A Framework for Procurement Process Re-Engineering in Industry 4.0. BPMJ 2020, 27, 439–458. [Google Scholar] [CrossRef]

- Lee, S.M.; Lee, D.; Kim, Y.S. The Quality Management Ecosystem for Predictive Maintenance in the Industry 4.0 Era. Int. J. Qual. Innov. 2019, 5, 4. [Google Scholar] [CrossRef]

- Afanasev, M.Y.; Fedosov, Y.V.; Krylova, A.A.; Shorokhov, S.A. An Application of Blockchain and Smart Contracts for Machine-to-Machine Communications in Cyber-Physical Production Systems. In Proceedings of the 2018 IEEE Industrial Cyber-Physical Systems (ICPS), St. Petersburg, Russia, 15–18 May 2018; pp. 13–19. [Google Scholar] [CrossRef]

- Deebak, B.D.; AL-Turjman, F. A Robust and Distributed Architecture for 5G-Enabled Networks in the Smart Blockchain Era. Comput. Commun. 2022, 181, 293–308. [Google Scholar] [CrossRef]

- Borangiu, T.; Trentesaux, D.; Thomas, A.; Leitão, P.; Barata, J. Digital Transformation of Manufacturing through Cloud Services and Resource Virtualization. Comput. Ind. 2019, 108, 150–162. [Google Scholar] [CrossRef]

- Wang, L.; Wang, X.V.; Gao, L.; Váncza, J. A Cloud-Based Approach for WEEE Remanufacturing. CIRP Ann. 2014, 63, 409–412. [Google Scholar] [CrossRef]

- Adamson, G.; Wang, L.; Holm, M.; Moore, P. Cloud Manufacturing—A Critical Review of Recent Development and Future Trends. Int. J. Comput. Integr. Manuf. 2015, 1–34. [Google Scholar] [CrossRef]

- Altintas, Y.; Brecher, C.; Weck, M.; Witt, S. Virtual Machine Tool. CIRP Ann. 2005, 54, 115–138. [Google Scholar] [CrossRef]

- Cai, Y.; Starly, B.; Cohen, P.; Lee, Y.-S. Sensor Data and Information Fusion to Construct Digital-Twins Virtual Machine Tools for Cyber-Physical Manufacturing. Procedia Manuf. 2017, 10, 1031–1042. [Google Scholar] [CrossRef]

- Xu, X. Machine Tool 4.0 for the New Era of Manufacturing. Int. J. Adv. Manuf. Technol. 2017, 92, 1893–1900. [Google Scholar] [CrossRef]

- Stavropoulos, P. Digitization of Manufacturing Processes: From Sensing to Twining. Technologies 2022, 10, 98. [Google Scholar] [CrossRef]

- Zhang, J.; Deng, C.; Zheng, P.; Xu, X.; Ma, Z. Development of an Edge Computing-Based Cyber-Physical Machine Tool. Robot. Comput. -Integr. Manuf. 2021, 67, 102042. [Google Scholar] [CrossRef]

- Liu, C.; Zheng, P.; Xu, X. Digitalisation and Servitisation of Machine Tools in the Era of Industry 4.0: A Review. Int. J. Prod. Res. 2021, 1–33. [Google Scholar] [CrossRef]

- Shakur, M.S.; Islam, M.A.; Rahman, M.A. A Cyber Physical Industry 4.0 Framework of Image Based Defect Detection for Additive Manufacturing. In Proceedings of the 2021 International Conference on Computer, Communication, Chemical, Materials and Electronic Engineering (IC4ME2), Rajshahi, Bangladesh, 26–7 December 2021; pp. 1–6. [Google Scholar] [CrossRef]

- Gunasegaram, D.R.; Murphy, A.B.; Barnard, A.; DebRoy, T.; Matthews, M.J.; Ladani, L.; Gu, D. Towards Developing Multiscale-Multiphysics Models and Their Surrogates for Digital Twins of Metal Additive Manufacturing. Addit. Manuf. 2021, 46, 102089. [Google Scholar] [CrossRef]

