The Effect of Ink Supply Pressure on Piezoelectric Inkjet

Abstract

:1. Introduction

2. Experimental Setup

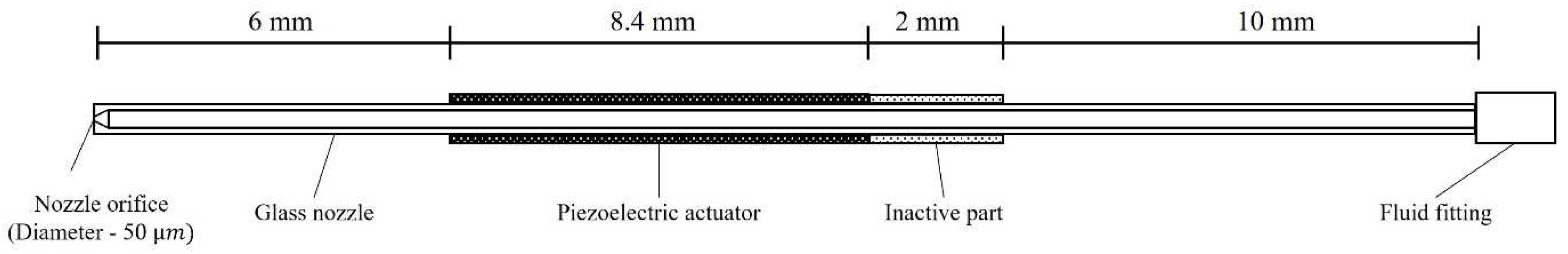

2.1. Inkjet Head and Ink

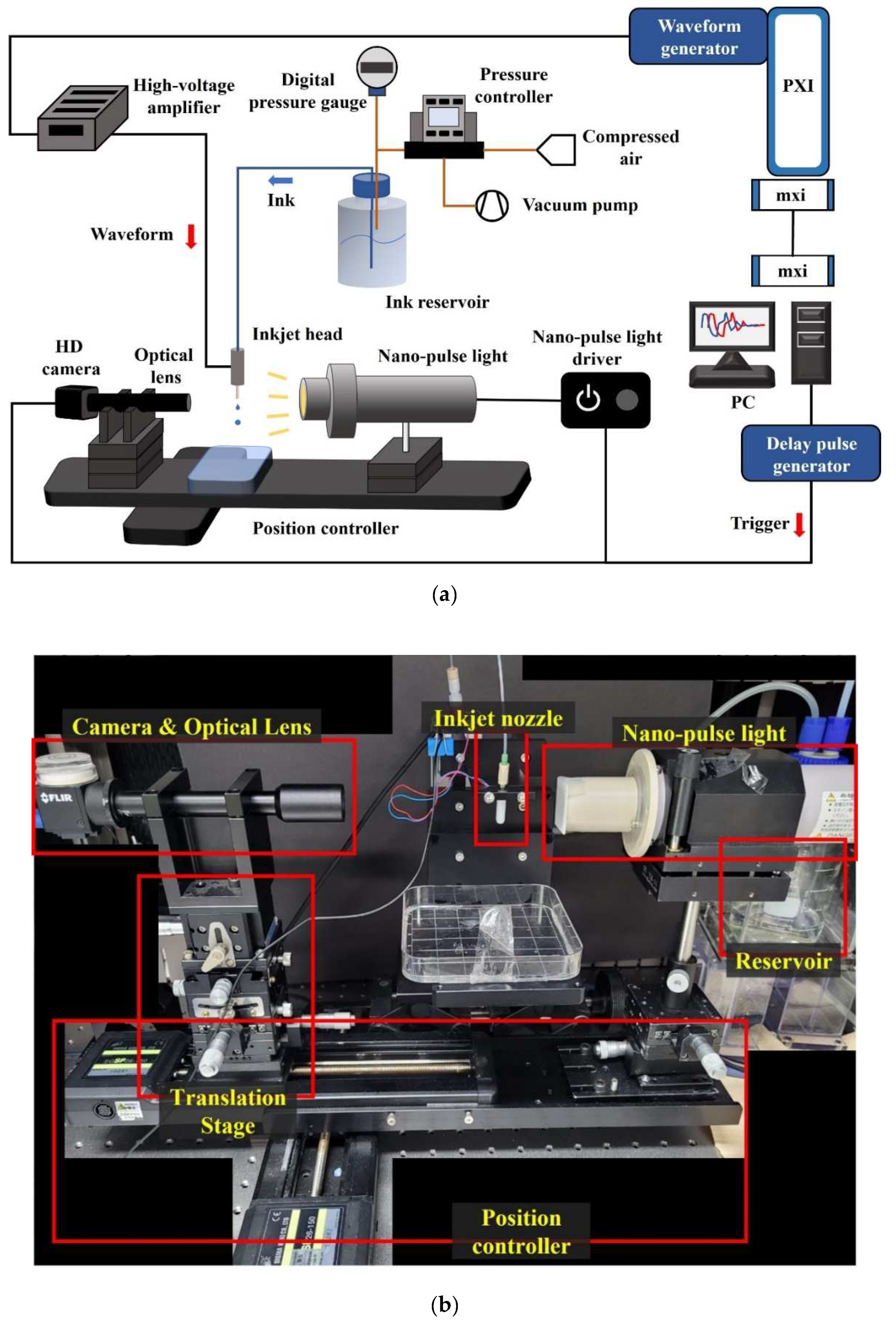

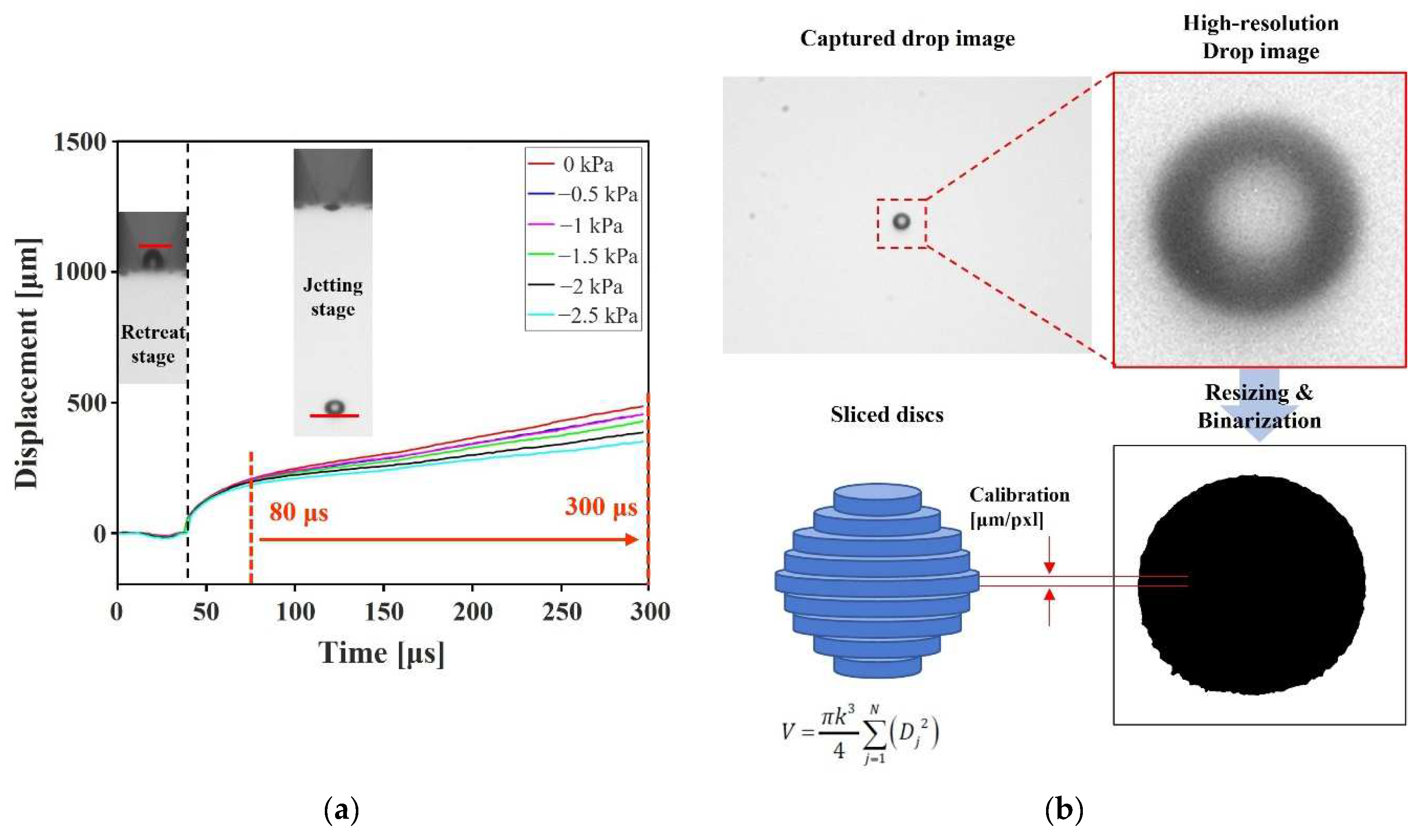

2.2. Drop Monitoring System

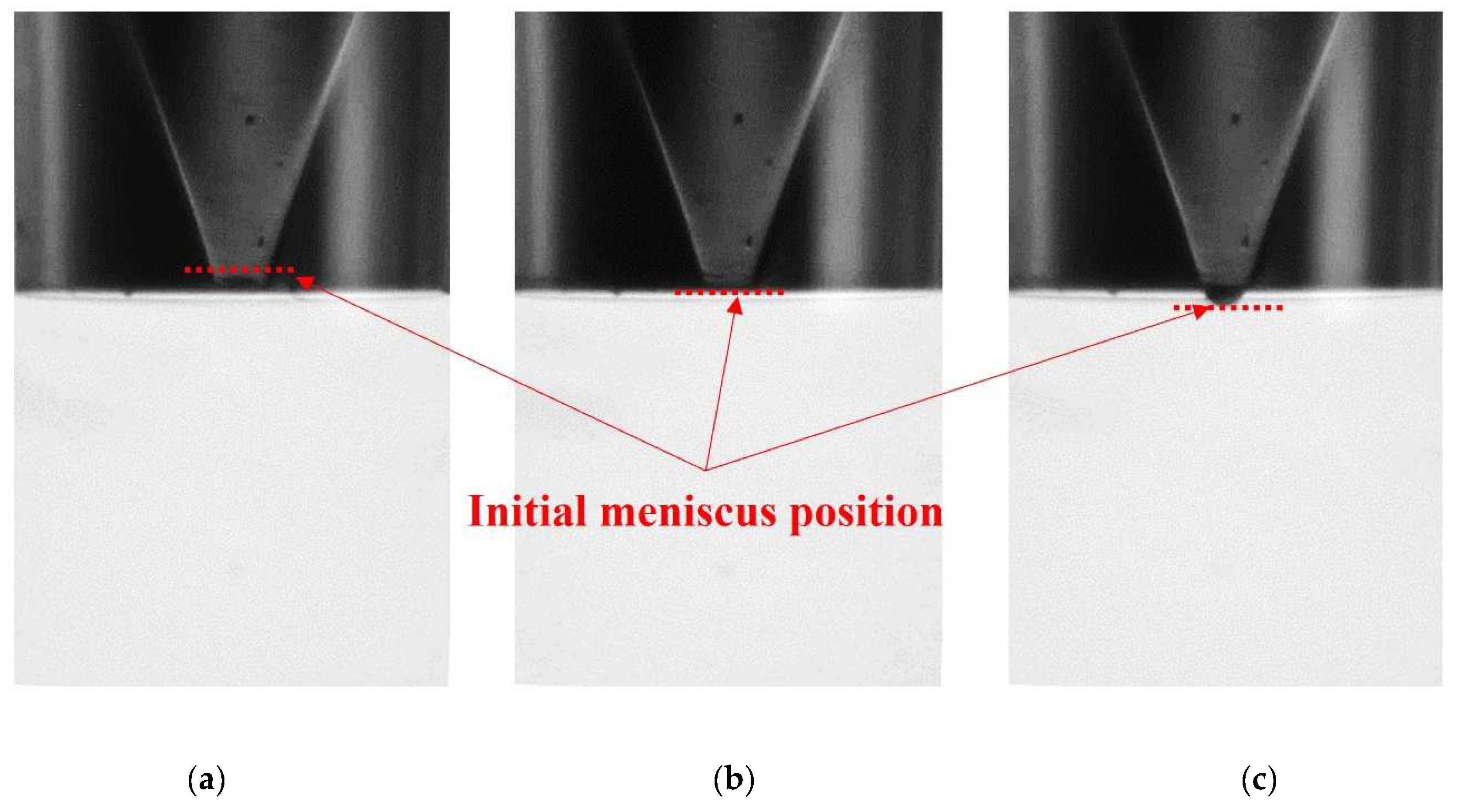

2.3. Pressure Control

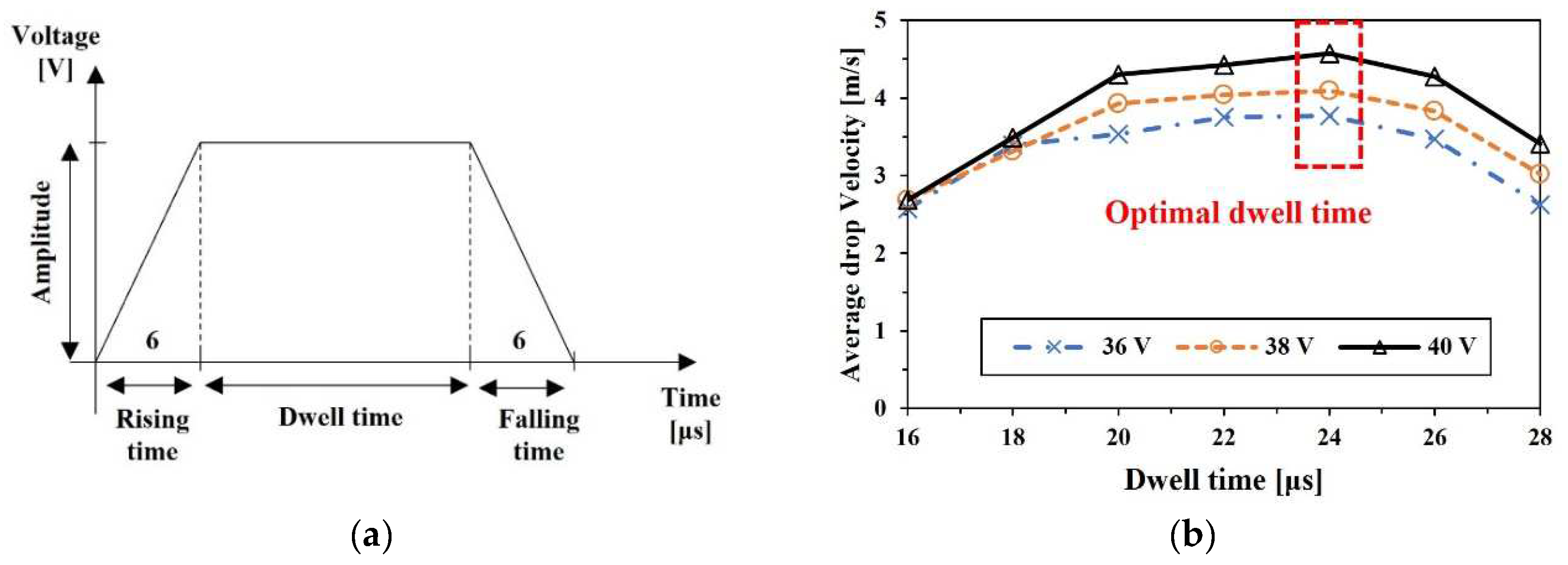

2.4. Waveform

2.5. Image Processing

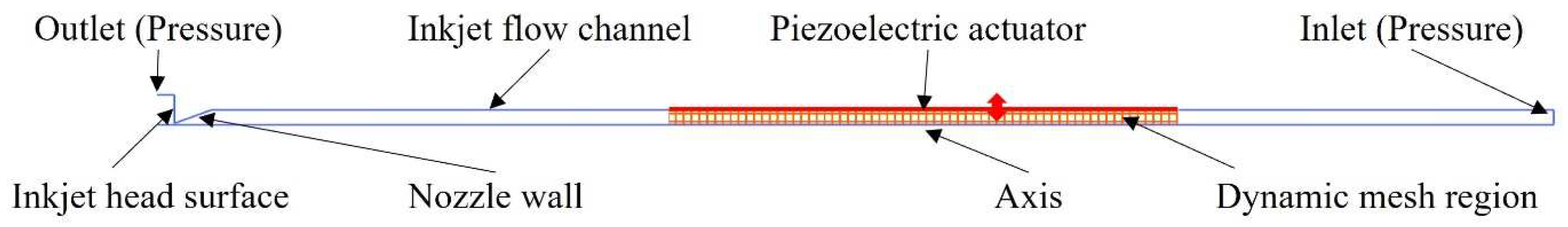

3. Numerical Method

3.1. Boundary Conditions

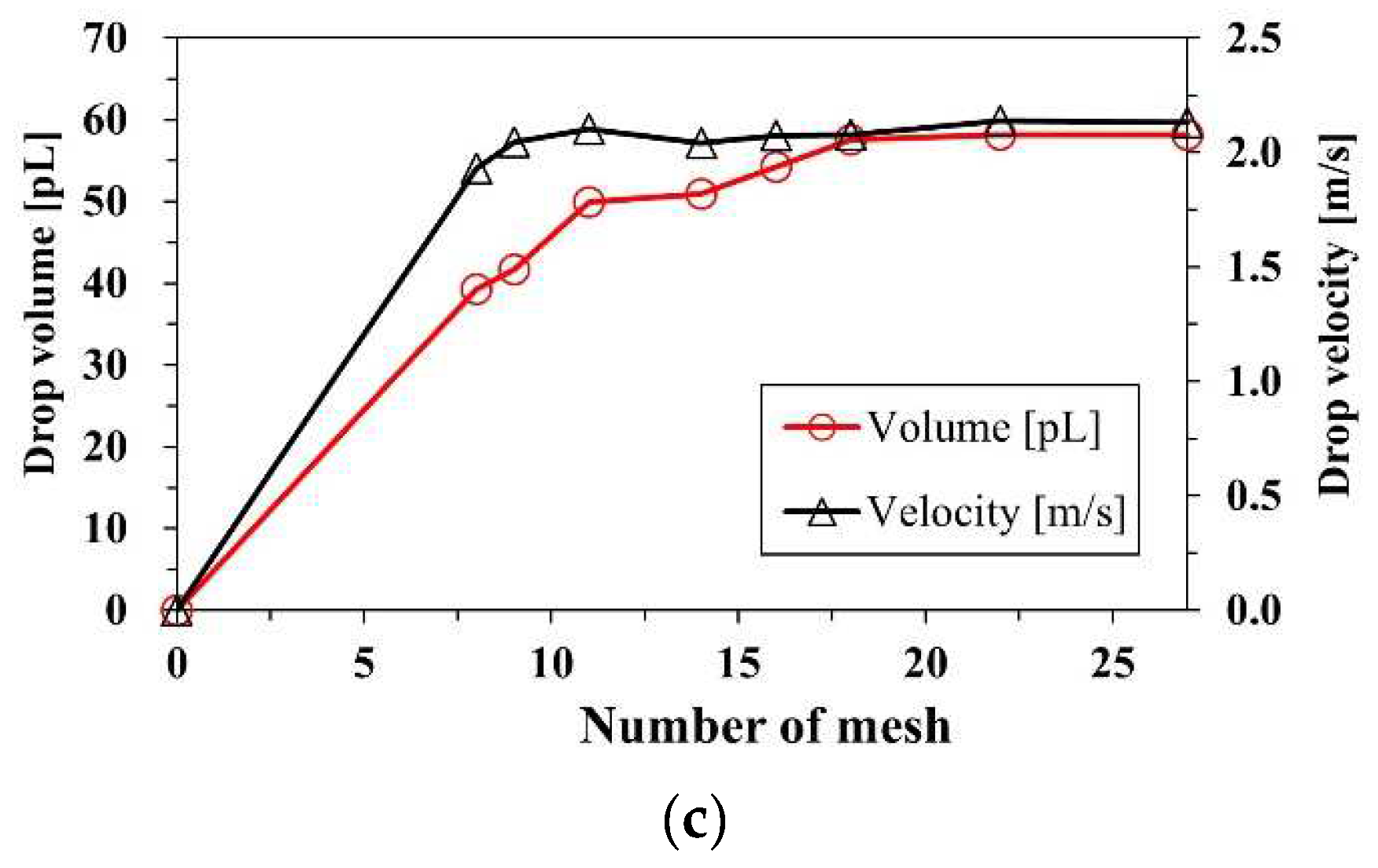

