Abstract

A gas cooler is one of the important parts of a carbon dioxide (CO2) heat pump water heater, and it must meet the needs of not only pressurization but also heat transfer. It is important to study gas coolers. In this paper, a heat exchanger with a spiral channel is studied. ANSYS CFX software was used to analyze the flow and heat transfer characteristics of the heat exchanger (single-plate model). The influences of the cooling pressure of CO2, the mass flux of CO2, the mass flux of water and the channel radius of CO2 are discussed. In this paper, the results show that the cooling pressure of CO2, the mass flux of CO2 and the channel radius of CO2 all have a large influence on the local heat transfer coefficient: with an increase in the cooling pressure of CO2, the peak value of the heat transfer coefficient of CO2 decreases and the average heat transfer coefficient decreases; with an increase in the mass flux of CO2, the peak value of the heat transfer coefficient of CO2 increases and the average heat transfer coefficient increases; and with a decrease in the channel radius of CO2, the peak value of the heat transfer coefficient of CO2 increases. The water mass flux has only a slight effect on heat transfer, and the lower cooling pressure of CO2 corresponds to a higher peak heat transfer coefficient, which can reach 27.5 kW∙m−2∙K−1 at 9 MPa.

1. Introduction

CO2 is an excellent candidate due to its nontoxicity, incombustibility, safety, low cost and environmentally benign nature (ODP = 0, GWP = 1). It is widely implemented in refrigeration and heat pump systems, air conditioning and various industrial uses. Lorentzen first proposed the application of trans-critical carbon dioxide cycles to automotive heat pumps in 1993, and this was the beginning of the widespread application of carbon dioxide heat pumps in various fields [1]. The gas cooler is one of the important parts of a CO2 heat pump. According to the different cooling media used, gas coolers are mainly divided into air-cooled and water-cooled. The air-cooled type is mainly used for automotive heat pumps, divided into tube-fin and microchannel coolers; the water-cooled type is mainly used for trans-critical CO2 heat pump water heaters, mostly using double pipes. Chang analyzed tube-fin gas coolers with different circuits through an experimental study, as well as the effect of geometric factors on heat transfer, and found that three circuits were optimal [2]. Chai simulated a tube-fin gas cooler with distributed modeling and used the ε-NTU method to research the effect of design factors on the cooling performance of the whole gas cooler [3]. Wang studied a herringbone wavy-fin gas cooler and proposed a new heat transfer correlation with an average error of 8.82% [4]. Ge first constructed a mathematical model by dividing the tube-fin gas cooler into four regions and verified it with experimental results, which matched well; then, a finite difference model was developed to simulate the performance of the gas cooler; finally, the model was used to simulate and analyze the gas cooler with different circuits [5,6,7]. Zhang analyzed the heat transfer performance of an existing tube-fin gas cooler model with the CFD method [8,9]. Zilio and Simone designed three different shell and tube gas coolers and performed experimental and simulation analyses; they found that the influence of different tube types of inlet water flow rates on the heat production rate was reduced at 10 MPa, and the heat production rate was relatively high for smooth and internally grooved tubes [10]. Fronk designed a cross-flow plate type microchannel gas cooler and researched the heat transfer and pressure drop characteristics of the gas cooler with both five water flow channels and with seven water flow channels, at different inlet flow rates and inlet temperatures, and he summarized the heat transfer correlations based on the experimental results and also simulated the performance of a microchannel heat exchanger with 12 water flow channels. The study showed that the microchannel gas cooler was superior to the double pipe gas cooler [11,12]. Starace proposed a method to investigate and find the overall performance of a heat exchanger starting from CFD simulations at the micro-scale; the study showed that the multi-scale approach leads to a better accuracy level than the full-scale one [13]. Fiorentino carried out some numerical simulations of the evaporative condenser heat and mass transfer processes at the tube scale, then studied two different types of flow by varying the water-to-air mass flow ratio. He found that a decrease of 25% in the water-to-air mass flow ratio led to the film separating into droplets. A test rig to investigate the evaporative condenser at small scale had been designed and built. An increase of 37.5% in the air flow rate (at a constant rate of sprayed water) led to a maximum reduction in the heat transfer rate of 50% [14,15]. Bilal used the fouling model to investigate the risk-based thermal performance of these evaporative heat exchangers and carried out sensitivity analysis, finding that the condensing temperature is the most sensitive parameter; for any increase in the inlet’s relative humidity, the normalized sensitivity of the surface area increased [16,17]. Scattina developed a new methodology that allows scaling-up from the CFD analysis of a small element to the prediction of the performance of an entire compact heat exchanger [18].

Current research on trans-critical CO2 heat pump gas coolers is focused on the double pipe and tube-fin types, with no structural innovation. Gas coolers must be able to withstand high pressure, with high reliability, low costs, compactness, efficiency and other requirements. A double pipe gas cooler is not compact enough, not easy to scale and is difficult to clean, so it is not good enough to meet the above needs. The concept of a spiral heat exchanger was first proposed in the late nineteenth century and was reinvented in Sweden during the 1930s. Up to now, much research relating to the characteristics of spiral heat exchangers has been presented by researchers. According to Bes, spiral heat exchangers have high thermal efficiency and compactness, and they have only one cross-sectional channel for each fluid, in which the flow direction is constantly changing, thus eliminating the flow stagnation zone channel and making it difficult for fouling to remain, and it rarely scales [19]. If the heat exchanger is fouled, this can be soaked in white vinegar, dissolved with anhydrous ethanol, and finally blown with dry compressed air since the CO2 channel must be kept dry. In this paper, a new spiral plate mini-channel gas cooler with asymmetric channels on both sides is proposed for CO2 heat pump gas coolers with relatively large water and CO2 flow rates.

