Input–Output-Improved Reservoir Computing Based on Duffing Resonator Processing Dynamic Temperature Compensation for MEMS Resonant Accelerometer

Abstract

1. Introduction

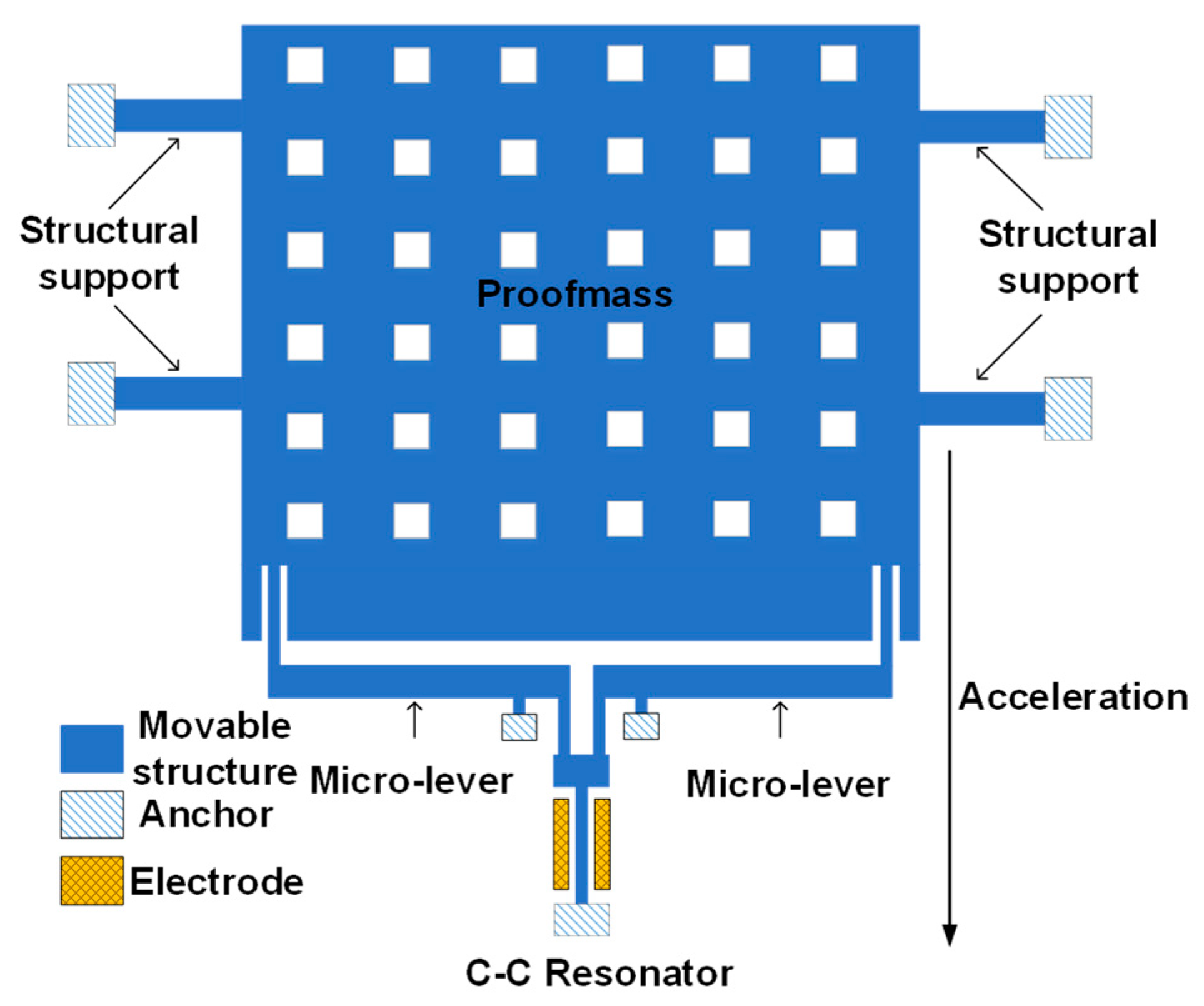

2. Materials and Methods

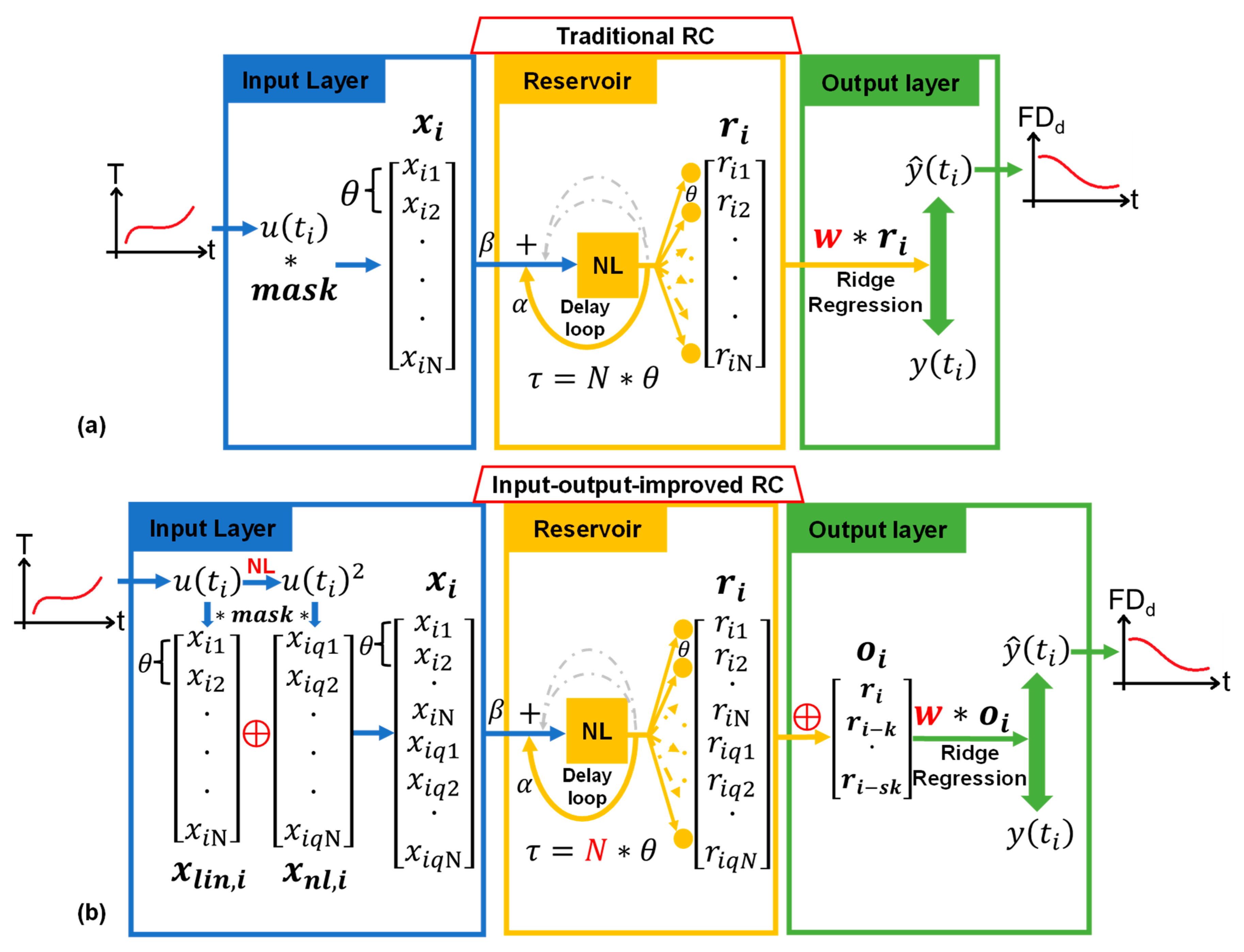

2.1. Input–Output-Improved Reservoir Computing

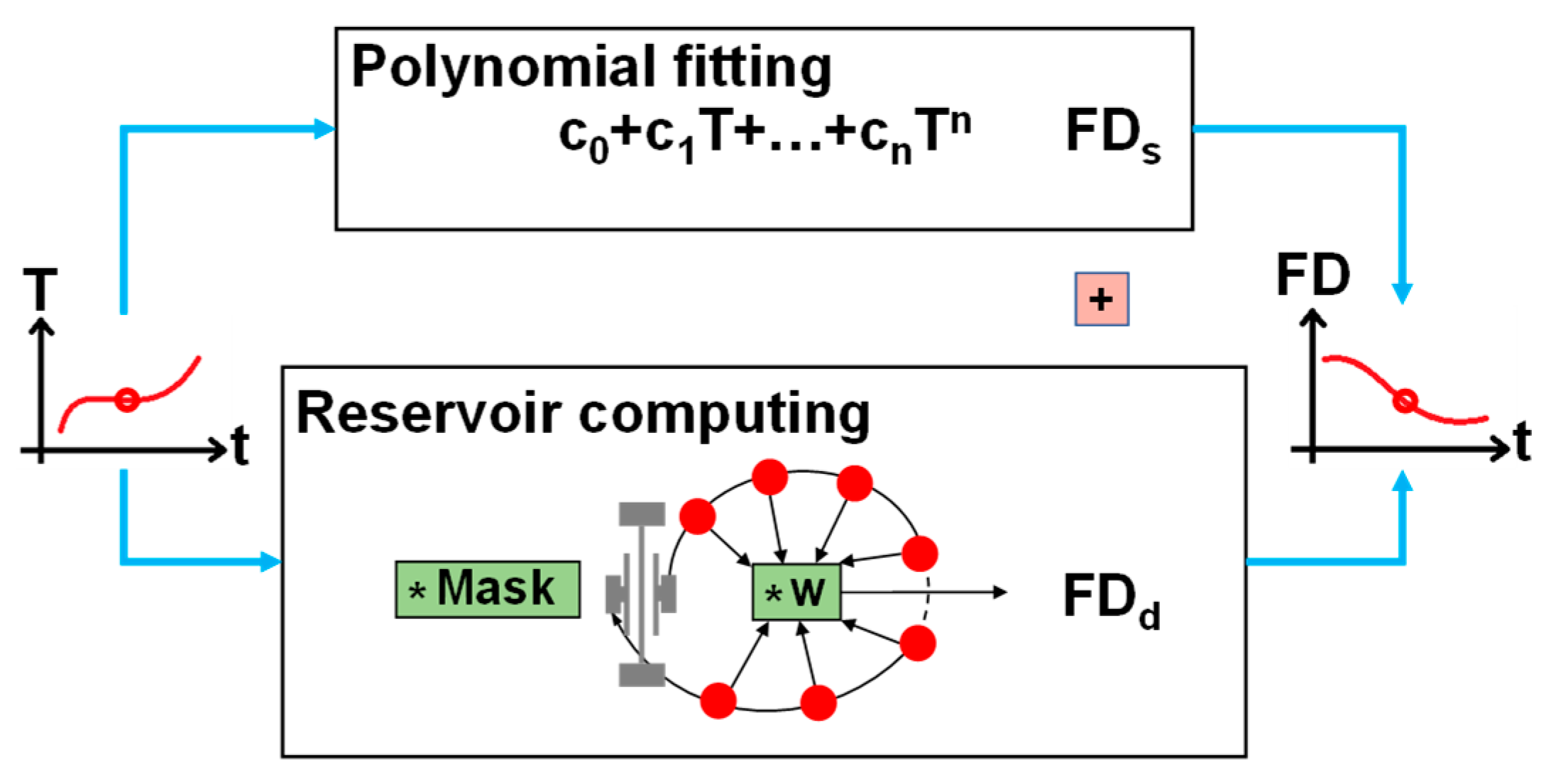

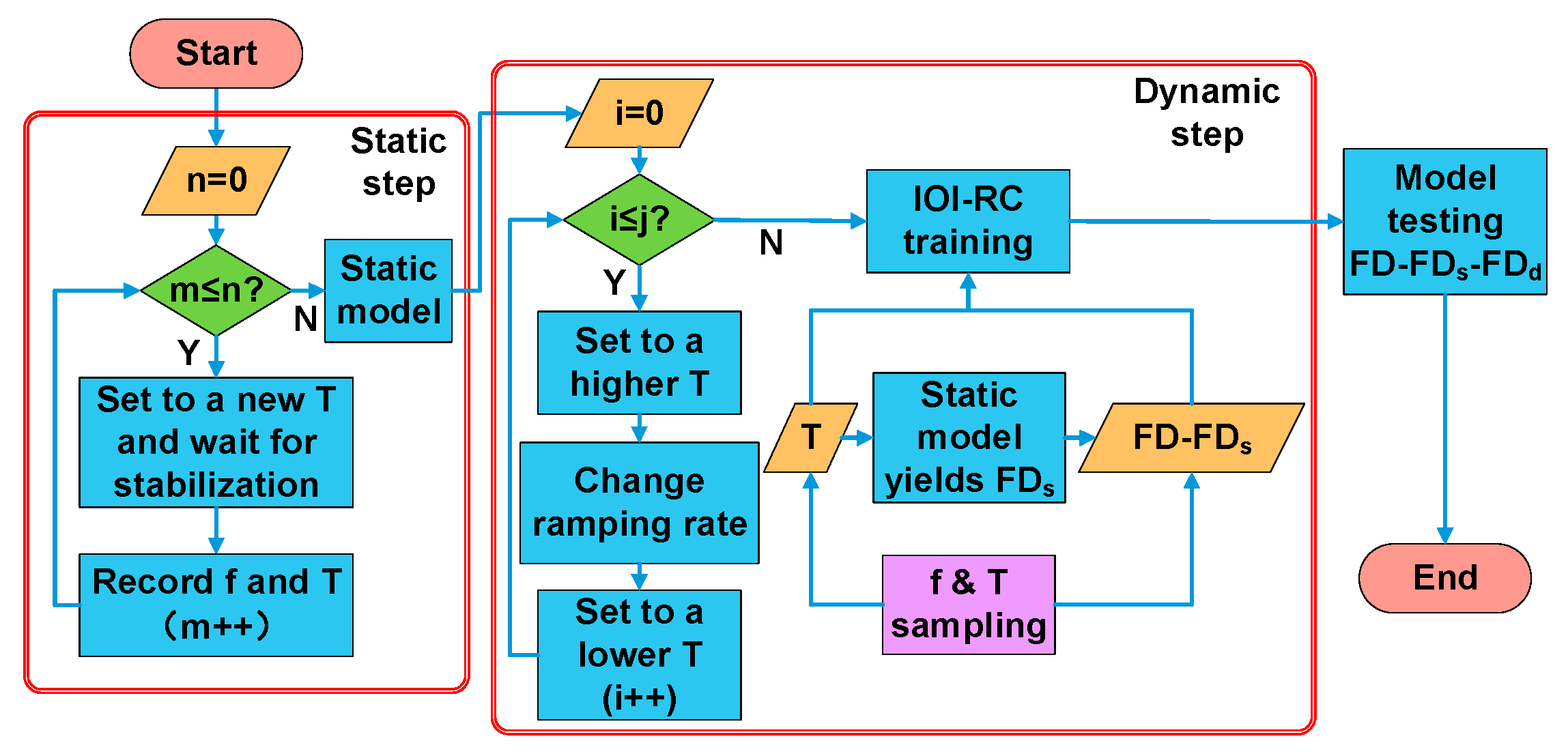

2.2. Temperature Compensation Method

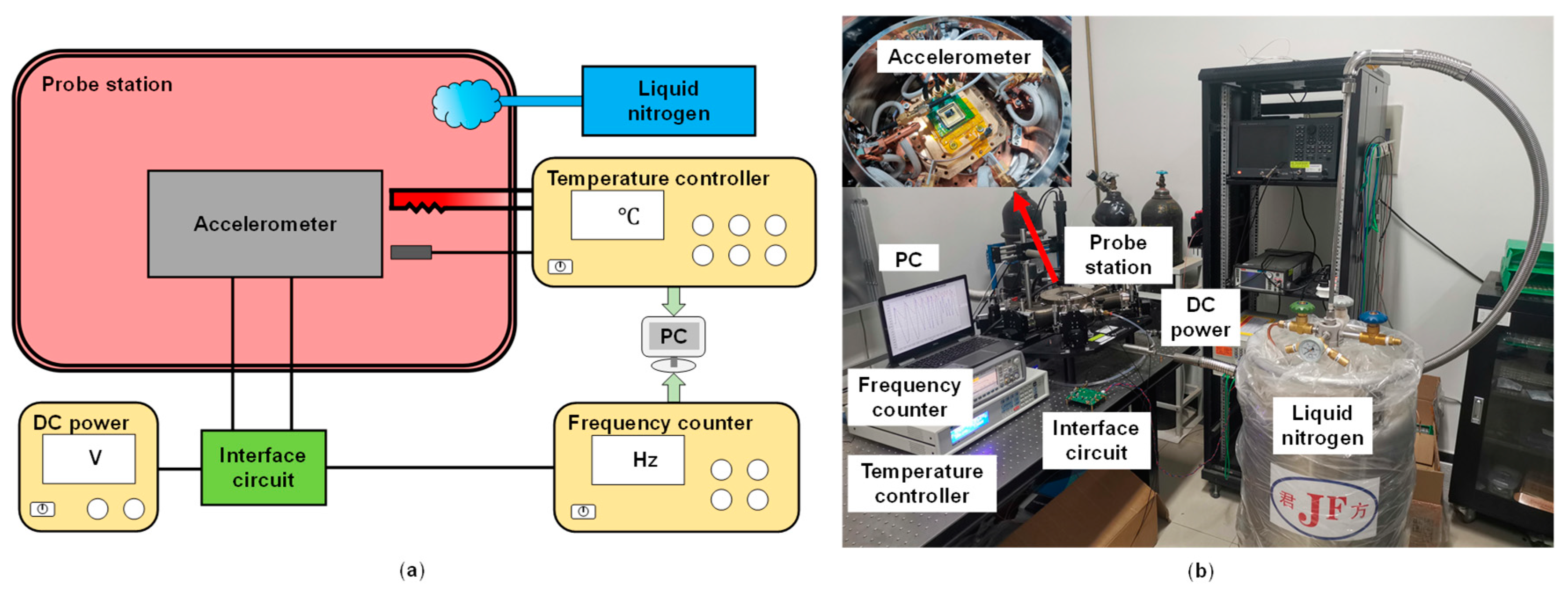

