Study on Leakage Effect Factors of Two-Stroke Micro Free Piston Swing Engine

Abstract

:1. Introduction

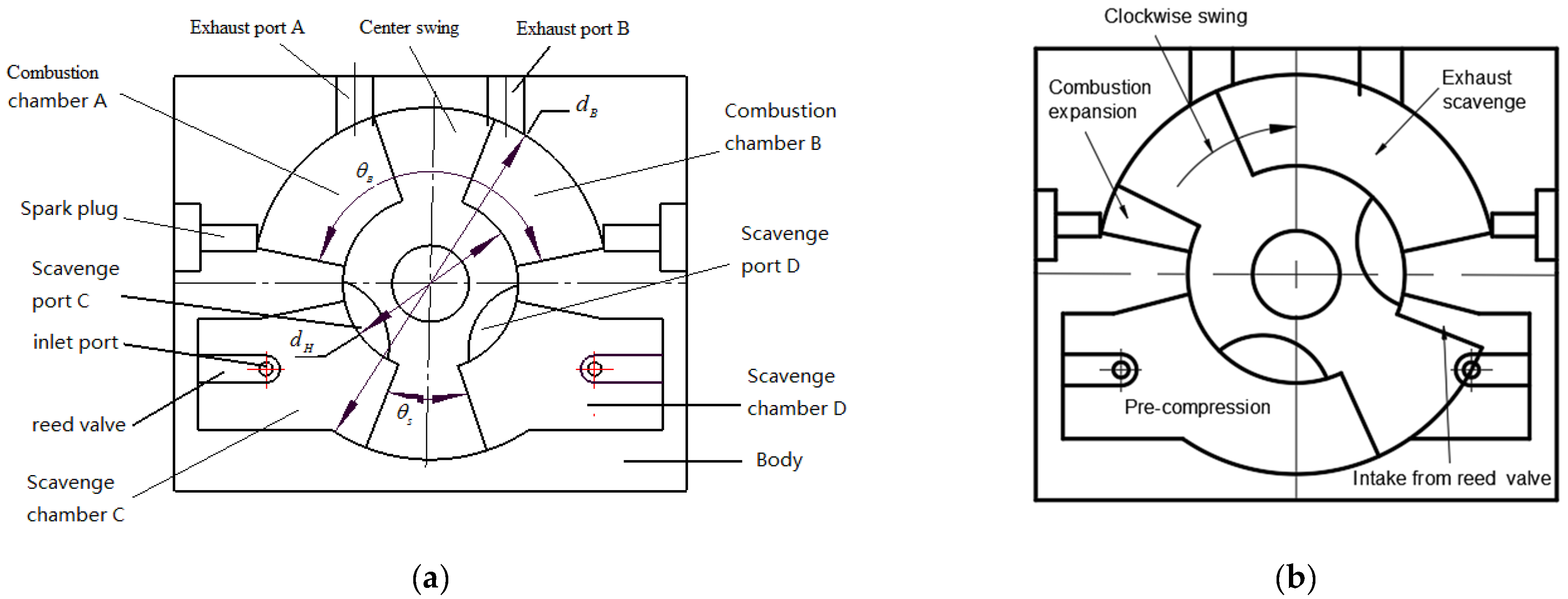

2. Structure and Working Principle of MFPSE

2.1. Structure Description

2.2. Working Principle

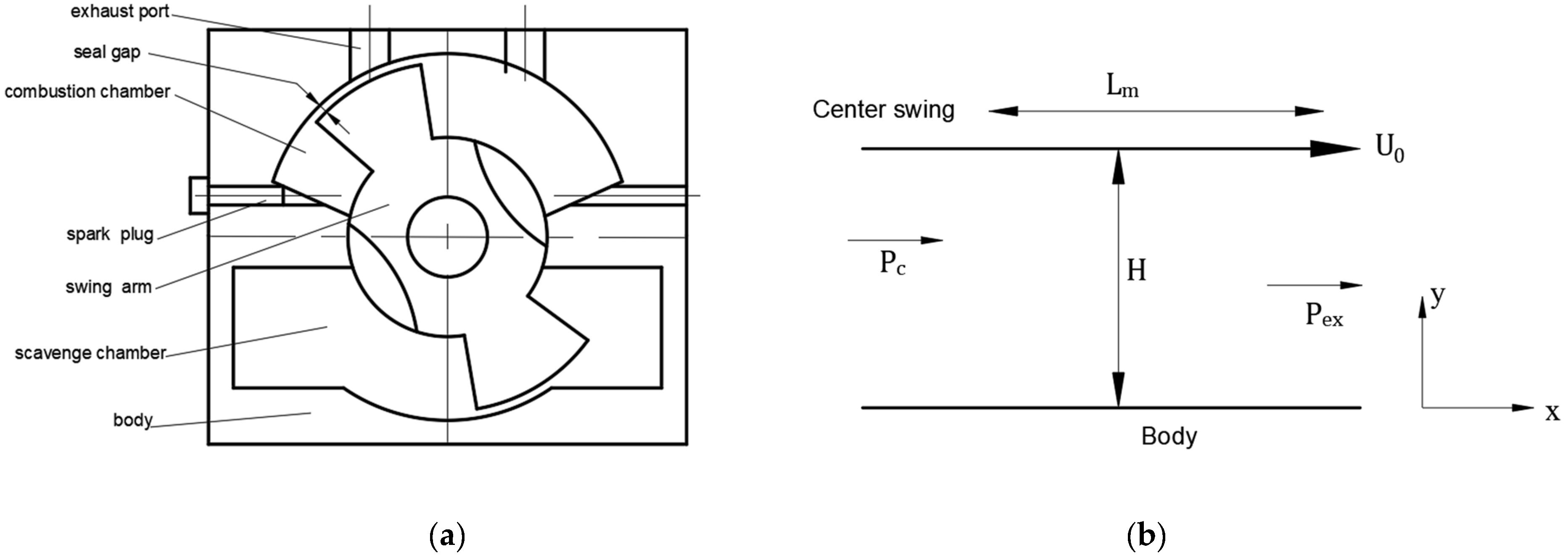

3. Leakage Model Established

3.1. Pressure and Temperature of Combustion/Scavenge Chamber

3.2. Leakage Model

- (1)

- The gap height between the body and the center swing was significantly smaller than the center swing radius, and thus the gap seal was modeled as a moving semi-infinite plane. In the same way, .

- (2)

- The quasi-static laminar, one-dimensional, and compressible flow was through the leakage gap.

- (3)

- Flow was viscous, taking the mixture as the working fluid.

- (4)

- We assumed no slip on the center swing or body walls.