ANSYS CFX software (ANSYS, Canonsburg, PA, USA) was used to simulate the flow and heat transfer characteristics of supercritical carbon dioxide in the new mini-channel gas cooler, and to analyze the influence of different structural parameters and working conditions on heat transfer, so as to provide more directions and new ideas for research on trans-critical carbon dioxide heat pump gas coolers.

2. Physical Model

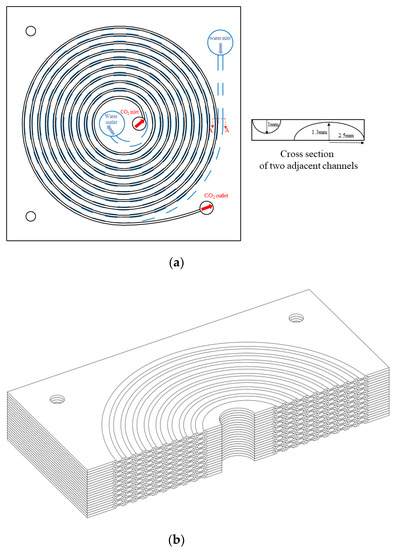

The geometric details of the new mini-channel heat exchanger are shown in Figure 1. The mini-channel heat exchanger consists of two different plates alternating in sequence. Figure 1a shows one of them with a semi-circular channel of CO2 above and a semi-elliptical channel of CO2 below; the other plate has a semi-elliptical channel above and a semi-circular channel below, and the two plates are alternately stacked in sequence to form the whole heat exchanger. The overall schematic is shown in Figure 1b, and the important dimensions of the gas cooler are listed in Table 1. The hydraulic diameters of the CO2 channels and the water channels were selected according to plate thicknesses available on the market, pressure-bearing capacity and mass flow rate. CO2 and water are counter-flowing, with CO2 flowing from inside to outside and water flowing from outside to inside, as seen in Figure 1a. Two different channels are distributed on both sides of the plate, which can prevent the mixing of fluids. Each plate is stacked and combined into a whole, connected together by diffusion welding, and can withstand high pressure. Diffusion welding is a kind of pressure welding and refers to the process of surfaces being brought into mutual contact under the action of high temperature pressure. With the connected surfaces close to each other, and local plastic deformation, after a certain period of time the atoms of the bonding layer diffuse and intersperse with each other, forming a reliable connection of the whole.

Figure 1.

(a) A type of structural plate; (b) Overall schematic.

Table 1.

Important dimensions of the gas cooler.

3. Structural Strength Analysis

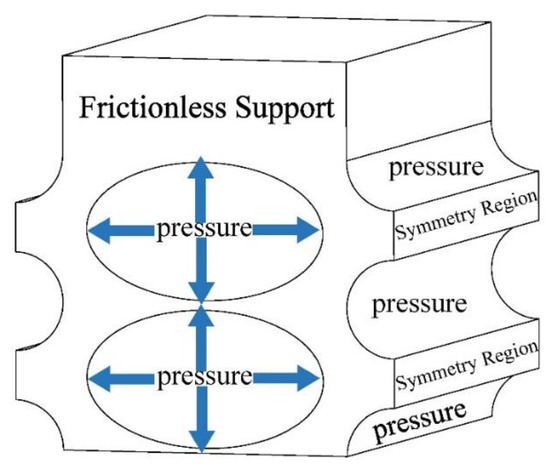

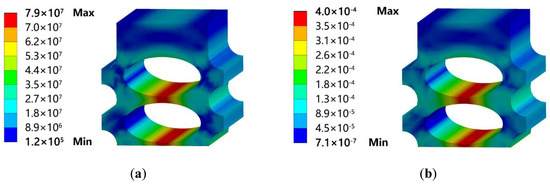

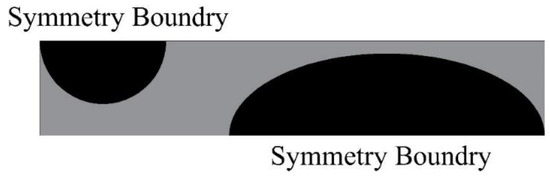

As the CO2 side of the gas cooler must be able to withstand high pressures of at least 13 MPa, the strength analysis of the designed heat exchanger was first performed to determine whether its pressure bearing capacity meets the requirements. The ANSYS Static Structural test was used for the analysis, and the model was simplified to a straight section of 1 cm in length, as shown in Figure 2. The bottom and right side of the models were set as symmetric boundary conditions, and the front face was set as frictionless support. After setting up the conditions, the stress and strain solutions were carried out. The stress and strain are displayed in Figure 3. Figure 3 shows the results with the boundary conditions of 20 MPa applied on the CO2 side and 0.5 MPa applied on the water side. It was found that the elliptical channel can bear 20 MPa pressure, which was far beyond the pressurization.

Figure 2.

Strength analysis model and boundary condition setting.

Figure 3.

(a) Stress; (b) Strain.

