Flux Pinning Properties of Single-Grain Bulk GdBCO Superconductors Processed by Different Thicknesses of Y123 Liquid Source

Abstract

:1. Introduction

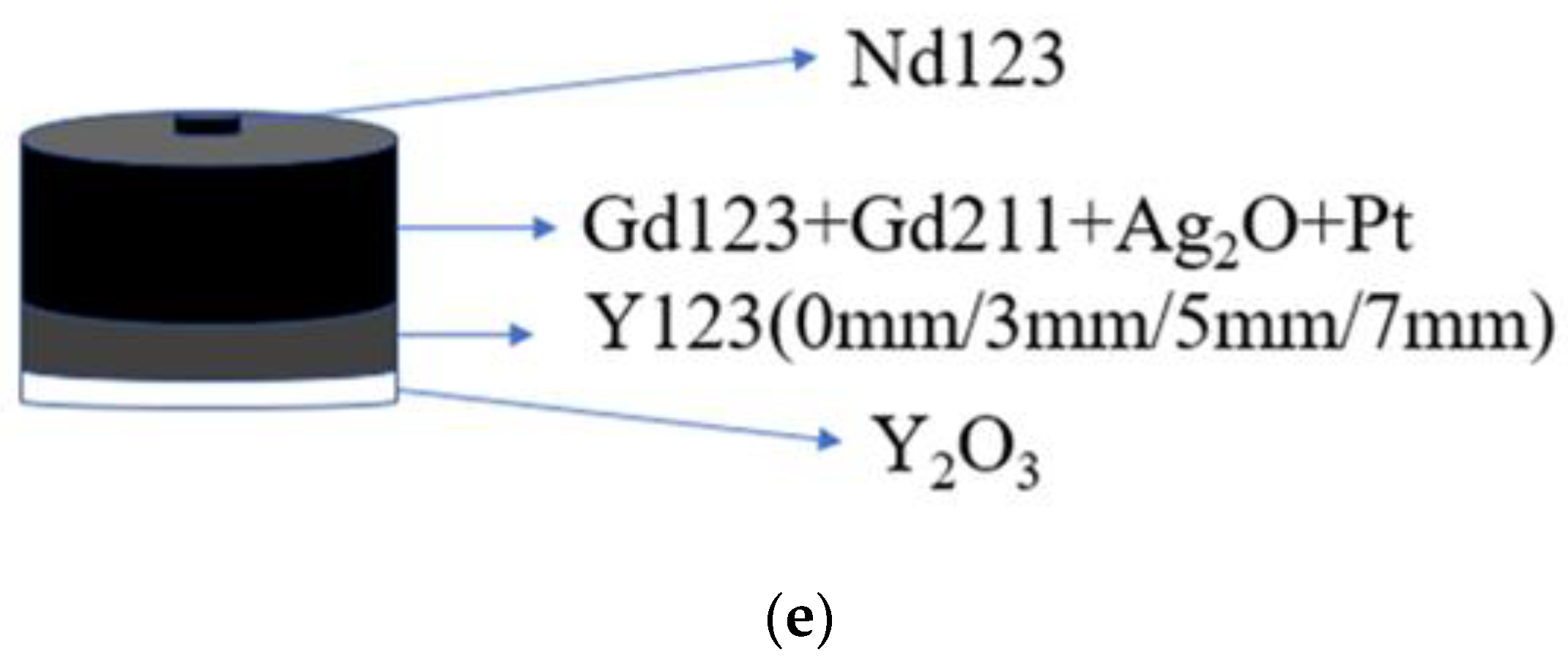

2. Materials and Methods

2.1. Growth in GdBCO Single Grains

2.2. Characterization of GdBCO Single Grains

3. Results

3.1. Photographs of GdBCO Single Grains

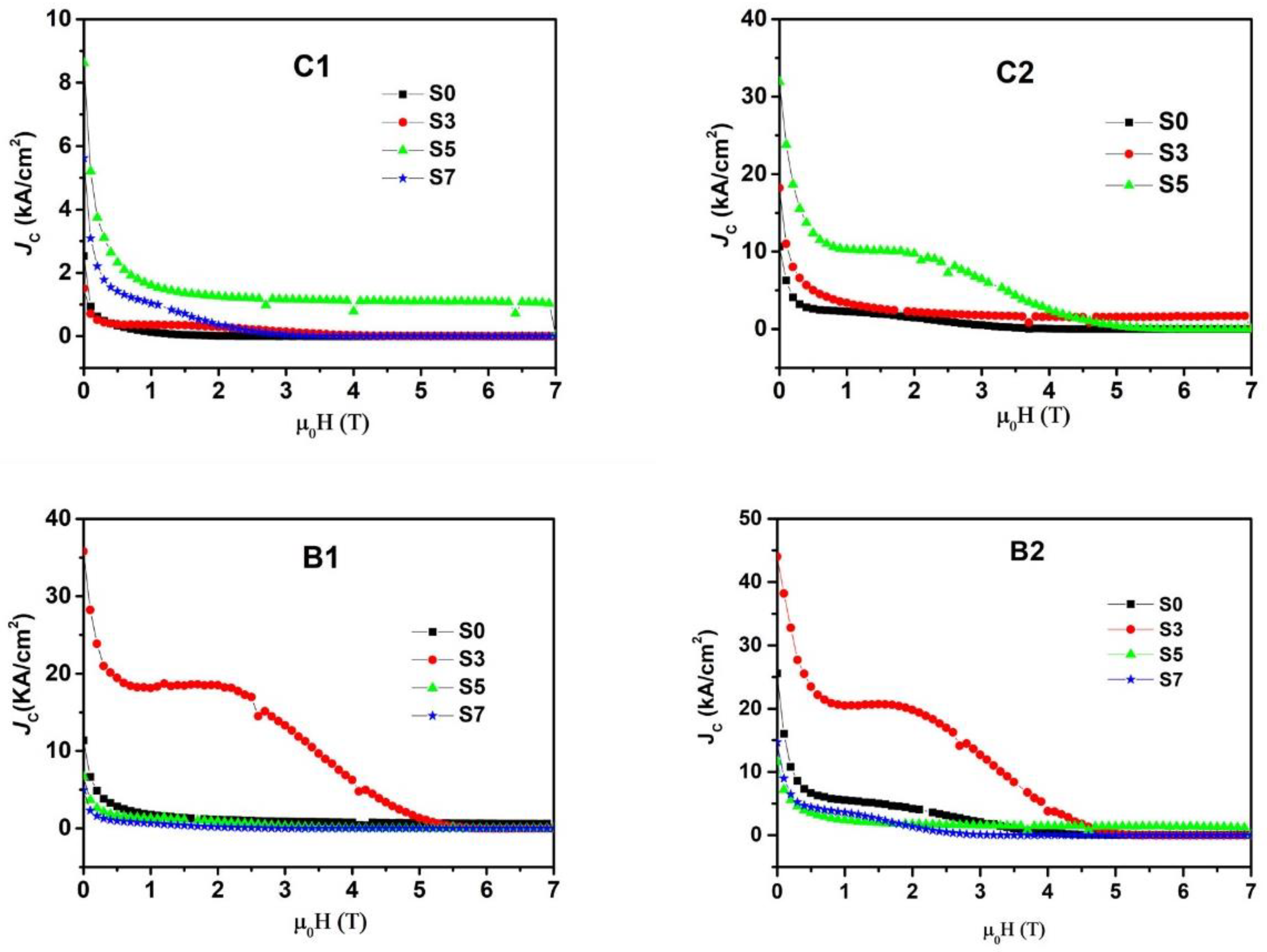

