Adhesion Evaluation of an Embedded SiN/GaAs Interface Using a Novel “Push-Out” Technique

Abstract

1. Introduction

2. Methodology

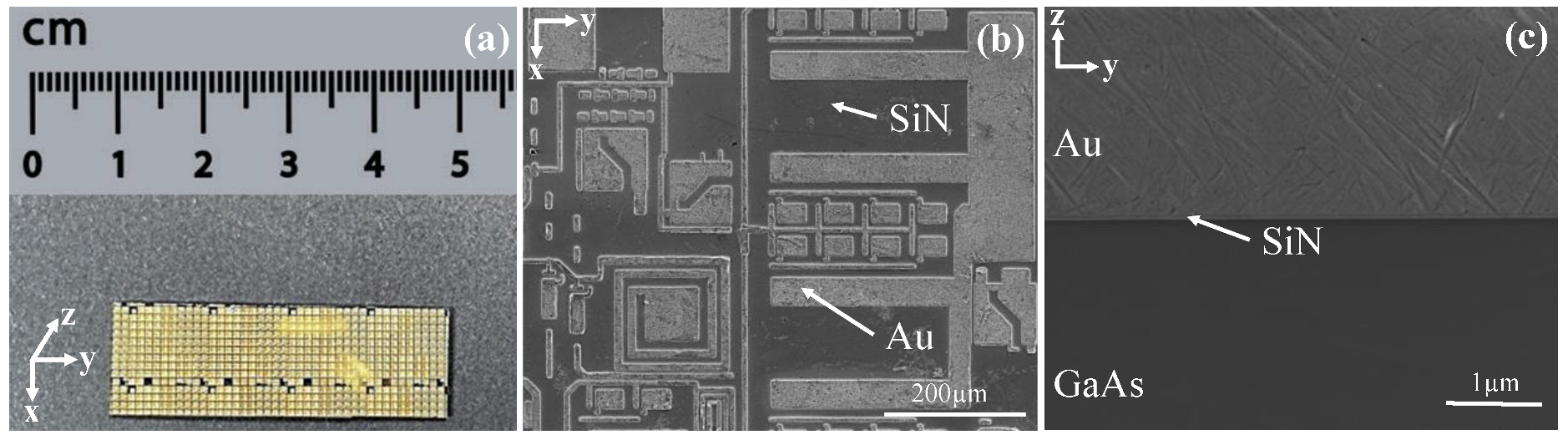