4. Numerical Model

4.1. Data Reduction

The relevant governing equations for the turbulence model are shown in Appendix A. The local bulk temperature of the supercritical CO2 and the cooling water, the inner wall temperature of the channel and the heat flux on the wall along the channel were obtained from the numerical results. The heat transfer coefficient of the supercritical CO2 flowing in the channel was calculated as:

where qx and TW,x are the circumferentially averaged heat flux and temperature on the inner wall along the channel, respectively, which were calculated as:

L is the length of the semicircle arc on the inner wall where the axial position is equal to x. x represents the axial location along the channel. Unlike the traditional definition of the bulk temperature of fluids with constant properties, the bulk temperature of the supercritical CO2 was determined by the average enthalpy, which was calculated as:

The bulk temperature of the supercritical CO2 was defined as:

The mass flux was defined as:

4.2. Reliability Verification

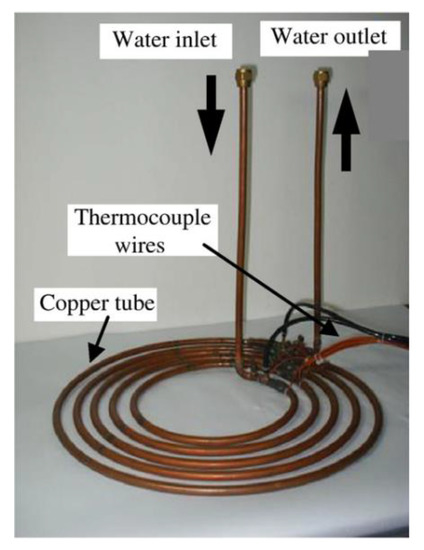

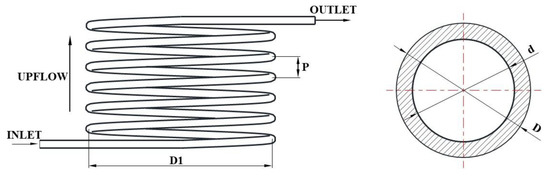

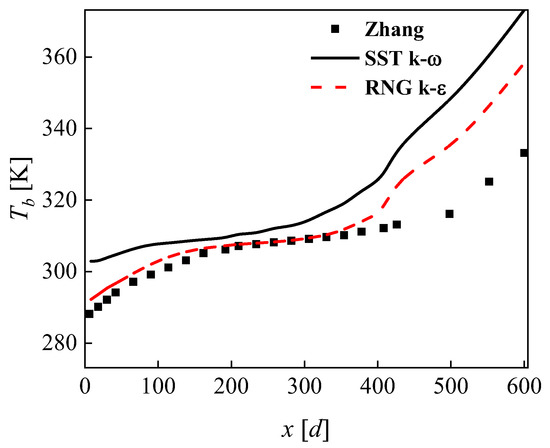

Because of the novel structure proposed in this paper, there were no relevant experiments for CO2 heat exchangers that could be verified. In Paisarn’s study, numerical and experimental results of the heat transfer and flow characteristics of a horizontal spiral-coil tube (Figure 4) were investigated. The RNG two-equation turbulence model was applied to simulate turbulent flow and heat transfer characteristics. Reasonable agreement was obtained by comparison between the results from the experiment and those obtained from the model [20]. The channel of CO2 in this paper was a circular cross-section spiral channel, and a similar spiral tube was selected for turbulence model verification. Experimental results for the conjugate heat transfer between supercritical CO2 and water by Zhang were used to validate the numerical method [21]. The geometric model of the spiral tube is shown in Figure 5. The specific dimensions of the spiral tube used in the simulation were: inner diameter 9 mm, outer diameter 12 mm, coil diameter 283 mm, pitch 32 mm. Supercritical CO2 flowed from the bottom to the top inside the spiral tube and was heated by the wall. The pressure was 8.02 MPa, the inlet mass flux was 97.92 kg/(m2·s), the inlet temperature was 288.15 K and the heat flux was 10.4 kW/m2. Figure 5 shows the variation in the bulk temperature with x/d at different cross sections simulated by the two turbulence models compared with the experimental data of Zhang. The horizontal coordinate x/d in the figure indicates the ratio of the distance from this cross-section to the inlet cross-section to the pipe diameter. It can be seen from Figure 6 that the results obtained from the RNG model simulations are in better agreement with the experimental data, indicating that the RNG model has higher accuracy in calculating the rotational flow. The large deviation in the two turbulence models in the high temperature prediction may be attributed to the constant heat flow conditions that cause heat to accumulate at the outlet. The RNG model was used in the subsequent simulations.

Figure 4.

The physical model of spiral-coil tube.

Figure 5.

Schematic of spiral tube geometry model.

Figure 6.

Comparison of simulation and experimental values of the average temperature of the inner cross-section of the spiral tube.

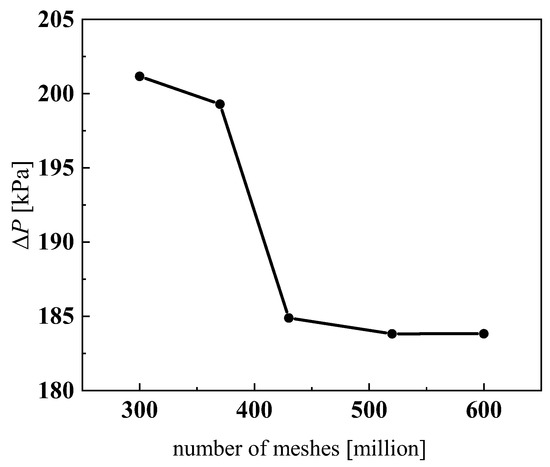

4.3. Grid Independence

Due to the large computational resources consumed by the overall analysis, a single plate of the heat exchanger was used for the analysis in this paper, as shown in Figure 1a. The spiral channel of CO2 on one side of the plate had a 1 mm radius semicircle cross-section, a spiral start radius of 10 mm, an end radius of 90 mm and a pitch of 8 mm. On the other side, for the spiral channel of water, the long semi-axis of the channel cross-section was 2.5 mm, the short semi-axis was 1.3 mm, the spiral start radius was 14 mm, the end radius was 86 mm and the pitch was 8 mm. The veneer was a 200 mm × 200 mm square.

