Polyimide-Based High-Performance Film Bulk Acoustic Resonator Humidity Sensor and Its Application in Real-Time Human Respiration Monitoring

Abstract

:1. Introduction

2. Materials and Methods

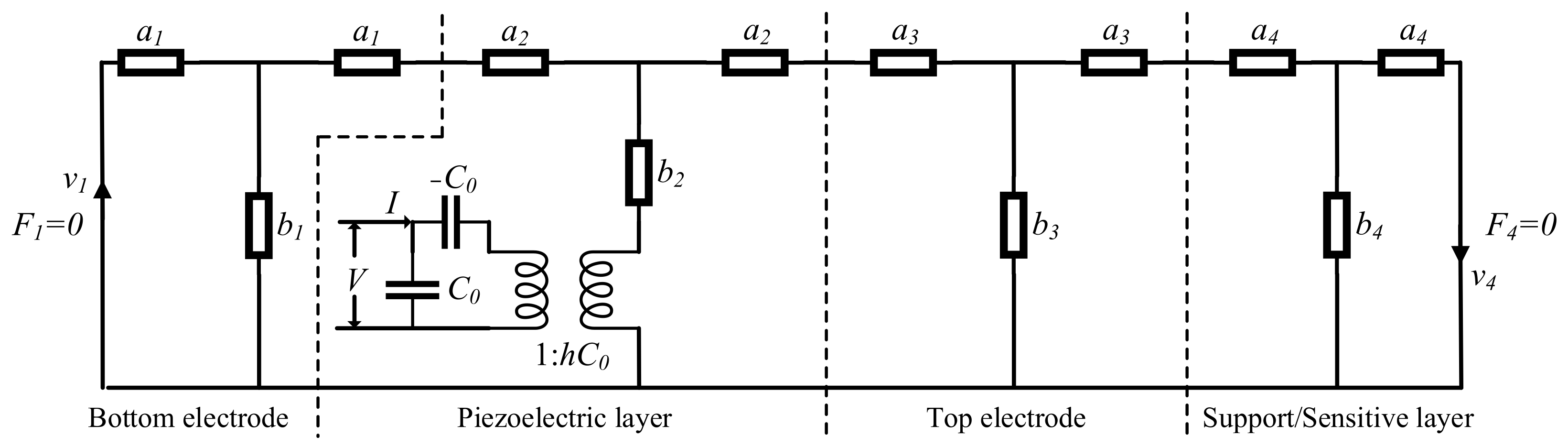

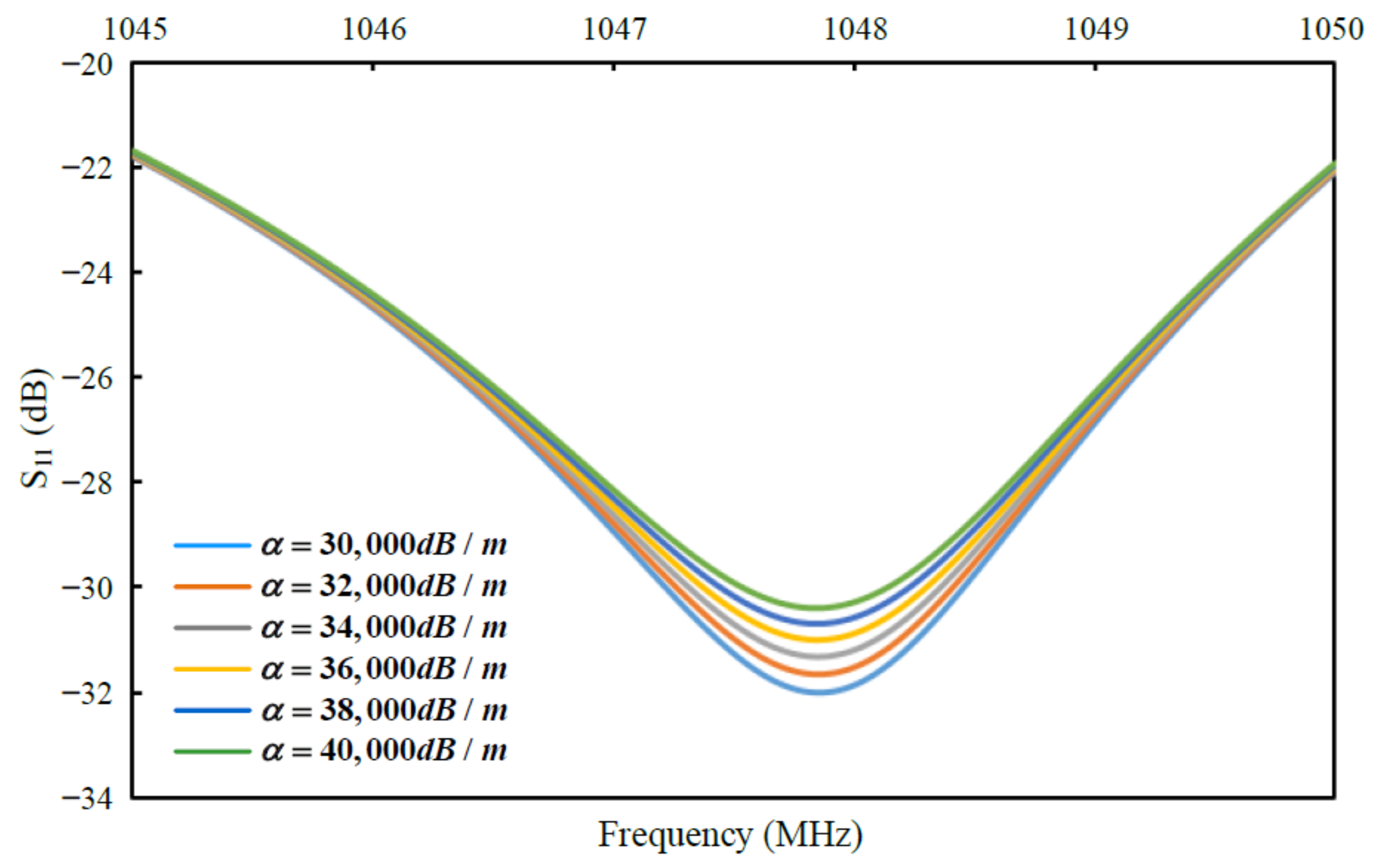

2.1. Analysis and Simulation of S11 Response

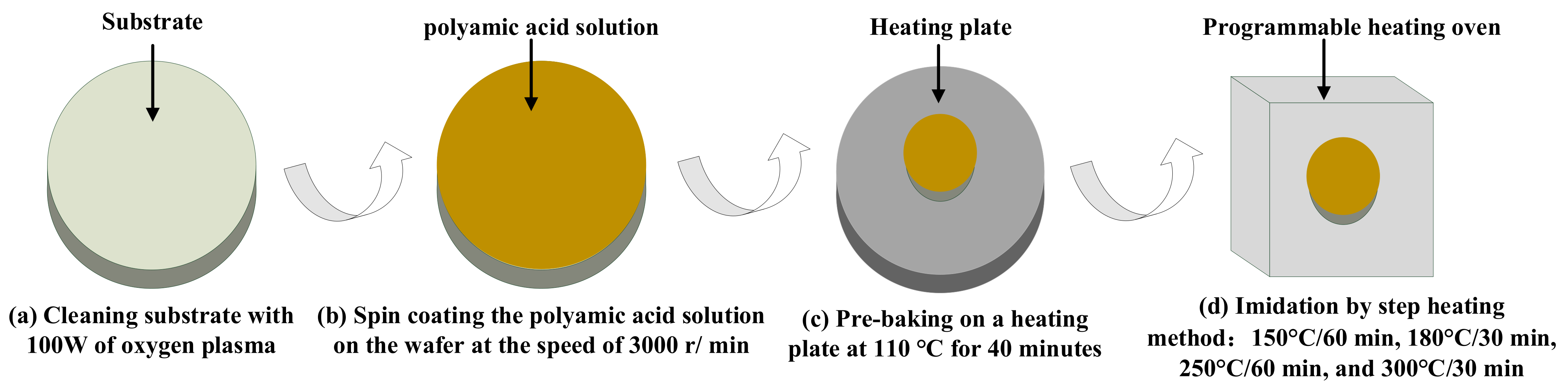

2.2. Fabrication of PI-Based FBAR Humidity Sensor

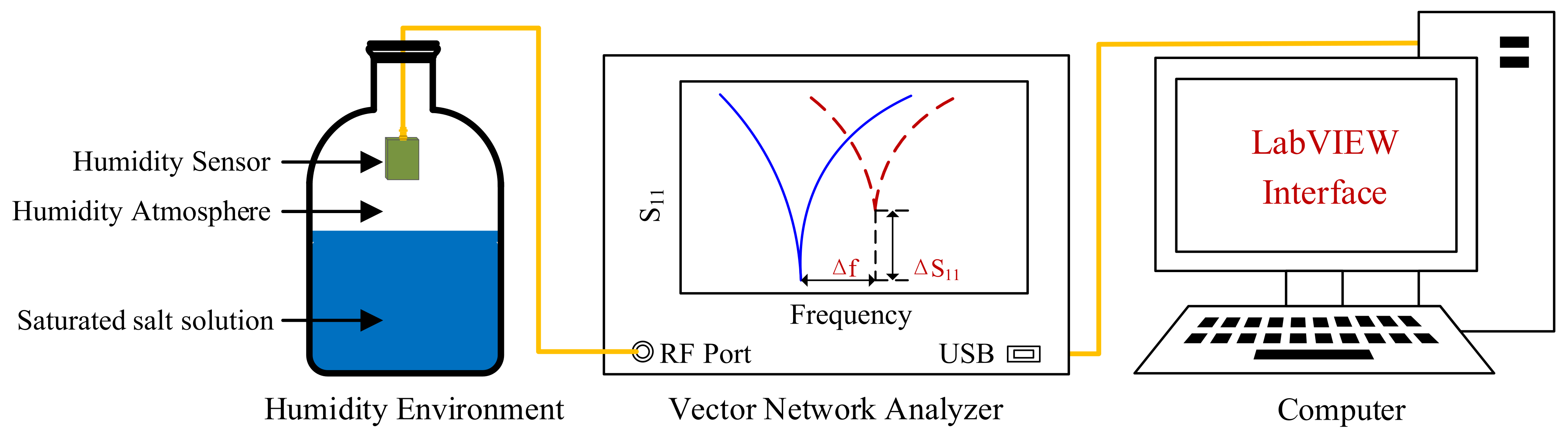

2.3. Apparatus for Humidity Measurement and Breath Monitoring

3. Results and Discussion

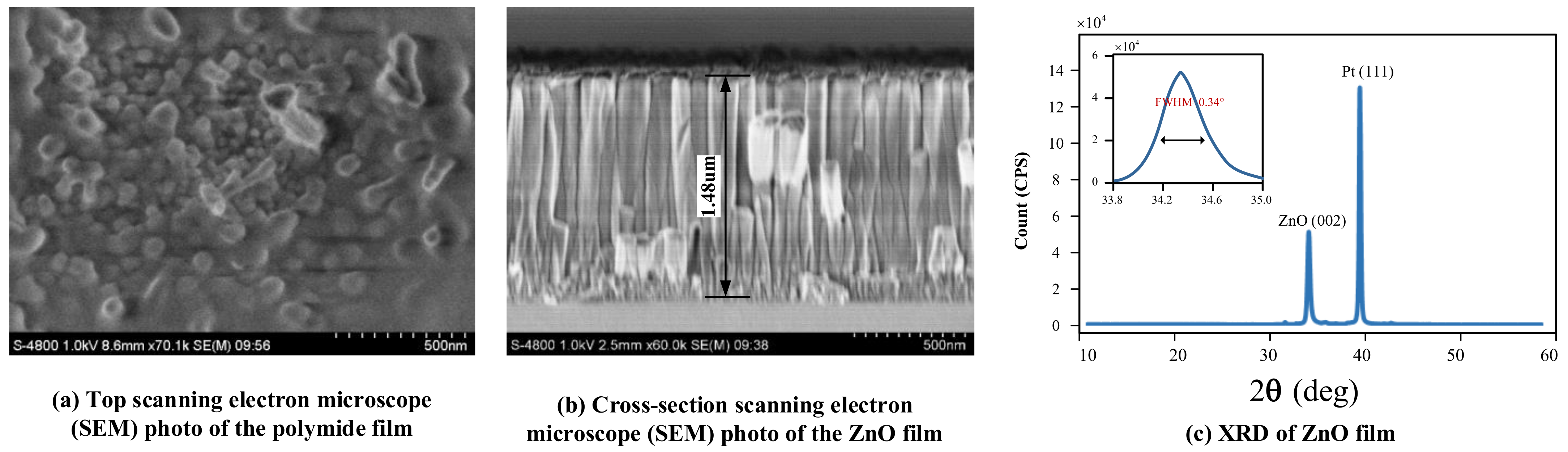

