Evaluation of Thin Wall Milling Ability Using Disc Cutters

Abstract

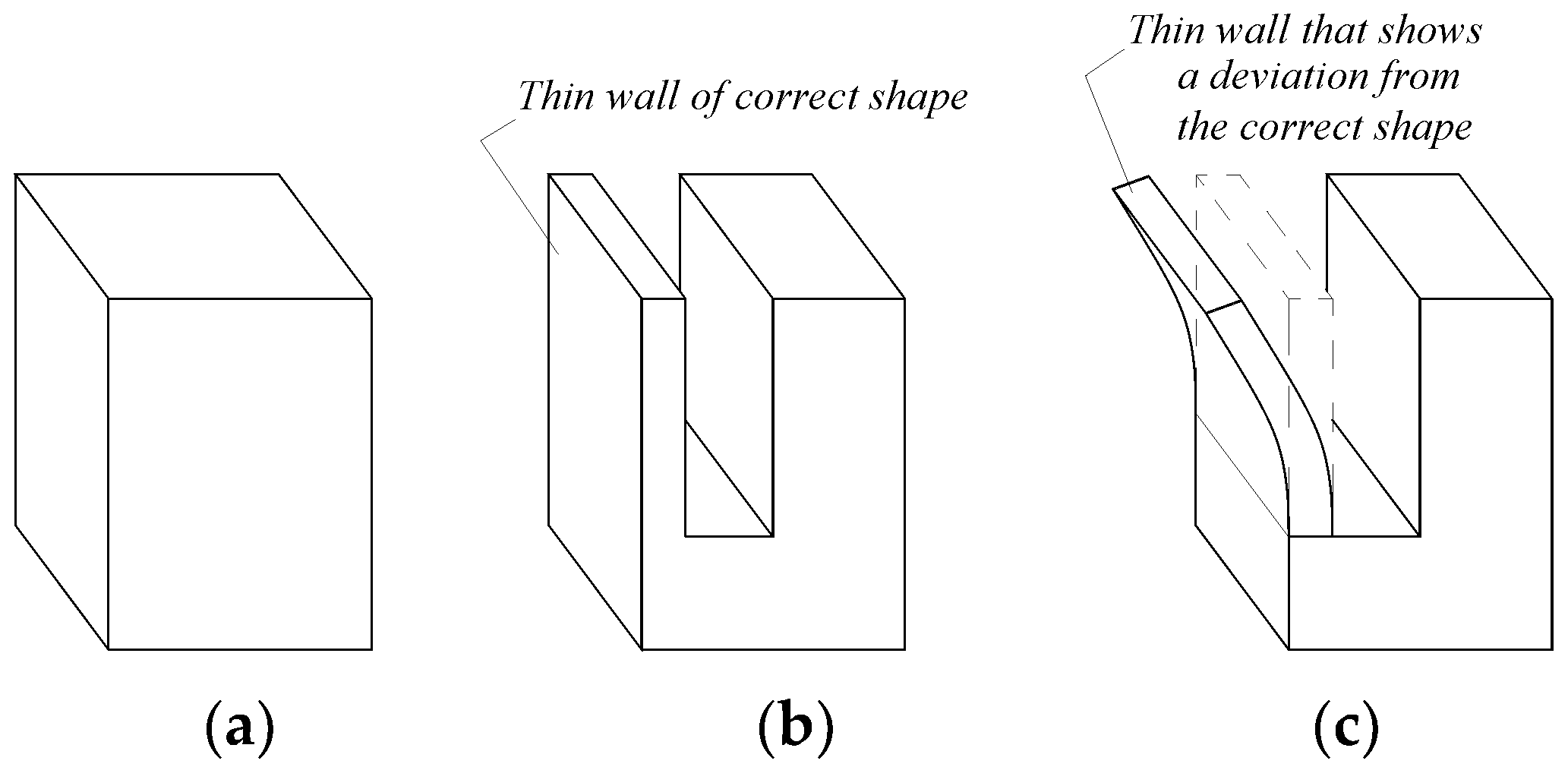

1. Introduction

- -

- -

- -

- -

- -

- -

- -

- -

2. Materials and Methods

2.1. Background

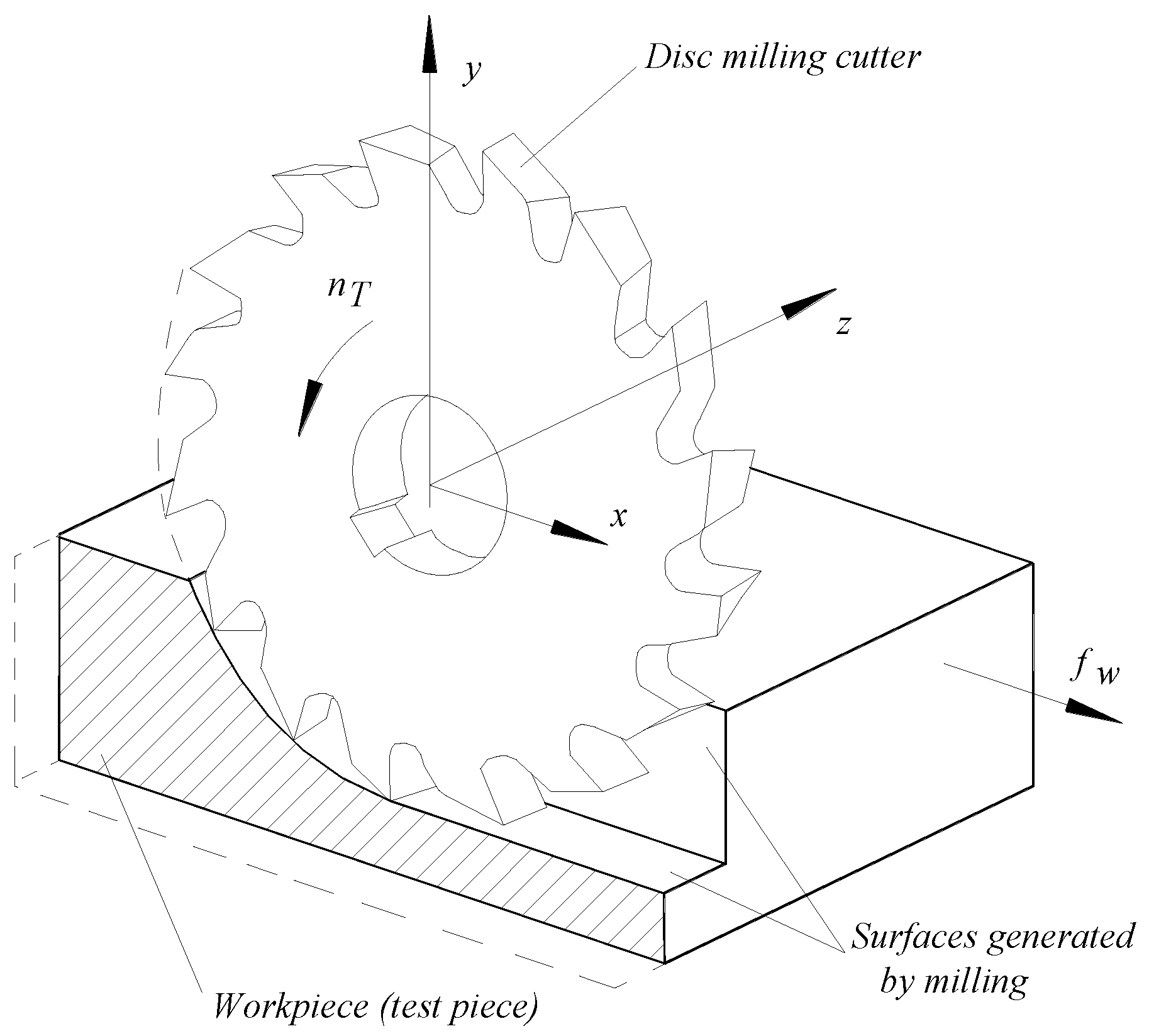

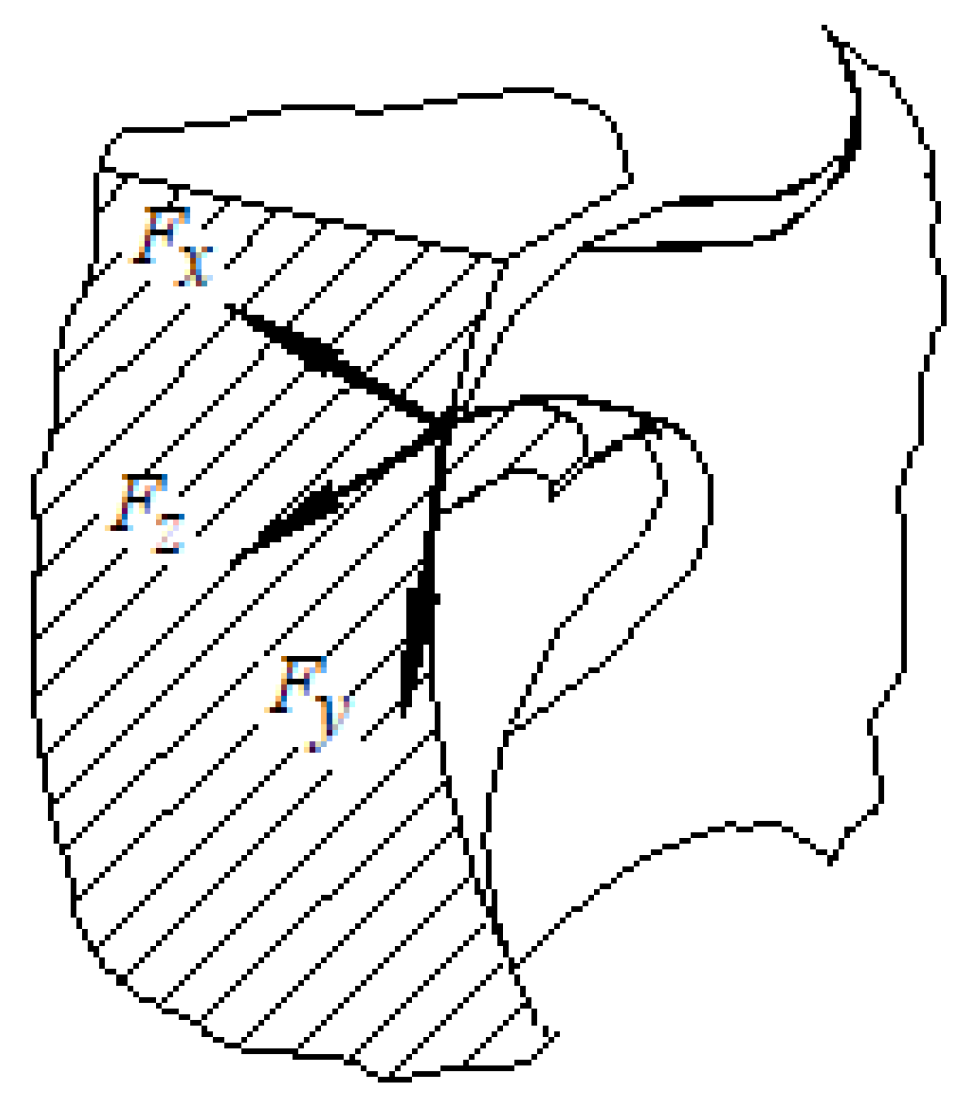

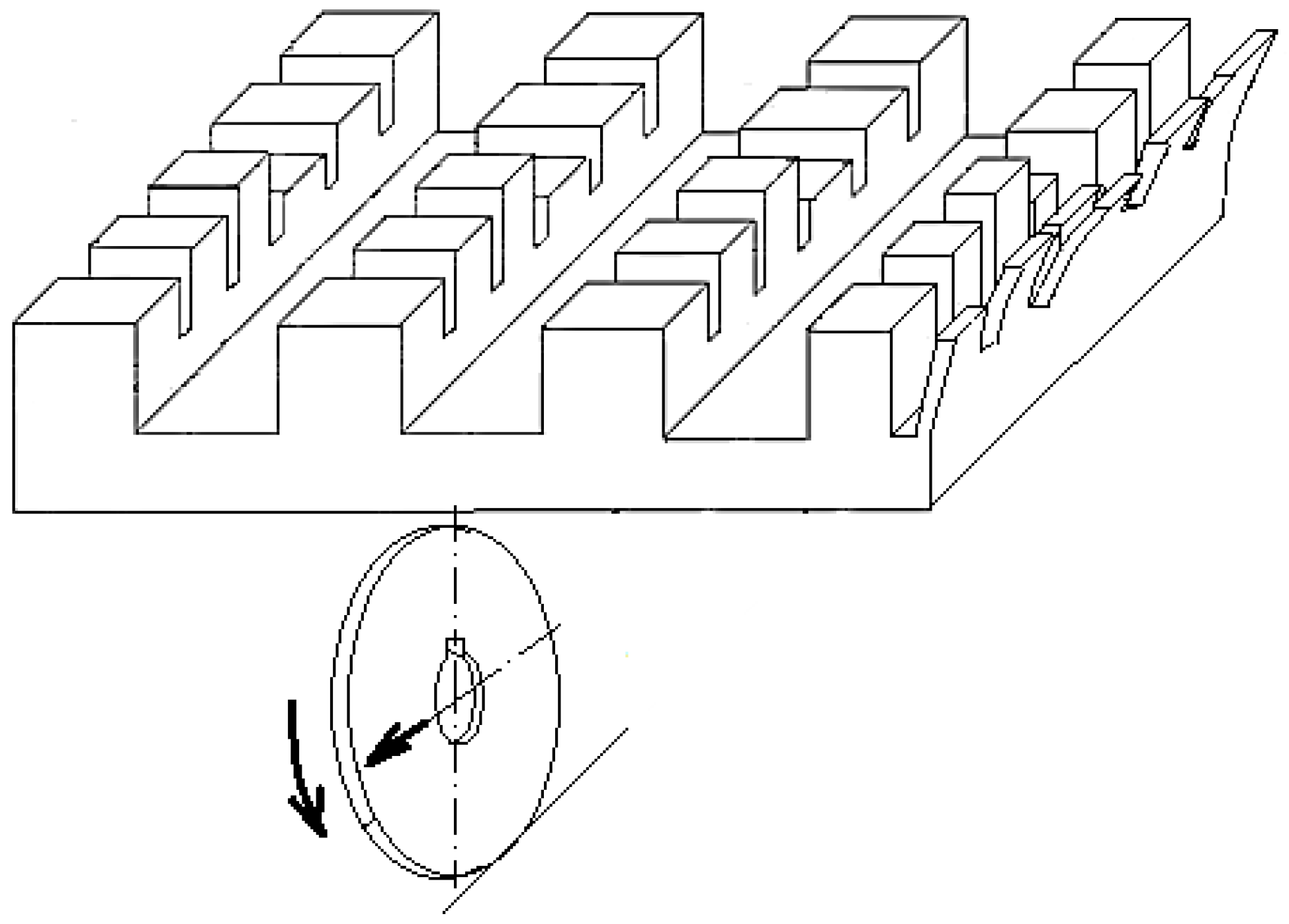

2.2. Analysis of the Cutting Process with Disc Cutters

- (a)

- The physical-mechanical properties of the workpiece material. A higher mechanical resistance could lead to lower values of the deviation ε;

- (b)

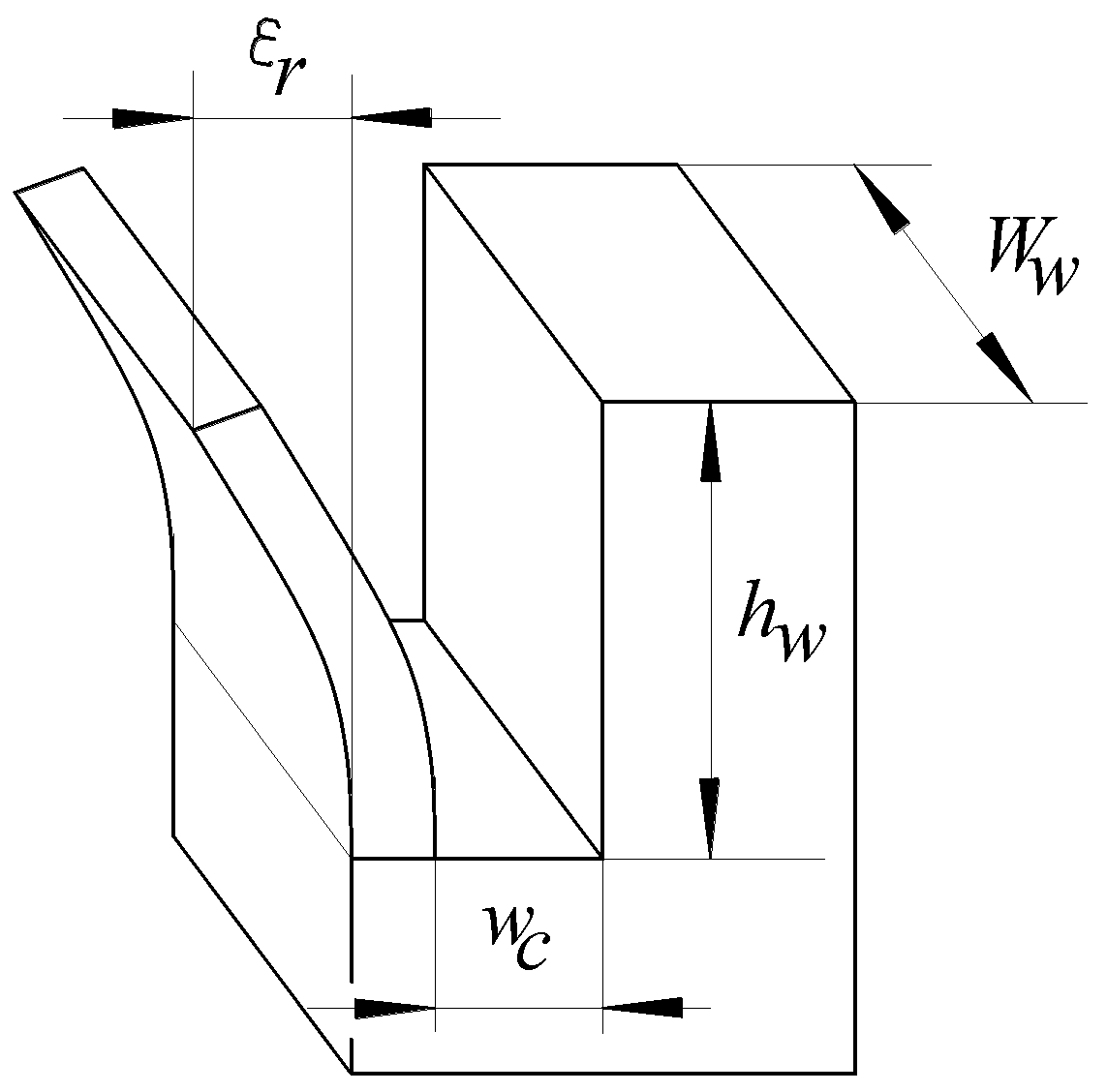

- The dimensions that define the workpiece and the groove to separate the thin wall (height hw and width ww of the thin wall, width wc of the groove (in direct correspondence with the thickness tt of the disc cutter) (Figure 4);

- (c)

- The number of cutting teeth and the dimensions that define the geometry of the cutting teeth of the disc cutter (angles, edge rounding radii, etc.). An important influence on the size of the shape deviation of the thin wall can be exerted by the geometric characteristics (back rake angle, tool nose radius, side clearance angle, etc.) of the secondary cutting edge of the disk cutter that generates the thin wall. Such characteristics determine the magnitude of the Fz component of the cutting force that will lead to the deformation of the thin wall;

- (d)

- The level of wear of the active edges of the cutting teeth of the disc cutter;

- (e)

- The values of some parameters characterizing the machining conditions (cutting speed vc, feed rate f);

- (f)

- The physical-mechanical properties of the disc cutter material. A possible elastic deformation of the cutting teeth along different directions could lead to the modification of the deviation value ε.