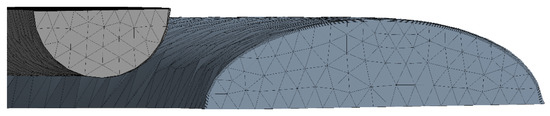

Workbench meshing was used to divide the fluid domain and the solid domain into meshes, and the cross-sections of two adjacent channels of heat transfer units in a single plate are displayed in Figure 7. To eliminate the impact of the entrance and exit regions, some extensions were made to the channel. In order to obtain more accurate calculation results, and at the same time avoid excessive calculation, it was necessary to compare the calculation results under different grid numbers, and that grid division is shown in Figure 8. The first layer thickness in the CO2 region was set to 0.0000003 mm to make sure that the dimensionless wall distance y+ < 1. The mass flow rates of CO2 and water were 0.0033 kg·s−1 and 0.01 kg·s−1, respectively. The inlet temperatures of CO2 and water were 373.15 K and 293.15 K, respectively. The pressure of CO2 and water were 9 MPa and 0.5 MPa, respectively. Setting symmetric boundary conditions on the surface of the two fluid domains, the residuals reached 10−6 and the calculation converged. In this paper, five sets of different grid dimensions with total grid numbers of 3.0 million, 3.7 million, 4.3 million, 5.2 million and 6.0 million were selected to carry out subsequent numerical simulations by calculating the pressure drop of CO2, as displayed in Figure 9, and finally, a 5.2 million grid was selected.

Figure 7.

Heat exchanger unit boundary conditions.

Figure 8.

Grid partition.

Figure 9.

Grid independence.

5. Results and Discussion

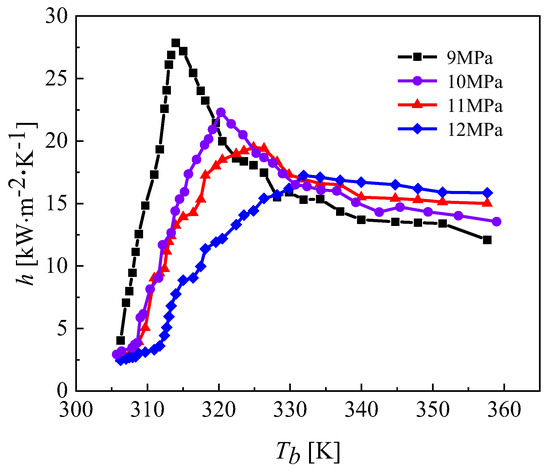

5.1. Effect of Cooling Pressure of CO2 on Heat Transfer

In this section, the main goal is to research the effects of different cooling pressures on heat transfer. The mass flow rates of CO2 and water were 0.0033 kg·s−1 and 0.01 kg·s−1, respectively. The inlet temperatures of CO2 and water were 373.15 K and 293.15 K, respectively. The pressure of CO2 and water were 10 MPa and 0.5 MPa, respectively. The CO2 heat transfer coefficient under cooling pressure is shown in Figure 10. The specific calculation conditions are listed in Table 2.

Figure 10.

Effect on the heat transfer coefficient of CO2 at different cooling pressures.

Table 2.

Calculation conditions.

