Study on the Mechanical Properties of Monocrystalline Germanium Crystal Planes Based on Molecular Dynamics

Abstract

:1. Introduction

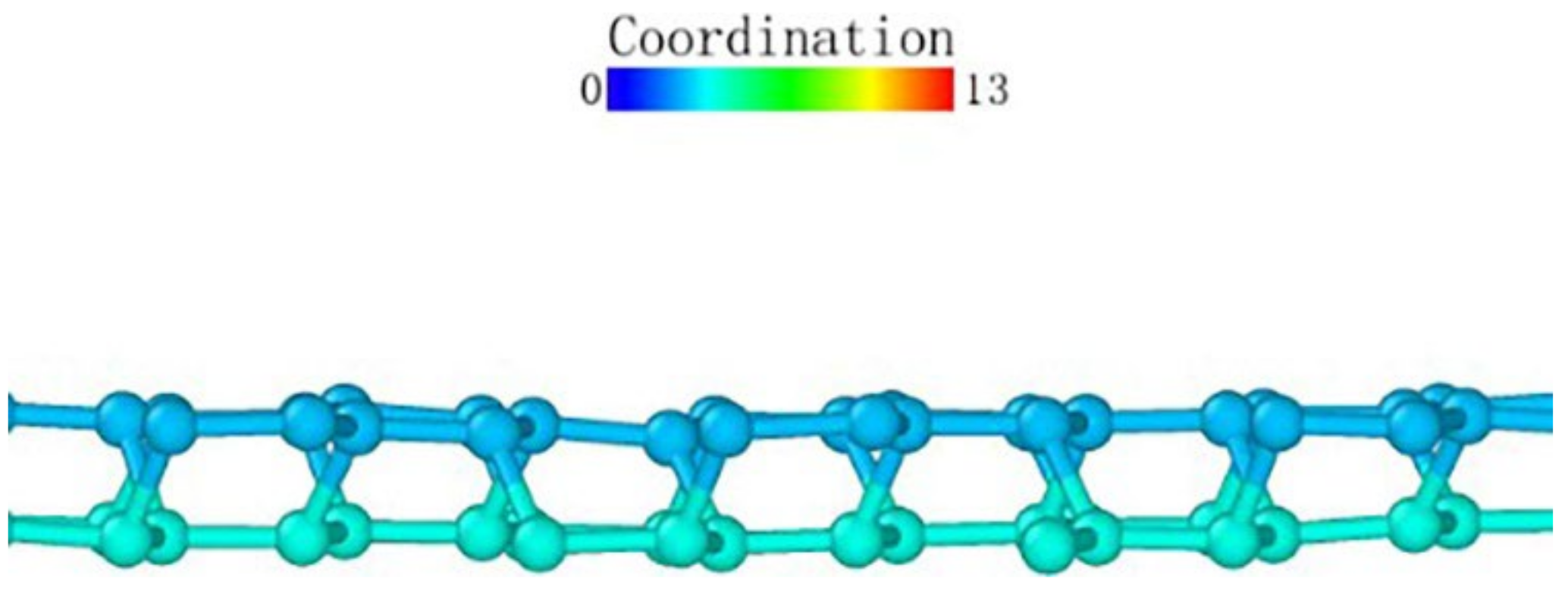

2. Preparing for Simulation

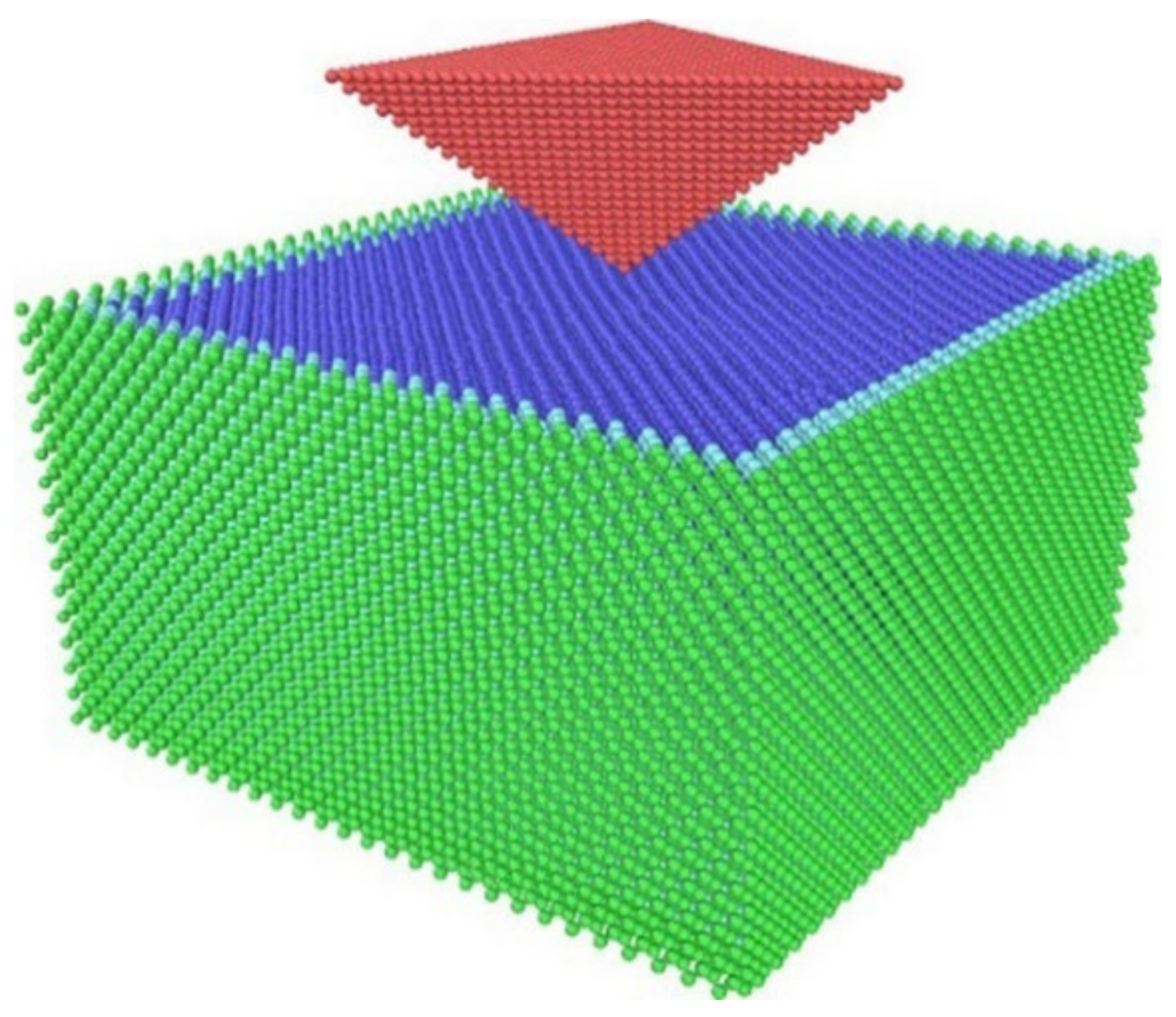

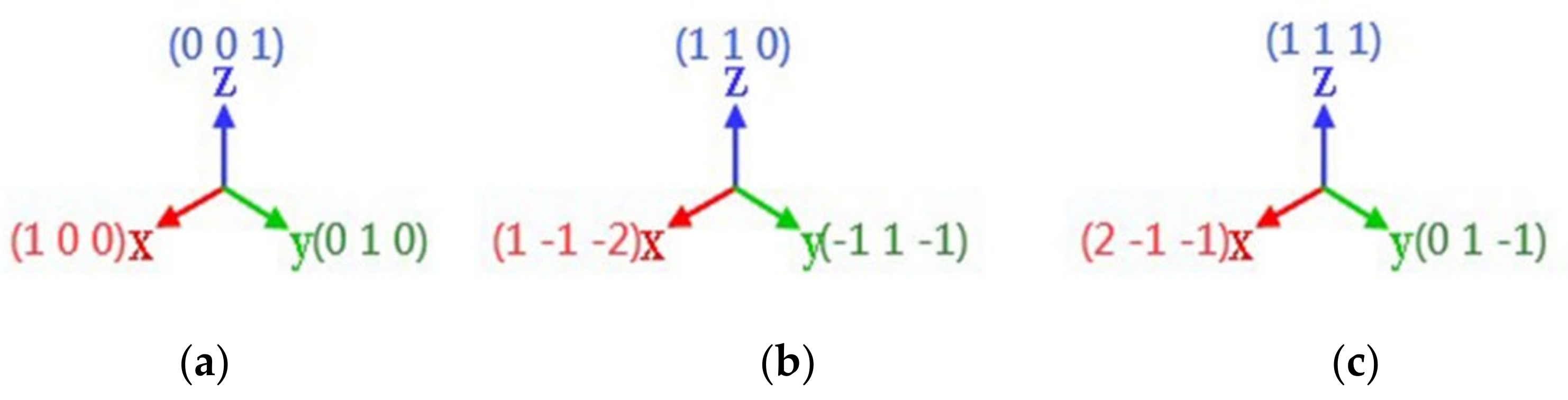

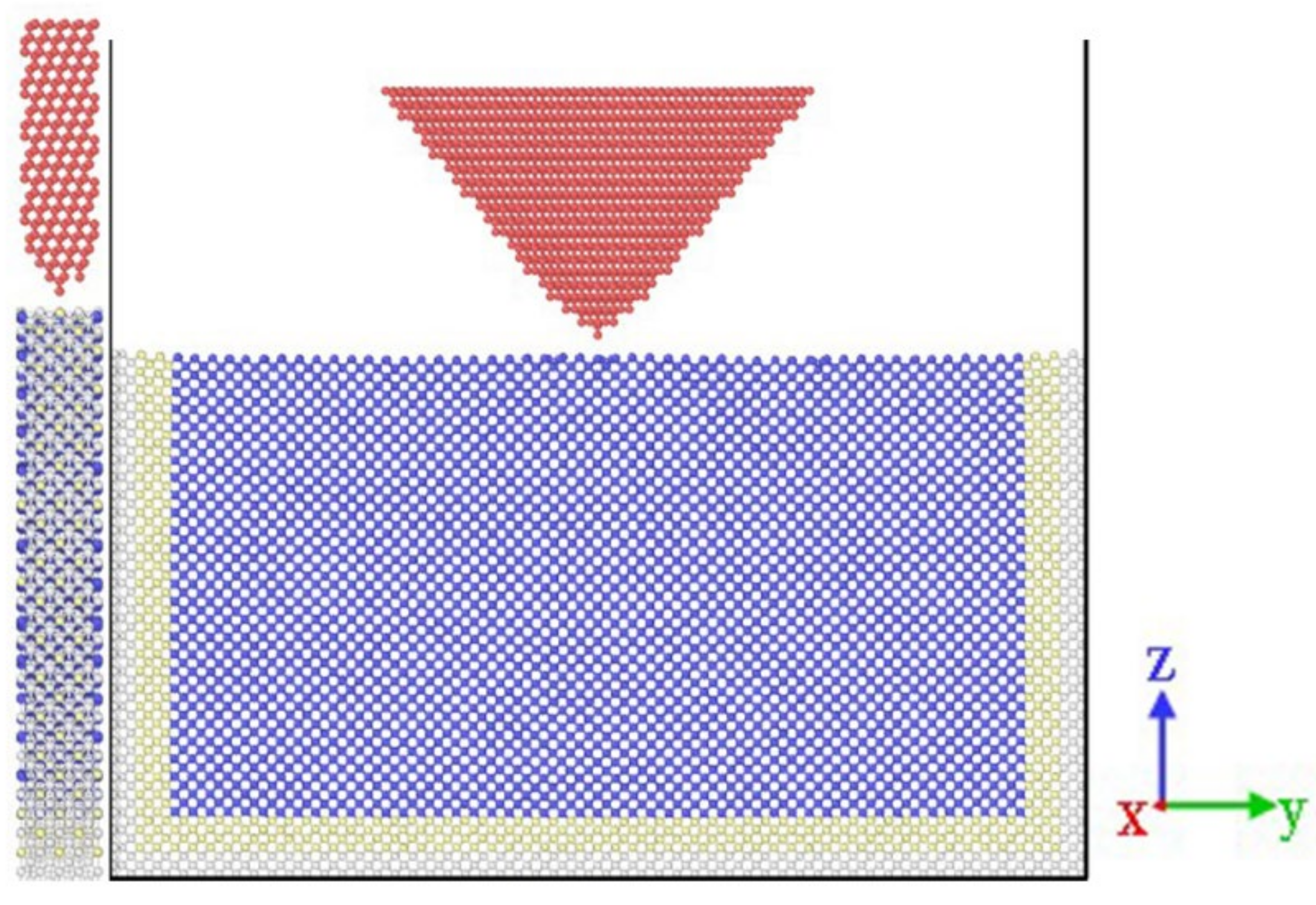

The Establishment of Single-Crystal Germanium Nano-Indentation Molecular Dynamics Model