2.3. Experiment

3. Results

3.1. NARMA10 Task

3.2. Dynamic Temperature Compensation Task

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Zou, X.; Seshia, A.A. A high-resolution resonant MEMS accelerometer. In Proceedings of the 2015 Transducers—2015 18th International Conference on Solid-State Sensors, Actuators and Microsystems (TRANSDUCERS), Anchorage, Alaska, 21–25 June 2015; pp. 1247–1250. [Google Scholar]

- Ding, H.; Ma, Y.; Guan, Y.; Ju, B.-F.; Xie, J. Duplex mode tilt measurements based on a MEMS biaxial resonant accelerometer. Sens. Actuators A Phys. 2019, 296, 222–234. [Google Scholar] [CrossRef]

- Zhang, H.; Pandit, M.; Sobreviela, G.; Parajuli, M.; Chen, D.; Sun, J.; Zhao, C.; Seshia, A.A. Mode-localized accelerometer in the nonlinear Duffing regime with 75 ng bias instability and 95 ng/√Hz noise floor. Microsyst. Nanoeng. 2022, 8, 17. [Google Scholar] [CrossRef]

- Samarao, A.K.; Ayazi, F. Temperature Compensation of Silicon Resonators via Degenerate Doping. IEEE Trans. Electron. Devices 2011, 59, 87–93. [Google Scholar] [CrossRef]

- Hao, Y.; Yuan, W.; Xie, J.; Shen, Q.; Chang, H. Design and Verification of a Structure for Isolating Packaging Stress in SOI MEMS Devices. IEEE Sens. J. 2016, 17, 1246–1254. [Google Scholar] [CrossRef]

- Cui, J.; Yang, H.; Li, D.; Song, Z.; Zhao, Q. A Silicon Resonant Accelerometer Embedded in An Isolation Frame with Stress Relief Anchor. Micromachines 2019, 10, 571. [Google Scholar]

- Cai, P.; Xiong, X.; Wang, K.; Ma, L.; Wang, Z.; Liu, Y.; Zou, X. A Novel Self-Temperature Compensation Method for Mode-Localized Accelerometers. Micromachines 2022, 13, 437. [Google Scholar] [CrossRef]

- Esterline, J.C. Temperature compensation of crystal oscillators using an Artificial Neural Network. In Proceedings of the 2012 IEEE International Frequency Control Symposium Proceedings, Baltimore, MD, USA, 21–24 May 2012; pp. 1–7. [Google Scholar]