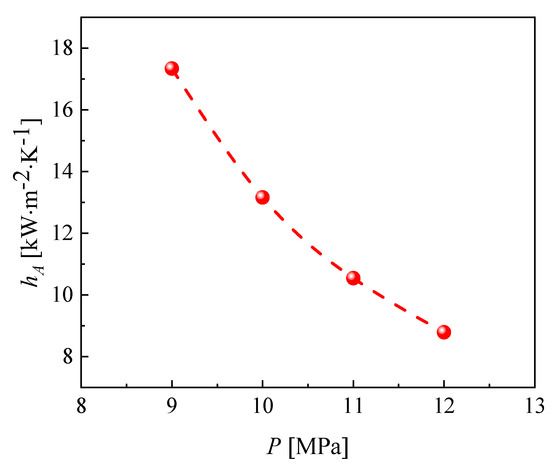

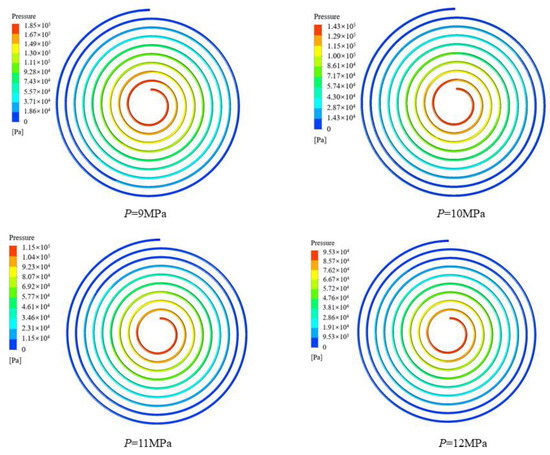

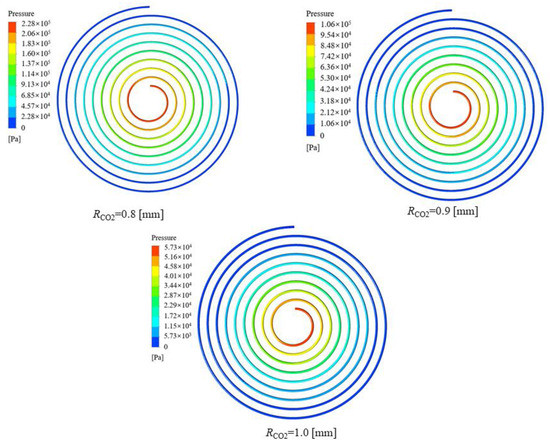

It can be seen from Figure 10 that the peak value of the local heat transfer coefficient of CO2 decreases as the cooling pressure increases, and the critical temperature corresponding to the peak value is different. The fluid temperatures corresponding to the peak heat transfer coefficients at cooling pressures of 9, 10, 11 and 12 MPa were 313.15 K, 320.15 K, 324.15 K and 334.15 K, respectively. The closer to the pseudocritical point, the higher the constant pressure specific heat capacity and thermal conductivity of CO2, hence the higher the corresponding local heat transfer coefficient. The reason the heat transfer coefficients are relatively close at different pressures away from the pseudocritical point is that the specific heat capacity of carbon dioxide changes slightly at different pressures and the larger thermodynamic changes are mainly concentrated near the pseudocritical point. The peak heat transfer coefficient of CO2 reaches 27.5 kW∙m−2∙K−1 at a cooling pressure of 9 MPa. Figure 11 shows that the average CO2 heat transfer coefficient decreases gradually as the cooling pressure increases. Figure 12 illustrates the pressure distribution of CO2.

Figure 11.

Variation in the average heat transfer coefficient of CO2 at different cooling pressures.

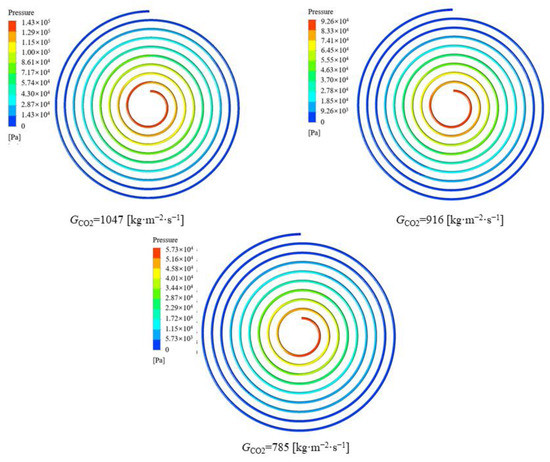

Figure 12.

Variation in the pressure contour of CO2 at different cooling pressures.

5.2. Effect of Inlet Mass Flux of CO2 on Heat Transfer

In this section, the effects of different mass fluxes of CO2 on the heat transfer characteristics are discussed. The conditions were the same as in the previous section except for the mass flux of CO2. The mass flow rate of water was 0.01 kg·s−1. The inlet temperatures of CO2 and water were 373.15 K and 293.15 K, respectively. The pressure of CO2 and water were 10 MPa and 0.5 MPa, respectively. The specific calculation conditions are given in Table 3.

Table 3.

Calculation conditions.