2.3. Finite Element Modeling Elements

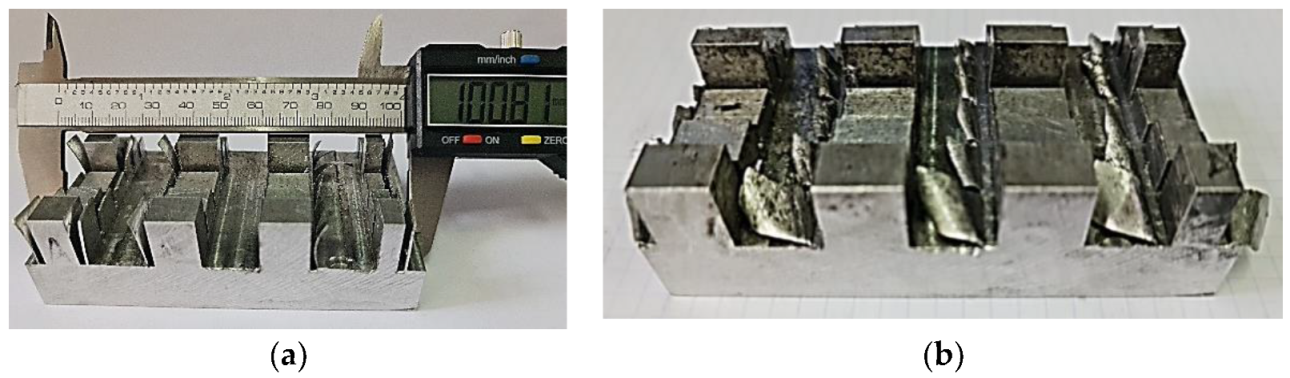

2.4. Experimental Conditions

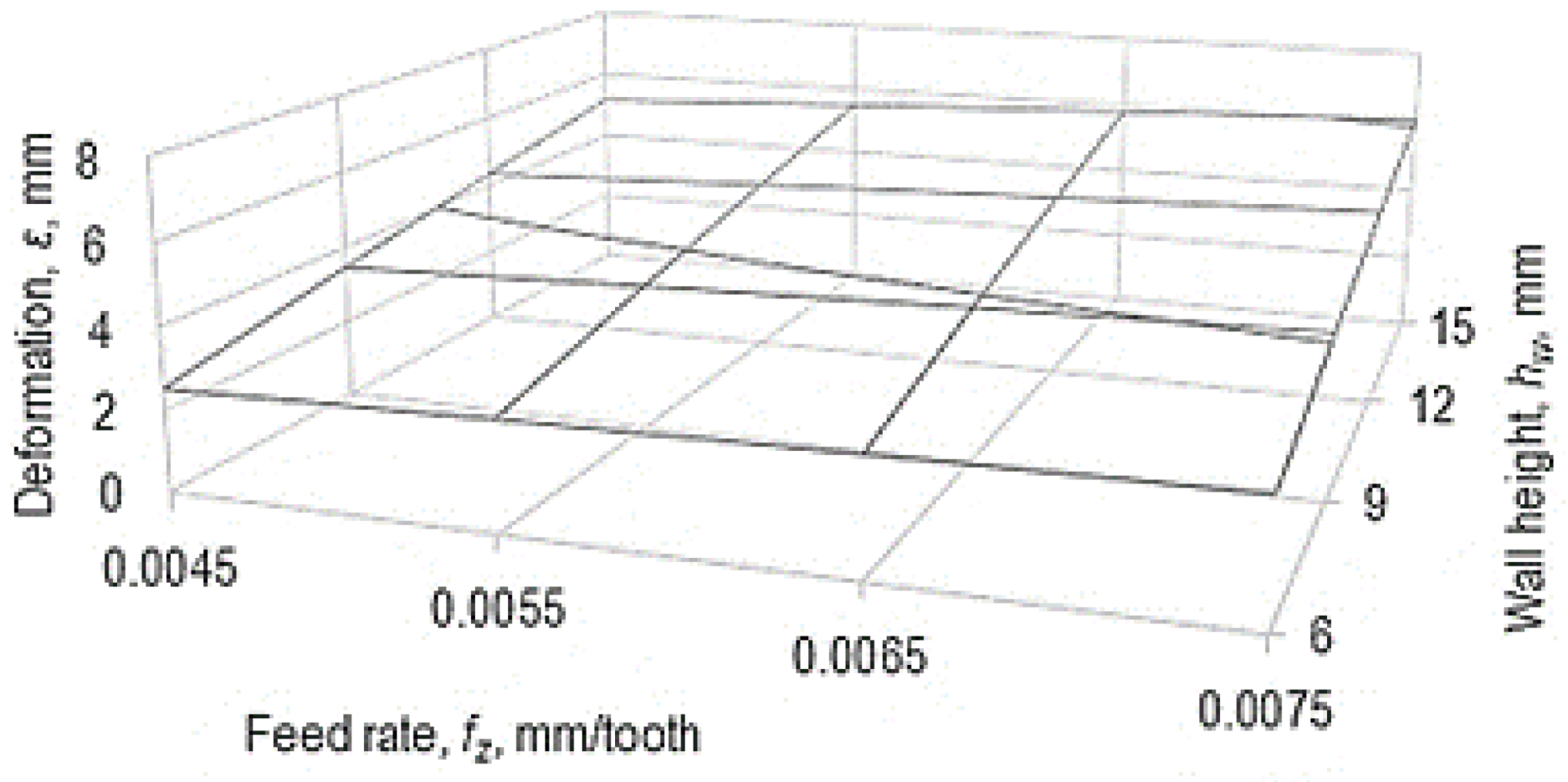

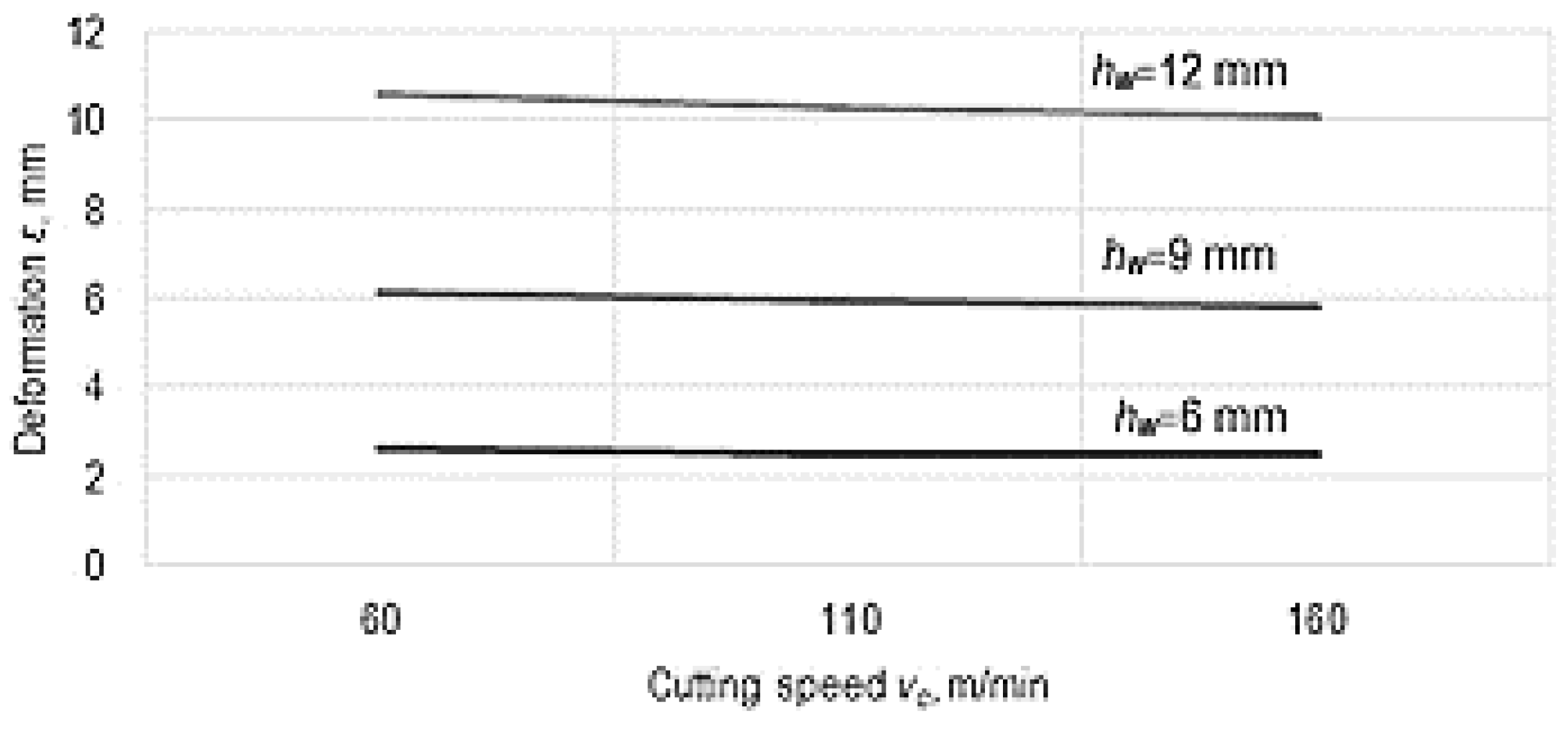

3. Results

−0.887ww + 0.0662ww2 − 0.361hw + 0.00108hw2,

4. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Reznicek, M.; Horava, C.; Ovsik, M. Percentage ratios of cutting forces during high-reed face milling. Materials 2023, 16, 384. [Google Scholar] [CrossRef] [PubMed]

- Leksycki, K.; Feldshtein, E.; Lisowicz, J.; Chudy, R.; Mrugalski, R. Cutting forces and chip shaping when finish turning of 17-4 PH stainless steel under dry, wet, and MQL machining conditions. Metals 2020, 10, 1187. [Google Scholar] [CrossRef]

- Bravo, U.; Altuzarra, O.; López de Lacalle, L.N.; Sánchez, J.A.; Campa, F.J. Stability limits of milling considering the flexibily of the workpiece and the machine. Int. J. Mach.Tools Manuf. 2005, 45, 1669–1680. [Google Scholar] [CrossRef]

- Grossi, N.; Scippa, A.; Croppi, L.; Morelli, L.; Campatelli, G. Adaptive toolpath for 3-axis milling of thin walled parts. MM Sci. J. 2019, 2019, 3378–3385. [Google Scholar] [CrossRef]

- Artetxe, E.; Olvera, D.; Lopez de Lacalle, L.N.; Campa, J.; Olvera, D.; Lamikiz, A. Solid subtraction model for the surface topography prediction in flank milling of thin-walled integral blade rotors (IBRs). Int. J. Adv. Manuf. Technol. 2017, 90, 741–752. [Google Scholar] [CrossRef]

- Jiang, X.; Yang, N.; Zhang, Y.; Gao, S. An improved dynamics modeling during milling of the thin-walled parts based on magnetorheological damping fixture. Int. J. Adv. Manuf. Technol. 2022, 121, 2683–2698. [Google Scholar] [CrossRef]

- Budak, E. Mechanics and Dynamics of Milling Thin Walled Structures. Ph.D. Thesis, The University of British Columbia, Vancouver, BC, Canada, 1994. [Google Scholar]