2.1. Sample Preparation

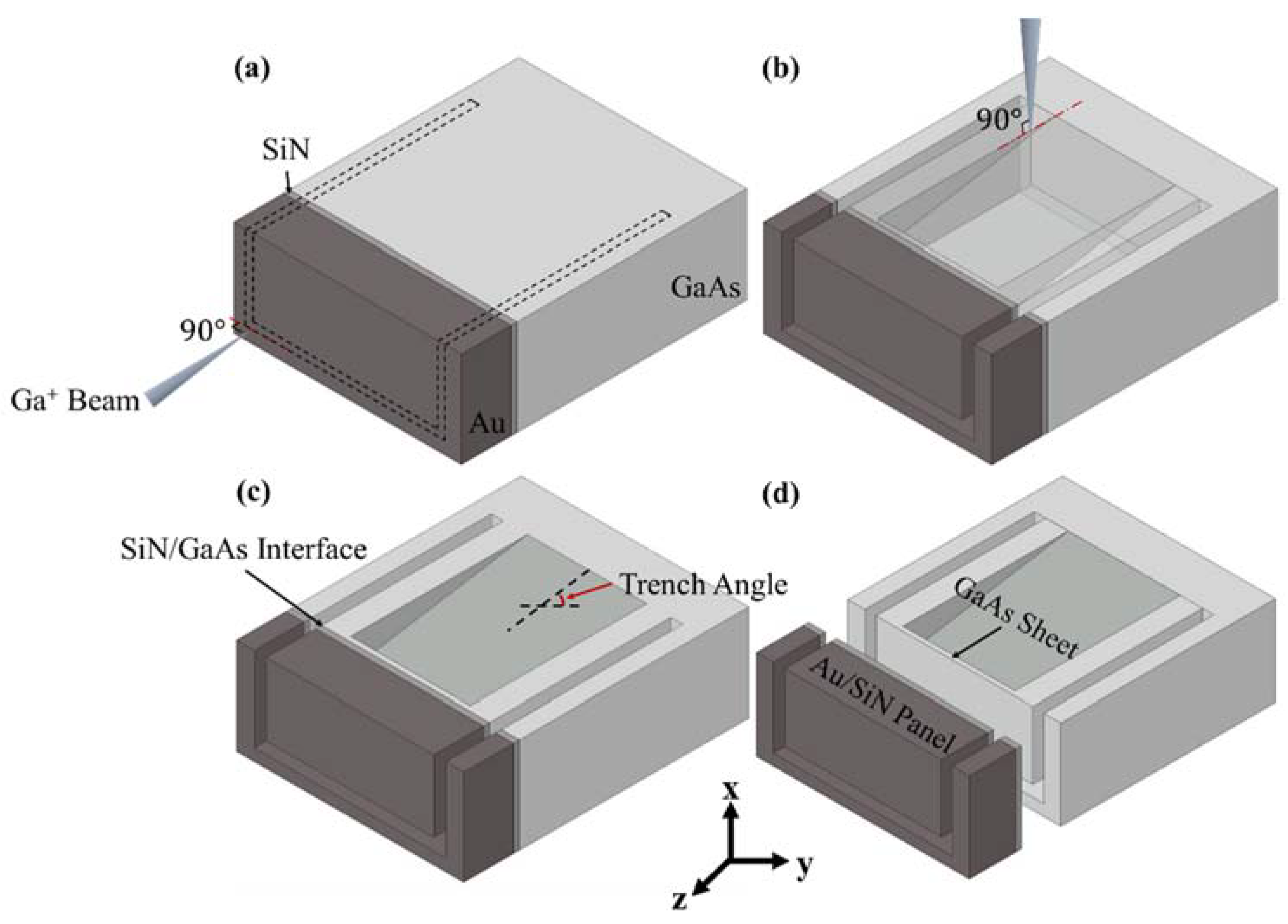

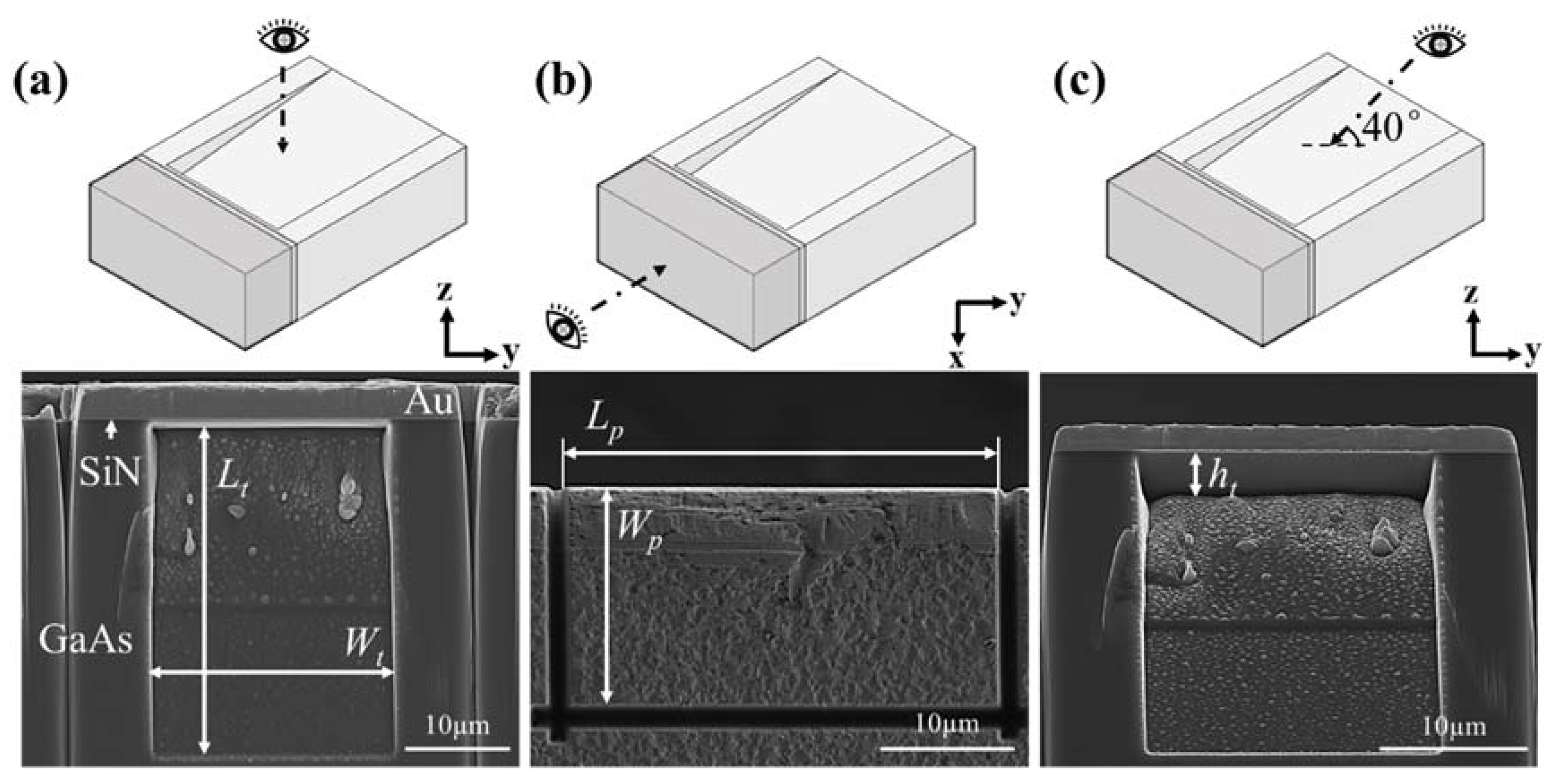

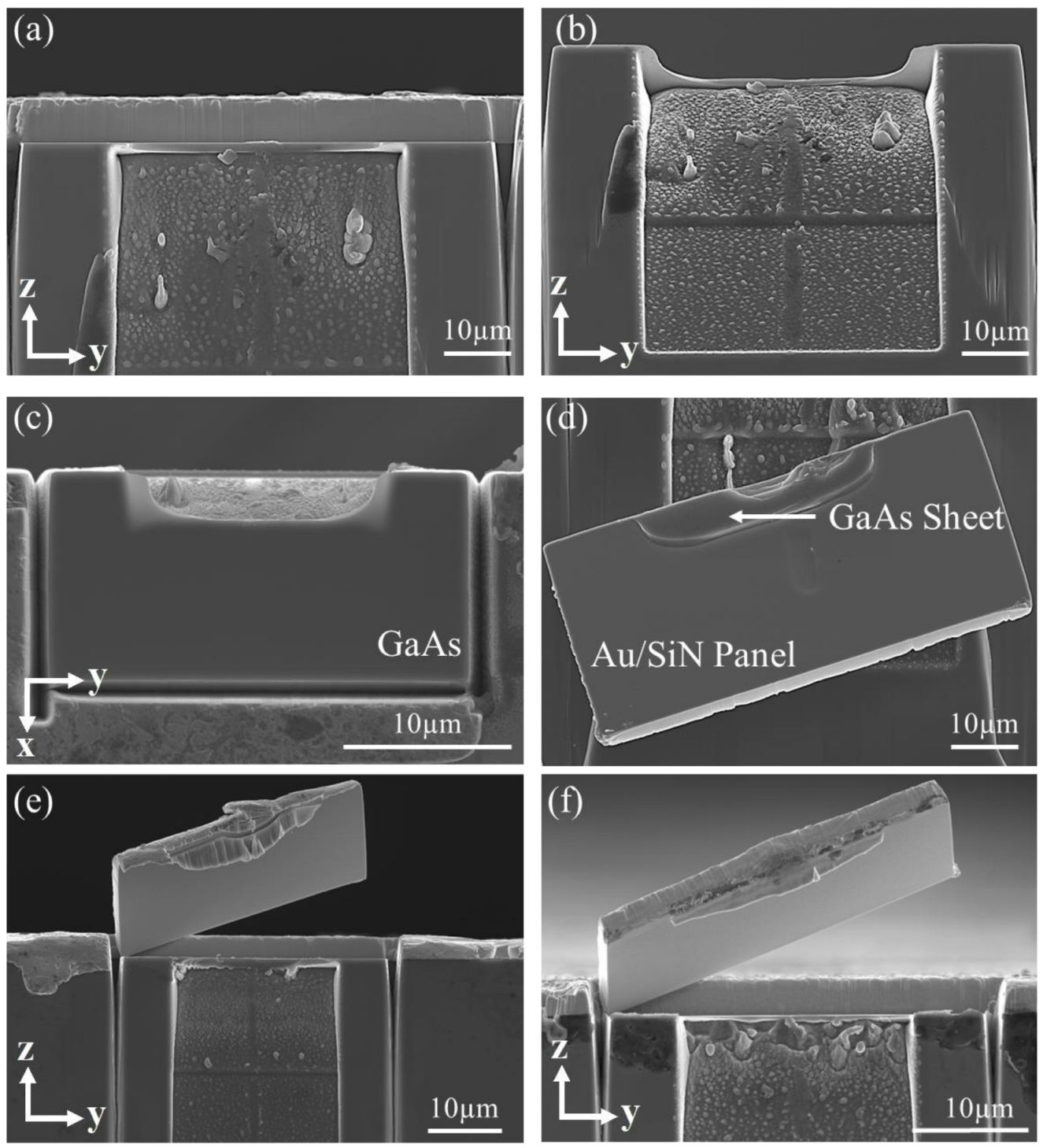

