Transient Heat Transfer Characteristics in a Flat Plate Heat Sink with Mini-Channels for Cooling High Heat Flux IGBT

Abstract

:1. Introduction

2. Heat Sink Design and Experimental System

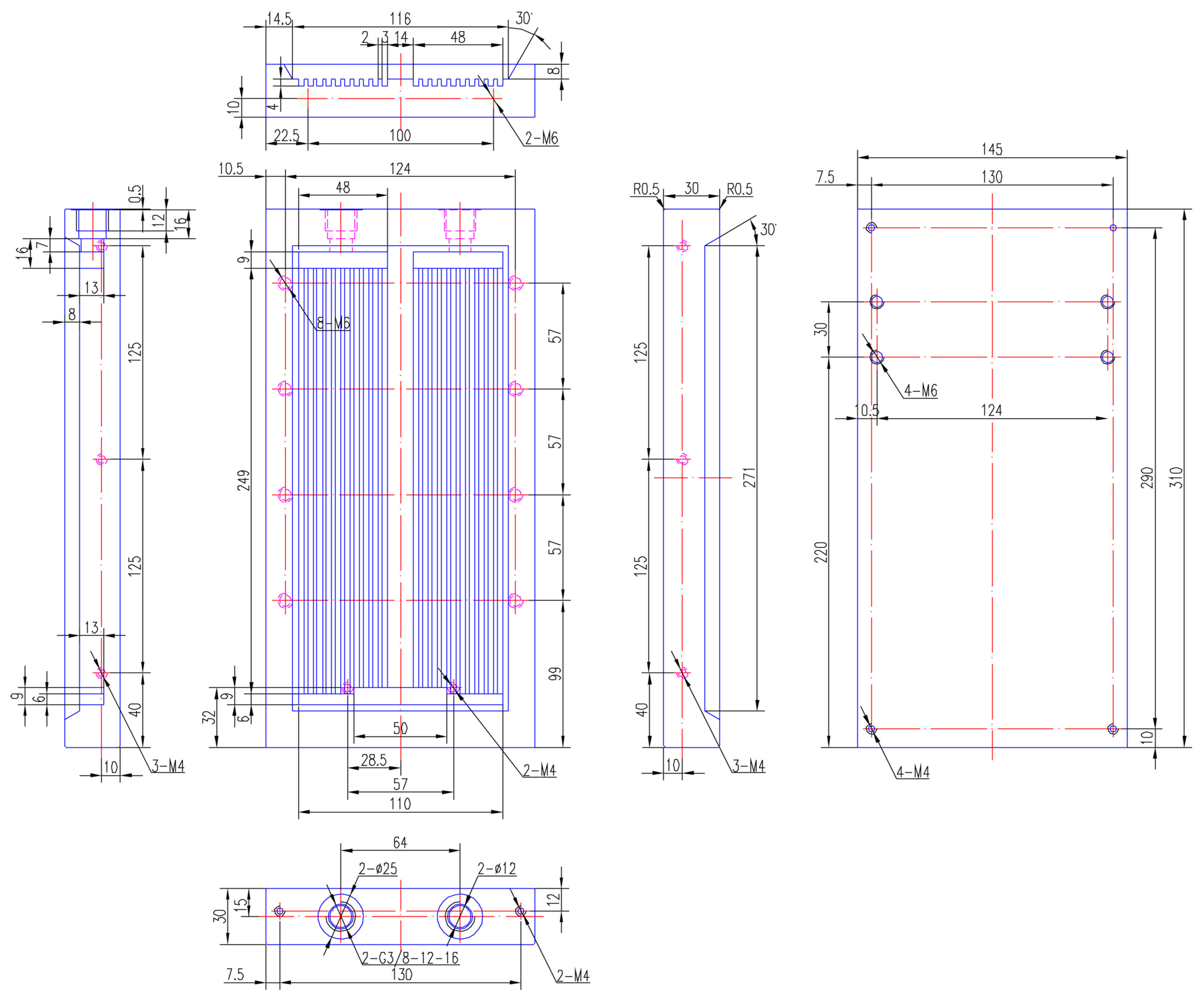