- Prikhodko, I.P.; Trusov, A.; Shkel, A.M. Achieving long-term bias stability in high-q inertialmems by temperature self-sensing with 0.5 millicelcius precision. In Proceedings of the Solid State Sensors, Actuators, and Microsystems Workshop 2012, Hilton Head Island, SC, USA, 3–7 June 2012. [Google Scholar]

- Li, M.-H.; Chen, C.-Y.; Li, C.-S.; Chin, C.-H.; Li, S.-S. Design and Characterization of a Dual-Mode CMOS-MEMS Resonator for TCF Manipulation. J. Microelectromech. Syst. 2014, 24, 446–457. [Google Scholar]

- Xu, D.; Yang, Z.; Zhao, H.; Zhou, X. A temperature compensation method for MEMS accelerometer based on LM_BP neural network. In Proceedings of the 2016 IEEE Sensors, Orlando, FL, USA, 30 October–3 November 2016. [Google Scholar]

- Ma, L.; Chen, W.W.; Li, B.; Chen, Z.G.; You, Z. Thermal Modeling and Compensation of MEMS Accelerometer. Appl. Mech. Mater. 2014, 668–669, 1015–1018. [Google Scholar] [CrossRef]

- Deng, X.; Wang, S.; Jing, S.; Huang, X.; Huang, W.; Cui, B. Dynamic Frequency-Temperature Characteristic Modeling for Quartz Crystal Resonator Based on Improved Echo State Network. IEEE Trans. Ultrason. Ferroelectr. Freq. Control 2021, 69, 438–446. [Google Scholar] [CrossRef]

- Verstraeten, D.; Schrauwen, B.; D’Haene, M.; Stroobandt, D. An experimental unification of reservoir computing methods. Neural Netw. 2007, 20, 391–403. [Google Scholar] [CrossRef]

- Appeltant, L.; Soriano, M.C.; Van der Sande, G.; Danckaert, J.; Massar, S.; Dambre, J.; Schrauwen, B.; Mirasso, C.; Fischer, I. Information processing using a single dynamical node as complex system. Nat. Commun. 2011, 2, 468. [Google Scholar] [CrossRef]

- Paquot, Y.; Duport, F.; Smerieri, A.; Dambre, J.; Schrauwen, B.; Haelterman, M.; Massar, S. Optoelectronic Reservoir Computing. Sci. Rep. 2012, 2, 287. [Google Scholar] [CrossRef]

- Kanno, K.; Uchida, A. Photonic reinforcement learning based on optoelectronic reservoir computing. Sci. Rep. 2022, 12, 3720. [Google Scholar] [CrossRef]

- Kan, S.; Nakajima, K.; Asai, T.; Akai-Kasaya, M. Physical Implementation of Reservoir Computing through Electrochemical Reaction. Adv. Sci. 2021, 9, 2104076. [Google Scholar] [CrossRef]

- Dion, G.; Mejaouri, S.; Sylvestre, J. Reservoir computing with a single delay-coupled non-linear mechanical oscillator. J. Appl. Phys. 2018, 124, 152132. [Google Scholar] [CrossRef]

- Sun, J.; Yang, W.; Zheng, T.; Xiong, X.; Liu, Y.; Wang, Z.; Li, Z.; Zou, X. Novel nondelay-based reservoir computing with a single micromechanical nonlinear resonator for high-efficiency information processing. Microsyst. Nanoeng. 2021, 7, 83. [Google Scholar] [CrossRef]

- Zheng, T.Y.; Yang, W.H.; Sun, J.; Xiong, X.Y.; Li, Z.T.; Zou, X.D. Parameters optimization method for the time-delayed reservoir computing with a nonlinear duffing mechanical oscillator. Sci. Rep. 2021, 11, 997. [Google Scholar] [CrossRef]

- Sun, J.; Yang, W.; Zheng, T.; Xiong, X.; Guo, X.; Zou, X. Enhancing the Recognition Task Performance of MEMS Resonator-Based Reservoir Computing System via Nonlinearity Tuning. Micromachines 2022, 13, 317. [Google Scholar] [CrossRef]

- Gauthier, D.J.; Bollt, E.; Griffith, A.; Barbosa, W.A.S. Next generation reservoir computing. Nat. Commun. 2021, 12, 5564. [Google Scholar] [CrossRef]