3. Simulation Process Analysis

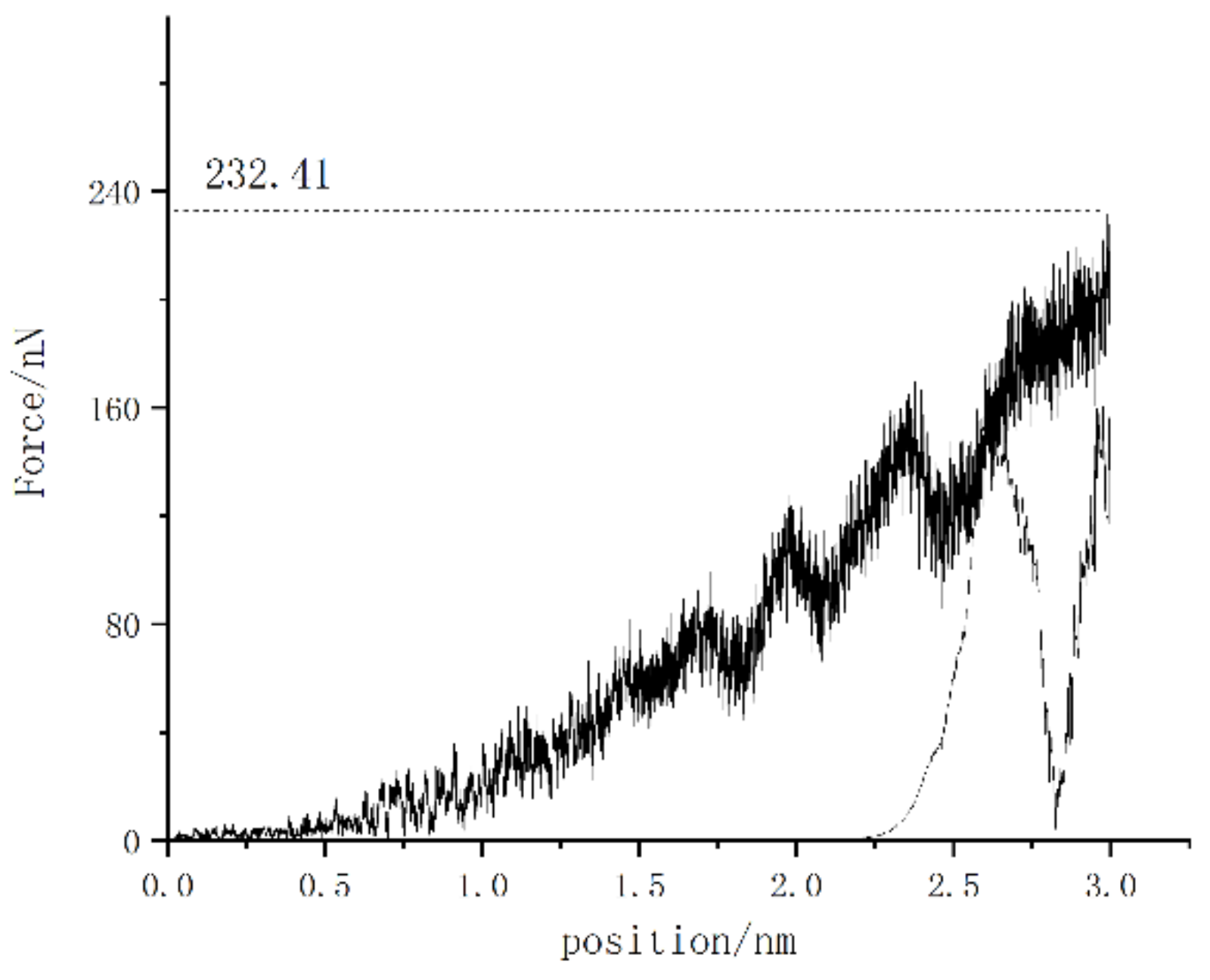

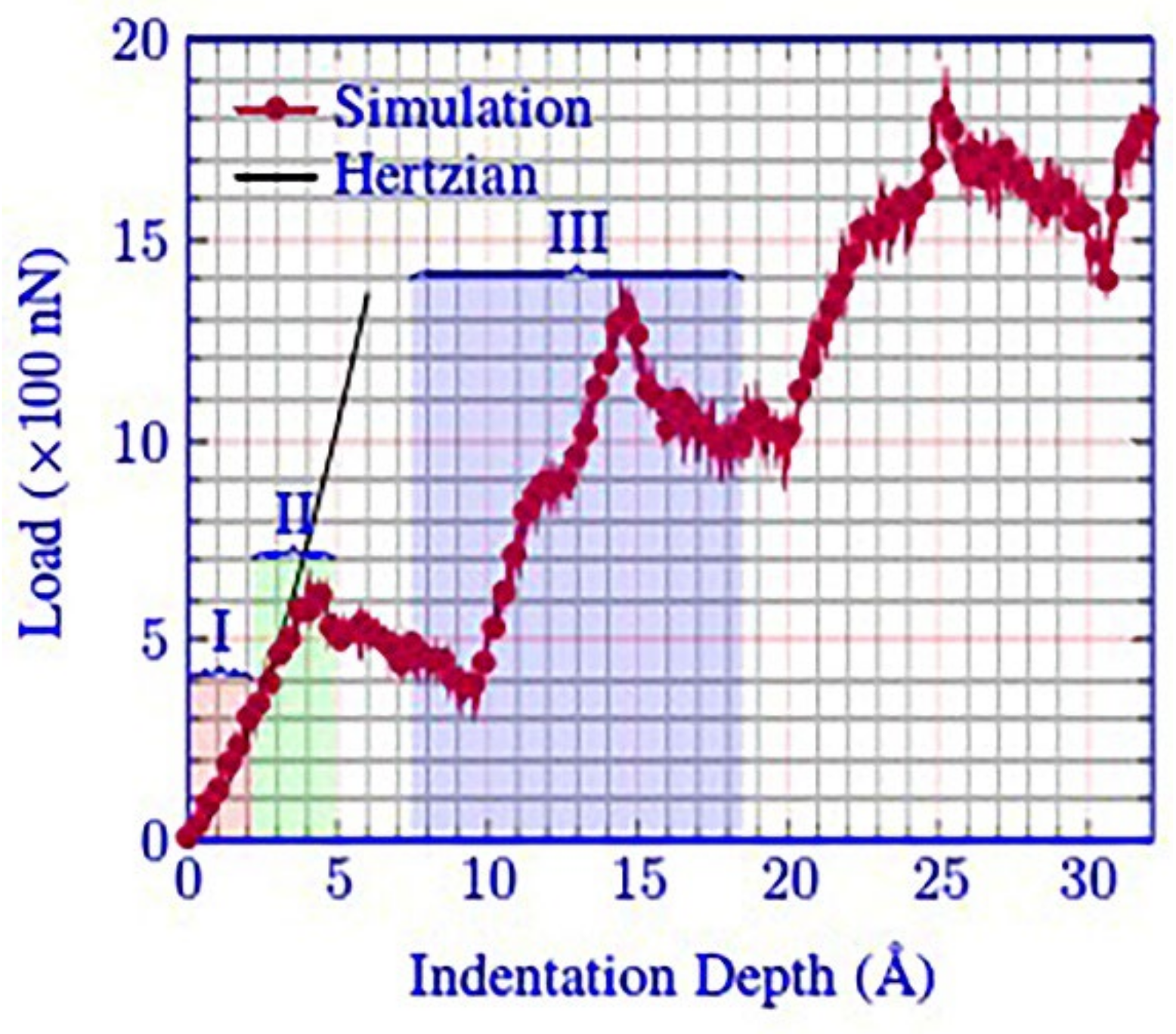

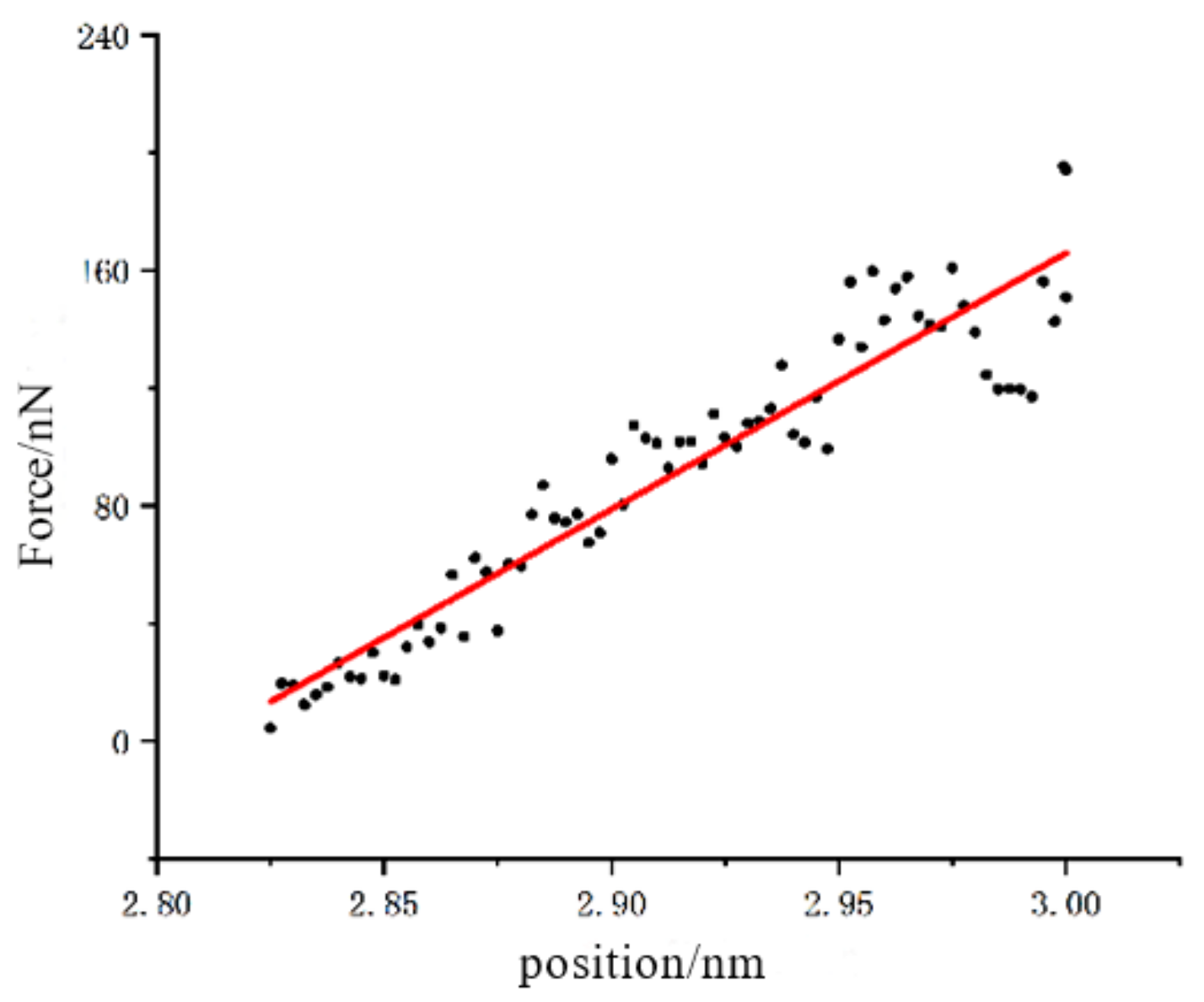

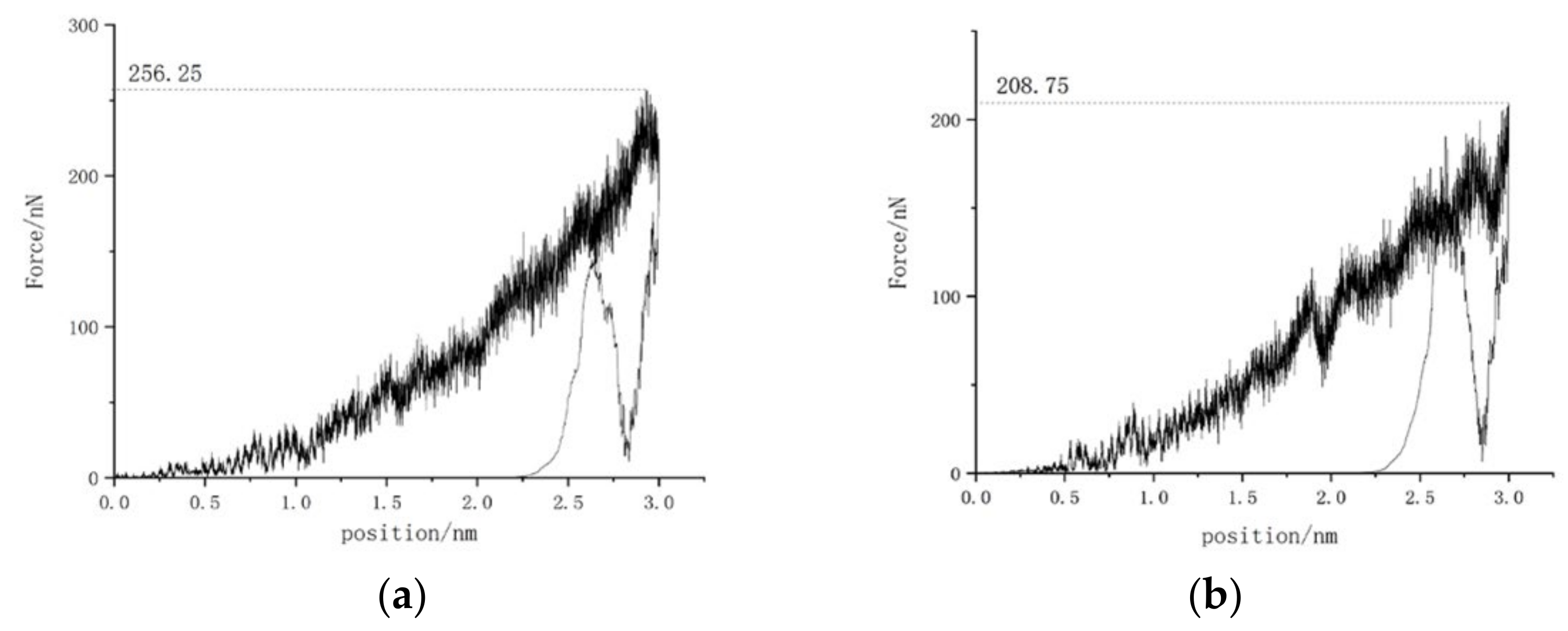

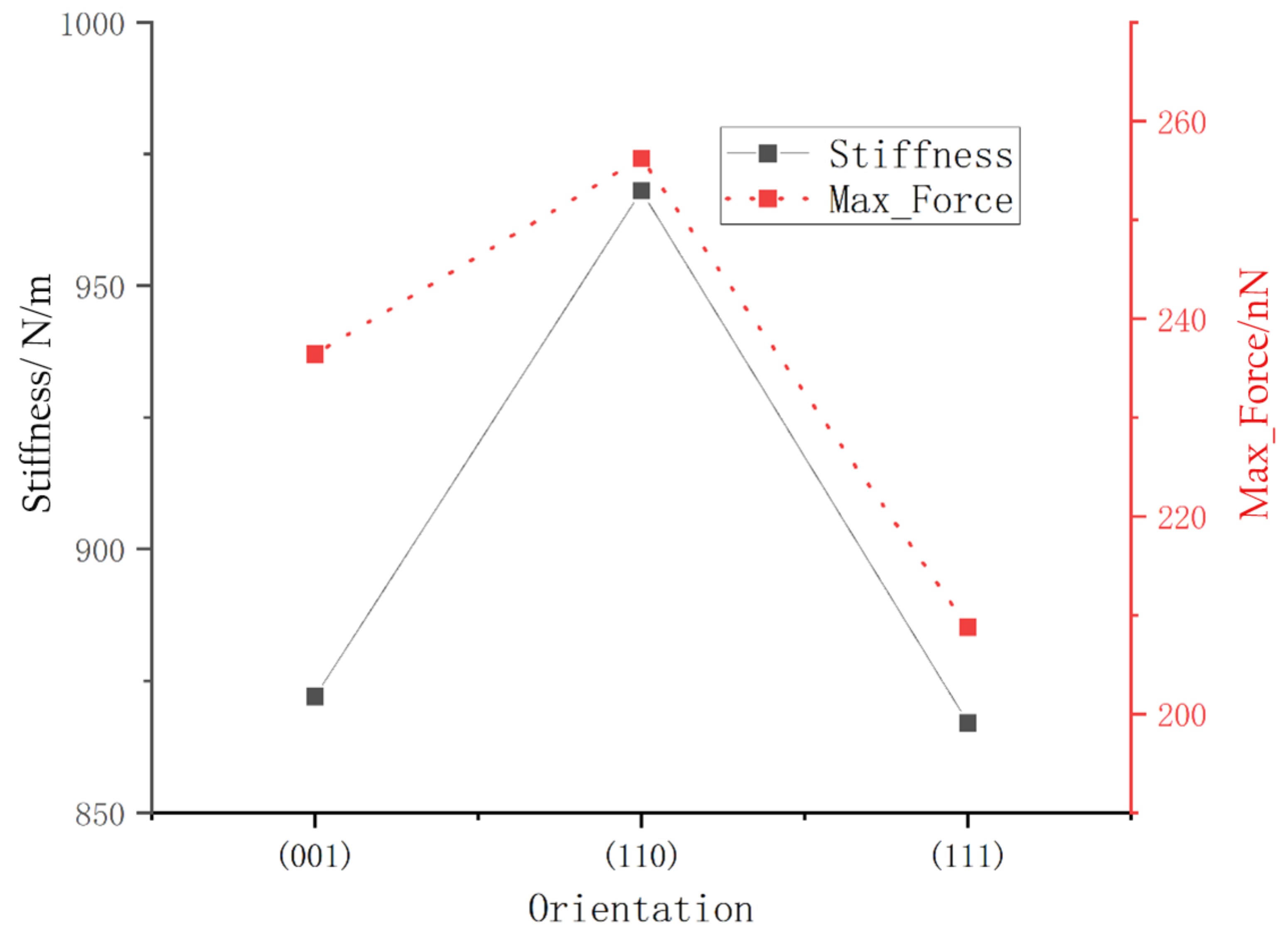

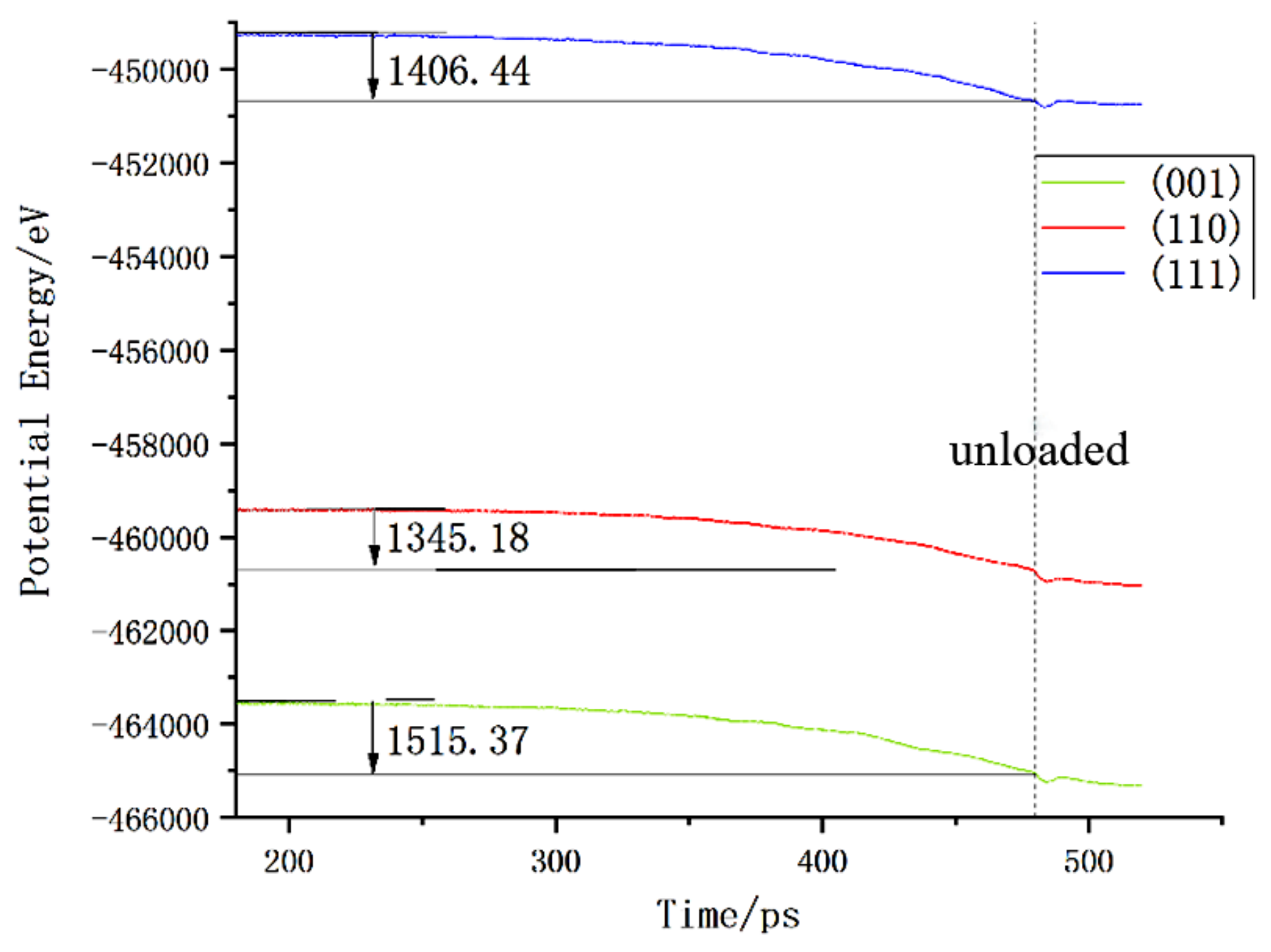

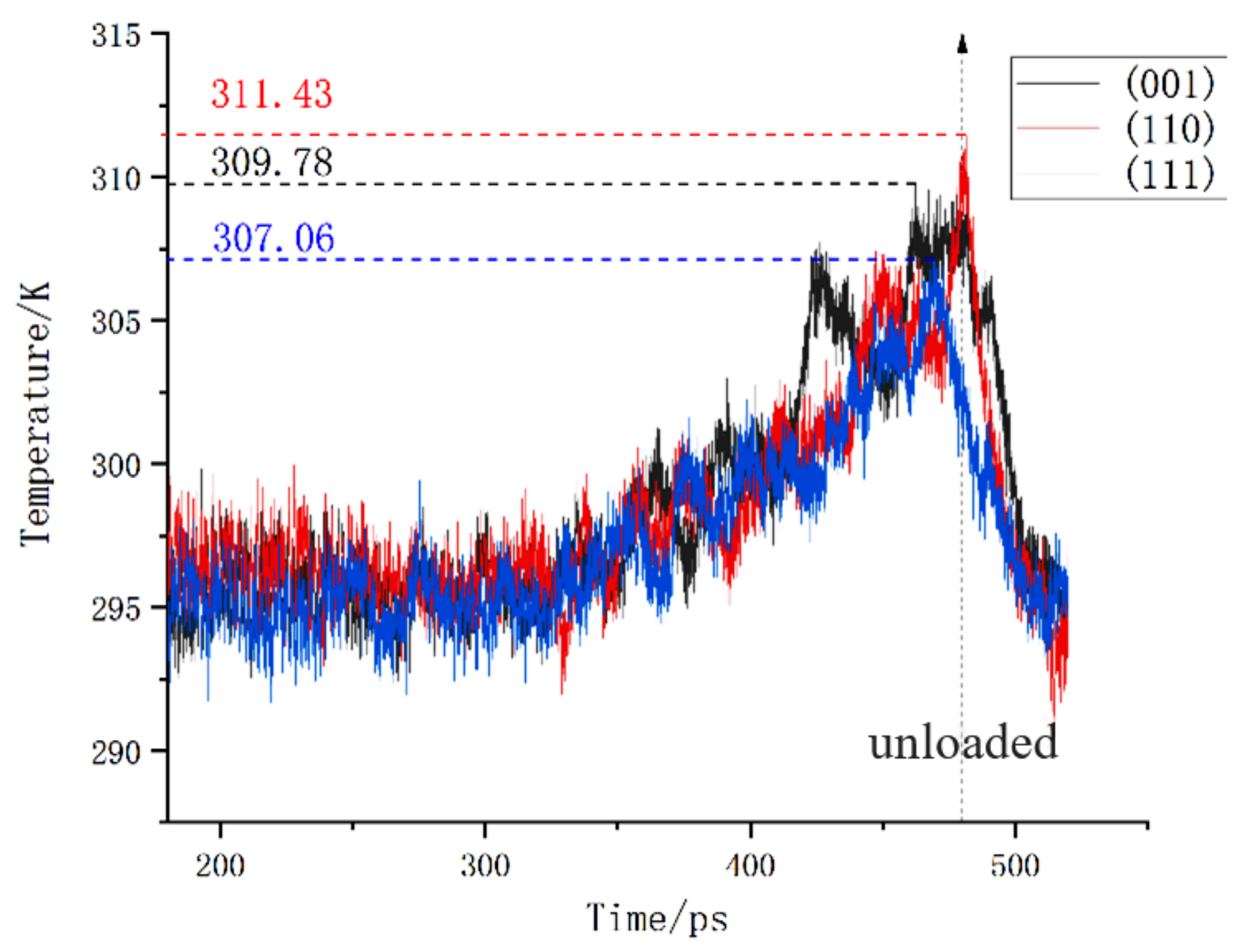

3.1. Overall Data Analysis of the Loading Process

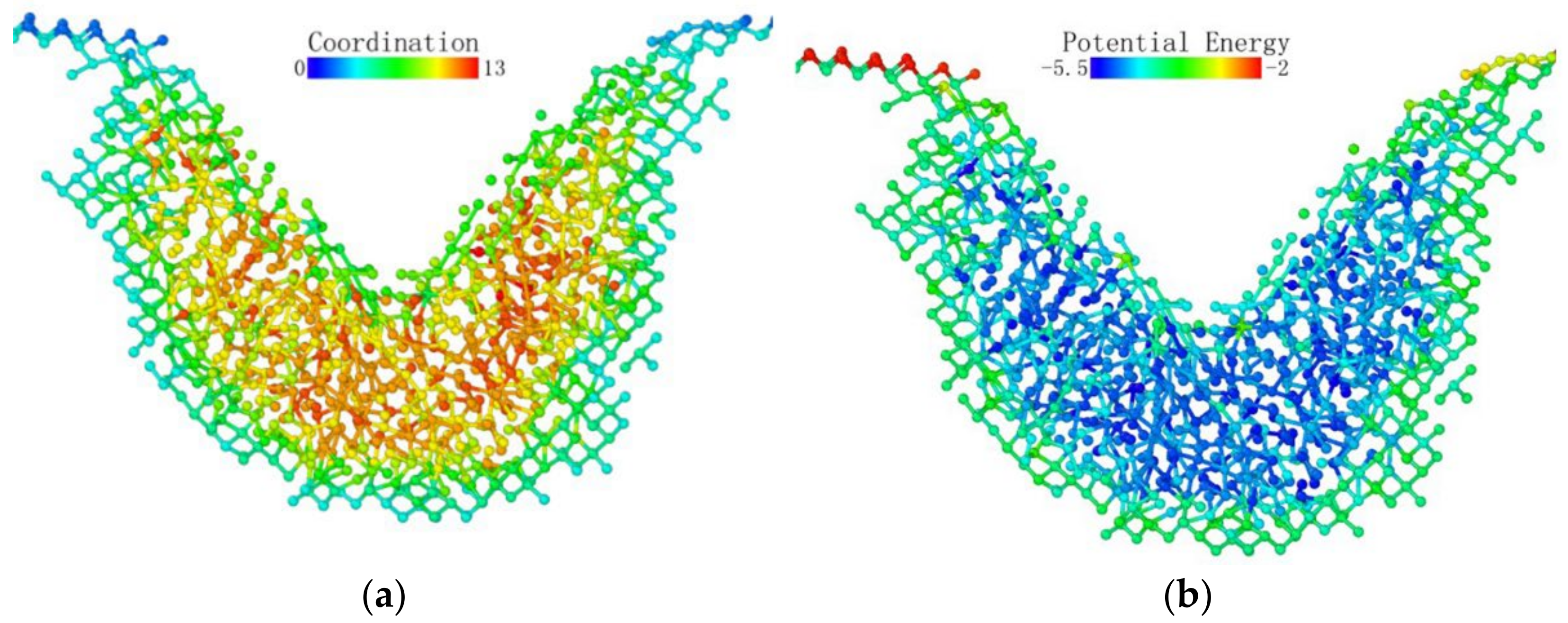

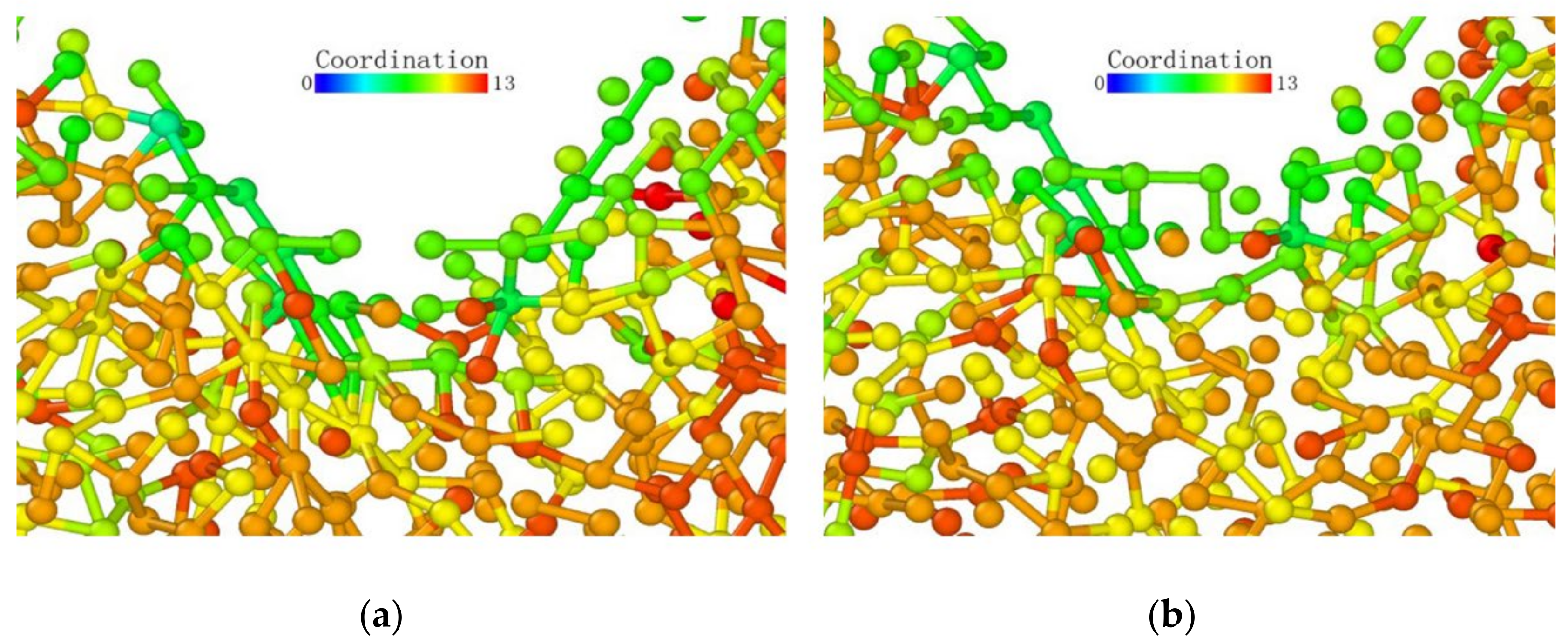

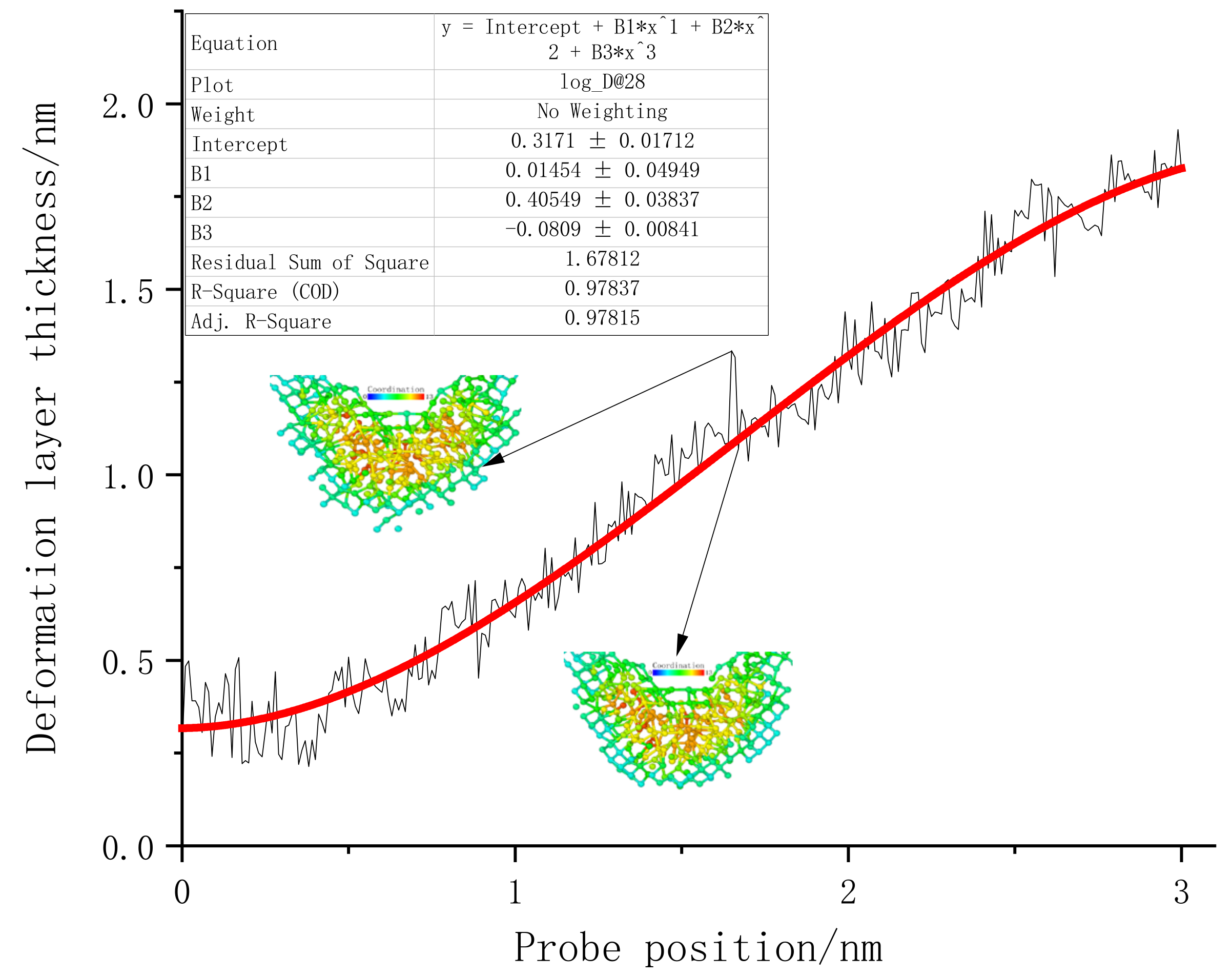

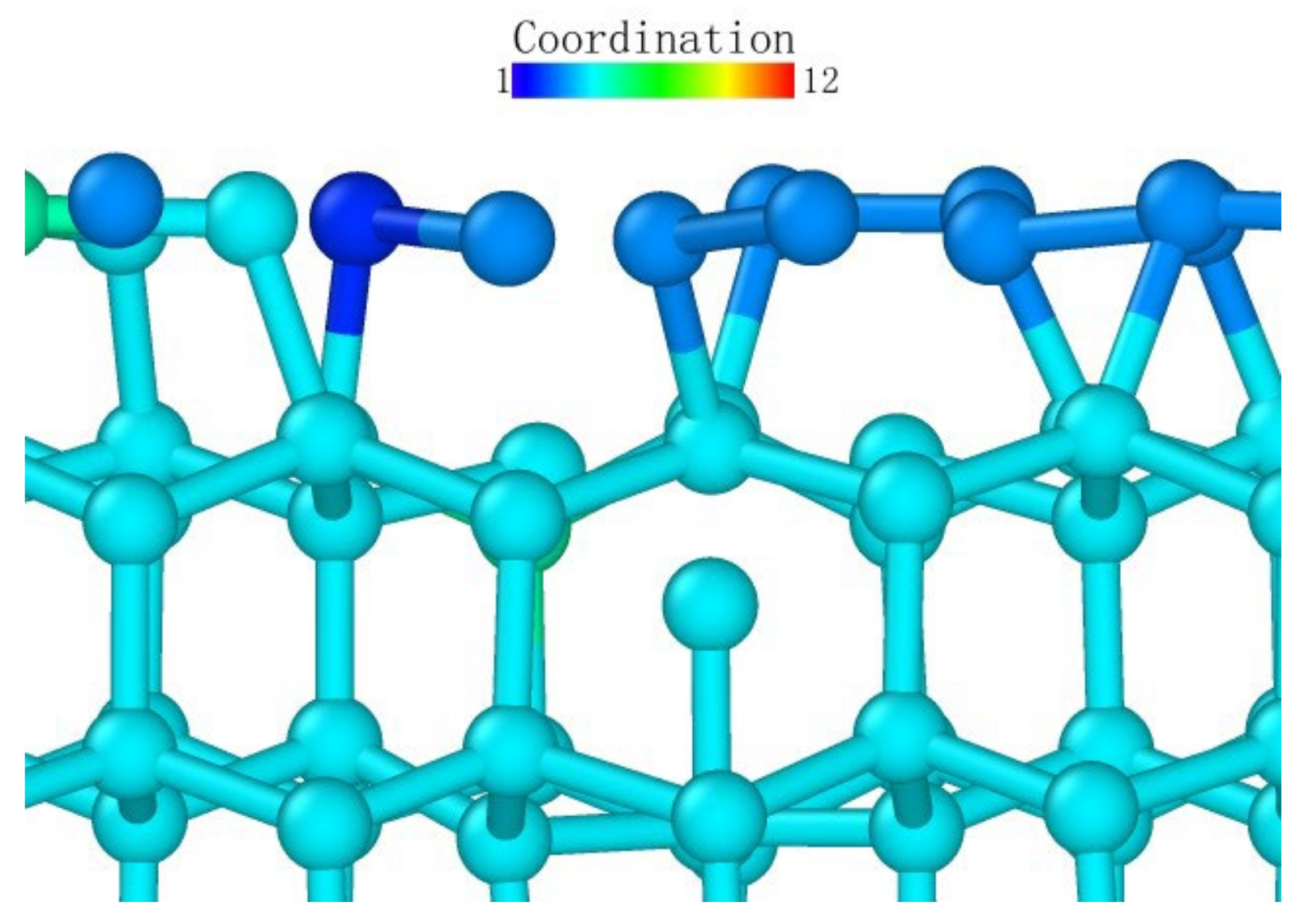

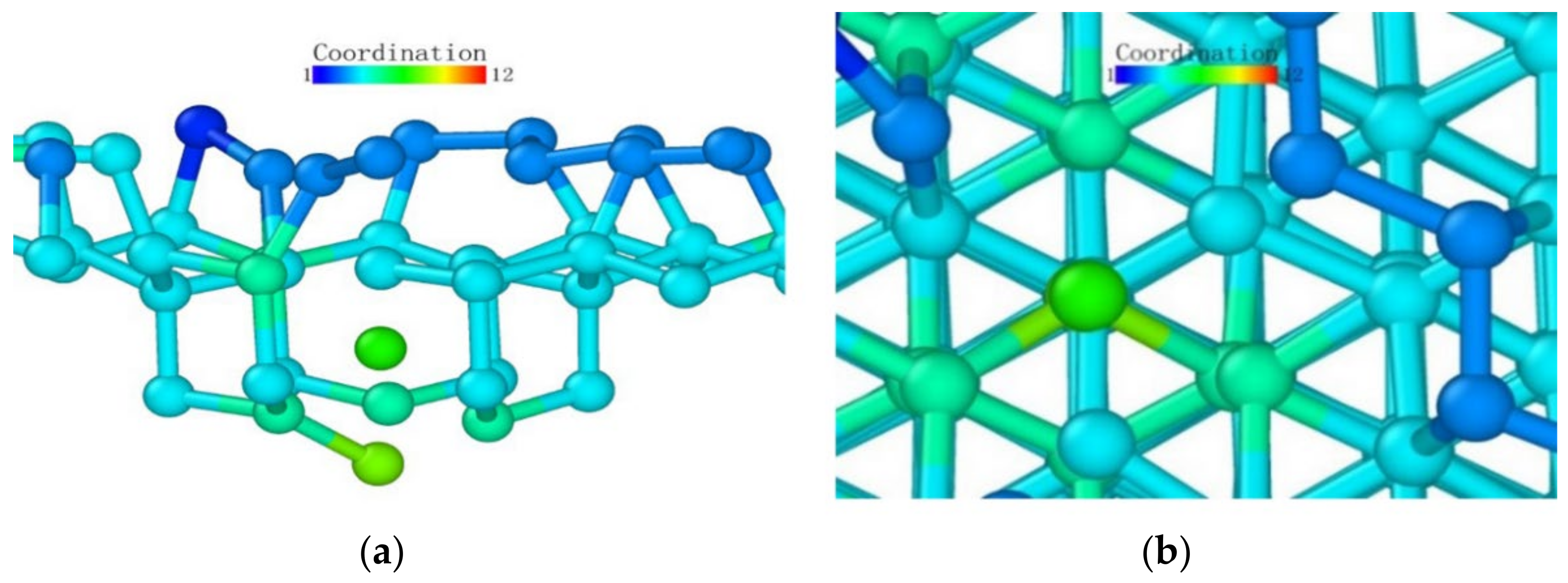

3.2. Atomic Transient Analysis

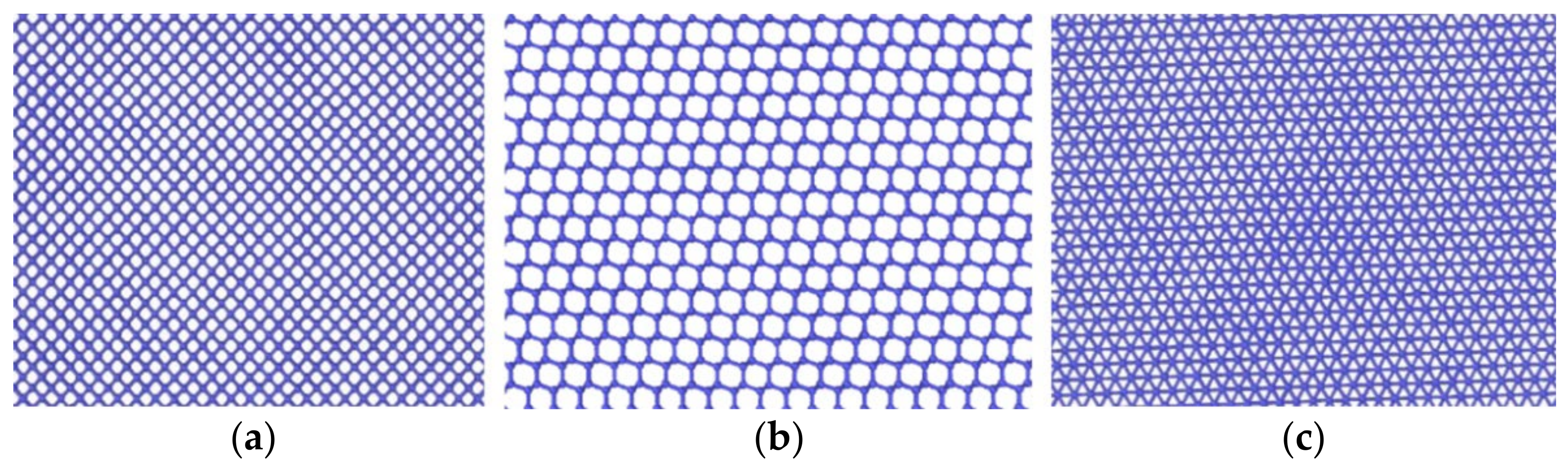

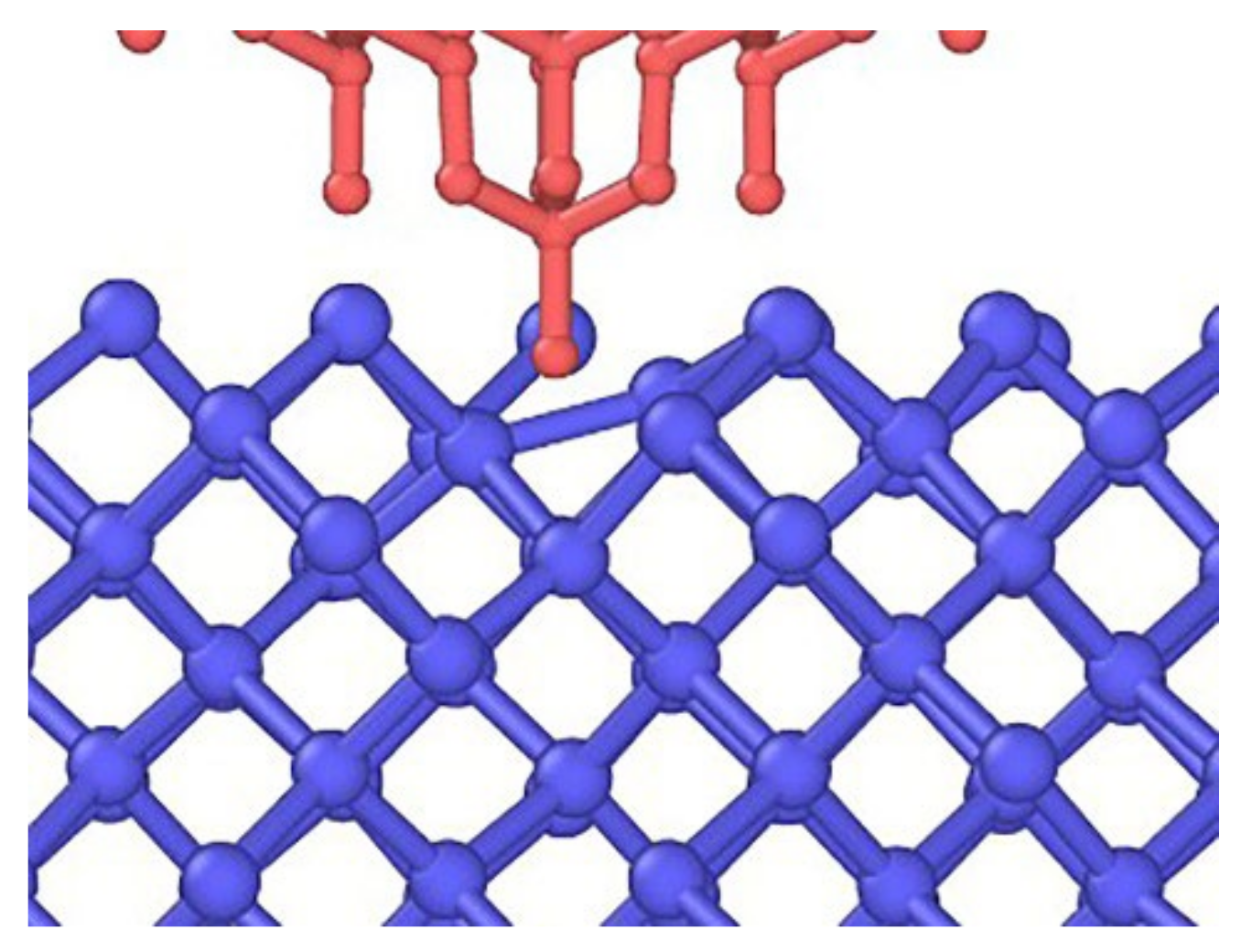

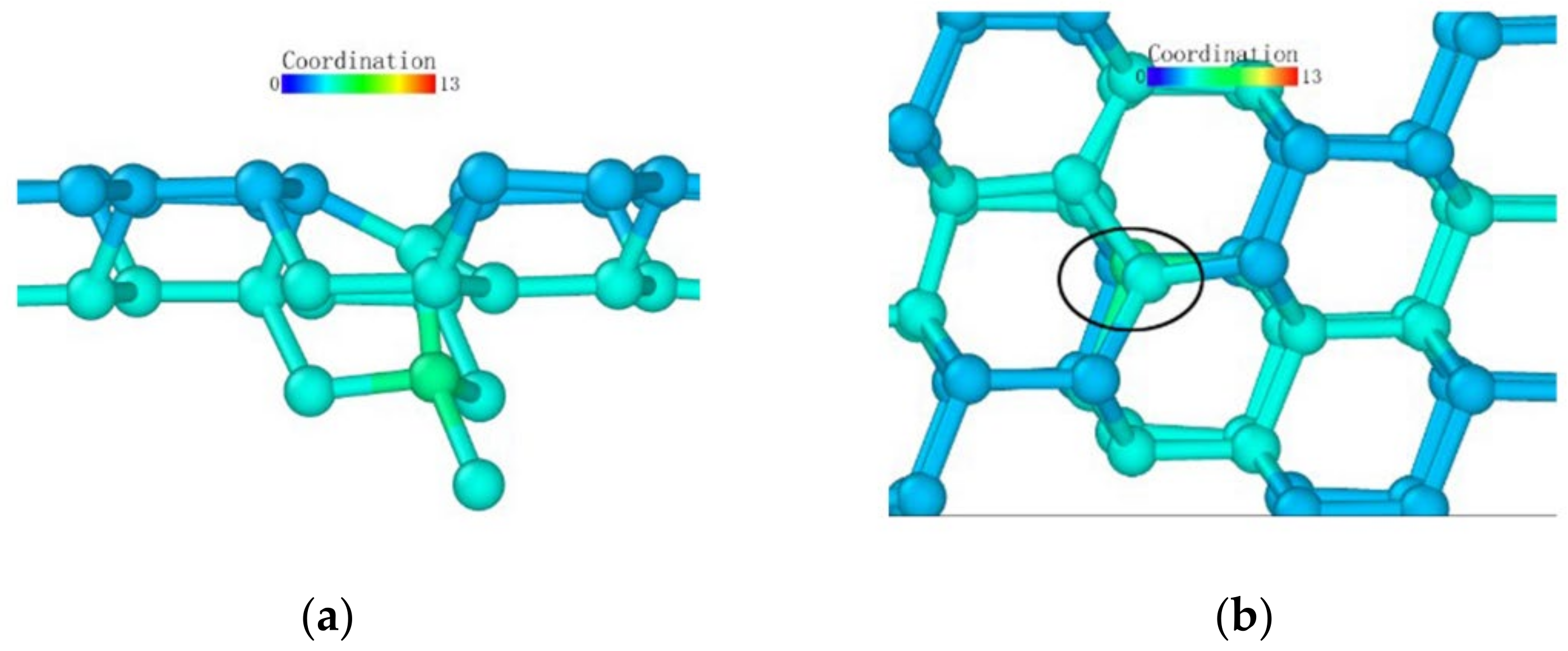

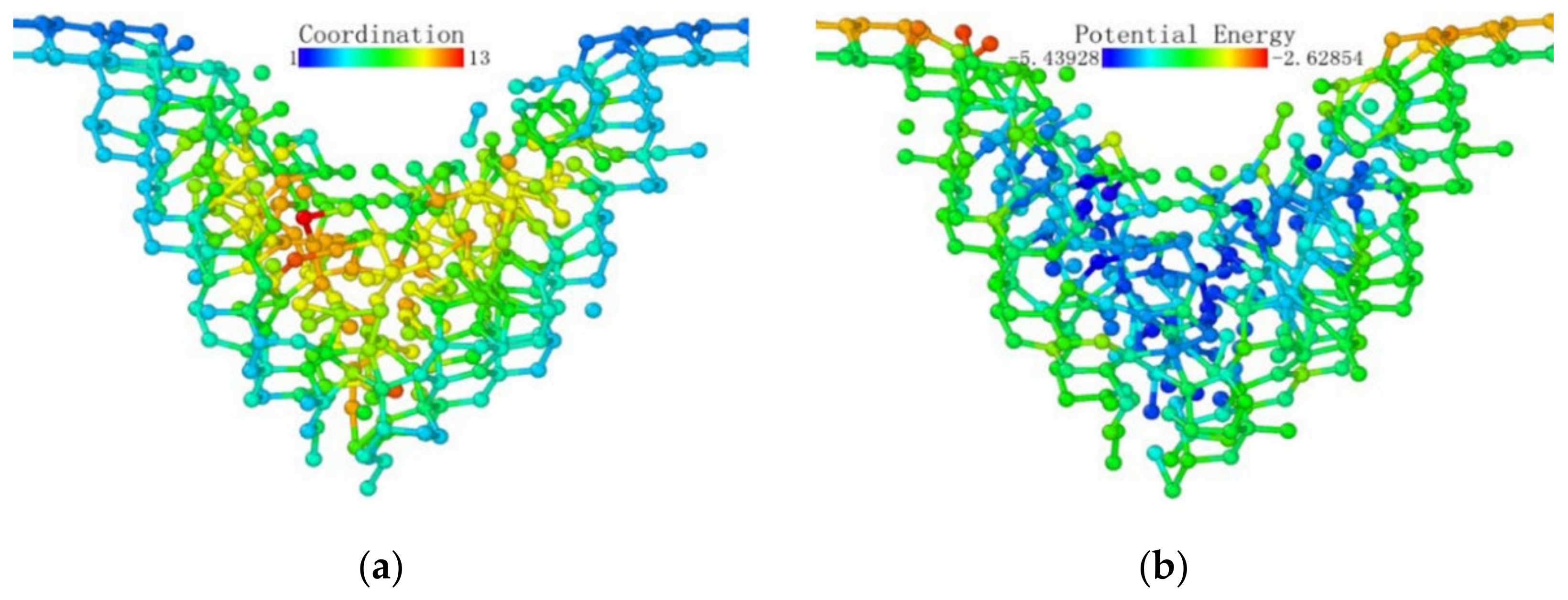

3.2.1. Analysis of the Atomic Transient Diagram Loaded on the (001) Crystal Plane

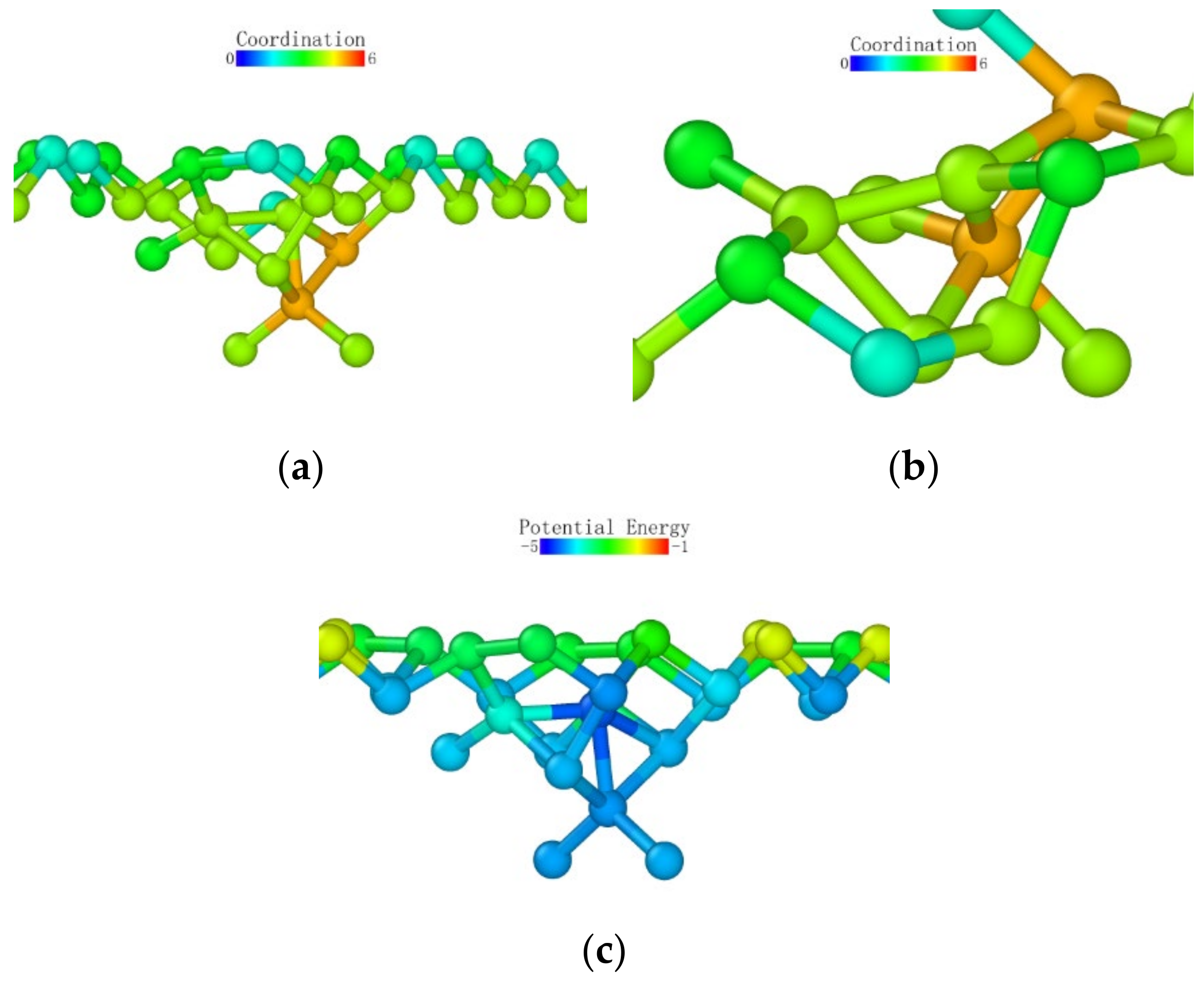

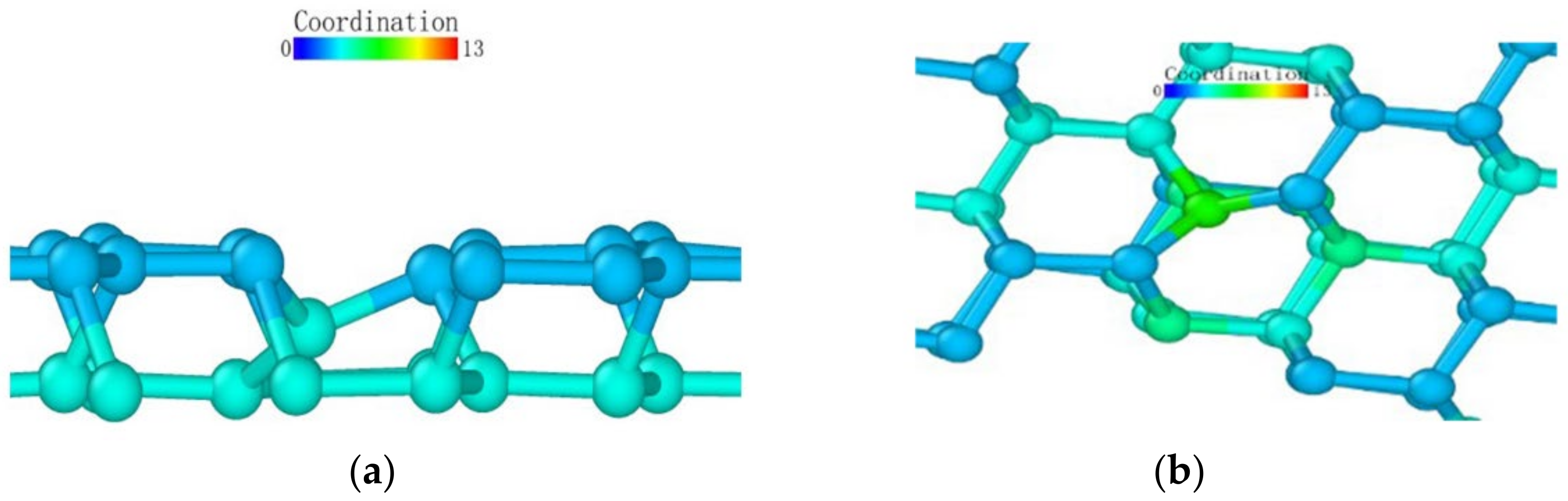

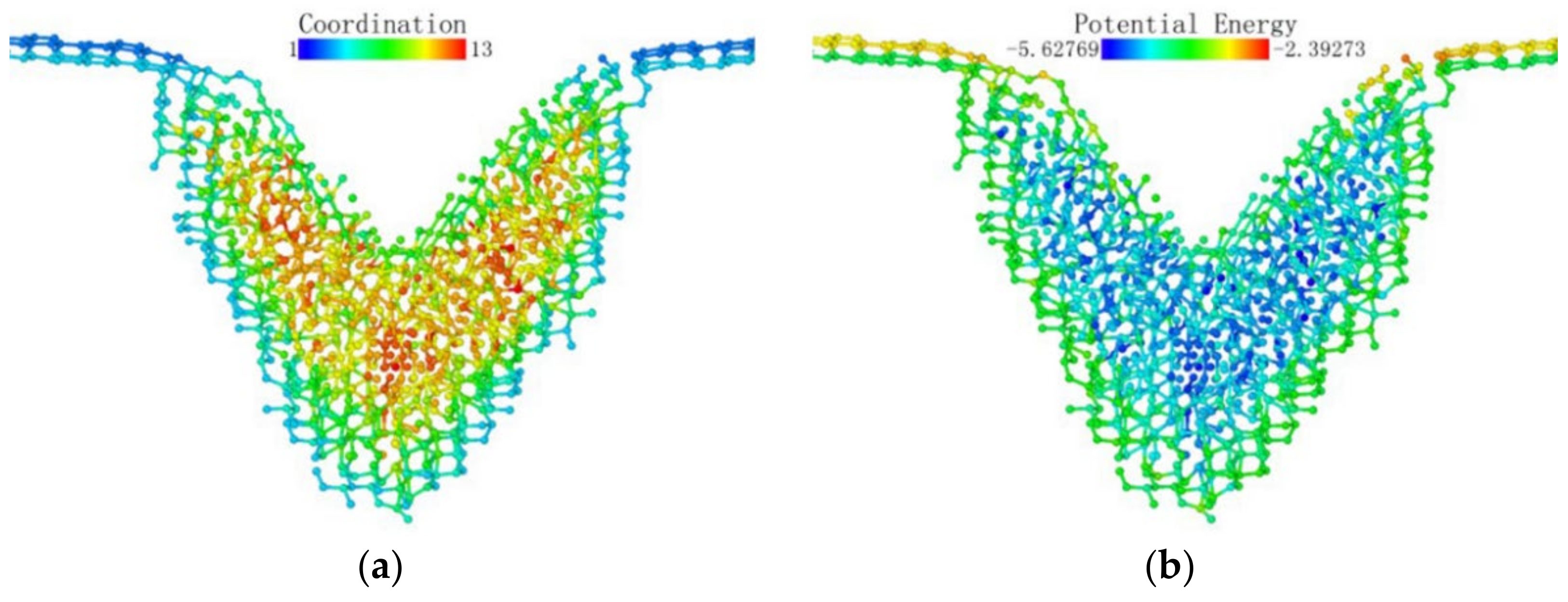

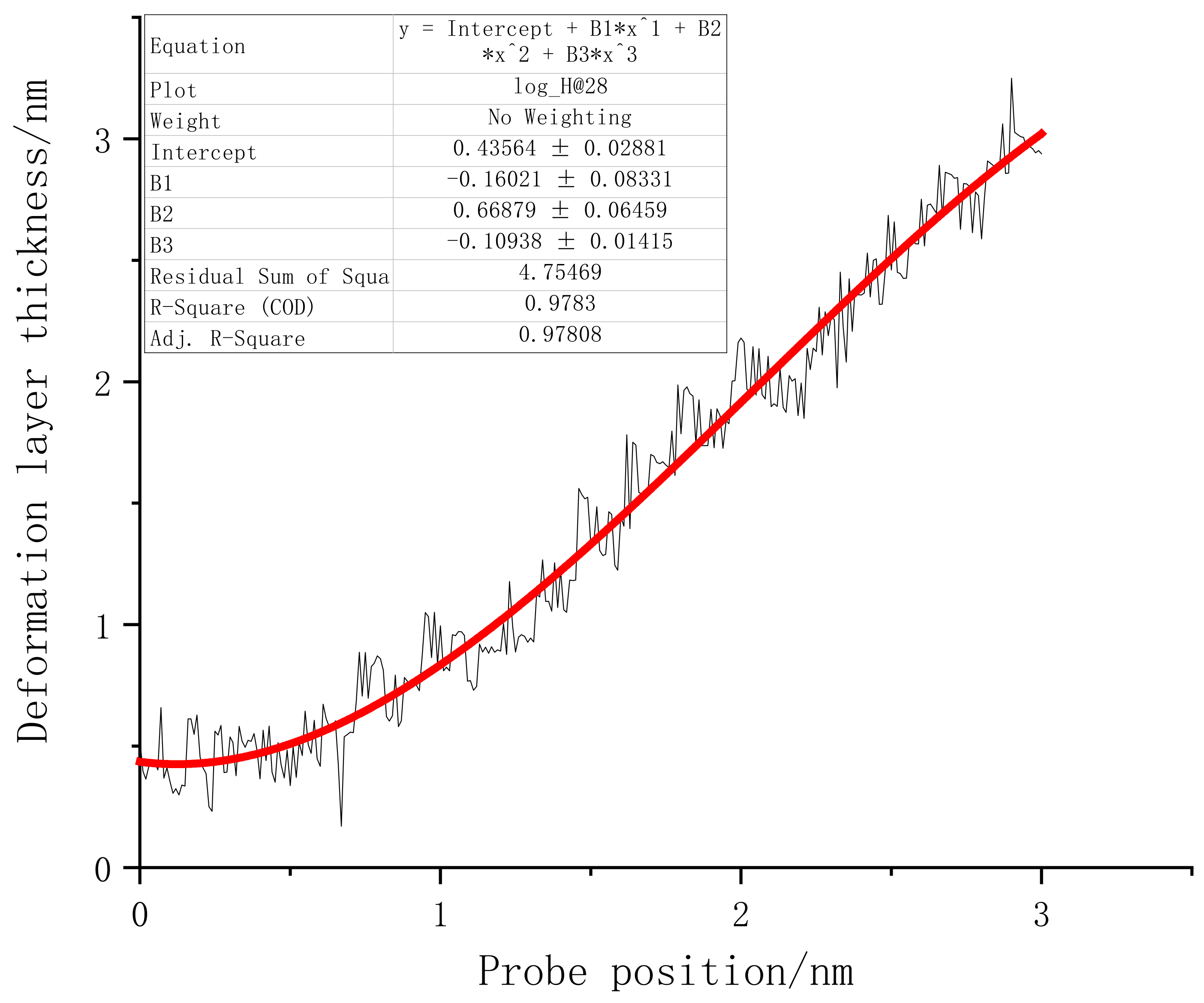

3.2.2. Analysis of the Atomic Transient Diagram Loaded on the (110) Crystal Plane

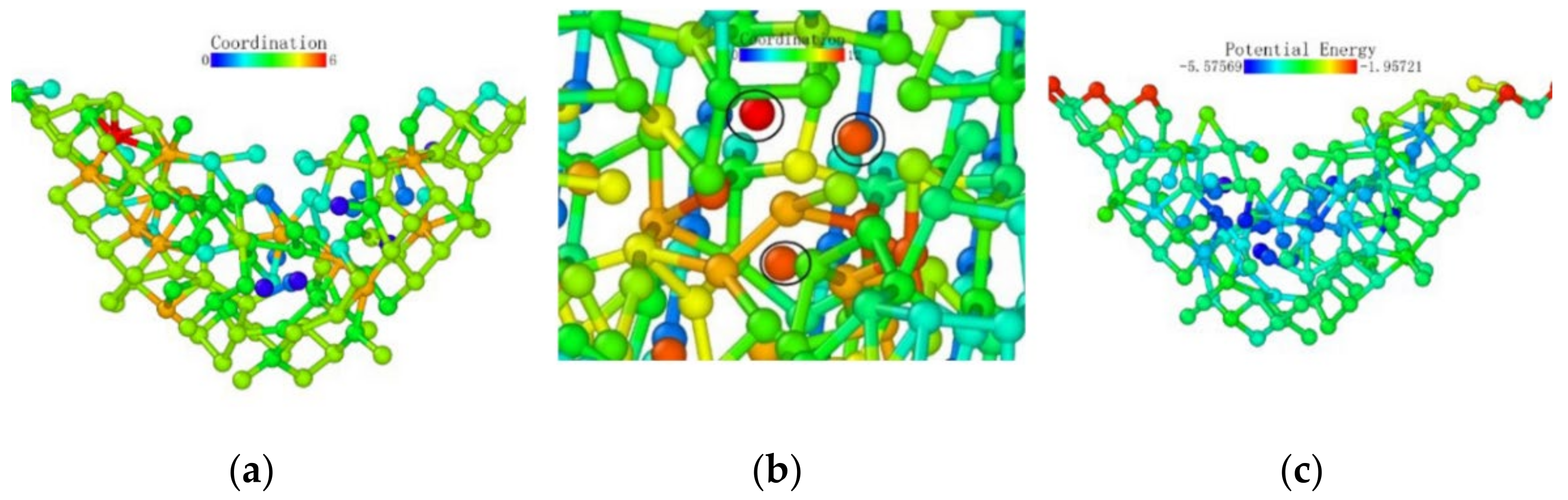

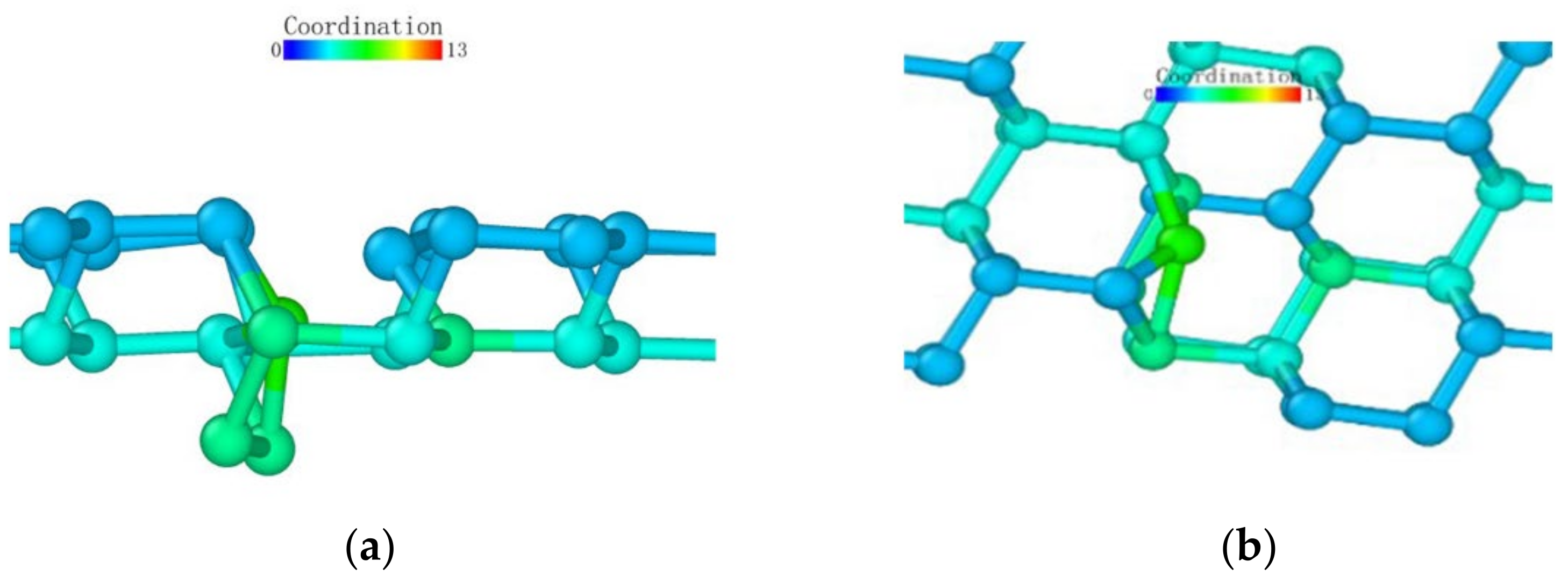

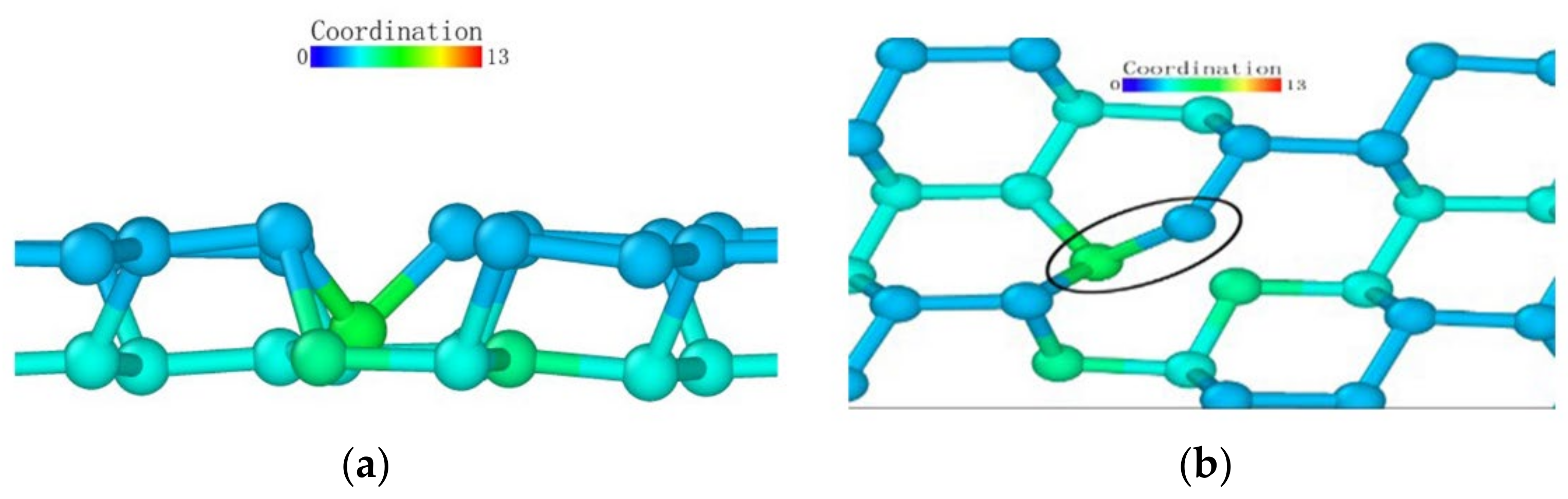