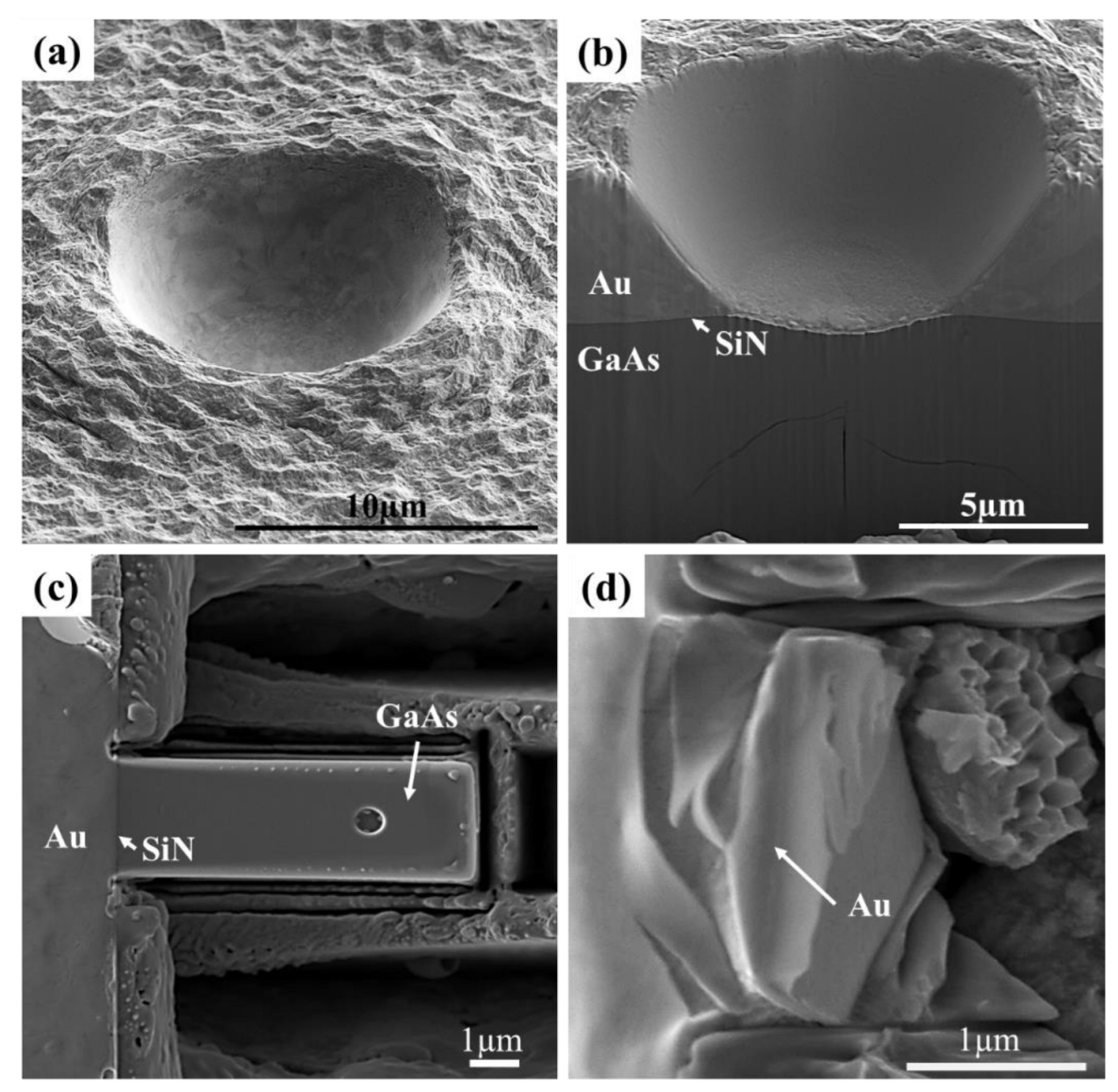

2.2. Focused Ion Beam (FIB) Milling of Push-Out Specimens

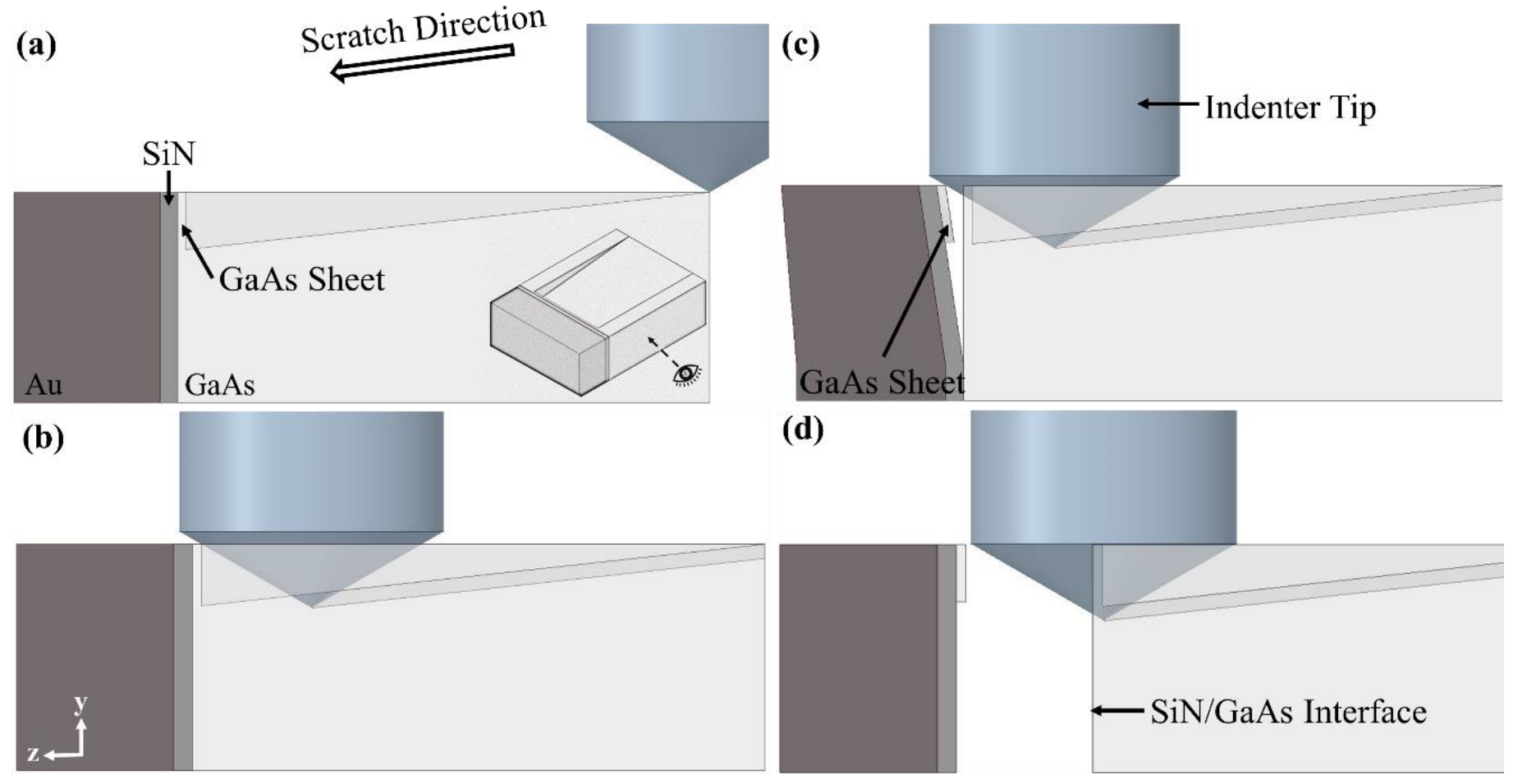

2.3. Push-Out Test