3.2. Mesh Convergence Study

4. Results and Discussion

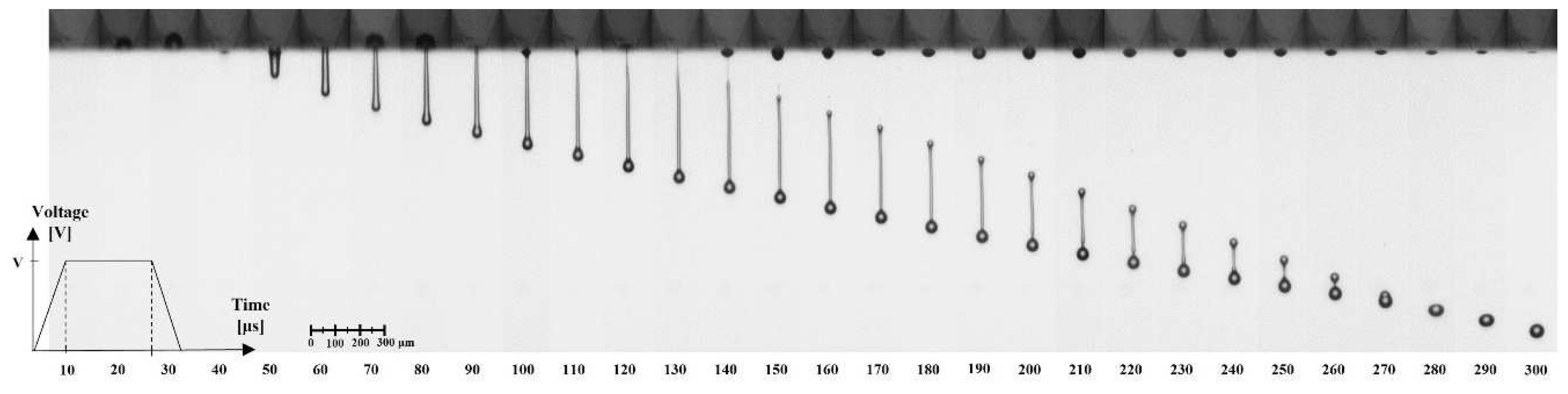

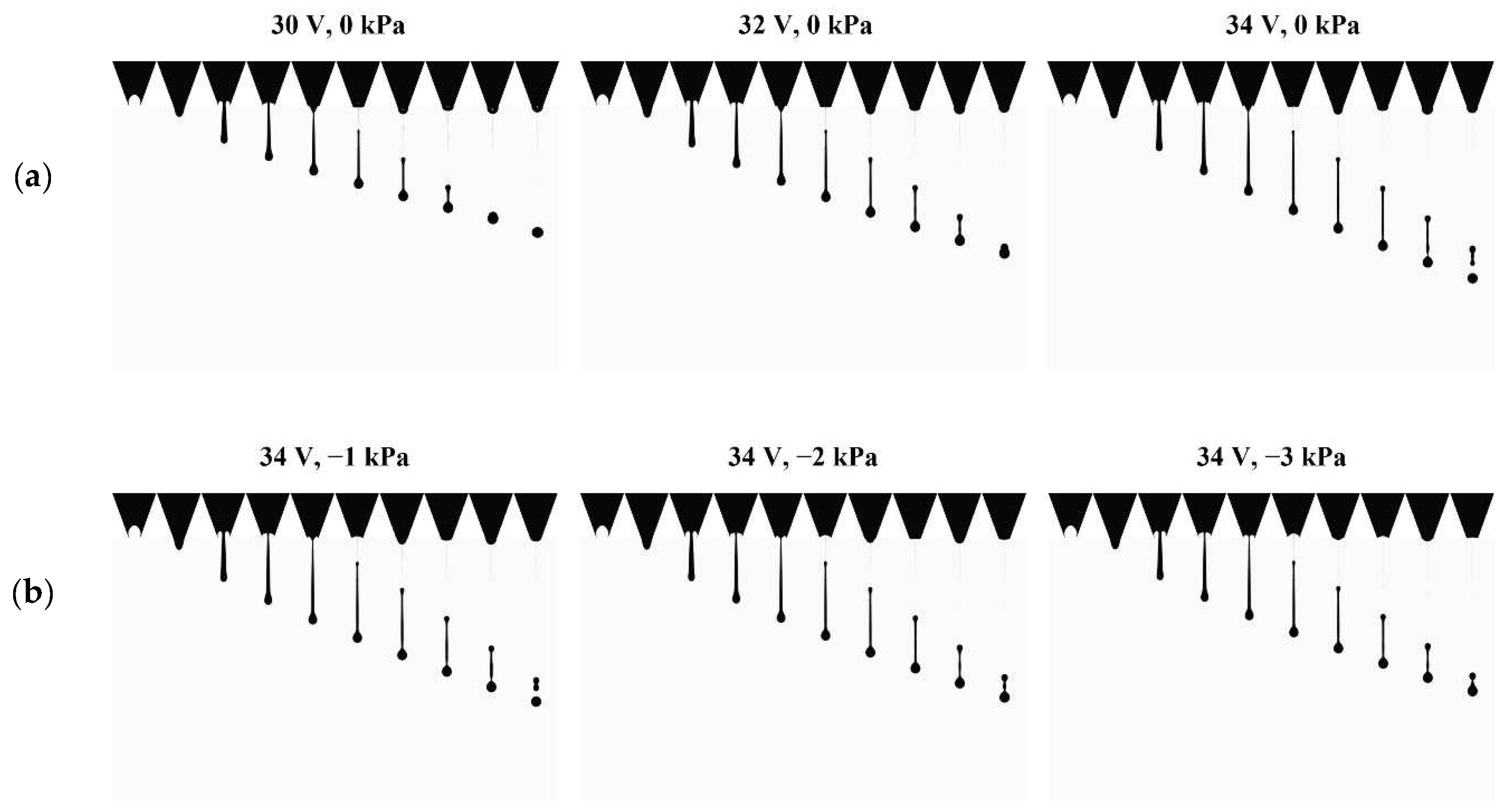

4.1. Drop Formation

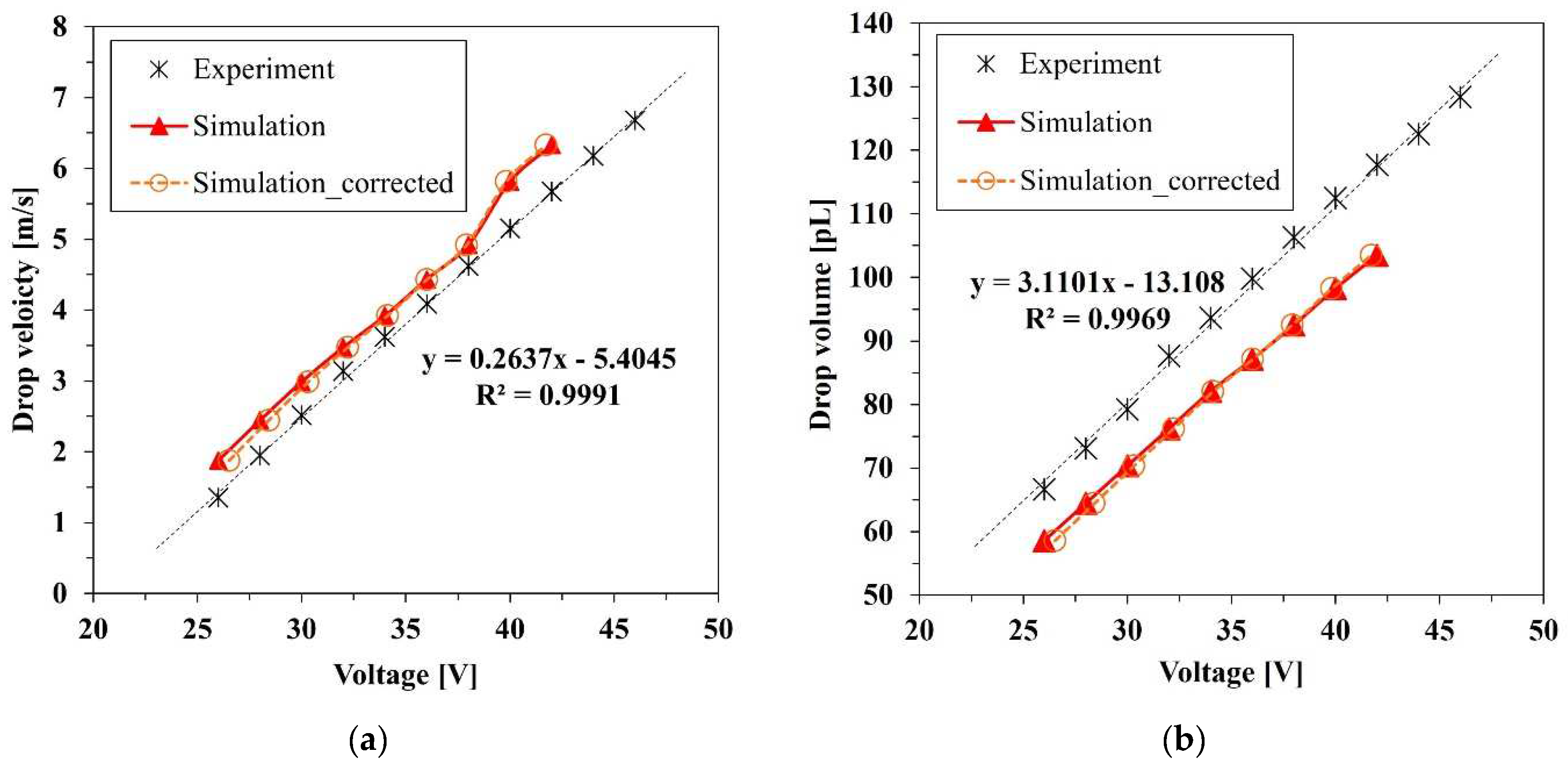

4.2. Drop Velocity and Volume

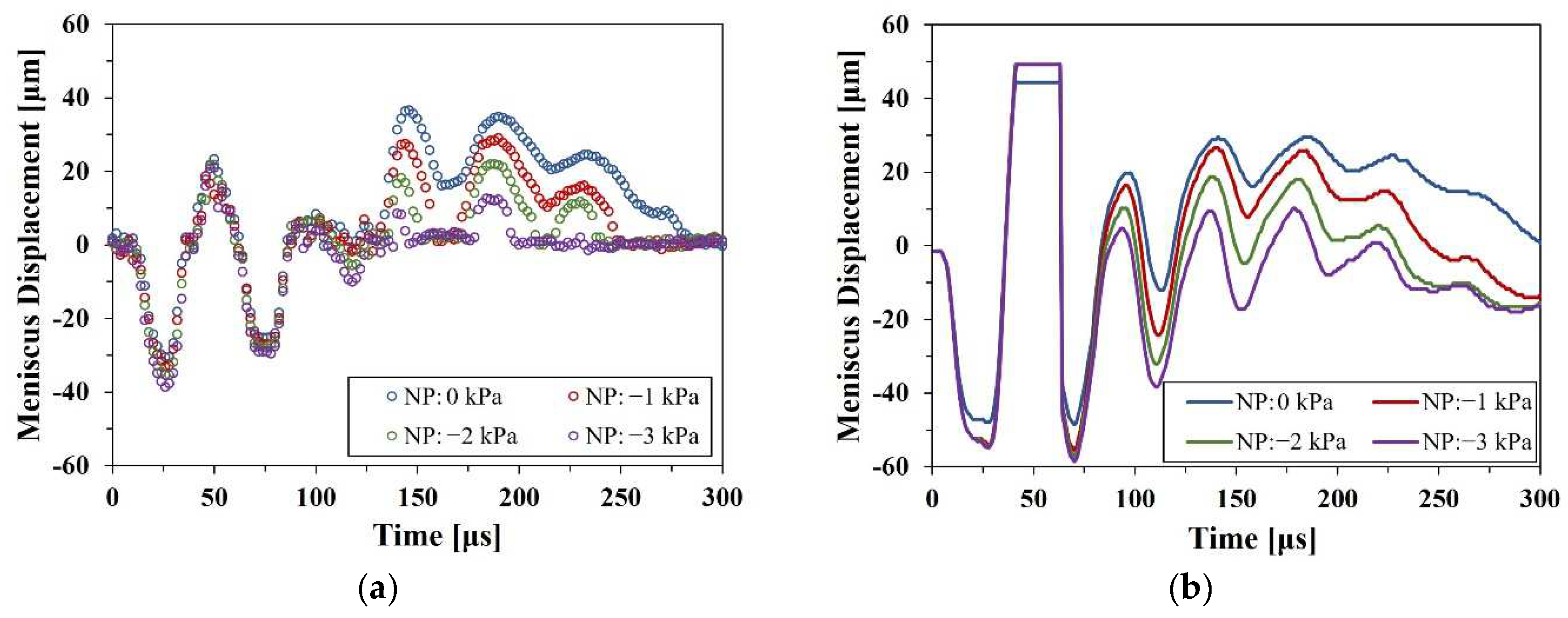

4.3. Residual Vibration of Meniscus

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Calvert, P. Inkjet printing for materials and devices. Chem. Mater. 2001, 13, 3299–3305. [Google Scholar] [CrossRef]