3.1. Structure Characterization

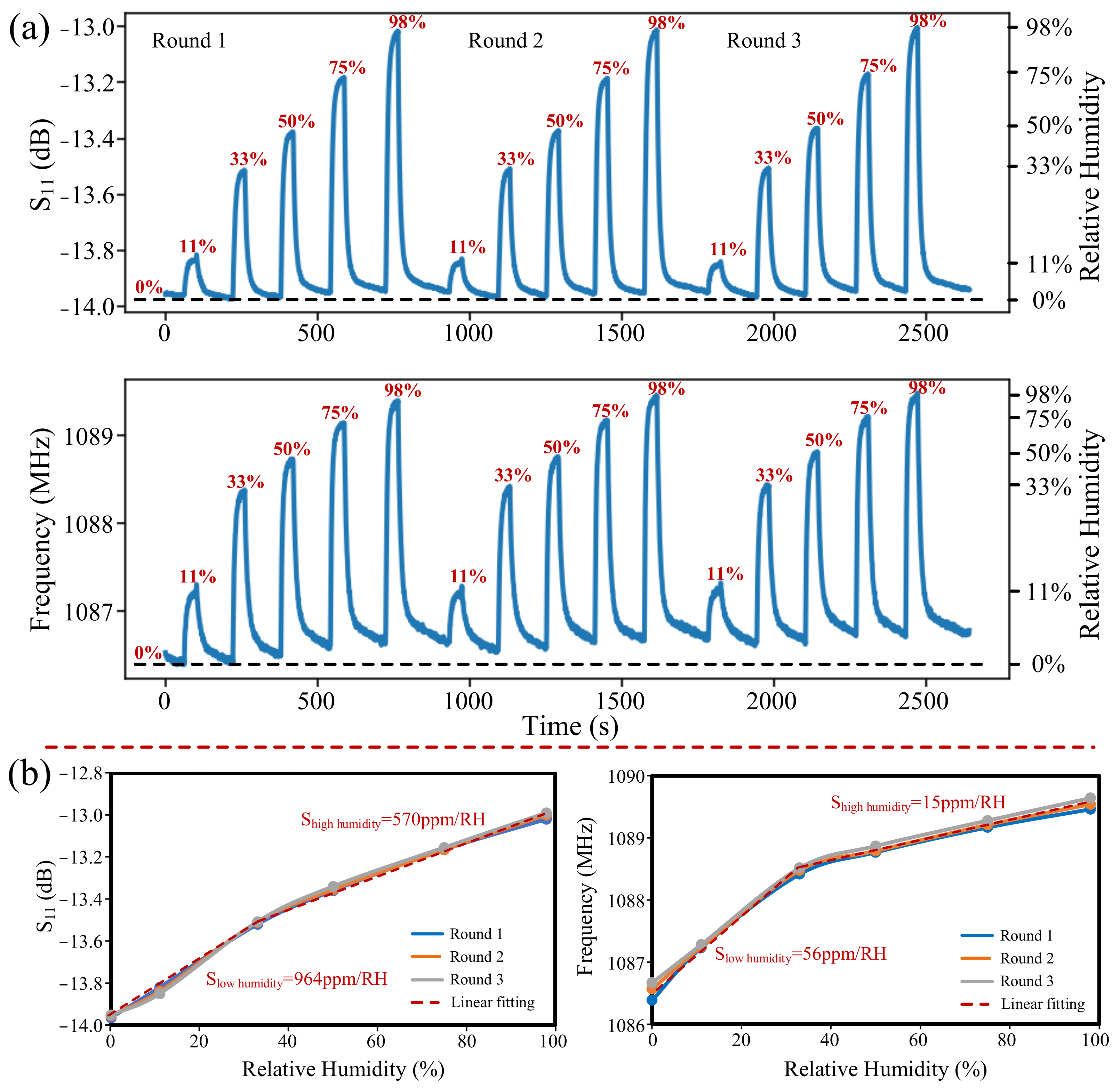

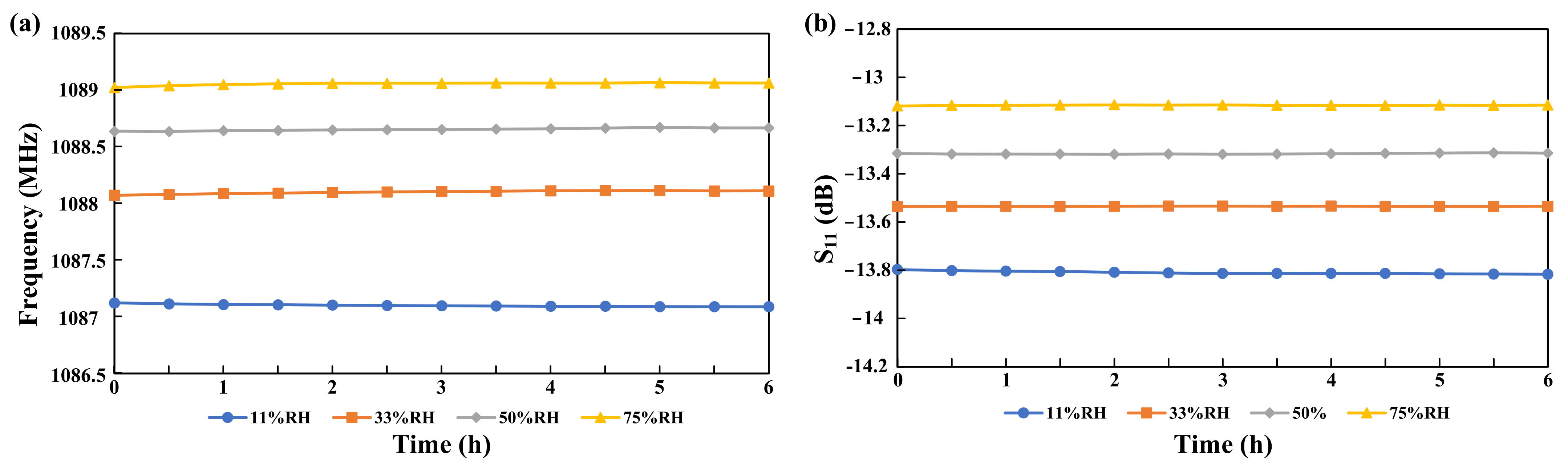

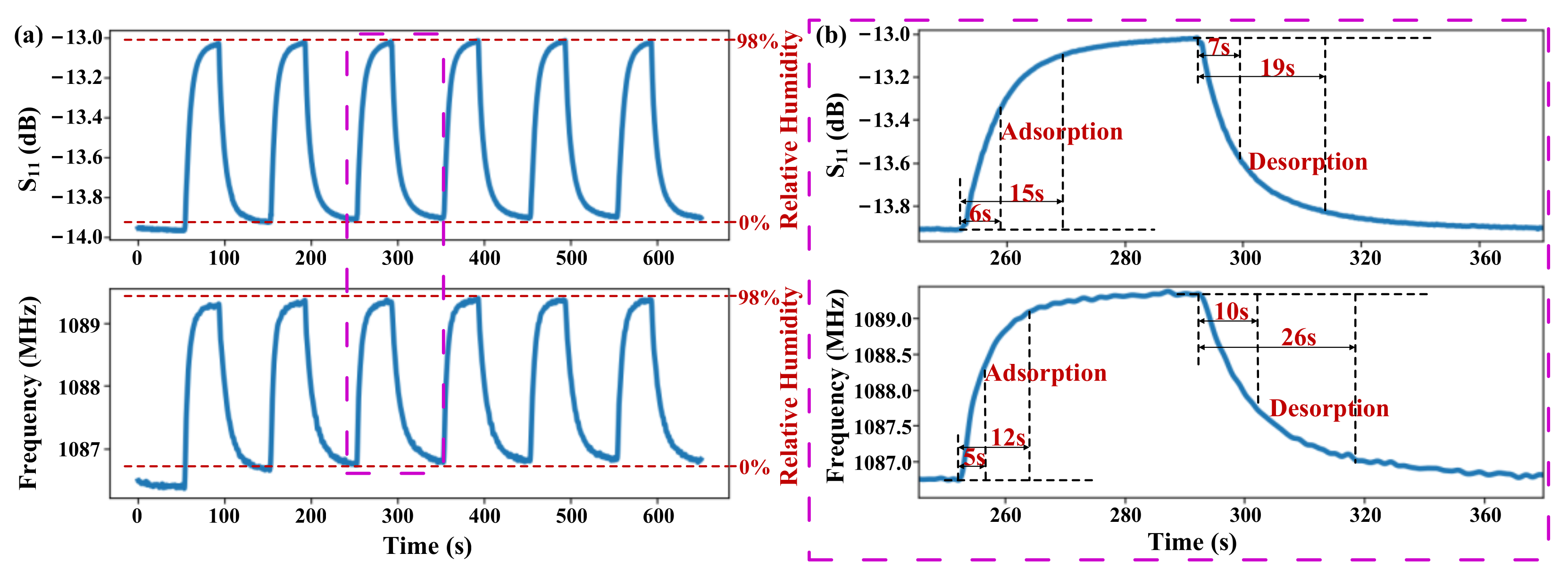

3.2. Humidity Response of PI-FBAR Sensor

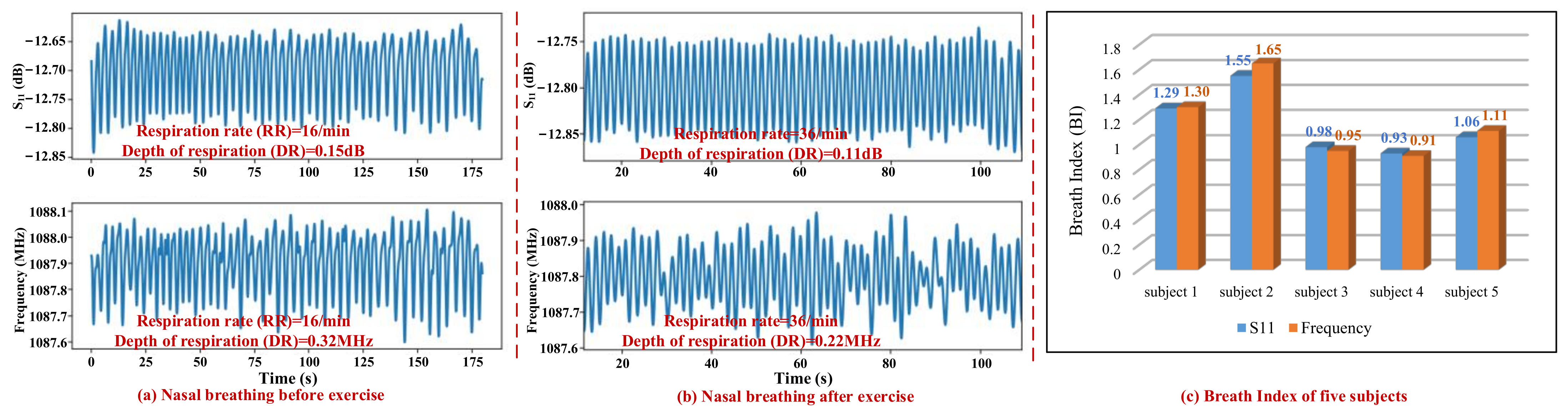

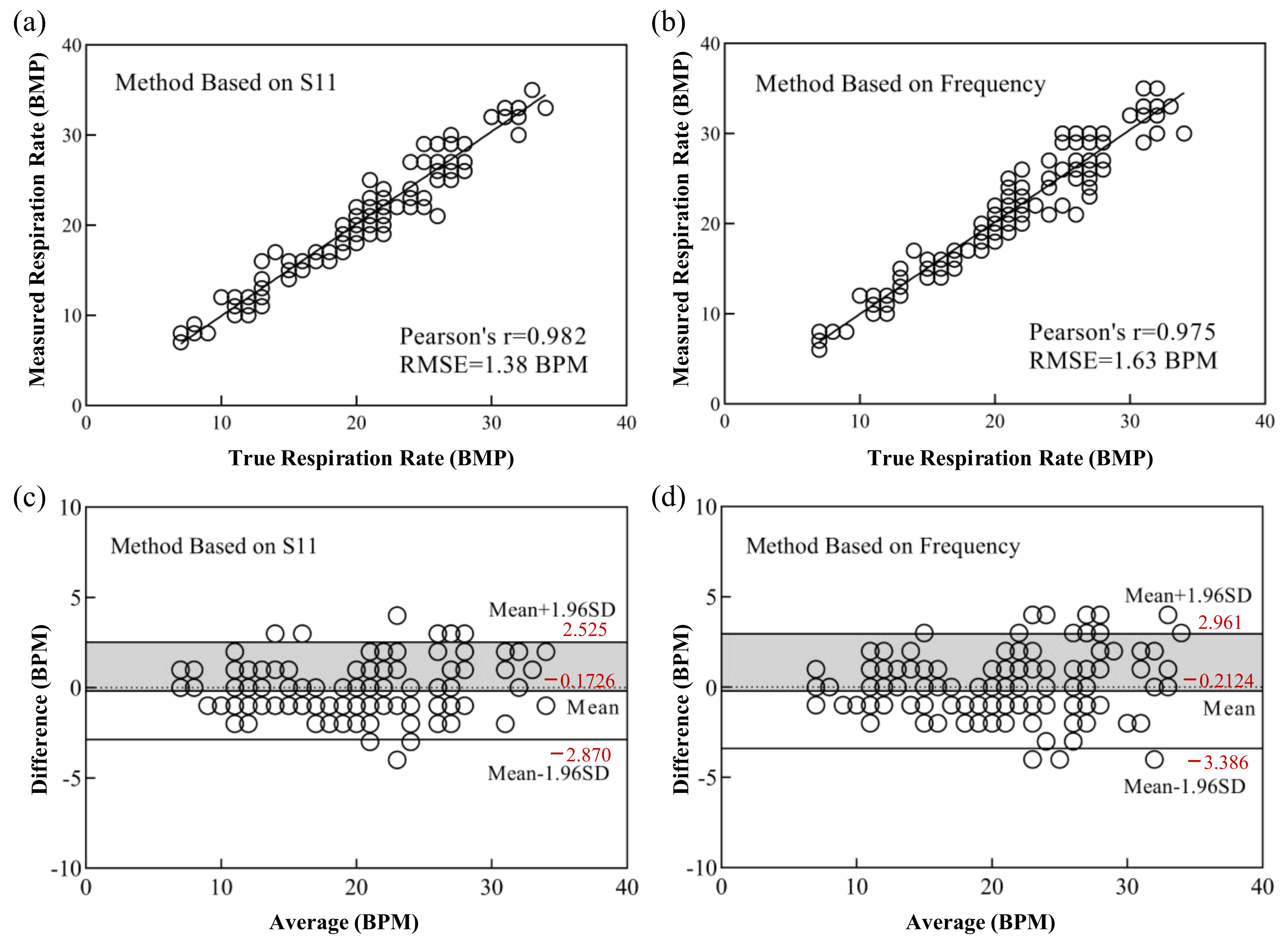

3.3. Respiration Monitoring Using Humidity Sensor

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Informed Consent Statement

Conflicts of Interest

References

- Woollard, M.; Greaves, I. The ABC of community emergency care: 4 shortness of breath. Emerg. Med. J. 2004, 21, 341–350. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Oki, Y.; Kaneko, M.; Fujimoto, Y.; Sakai, H.; Misu, S.; Mitani, Y.; Ishikawa, A. Usefulness of the 6-minute walk test as a screening test for pulmonary arterial enlargement in COPD. Int. J. Chronic Obstr. Pulm. Dis. 2016, 11, 2869–2875. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Tatara, T.; Tsuzaki, K. An Apnea monitor using a rapid-response hygrometer. J. Clin. Monit. 1997, 13, 5–9. [Google Scholar] [CrossRef] [PubMed]

- Tao, L.Q.; Zhang, K.N.; Tian, H.; Liu, Y.; Wang, D.Y.; Chen, Y.Q. Graphene-paper pressure sensor for detecting human motions. ACS Nano 2017, 11, 8790–8795. [Google Scholar] [CrossRef]

- Webb, R.C.; Bonifas, A.P.; Behnaz, A.; Zhang, Y.; Yu, K.J.; Cheng, H.; Rogers, J.A. Ultrathin conformal devices for precise and continuous thermal characterization of human skin. Nat. Mater. 2013, 12, 938–944. [Google Scholar] [CrossRef]

- Chen, S.; Wu, N.; Ma, L.; Lin, S.; Yuan, F.; Xu, Z.; Zhou, J. Noncontact heartbeat and respiration monitoring based on a hollow micro-structured self-powered pressure sensor. ACS Appl. Mater. Interfaces 2018, 10, 3660–3667. [Google Scholar] [CrossRef]