3. Results and Discussion

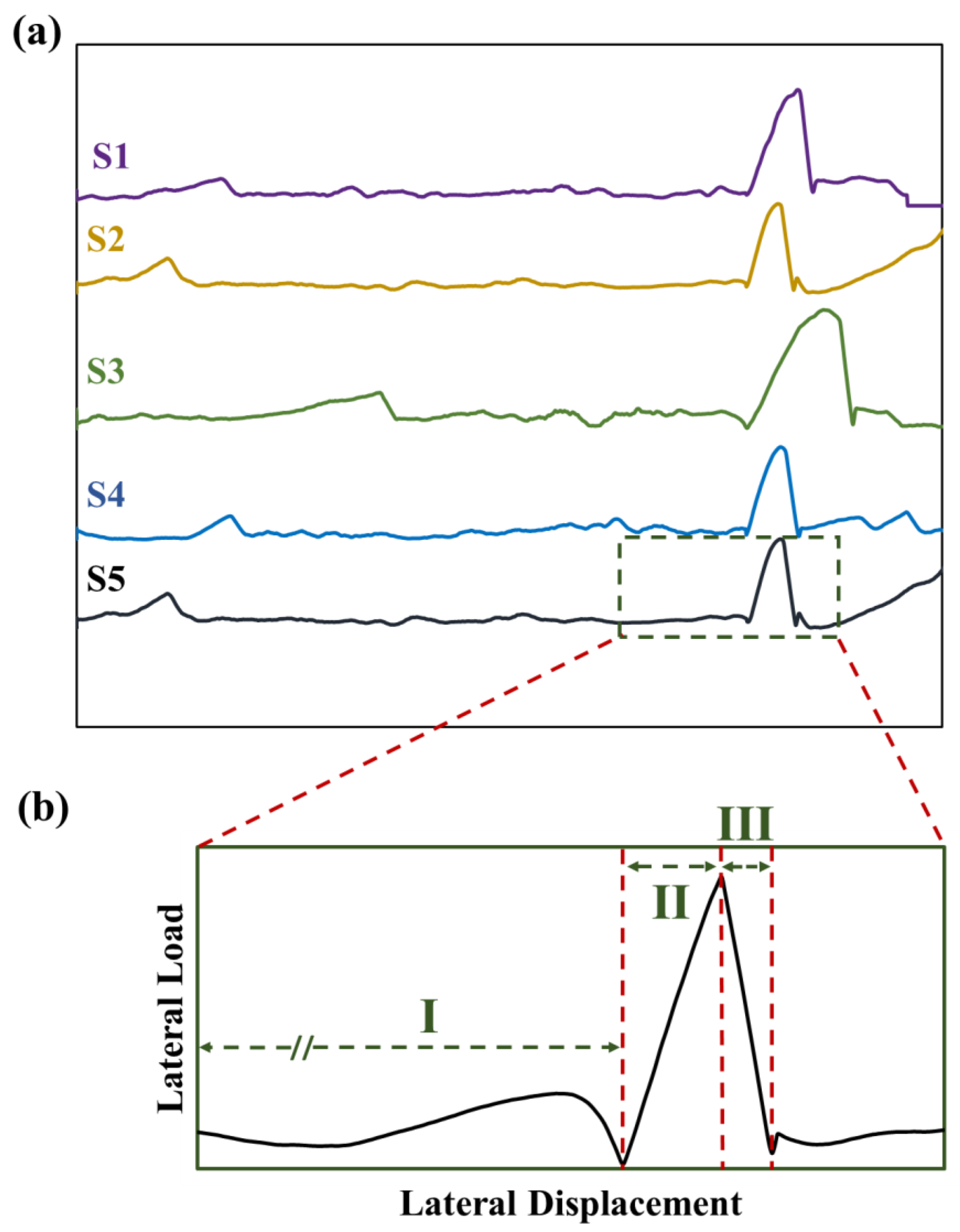

3.1. Interfacial Delamination

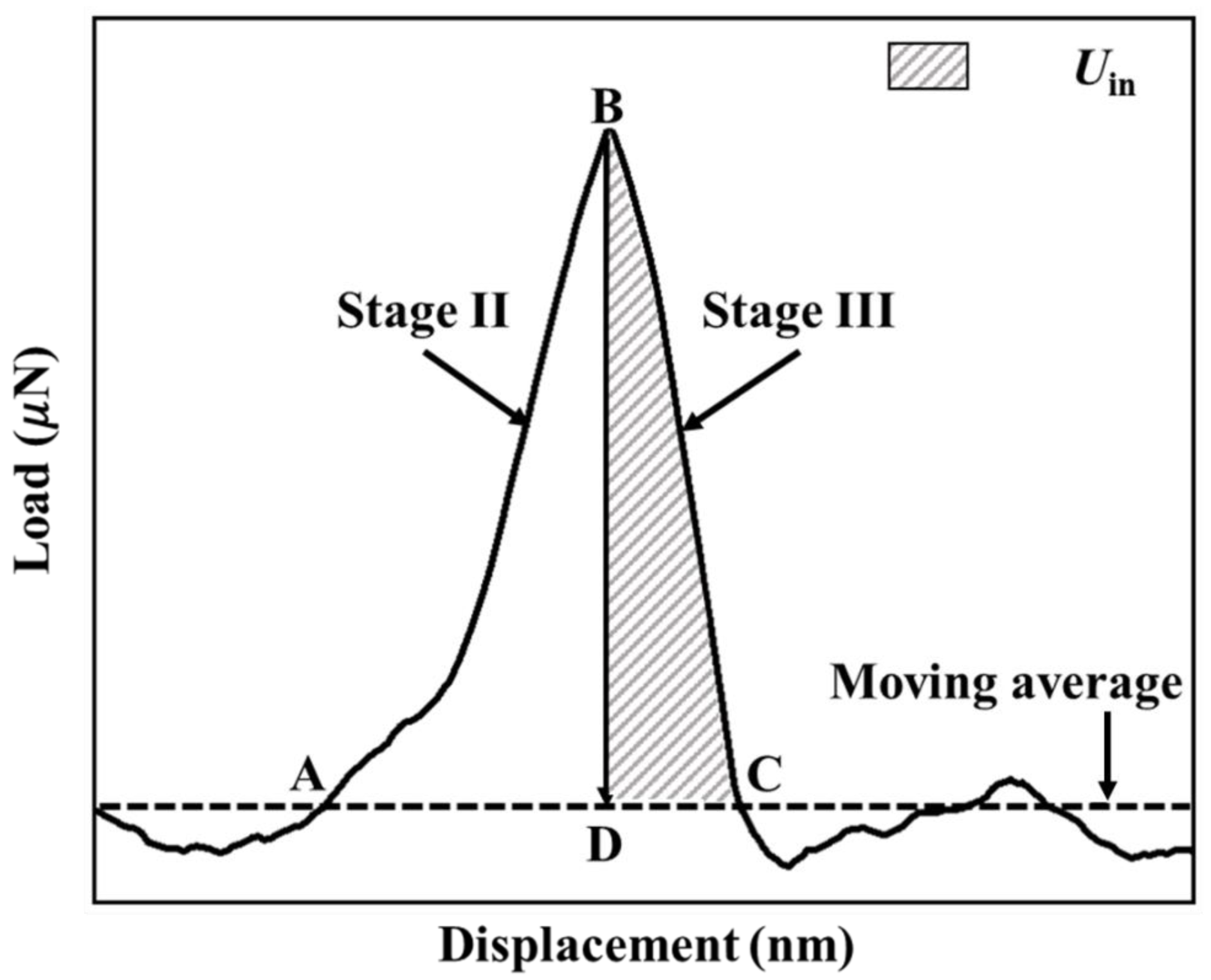

