Effect of Time and Frequency of Magnetic Field Application on MRF Pressure Performance

Abstract

:1. Introduction

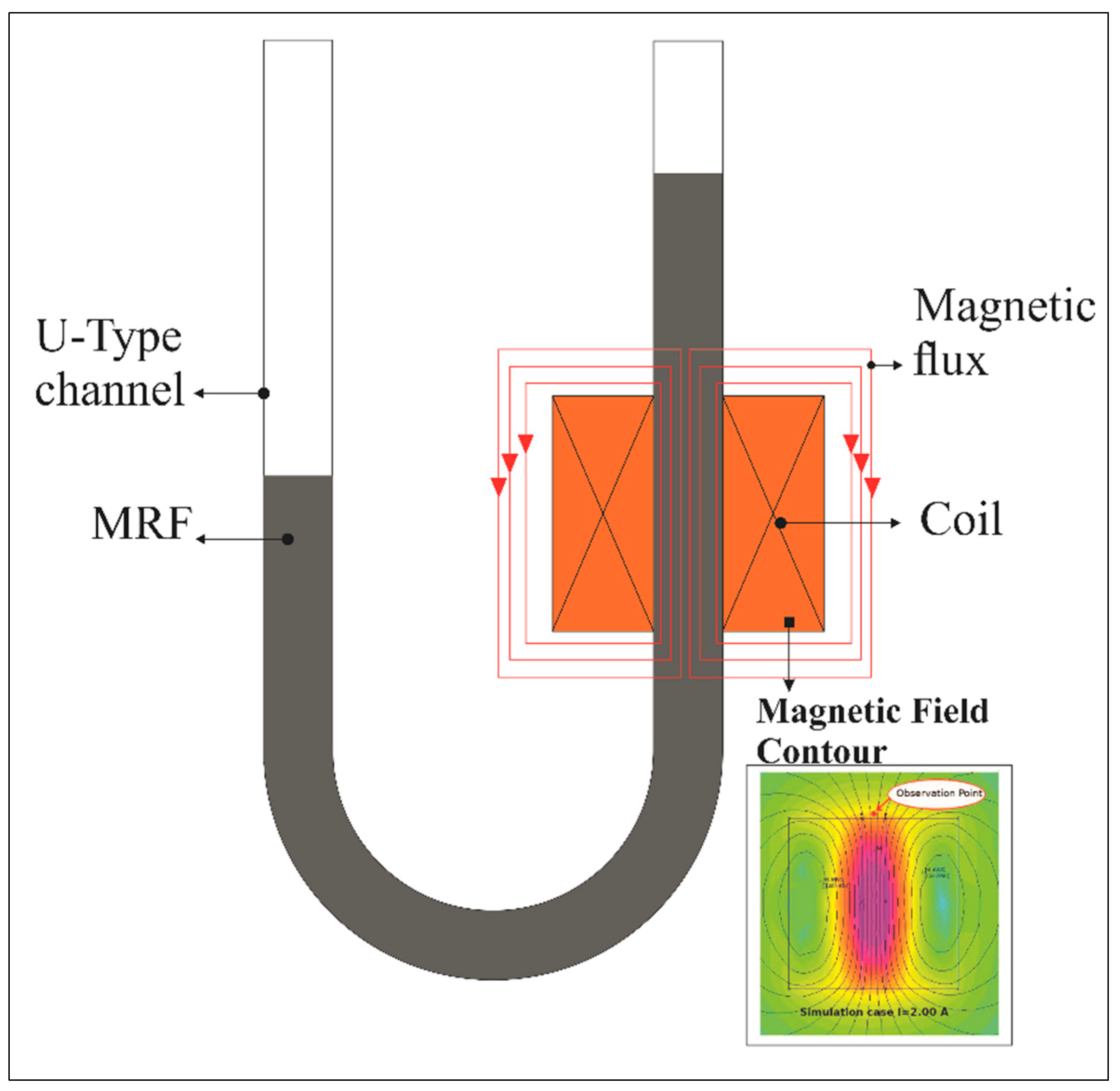

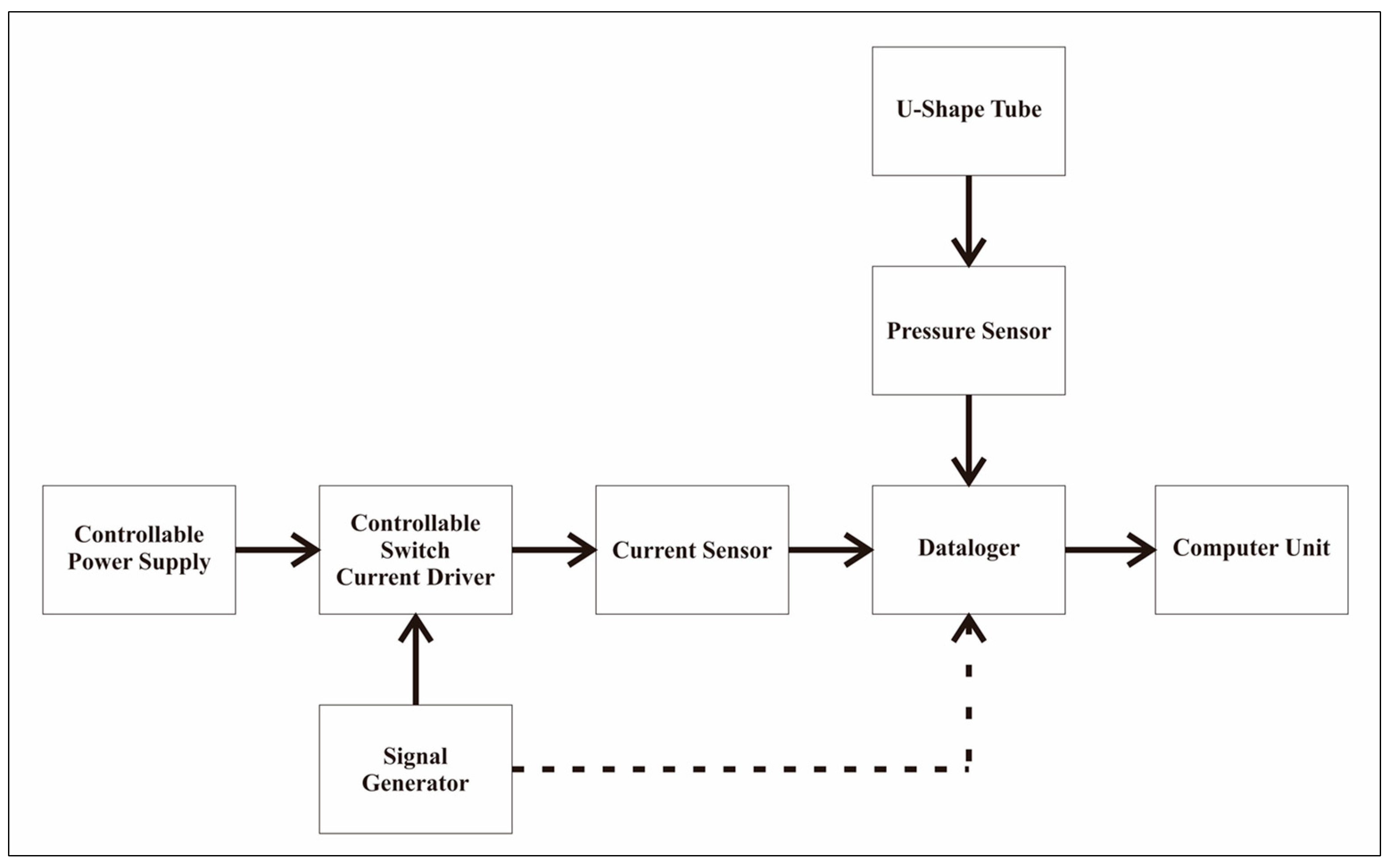

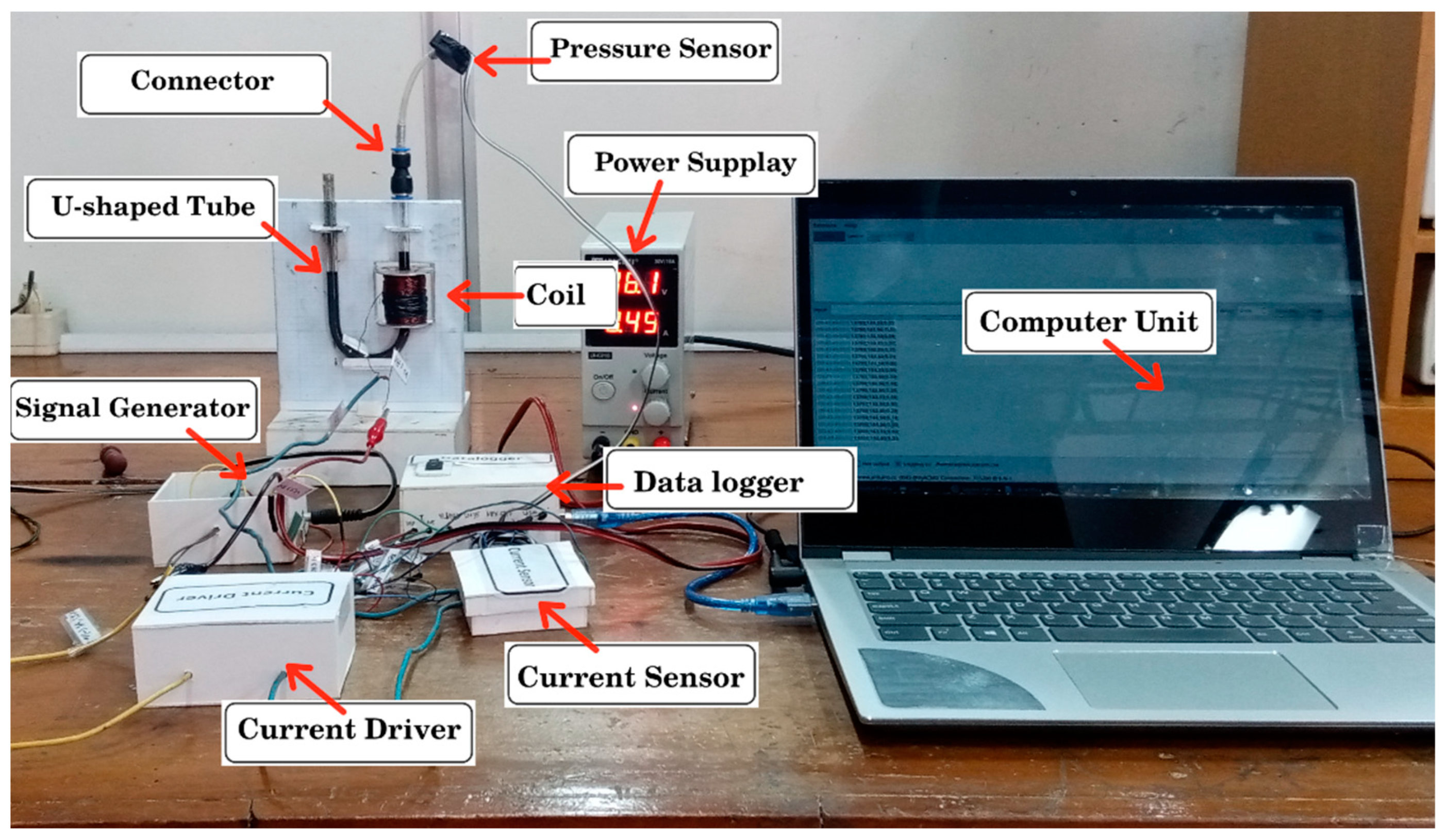

2. Materials and Methods

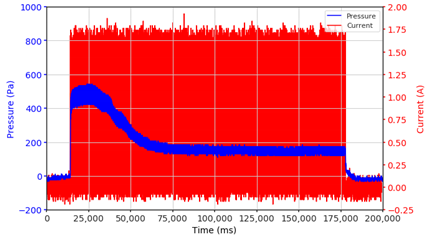

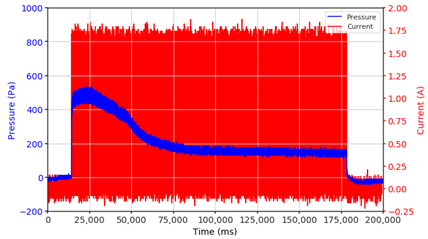

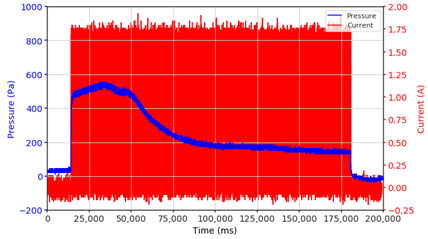

3. Result

4. Discussion

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Lu, G.; Sun, Z. Automation Technology in Equipment Installation Technology and Quality Management. In Journal of Physics: Conference Series; IOP Publishing: Bristol, UK, 2021; Volume 1744, p. 022116. [Google Scholar] [CrossRef]

- Ashima, R.; Haleem, A.; Bahl, S.; Javaid, M.; Mahla, S.K.; Singh, S. Automation and manufacturing of smart materials in additive manufacturing technologies using Internet of Things towards the adoption of industry 4.0. Mater. Today Proc. 2021, 45, 5081–5088. [Google Scholar] [CrossRef]