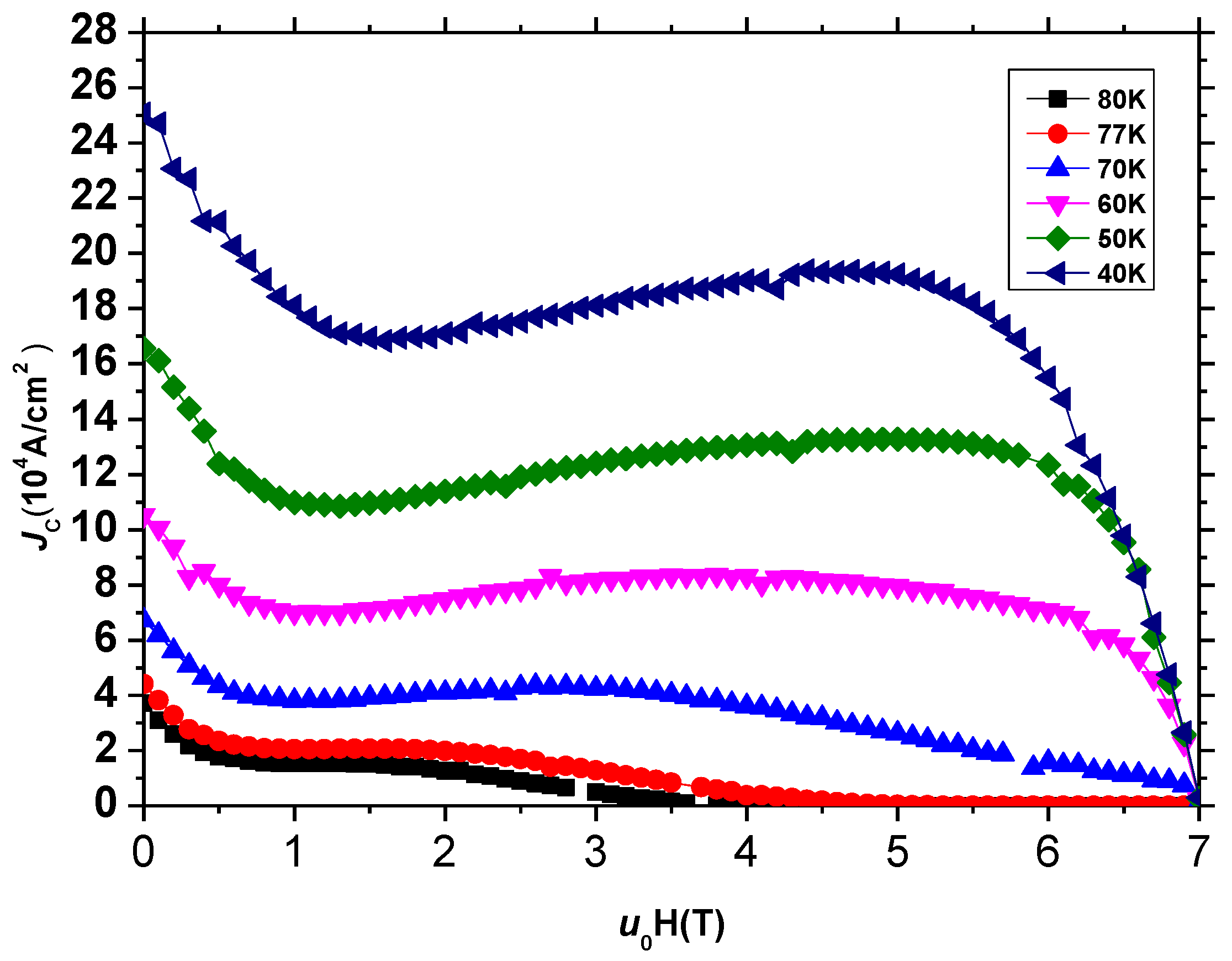

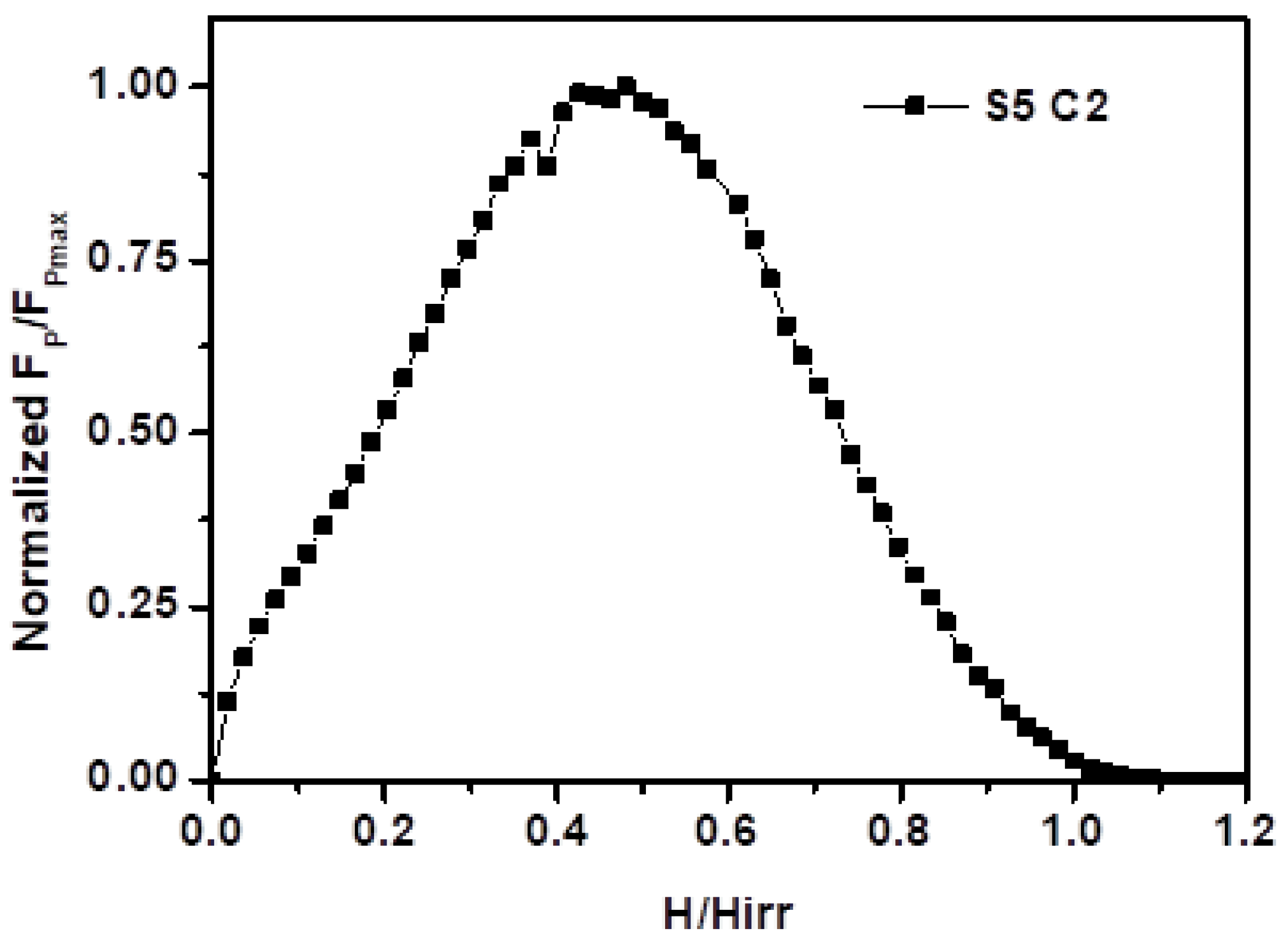

3.2. Superconducting Properties

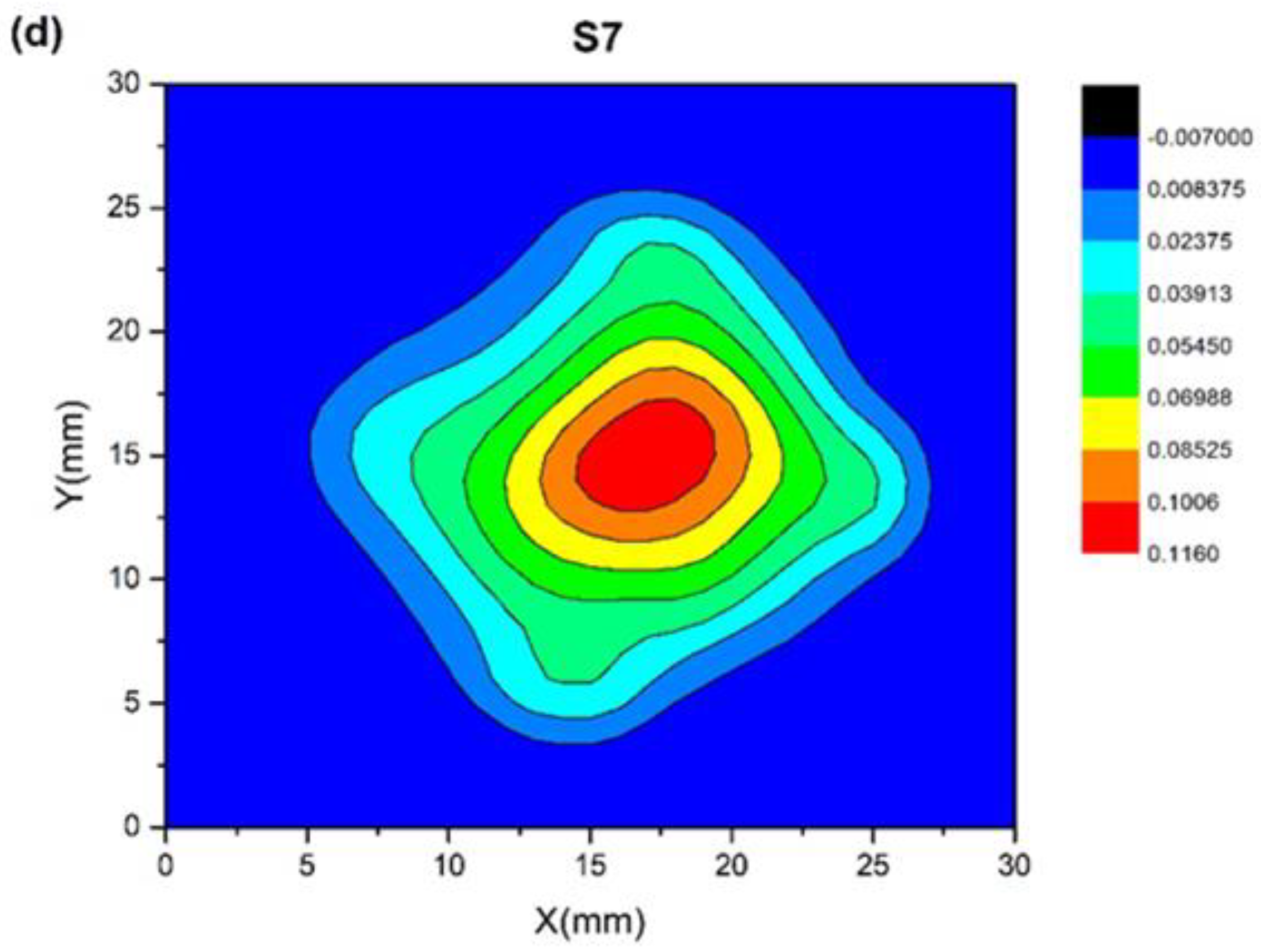

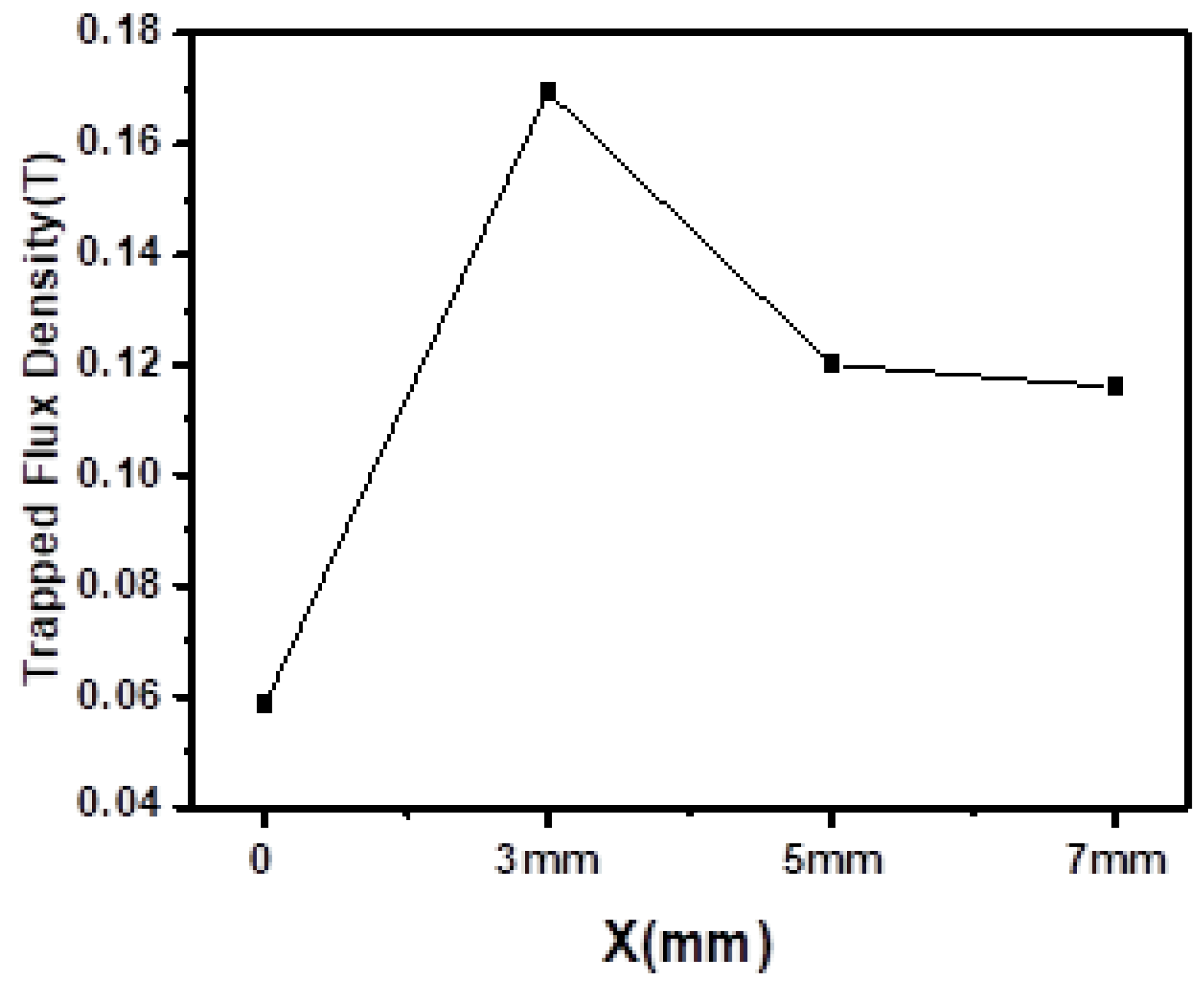

3.3. The Distribution of the Trapped Magnetic Field

3.4. Microstructure

3.5. Discussion

4. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Tomita, M.; Murakami, M. High-temperature superconductor bulk magnets that can trap