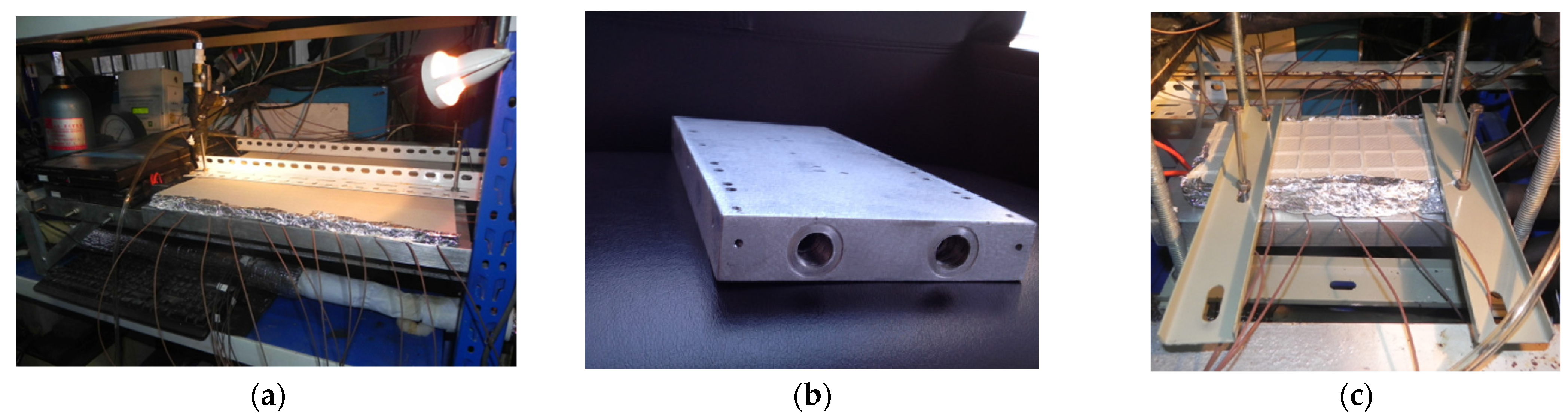

2.1. Design of the Flat Plate Heat Sink with Mini-Channels

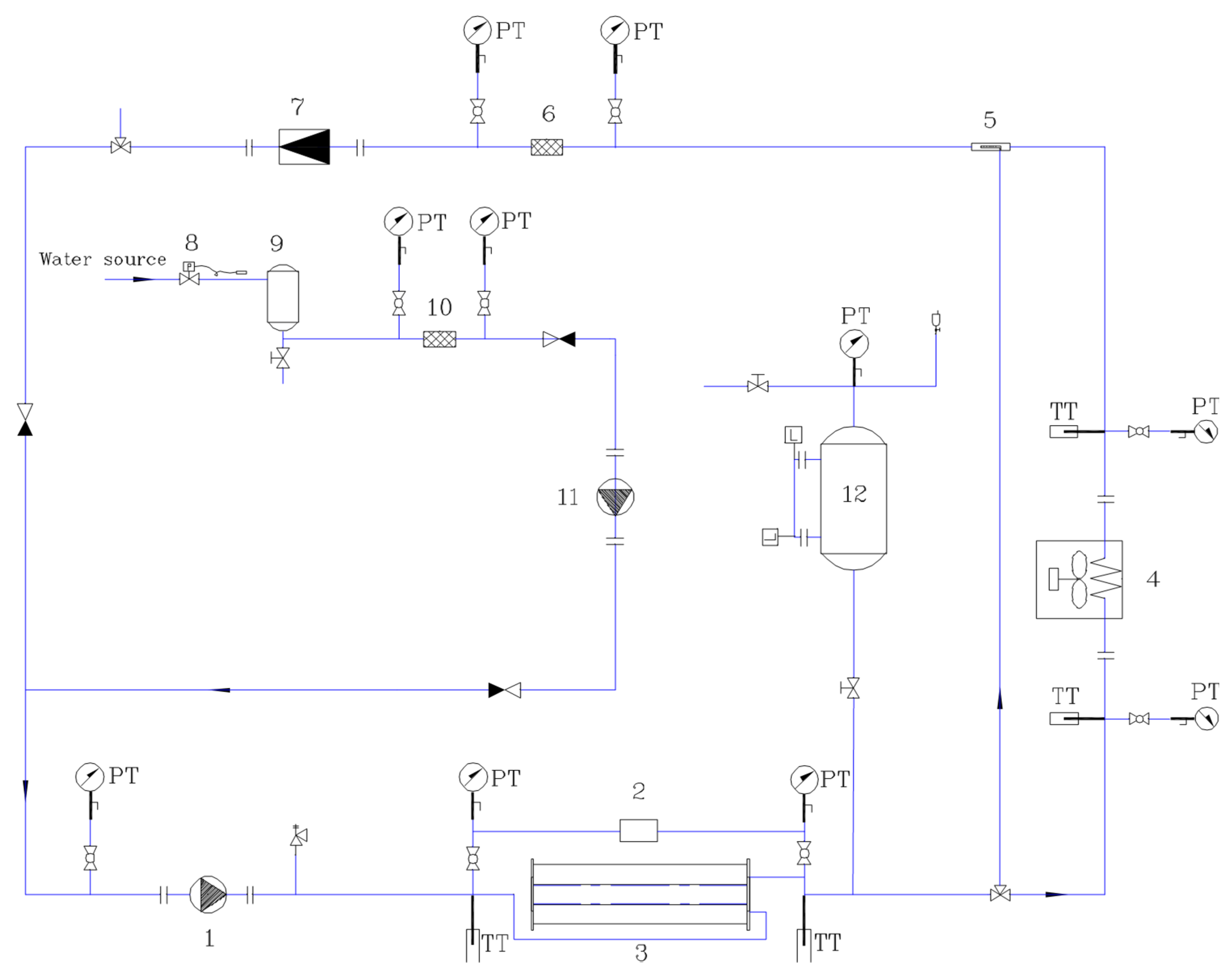

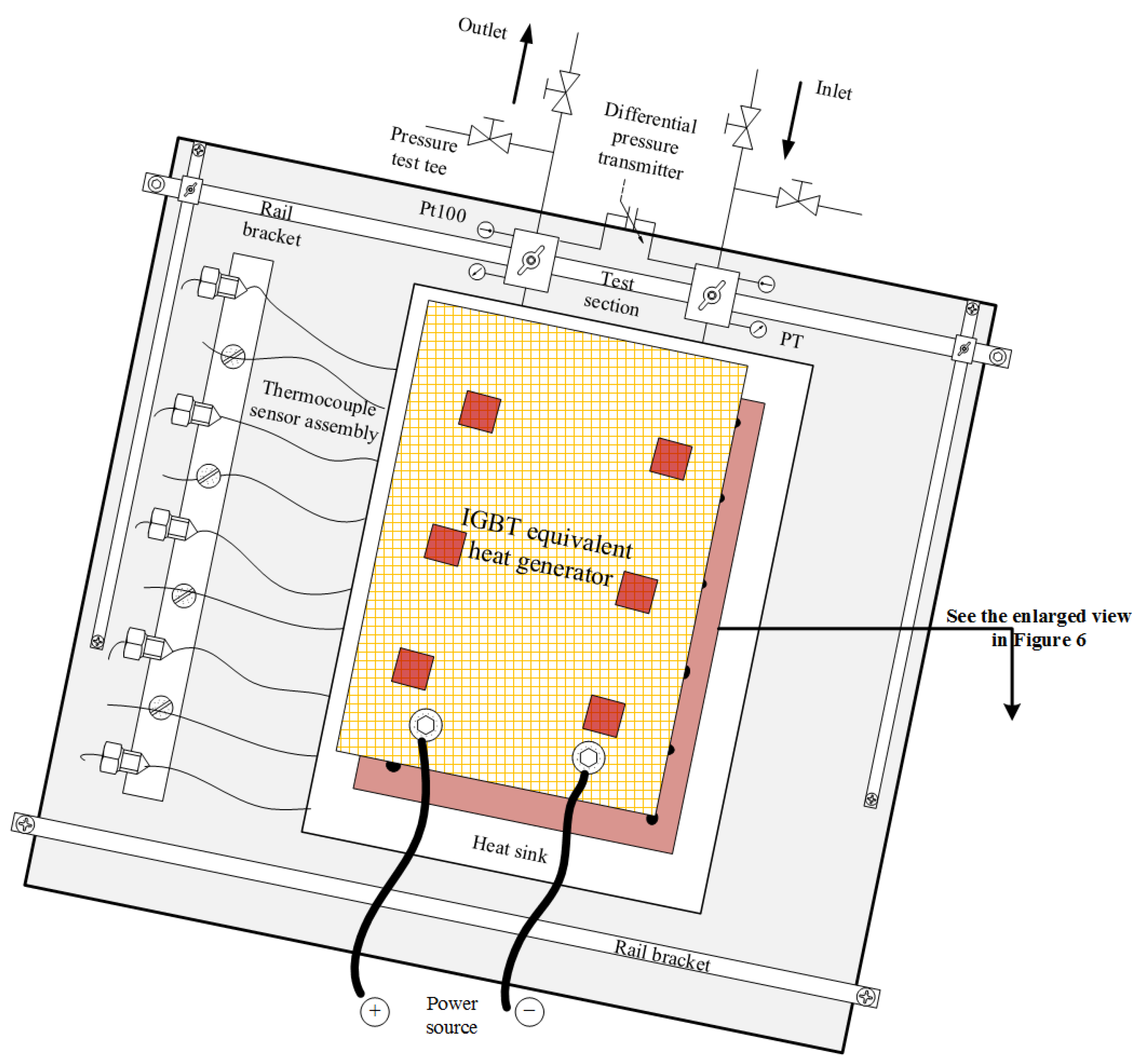

2.2. Experimental System Set-Up