- Hernaez, M.; Acevedo, B.; Mayes, A.G.; Melendi-Espina, S. High-performance optical fiber humidity sensor based on lossy mode resonance using a nanostructured polyethylenimine and graphene oxide coating. Sens. Actuators B Chem. 2019, 286, 408–414. [Google Scholar] [CrossRef] [Green Version]

- Guo, J.; Chang, M.; Xiao, Y.; Song, Q.; Jia, B. Simple high-sensitivity optical fiber humidity sensor. Appl. Opt. 2021, 60, 5990–5994. [Google Scholar] [CrossRef]

- Yan, Z.; Wang, C.; Yu, R.; Hu, Z.; Xiao, L. Graphitic carbon nitride for enhancing humidity sensing of microfibers. J. Lightwave Technol. 2020, 39, 3896–3902. [Google Scholar] [CrossRef]

- Zhao, Y.; Yang, B.; Liu, J. Effect of interdigital electrode gap on the performance of SnO2 -modified MoS2 capacitive humidity sensor. Sens. Actuators B Chem. 2018, 271, 256–263. [Google Scholar] [CrossRef]

- Jamila, B.; Matthias, S.; Hanns-Erik, E.; Andreas, D.; Ignaz, E.; Christoph, K. Polyimide-based capacitive humidity sensor. Sensors 2018, 18, 1516. [Google Scholar]

- Yu, X.; Chen, X.; Ding, X.; Chen, X.; Yu, X.; Zhao, X. High-sensitivity and low-hysteresis humidity sensor based on hydrothermally reduced graphene oxide/nano diamond. Sens. Actuators B Chem. 2019, 283, 761–768. [Google Scholar] [CrossRef]