magnetic fields of over 17 tesla at 29 K. Nature 2003, 421, 517–520. [Google Scholar] [CrossRef] [PubMed]

- Durrell, J.; Dennis, A.R.; Jaroszynski, J.; Ainslie, M.; Palmer, K.G.B.; Shi, Y.-H.; Campbell, A.M.; Hull, J.R.; Strasik, M.; E Hellstrom, E.; et al. A trapped field of 17.6 T in melt-processed, bulk Gd-Ba-Cu-O reinforced with shrink-fit steel. Supercond. Sci. Technol. 2014, 27. [Google Scholar] [CrossRef]

- Hull, J.; Murakami, M. Applications of bulk high-temperature Superconductors. Proc. IEEE 2004, 92, 1705–1718. [Google Scholar] [CrossRef] [Green Version]

- Miki, M.; Felder, B.; Tsuzuki, K.; Xu, Y.; Deng, Z.; Izumi, M.; Hayakawa, H.; Morita, M.; Teshima, H. Materials processing and machine applications of bulk HTS. Supercond. Sci. Technol. 2010, 23. [Google Scholar] [CrossRef]

- Zhang, Y.; Zhou, D.; Ida, T.; Miki, M.; Izumi, M. Melt-growth bulk superconductors and application to an axial-gap-type rotating machine. Supercond. Sci. Technol. 2016, 29, 44005. [Google Scholar] [CrossRef]

- Werfel, F.N.; Floegel-Delor, U.; Rothfeld, R.; Riedel, T.; Goebel, B.; Wippich, D.; Schirrmeister, P. Superconductor bearings, flywheels and transportation. Supercond. Sci. Technol. 2012, 25, 014007. [Google Scholar] [CrossRef]