3.3. Nondimensional Mass Leakage

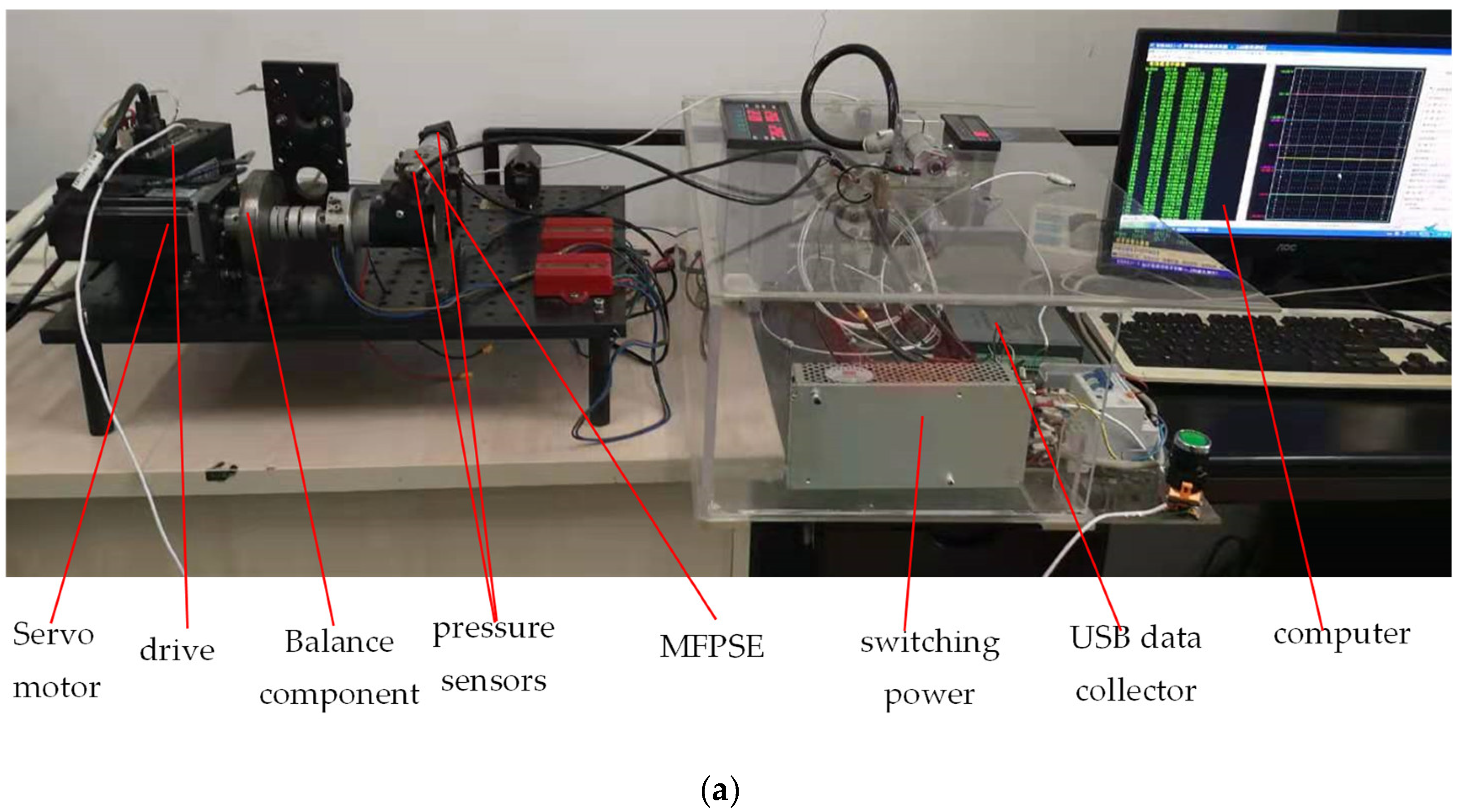

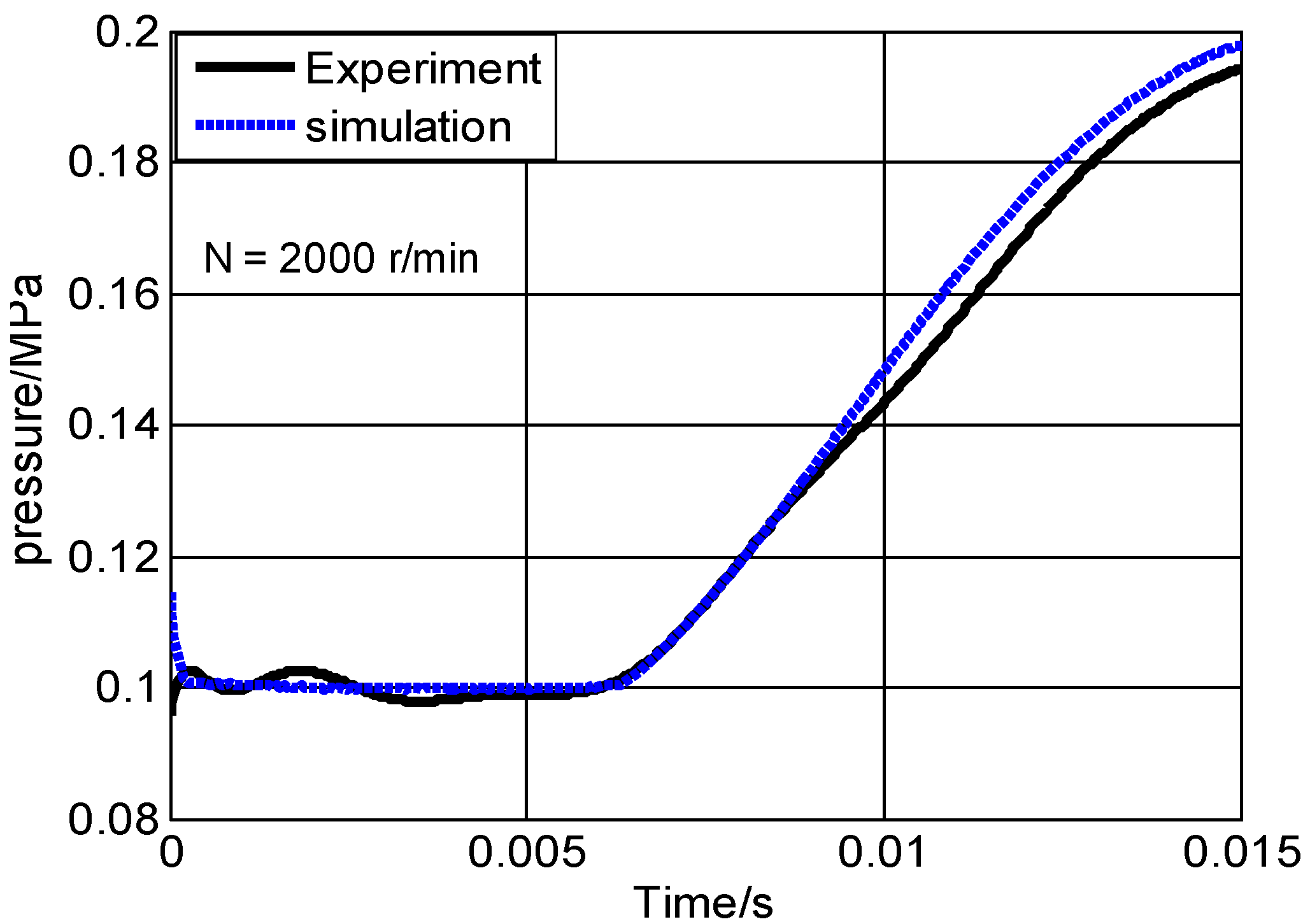

3.4. Model Validation

4. Results and Discussion

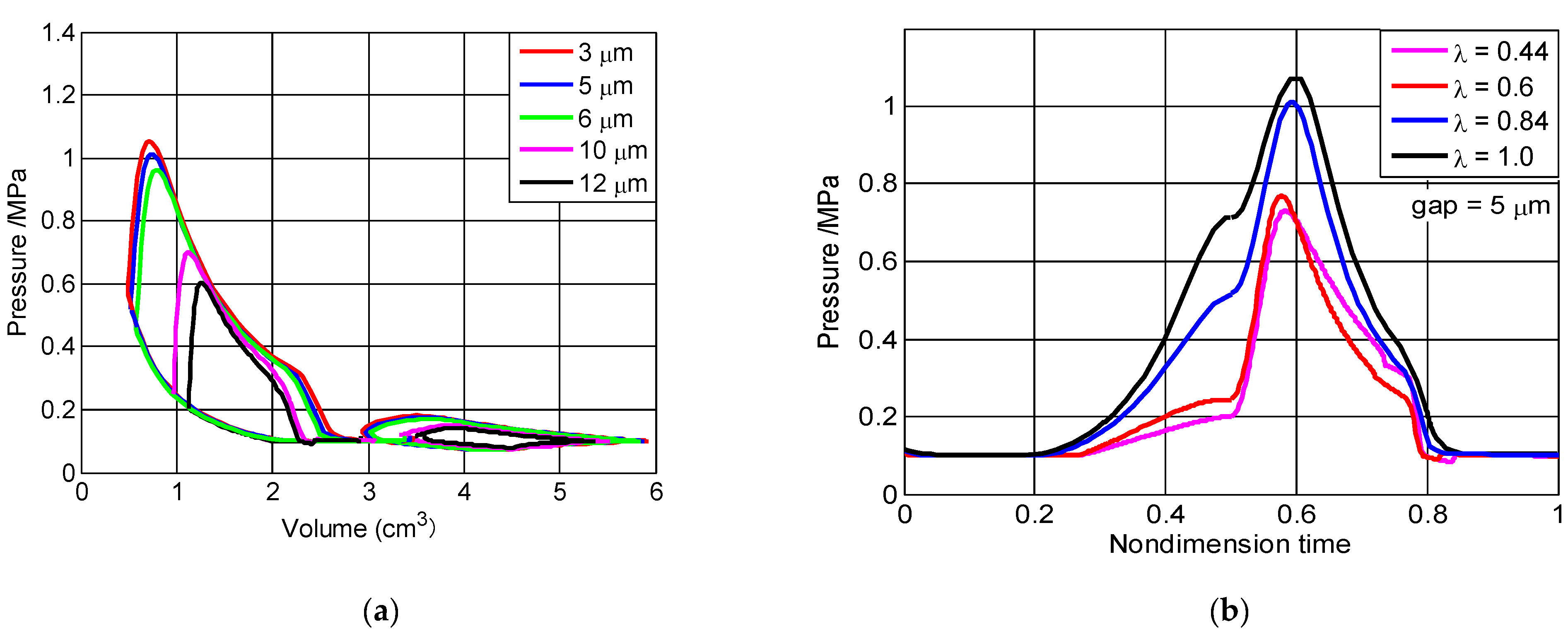

4.1. The Effects of Pressure at Different Seal Gap Heights and Size Factors

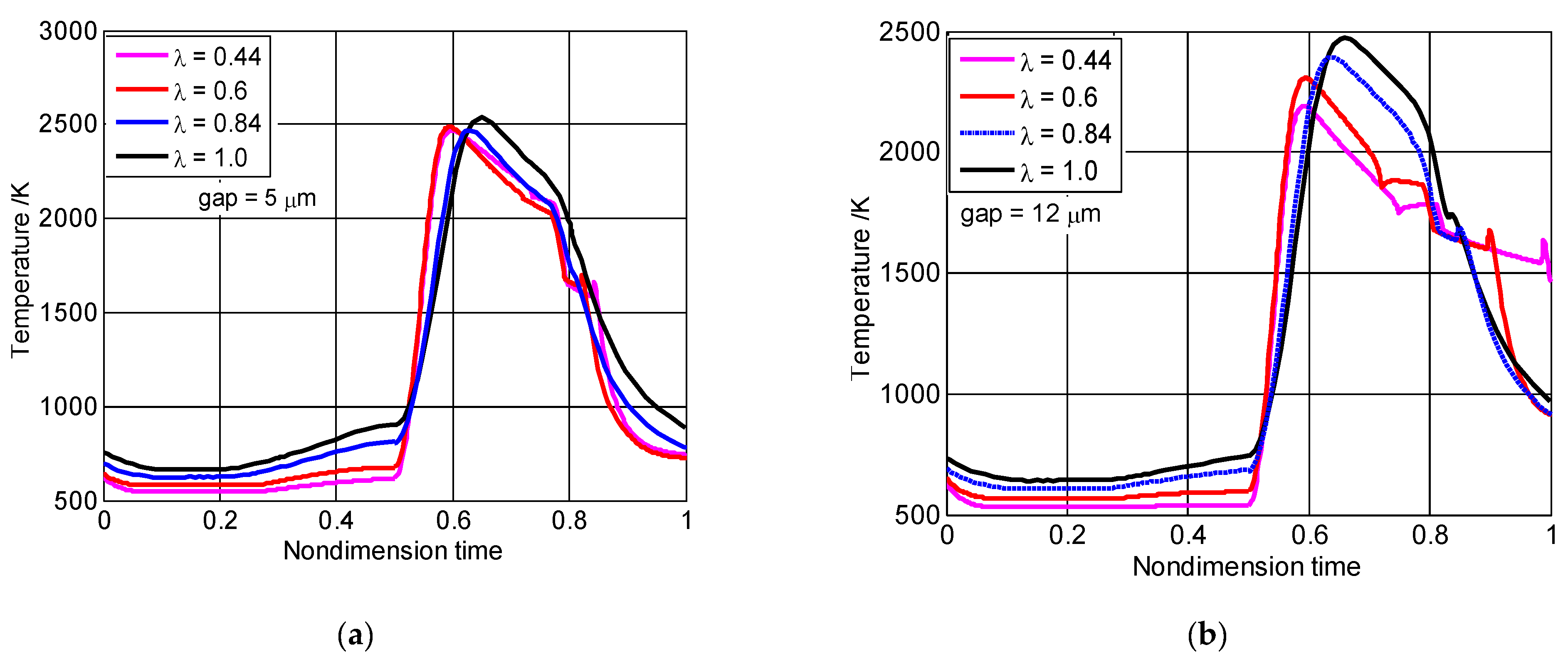