- Singh, M.; Haverinen, H.M.; Dhagat, P.; Jabbour, G.E. Inkjet printing—process and its applications. Adv. Mater. 2010, 22, 673–685. [Google Scholar] [CrossRef] [PubMed]

- Kwon, K.-S.; Rahman, M.K.; Phung, T.H.; Hoath, S.D.; Jeong, S.; Kim, J.S. Review of digital printing technologies for electronic materials. Flex. Print. Electron. 2020, 5, 043003. [Google Scholar] [CrossRef]

- Graf, D.; Jung, J.; Hanemann, T. Formulation of a Ceramic Ink for 3D Inkjet Printing. Micromachines 2021, 12, 1136. [Google Scholar] [CrossRef] [PubMed]

- Zhou, X.; Wu, H.; Wen, H.; Zheng, B. Advances in Single-Cell Printing. Micromachines 2022, 13, 80. [Google Scholar] [CrossRef]

- Hoath, S.D. Fundamentals of Inkjet Printing: The Science of Inkjet and Droplets; John Wiley & Sons: New York, NY, USA, 2016; ISBN 3527337857. [Google Scholar]

- Basaran, O.A.; Gao, H.; Bhat, P.P. Nonstandard inkjets. Annu. Rev. Fluid Mech. 2013, 45, 85–113. [Google Scholar] [CrossRef]

- Lohse, D. Fundamental fluid dynamics challenges in inkjet printing. Annu. Rev. Fluid Mech. 2022, 54, 349–382. [Google Scholar] [CrossRef]