- Cao, W.; Cudney, H.H.; Waser, R. Smart materials and structures. Proc. Natl. Acad. Sci. USA 1999, 96, 8330–8331. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Kamila, S. Introduction, classification and applications of smart materials: An overview. Am. J. Appl. Sci. 2013, 10, 876–880. [Google Scholar] [CrossRef]

- Tzou, H.S.; Lee, H.-J.; Arnold, S.M. Smart Materials, Precision Sensors/Actuators, Smart Structures, and Structronic Systems. Mech. Adv. Mater. Struct. 2004, 11, 367–393. [Google Scholar] [CrossRef] [Green Version]

- Gangele, A.; Mishra, A. A Review on Smart Materials, Types and Modelling: Need of the Modern Era. Mater. Today Proc. 2021, 47, 6469–6474. [Google Scholar] [CrossRef]

- Ubaidillah, U.; Lenggana, B.W. Finite Element Magnetic Method for Magnetorheological Based Actuators. In Finite Element Methods and Their Applications; Baccouch, M., Ed.; IntechOpen: London, UK, 2020; Available online: https://www.intechopen.com/chapters/73750 (accessed on 11 November 2021). [CrossRef]

- Rabinow, J. The Magnetic Fluid Clutch. Cond. Affect. Success Main Line Electrif. 1948, 67, 1308–1315. [Google Scholar] [CrossRef]

- Zareie, S.; Zabihollah, A. The Recent Advances in Magnetorheological Fluids-Based Applications. In Emerging Trends in Mechatronics; Azizi, A., Ed.; IntechOpen: London, UK. Available online: https://www.intechopen.com/chapters/67315 (accessed on 2 June 2021). [CrossRef] [Green Version]

- Ubaidillah, U.; Hudha, K.; Kadir, F.A.A. Modelling, characterisation and force tracking control of a magnetorheological damper under harmonic excitation. Int. J. Model. Identif. Control 2011, 13, 9–21. [Google Scholar] [CrossRef] [Green Version]

- Imaduddin, F.; Mazlan, S.A.; Zamzuri, H. A design and modelling review of rotary magnetorheological damper. Mater. Des. 2013, 51, 575–591. [Google Scholar] [CrossRef]

- Imaduddin, F.; Mazlan, S.A.; Rahman, M.A.A.; Zamzuri, H.; Ubaidillah, U.; Ichwan, B. A high performance magnetorheo-logical valve with a meandering flow path. Smart Mater. Struct. 2014, 23, 065017. [Google Scholar] [CrossRef]

- Idris, M.H.; Imaduddin, F.; Ubaidillah; Mazlan, S.A.; Choi, S.-B. A Concentric Design of a Bypass Magnetorheological Fluid Damper with a Serpentine Flux Valve. Actuators 2020, 9, 16. [Google Scholar] [CrossRef] [Green Version]

- Ubaidillah, U.; Imaduddin, F.; Nizam, M.; Mazlan, S.A. Response of A Magnetorheologi cal Brake under Inertial Loads. Int. J. Electr. Eng. Inform. 2015, 7, 308–322. [Google Scholar] [CrossRef]

