Thin Film Piezoelectric Nanogenerator Based on (100)-Oriented Nanocrystalline AlN Grown by Pulsed Laser Deposition at Room Temperature

Abstract

1. Introduction

2. Experimental Section and Discussion

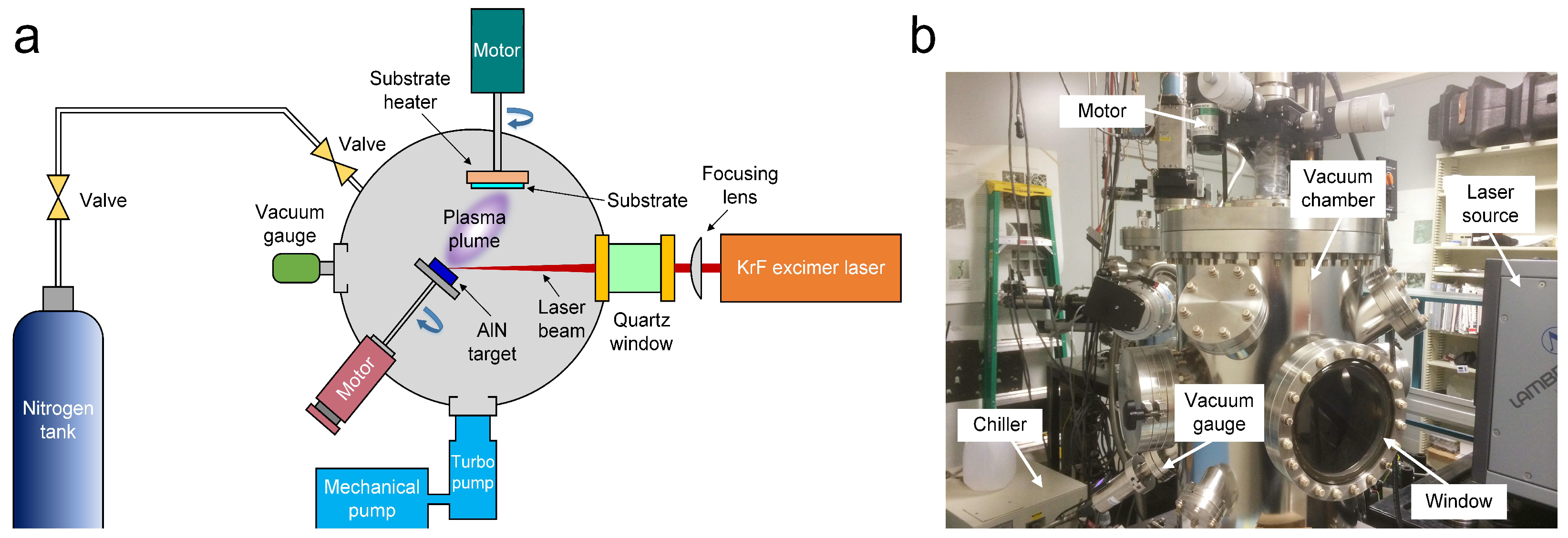

2.1. Fabrication of Flexible AlN Piezoelectric Nanogenerators

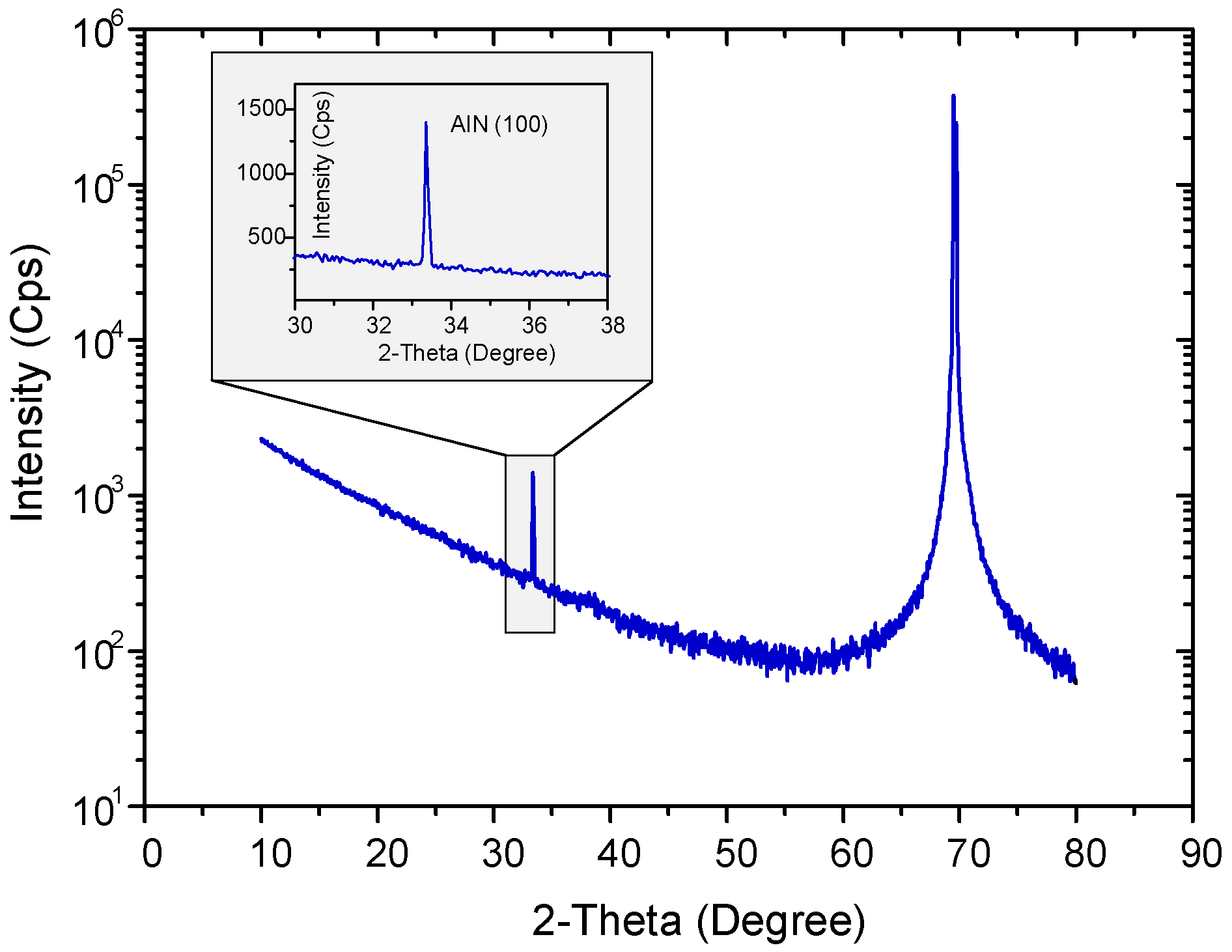

2.2. Characterization of AlN Thin Film

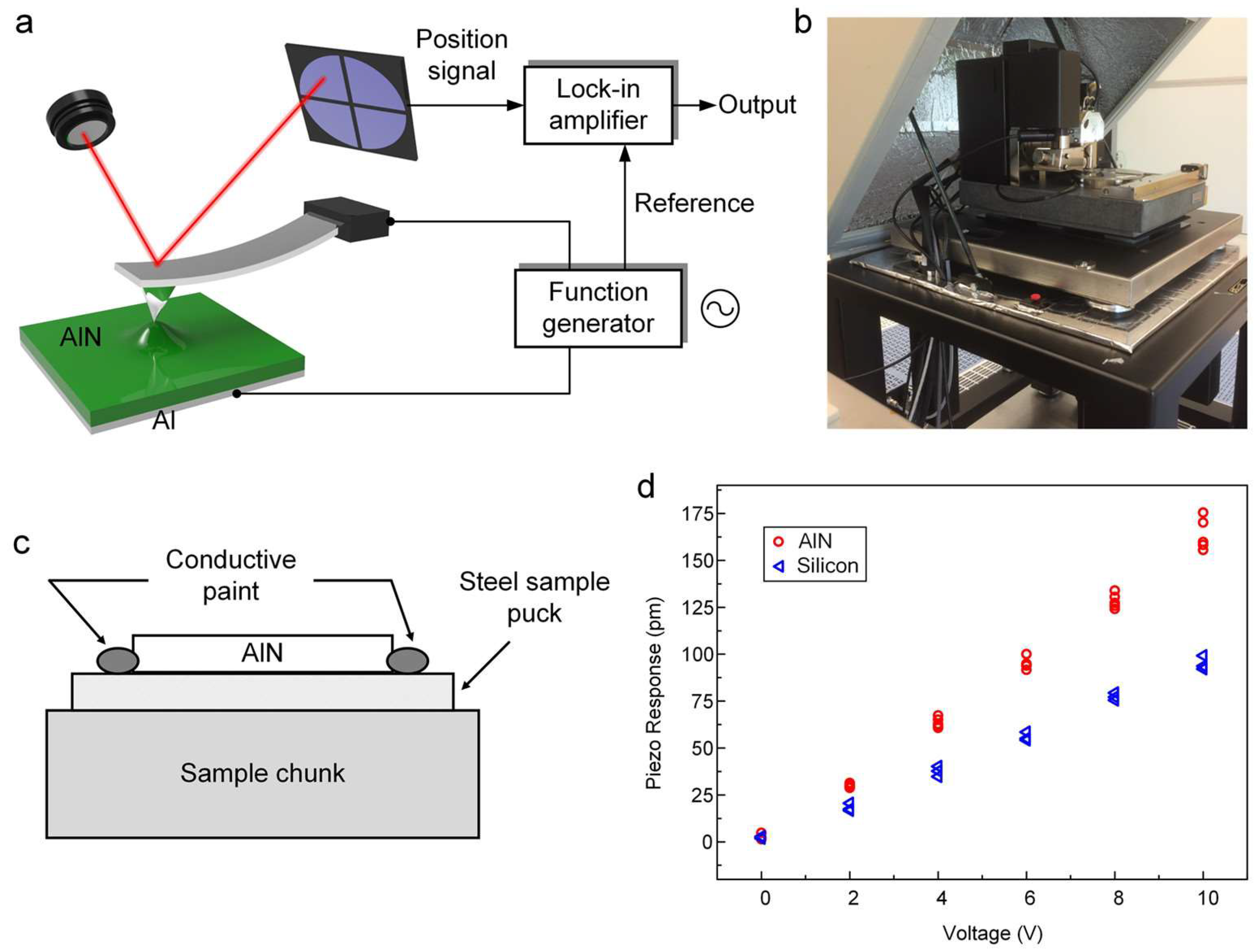

2.3. Piezoresponse Force Microscopy of AlN Thin Film

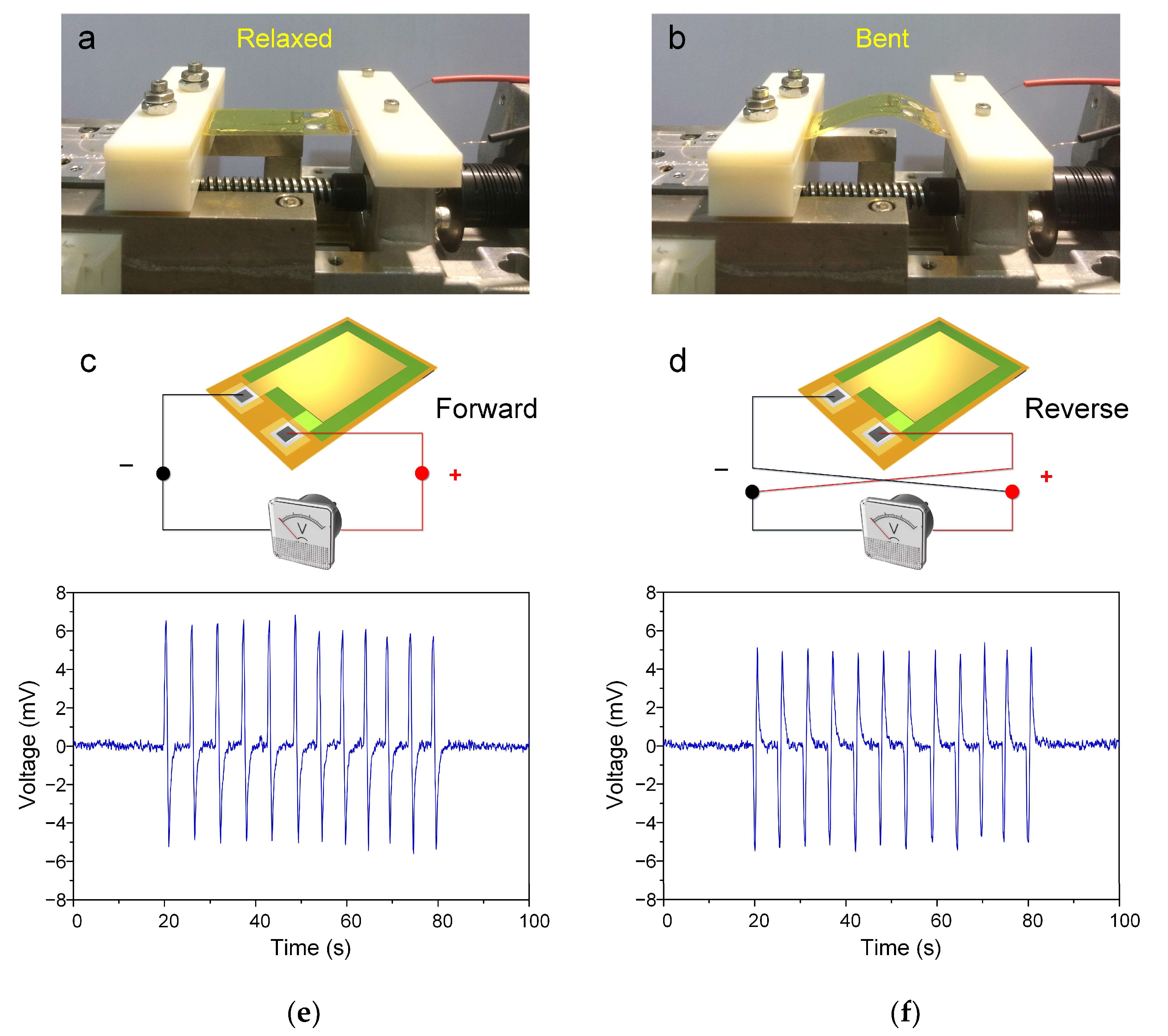

2.4. Energy Conversion of AlN-PNG

3. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Surmenev, R.A.; Chernozem, R.V.; Pariy, I.O.; Surmeneva, M.A. A Review on Piezo- and Pyroelectric Responses of Flexible Nano- and Micropatterned Polymer Surfaces for Biomedical Sensing and Energy Harvesting Applications. Nano Energy 2021, 79, 105442. [Google Scholar] [CrossRef]