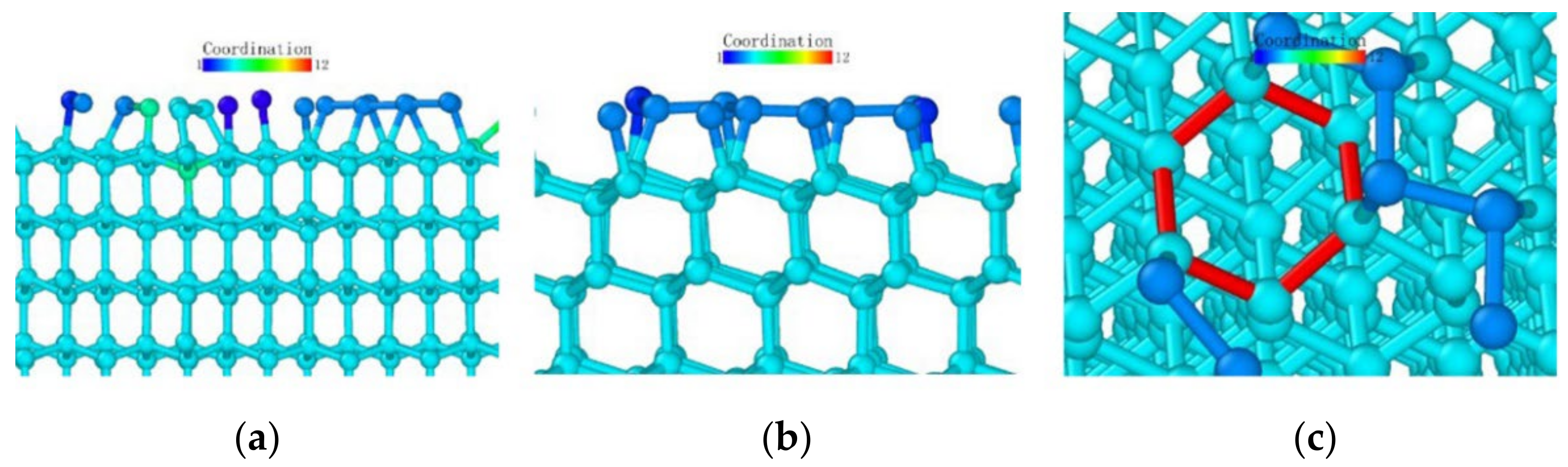

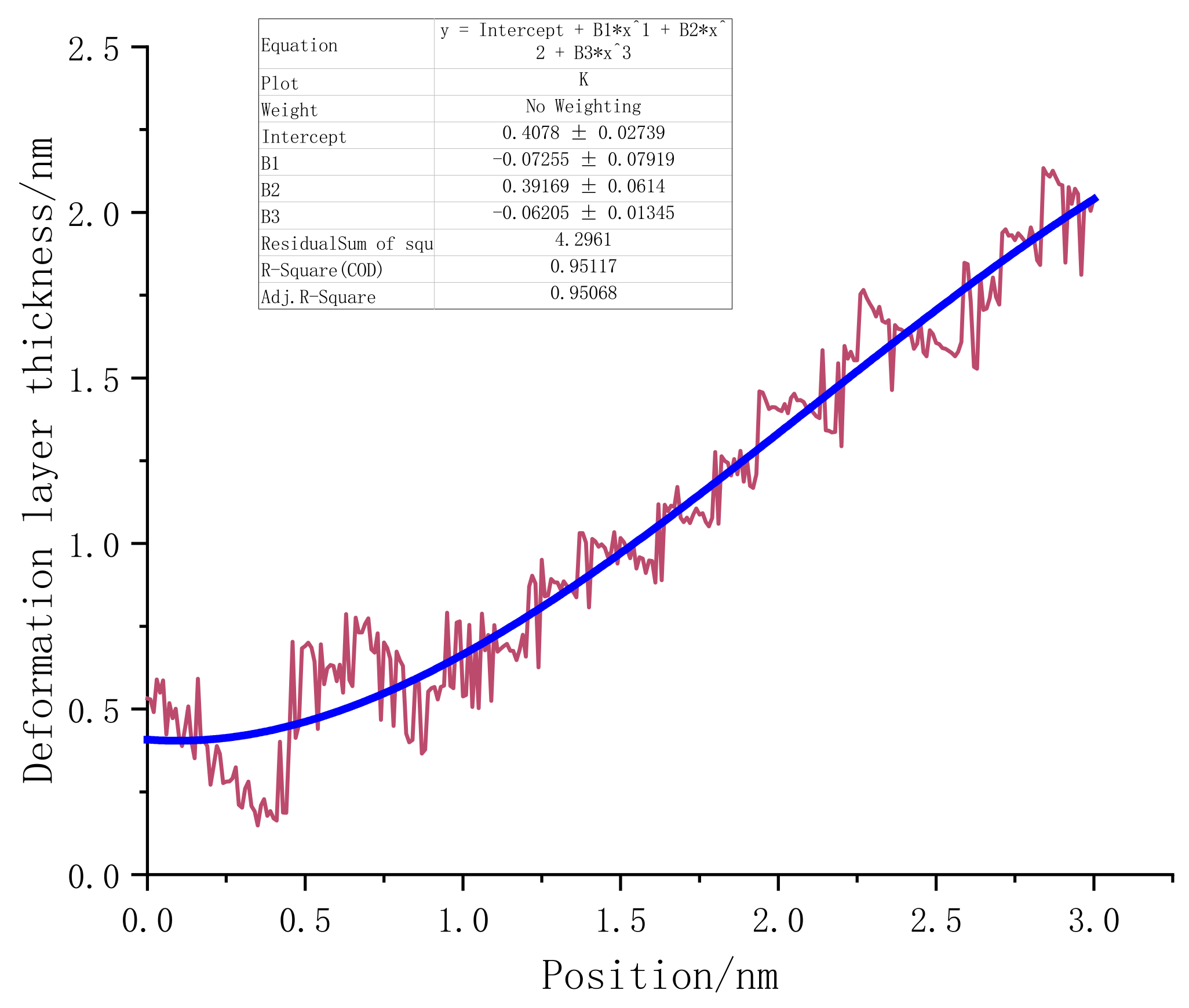

3.2.3. Analysis of the Atomic Transient Diagram Loaded on the (111) Crystal Plane

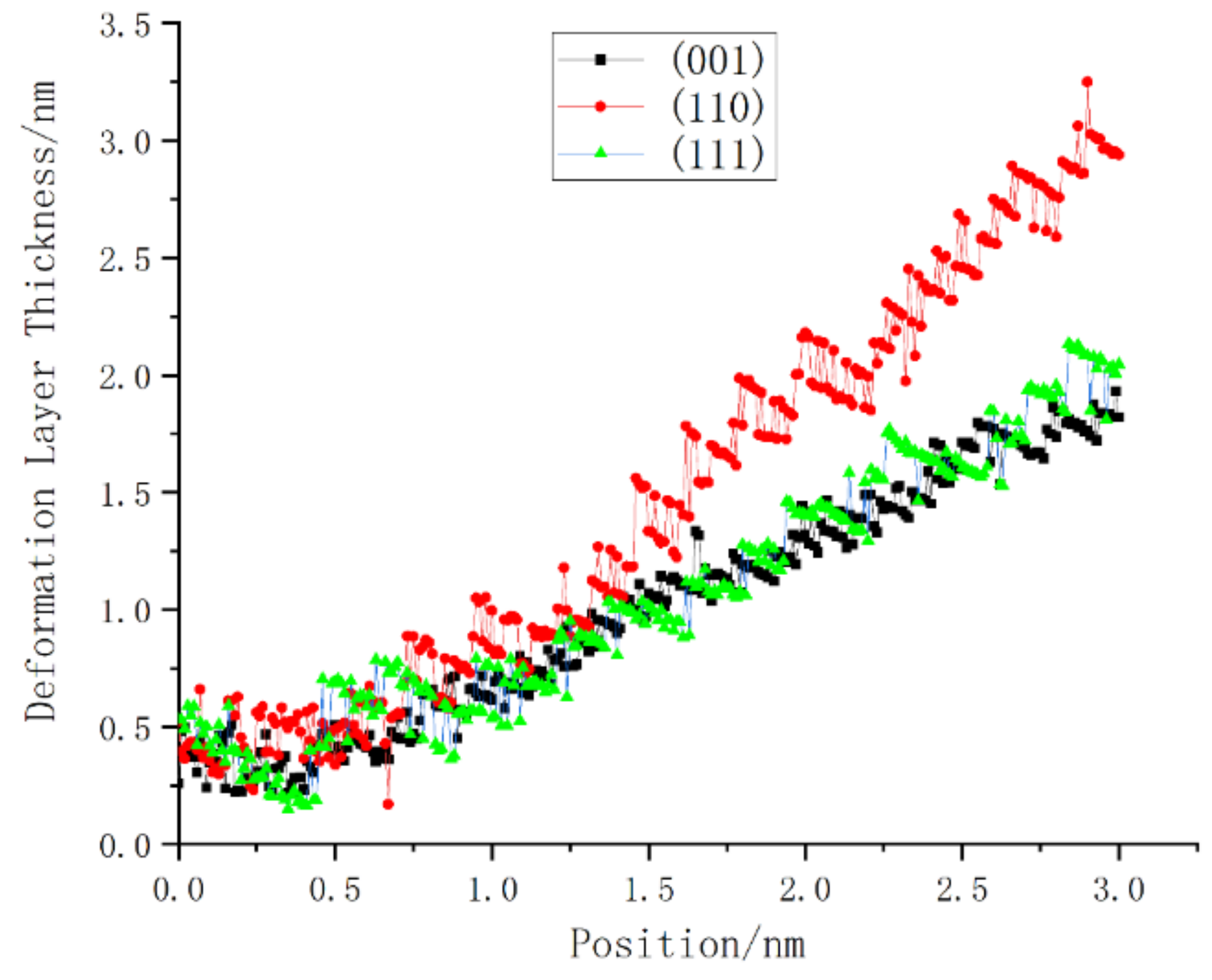

4. Discussion

5. Conclusions

- (1)

- It was found that (110) crystal faces were the hardest and had the greatest impact when loaded. Thus, more work was required for the same loading depth. The (001) face featured intermediate hardness between the (111) and (110) faces, but the smallest subsurface thickness could be obtained during machining. The (111) subsurface lattice had the greatest elasticity under load. However, this crystal surface was the hardest and had a lower temperature rise under load than the other crystal surfaces.

- (2)

- The atomic structure analysis showed that smaller subsurface defects could be obtained on the (001) and (111) faces, and that the (111) face was the best loading face due to the lower hardness of the (111) face, being conducive to more efficient processing.

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Goel, B.; Singh, S.; Sarepaka, R.V. Optimizing single point diamond turning for mono-crystalline germanium using grey relational analysis. Mater. Manuf. Processes 2015, 30, 1018–1025. [Google Scholar] [CrossRef]