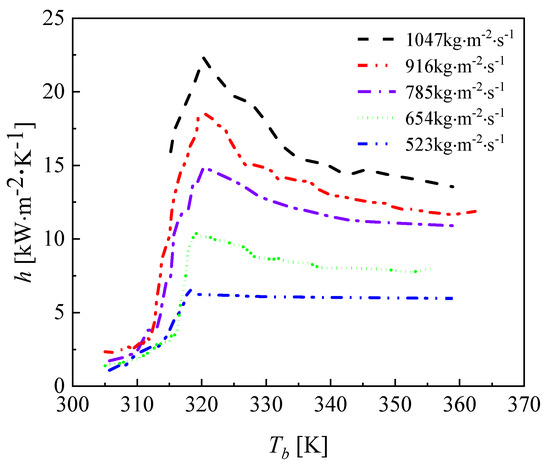

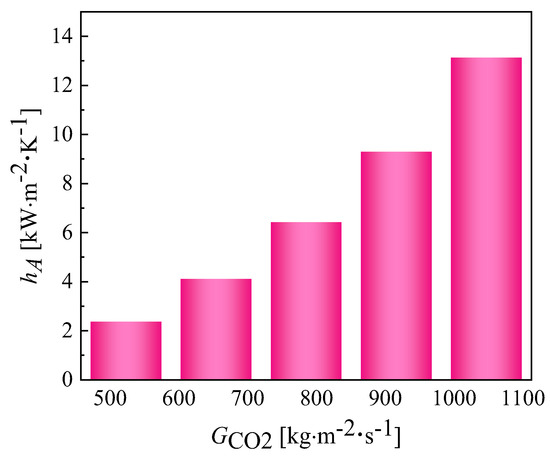

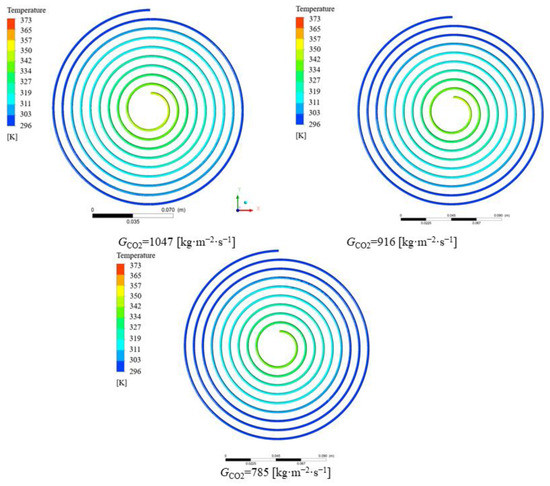

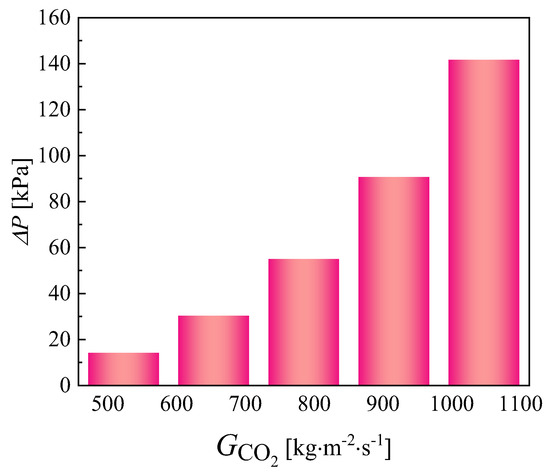

The variation in the convective heat transfer coefficient with different mass fluxes in the CO2 channel is given in Figure 13. As the mass flux increases, the convective heat transfer coefficient of CO2 also increases. The reason for this is that as the mass flux increases, the intensity of the turbulence in the channel increases and the fluid continuously scours the wall, affecting the formation of the boundary layer. The changing pattern of the average heat transfer coefficient at different mass fluxes is described in Figure 14. Figure 15 shows the variation in temperature of CO2 at different mass fluxes. It can be seen from the figure that the heat transfer in the outer ring is becoming worse and the channel length can be considered to be shortened in the subsequent optimization. Figure 16 and Figure 17 give the variation in the pressure drop in the channel of CO2 with the mass flux. With the increase in the mass flux, the pressure drop in the channel increases continuously, and the variation in the pressure drop in the channel at the lower mass flux is slightly smaller than that at the larger mass flux. The difference in the pressure drop tends to increase gradually with the increasing of the mass flux. According to the changing of the pressure drop and the heat transfer coefficient with the mass flux, it is necessary to balance the two conditions to choose the most suitable working condition. In the conventional type of heat exchangers, the average heat transfer coefficient of double pipe and shell and tube heat exchangers is mostly below 5 kW∙m−2∙K−1, while the average heat transfer coefficient of PCHE and microtube heat exchangers can reach 10 kW∙m−2∙K−1; the pressure drop is mostly below 100 kpa, so the disadvantage of spiral heat exchangers is the large pressure drop. According to the ngo study, the volumetric thermal capacity of PCHE can reach 25,000 kw/m3 with a hydraulic diameter of 1 mm and the volumetric thermal capacity of a spiral heat exchanger is 19,000 kw/m3 [22].

Figure 13.

Variation in the heat transfer coefficient of CO2 at different mass fluxes.

Figure 14.

Variation in the average heat transfer coefficient of CO2 at different mass fluxes.

Figure 15.

Variation in the temperature of CO2 at different mass fluxes.

Figure 16.

Variation in the pressure drop of CO2 at different mass fluxes.

Figure 17.

Variation in the pressure contour of CO2 at different mass fluxes.

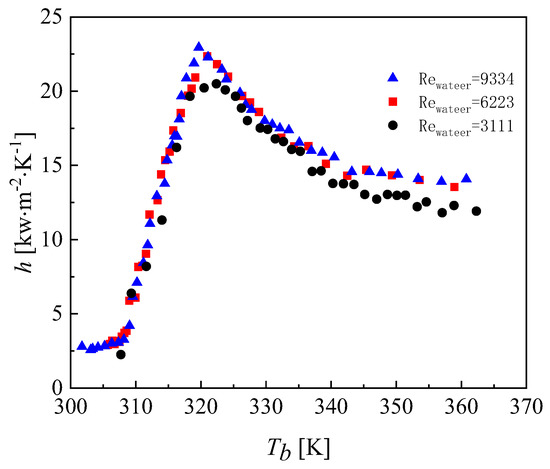

Figure 18 shows the effect of different mass fluxes in the water channel on the heat transfer coefficient of CO2. From Figure 15, it can be seen that increasing the inlet mass flux on the water side slightly increases the heat transfer coefficient of CO2. Due to the heat transfer between the water and the outer surface of the metal wall increasing with the intensity of the water turbulence as the mass flux of the water increases, the heat transfer coefficient between carbon dioxide and the metal wall increases accordingly. The water flow rate affects the outer wall surface temperature of CO2, and enhanced heat transfer can be achieved by changing the outer wall surface temperature of the CO2. This also corroborates the study of Jiang that proposed that, to enhance heat transfer, the heat transfer of water is an influential factor that needs to be considered comprehensively [23].

Figure 18.

Variation in the heat transfer coefficient of CO2 at different water mass fluxes.

5.3. Effect of Channel Size of CO2 on Heat Transfer

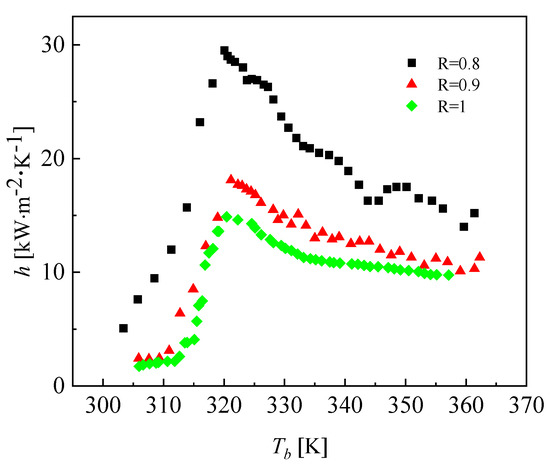

In this section, the effects of different channel radiuses of CO2 on the heat transfer characteristics are investigated. The mass flow rates of CO2 and water were 0.002466 kg·s−1 and 0.01 kg·s−1, respectively. The inlet temperatures of CO2 and water were 373.15 K and 293.15 K, respectively. The pressure of CO2 and water were 10 MPa and 0.5 MPa, respectively. The effects on the heat transfer coefficient of CO2 at different channel radiuses are shown in Figure 19.

Figure 19.

Effect of channel radius on the heat transfer coefficient of CO2.