- Nya’ubit, I.R.; Priyandoko, G.; Imaduddin, F.; Adiputra, D.; Indonesia, I. Torque Characterization of T-shaped Magnetorhe-ological Brake Featuring Serpentine Magnetic Flux. J. Adv. Res. Fluid Mech. Therm. Sci. 2020, 78, 85–97. [Google Scholar] [CrossRef]

- Nya’ubit, I.R.; Priyandoko, G.; Imaduddin, F.; Adiputra, D.; Ubaidillah, U. Characterization of T-shaped magneto-rheological brake. J. Adv. Res. Mater. Sci. 2020, 71, 1–11. [Google Scholar] [CrossRef]

- Fatah, A.Y.A.; Mazlan, S.A.; Koga, T.; Zamzuri, H.; Imaduddin, F. Design of magnetorheological valve using serpentine flux path method. Int. J. Appl. Electromagn. Mech. 2016, 50, 29–44. [Google Scholar] [CrossRef]

- Bahiuddin, I.; Imaduddin, F.; Mazlan, S.A.; Ariff, M.H.; Mohmad, K.B.; Sabino, U.; Choi, S. Accurate and fast estimation for field-dependent nonlinear damping force of meandering valve-based magnetorheological damper using extreme learning machine method. Sens. Actuators A Phys. 2021, 318, 112479. [Google Scholar] [CrossRef]

- Ichwan, B.; Mazlan, S.A.; Imaduddin, F.; Ubaidillah, U.; Koga, T.; Idris, M.H. Development of a modular MR valve using meandering flow path structure. Smart Mater. Struct. 2016, 25, 037001. [Google Scholar] [CrossRef]

- Bhavsar, P.; Unune, D.R. Magnetorheological Polishing Tool for Nano-Finishing of Biomaterials. In Proceedings of the 10th International Conference on Precesion, Meso, Micro and Nano Engineering, Chennai, India, 6–10 January 2018. [Google Scholar]

- Kumar, M.; Kumar, A.; Alok, A.; Das, M. Magnetorheological method applied to optics polishing: A review. In Proceedings of the IOP Conference Series: Materials Science and Engineering, New Delhi, India, 6–10 January 2020; Volume 804, p. 012012. [Google Scholar]

- Lu, H.; Hua, D.; Wang, B.; Yang, C.; Hnydiuk-Stefan, A.; Królczyk, G.; Liu, X.; Li, Z. The Roles of Magnetorheological Fluid in Modern Precision Machining Field: A Review. Front. Mater. 2021, 8, 147. [Google Scholar] [CrossRef]

- Kikuchi, T.; Noma, J.; Akaiwa, S.; Ueshima, Y. Response time of magnetorheological fluid–based haptic device. J. Intell. Mater. Syst. Struct. 2015, 27, 859–865. [Google Scholar] [CrossRef]

- Heo, Y.H.; Choi, D.-S.; Yun, I.-H.; Kim, S.-Y. A Tiny Haptic Knob Based on Magnetorheological Fluids. Appl. Sci. 2020, 10, 5118. [Google Scholar] [CrossRef]

- Simonelli, C.; Musolino, A.; Rizzo, R.; Jones, L.A. Development of an Innovative Magnetorheological Fluids-based Haptic Device Excited by Permanent Magnets. In Proceedings of the 2021 IEEE World Haptics Conference (WHC), Montreal, QC, Canada, 6–9 July 2021; pp. 61–66. [Google Scholar]

- York, D.; Wang, X.; Gordaninejad, F. A New Magnetorheological Mount for Vibration Control. J. Vib. Acoust. 2011, 133, 031003. [Google Scholar] [CrossRef]

- Do, X.-P.; Park, J.-H.; Woo, J.-K.; Choi, S.-B. Optimal Design of New Magnetorheological Mount for Diesel Engines of Ships. Trans. Korean Soc. Noise Vib. Eng. 2013, 23, 209–217. [Google Scholar] [CrossRef] [Green Version]

- Sapiński, B. Simulation of an MR squeeze-mode damper for an automotive engine mount. In Proceedings of the 17th Interna-tional Carpathian Control Conference (ICCC), High Tatras, Slovakia, 29 May–1 June 2016; pp. 641–644. [Google Scholar]