- Castelli, M.; Jourdain, R.; Morantz, P.; Shore, P. Reactive atom plasma for rapid figure correction of optical surfaces. In Key Engineering Materials; Trans Tech Publications Ltd.: Bäch, Switzerland, 2012; Volume 496, pp. 182–187. [Google Scholar] [CrossRef]

- Oliver, W.C.; Pharr, G.M. An improved technique for determining hardness and elastic modulus using load and displacement sensing indentation experiments. J. Mater. Res. 1992, 7, 1564–1583. [Google Scholar] [CrossRef]

- Fleck, N.; Muller, G.; Ashby, M.; Hutchinson, J. Strain gradient plasticity: Theory and experiment. Acta Metall. Mater. 1994, 42, 475–487. [Google Scholar] [CrossRef]

- Nix, W.D.; Gao, H. Indentation size effects in crystalline materials: A law for strain gradient plasticity. J. Mech. Phys. Solids 1998, 46, 411–425. [Google Scholar] [CrossRef]

- Hainsworth, S.; Chandler, H.W.; Page, T.F. Analysis of nanoindentation load-displacement loading curves. J. Mater. Res. 1996, 11, 1987–1995. [Google Scholar] [CrossRef]

- Vardanyan, V.H.; Urbassek, H.M. Strength of Graphene-Coated Ni Bi-Crystals: A Molecular Dynamics Nano-Indentation Study. Materials 2020, 13, 1683. [Google Scholar] [CrossRef] [Green Version]