- Feng, H.; Zhao, C.; Tan, P.; Liu, R.; Chen, X.; Li, Z. Nanogenerator for Biomedical Applications. Adv. Healthc. Mater. 2018, 7, 1701298. [Google Scholar] [CrossRef] [PubMed]

- Li, W.; Torres, D.; Díaz, R.; Wang, Z.; Wu, C.; Wang, C.; Lin Wang, Z.; Sepúlveda, N. Nanogenerator-Based Dual-Functional and Self-Powered Thin Patch Loudspeaker or Microphone for Flexible Electronics. Nat. Commun. 2017, 8, 15310. [Google Scholar] [CrossRef]

- Sun, M.; Li, Z.; Yang, C.; Lv, Y.; Yuan, L.; Shang, C.; Liang, S.; Guo, B.; Liu, Y.; Li, Z.; et al. Nanogenerator-Based Devices for Biomedical Applications. Nano Energy 2021, 89, 106461. [Google Scholar] [CrossRef]

- Haq, M. Application of Piezo Transducers in Biomedical Science for Health Monitoring and Energy Harvesting Problems. Mater. Res. Express 2018, 6, 022002. [Google Scholar] [CrossRef]

- Li, W.; Torres, D.; Wang, T.; Wang, C.; Sepúlveda, N. Flexible and Biocompatible Polypropylene Ferroelectret Nanogenerator (FENG): On the Path toward Wearable Devices Powered by Human Motion. Nano Energy 2016, 30, 649–657. [Google Scholar] [CrossRef]

- Cao, Y.; Li, W.; Sepulveda, N. Performance of Self-Powered, Water-Resistant Bending Sensor Using Transverse Piezoelectric Effect of Polypropylene Ferroelectret Polymer. IEEE Sens. J. 2019, 19, 10327–10335. [Google Scholar] [CrossRef]

- Cao, Y.; Li, W.; Figueroa, J.; Wang, T.; Torres, D.; Wang, C.; Wang, Z.L.; Sepúlveda, N. Impact-Activated Programming of Electro-Mechanical Resonators through Ferroelectret Nanogenerator (FENG) and Vanadium Dioxide. Nano Energy 2018, 43, 278–284. [Google Scholar] [CrossRef]