- Verkouteren, R.M.; Verkouteren, J.R. Inkjet metrology II: Resolved effects of ejection frequency, fluidic pressure, and droplet number on reproducible drop-on-demand dispensing. Langmuir 2011, 27, 9644–9653. [Google Scholar] [CrossRef]

- Derby, B. Inkjet printing of functional and structural materials: Fluid property requirements, feature stability, and resolution. Annu. Rev. Mater. Res. 2010, 40, 395–414. [Google Scholar] [CrossRef]

- Oktavianty, O.; Kyotani, T.; Haruyama, S.; Kaminishi, K. New actuation waveform design of DoD inkjet printer for single and multi-drop ejection method. Addit. Manuf. 2019, 25, 522–531. [Google Scholar] [CrossRef]

- Dong, H.; Carr, W.W.; Morris, J.F. An experimental study of drop-on-demand drop formation. Phys. Fluids 2006, 18, 072102. [Google Scholar] [CrossRef]

- Wijshoff, H. The dynamics of the piezo inkjet printhead operation. Phys. Rep. 2010, 491, 77–177. [Google Scholar] [CrossRef]

- Dijksman, J. Hydrodynamics of small tubular pumps. J. Fluid Mech. 1984, 139, 173–191. [Google Scholar] [CrossRef]

- Jang, D.; Kim, D.; Moon, J. Influence of fluid physical properties on ink-jet printability. Langmuir 2009, 25, 2629–2635. [Google Scholar] [CrossRef] [PubMed]

- Kang, S.-H.; Kim, S.; Sohn, D.K.; Ko, H.S. Analysis of drop-on-demand piezo inkjet performance. Phys. Fluids 2020, 32, 022007. [Google Scholar]

- Ohnesorge, W.V. Die Bildung von Tropfen an Düsen und die Auflösung flüssiger Strahlen. J. Appl. Math. Mech. 1936, 355, 16. [Google Scholar] [CrossRef]

- Liu, Y.; Derby, B. Experimental study of the parameters for stable drop-on-demand inkjet performance. Phys. Fluids 2019, 31, 032004. [Google Scholar] [CrossRef] [Green Version]