- Vardanyan, V.H.; Urbassek, H.M. Dislocation interactions during nanoindentation of nickel-graphene nanocomposites. Comput. Mater. Sci. 2019, 170, 109158. [Google Scholar] [CrossRef]

- Zhao, Y.; Peng, X.; Fu, T.; Huang, C.; Feng, C.; Yin, D.; Wang, Z. Molecular dynamics simulation of nano-indentation of (111) cubic boron nitride with optimized Tersoff potential. Appl. Surf. Sci. 2016, 382, 309–315. [Google Scholar] [CrossRef]

- Feng, H.; Tang, J.; Chen, H.; Tian, Y.; Fang, Q.; Li, J.; Liu, F. Indentation-induced plastic behaviour of nanotwinned Cu/high entropy alloy FeCoCrNi nanolaminate: An atomic simulation. RSC Adv. 2020, 10, 9187–9192. [Google Scholar] [CrossRef] [Green Version]

- Prasolov, N.D.; Gutkin, A.A.; Brunkov, P.N. Molecular-Dynamics Simulation of the Low-Temperature Surface Reconstruction of a GaAs(001) Surface during the Nanoindentation Process. Semiconductors 2019, 53, 1386–1388. [Google Scholar] [CrossRef]

- Jiao, S.; Tu, W.; Zhang, P.; Zhang, W.; Qin, L.; Sun, Z.; Chen, J. Atomistic insights into the prismatic dislocation loop on Al (1 0 0) during nanoindentation investigated by molecular dynamics. Comput. Mater. Sci. 2018, 143, 384–390. [Google Scholar] [CrossRef]