- Yavari, R.; Riensche, A.; Tekerek, E.; Jacquemetton, L.; Halliday, H.; Vandever, M.; Tenequer, A.; Perumal, V.; Kontsos, A.; Smoqi, Z.; et al. Digitally Twinned Additive Manufacturing: Detecting Flaws in Laser Powder Bed Fusion by Combining Thermal Simulations with in-Situ Meltpool Sensor Data. Mater. Des. 2021, 211, 110167. [Google Scholar] [CrossRef]

- Gunasegaram, D.R.; Murphy, A.B.; Matthews, M.J.; DebRoy, T. The Case for Digital Twins in Metal Additive Manufacturing. J. Phys. Mater. 2021, 4, 40401. [Google Scholar] [CrossRef]

- Liu, C.; le Roux, L.; Körner, C.; Tabaste, O.; Lacan, F.; Bigot, S. Digital Twin-Enabled Collaborative Data Management for Metal Additive Manufacturing Systems. J. Manuf. Syst. 2022, 62, 857–874. [Google Scholar] [CrossRef]

- Gupta, P.; Krishna, C.; Rajesh, R.; Ananthakrishnan, A.; Vishnuvardhan, A.; Patel, S.S.; Kapruan, C.; Brahmbhatt, S.; Kataray, T.; Narayanan, D.; et al. Industrial Internet of Things in Intelligent Manufacturing: A Review, Approaches, Opportunities, Open Challenges, and Future Directions. Int. J. Interact. Des. Manuf. 2022, 1–23. [Google Scholar] [CrossRef]

- Kim, J.; Takahashi, H.; Miyashita, H.; Annett, M.; Yeh, T. Machines as Co-Designers: A Fiction on the Future of Human-Fabrication Machine Interaction. In Proceedings of the 2017 CHI Conference Extended Abstracts on Human Factors in Computing Systems, Denver, CO, USA, 6–11 May 2017; ACM: Denver, CO, USA, 2017; pp. 790–805. [Google Scholar] [CrossRef]

- Ardanza, A.; Moreno, A.; Segura, Á.; de la Cruz, M.; Aguinaga, D. Sustainable and Flexible Industrial Human Machine Interfaces to Support Adaptable Applications in the Industry 4.0 Paradigm. Int. J. Prod. Res. 2019, 57, 4045–4059. [Google Scholar] [CrossRef]

- Reisch, R.T.; Hauser, T.; Lutz, B.; Tsakpinis, A.; Winter, D.; Kamps, T.; Knoll, A. Context Awareness in Process Monitoring of Additive Manufacturing Using a Digital Twin. Int. J. Adv. Manuf. Technol. 2022, 119, 3483–3500. [Google Scholar] [CrossRef]

- Morgan, J.; Halton, M.; Qiao, Y.; Breslin, J.G. Industry 4.0 Smart Reconfigurable Manufacturing Machines. J. Manuf. Syst. 2021, 59, 481–506. [Google Scholar] [CrossRef]

- Borish, M.; Westfall, J. Additive and Subtractive Manufacturing Augmented Reality Interface (ASMARI). In Proceedings of the 2020 SoutheastCon, Raleigh, NC, USA, 28–29 March 2020; pp. 1–6. [Google Scholar] [CrossRef]

- Phua, A.; Davies, C.H.J.; Delaney, G.W. A Digital Twin Hierarchy for Metal Additive Manufacturing. Comput. Ind. 2022, 140, 103667. [Google Scholar] [CrossRef]

- Phua, A.; Delaney, G.W.; Cook, P.S.; Davies, C.H.J. Intelligent Digital Twins Can Accelerate Scientific Discovery and Control Complex Multi-Physics Processes. In Proceedings of the ICML 2022 2nd AI for Science Workshop, Baltimore, AR, USA, 22 July 2022. [Google Scholar]

| Process | Advantage | Disadvantage |

|---|---|---|

| Subtractive Manufacturing (SM) |

| |

| Additive Manufacturing (AM) |

|

|

| Hybrid Manufacturing (HM) |

|

|

| Sl | Process | Material Supply Phase | Example | Phase Change Type | Description |