4.2. The Influence of Temperature for Different Size Factors

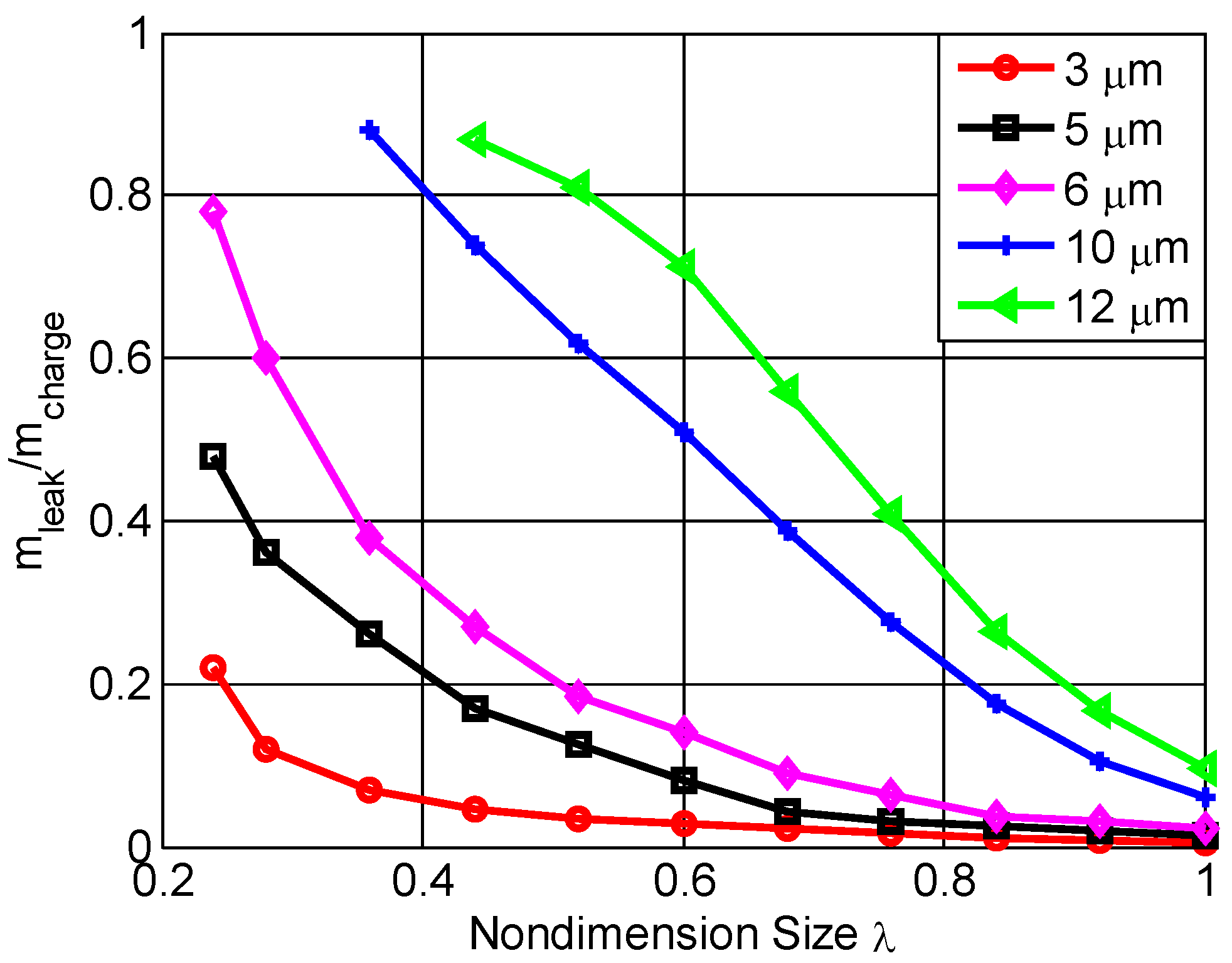

4.3. The Effect of Mass Loss for Different Size Factors

4.4. The Effect of Mass Leakage on the Compression Ratio

4.5. The Effect of Mass Leakage on the Size Factor

4.6. The Effect of Mass Leakage on the Dynamic Viscosity Coefficient

5. Conclusions

- (1)

- The leakage model of gap seal flow between the body and the center swing was established by the compressible flow Reynolds Navier–Stokes equation.

- (2)

- The nondimensional mass leakage of the combustion chamber was obtained. It was nonlinearly related to the seal gap, size factor, compression ratio, and seal inlet pressure.

- (3)

- When the seal gap was less than 5 μm, the maximum pressure, maximum temperature, and cycle power of combustion chambers were less affected. On the contrary, the maximum pressure and temperature decreased notably with decreases of size factor.