- Hua, D.; Ye, W.; Jia, Q.; Zhou, Q.; Xia, Q.; Shi, J.; Deng, Y.; Wang, H. Molecular dynamics simulation of nanoindentation on amorphous/amorphous nanolaminates. Appl. Surf. Sci. 2020, 511, 145545. [Google Scholar] [CrossRef]

- Tian, Y.; Fang, Q.; Li, J. Molecular dynamics simulations for nanoindentation response of nanotwinned FeNiCrCoCu high entropy alloy. Nanotechnology 2020, 31, 465701. [Google Scholar] [CrossRef]

- Feng, Q.; Song, X.; Xie, H.; Wang, H.; Liu, X.; Yin, F. Deformation and plastic coordination in WC-Co composite—Molecular dynamics simulation of nanoindentation. Mater. Des. 2017, 120, 193–203. [Google Scholar] [CrossRef]

- Li, J.; Dong, L.; Zang, X.; Zhang, X.; Zhao, W.; Wang, F. Study on micro-crack propagation behavior of single-crystal α-Ti under shear stress based on molecular dynamics. Mater. Today Commun. 2020, 25, 101622. [Google Scholar] [CrossRef]

- Wang, Z.; Zhang, J.; Ma, A.; Hartmaier, A.; Yan, Y.; Sun, T. On the crystallographic anisotropy of plastic zone size in single crystalline copper under Berkovich nanoindentation. Mater. Today Commun. 2020, 25, 101314. [Google Scholar] [CrossRef]

- Dub, S.N.; Haftaoglu, C.; Kindrachuk, V.M. Estimate of theoretical shear strength of C60 single crystal by nanoindentation. J. Mater. Sci. 2021, 56, 10905–10914. [Google Scholar] [CrossRef]