|---|---|---|---|---|---|

| 1. | Vat photopolymerization | Liquid | Stereolithography (SLA), Direct Light Processing (DLP), Solid Ground Curing (SGC), Continuous Liquid Interface Production (CLIP), Continuous Direct Light Processing (CDLP) | Photopolymerization | Light-activated polymerization selectively cures liquid photopolymer in a vat. |

| 2. | Material jetting | Liquid | Ink-Jet Printing, PolyJet, Nano Particle Jetting (NPJ), Drop on Demand (DOD) | Photopolymerization | Built material droplets are selectively deposited onto the build platform to solidify and build the model. |

| 3. | Binder jetting or PolyJet | Powder and liquid | Binder Jetting Three-Dimensional Printing (Bj3DP) | Densification | A thin layer of powder materials is selectively applied using a liquid bonding agent. |

| 4. | Powder bed fusion | Powder | Selective Laser Sintering (SLS), Selective Laser Melting (SLM), Electron Beam Powder Bed Fusion (E-PBF), Direct Metal Laser Sintering (DMLS), High-Speed Sintering (HSS), Selective Heat Sintering (SHS) | Sintering or melting | Thermal energy, such as a laser or electron beam, selectively fuses powder material regions. |

| 5. | Directed energy deposition | Powder or wire | Laser Engineered Net Shaping (LENS), Electron Beam Additive Manufacturing (EBAM), Wire Arc Additive Manufacturing (WAAM), Aerosol Jetting (AJ), Directed Light Fabrication (DLF), Laser Deposition Welding (LDW) | Melting | Focused thermal energy is applied to melt and fuse materials simultaneously, as they are deposited on a surface by a nozzle. |

| 6. | Material extrusion | Filament wire | Fused Deposition Modeling (FDM), Fused Pellet Modeling (FPM), Powder Melt Extrusion (PME) | Solidification by cooling | A moving heated extruder head selectively dispenses continuous filament material, which is subsequently deposited via a nozzle or orifice. |

| 7. | Laminated object | Solid | Ultrasonic Consolidation (UC), Ultrasonic Additive Manufacturing (UAM) | No phase change | Heat and pressure are applied to fuse or laminate adhesive-coated sheets of material together to make an item. |

| Principle of Sensing | Type of Defect | Notes | Ref. |

|---|---|---|---|

| Ultrasonic Testing | Porosity, balling | For qualitative purposes | [124,125,126] |

| Acoustic Emission Spectroscopy | Overheating, cracking | For qualitative purposes | [127,128,129,130] |

| Optical Imaging | Powder bed irregularities, overheating | Potential to detect thermal anomalies | [131,132] |

| Optical Emission Spectroscopy | Overheating, monitor/predict defects | Mostly used in plasma-based processes | [133,134] |

| Optical Tomography | Balling | For sub-surface detection | [135,136] |

| X-ray Tomography | Surface roughness, dimensional accuracy | Early phase of development | [137,138] |

| Optical Coherence Tomography | Powder bed irregularities, lack of fusion defects, keyhole fluctuation, melt pool fluctuation, keyhole pore formation | Limited to surface defects | [139] |

| Pyrometry | Overheating | Suitable for multiple scan areas | [140,141] |

| Infrared Imaging | Overheating | Potential to scan entire build area | [141] |

| In-Situ X-ray Imaging/Diffraction | Keyhole pore formation, melt pool size/shape, powder ejection solidification, phase transformation | For quantitative structural information | [142] |

| Model Name | Configuration | |

|---|---|---|

| Optomec [172] | LENS 860 Hybrid Open Atmosphere System, LENS 860 Hybrid Controlled Atmosphere | Combines LENS and CNC machining (up to 5 axes) |

| DMG MORI [173] | LASERTEC 65, 125, 300, 6000 | Combines LENS and CNC machining (up to 5 axes) |

| MAZAK [174] | INTEGREX i-250S AM, INTEGREX i-400 AM, INTEGREX i-600/5X | i-250S AM combines LENS (multiple laser beams) and CNC machining (up to 5 axis), i-400 AM combines LENS (single laser beam) and CNC machining (up to 5 axes), i-600/5X combines wire-arc and CNC machining (up to 5 axes) |