3. Experimental Details and Data Reduction

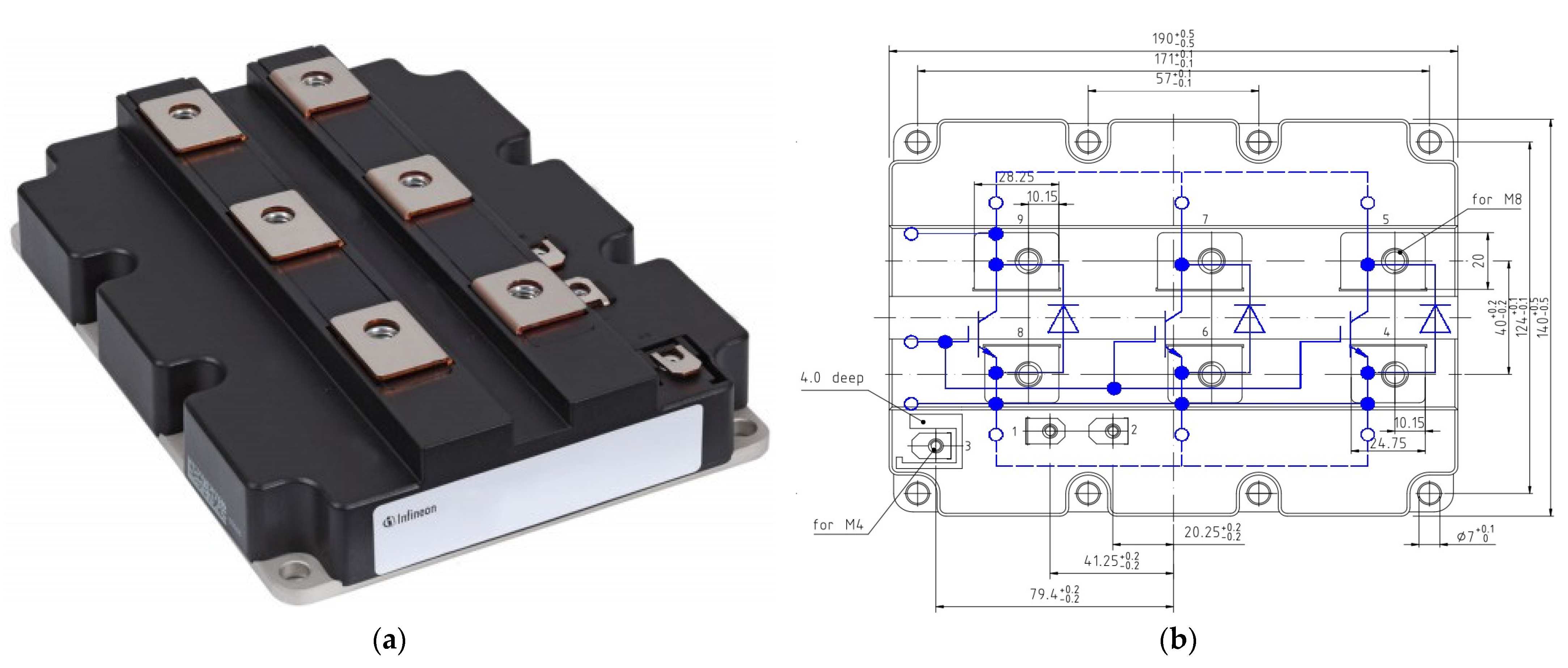

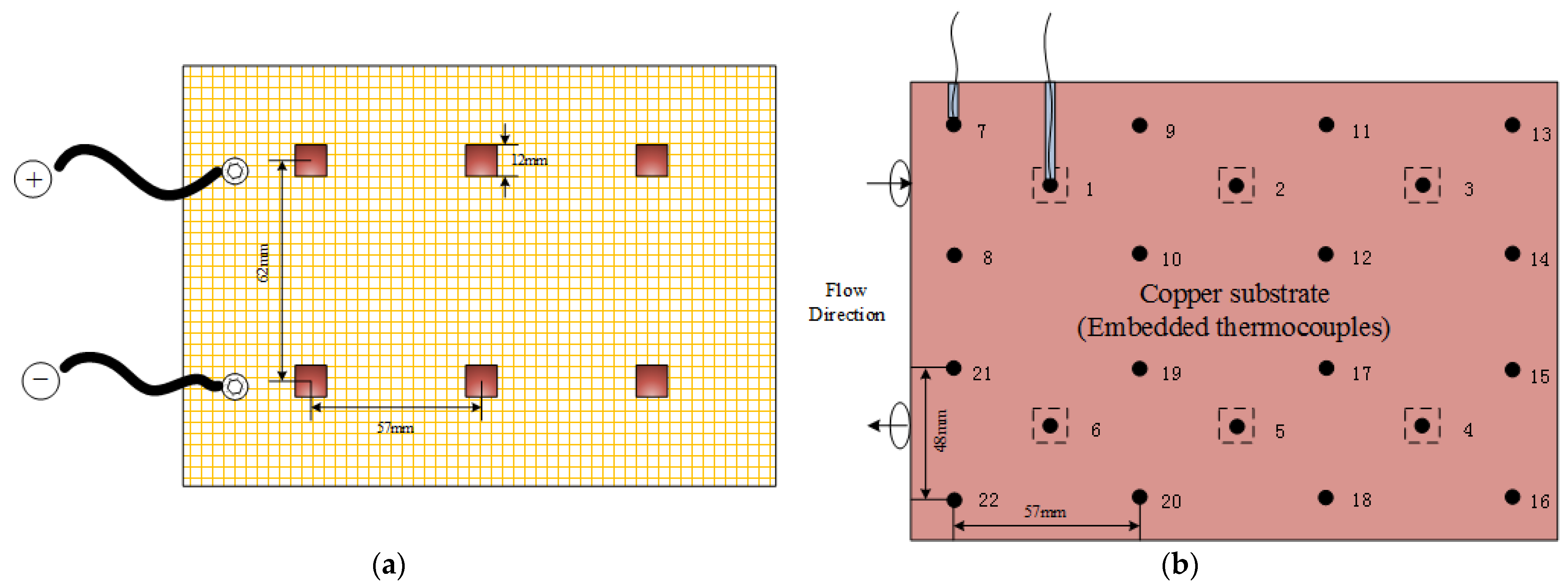

3.1. Experimental Details

3.2. Data Reduction

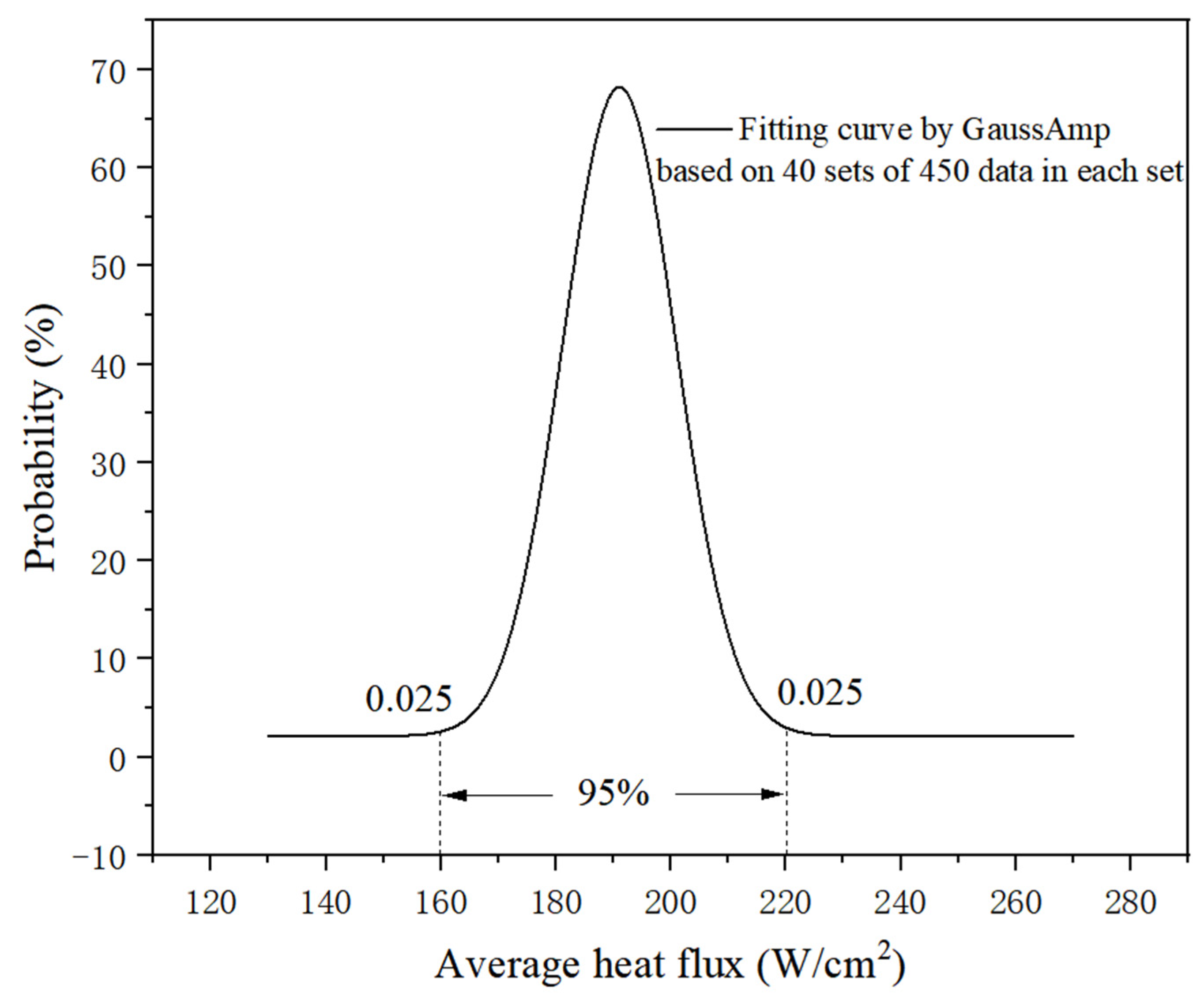

3.3. Experimental Conditions and Uncertainties