- Juri, A.Z.; Basak, A.K.; Yin, L. Microstructural responses of Zirconia materials to in-situ SEM nanoindentation. J. Mech. Behav. Biomed. Mater. 2021, 118, 104450. [Google Scholar] [CrossRef]

- Rahman, M.R.; Riscob, B.; Singh, B.; Bhatt, R.; Bhaumik, I.; Ganesamoorthy, S.; Vijayan, N.; Karnal, A.; Bdikin, I.; Nair, L. Nanoindentation and structural studies of MgO-doped congruent LiNbO3 single crystals. Mater. Chem. Phys. 2021, 264, 124425. [Google Scholar] [CrossRef]

- Valencia, F.J.; Santiago, J.; González, R.I.; González-Arrabal, R.; Ruestes, C.; Díaz, M.P.; Monclus, M.A.; Molina-Aldareguia, J.; Nuñez, P.D.; Munoz, F.; et al. Nanoindentation of Amorphous Carbon: A combined experimental and simulation approach. Acta Mater. 2021, 203, 116485. [Google Scholar] [CrossRef]

- Tian, T.; Nakano, M.; Li, W. Applications of shear thickening fluids: A review. Int. J. Hydromechatronics 2018, 1, 238. [Google Scholar] [CrossRef]

- Cinefra, M. Hydro-mechanical analysis of pipe armed by nanoparticles based on numerical methods. Int. J. Hydromechatronics 2019, 2, 247. [Google Scholar] [CrossRef]

| Attributes | RSS | Deformation Layer Atom Number | Hardness (GPa) | |||