- Li, G.-Z.; Yang, W.-M. A Novel Configuration for Infiltration and Growth of Single-Domain Gd-Ba-Cu-O Bulk Superconductor. J. Am. Ceram. Soc. 2010, 93, 4033–4035. [Google Scholar] [CrossRef]

- Li, J.; Yang, W.; Wang, M.; Guo, Y.; Feng, Z. High-Efficient Method for Introducing Nanometer Y2Ba4CuNbOx Flux Pinning Centers in Single-Domain YBa2Cu3O7−δ Bulk Superconductors by TSIG Process. J. Supercond. Nov. Magn. 2015, 28, 1725–1728. [Google Scholar] [CrossRef]

- Pavan Kumar Naik, S.; Muralidhar, M.; Jirsa, M.; Murakami, M. Enhanced flux pinning of single grain bulk (Gd, Dy) BCO su-perconductors processed by cold-top-seeded infiltration growth method. Mater. Sci. Eng. B 2020, 253, 114494. [Google Scholar] [CrossRef]

- Naik, S.P.K.; Muralidhar, M.; Takemura, K.; Jirsa, M.; Murakami, M. Infiltration growth processing of single grain (Gd,Dy)BCO bulk superconductors: Optimization of liquid phase mass and characterization of physical properties. J. Appl. Phys. 2019, 125, 093907. [Google Scholar] [CrossRef]

- Naik, S.P.K.; Muralidhar, M.; Murakami, M. Optimization of the Dy Content in Single Crystalline GdBCO Bulk Superconductors Fabricated in Air Via Top-Seeded Infiltration Growth Process. J. Supercond. Nov. Magn. 2018, 31, 981–987. [Google Scholar] [CrossRef]

- Litzkendorf, D.; Habisreuther, T.; Bierlich, J.; Surzhenko, O.; Zeisberger, M.; Kracunovska, S.; Gawalek, W. Increased efficiency of batch-processed melt-textured YBCO. Supercond. Sci. Technol. 2005, 18, S206–S208. [Google Scholar] [CrossRef]

- Wang, J.; Monot, I.; Marinel, S.; Desgardin, G. Controlled growth of single-grain YBa2Cu3O7 by top-seeding melt-texturing. Mater. Lett. 1997, 33, 215–219. [Google Scholar] [CrossRef]

- Yu, D.J.; Cheng, L.; Peng, B.N.; Chen, Y.Y.; Xu, H.H.; Li, H.; Yao, X.; Ikuta, H. Two-layer batch-process of YBa2Cu3Ox bulk superconductors induced by NdBa2Cu3Ox film-seeds. J. Appl. Phys. 2013, 113, 203914. [Google Scholar] [CrossRef]

- Zhou, D.; Hara, S.; Li, B.; Xu, K.; Noudem, J.; Izumi, M. Significant improvement of trapped flux in bulk Gd-Ba-Cu-O grains fabricated by a modified top-seeded melt growth process. Supercond. Sci. Technol. 2013, 26. [Google Scholar] [CrossRef]

- Zhou, D.; Hara, S.; Li, B.; Noudem, J.; Izumi, M. Flux pinning properties of Gd-Ba-Cu-O trapped field magnets grown by a modified top-seeded melt growth. Supercond. Sci. Technol. 2014, 27, 44015. [Google Scholar] [CrossRef]

- Murakami, M.; Sakai, N.; Higuchi, T.; Yoo, S.-I. Melt-processed light rare earth element-Ba-Cu-O. Supercond. Sci. Technol. 1996, 9, 1015–1032. [Google Scholar] [CrossRef]

- Xu, C.; Hu, A.; Sakai, N.; Izumi, M.; Hirabayashi, I. Effect of BaO2 and fine Gd2BaCuO7−δ addition on the superconducting properties of air-processed GdBa2Cu3O7−δ. Supercond. Sci. Technol. 2004, 18, 229–233. [Google Scholar] [CrossRef]

- Zhang, J.; Zhang, Y.; Lou, Z.; Zhang, P.; Li, C.; Yuan, J.; Zhang, X.; Peng, L.; Ma, Y.; Xu, J.; et al. Improved Flux Pinning Performance of GdBCO Superconductor Bulks by Gd3ZrO7 Additions. Acta Phys. Pol. A 2021, 140, 40–49. [Google Scholar] [CrossRef]

- Zhang, Y.; Izumi, M.; Li, Y.; Murakami, M.; Gao, T.; Liu, Y.; Li, P. Enhanced JC in air-processed GdBa2Cu3O7−δ superconductor bulk grown by the additions of nano-particles. Phys. C Supercond. 2011, 471, 840–842. [Google Scholar] [CrossRef]

- Zhang, Y.; Izumi, M.; Kimura, Y.; Xu, Y. Growth and properties of air-processed GdBa2Cu3O7−δ superconductors with fined Gd2BaCuO5 and Gd2Ba4CuFeOy additions. Phys. C Supercond. 2009, 469, 1169–1172. [Google Scholar] [CrossRef]

- Chen, D.; Goldfarb, R. Kim model for magnetization of type-II superconductors. J. Appl. Phys. 1989, 66, 2489–2500. [Google Scholar] [CrossRef]