- Stojković, M.; Madić, M.; Trifunović, M.; Turudija, R. Determining the optimal cutting parameters for required productivity for the case of rough external turning of AISI 1045 steel with minimal energy consumption. Metals 2022, 12, 1793. [Google Scholar] [CrossRef]

- Patil, P.; Karande, P. Experimental investigations and optimization of machining parameters in CNC turning of SS304 using coolant at 0 °C. J. Manuf. Mater. Process. 2022, 6, 128. [Google Scholar] [CrossRef]

- Ratchev, S.; Huang, W.; Liu, S.; Becker, A.A. Modelling and simulation environment for machining of low-rigidity components. J. Mater. Process. Tech. 2004, 153, 7–73. [Google Scholar] [CrossRef]

- Ratchev, S.; Liu, S.; Becker, A.A. Error compensation strategy in milling flexible thin-wall parts. J. Mater. Process. Tech. 2005, 162, 673–681. [Google Scholar] [CrossRef]

- Ratchev, S.; Liu, S.; Huang, W.; Becker, A.A. A flexible force model for end milling of low-rigidity parts. J. Mater. Process. Tech. 2004, 153, 134–138. [Google Scholar] [CrossRef]

- Ratchev, S.; Liu, S.; Huang, W.; Becker, A.A. Milling error prediction and compensation in machining of low-rigidity parts. Int. J. Mach. Tool. Manuf. 2004, 44, 1629–1641. [Google Scholar] [CrossRef]

- Ratchev, S.; Nikov, S.; Moualek, I. Material removal simulation of peripheral milling of thin wall low-rigidity structures using FEA. Adv. Eng. Softw. 2004, 35, 481–491. [Google Scholar] [CrossRef]

- Guo, J.; Lee, K.-M.; Liu, W.; Wang, B. Design criteria based on modal analysis for vibration sensing of thin-wall plate machining. IEEE/ASME Trans. Mechatron. 2015, 20, I406–I417. [Google Scholar] [CrossRef]

- Guo, J.; Liu, R.; Lee, K.-M. Displacement field sensing and reconstruction for vibration of a thin-wall plate. In Proceedings of the 2015 IEEE International Conference on Advanced Intelligent Mechatronics (AIM), Busan, Republic of Korea, 7–11 July 2015. [Google Scholar]