- Bengio, Y.; Boulanger-Lewandowski, N.; Pascanu, R. Advances in optimizing recurrent networks. In Proceedings of the 2013 IEEE International Conference on Acoustics, Speech and Signal Processing, Vancouver, BC, Canada, 26–31 May 2013; pp. 8624–8628. [Google Scholar]

- Kaajakari, V.; Mattila, T.; Oja, A.; Seppa, H. Nonlinear Limits for Single-Crystal Silicon Microresonators. J. Microelectromech. Syst. 2004, 13, 715–724. [Google Scholar] [CrossRef]

- Atiya, A.; Parlos, A. New results on recurrent network training: Unifying the algorithms and accelerating convergence. IEEE Trans. Neural Netw. 2000, 11, 697–709. [Google Scholar] [CrossRef]

- Mackey, M.C.; Glass, L. Oscillation and Chaos in Physiological Control Systems. Science 1977, 197, 287–289. [Google Scholar] [CrossRef]

- Han, Z.; Hong, L.; Meng, J.; Li, Y.; Gao, Q. Temperature drift modeling and compensation of capacitive accelerometer based on AGA-BP neural network. Measurement 2020, 164, 108019. [Google Scholar] [CrossRef]

- Araghi, G.; Landry, R.J. Temperature compensation model of MEMS inertial sensors based on neural network. In Proceedings of the 2018 IEEE/ION Position, Location and Navigation Symposium (PLANS), Monterey, CA, USA, 23–26 April 2018. [Google Scholar]

- Zheng, W.; Xiong, X.; Li, Z.; Wang, K.; Yang, W.; Zou, X. Enhancing Parametric Sensitivity Using Micro-Lever Coupler in Mechanical Coupling Mode-Localized Mems Accelerometer. In Proceedings of the 2019 20th International Conference on Solid-State Sensors, Actuators and Microsystems & Eurosensors XXXIII (TRANSDUCERS & EUROSENSORS XXXIII), Berlin, Germany, 23–27 June 2019. [Google Scholar]

| Methods | NMSE |

|---|---|

| ESN | 0.3045 |

| T-RC | 0.1142 |

| IOI-RC | 0.0852 |

| Method | TeDs1 | TeDs2 | ||

|---|---|---|---|---|

| RMSE (ppm) | MAE (ppm) | RMSE (ppm) | MAE (ppm) | |

| raw | 651 | 1580 | 715 | 1580 |

| PF | 701 | 1435 | 627 | 1233 |

| PF–ESN | 328 | 1550 | 423 | 1974 |

| PF–T-RC | 290 | 769 | 249 | 707 |

| IOI-RC | 165 | 146 | 96 | 165 |

| PF–IOI-RC | 132 | 164 | 76 | 114 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Guo, X.; Yang, W.; Zheng, T.; Sun, J.; Xiong, X.; Wang, Z.; Zou, X. Input–Output-Improved Reservoir Computing Based on Duffing Resonator Processing Dynamic Temperature Compensation for MEMS Resonant Accelerometer. Micromachines 2023, 14, 161. https://doi.org/10.3390/mi14010161

Guo X, Yang W, Zheng T, Sun J, Xiong X, Wang Z, Zou X. Input–Output-Improved Reservoir Computing Based on Duffing Resonator Processing Dynamic Temperature Compensation for MEMS Resonant Accelerometer. Micromachines. 2023; 14(1):161. https://doi.org/10.3390/mi14010161

Chicago/Turabian StyleGuo, Xiaowei, Wuhao Yang, Tianyi Zheng, Jie Sun, Xingyin Xiong, Zheng Wang, and Xudong Zou. 2023. "Input–Output-Improved Reservoir Computing Based on Duffing Resonator Processing Dynamic Temperature Compensation for MEMS Resonant Accelerometer" Micromachines 14, no. 1: 161. https://doi.org/10.3390/mi14010161

APA StyleGuo, X., Yang, W., Zheng, T., Sun, J., Xiong, X., Wang, Z., & Zou, X. (2023). Input–Output-Improved Reservoir Computing Based on Duffing Resonator Processing Dynamic Temperature Compensation for MEMS Resonant Accelerometer. Micromachines, 14(1), 161. https://doi.org/10.3390/mi14010161