- Choi, K.H.; Sajid, M.; Aziz, S.; Yang, B.S. Wide range high speed relative humidity sensor based on PEDOT: PSS–PVA composite on an IDT printed on piezoelectric substrate. Sens. Actuators A Phys. 2015, 228, 40–49. [Google Scholar] [CrossRef]

- Shaukat, R.A.; Khan, M.U.; Saqib, Q.M.; Chougale, M.Y.; Kim, J.; Bermak, A.; Bae, J. Two dimensional Zirconium diselenide based humidity sensor for flexible electronics. Sens. Actuators B Chem. 2022, 358, 131507. [Google Scholar] [CrossRef]

- Khan, M.U.; Hassan, G.; Shaukat, R.A.; Saqib, Q.M.; Chougale, M.Y.; Kim, J.; Bae, J. Wide range and highly linear signal processed systematic humidity sensor array using Methylene Blue and Graphene composite. Sci. Rep. 2021, 11, 16665. [Google Scholar] [CrossRef] [PubMed]

- Qian, J.; Peng, Z.; Shen, Z.; Zhao, Z.; Zhang, G.; Fu, X. Positive impedance humidity sensors via single-component materials. Sci. Rep. 2016, 6, 25574. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Zhang, D.; Zong, X.; Wu, Z.; Zhang, Y. Ultrahigh-performance impedance humidity sensor based on layer-by-layer self-assembled tin disulfide/titanium dioxide nano-hybrid film. Sens. Actuators B Chem. 2018, 266, 52–62. [Google Scholar] [CrossRef]

- Wu, Z.; Yang, J.; Sun, X.; Wu, Y.; Wang, L.; Meng, G.; He, Y. An excellent impedance-type humidity sensor based on halide perovskite cspbbr3 nanoparticles for human respiration monitoring. Sens. Actuators B Chem. 2021, 337, 129772. [Google Scholar] [CrossRef]

- Sun, C.; Shi, Q.; Hasan, D.; Yazici, M.S.; Zhu, M.; Ma, Y.; Lee, C. Self-powered multifunctional monitoring system using hybrid integrated triboelectric nanogenerators and piezoelectric microsensors. Nano Energy 2019, 58, 612–623. [Google Scholar] [CrossRef]

- Le, X.; Wang, X.; Pang, J.; Liu, Y.; Fang, B.; Xu, Z. A high performance humidity sensor based on surface acoustic wave and graphene oxide on AlN/Si layered structure. Sens. Actuators B Chem. 2018, 255, 2454–2461. [Google Scholar] [CrossRef]

- Li, D.; Zu, X.; Ao, D.; Tang, Q.; Fu, Y.; Guo, Y.; Tang, Y. High humidity enhanced surface acoustic wave (saw) H2S sensors based on sol–gel CuO films. Sens. Actuators B Chem. 2019, 294, 55–61. [Google Scholar] [CrossRef]

- Su, Y.; Li, C.; Li, M.; Li, H.; Xu, S.; Qian, L.; Yang, B. Surface acoustic wave humidity sensor based on three-dimensional architecture graphene/PVA/SiO2 and its application for respiration monitoring. Sens. Actuators B Chem. 2020, 308, 127693. [Google Scholar] [CrossRef]

- Fang, H.; Lin, J.; Hu, Z.; Liu, H.; Tang, Z.; Shi, T.; Liao, G. Cu(OH)2 nanowires/graphene oxide composites based QCM humidity sensor with fast-response for real-time respiration monitoring. Sens. Actuators B Chem. 2020, 304, 127313. [Google Scholar] [CrossRef]

- Liu, J.; Zhao, Z.; Fang, Z.; Liu, Z.; Zhu, Y.; Du, L. High-Performance FBAR Humidity Sensor based on the PI film as the Multifunctional Layer. Sens. Actuators B Chem. 2020, 308, 127694. [Google Scholar] [CrossRef]

- Zhu, Y.; Xia, P.; Liu, J.; Du, L.; Fang, Z.; Zhao, Z. PI-based dual-mode FBAR humidity sensor towards ultra-high sensitivity and self-temperature-compensation capability. IEEE Sens. J. 2021, 21, 26574–26585. [Google Scholar] [CrossRef]

- Ashley, G.M.; Kirby, P.B.; Butler, T.P.; Whatmore, R.; Luo, J.K. Chemically sensitized thin film bulk acoustic wave resonators as humidity sensors. J. Electrochem. Soc. 2010, 157, 3–8. [Google Scholar] [CrossRef]

- Xuan, W.; Cole, M.; Gardner, J.W.; Thomas, S.; Villa-López, F.H.; Wang, X.; Luo, J. A film bulk acoustic resonator oscillator based humidity sensor with graphene oxide as the sensitive layer. J. Micromech. Microeng. 2017, 27, 055017. [Google Scholar] [CrossRef]

- Zhang, M.; Du, L.; Fang, Z.; Zhao, Z. A sensitivity-enhanced film bulk acoustic resonator gas sensor with an oscillator circuit and its detection application. Micromachines 2017, 8, 25. [Google Scholar] [CrossRef] [Green Version]

- Li, X.; Liang, J.; Zhang, H.; Yang, X.; Zhang, H.; Pang, W.; Zhang, M. Resonant and resistive dual-mode uncooled infrared detectors toward expanded dynamic range and high linearity. Appl. Phys. Lett. 2017, 110, 263502. [Google Scholar] [CrossRef]