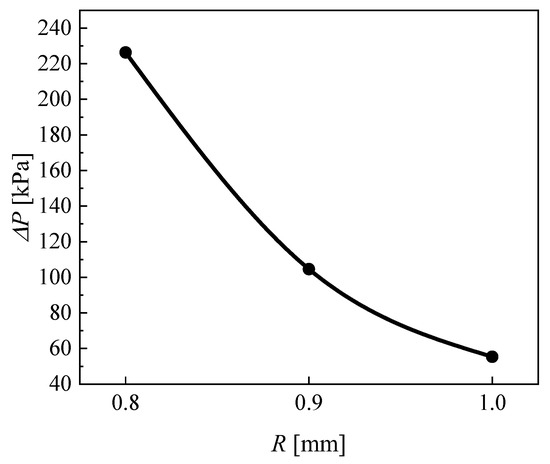

Figure 19 illustrates the effect of the channel radius on the heat transfer coefficient of CO2. It can be seen that the heat transfer coefficient of CO2 increases as the channel radius of CO2 decreases. The reason is that reducing the channel radius of CO2 corresponds to reducing the cross-section, which is equivalent to increasing the mass flux under the same conditions and increasing the turbulence intensity. Furthermore, the increase in the heat transfer coefficient was larger when the channel radius of CO2 was 0.8 mm, and this was accompanied by a dramatic increase in the pressure drop. Under this condition, the heat transfer coefficients of CO2 with all three different channel radiuses reached the peak at the pseudocritical point. Figure 20 and Figure 21 display the effect of the channel radius on the pressure drop of CO2. As the channel radius decreases, the pressure drop increases.

Figure 20.

Effect of channel radius on the pressure drop of CO2.

Figure 21.

The pressure contour of CO2 at different channel radiuses.

5.4. Field Synergy Principle of Heat Exchange

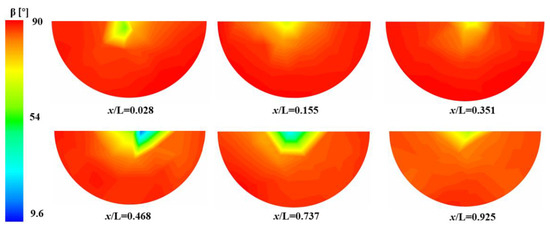

A further analysis of the heat transfer characteristics of CO2 used the field synergy principle. This starts from the two-dimensional boundary layer convective heat transfer differential equation. Guo deduced the field synergy principle by considering convection as a special endothermic source [24]. Generally, the most frequently used field synergy principle analysis mainly uses the synergy angle as a primary indicator of synergy degree to analyze the mechanism of convective heat transfer enhancements. The synergy angle can be calculated with the following equation:

Figure 22 shows the long-range synergy angle distribution within the channel of CO2. The smaller synergy angle is concentrated in the center of the channel, mainly because the temperature gradient at the center of the channel is along the axial direction and the flow direction consistency is higher. Heat transfer from the channel wall is dominated by thermal conduction near the wall boundary layer, so the temperature gradient is mainly along the wall normal direction, with a large angle to the flow direction. The location of the better synergy within the channel of CO2 is at the peak heat transfer coefficient (x/L = 0.468).

Figure 22.

The variation in the synergy angle in different axial positions.

6. Conclusions

In this study, the heat transfer between CO2 and water in a spiral heat exchanger is numerically analyzed. The main results of this study are as follows:

- Spiral plate heat exchanger pressurization is good; when the radius of the circular channel is 1 mm, the elliptical channel short axis is 2.3 mm and the long axis is 5 mm, it can withstand the high pressure of 20 MPa.

- As the cooling pressure decreases, the average heat transfer coefficient of CO2 increases, the heat transfer capacity is enhanced and the peak heat transfer increases. Mainly owing to the fact that the lower the pressure, the higher the specific heat will be at constant pressure, the average heat transfer coefficient of CO2 is also higher.

- The higher the mass flux of CO2, the higher the corresponding peak local convective heat transfer coefficient, which occurs near the pseudocritical temperature corresponding to the cooling pressure.

- The effects of changing the mass fluxes of water and CO2 on the heat transfer coefficient of CO2 are different. The increase in the mass flux of CO2 and the decrease in the channel radius have a more obvious effect on the heat transfer coefficient, while the increase in the mass flux of water affects the temperature of the wall surface of CO2.

- The locations with smaller synergy angles within the channel of CO2 are distributed in the center of the channel, and the locations with better synergy occur at the location of the peak heat transfer coefficient of CO2.

Author Contributions

J.J. conceived this review and wrote the manuscript; C.G. and C.J. designed section structures and produced figures; L.W. reviewed; S.L. reviewed, proposed the idea, edited and was responsible for funding acquisition. All authors have read and agreed to the published version of the manuscript.

Funding

This work was supported by the general fund project of the National Natural Science Foundation of China (No. 52176090); the special project for clean energy leading science and technology, Chinese Academy of Sciences (Grant No. XDA21010201); and the Key Research & Development Program of Shandong Province (Grant No. 2019GSF109019).

Conflicts of Interest

The authors declare no conflict of interest.

Appendix A. Governing Equations

In this section, we present governing equations of design and analysis.