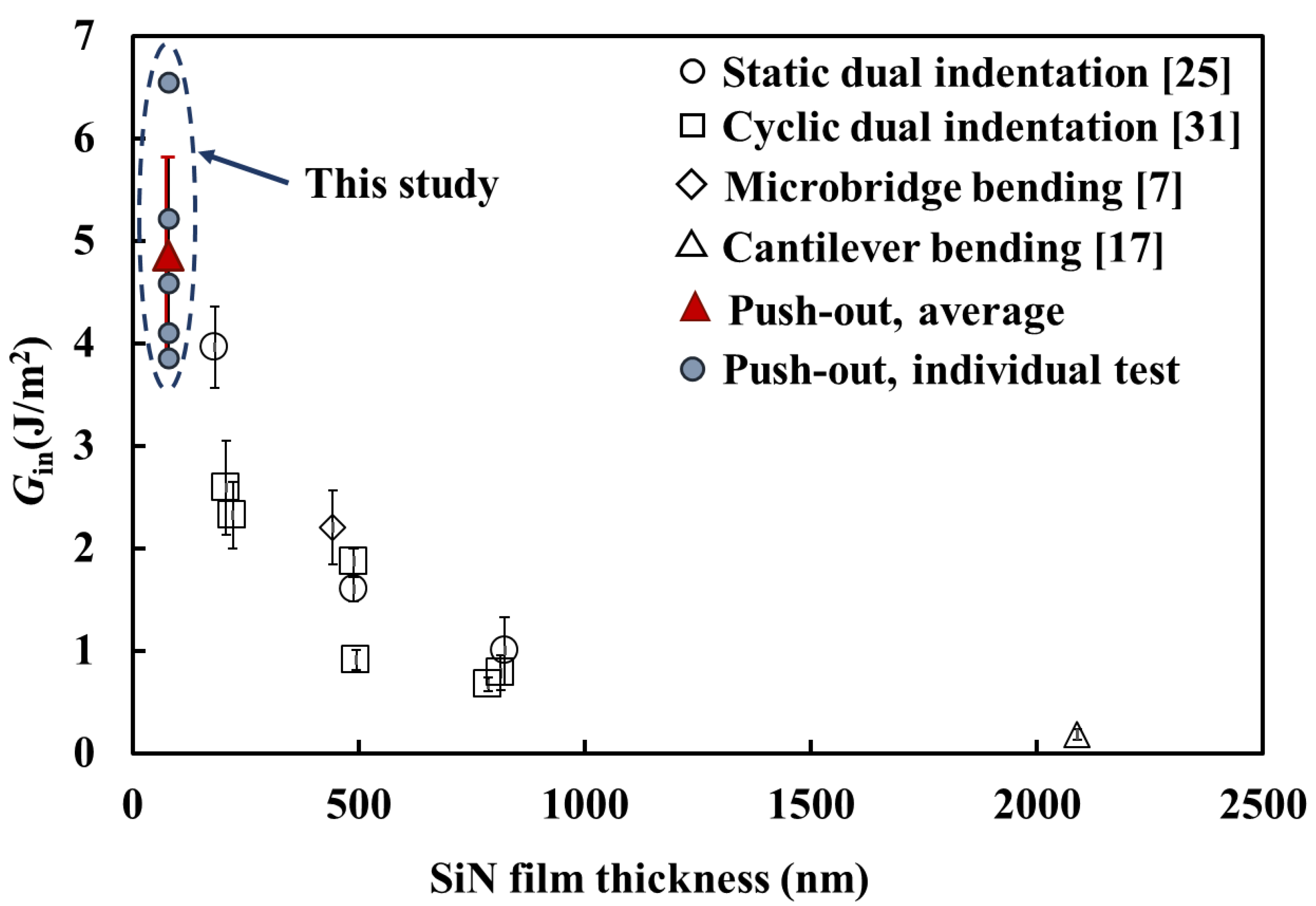

3.2. Interfacial Toughness (Gin)

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Khanna, V. Adhesion–delamination phenomena at the surfaces and interfaces in microelectronics and MEMS structures and packaged devices. J. Phys. D Appl. Phys. 2010, 44, 034004. [Google Scholar] [CrossRef]