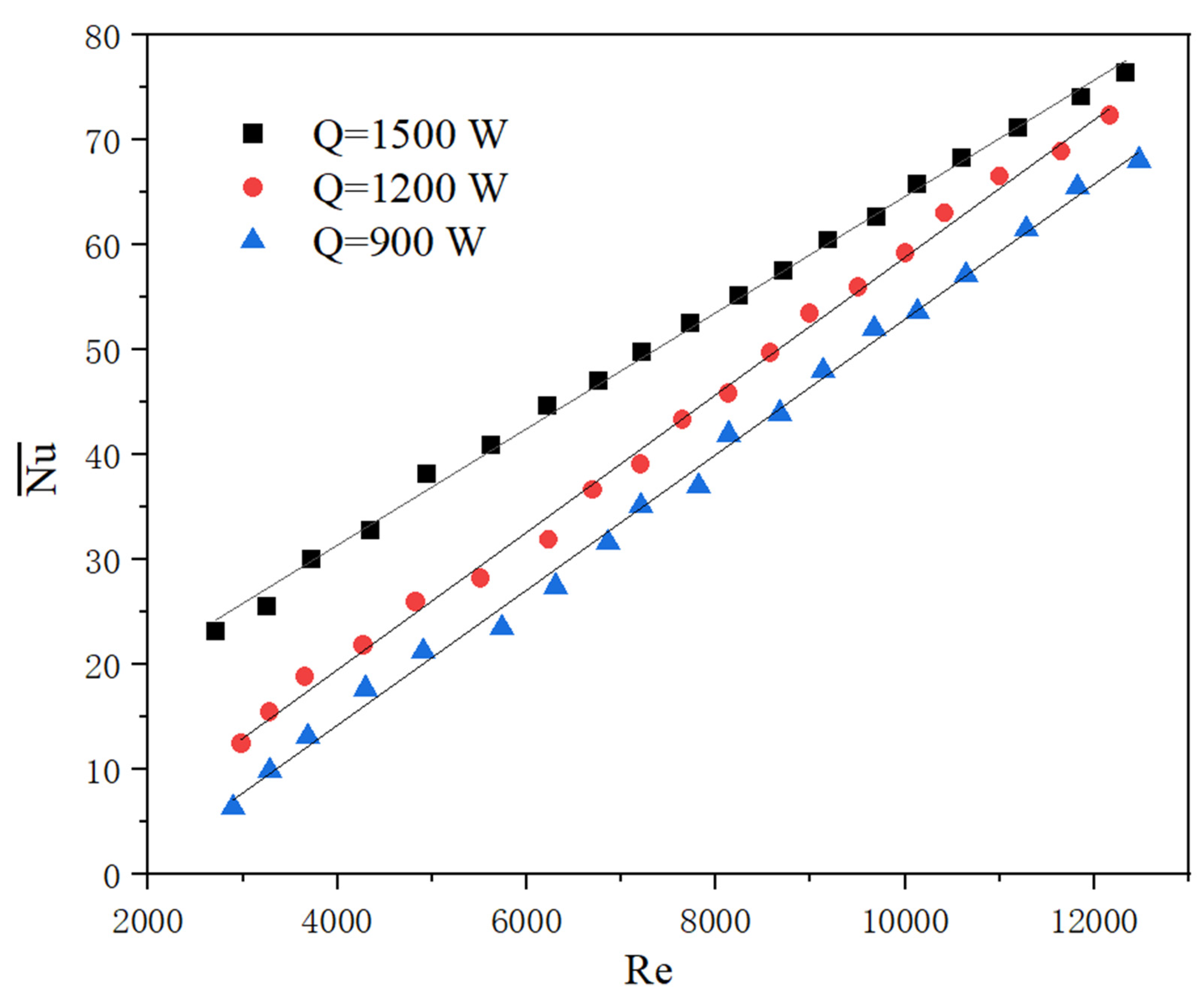

4. Results and Discussion

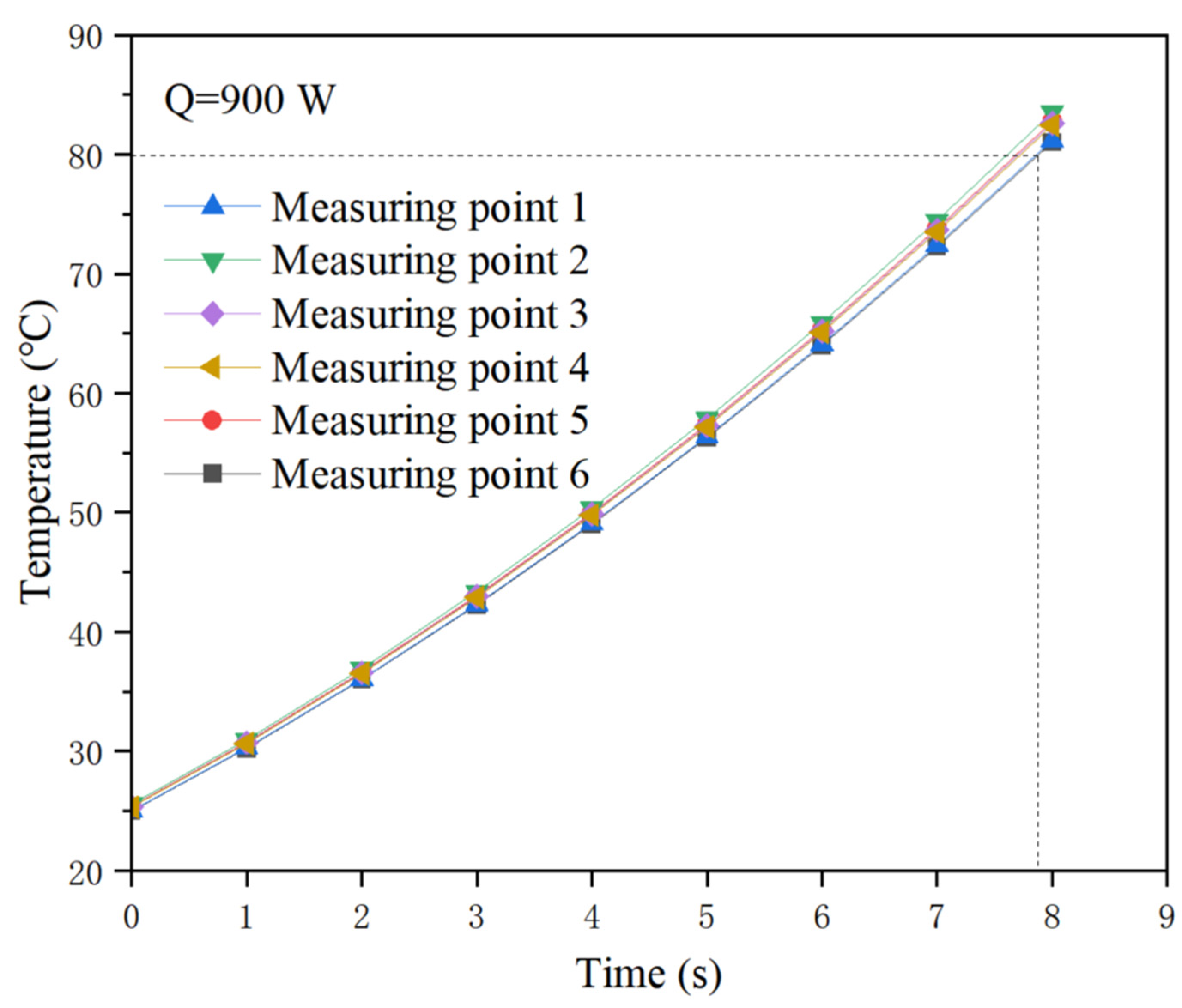

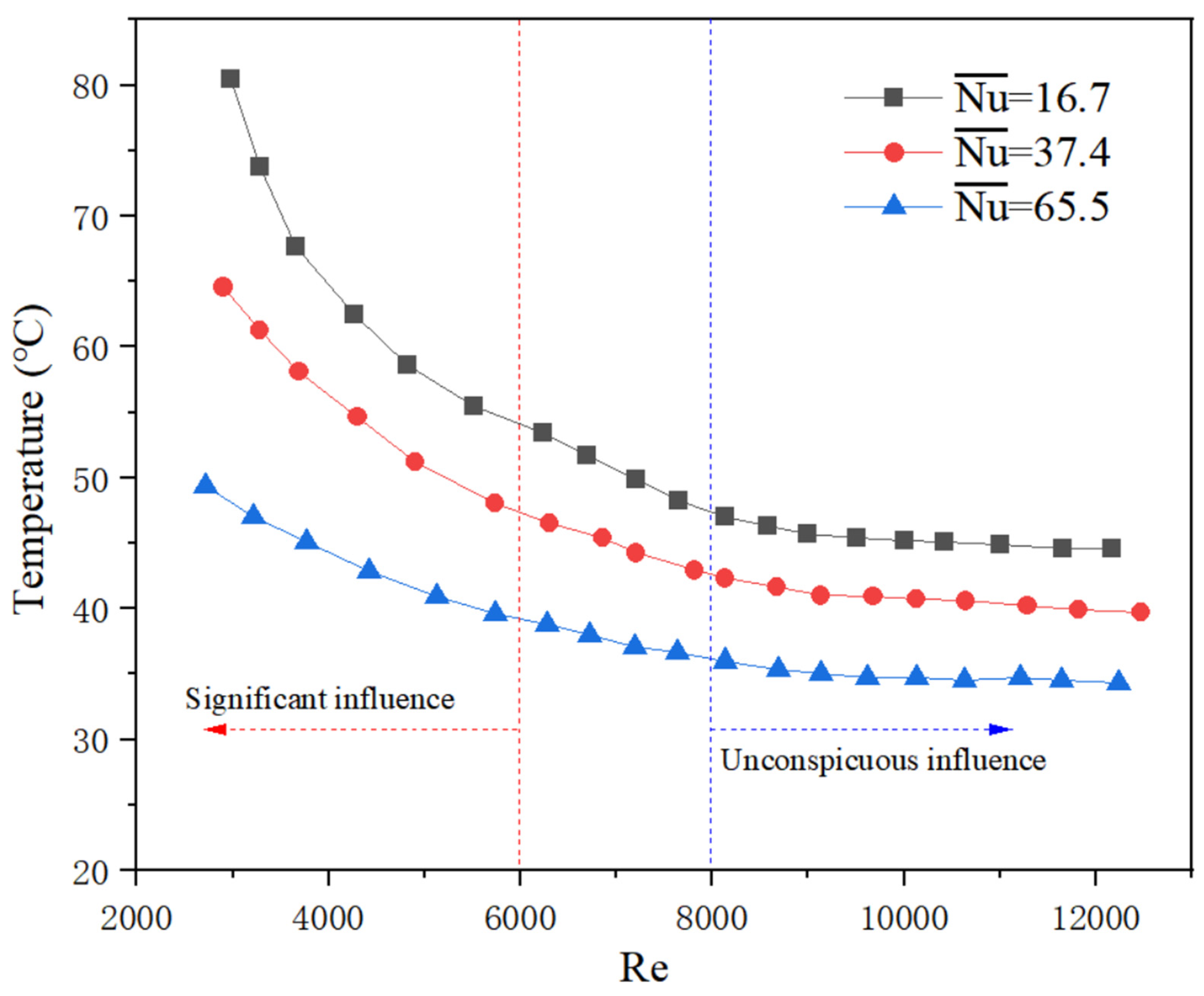

4.1. Pre Experiments and Analysis

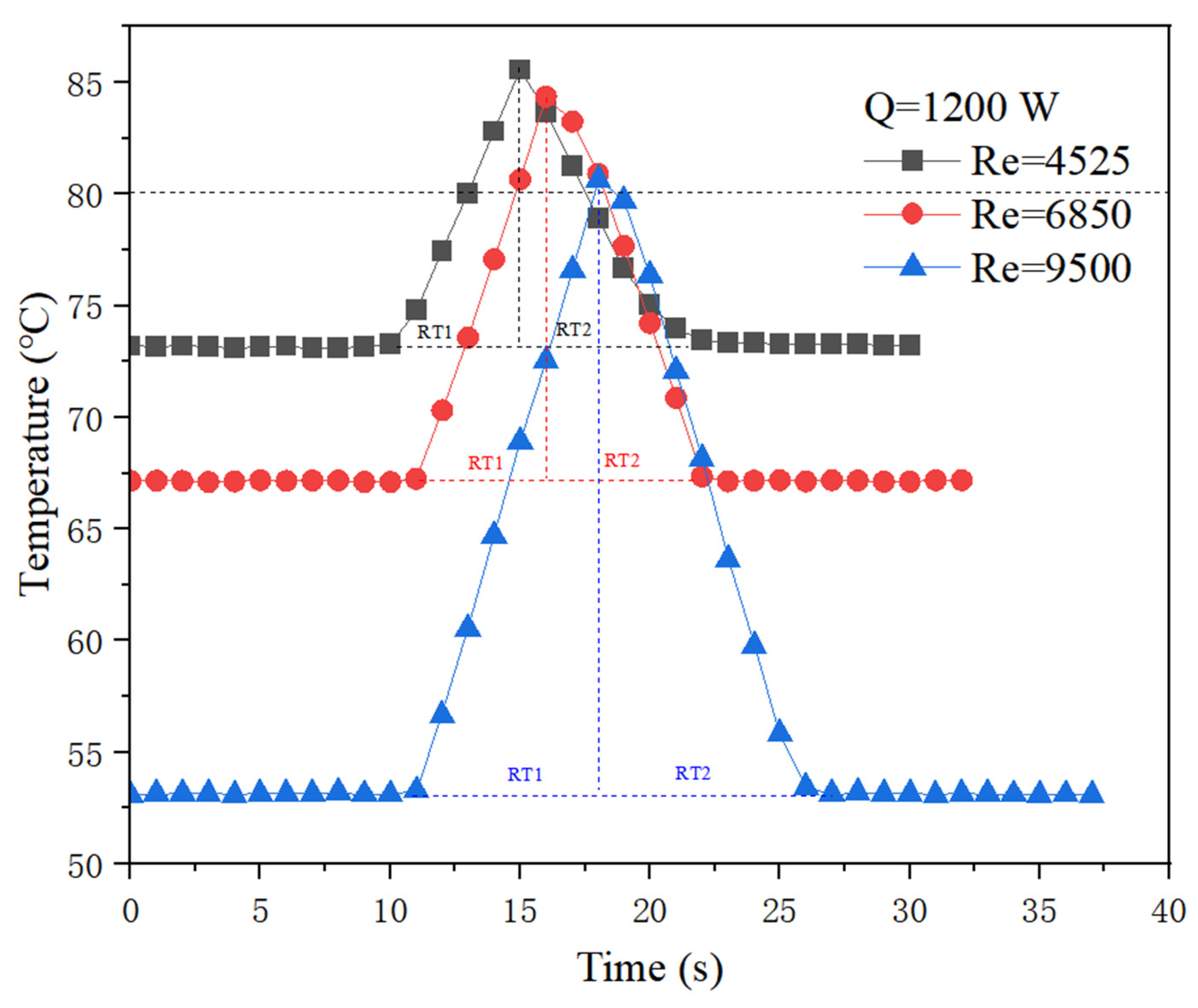