- Izumi, T.; Nakamura, Y.; Shiohara, Y. Diffusion solidification model on Y-system superconductors. J. Mater. Res. 1992, 7, 1621–1628. [Google Scholar] [CrossRef]

- Izumi, T.; Shiohara, Y. Growth mechanism of YBa2Cu3Oy superconductors prepared by the horizontal Bridgman method. J. Mater. Res. 1992, 7, 16–23. [Google Scholar] [CrossRef]

- Nakamura, Y.; Shiohara, Y. Peritectic solidification model for Y-system superconductive oxides. J. Mater. Res. 1996, 11, 2450–2457. [Google Scholar] [CrossRef]

- Krauns, C.; Sumida, M.; Tagami, M.; Yamada, Y.; Shiohara, Y. Solubility of RE elements into Ba−Cu−O melts and the enthalpy of dissolution. Eur. Phys. J. B 1994, 96, 207–212. [Google Scholar] [CrossRef]

- Jirsa, M.; Pust, L.; Dlouhý, D.; Koblischka, M.R. Fishtail shape in the magnetic hysteresis loop for superconductors: Interplay between different pinning mechanisms. Phys. Rev. B 1997, 55, 3276–3284. [Google Scholar] [CrossRef] [Green Version]

- Koblischka, M.R.; Van Dalen, A.J.J.; Higuchi, T.; Yoo, S.I.; Murakami, M. Analysis of pinning in NdBa2Cu3O7−δ superconductors. Phys. Rev. B 1998, 58, 2863–2867. [Google Scholar] [CrossRef]

- Bean, C.P. Magnetization of High-Field Superconductors. Rev. Mod. Phys. 1964, 36, 31–39. [Google Scholar] [CrossRef]

- Liao, H.; Zheng, J.; Jin, L.; Huang, H.; Deng, Z.; Shi, Y.; Zhou, D.; A Cardwell, D. Dynamic levitation performance of Gd–Ba–Cu–O and Y–Ba–Cu–O bulk superconductors under a varying external magnetic field. Supercond. Sci. Technol. 2018, 31, 035010. [Google Scholar] [CrossRef]

- Shi, Y.; Gough, M.; Dennis, A.R.; Durrell, J.H.; A Cardwell, D. Distribution of the superconducting critical current density within a Gd–Ba–Cu–O single grain. Supercond. Sci. Technol. 2020, 33, 044009. [Google Scholar] [CrossRef]

- Kim, C.-J.; Kim, K.-B.; Hong, G.-W.; Lee, H.-Y. Nonuniform distribution of second phase particles in melt-textured Y–Ba–Cu–O oxide with metal oxide (CeO2, SnO2, and ZrO2) addition. J. Mater. Res. 1995, 10, 1605–1610. [Google Scholar] [CrossRef]

- Endo, A.; Chauhan, H.S.; Egi, T.; Shiohara, Y. Macrosegregation of Y2Ba1Cu1O5 particles in Y1Ba2Cu3O7−δ crystals grown by an undercooling method. J. Mater. Res. 1996, 11, 795–803. [Google Scholar] [CrossRef]

- Cloots, R.; Koutzarova, T.; Mathieu, J.-P.; Ausloos, M. From RE-211 to RE-123. How to control the final microstructure of superconducting single-domains. Supercond. Sci. Technol. 2005, 18, R9–R23. [Google Scholar] [CrossRef] [Green Version]

- Varanasi, C.; McGinn, P.J.; Blackstead, H.A.; Pulling, D.B. Flux pinning enhancement in melt processed YBa2Cu3O7−δ through rare-earth ion (Nd, La) substitutions. Appl. Phys. Lett. 1995, 67, 1004–1006. [Google Scholar] [CrossRef]

- Zheng, H.; Jiang, M.; Huang, Y.; Veal, B.; Claus, H. Growth and physical properties of melt textured (Gd,Y) Ba2Cu3Ox. Phys. C Supercond. 1998, 307, 284–290. [Google Scholar] [CrossRef]

- Izumi, T.; Nakamura, Y.; Shiohara, Y. Doping effects on coarsening of Y2BaCuO5 phase in liquid. J. Mater. Res. 1993, 8, 1240–1246. [Google Scholar] [CrossRef]

- Athur, S.P.; Selvamanickam, V.; Balachandran, U.; Salama, K. Study of growth kinetics in melt-textured YBa2Cu3O7−x. J. Mater. Res. 1996, 11, 2976–2989. [Google Scholar] [CrossRef]

- Kim, C.-J.; Hong, G.-W. Defect formation, distribution and size reduction of in melt-processed YBCO superconductors. Supercond. Sci. Technol. 1999, 12, R27–R42. [Google Scholar] [CrossRef]

- Dew-Hughes, D. Flux pinning mechanisms in type II superconductors. Philos. Mag. 1974, 30, 293–305. [Google Scholar] [CrossRef]