| Hermle [175] | N/A | Combines proprietary metal-powder-application (MPA) and CNC machining (up to 5 axes) |

| Fabrisonic [176] | N/A | Combines ultrasonic additive manufacturing and 3 axes CNC machining |

| 3D Metal Forge [177] | H-WAAM | Uses two robotic arms—one for wire-arc additive manufacturing and the other for robotic machining |

| Hybrid Manufacturing Technologies [178] | AMBIT ONE, AMBIT FLEX, AMBIT EDDY, AMBIT XTRUDE, AMBIT MULTI, AMBIT WAVE, AMBIT SCAN | Develops end effectors for DED (laser), scanning and sensing which attach to CNC machines |

| 3D-Hybrid [179] | Laser, Arc, Cold Spray | Develops end effectors for laser DED, wire-arc DED, and cold-spray. |

| Challenges | Description of the Challenges | Next Step |

|---|---|---|

| Expandability | Intelligent techniques are mostly AI-based, where AI models, such as CNNs have been widely employed. However, lack of transparency due to the complex computing architecture has resulted in reduced trustworthiness of AI predictions. | Development of in-situ sensors and sensor fusion in benchmarking training data set. |

| Lack of data | For several complex processes, such as AM, the generation of a large dataset is very challenging due to the cost and time restrictions. | The training data set representing real-world situations. |

| Variability in processing requirements | Different technologies demand different post-processing techniques which are extremely difficult to capture through intelligent techniques. | Knowledge of domain expert with AI knowledge is required. |

| Lack of robustness | The intelligent post-process techniques are often developed for a specific application (mostly DED), machine and controlled test conditions. | CSAM and powder bed fusion AM process need more R&D. |

| Material dependency | It is difficult to capture the intrinsic process–property–performance relationship through intelligent techniques. | Process fingerprints are introduced. |

| Integration quality control | Seamless integration of post-processing and final quality compliance in terms of dimensional accuracy, form tolerance and material properties are difficult. | The autonomous models are yet to be developed. |

| Environment control | Management of coolant for machining vs. inert gas environment for AM can be challenging. | Dry/cryogenic machining with active chip removal. |

| Other post processing | With near net shape AM parts, polishing and grinding operations may suffice and replace machining. | Improvement for net-shape. |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Rahman, M.A.; Saleh, T.; Jahan, M.P.; McGarry, C.; Chaudhari, A.; Huang, R.; Tauhiduzzaman, M.; Ahmed, A.; Mahmud, A.A.; Bhuiyan, M.S.; et al. Review of Intelligence for Additive and Subtractive Manufacturing: Current Status and Future Prospects. Micromachines 2023, 14, 508. https://doi.org/10.3390/mi14030508

Rahman MA, Saleh T, Jahan MP, McGarry C, Chaudhari A, Huang R, Tauhiduzzaman M, Ahmed A, Mahmud AA, Bhuiyan MS, et al. Review of Intelligence for Additive and Subtractive Manufacturing: Current Status and Future Prospects. Micromachines. 2023; 14(3):508. https://doi.org/10.3390/mi14030508

Chicago/Turabian StyleRahman, M. Azizur, Tanveer Saleh, Muhammad Pervej Jahan, Conor McGarry, Akshay Chaudhari, Rui Huang, M. Tauhiduzzaman, Afzaal Ahmed, Abdullah Al Mahmud, Md. Shahnewaz Bhuiyan, and et al. 2023. "Review of Intelligence for Additive and Subtractive Manufacturing: Current Status and Future Prospects" Micromachines 14, no. 3: 508. https://doi.org/10.3390/mi14030508

APA StyleRahman, M. A., Saleh, T., Jahan, M. P., McGarry, C., Chaudhari, A., Huang, R., Tauhiduzzaman, M., Ahmed, A., Mahmud, A. A., Bhuiyan, M. S., Khan, M. F., Alam, M. S., & Shakur, M. S. (2023). Review of Intelligence for Additive and Subtractive Manufacturing: Current Status and Future Prospects. Micromachines, 14(3), 508. https://doi.org/10.3390/mi14030508