4.2. Analysis of Instantaneous Start-Stop Conditions

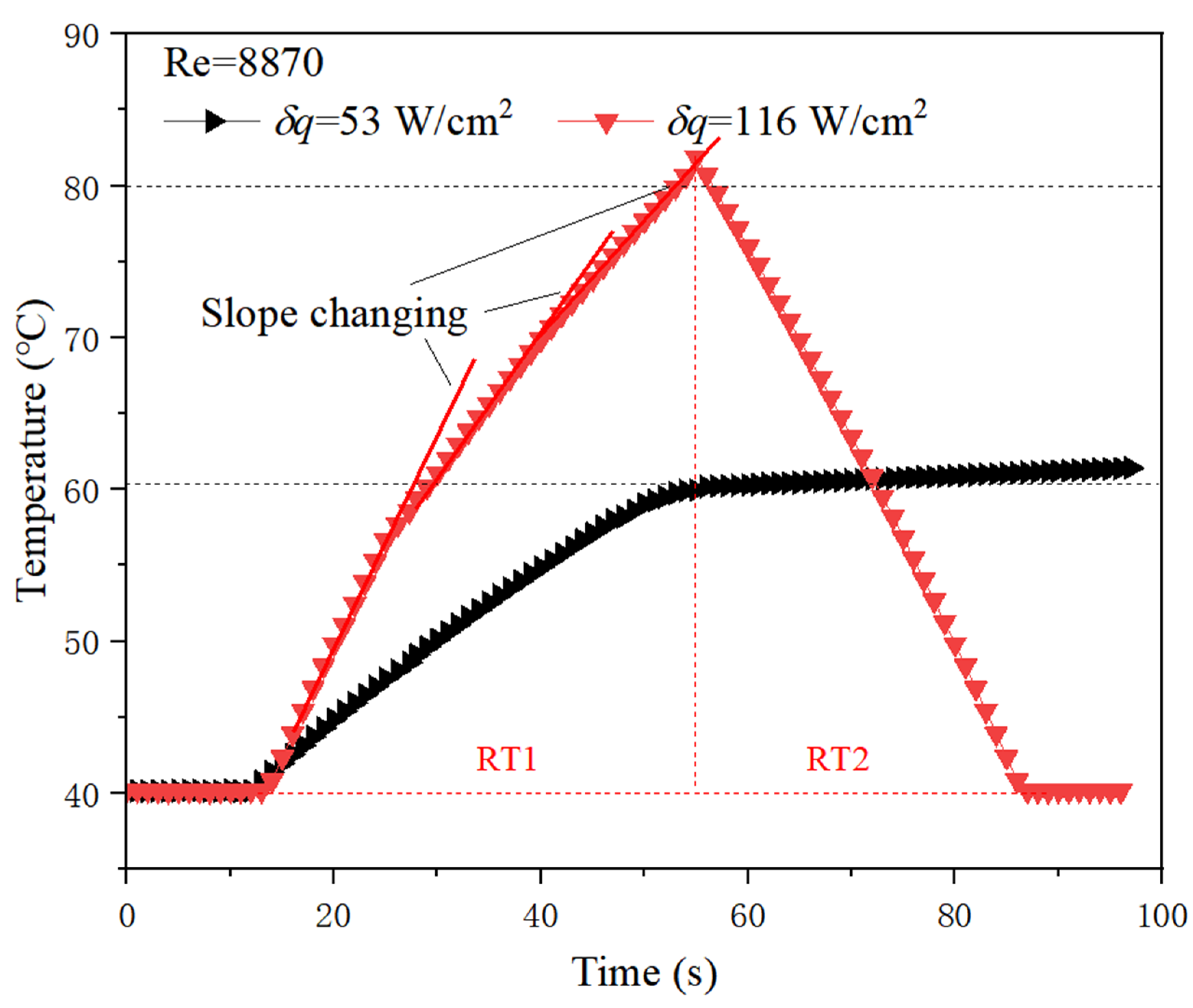

4.3. Analysis of Transient Heating Power Variation

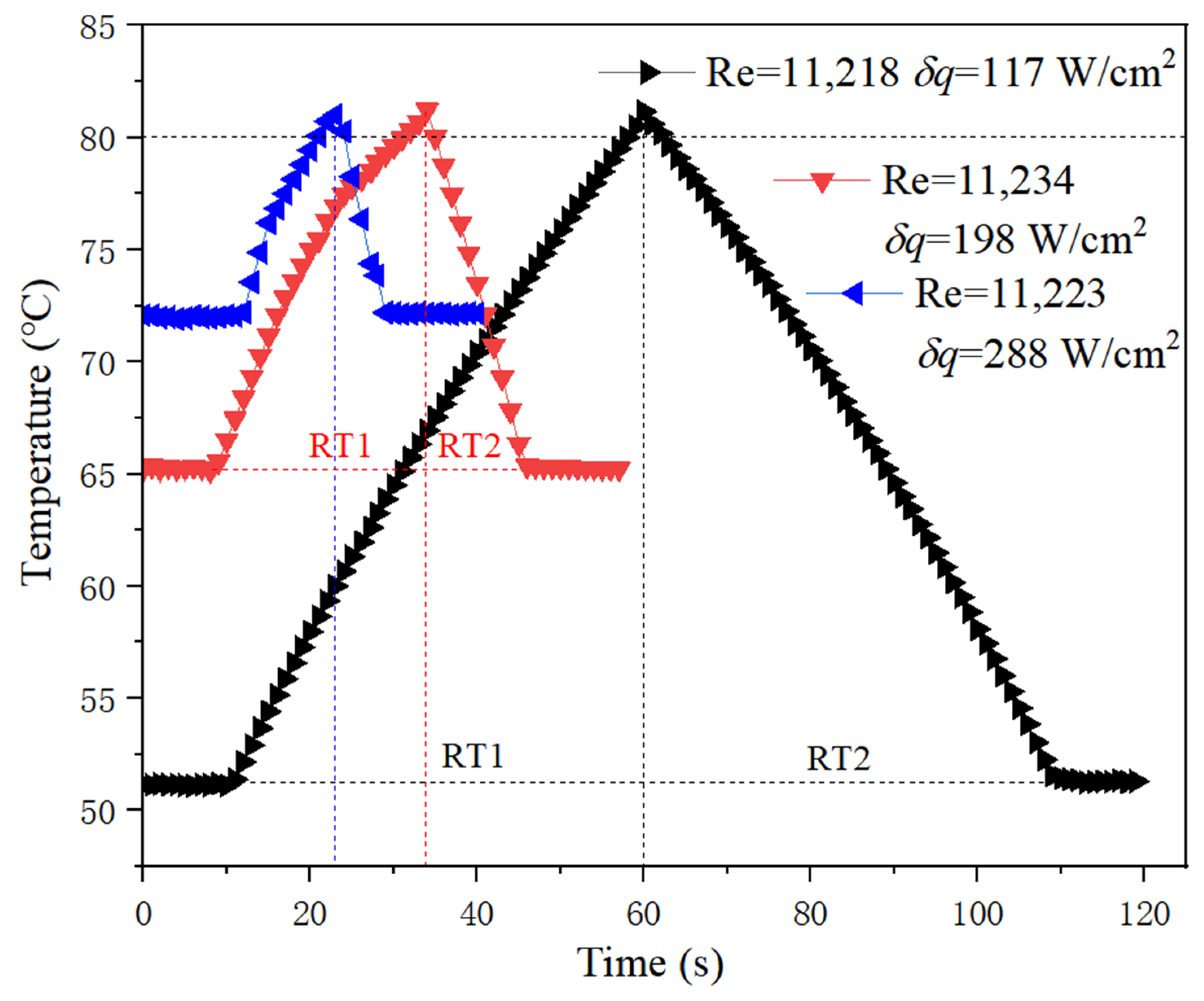

4.4. Analysis of Flow Fluctuation Conditions

5. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Gavrilović, A. 32-HVDC. In Electrical Engineer’s Reference Book, 6th ed.; Laughton, M.A., Warne, D.J., Eds.; Newnes: Oxford, UK, 2003; pp. 32-31–32-46. [Google Scholar]