- Chen, C.; Shang, Z.; Zhang, F.; Zhou, H.; Yang, J.; Wang, D.; Mu, X. Dual-mode resonant infrared detector based on film bulk acoustic resonator toward ultra-high sensitivity and anti-interference capability. Appl. Phys. Lett. 2018, 112, 243501. [Google Scholar] [CrossRef]

- Jia, L.; Gao, Y.; Han, C. A modified method of mason model for bulk acoustic wave resonators. Yadian Yu Shengguang/Piezoelectr. Acoustoopt. 2018, 40, 352–355 and 361. [Google Scholar]

- Harper, B.D.; Rao, J.M. Some effects of water immersion on the mechanical behavior of a polyimide film. J. Electron. Packag. 1994, 116, 317–319. [Google Scholar] [CrossRef]

- Liu, J.; Zhao, Z.; Jin, J.; Fang, Z.; Du, L. High-precision humidity sensor response time measurement based on the switchable chamber with the hydrophobic interface. IEEE Sens. J. 2020, 20, 5566–5574. [Google Scholar] [CrossRef]

- Güder, F.; Ainla, A.; Redston, J.; Mosadegh, B.; Glavan, A.; Martin, T.J.; Whitesides, G.M. Paper-Based Electrical Respiration Sensor. Angew. Chem. Int. Ed. 2016, 55, 5727–5732. [Google Scholar] [CrossRef] [Green Version]

- Thiyagarajan, K.; Rajini, G.K.; Maji, D. Flexible, highly sensitive paper-based screen printed MWCNT/PDMS composite breath sensor for human respiration monitoring. IEEE Sens. J. 2021, 21, 13985–13995. [Google Scholar] [CrossRef]

- Bland, J.M.; Altman, D. Statistical methods for assessing agreement between two methods of clinical measurement. Lancet 1986, 327, 307–310. [Google Scholar] [CrossRef]

| Layer | Material | Thickness d (um) | Elasticity Coefficient (GPa) | Density (kg/m3) | Longitudinal Sound Velocity v (m/s) | Attenuation Factor α (dB/m) | ||

|---|---|---|---|---|---|---|---|---|

| Bottom electrode | Pt | 0.2 | 168 | 21,450 | / | 2800 | 6.00 | 17,760 |

| Piezoelectric layer | ZnO | 1.5 | 211 | 5600 | 7.79 | 6340 | 3.62 | 2500 |

| Top electrode | Pt | 0.2 | 168 | 21,450 | / | 2800 | 6.00 | 17,760 |

| Support/Sensitive layer | PI | 4.2 | 5.4 | 1300 | / | 2038 | 0.26 | 30,000 |

| Saturated Salt Solution | Relative Humidity (%RH) |

|---|---|

| LiCl | 11 |

| MgCl2 | 33 |

| K2CO3 | 43 |

| KI | 70 |

| NaCl | 75 |

| K2SO4 | 98 |

| Reference | Device Type | Resonant Frequency (MHz) | Sensitive Material | RH Range (%RH) | Sensitivity (ppm/%RH) | Linear |

|---|---|---|---|---|---|---|

| [26] | FBAR | 700 | PVP | 20–70 | −157 | No |

| [27] | FBAR | 1250 | GO | 3–7070–80 | −4 −20.4 | No |

| [28] | FBAR | 1265 | ZnO | 25–88 | −9.2 | No |

| [24] | FBAR | 1055 | PI | 15–85 | +63.8 | Yes |

| [25] | FBAR | 1048 | PI | 20–80 | +28.56 (frequency mode) +2078 (S11 response) | Yes No |

| [20] | SAW | 392 | GO | 10–90 | −107 | No |

| [22] | SAW | 202 | 3DAG/PVA/SiO2 | 5–5555–90 | −4.96−12.1 | No |

| This work | FBAR | 1089 | PI | 11–33 | +56 (frequency mode) +965 (S11 response) | Yes |

| 33–98 | +15 (frequency mode) +570 (S11 response) | Yes |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhu, Y.; Xia, P.; Liu, J.; Fang, Z.; Du, L.; Zhao, Z. Polyimide-Based High-Performance Film Bulk Acoustic Resonator Humidity Sensor and Its Application in Real-Time Human Respiration Monitoring. Micromachines 2022, 13, 758. https://doi.org/10.3390/mi13050758

Zhu Y, Xia P, Liu J, Fang Z, Du L, Zhao Z. Polyimide-Based High-Performance Film Bulk Acoustic Resonator Humidity Sensor and Its Application in Real-Time Human Respiration Monitoring. Micromachines. 2022; 13(5):758. https://doi.org/10.3390/mi13050758

Chicago/Turabian StyleZhu, Yusi, Pan Xia, Jihang Liu, Zhen Fang, Lidong Du, and Zhan Zhao. 2022. "Polyimide-Based High-Performance Film Bulk Acoustic Resonator Humidity Sensor and Its Application in Real-Time Human Respiration Monitoring" Micromachines 13, no. 5: 758. https://doi.org/10.3390/mi13050758

APA StyleZhu, Y., Xia, P., Liu, J., Fang, Z., Du, L., & Zhao, Z. (2022). Polyimide-Based High-Performance Film Bulk Acoustic Resonator Humidity Sensor and Its Application in Real-Time Human Respiration Monitoring. Micromachines, 13(5), 758. https://doi.org/10.3390/mi13050758