- (4)

- The mass leakage dramatically increased when the seal gap height μm, the size factor , or the compression ratio . Conversely, the mass leakage was not strongly affected.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Kaoru, M. Micro and Mesoscale Combustion. Proc. Combust. Inst. 2011, 33, 125–150. [Google Scholar]

- Sher, E.; Sher, I. Theoretical limits of scaling-down internal combustion engines. Chem. Eng. Sci. 2011, 66, 260–267. [Google Scholar] [CrossRef]

- Tang, G.Z.; Wang, S.B.; Zhang, L.; Shang, H.C. Diagnosis and improvement of combustion characteristics of methanol miniature reciprocating piston internal combustion engine. Micromachines 2020, 11, 96. [Google Scholar] [CrossRef] [PubMed]

- Epstein, A.; Senturia, S.; Al-Midani, O.; Anathasuresh, G.; Epstein, A.; Senturia, S.; Al-Midani, O.; Anathasuresh, G.; Ayon, A.; Breuer, K.; et al. Micro-heat engines, gas turbines, and rocket engines-the MIT micro engine project. In Proceedings of the 28th AIAA Fluid Dynamic Conference, Snowmass Village, CO, USA, 29 June–2 July 1997. [Google Scholar]

- Fu, K.; Knobloch, A.J.; Martinez, F.C.; Walther, D.C.; Fernandez-Pello, C.; Pisano, A.P.; Liepmann, D. Design and fabrication of a silicon-based MEMS rotary engine. In Proceedings of the 2001 ASME International Mechanical Engineering Congress and Exposition, New York, NY, USA, 11–16 November 2001; Volume 41, pp. 303–308. [Google Scholar]

- Wang, Q.; Wu, F.; Zhao, Y.; Bai, J.; Huang, R. Study on combustion characteristics and ignition limits extending of micro free–piston engines. Energy 2019, 179, 805–814. [Google Scholar] [CrossRef]

- Dahm, W.; Mijit, J.; Mayor, R.; Qiao, G.; Benajmin, A.; Gu, Y.; Lei, Y.; Papke, M.; Wu, S. Micro internal combustion swing engine (MICSE) for portable power generation systems. In Proceedings of the 40th AIAA Aerospace Science Meeting and Exhibition, Reno, NV, USA, 14–17 January 2002; p. 722. [Google Scholar]

- Lee, D.H.; Kwon, S. Heat Transfer and quenching analysis of combustion in a micro combustion vessel. J. Micromech. Microeng. 2002, 12, 670–676. [Google Scholar] [CrossRef]

- Ghobad, B.; Seyed, E.H. Impacts of inner/outer reactor heat recirculation on the characteristic of micro-scale combustion system. Energy Convers. Manag. 2015, 105, 45–53. [Google Scholar]

- Ren, T.A.; Zhang, C.F.; Jiang, Z.D. Study on the micro-size effect in ignition and combustion in micro-engine. J. Xi’an JiaoTong Univ. 2007, 41, 776–779. [Google Scholar]

- Hua, J.S.; Wu, M.; Kumar, K. Numerical simulation of the combustion of hydrogen-air mixture in micro-scaled chamber Part I: Fundamental study. Chem. Eng. Sci. 2005, 60, 3497–3506. [Google Scholar] [CrossRef]

- Aichlmayer, H.T.; Kittelson, D.B.; Zachariah, M.R. Micro-HCCI Combustion: Experimental Characterization and Development of a Detailed Chemical Kinetic Model with Coupled Piston Motion. Combust. Flame 2003, 135, 227–248. [Google Scholar] [CrossRef]

- Aichlmayr, H.T.; Kittelson, D.B.; Zachariah, M.R. Miniature free-piston homogeneous charge compression ignition engine-compressor concept—Part I: Performance estimation and design considerations unique to small dimensions. Chem. Eng. Sci. 2002, 57, 4161–4171. [Google Scholar] [CrossRef]

- Aichlmayr, H.T.; Kittelson, D.B.; Zachariah, M.R. Miniature free-piston homogeneous charge compression ignition engine-compressor concept—Part II: Modeling HCCI combustion in small scales with detailed homogeneous gas phase chemical kinetics. Chem. Eng. Sci. 2002, 57, 4173–4186. [Google Scholar] [CrossRef]

- Sher, E.; Sher, L.D. Scaling-Down of Miniature Internal Combustion Engines: Limitations and Challenges. Heat Trans. Eng. 2005, 26, 1–4. [Google Scholar] [CrossRef]