- Purnomo, E.D.; Ubaidillah, U.; Imaduddin, F.; Yahya, I.; Mazlan, S.A. Preliminary experimental evaluation of a novel loud-speaker featuring magnetorheological fluid surround absorber. Indones. J. Electr. Eng. Comput. Sci. 2020, 17, 922–928. [Google Scholar] [CrossRef] [Green Version]

- Kumara, K.A.D.; Ubaidillah, U.; Yahya, I.; Priyandoko, G.; Wibowo, W. Magnetostatic Simulation in a Novel Magnetorheo-logical Elastomer Based Loudspeaker Surround. In Proceedings of the 2019 6th International Conference on Electric Vehicu-lar Technology (ICEVT), Bali, Indonesia, 18–21 November 2019; pp. 295–299. [Google Scholar]

- John, S.; Yoo, J.; Sirohi, J.; Wereley, N.M. Bi-Directional actuation of a piston using mr valves and a piezoelectric pump. In Proceedings of the ASME International Mechanical Engineering Congress and Exposition, Orlando, FL, USA, 5–11 November 2005; pp. 1–10. [Google Scholar]

- Lee, T.; Shin, S.; Cha, S. Fine position control of a vehicle maintenance lift system using a hydraulic unit activated by magnetorheological valves. J. Intell. Mater. Syst. Struct. 2019, 30, 896–907. [Google Scholar] [CrossRef]

- Widodo, P.J.; Budiana, E.P.; Ubaidillah, U.; Imaduddin, F. Magnetically-Induced Pressure Generation in Magnetorheological Fluids under the Influence of Magnetic Fields. Appl. Sci. 2021, 11, 9807. [Google Scholar] [CrossRef]

- Lord Technical Data. MRF-122EG Magneto-Rheological Fluid; LORD Corporation: Cary, NC, USA, 2019. [Google Scholar]

- Allegro-Microsystem. Fully Integrated, Hall Effect-Based Linear Current Sensor with 2.1 kVRMS Voltage Isolation and a Low-Resistance Current Conductor (Issue ACS712); Allegro-Microsystem: Manchester, NH, USA, 2006. [Google Scholar]

- Freescale-Semiconductors. Integrated Silicon Pressure Sensor on-Chip Signal Conditioned, Temperature Compensated and Calibrated, Technical Data Sheet: MPXV5010DP, 0 to 10 kPa, Differential, Gauge, and Absolute, Integrated, Pressure Sensors (Issue MPX5010); Freescale-Semiconductors: Austin, TX, USA, 2012. [Google Scholar]

- Yazid, I.I.M.; Mazlan, S.A.; Kikuchi, T.; Zamzuri, H.; Imaduddin, F. Design of magnetorheological damper with a combina-tion of shear and squeeze modes. Mater. Des. 2014, 54, 87–95. [Google Scholar] [CrossRef]

- Wirawan, J.W.; Ubaidillah, U.; Lenggana, B.W.; Purnomo, E.D.; Widyarso, W.; Mazlan, S.A. Design and Performance Analysis of Magnetorheological Valve for Upside-Down Damper. J. Adv. Res. Fluid Mech. Therm. Sci. 2019, 2, 164–173. [Google Scholar]

- Ismail, I.; Aqida, S.N. Fluid-Particle Separation of Magnetorheological (MR) Fluid in MR Machining Application. Key Eng. Mater. 2014, 611–612, 746–755. [Google Scholar] [CrossRef]

- Ismail, I.; Mazlan, S.A.; Zamzuri, H.; Olabi, A.G. Fluid–Particle Separation of Magnetorheological Fluid in Squeeze Mode. Jpn. J. Appl. Phys. 2012, 51, 67301. [Google Scholar] [CrossRef]