- Gunda, M.; Kumar, P.; Katiyar, M. Review of Mechanical Characterization Techniques for Thin Films Used in Flexible Electronics. Crit. Rev. Solid State Mater. Sci. 2017, 42, 129–152. [Google Scholar] [CrossRef]

- Persano, A.; Quaranta, F.; Taurino, A.; Siciliano, P.A.; Iannacci, J. Thin Film Encapsulation for RF MEMS in 5G and Modern Telecommunication Systems. Sensors 2020, 20, 2133. [Google Scholar] [CrossRef] [PubMed]

- Chen, Z.; Zhou, K.; Lu, X.; Lam, Y.C. A review on the mechanical methods for evaluating coating adhesion. Acta Mech. 2014, 225, 431–452. [Google Scholar] [CrossRef]

- Lu, M.Y.; Xie, H.T.; Huang, H. Characterisation of interfacial adhesion of thin film/substrate systems using indentation-induced delamination: A focused review. Key Eng. Mater. 2013, 533, 201–222. [Google Scholar]

- Kim, H.-S.; Huh, J.; Ryu, J. Investigation of moisture-induced delamination failure in a semiconductor package via multi-scale mechanics. J. Phys. D Appl. Phys. 2010, 44, 034007. [Google Scholar] [CrossRef]

- Mead, J.L.; Lu, M.; Huang, H. Microscale interfacial adhesion assessment in a multilayer by a miniaturised four-point bending test. Mech. Mater. 2019, 129, 341–351. [Google Scholar] [CrossRef]

- Sánchez, J.; El-Mansy, S.; Sun, B.; Scherban, T.; Fang, N.; Pantuso, D.; Ford, W.; Elizalde, M.; Martínez-Esnaola, J.; Martín-Meizoso, A.; et al. Cross-sectional nanoindentation: A new technique for thin film interfacial adhesion characterization. Acta Mater. 1999, 47, 4405–4413. [Google Scholar] [CrossRef]

- Gorokhovsky, V. LAFAD-Assisted Plasma Surface Engineering Processes for Wear and Corrosion Protection: A Review. In Advanced Ceramic Coatings and Interfaces V; Ceramic Engineering and Science Proceedings; Wiley: New York, NY, USA, 2010; Volume 31, pp. 105–122. [Google Scholar]

- De Boer, M.; Gerberich, W. Microwedge indentation of the thin film fine line—I. Mechanics. Acta Mater. 1996, 44, 3169–3175. [Google Scholar] [CrossRef]

- Chang, S.-Y.; Tsai, H.-C.; Chang, J.-Y.; Lin, S.-J.; Chang, Y.-S. Analyses of interface adhesion between porous SiOCH low-k film and SiCN layers by nanoindentation and nanoscratch tests. Thin Solid Film. 2008, 516, 5334–5338. [Google Scholar] [CrossRef]

- Wang, X.; Wang, C.; Atkinson, A. Interface fracture toughness in thermal barrier coatings by cross-sectional indentation. Acta Mater. 2012, 60, 6152–6163. [Google Scholar] [CrossRef]

- Malzbender, J.; de With, G. Scratch testing of hybrid coatings on float glass. Surf. Coat. Technol. 2001, 135, 202–207. [Google Scholar] [CrossRef]

- Bull, S.; Berasetegui, E. An overview of the potential of quantitative coating adhesion measurement by scratch testing. Tribol. Int. 2006, 39, 99–114. [Google Scholar] [CrossRef]

- Mead, J.L.; Lu, M.; Huang, H. Inducing stable interfacial delamination in a multilayer system by four-point bending of microbridges. Surf. Coat. Technol. 2017, 320, 478–482. [Google Scholar] [CrossRef]

- Harry, E.; Rouzaud, A.; Ignat, M.; Juliet, P. Mechanical properties of W and W (C) thin films: Young’s modulus, fracture toughness and adhesion. Thin Solid Film. 1998, 332, 195–201. [Google Scholar] [CrossRef]

- Lin, W.; Zhao, Y.; Wang, F.; Huang, H.; Lu, M. Interfacial adhesion assessment of SiN/GaAs film/substrate system using microcantilever bending technique. J. Phys. D Appl. Phys. 2022, 55, 245104. [Google Scholar] [CrossRef]

- Lu, M.; Mead, J.; Wu, Y.; Russell, H.; Huang, H. A study of the deformation and failure mechanisms of protective intermetallic coatings on AZ91 Mg alloys using microcantilever bending. Mater. Charact. 2016, 120, 337–344. [Google Scholar] [CrossRef]

- Chen, J.; Bull, S. Approaches to investigate delamination and interfacial toughness in coated systems: An overview. J. Phys. D Appl. Phys. 2010, 44, 034001. [Google Scholar] [CrossRef]