- Liu, H.; Zhong, J.; Lee, C.; Lee, S.-W.; Lin, L. A Comprehensive Review on Piezoelectric Energy Harvesting Technology: Materials, Mechanisms, and Applications. Appl. Phys. Rev. 2018, 5, 041306. [Google Scholar] [CrossRef]

- Dagdeviren, C.; Shi, Y.; Joe, P.; Ghaffari, R.; Balooch, G.; Usgaonkar, K.; Gur, O.; Tran, P.L.; Crosby, J.R.; Meyer, M.; et al. Conformal Piezoelectric Systems for Clinical and Experimental Characterization of Soft Tissue Biomechanics. Nat. Mater. 2015, 14, 728–736. [Google Scholar] [CrossRef]

- Dagdeviren, C.; Yang, B.D.; Su, Y.; Tran, P.L.; Joe, P.; Anderson, E.; Xia, J.; Doraiswamy, V.; Dehdashti, B.; Feng, X.; et al. Conformal Piezoelectric Energy Harvesting and Storage from Motions of the Heart, Lung, and Diaphragm. Proc. Natl. Acad. Sci. USA 2014, 111, 1927–1932. [Google Scholar] [CrossRef]

- Lin, M.; Hu, H.; Zhou, S.; Xu, S. Soft Wearable Devices for Deep-Tissue Sensing. Nat. Rev. Mater. 2022, 7, 850–869. [Google Scholar] [CrossRef]