- Van Hertem, D.; Delimar, M. 6-High Voltage Direct Current (HVDC) electric power transmission systems. In Electricity Transmission, Distribution and Storage Systems; Melhem, Z., Ed.; Woodhead Publishing: Sawston, UK, 2013; pp. 143–173. [Google Scholar]

- Alassi, A.; Bañales, S.; Ellabban, O.; Adam, G.; MacIver, C. HVDC Transmission: Technology Review, Market Trends and Future Outlook. Renew. Sustain. Energy Rev. 2019, 112, 530–554. [Google Scholar] [CrossRef]

- Mudawar, I. Assessment of high-heat-flux thermal management schemes. In Proceedings of the ITHERM 2000, The Seventh Intersociety Conference on Thermal and Thermomechanical Phenomena in Electronic Systems (Cat. No.00CH37069), Istanbul, Turkey, 5–9 June 2000. [Google Scholar]

- Chen, J.Y.; Wu, W.W. Cooling Technology for High Power Converter and Its Development. High. Power Convert. Technol. 2010, 15-24, 30. [Google Scholar]

- Baburske, R.; Niedernostheide, F.J.; Schulze, H.J.; Bhojani, R.; Kowalsky, J.; Lutz, J. Unified view on energy and electrical failure of the short-circuit operation of IGBTs. Microelectron. Reliab. 2018, 88–90, 236–241. [Google Scholar] [CrossRef]

- Marshall, G.J.; Mahony, C.P.; Rhodes, M.J.; Daniewicz, S.R.; Tsolas, N.; Thompson, S.M. Thermal Management of Vehicle Cabins, External Surfaces, and Onboard Electronics: An Overview. Engineering 2019, 5, 954–969. [Google Scholar] [CrossRef]

- Li, L.; He, Y.; Wang, L.; Wang, C.; Liu, X. IGBT lifetime model considering composite failure modes. Mater. Sci. Semicond. Process. 2022, 143, 106529. [Google Scholar] [CrossRef]

- Anandan, S.S.; Ramalingam, V. Thermal management of electronics: A review of literature. Therm. Sci. 2008, 12, 5–26. [Google Scholar] [CrossRef]

- Kang, S.S. Advanced Cooling for Power Electronics. In Proceedings of the 2012 7th International Conference on Integrated Power Electronics Systems (CIPS), Nuremberg, Germany, 6–8 March 2012. [Google Scholar]

- Zhang, Z.Y.; Xu, G.Q.; Shen, X.L. Analyzing and Designing of Dissipation System of Inverter. J. Tongji Univ. (Nat. Sci.) 2004, 6, 775–778. [Google Scholar]

- Vasiliev, L.; Lossouarn, D.; Romestant, C.; Alexandre, A.; Bertin, Y.; Piatsiushyk, Y.; Romanenkov, V. Loop heat pipe for cooling of high-power electronic components. Int. J. Heat Mass Transf. 2009, 52, 301–308. [Google Scholar] [CrossRef]

- Lu, J.; Shen, L.; Huang, Q.; Sun, D.; Li, B.; Tan, Y. Investigation of a rectangular heat pipe radiator with parallel heat flow structure for cooling high-power IGBT modules. Int. J. Therm. Sci. 2019, 135, 83–93. [Google Scholar] [CrossRef]

- Nellis, G.; Klein, S.A. Heat Transfer; Cambridge University Press: New York, NY, USA; Cambridge, UK, 2009; p. xxxvii. 1107p. [Google Scholar]

- Gillot, C.; Schaeffer, C.; Massit, C.; Meysenc, L. Double-sided cooling for high power IGBT modules using flip chip technology. IEEE Trans. Compon. Packag. Technol. 2001, 24, 698–704. [Google Scholar] [CrossRef]

- Parida, P.R.; Ekkad, S.V.; Ngo, K. Impingement-based high performance cooling configurations for automotive power converters. Int. J. Heat Mass Transf. 2012, 55, 834–847. [Google Scholar] [CrossRef]

- Pan, M.; Hu, m.; Wang, H. Study of the performance of an integrated liquid cooling heat sink for high-power IGBTs. Appl. Therm. Eng. 2021, 190, 116827. [Google Scholar] [CrossRef]

- Lee, T.Y. Design optimization of an integrated liquid-cooled IGBT power module using CFD technique. IEEE Trans. Compon. Packag. Technol. 2000, 23, 55–60. [Google Scholar] [CrossRef]

- Valenzuela, J.; Jasinski, T.; Sheikh, Z. Liquid cooling for high-power electronics. Power Electron. Technol. 2005, 31, 50–56. [Google Scholar]

- Schulz-Harder, J.; Exel, K.; Meyer, A. Direct Liquid Cooling of Power Electronics Devices. In Proceedings of the 4th International Conference on Integrated Power Systems, Frankfurt am Main, Germany, 7–9 June 2006; pp. 1–6. [Google Scholar]

- Wang, Y.; Jones, S.; Dai, A.; Liu, G. Reliability enhancement by integrated liquid cooling in power IGBT modules for hybrid and electric vehicles. Microelectron. Reliab. 2014, 54, 1911–1915. [Google Scholar] [CrossRef]

- Lim, K.; Lee, J. 1-D two-phase flow analysis for interlocking double layer counter flow mini-channel heat sink. Int. J. Heat Mass Transf. 2019, 135, 305–317. [Google Scholar] [CrossRef]

- Peiyi, W.; Little, W.A. Measurement of friction factors for the flow of gases in very fine channels used for microminiature Joule-Thomson refrigerators. Cryogenics 1983, 23, 273–277. [Google Scholar] [CrossRef]

- Qu, W.; Mudawar, I. Experimental and numerical study of pressure drop and heat transfer in a single-phase micro-channel heat sink. Int. J. Heat Mass Transf. 2002, 45, 2549–2565. [Google Scholar] [CrossRef]

- Kandlikar, S.G. Chapter 5-Flow Boiling in Minichannels and Microchannels. In Heat Transfer and Fluid Flow in Minichannels and Microchannels, 2nd ed.; Kandlikar, S.G., Garimella, S., Li, D., Colin, S., King, M.R., Eds.; Butterworth-Heinemann: Oxford, UK, 2014; pp. 221–293. [Google Scholar]

- Khan, A.; Hadi, F.; Akram, N.; Bashir, M.A.; Ali, H.M.; Janjua, M.M.; Hussain, A.; Pasha, R.A.; Janjua, A.B.; Farukh, F. Review of micro and mini channels, porous heat sinks with hydrophobic surfaces for single phase fluid flow. J. Taiwan Inst. Chem. Eng. 2022, 132, 104186. [Google Scholar] [CrossRef]

- Vasilev, M.P.; Abiev, R.S.; Kumar, R. Effect of microchannel heat sink configuration on the thermal performance and pumping power. Int. J. Heat Mass Transf. 2019, 141, 845–854. [Google Scholar] [CrossRef]

- Ki, S.; Lee, J.; Ryu, S.; Bang, S.; Kim, K.; Nam, Y. A bio-inspired, low pressure drop liquid cooling system for high-power IGBT modules for EV/HEV applications. Int. J. Therm. Sci. 2021, 161, 106708. [Google Scholar] [CrossRef]

- Tan, L.; Liu, P.; She, C.; Xu, P.; Yan, L.; Quan, H. Heat Dissipation Characteristics of IGBT Module Based on Flow-Solid Coupling. Micromachines 2022, 13, 554. [Google Scholar] [CrossRef] [PubMed]

- Collier, J.G.; Thome, J.R. Convective Boiling and Condensation, 3rd ed.; Clarendon: Oxford, UK, 1994; p. xliii. 596p. [Google Scholar]

- Thome, J.R. Boiling in microchannels: A review of experiment and theory. Int. J. Heat Fluid Fl. 2004, 25, 128–139. [Google Scholar] [CrossRef]

- Campbell, J.B.; Tolbert, L.M.; Ayers, C.W.; Ozpineci, B.; Lowe, K.T. Two-phase cooling method using the R134a refrigerant to cool power electronic devices. IEEE Trans. Ind. Appl. 2007, 43, 648–656. [Google Scholar] [CrossRef]