- Guo, J.; Lee, K.-M.; Liu, W.; Wang, B. Dynamic analysis and experimental validation of vibration sensing for machining thin-walled plate. In Proceedings of the IEEE International Conference on Advanced Intelligent Mechatronics, Besancon, France, 8–11 July 2014; pp. 512–517. [Google Scholar]

- Wan, M.; Zhang, W.H.; Qin, G.H.; Wang, Z.P. Strategies for error prediction and error control in peripheral milling of thin-walled workpiece. Int. J. Mach. Tool. Manuf. 2008, 48, 1366–1374. [Google Scholar] [CrossRef]

- Izamshah, R.R.A.; Mo, J.P.T.; Ding, S. Finite element analysis of machining thin-wall parts. Key Eng. Mater. 2010, 458, 283–288. [Google Scholar] [CrossRef]

- Huang, Y.; Zhang, X.; Xiong, Y. Finite Element Analysis of Machining Thin-Wall Parts: Error Prediction and Stability Analysis. In Finite Element Analysis—Applications in Mechanical Engineering; Ebrahimi, F., Ed.; IntechOpen: London, UK, 2012; pp. 327–354. [Google Scholar] [CrossRef]

- Huang, N.; Yin, C.; Liang, L.; Hu, J.; Wu, S. Error compensation for machining of large thin-walled part with sculptured surface based on on-machine measurement. Int. J. Adv. Manuf. Technol. 2018, 96, 4345–4352. [Google Scholar] [CrossRef]

- Isaev, A.; Grechishnikov, V.; Pivkin, P.; Kozochkin, M.; Ilyuhin, Y.; Vorotnikov, A. Machining of thin-walled parts produced by additive manufacturing technologies. Procedia CIRP 2016, 41, 1023–1026. [Google Scholar] [CrossRef]

- Sathish, K.; Senthil, K.S.; Magal, T.R.; Selvaraj, V.; Narasimharaj, V.; Karthikeyan, R.; Sabarinathan, G.; Tiwari, M.; Kassa, A.E. A comparative study on subtractive manufacturing and additive manufacturing. Adv. Mater. Sci. Eng. 2022, 2022, 2641. [Google Scholar] [CrossRef]

- Yang, T.; Mazumder, S.; Jin, Y.; Squires, B.; Sofield, M.; Pantawane, M.V.; Dahotre, N.B.; Neogi, A. A review of diagnostics methodologies for metal additive manufacturing processes and products. Materials 2021, 14, 4929. [Google Scholar] [CrossRef]

- Slătineanu, L.; Nagîț, G.; Dodun, O.; Coteață, M.; Munteanu, A.; Beșliu-Băncescu, I.; Gherman, A.-L.; Hrițuc, A.; Chinesta, F.; Goncalves-Coelho, A.; et al. Electrophysical and Chemical Manufacturing Processes; Publishing House Tehnica Info: Chișinău, Republic of Moldova, 2020. [Google Scholar]

- Plott, J.; Tian, X.; Shih, A.J. Measurement and modeling of forces in extrusion-based additive manufacturing of flexible silicone elastomer with thin wall structures. J. Manuf. Sci. Eng. 2018, 140, 1–11. [Google Scholar] [CrossRef]

- Wu, Q.; Li, D.-P.; Zhang, Y.-D. Detecting Milling Deformation in 7075 Aluminum Alloy Aeronautical Monolithic Components Using the Quasi-Symmetric Machining Method. Metals 2016, 6, 80. [Google Scholar] [CrossRef]

- Vaughan, D.; Saldana, C.; Kurfess, T.; Nycz, A. Implementation of Sacrificial Support Structures for Hybrid Manufacturing of Thin Walls. J. Manuf. Mater. Process. 2022, 6, 70. [Google Scholar] [CrossRef]

- Del Sol, I.; Rivero, A.; López de Lacalle, L.N.; Gamez, A.J. Thin-wall machining of light alloys: A review of models and industrial approaches. Materials 2019, 12, 2012. [Google Scholar] [CrossRef]

- Wu, G.; Li, G.; Pan, W.; Raja, I.; Wang, X.; Ding, S. A state-of-art review on chatter and geometric errors in thin-wall machining processes. J. Manuf. Process. 2021, 68, 454–480. [Google Scholar] [CrossRef]

- Ma, J.; Li, Y.; Zhang, D.; Zhao, B.; Pang, X. Dynamic characteristic reconfiguration of a fixture-workpiece system for vibration suppression in milling of thin-walled workpieces based on MR damping fixture. Int. J. Adv. Manuf. Technol. 2022, 1222, 3751–3768. [Google Scholar] [CrossRef]

- Eremeykin, P.A.; Zhargalova, A.D.; Gavriushin, S.S. Experimental substantiation of soft cutting modes method. In Advances in Artificial Systems for Medicine and Education II; Hu, Z., Petoukhov, S., He, M., Eds.; Springer: Cham, Switzerland, 2018; Volume 902, pp. 539–547. [Google Scholar] [CrossRef]

- Eremeykin, P.A.; Zhargalova, A.D.; Gavriushin, S.S. A software system for thin-walled parts deformation analysis. In Advances in Intelligent Systems and Computing; Hu, Z., Petoukhov, S., He, M., Eds.; Springer: Cham, Switzerland, 2017; Volume 658. [Google Scholar] [CrossRef]

- Arnaud, L.; Gonzalo, O.; Seuy, S.; Jauregi, H.; Peigné, G. Simulation of low rigidity part machining applied to thin-walled structures. Int. J. Adv. Manuf. Technol. 2011, 54, 479–488. [Google Scholar] [CrossRef]

- Qi, H.; Tian, Y.; Zhang, D. Machining forces prediction for peripheral milling of low-rigidity component with curved geometry. Int. J. Adv. Manuf. Technol. 2013, 64, 1599–1610. Available online: https://link.springer.com/article/10.1007/s00170-012-4126-z (accessed on 21 December 2022). [CrossRef]

- Herranz, S.; Campa, F.J.; López de Lacalle, L.N.; Rivero, A.; Lamikiz, A.; Ukar, E.; Sánchez, J.A.; Bravo, J.A. The milling of airframe components with low rigidity: A general approach to avoid static and dynamic problems. Proc. Inst. Mech. Eng. Part B J. Eng. Manuf. 2005, 219, 789–802. [Google Scholar] [CrossRef]

- Campa, F.J.; López de Lacalle, L.N.; Urbicain, G.; Lamikiz, A.; Seguy, S.; Arnaud, L. Critical thickness and dynamic stiffness for chatter avoidance in thin floors milling. Adv. Mater. Res. 2011, 188, 116–121. [Google Scholar] [CrossRef]

- Campa, F.J.; López Lacalle, L.L.; Urbikain, G.; Ruiz, D. Definition of cutting conditions for thin-to-thin milling of 10 aerospace low rigidity parts. In Proceedings of the International Manufacturing Science and Engineering Conference, Evanston, IL, USA, 7–10 October 2008; pp. 359–368. [Google Scholar]