- Lin, W.; Wang, B.; Peng, G.; Shan, Y.; Hu, H.; Yang, Z. Skin-Inspired Piezoelectric Tactile Sensor Array with Crosstalk-Free Row+Column Electrodes for Spatiotemporally Distinguishing Diverse Stimuli. Adv. Sci. 2021, 8, 2002817. [Google Scholar] [CrossRef] [PubMed]

- Dong, L.; Jin, C.; Closson, A.B.; Trase, I.; Richards, H.C.; Chen, Z.; Zhang, J.X.J. Cardiac Energy Harvesting and Sensing Based on Piezoelectric and Triboelectric Designs. Nano Energy 2020, 76, 105076. [Google Scholar] [CrossRef]

- Azimi, S.; Golabchi, A.; Nekookar, A.; Rabbani, S.; Amiri, M.H.; Asadi, K.; Abolhasani, M.M. Self-Powered Cardiac Pacemaker by Piezoelectric Polymer Nanogenerator Implant. Nano Energy 2021, 83, 105781. [Google Scholar] [CrossRef]

- Liu, L.; Chen, B.; Liu, K.; Gao, J.; Ye, Y.; Wang, Z.; Qin, N.; Wilson, D.A.; Tu, Y.; Peng, F. Wireless Manipulation of Magnetic/Piezoelectric Micromotors for Precise Neural Stem-Like Cell Stimulation. Adv. Funct. Mater. 2020, 30, 1910108. [Google Scholar] [CrossRef]

- Xu, Q.; Gao, X.; Zhao, S.; Liu, Y.; Zhang, D.; Zhou, K.; Khanbareh, H.; Chen, W.; Zhang, Y.; Bowen, C. Construction of Bio-Piezoelectric Platforms: From Structures and Synthesis to Applications. Adv. Mater. 2021, 33, 2008452. [Google Scholar] [CrossRef]

- Park, K.-I.; Son, J.H.; Hwang, G.-T.; Jeong, C.K.; Ryu, J.; Koo, M.; Choi, I.; Lee, S.H.; Byun, M.; Wang, Z.L. Highly-efficient, Flexible Piezoelectric PZT Thin Film Nanogenerator on Plastic Substrates. Adv. Mater. 2014, 26, 2514–2520. [Google Scholar] [CrossRef]

- Zou, D.; Liu, S.; Zhang, C.; Hong, Y.; Zhang, G.; Yang, Z. Flexible and Translucent PZT Films Enhanced by the Compositionally Graded Heterostructure for Human Body Monitoring. Nano Energy 2021, 85, 105984. [Google Scholar] [CrossRef]

- Liu, H.; Lin, X.; Zhang, S.; Huan, Y.; Huang, S.; Cheng, X. Enhanced Performance of Piezoelectric Composite Nanogenerator Based on Gradient Porous PZT Ceramic Structure for Energy Harvesting. J. Mater. Chem. A 2020, 8, 19631–19640. [Google Scholar] [CrossRef]

- Wankhade, S.H.; Tiwari, S.; Gaur, A.; Maiti, P. PVDF–PZT Nanohybrid Based Nanogenerator for Energy Harvesting Applications. Energy Rep. 2020, 6, 358–364. [Google Scholar] [CrossRef]

- Niu, X.; Jia, W.; Qian, S.; Zhu, J.; Zhang, J.; Hou, X.; Mu, J.; Geng, W.; Cho, J.; He, J. High-Performance PZT-Based Stretchable Piezoelectric Nanogenerator. ACS Sustain. Chem. Eng. 2018, 7, 979–985. [Google Scholar] [CrossRef]

- Li, W.; Chen, X. Compensation of Hysteresis in Piezoelectric Actuators without Dynamics Modeling. Sens. Actuators A Phys. 2013, 199, 89–97. [Google Scholar] [CrossRef]

- Li, W.; Chen, X.; Li, Z. Inverse Compensation for Hysteresis in Piezoelectric Actuator Using an Asymmetric Rate-Dependent Model. Rev. Sci. Instrum. 2013, 84, 115003. [Google Scholar] [CrossRef] [PubMed]

- Chen, X.; Li, W. A Monolithic Self-Sensing Precision Stage: Design, Modeling, Calibration, and Hysteresis Compensation. IEEE/ASME Trans. Mechatron. 2015, 20, 812–823. [Google Scholar] [CrossRef]

- Chen, Y.; Zhao, H.; Mao, J.; Chirarattananon, P.; Helbling, E.F.; Hyun, N.P.; Clarke, D.R.; Wood, R.J. Controlled Flight of a Microrobot Powered by Soft Artificial Muscles. Nature 2019, 575, 324–329. [Google Scholar] [CrossRef] [PubMed]

- Fath, A.; Xia, T.; Li, W. Recent Advances in the Application of Piezoelectric Materials in Microrobotic Systems. Micromachines 2022, 13, 1422. [Google Scholar] [CrossRef] [PubMed]