- Hu, A.; Schätzle, P.; Bieger, W.; Verges, P.; Fuchs, G.; Krabbes, G. Enhanced flux pinning in (Nd0.33Sm0.67) Ba2Cu3O7−δ melt-processed superconductors by Ar postannealing. Appl. Phys. Lett. 1999, 75, 259–261. [Google Scholar] [CrossRef]

| Sample | S0 | S3 | S5 | S7 | |

|---|---|---|---|---|---|

| ΔTC | 4.2 K | 1.2 K | 3.7 K | 4.7 K | |

| Btrap | 0.058 T | 0.169 T | 0.120 T | 0.116 T | |

| JC,self-field(104 A/cm2) | C1 | 0.25 | 0.15 | 0.86 | 0.56 |

| C2 | 1.06 | 1.82 | 3.19 | ||

| B1 | 1.14 | 3.58 | 0.67 | 0.49 | |

| B2 | 2.56 | 4.4 | 1.16 | 1.47 | |

| Sample | Spot | Gd/% | Ba/% | Cu/% | O/% | Y/% | Ag/% | Possible Particles |

|---|---|---|---|---|---|---|---|---|

| S5-C2 | A | 9.8 | 15.9 | 24.3 | 48.4 | Gd1+xBa2−xCu3O7−δ (Gd:Ba:Cu = 1.21:1.96:3.00) | ||

| B | 22.1 | 15.2 | 17.2 | 45.5 | Gd2BaCuO5 + 0.38BaCuO2 + 0.18CuO (Gd:Ba:Cu = 2.00:1.38:1.56) | |||

| C | 10.8 | 16 | 23 | 49.9 | Gd1+xBa2−xCu3O7−δ (Gd:Ba:Cu = 1.41:2.09:3.00) | |||

| D | 19.7 | 10.8 | 11.4 | 58.2 | Gd2BaCuO5 (Gd:Ba:Cu = 2.00:1.10:1.16) | |||

| E | 7.9 | 12.4 | 18.6 | 61.1 | Gd1+xBa2−xCu3O7−δ (Gd:Ba:Cu = 1.27:2.00:3.00) | |||

| F | 21.6 | 11.5 | 11.7 | 55.2 | Gd2BaCuO5 (Gd:Ba:Cu = 2.00:1.06:1.08) | |||

| G | 8.5 | 16.5 | 24.3 | 50.6 | GdBa2Cu3O7−δ (Gd:Ba:Cu = 1.05:2.04:3.00) | |||

| S7-C2 | H | 100 | Ag | |||||

| I | 18.1 | 11.6 | 13.3 | Gd2BaCuO5 + 0.28BaCuO2 + 0.19CuO (Gd:Ba:Cu = 2:1.28:1.47) | ||||

| J | 7.9 | 15 | 23.8 | Gd1+xBa2−xCu3O7−δ (Gd:Ba:Cu = 1.00:1.89:3.00) | ||||

| K | 26.2 | 14.8 | 17.5 | Gd2BaCuO5 + 0.13BaCuO2 + 0.21CuO (Gd:Ba:Cu = 2:1.13:1.34) | ||||

| L | 18.2 | 10.5 | 12.1 | 1 | Y3+ + Gd2BaCuO5 + 0.15BaCuO2 + 0.18CuO (Gd:Ba:Cu:Y = 2:1.15:1.33:0.9) | |||

| M | 17.6 | 13 | 21.9 | Gd1+xBa2−xCu3O7−δ (Gd:Ba:Cu = 2.41:1.78:3) | ||||

| N | 11.3 | 17.2 | 26.3 | Gd1+xBa2−xCu3O7−δ (Gd:Ba:Cu = 1.29:1.96:3) | ||||

| O | 26.9 | 14.1 | 15.9 | Gd2BaCuO5 + 0.05BaCuO2 + 0.13CuO (Gd:Ba:Cu = 2:1.05:1.18) |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhang, Y.; Lou, Z.; Zhang, P.; Li, C.; Zhang, J.; Zhang, X. Flux Pinning Properties of Single-Grain Bulk GdBCO Superconductors Processed by Different Thicknesses of Y123 Liquid Source. Micromachines 2022, 13, 701. https://doi.org/10.3390/mi13050701

Zhang Y, Lou Z, Zhang P, Li C, Zhang J, Zhang X. Flux Pinning Properties of Single-Grain Bulk GdBCO Superconductors Processed by Different Thicknesses of Y123 Liquid Source. Micromachines. 2022; 13(5):701. https://doi.org/10.3390/mi13050701

Chicago/Turabian StyleZhang, Yufeng, Ziwei Lou, Penghe Zhang, Chunyan Li, Jiaying Zhang, and Xiaojuan Zhang. 2022. "Flux Pinning Properties of Single-Grain Bulk GdBCO Superconductors Processed by Different Thicknesses of Y123 Liquid Source" Micromachines 13, no. 5: 701. https://doi.org/10.3390/mi13050701

APA StyleZhang, Y., Lou, Z., Zhang, P., Li, C., Zhang, J., & Zhang, X. (2022). Flux Pinning Properties of Single-Grain Bulk GdBCO Superconductors Processed by Different Thicknesses of Y123 Liquid Source. Micromachines, 13(5), 701. https://doi.org/10.3390/mi13050701