- Dalkilic, A.S.; Ozman, C.; Sakamatapan, K.; Wongwises, S. Experimental investigation on the flow boiling of R134a in a multi-microchannel heat sink. Int. Commun. Heat Mass 2018, 91, 125–137. [Google Scholar] [CrossRef]

- Ghodsinezhad, H.; Sharifpur, M.; Meyer, J.P. Experimental investigation on cavity flow natural convection of Al2O3-water nanofluids. Int. Commun. Heat Mass 2016, 76, 316–324. [Google Scholar] [CrossRef]

- Arani, A.A.A.; Sadripour, S.; Kermani, S. Nanoparticle shape effects on thermal-hydraulic performance of boehmite alumina nanofluids in a sinusoidal wavy mini-channel with phase shift and variable wavelength. Int. J. Mech. Sci. 2017, 128, 550–563. [Google Scholar] [CrossRef]

- Bahiraei, M.; Heshmatian, S. Electronics cooling with nanofluids: A critical review. Energ. Convers. Manag. 2018, 172, 438–456. [Google Scholar] [CrossRef]

- Khetib, Y.; Abo-Dief, H.M.; Alanazi, A.K.; Sajadi, S.M.; Sharifpur, M.; Meyer, J.P. A Computational Fluid Dynamic Study on Efficiency of a Wavy Microchannel/Heat Sink Containing Various Nanoparticles. Micromachines 2021, 12, 1192. [Google Scholar] [CrossRef]

- Ghachem, K.; Aich, W.; Kolsi, L. Computational analysis of hybrid nanofluid enhanced heat transfer in cross flow micro heat exchanger with rectangular wavy channels. Case Stud. Therm. Eng. 2021, 24, 100822. [Google Scholar] [CrossRef]

- Omri, M.; Smaoui, H.; Frechette, L.; Kolsi, L. A new microchannel heat exchanger configuration using CNT-nanofluid and allowing uniform temperature on the active wall. Case Stud. Therm. Eng. 2022, 32, 101866. [Google Scholar] [CrossRef]

- Miner, A.; Ghoshal, U. Cooling of high-power-density microdevices using liquid metal coolants. Appl. Phys. Lett. 2004, 85, 506–508. [Google Scholar] [CrossRef]

- Jaeger, W. Heat transfer to liquid metals with empirical models for turbulent forced convection in various geometries. Nucl. Eng. Des. 2017, 319, 12–27. [Google Scholar] [CrossRef]

- Wu, T.; Wang, L.; Tang, Y.; Yin, C.; Li, X. Flow and Heat Transfer Performances of Liquid Metal Based Microchannel Heat Sinks under High Temperature Conditions. Micromachines 2022, 13, 95. [Google Scholar] [CrossRef] [PubMed]

- Mehendale, S.S.; Jacobi, A.M.; Shah, R.K. Fluid Flow and Heat Transfer at Micro- and Meso-Scales With Application to Heat Exchanger Design. Appl. Mech. Rev. 2000, 53, 175–193. [Google Scholar] [CrossRef]

- Kandlikar, S.G. Two-phase flow patterns, pressure drop, and heat transfer during boiling in minichannel flow passages of compact evaporators. Heat Transf. Eng. 2002, 23, 5–23. [Google Scholar] [CrossRef]

- Infineon. FZ1500R33HE3 IHM-B Modul, Version_1.10, Infineon Data Sheet. Available online: https://www.infineon.com/dgdl/Infineon-FZ1500R33HE3-DataSheet-v01_10-EN.pdf?fileId=8ac78c8c7cdc391c017ce117f26d2d90 (accessed on 15 October 2021).

- Moffat, R.J. Describing the Uncertainties in Experimental Results. Exp. Therm. Fluid Sci. 1988, 1, 3–17. [Google Scholar] [CrossRef] [Green Version]

| Diameter of Inlet/mm | Diameter of Outlet/mm | Length of Single Mini-Channel/mm | Cross-Section Size/mm | Number of Flow Channels |

|---|---|---|---|---|

| 12 | 12 | 249 | 3 × 4 | 20 |

| Classifications | Mehendal et al. [43] | Kandlikar et al. [44] |

|---|---|---|

| Macro-channel | Dh > 6 mm | Dh > 3 mm |

| Mini-channel | 100 μm < Dh < 6 mm | 200 μm < Dh < 3 mm |

| Micro-channel | Dh < 100 μm | Dh < 200 μm |

| Technical Parameters | IMP 3595 1A | IMP 3595 1C | |

|---|---|---|---|

| Basic features | Number of channels | 20 | 20 |

| Switching | solid-state, 3-pole | reed-relay, 3-pole | |

| Maximum signal measured | ±12 V | ±12 V | |

| Overload protection, continuous | 50 V | 50 V | |

| Maximum voltage between any input and any guard | 14 V | 200 V | |

| Common mode, between IMPs | 500 V | 500 V | |

| Measurement | Voltage dc | 0 to ±12 V | 0 to ±12 V |

| Current dc (assuming 100½ shunt) | 0 to 20 mA | 0 to 20 mA | |

| Thermocouple types | B, E, J, K, N, T, R, S | B, E, J, K, N, T, R, S | |

| Thermocouple cold junction | External or automatic | External or automatic | |

| Thermocouple open circuit detection | programmable | programmable | |

| Manufacturer | Model | Electrical Features | Average Power Dissipation | Maximum Junction Temperature |

|---|---|---|---|---|

| Infineon® | FZ1500R33HE3 | VCES = 3300 V IC, nom = 1500 A/ICRM = 3000 A | 1200 W | 125 °C |

| System Parameters | Experimental Conditions | ||

|---|---|---|---|

| Instantaneous Start-Stop | Transient Heating Power Variation | Flow Fluctuation | |

| Inlet temperature | 25–35 °C | 25–35 °C | 30–35 °C |

| Flow rate | 4.1–9.0 L/min | 3.5–9.5 L/min | 3.2–9.5 L/min |

| Heating power | 960–1500 W | 920–1500 W | 900–1500 W |

| Heat flux of hot spot | 120–298 W/cm2 | 112–316 W/cm2 | 104–347 W/cm2 |

| Measuring Points | 1 | 2 | 3 | 4 | 5 | 6 |

|---|---|---|---|---|---|---|

| Frequency | 10 | 13 | 12 | 15 | 19 | 17 |

| Probability | 11.6% | 15.1% | 13.9% | 17.4% | 22.1% | 19.8% |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Chen, C.; Zhao, H.; Liu, C.; Chen, J.; Liu, C.; Zhang, T.; Gong, W. Transient Heat Transfer Characteristics in a Flat Plate Heat Sink with Mini-Channels for Cooling High Heat Flux IGBT. Micromachines 2022, 13, 1417. https://doi.org/10.3390/mi13091417

Chen C, Zhao H, Liu C, Chen J, Liu C, Zhang T, Gong W. Transient Heat Transfer Characteristics in a Flat Plate Heat Sink with Mini-Channels for Cooling High Heat Flux IGBT. Micromachines. 2022; 13(9):1417. https://doi.org/10.3390/mi13091417

Chicago/Turabian StyleChen, Changnian, Haoran Zhao, Chaoyu Liu, Jian Chen, Chunyang Liu, Tiezhu Zhang, and Weiping Gong. 2022. "Transient Heat Transfer Characteristics in a Flat Plate Heat Sink with Mini-Channels for Cooling High Heat Flux IGBT" Micromachines 13, no. 9: 1417. https://doi.org/10.3390/mi13091417

APA StyleChen, C., Zhao, H., Liu, C., Chen, J., Liu, C., Zhang, T., & Gong, W. (2022). Transient Heat Transfer Characteristics in a Flat Plate Heat Sink with Mini-Channels for Cooling High Heat Flux IGBT. Micromachines, 13(9), 1417. https://doi.org/10.3390/mi13091417