- Suzuki, H.; Wood, R.J. Origami-Inspired Miniature Manipulator for Teleoperated Microsurgery. Nat. Mach. Intell. 2020, 2, 437–446. [Google Scholar] [CrossRef]

- Pradel, K.C.; Wu, W.; Ding, Y.; Wang, Z.L. Solution-Derived ZnO Homojunction Nanowire Films on Wearable Substrates for Energy Conversion and Self-Powered Gesture Recognition. Nano Lett. 2014, 14, 6897–6905. [Google Scholar] [CrossRef]

- Le, A.T.; Ahmadipour, M.; Pung, S.-Y. A Review on ZnO-Based Piezoelectric Nanogenerators: Synthesis, Characterization Techniques, Performance Enhancement and Applications. J. Alloys Compd. 2020, 844, 156172. [Google Scholar] [CrossRef]

- Lee, Y.-P.; Lin, C.-C.; Hsiao, C.-C.; Chou, P.-A.; Cheng, Y.-Y.; Hsieh, C.-C.; Dai, C.-A. Nanopiezoelectric Devices for Energy Generation Based on ZnO Nanorods/Flexible-Conjugated Copolymer Hybrids Using All Wet-Coating Processes. Micromachines 2019, 11, 14. [Google Scholar] [CrossRef]

- Qian, Y.; Cheng, Y.; Song, J.; Xu, Y.; Yuan, W.-E.; Fan, C.; Zheng, X. Mechano-informed Biomimetic Polymer Scaffolds by Incorporating Self-powered Zinc Oxide Nanogenerators Enhance Motor Recovery and Neural Function. Small 2020, 16, 2000796. [Google Scholar] [CrossRef] [PubMed]

- Lee, S.; Bae, S.-H.; Lin, L.; Yang, Y.; Park, C.; Kim, S.-W.; Cha, S.N.; Kim, H.; Park, Y.J.; Wang, Z.L. Super-flexible Nanogenerator for Energy Harvesting from Gentle Wind and as an Active Deformation Sensor. Adv. Funct. Mater. 2013, 23, 2445–2449. [Google Scholar] [CrossRef]

- Voiculescu, I.; Li, F.; Kowach, G.; Lee, K.-L.; Mistou, N.; Kastberg, R. Stretchable Piezoelectric Power Generators Based on ZnO Thin Films on Elastic Substrates. Micromachines 2019, 10, 661. [Google Scholar] [CrossRef] [PubMed]

- He, Q.; Li, X.; Zhang, J.; Zhang, H.; Briscoe, J. P–N Junction-Based ZnO Wearable Textile Nanogenerator for Biomechanical Energy Harvesting. Nano Energy 2021, 85, 105938. [Google Scholar] [CrossRef]

- Lee, E.; Park, J.; Yim, M.; Kim, Y.; Yoon, G. Characteristics of Piezoelectric ZnO/AlN− Stacked Flexible Nanogenerators for Energy Harvesting Applications. Appl. Phys. Lett. 2015, 106, 023901. [Google Scholar] [CrossRef]

- Akiyama, M.; Morofuji, Y.; Kamohara, T.; Nishikubo, K.; Ooishi, Y.; Tsubai, M.; Fukuda, O.; Ueno, N. Preparation of Oriented Aluminum Nitride Thin Films on Polyimide Films and Piezoelectric Response with High Thermal Stability and Flexibility. Adv. Funct. Mater. 2007, 17, 458–462. [Google Scholar] [CrossRef]

- Shih, W.-C.; Chen, Y.-C.; Chang, W.-T.; Cheng, C.-C.; Liao, P.-C.; Kao, K.-S. Design and Fabrication of Nanoscale IDTs Using Electron Beam Technology for High-Frequency SAW Devices. J. Nanomater. 2014, 2014, 643672. [Google Scholar] [CrossRef]

- Bi, X.; Wu, Y.; Wu, J.; Li, H.; Zhou, L. A Model for Longitudinal Piezoelectric Coefficient Measurement of the Aluminum Nitride Thin Films. J. Mater. Sci. Mater. Electron. 2014, 25, 2435–2442. [Google Scholar] [CrossRef]

- Trolier-McKinstry, S.; Muralt, P. Thin Film Piezoelectrics for MEMS. J. Electroceram. 2004, 12, 7–17. [Google Scholar] [CrossRef]

- Radi, Z.; Lábár, J.L.; Barna, P.B. Diffusion Coefficient of Al in Metastable, Amorphous Al–Pt Phase. Appl. Phys. Lett. 1998, 73, 3220–3222. [Google Scholar] [CrossRef]