- Sher, I.; Sher, L.D.; Sher, E. Miniaturization limitations of HCCI internal combustion engines. App. Therm. Eng. 2009, 29, 400–411. [Google Scholar] [CrossRef]

- Wang, W.; Zuo, Z.X.; Liu, J.X. Miniaturization limitations of rotary internal combustion engines. Energy Convers. Manag. 2016, 112, 101–114. [Google Scholar] [CrossRef]

- Gu, Y. Gas Dynamic Modeling and Parametric Study of Mesoscale Internal Combustion Swing Engine/Generator Systems. Proquest Dissertations and Theses and Ph.D. Thesis, University of Michigan, Ann Arbor, MI, USA, 2006. [Google Scholar]

- Zhang, S.M.; Guo, Z.P.; Wang, J.S. Performance analysis of a 2-stroke micro free-piston swing engine. Pet. Sci. 2009, 3, 313–318. [Google Scholar] [CrossRef]

- Sun, M.; Zhang, Z.Y.; Kong, W.J. Design of sealing structure and analysis of the flow filed in micro internal combustion swing engine. Appl. Mech. Mater. 2014, 670, 930–935. [Google Scholar] [CrossRef]

- Shi, B.; Yu, H.; Zhang, J. The effects of the various factors and the engine size on micro internal combustion swing engine (MICSE). Appl. Therm. Eng. 2018, 144, 262–268. [Google Scholar] [CrossRef]

- Zhou, X.; Zhang, Z.; Kong, W.; Du, N. Investigations of leakage mechanisms and its influences on a micro swing engine considering rarefaction effects. Appl. Therm. Eng. 2016, 106, 674–680. [Google Scholar] [CrossRef]

- Du, N.; Kong, W.J. Experimental and Numerical studies of Microscale internal combustion Swing Engine (MICSE). J. Therm. Sci. 2021, 30, 1705–1717. [Google Scholar] [CrossRef]

- Zhang, S.M.; Wang, J.S.; Guo, Z.P. Novel Micro Free-Piston Swing Engine and Its Feasibility Validation. Tsinghua Sci. Technol. 2005, 10, 381–386. [Google Scholar] [CrossRef]

- Heywood, J.B. Internal Combustion Engine Fundamentals; McGraw Hill Book Company: New York, NY, USA, 1988. [Google Scholar]

- Hohenberg, G.F. Advanced Approaches for Heat Transfer Calculations; SP-449; SAE International Publications: Pittsburgh, PA, USA, 1979; pp. 61–79. [Google Scholar]

- Epstein, A.H. Millimeter-scale, micro-Electro-Mechanical systems gas turbine engines. J. Eng. Gas Turbines Power 2004, 126, 205–226. [Google Scholar] [CrossRef]

| Initial Parameters | Value |

|---|---|

| /mm | 46 |

| /mm | 25 |

| /° | 120 |

| /° | 44 |

| Intake pressure/MPa | 0.1 |

| Intake temperature/K | 300 |

| Exhaust pressure/MPa | 0.1 |

| Exhaust temperature/K | 300 |

| Equivalent ratio | 0.6 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Miao, S.; Liu, H.; Cen, H.; Liu, J.; Li, H.; Xu, G. Study on Leakage Effect Factors of Two-Stroke Micro Free Piston Swing Engine. Micromachines 2022, 13, 1314. https://doi.org/10.3390/mi13081314

Miao S, Liu H, Cen H, Liu J, Li H, Xu G. Study on Leakage Effect Factors of Two-Stroke Micro Free Piston Swing Engine. Micromachines. 2022; 13(8):1314. https://doi.org/10.3390/mi13081314

Chicago/Turabian StyleMiao, Shujing, Haiyang Liu, Haitang Cen, Jiang Liu, Huaqiang Li, and Gang Xu. 2022. "Study on Leakage Effect Factors of Two-Stroke Micro Free Piston Swing Engine" Micromachines 13, no. 8: 1314. https://doi.org/10.3390/mi13081314

APA StyleMiao, S., Liu, H., Cen, H., Liu, J., Li, H., & Xu, G. (2022). Study on Leakage Effect Factors of Two-Stroke Micro Free Piston Swing Engine. Micromachines, 13(8), 1314. https://doi.org/10.3390/mi13081314