- Chen, W.; Xue, J.; Tang, D.; Chen, H.; Qu, S. Deformation prediction and error compensation in multilayer milling processes for thin-walled parts. Int. J. Mach. Tool. Manuf. 2009, 49, 859–864. [Google Scholar] [CrossRef]

- Kolluru, K.; Axinte, D.; Becker, A. A solution for minimising vibrations in milling of thin walled casings by applying dampers to workpiece surface. CIRP Ann. Manuf. Technol. 2013, 62, 415–418. [Google Scholar] [CrossRef]

- Kolluru, K.; Axinte, D. Coupled interaction of dynamic responses of tool and workpiece in thin wall milling. J. Mater. Process. Tech. 2013, 213, 1565–1574. [Google Scholar] [CrossRef]

- Ma, J.; Zhang, D.; Baohai, W.; Ming, L.; Bing, C. Vibration suppression of thin-walled workpiece machining considering external damping properties based on magnetorheological fluids flexible fixture. Chin. J. Aeronaut. 2016, 29, 1074–1083. [Google Scholar] [CrossRef]

- Ma, J.; Zhang, D.; Wu, B.; Luo, M.; Liu, Y. Stability improvement and vibration suppression of the thin-walled workpiece in milling process via magnetorheological fluid flexible fixture. Int. J. Adv. Manuf. Technol. 2017, 88, 1231–1242. [Google Scholar] [CrossRef]

- Ma, J.; Li, Y.; Zhang, D.; Zhao, B.; Wang, G.; Pang, X. Dynamic response prediction model of thin-wall workpiece-fixture system with magnetorheological damping in milling. J. Manuf. Process. 2022, 74, 500–510. [Google Scholar] [CrossRef]

- Yang, Y.; Zhang, W.H.; Ma, Y.C.; Wan, M. Chatter prediction f or the peripheral milling of thin-walled workpieces with curved surfaces. Int. J. Mach. Tool. Manuf. 2016, 109, 36–48. [Google Scholar] [CrossRef]

- Umezu, T.; Kono, D. Machining process for a thin-walled workpiece using on-machine measurement of the workpiece compliance. Int. J. Autom. Technol. 2019, 13, 631–638. [Google Scholar] [CrossRef]

- Isaev, A.V.; Kozochkin, M.P. Use of a measurement information system to increase the precision with which thin-walled parts are machined on numerically controlled milling machines. Meas. Tech. 2014, 56, 1155–1161. Available online: https://link.springer.com/article/10.1007/s11018-014-0348-9 (accessed on 21 December 2022). [CrossRef]

- Li, X.; Zhao, W.; Li, L.; He, N.; Chi, S. Modeling and application of process damping in milling of thin-walled workpiece made of titanium alloy. Shock Vib. 2015, 2015, 431476. [Google Scholar] [CrossRef]

- McGeough, J. Micromachining of Engineering Materials; Marcel Dekker Inc.: New York, NY, USA, 2002. [Google Scholar]

- Urbikain Pelayo, G.; López De La Calle, L. Stability charts with large curve-flute end-mills for thin-walled workpieces. Mach. Sci. Technol. 2018, 22, 585–603. [Google Scholar] [CrossRef]

- Campa, F.J.; López de Lacalle, L.N.; Herranz, S.; Lamikiz, A.; Rivero, A. Avoiding instability on the milling of parts with thin features. Mater. Sci. Forum 2006, 526, 37–42. [Google Scholar] [CrossRef]

- Campa, F.J.; Seguy, S.; López Lacalle, L.L.; Arnaud, L.; Dessein, G.; Aramendi, G. Stable milling of thin-walled parts with variable dynamics. In Proceedings of the 6th International Conference on High Speed Machining, San Sebastian, Spain, 21–22 March 2007. [Google Scholar]

- López de Lacalle, L.N.L.; Lamikiz, A.; Sanchez, J.A.; De Bustos, I.F. Simultaneous measurement of forces and machine tool position for diagnostic of machining tests. IEEE Trans. Instrum. Meas. 2005, 54, 2329–2335. [Google Scholar] [CrossRef]

- Urbikain, G.; Artetxe, E.; López de Lacalle, L.N. Numerical simulation of milling forces with barrel-shaped tools considering runout and tool inclination angles. Appl. Math. Model. 2017, 47, 619–636. [Google Scholar] [CrossRef]

- Yanis, M.; Mohruni, A.S.; Sharif, S.; Yani, I. Optimum performance of green machining on thin walled TI6AL4V using RSM and ANN in terms of cutting force and surface roughness. J. Teknol. 2019, 81, 51–60. [Google Scholar] [CrossRef]

- Fei, J.; Lin, B.; Xiao, J.; Ding, M.; Yan, S.; Zhang, X.; Jin, Z. Investigation of moving fixture on deformation suppression during milling process of thin-walled structures. J. Manuf. Process. 2018, 32, 403–411. [Google Scholar] [CrossRef]

- Casuso, M.; Veiga, F.; Suárez, A.; Bhujangrao, T.; Aldalur, E.; Artaza, T.; Amondarain, J.; Lamikiz, A. Model for the prediction of deformations in the manufacture of thin-walled parts by wire arc additive manufacturing technology. Metals 2021, 11, 678. [Google Scholar] [CrossRef]

- Guo, M.; Jiang, X.; Ye, Y.; Ding, Z.; Zhang, Z. Investigation of redistribution mechanism of residual stress during multi-process milling of thin-walled parts. Int. J. Adv. Manuf. Technol. 2019, 103, 1459–1466. [Google Scholar] [CrossRef]

- Jiang, X.; Zhu, Y.; Zhang, Z.; Guo, M.; Ding, Z. Investigation of residual impact stress and its effects on the precision during milling of the thin-walled part. Int. J. Adv. Manuf. Technol. 2018, 97, 877–892. Available online: https://link.springer.com/article/10.1007/s00170-018-1941-x (accessed on 21 December 2022). [CrossRef]

- Vukman, J.; Lukić, D.; Milošević, M.; Borojević, S.; Antić, A.; Đurđev, M. Fundamentals of the optimization of machining process planning for the thin-walled aluminium parts. J. Prod. Eng. 2016, 19, 53–56. Available online: http://www.jpe.ftn.uns.ac.rs/papers/2016/no2/10-Vukman_JPE_19_No2.pdf (accessed on 21 December 2022).