- Pinto, R.M.; Gund, V.; Dias, R.A.; Nagaraja, K.; Vinayakumar, K. CMOS-Integrated Aluminum Nitride MEMS: A Review. J. Microelectromech. Syst. 2022, 31, 500–523. [Google Scholar] [CrossRef]

- Yue, Y.; Sun, M.; Chen, J.; Yan, X.; He, Z.; Zhang, J.; Sun, W. Improvement of Crystal Quality of AlN Films with Different Polarities by Annealing at High Temperature. Micromachines 2022, 13, 129. [Google Scholar] [CrossRef] [PubMed]

- Fei, S.; Ren, H. Temperature Characteristics of a Contour Mode MEMS AlN Piezoelectric Ring Resonator on SOI Substrate. Micromachines 2021, 12, 143. [Google Scholar] [CrossRef] [PubMed]

- Gablech, I.; Klempa, J.; Pekárek, J.; Vyroubal, P.; Hrabina, J.; Holá, M.; Kunz, J.; Brodský, J.; Neužil, P. Simple and Efficient AlN-Based Piezoelectric Energy Harvesters. Micromachines 2020, 11, 143. [Google Scholar] [CrossRef] [PubMed]

- Gupta, S.; Yogeswaran, N.; Giacomozzi, F.; Lorenzelli, L.; Dahiya, R. Flexible AlN Coupled MOSFET Device for Touch Sensing. In Proceedings of the 2018 IEEE SENSORS, New Delhi, India, 28–31 October 2018; pp. 1–4. [Google Scholar]

- Xu, C.; Piazza, G. Magnet-Less Circulator Using AlN MEMS Filters and CMOS RF Switches. J. Microelectromech. Syst. 2019, 28, 409–418. [Google Scholar] [CrossRef]

- Gao, A.; Liu, K.; Liang, J.; Wu, T. AlN MEMS Filters with Extremely High Bandwidth Widening Capability. Microsyst. Nanoeng. 2020, 6, 74. [Google Scholar] [CrossRef]

- Strite, A.S.; Morkoç, H. GaN, AlN, and InN: A Review. J. Vac. Sci. Technol. B Microelectron. Nanometer Struct. Process. Meas. Phenom. 1992, 10, 1237–1266. [Google Scholar] [CrossRef]

- Schander, A.; Gancz, J.M.; Tintelott, M.; Lang, W. Towards Long-Term Stable Polyimide-Based Flexible Electrical Insulation for Chronically Implanted Neural Electrodes. Micromachines 2021, 12, 1279. [Google Scholar] [CrossRef]

- Huang, X.; Ge, G.; She, M.; Ma, Q.; Lu, Y.; Zhao, W.; Shen, Q.; Wang, Q.; Shao, J. Self-Healing Hydrogel with Multiple Dynamic Interactions for Multifunctional Epidermal Sensor. Appl. Surf. Sci. 2022, 598, 153803. [Google Scholar] [CrossRef]

- Ge, G.; Zhang, Y.-Z.; Zhang, W.; Yuan, W.; El-Demellawi, J.K.; Zhang, P.; Di Fabrizio, E.; Dong, X.; Alshareef, H.N. Ti3C2Tx MXene-Activated Fast Gelation of Stretchable and Self-Healing Hydrogels: A Molecular Approach. ACS Nano 2021, 15, 2698–2706. [Google Scholar] [CrossRef] [PubMed]

- Ge, G.; Wang, Q.; Zhang, Y.-Z.; Alshareef, H.N.; Dong, X. 3D Printing of Hydrogels for Stretchable Ionotronic Devices. Adv. Funct. Mater. 2021, 31, 2107437. [Google Scholar] [CrossRef]

- Kalinin, S.V.; Rar, A.; Jesse, S. A Decade of Piezoresponse Force Microscopy: Progress, Challenges, and Opportunities. IEEE Trans. Ultrason. Ferroelectr. Freq. Control 2006, 53, 2226–2252. [Google Scholar] [CrossRef] [PubMed]

- Soergel, E. Piezoresponse Force Microscopy (PFM). J. Phys. D Appl. Phys. 2011, 44, 464003. [Google Scholar] [CrossRef]

- Lefki, K.; Dormans, G.J.M. Measurement of Piezoelectric Coefficients of Ferroelectric Thin Films. J. Appl. Phys. 1994, 76, 1764–1767. [Google Scholar] [CrossRef]

- Wright, A.F. Elastic Properties of Zinc-Blende and Wurtzite AlN, GaN, and InN. J. Appl. Phys. 1997, 82, 2833–2839. [Google Scholar] [CrossRef]

- Tonisch, K.; Cimalla, V.; Foerster, C.; Romanus, H.; Ambacher, O.; Dontsov, D. Piezoelectric Properties of Polycrystalline AlN Thin Films for MEMS Application. Sens. Actuators A Phys. 2006, 132, 658–663. [Google Scholar] [CrossRef]