- Zhong, Y.; Fang, H.; Ma, Q.; Dong, X. Analysis of droplet stability after ejection from an inkjet nozzle. J. Fluid Mech. 2018, 845, 378–391. [Google Scholar] [CrossRef]

- Liou, T.-M.; Chan, C.-Y.; Shih, K.-C. Effects of actuating waveform, ink property, and nozzle size on piezoelectrically driven inkjet droplets. Microfluid. Nanofluid. 2010, 8, 575–586. [Google Scholar] [CrossRef]

- Xu, Q.; Basaran, O.A. Computational analysis of drop-on-demand drop formation. Phys. Fluids 2007, 19, 102111. [Google Scholar] [CrossRef]

- Shin, D.-Y.; Grassia, P.; Derby, B. Numerical and experimental comparisons of mass transport rate in a piezoelectric drop-on-demand inkjet print head. Int. J. Mech. Sci. 2004, 46, 181–199. [Google Scholar] [CrossRef]

- Bertolucci, F.; Berdozzi, N.; Rebaioli, L.; Patil, T.; Vertechy, R.; Fassi, I. Assessing the Relationships between Interdigital Geometry Quality and Inkjet Printing Parameters. Micromachines 2022, 13, 57. [Google Scholar] [CrossRef] [PubMed]

- Shah, M.A.; Lee, D.G.; Hur, S. Design and Characteristic Analysis of a MEMS Piezo-Driven Recirculating Inkjet Printhead Using Lumped Element Modeling. Micromachines 2019, 10, 757. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Chang, J.; Jiang, F.; Liu, Z.; Zhu, D.; Shen, T. Simulation and experimental study on droplet breakup modes and redrawing of their phase diagram. Phys. Fluids 2021, 33, 082105. [Google Scholar] [CrossRef]

- McKinley, G.H.; Renardy, M. Wolfgang von Ohnesorge. Phys. Fluids 2011, 23, 127101. [Google Scholar] [CrossRef] [Green Version]

- Kye-Si, K. Waveform Design Methods for Piezo Inkjet Dispensers Based on Measured Meniscus Motion. J. Microelectromech. Syst. 2009, 18, 1118–1125. [Google Scholar] [CrossRef]

- Bogy, D.B.; Talke, F. Experimental and theoretical study of wave propagation phenomena in drop-on-demand ink jet devices. IBM J. Res. Dev. 1984, 28, 314–321. [Google Scholar] [CrossRef]

- Sauvola, J.; Pietikäinen, M. Adaptive document image binarization. Pattern Recognit. 2000, 33, 225–236. [Google Scholar] [CrossRef] [Green Version]

- Zhang, X. Dynamics of drop formation in viscous flows. Chem. Eng. Sci. 1999, 54, 1759–1774. [Google Scholar] [CrossRef]

- ANSYS. Ansys Fluent Tutorial Guide 2022 R1 Chapter 19: Using the VOF Model; ANSYS, Inc.: Canonsburg, PA, USA, 2022. [Google Scholar]

- Kwon, K.-S. Experimental analysis of waveform effects on satellite and ligament behavior via in situ measurement of the drop-on-demand drop formation curve and the instantaneous jetting speed curve. J. Micromech. Microeng. 2010, 20, 115005. [Google Scholar] [CrossRef] [Green Version]

- Kim, B.-H.; Kim, S.-I.; Lee, J.-C.; Shin, S.-J.; Kim, S.-J. Dynamic characteristics of a piezoelectric driven inkjet printhead fabricated using MEMS technology. Sens. Actuators A Phys. 2012, 173, 244–253. [Google Scholar] [CrossRef]

- Chang, J.; Liu, Y.; Huang, B. Steady State Response Analysis of a Tubular Piezoelectric Print Head. Sensors 2016, 16, 81. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- ANSYS. Ansys Fluent Tutorial Guide 2022 R1 Chapter 12: Using Overset and Dynamic Meshes; ANSYS, Inc.: Canonsburg, PA, USA, 2022. [Google Scholar]

- Wang, J.; Huang, J.; Peng, J. Hydrodynamic response model of a piezoelectric inkjet print-head. Sens. Actuators A Phys. 2019, 285, 50–58. [Google Scholar] [CrossRef]

- Wu, H.-C.; Hwang, W.-S.; Lin, H.-J. Development of a three-dimensional simulation system for micro-inkjet and its experimental verification. Mater. Sci. Eng. A 2004, 373, 268–278. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kim, S.; Choi, J.H.; Sohn, D.K.; Ko, H.S. The Effect of Ink Supply Pressure on Piezoelectric Inkjet. Micromachines 2022, 13, 615. https://doi.org/10.3390/mi13040615

Kim S, Choi JH, Sohn DK, Ko HS. The Effect of Ink Supply Pressure on Piezoelectric Inkjet. Micromachines. 2022; 13(4):615. https://doi.org/10.3390/mi13040615

Chicago/Turabian StyleKim, San, Jun Hyeok Choi, Dong Kee Sohn, and Han Seo Ko. 2022. "The Effect of Ink Supply Pressure on Piezoelectric Inkjet" Micromachines 13, no. 4: 615. https://doi.org/10.3390/mi13040615

APA StyleKim, S., Choi, J. H., Sohn, D. K., & Ko, H. S. (2022). The Effect of Ink Supply Pressure on Piezoelectric Inkjet. Micromachines, 13(4), 615. https://doi.org/10.3390/mi13040615