- Bolar, G.; Joshi, S.N. Experimental investigation and optimization of wall deflection and material removal rate in milling thin-wall parts. Manuf. Rev. 2021, 8, 17. [Google Scholar] [CrossRef]

- Seguy, S.; Dessein, G.; Arnaud, L. Surface roughness variation of thin wall milling, related to modal interactions. Int. J. Mach. Tools Manuf. 2008, 48, 261–274. [Google Scholar] [CrossRef]

- Mohruni, A.S.; Yanis, M.; Sharif, S.; Yani, I.; Yuliwati, E.; Ismail, A.F.; Shayfull, Z. A comparison RSM and ANN surface roughness models in thin-wall machining of Ti6Al4V using vegetable oils under MQL-condition. AIP Conf. Proc. 2017, 1885, 020161. [Google Scholar] [CrossRef]

- Casuso, M.; Rubio-Mateos, A.; Veiga, F.; Lamikiz, A. Influence of Axial Depth of Cut and Tool Position on Surface Quality and Chatter Appearance in Locally Supported Thin Floor Milling. Materials 2022, 15, 731. [Google Scholar] [CrossRef]

- Bustillo, A.; Urbikain, G.; Perez, J.M.; Pereira, O.M.; Lopez de Lacalle, L.N. Smart optimization of a friction-drilling process based on boosting ensembles. J. Manuf. Syst. 2018, 48, 108–121. [Google Scholar] [CrossRef]

- Rodríguez, A.; González, M.; Pereira, O.; López de Lacalle, N.L.; Esparta, M. Edge finishing of large turbine casings using defined multi-edge and abrasive tools in automated cells. Int. J. Adv. Manuf. Technol. 2023, 124, 3149–3159. [Google Scholar] [CrossRef]

- Rahman, H.; Yarali, E.; Zolfagharian, A.; Serjouei, A.; Bodaghi, M. Energy absorption and mechanical performance of functionally graded soft-hard lattice structures. Materials 2021, 14, 1366. [Google Scholar] [CrossRef]

- Cretu, G. Fundamentals of Experimental Research—Laboratory Handbook; “Gheorghe Asachi” Technical University of Iași: Iași, Romania, 1992. (In Romanian) [Google Scholar]

- Worthing, A.G.; Geffner, J. Treatment of Experimental Data; Editura Tehnică Publishing House: Bucharest, Romania, 1959. (In Romanian) [Google Scholar]

- Crețu, G.; Varvara, G. Experimental Research Methods in Machine Manufacturing; Publishing House Junimea: Iași, România, 1999. (In Romanian) [Google Scholar]

| Exp. No. | Input Factors (Coded Value/Real Value) | Wall Deviation, ε, mm | |||||

|---|---|---|---|---|---|---|---|

| Cutting Speed, Coded Value/, Real Value vc, m/min/Rotation Speed, n, rev/min | Feed Rate, Coded Value/fmin, mm/min/fz, mm/Tooth | Thickness of the Milling Cutter, Coded Value/Real Value, tt mm | Wall Thickness, Coded Value/Real Value, tw, mm | Wall Width, ww, mm | Wall Height, hw, mm | ||

| 1 | 1/98.91/500 | 1/100/0.0047 | 1/1.2 | 1/0.2 | 10 | 14.7 | 2.45 |

| 10 | 9 | 2.17 | |||||

| 10 | 6 | 1.92 | |||||

| 5 | 14.7 | 1.83 | |||||

| 5 | 9 | 2.21 | |||||

| 5 | 6 | 2.03 | |||||

| 2 | 1/98.91/500 | 1/100/0.0047 | 1/1.2 | 2/0.8 | 10 | 14.7 | 11.5 |

| 10 | 9 | 6.92 | |||||

| 10 | 6 | 4.19 | |||||

| 5 | 14.7 | 9.92 | |||||

| 5 | 9 | 5.05 | |||||

| 5 | 6 | 2.16 | |||||

| 3 | 1/62.31/315 | 2/100/0.0075 | 2/1.54 | 1/0.4 | 10 | 14.7 | 7.70 |

| 10 | 9 | 4.19 | |||||

| 10 | 6 | 2.23 | |||||

| 5 | 14.7 | 6.37 | |||||

| 5 | 9 | 3.28 | |||||

| 5 | 6 | 2.66 | |||||

| 4 | 1/62.31/315 | 2/160/0.0075 | 2/1.54 | 2/0.8 | 10 | 14.7 | 4.81 |

| 10 | 9 | 3.62 | |||||

| 10 | 6 | 2.65 | |||||

| 5 | 14.7 | 6.85 | |||||

| 5 | 9 | 2.81 | |||||

| 5 | 6 | 2.79 | |||||

| 5 | 2/98.91/500 | 1/100/0.0047 | 2/1.54 | 1/0.4 | 10 | 14.7 | 4.26 |

| 10 | 9 | 4.21 | |||||

| 10 | 6 | 2.67 | |||||

| 5 | 14.7 | 5.46 | |||||

| 5 | 9 | 3.77 | |||||

| 5 | 6 | 2.68 | |||||

| 6 | 2/98.91/500 | 1/100/0.0047 | 2/1.54 | 2/0.8 | 10 | 14.7 | 3.46 |

| 10 | 9 | 2.88 | |||||

| 10 | 6 | 2.54 | |||||

| 5 | 14.7 | 2.82 | |||||

| 5 | 9 | 2.57 | |||||

| 5 | 6 | 2.53 | |||||

| 7 | 2/158.25/800 | 2/250/0.0074 | 1/1.2 | 1/0.2 | 10 | 14.7 | 11.5 |

| 10 | 9 | 6.64 | |||||

| 10 | 6 | 3.84 | |||||

| 5 | 14.7 | 9.30 | |||||

| 5 | 9 | 4.25 | |||||

| 5 | 6 | 2.60 | |||||

| 8 | 2/158.25/800 | 2/250/0.0074 | 1/1.2 | 2/0.8 | 10 | 14.7 | 3.58 |

| 10 | 9 | 2.74 | |||||

| 10 | 6 | 2.25 | |||||

| 5 | 14.7 | 3.48 | |||||

| 5 | 9 | 2.65 | |||||

| 5 | 6 | 2.08 | |||||

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Hrițuc, A.; Mihalache, A.M.; Dodun, O.; Slătineanu, L.; Nagîț, G. Evaluation of Thin Wall Milling Ability Using Disc Cutters. Micromachines 2023, 14, 341. https://doi.org/10.3390/mi14020341

Hrițuc A, Mihalache AM, Dodun O, Slătineanu L, Nagîț G. Evaluation of Thin Wall Milling Ability Using Disc Cutters. Micromachines. 2023; 14(2):341. https://doi.org/10.3390/mi14020341

Chicago/Turabian StyleHrițuc, Adelina, Andrei Marius Mihalache, Oana Dodun, Laurențiu Slătineanu, and Gheorghe Nagîț. 2023. "Evaluation of Thin Wall Milling Ability Using Disc Cutters" Micromachines 14, no. 2: 341. https://doi.org/10.3390/mi14020341

APA StyleHrițuc, A., Mihalache, A. M., Dodun, O., Slătineanu, L., & Nagîț, G. (2023). Evaluation of Thin Wall Milling Ability Using Disc Cutters. Micromachines, 14(2), 341. https://doi.org/10.3390/mi14020341