- Reusch, M.; Holc, K.; Pletschen, W.; Kirste, L.; Žukauskaitė, A.; Yoshikawa, T.; Iankov, D.; Ambacher, O.; Lebedev, V. Analysis and Optimization of Sputter Deposited AlN-Layers for Flexural Plate Wave Devices. J. Vac. Sci. Technol. B Nanotechnol. Microelectron. Mater. Process. Meas. Phenom. 2016, 34, 052001. [Google Scholar] [CrossRef]

- Martin, F.; Muralt, P.; Dubois, M.-A.; Pezous, A. Thickness Dependence of the Properties of Highly C-Axis Textured AlN Thin Films. J. Vac. Sci. Technol. A Vac. Surf. Film. 2004, 22, 361–365. [Google Scholar] [CrossRef]

- Mortet, V.; Nesladek, M.; Haenen, K.; Morel, A.; D’Olieslaeger, M.; Vanecek, M. Physical Properties of Polycrystalline Aluminium Nitride Films Deposited by Magnetron Sputtering. Diam. Relat. Mater. 2004, 13, 1120–1124. [Google Scholar] [CrossRef]

- Li, Y.; Feng, J.; Zhao, Y.; Wang, J.; Xu, C. Ultrathin Flexible Linear-Piezoelectric ZnO Thin Film Actuators: Tuning the Piezoelectric Responses by in-Plane Epitaxial Strain. Appl. Surf. Sci. 2022, 599, 153969. [Google Scholar] [CrossRef]

- Christman, J.A.; Maiwa, H.; Kim, S.-H.; Kingon, A.I.; Nemanich, R.J. Piezoelectric Measurements with Atomic Force Microscopy. MRS Online Proc. Libr. (OPL) 1998, 541, 617. [Google Scholar] [CrossRef]

- Safari, A.; Akdogan, E.K. Piezoelectric and Acoustic Materials for Transducer Applications; Springer Science & Business Media: Berlin, Germany, 2008. [Google Scholar]

- Cibert, C.; Dutheil, P.; Champeaux, C.; Masson, O.; Trolliard, G.; Tetard, F.; Catherinot, A. Piezoelectric Characteristic of Nanocrystalline AlN Films Obtained by Pulsed Laser Deposition at Room Temperature. Appl. Phys. Lett. 2010, 97, 251906. [Google Scholar] [CrossRef]

- Cao, Y.; Figueroa, J.; Li, W.; Chen, Z.; Wang, Z.L.; Sepúlveda, N. Understanding the Dynamic Response in Ferroelectret Nanogenerators to Enable Self-Powered Tactile Systems and Human-Controlled Micro-Robots. Nano Energy 2019, 63, 103852. [Google Scholar] [CrossRef]

| Material | (pm/V) | Literature |

|---|---|---|

| AlN (002) | 4.15 | Tonisch et al. [58] |

| 6.8 | Reusch et al. [59] | |

| 2.8–5.2 | Martin et al. [60] | |

| 4.6–5.2 | Mortet et al. [61] | |

| ZnO (002) | 8.14 | Li et al. [62] |

| 13 | Christman et al. [63] | |

| 5.9 | Safari et al. [64] | |

| AlN (100) | 2.3–3.8 | Cibert et al. [65] |

| 5.9 | This work |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2022 by the author. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Li, W.; Cao, Y.; Sepúlveda, N. Thin Film Piezoelectric Nanogenerator Based on (100)-Oriented Nanocrystalline AlN Grown by Pulsed Laser Deposition at Room Temperature. Micromachines 2023, 14, 99. https://doi.org/10.3390/mi14010099

Li W, Cao Y, Sepúlveda N. Thin Film Piezoelectric Nanogenerator Based on (100)-Oriented Nanocrystalline AlN Grown by Pulsed Laser Deposition at Room Temperature. Micromachines. 2023; 14(1):99. https://doi.org/10.3390/mi14010099

Chicago/Turabian StyleLi, Wei, Yunqi Cao, and Nelson Sepúlveda. 2023. "Thin Film Piezoelectric Nanogenerator Based on (100)-Oriented Nanocrystalline AlN Grown by Pulsed Laser Deposition at Room Temperature" Micromachines 14, no. 1: 99. https://doi.org/10.3390/mi14010099

APA StyleLi, W., Cao, Y., & Sepúlveda, N. (2023). Thin Film Piezoelectric Nanogenerator Based on (100)-Oriented Nanocrystalline AlN Grown by Pulsed Laser Deposition at Room Temperature. Micromachines, 14(1), 99. https://doi.org/10.3390/mi14010099