- Marshall, D.B.; Cook, R.F.; Padture, N.P.; Oyen, M.L.; Pajares, A.; Bradby, J.E.; Reimanis, I.E.; Tandon, R.; Page, T.F.; Pharr, G.M.; et al. The compelling case for indentation as a functional exploratory and characterization tool. J. Am. Ceram. Soc. 2015, 98, 2671–2680. [Google Scholar] [CrossRef]

- Lu, M.; Russell, H.; Huang, H. Fracture strength characterization of protective intermetallic coatings on AZ91E Mg alloys using FIB-machined microcantilever bending technique. J. Mater. Res. 2015, 30, 1678–1685. [Google Scholar] [CrossRef]

- Hu, J.; Guan, X.; Choi, D.; Harris, J.S.; Saraswat, K.; Philip Wong, H.-S. Fermi Level Depinning for the Design of III–V FET Source/Drain Contacts. In Proceedings of the 2009 International Symposium on VLSI Technology, Systems, and Applications, Hsinchu, Taiwan, 27–29 April 2009. [Google Scholar]

- Yota, J. Interlevel dielectric processes using PECVD silicon nitride, polyimide, and polybenzoxazole for GaAs HBT technology. J. Electrochem. Soc. 2009, 156, G173. [Google Scholar] [CrossRef][Green Version]

- Gioti, M.; Logothetidis, S.; Charitidis, C. Stress relaxation and stability in thick amorphous carbon films deposited in layer structure. Appl. Phys. Lett. 1998, 73, 184–186. [Google Scholar] [CrossRef]

- Lu, M.; Huang, H. Determination of the energy release rate in the interfacial delamination of silicon nitride film on gallium arsenide substrate via nanoindentation. J. Mater. Res. 2014, 29, 801–810. [Google Scholar] [CrossRef]

- Utlaut, M. Focused Ion Beams for Nano-Machining And Imaging. In Nanolithography; Elsevier: Amsterdam, The Netherlands, 2014; pp. 116–157. [Google Scholar]

- Langford, R.M.; Nellen, P.M.; Gierak, J.; Fu, Y. Focused ion beam micro-and nanoengineering. MRS Bull. 2007, 32, 417–423. [Google Scholar] [CrossRef]

- Lawn, B.R. Fracture of Brittle Solids; Cambridge Solid State Science Series; Cambridge University Press: Cambridge, UK, 1993. [Google Scholar]

- Hainsworth, S.; McGurk, M.; Page, T. The effect of coating cracking on the indentation response of thin hard-coated systems. Surf. Coat. Technol. 1998, 102, 97–107. [Google Scholar] [CrossRef]

- Chen, J.; Bull, S.J. Indentation fracture and toughness assessment for thin optical coatings on glass. J. Phys. D Appl. Phys. 2007, 40, 5401–5417. [Google Scholar] [CrossRef]

- Lu, M.; Huang, H. Interfacial energy release rates of SiN/GaAs film/substrate systems determined using a cyclic loading dual-indentation method. Thin Solid Film. 2015, 589, 822–830. [Google Scholar] [CrossRef]

| Material | Thickness (µm) | Elastic Modulus (GPa) | Hardness (GPa) |

|---|---|---|---|

| Au | 3.3 | 48 | 0.7 ± 0.1 |

| SiN | 0.08 | 140 | 12.7 |

| GaAs | 650 | 122 | 8.2 |

| Specimens | Lp (µm) | Wp (µm) | ht (µm) | Lt (µm) | Wt (µm) |

|---|---|---|---|---|---|

| S1 | 36.0 | 20.0 | 3.8 | 33.5 | 22.5 |

| S2 | 32.9 | 16.2 | 3.1 | 28.5 | 20.5 |

| S3 | 32.9 | 16.5 | 2.9 | 28.8 | 20.7 |

| S4 | 32.2 | 17.0 | 3.3 | 28.5 | 20.6 |

| S5 | 32.6 | 16.0 | 3.8 | 28.5 | 20.6 |

| Specimen | Uin (J) | Ain (µm2) | Gin (J/m2) |

|---|---|---|---|

| S1 | 2323.00 | 601.09 | 3.86 |

| S2 | 1680.78 | 409.00 | 4.10 |

| S3 | 3106.90 | 474.00 | 6.55 |

| S4 | 2440.83 | 462.30 | 5.22 |

| S5 | 1989.60 | 433.30 | 4.59 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Dehkhoda, S.; Lu, M.; Huang, H. Adhesion Evaluation of an Embedded SiN/GaAs Interface Using a Novel “Push-Out” Technique. Micromachines 2023, 14, 37. https://doi.org/10.3390/mi14010037

Dehkhoda S, Lu M, Huang H. Adhesion Evaluation of an Embedded SiN/GaAs Interface Using a Novel “Push-Out” Technique. Micromachines. 2023; 14(1):37. https://doi.org/10.3390/mi14010037

Chicago/Turabian StyleDehkhoda, Sahar, Mingyuan Lu, and Han Huang. 2023. "Adhesion Evaluation of an Embedded SiN/GaAs Interface Using a Novel “Push-Out” Technique" Micromachines 14, no. 1: 37. https://doi.org/10.3390/mi14010037

APA StyleDehkhoda, S., Lu, M., & Huang, H. (2023). Adhesion Evaluation of an Embedded SiN/GaAs Interface Using a Novel “Push-Out” Technique. Micromachines, 14(1), 37. https://doi.org/10.3390/mi14010037