| Appearance | Dark Gray Liquid |

|---|---|

| Viscosity, Pa-s @40 °C (104 °F) | 0.042 ± 0.020 |

| calculated as slope 500–800 s−1 | |

| Density | |

| g/cm3 | 2.28–2.48 |

| (lb/gal) | (19.0–20.7) |

| Solid content by weight, % | 72 |

| Flash point, °C (°F) | >150 (>302) |

| Operating temperature, °C (°F) | −40 to +130 (−40 to +266) |

| Frequency | Current 0.5 A | Current 1.0 A | Current 1.5 A |

|---|---|---|---|

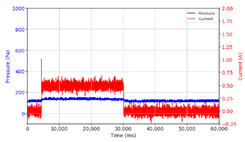

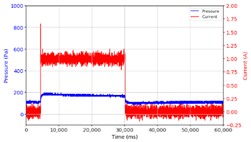

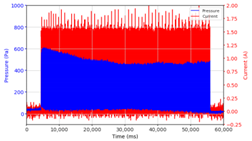

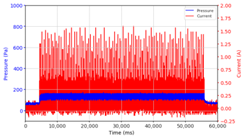

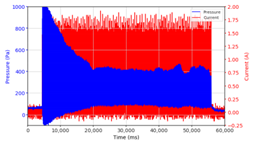

| On State |  |  |  |

| On–Off State |  |  |  |

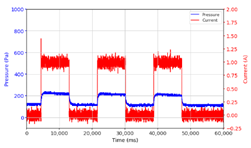

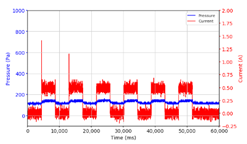

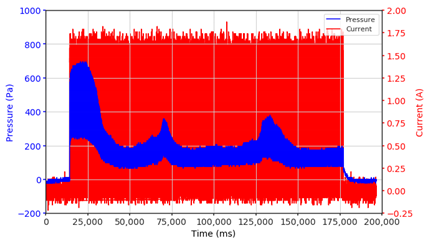

| 0.05 Hz |  |  |  |

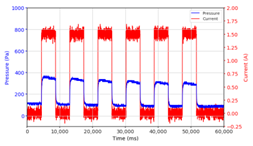

| 0.1 Hz |  |  |  |

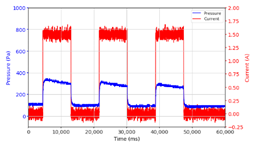

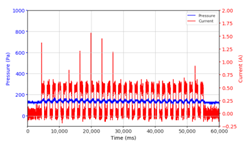

| 0.5 Hz |  |  |  |

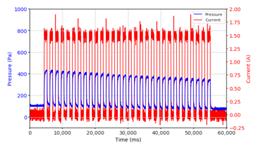

| 1 Hz |  |  |  |

| 5 Hz |  |  |  |

| 10 Hz |  |  |  |

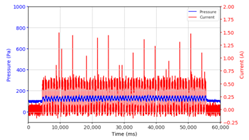

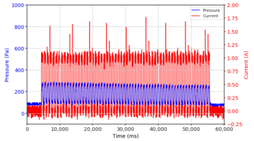

Frequency 20 Hz | Frequency 40 Hz. |

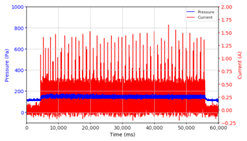

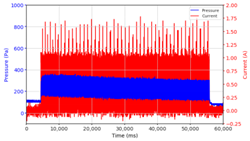

Frequency 50 Hz | Frequency 100 Hz |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Widodo, P.J.; Budiana, E.P.; Ubaidillah, U.; Imaduddin, F.; Choi, S.-B. Effect of Time and Frequency of Magnetic Field Application on MRF Pressure Performance. Micromachines 2022, 13, 222. https://doi.org/10.3390/mi13020222

Widodo PJ, Budiana EP, Ubaidillah U, Imaduddin F, Choi S-B. Effect of Time and Frequency of Magnetic Field Application on MRF Pressure Performance. Micromachines. 2022; 13(2):222. https://doi.org/10.3390/mi13020222

Chicago/Turabian StyleWidodo, Purwadi Joko, Eko Prasetya Budiana, Ubaidillah Ubaidillah, Fitrian Imaduddin, and Seung-Bok Choi. 2022. "Effect of Time and Frequency of Magnetic Field Application on MRF Pressure Performance" Micromachines 13, no. 2: 222. https://doi.org/10.3390/mi13020222

APA StyleWidodo, P. J., Budiana, E. P., Ubaidillah, U., Imaduddin, F., & Choi, S.-B. (2022). Effect of Time and Frequency of Magnetic Field Application on MRF Pressure Performance. Micromachines, 13(2), 222. https://doi.org/10.3390/mi13020222