By summarizing and analyzing the existing numerical simulation studies of supercritical pressure fluid heat transfer, it can be found that the RNG model and the SST model are more suitable turbulence models. Their continuity equation, momentum equation and energy equation are consistent, as shown in Equations (A1)–(A3):

The equation k and equation ε of the RNG model are shown in Equations (A4) and (A5):

The equation k and equation of the SST model are shown in Equations (A6) and (A7):

References

- Lorentzen, G.; Pettersen, J. A new, efficient and environmentally benign system for car air-conditioning. Int. J. Refrig. 1993, 16, 4–12. [Google Scholar] [CrossRef]

- Chang, Y.S.; Kim, M.S. Modeling and Performance Simulation of a Gas Cooler for a CO2 Heat Pump System. HVAC&R Res. 2007, 13, 445–456. [Google Scholar] [CrossRef]

- Chai, L.; Tsamos, K.M.; Tassou, S.A. Modelling and Evaluation of the Thermohydraulic Performance of Finned-Tube Supercritical Carbon Dioxide Gas Coolers. Energies 2020, 13, 1031. [Google Scholar] [CrossRef]

- Wang, C.C.; Hwang, Y.M.; Lin, Y.T. Empirical correlations for heat transfer and flow friction characteristics of herringbone wavy fin-and-tube heat exchangers. Int. J. Refrig. 2002, 25, 673–680. [Google Scholar] [CrossRef]

- Ge, Y.; Cropper, R. Performance evaluations of air-cooled condensers using pure and mixture refrigerants by four-section lumped modelling methods. Appl. Therm. Eng. 2005, 25, 1549–1564. [Google Scholar] [CrossRef]

- Ge, Y.; Cropper, R. Performance simulation of refrigerated display cabinets operating with refrigerants R22 and R404A. Appl. Energy 2008, 85, 694–707. [Google Scholar] [CrossRef]

- Ge, Y.T.; Cropper, R.T. Simulation and performance evaluation of finned-tube CO2 gas coolers for refrigeration systems. Appl. Therm. Eng. 2009, 29, 957–965. [Google Scholar] [CrossRef]

- Zhang, X.; Ge, Y.; Sun, J.; Li, L.; Tassou, S.A. CFD Modelling of Finned-tube CO2 Gas Cooler for Refrigeration Systems. Energy Procedia 2019, 161, 275–282. [Google Scholar] [CrossRef]

- Zhang, X.; Ge, Y.; Sun, J. Performance analysis of finned-tube CO2 gas cooler with advanced 1D-3D CFD modelling development and simulation. Appl. Therm. Eng. 2020, 176, 115421. [Google Scholar] [CrossRef]

- Zilio, C.; Mancin, S. Shell and tube carbon dioxide gas coolers-Experimental results and modelling. Int. J. Refrig. 2015, 56, 224–234. [Google Scholar] [CrossRef]

- Fronk, B.M.; Garimella, S. Water-coupled carbon dioxide microchannel gas cooler for heat pump water heaters: Part I-Experiments. Int. J. Refrig. 2011, 34, 7–16. [Google Scholar] [CrossRef]

- Fronk, B.M.; Garimella, S. Water-coupled carbon dioxide microchannel gas cooler for heat pump water heaters: Part II-Model development and validation. Int. J. Refrig. 2011, 34, 17–28. [Google Scholar] [CrossRef]

- Starace, G.; Fiorentino, M.; Longo, M.; Carluccio, E. A hybrid method for the cross flow compact heat exchangers design. Appl. Therm. Eng. 2017, 111, 1129–1142. [Google Scholar] [CrossRef]

- Fiorentino, M.; Starace, G. Numerical and Experimental Performance Analysis of Evaporative Condensers. Energy Procedia 2016, 101, 26–33. [Google Scholar] [CrossRef]

- Fiorentino, M.; Starace, G. Sensitivity analysis of evaporative condensers performance using an experimental approach. Energy Procedia 2017, 126, 345–352. [Google Scholar] [CrossRef]

- Qureshi, B.A.; Zubair, S.M. A comprehensive design and rating study of evaporative coolers and condensers. Part I. Performance evaluation. Int. J. Refrig. 2006, 29, 645–658. [Google Scholar] [CrossRef]

- Qureshi, B.A.; Zubair, S.M. A comprehensive design and rating study of evaporative coolers and condensers. Part II. Sensitivity analysis. Int. J. Refrig. 2006, 29, 659–668. [Google Scholar] [CrossRef]

- Ciuffini, A.; Scattina, A.; Carena, F.; Roberti, M.; Rivalta, G.T.; Chiavazzo, E.; Fasano, M.; Asinari, P. Multiscale Computational Fluid Dynamics Methodology for Predicting Thermal Performance of Compact Heat Exchangers. J. Heat Transf. 2016, 138, 071801. [Google Scholar] [CrossRef]

- Bes, T.; Roetzel, W. Thermal theory of the spiral heat exchanger. Int. J. Heat Mass Transf. 1993, 36, 765–773. [Google Scholar] [CrossRef]

- Naphon, P. Study on the heat transfer and flow characteristics in a spiral-coil tube. Int. Commun. Heat Mass Transf. 2011, 38, 69–74. [Google Scholar] [CrossRef]

- Zhang, W.; Wang, S.; Li, C.; Xu, J. Mixed convective heat transfer of CO2 at supercritical pressures flowing upward through a vertical helically coiled tube. Appl. Therm. Eng. 2015, 88, 61–70. [Google Scholar] [CrossRef]

- Ngo, T.L.; Kato, Y.; Nikitin, K.; Tsuzuki, N. New printed circuit heat exchanger with S-shaped fins for hot water supplier. Exp. Therm. Fluid Sci. 2006, 30, 811–819. [Google Scholar] [CrossRef]

- Jiang, P.X.; Zhao, C.R.; Shi, R.F.; Chen, Y.; Ambrosini, W. Experimental and numerical study of convection heat transfer of CO2 at super-critical pressures during cooling in small vertical tube. Int. J. Heat Mass Transf. 2009, 52, 4748–4756. [Google Scholar] [CrossRef]

- Guo, Z. Mechanism and control of convective heat transfer—Coordination of velocity and heat flow fields. Chin. Sci. Bull. 2000, 19, 2118–2122. [Google Scholar]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).