|---|---|---|---|---|---|---|

| Planes | ||||||

| 1 nm | 2 nm | 3 nm | ||||

| (001) | 1.67812 | 82 | 724 | 2695 | 38.83 | |

| (110) | 4.75469 | 69 | 727 | 2753 | 40.712 | |

| (111) | 4.2961 | 117 | 691 | 2426 | 35.58 | |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Song, L.; Song, J.; Li, J.; Wang, T.; Zhao, Z. Study on the Mechanical Properties of Monocrystalline Germanium Crystal Planes Based on Molecular Dynamics. Micromachines 2022, 13, 441. https://doi.org/10.3390/mi13030441

Song L, Song J, Li J, Wang T, Zhao Z. Study on the Mechanical Properties of Monocrystalline Germanium Crystal Planes Based on Molecular Dynamics. Micromachines. 2022; 13(3):441. https://doi.org/10.3390/mi13030441

Chicago/Turabian StyleSong, Linsen, Juncheng Song, Junye Li, Tiancheng Wang, and Zhenguo Zhao. 2022. "Study on the Mechanical Properties of Monocrystalline Germanium Crystal Planes Based on Molecular Dynamics" Micromachines 13, no. 3: 441. https://doi.org/10.3390/mi13030441

APA StyleSong, L., Song, J., Li, J., Wang, T., & Zhao, Z. (2022). Study on the Mechanical Properties of Monocrystalline Germanium Crystal Planes Based on Molecular Dynamics. Micromachines, 13(3), 441. https://doi.org/10.3390/mi13030441