Tiny Piezoelectric Multi-Layered Actuators with Application in a Compact Camera Module—Design, Fabrication, Assembling and Testing Issues

Abstract

:1. Introduction

2. Piezoelectric Multi-Layered Actuators (PMLAs) as Previously Applied to Compact Camera Modules (CCMs)

2.1. Helimorph Actuator Based on Superhelix Structures with Bimorph and Multi-Layered Configurations

2.2. Lobster Actuator for a Compact Camera Module (CCM)

3. Two-Degrees-of-Freedom USMs—Design, Fabrication, Assembling and Testing Issues

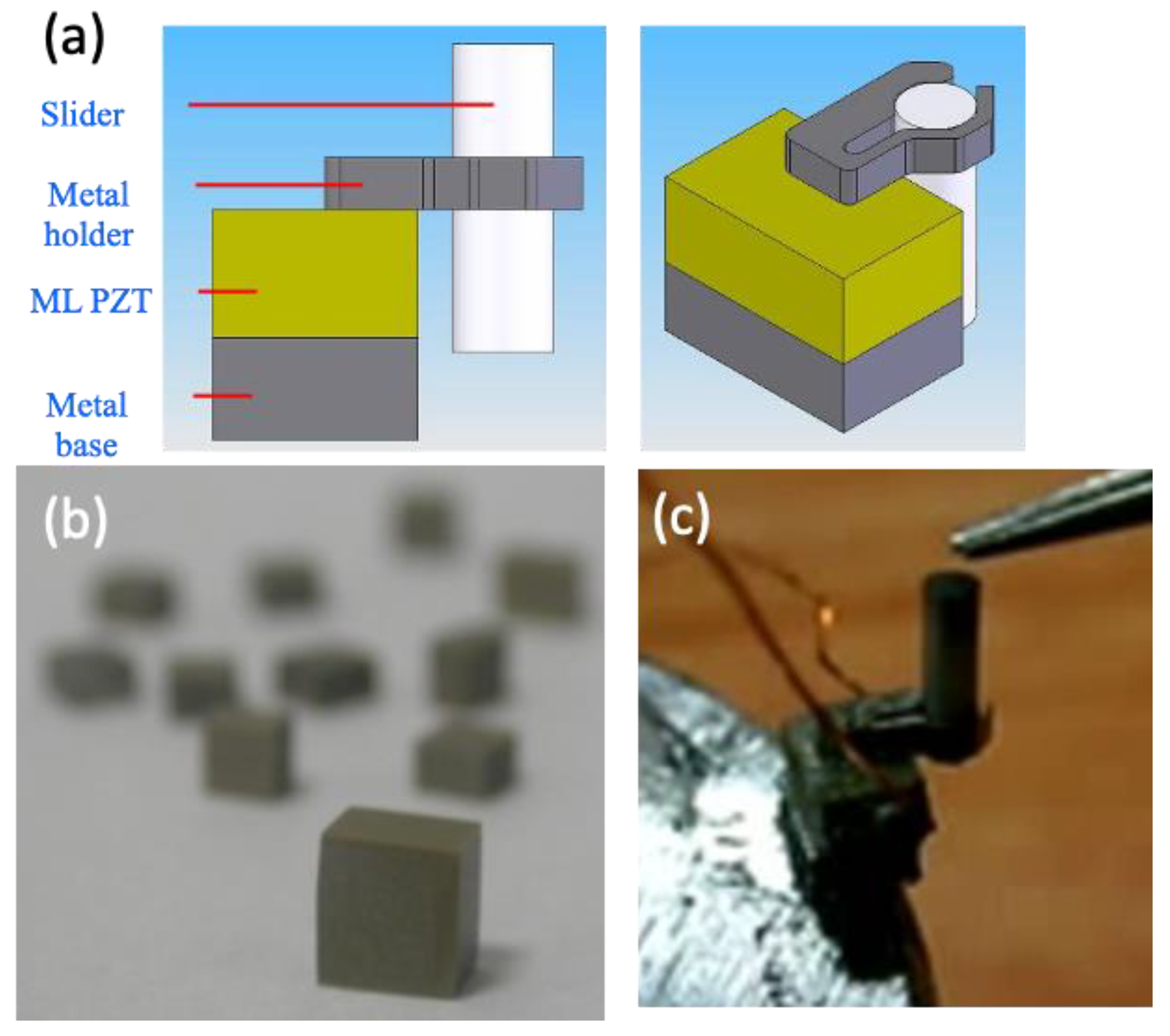

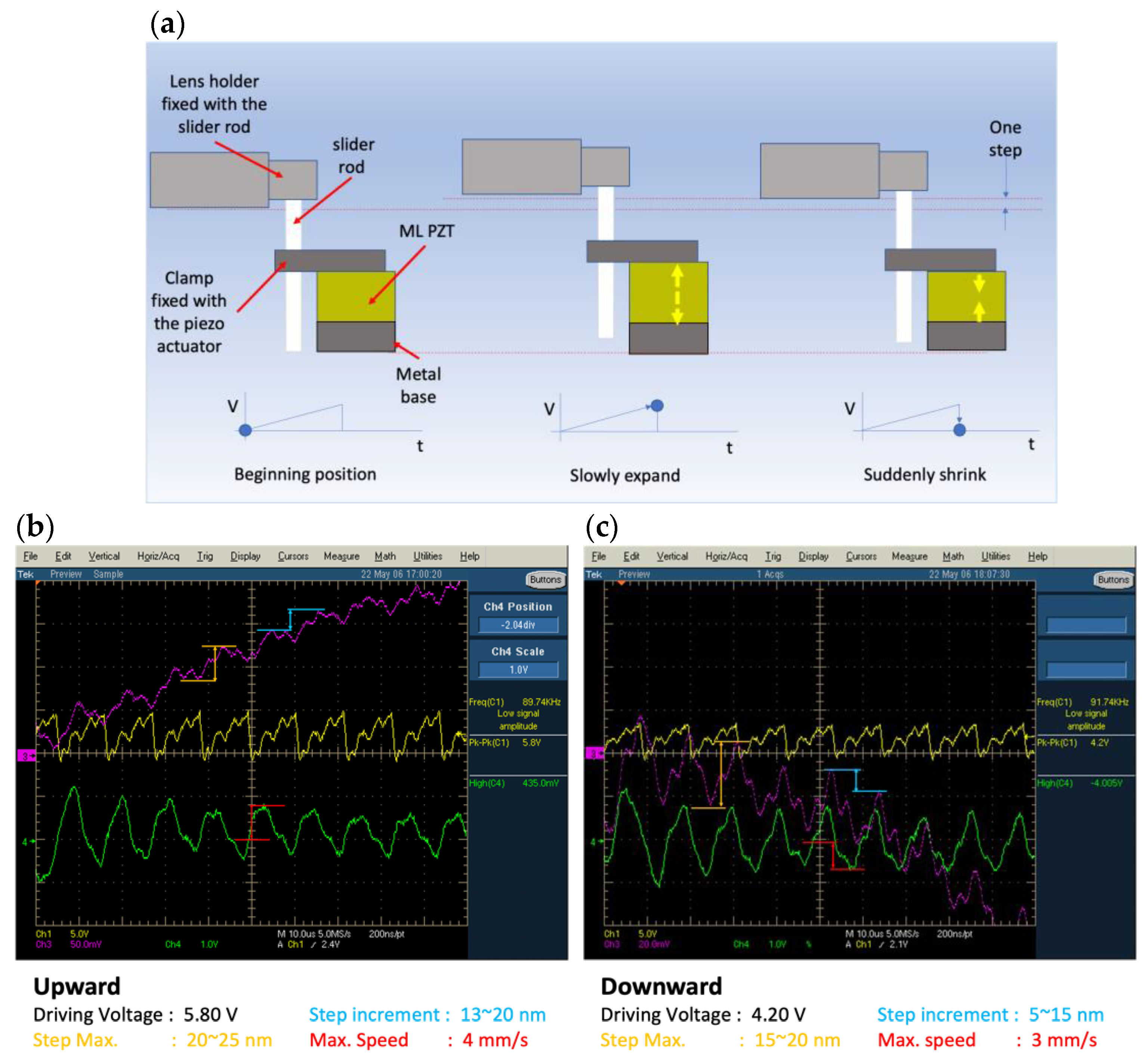

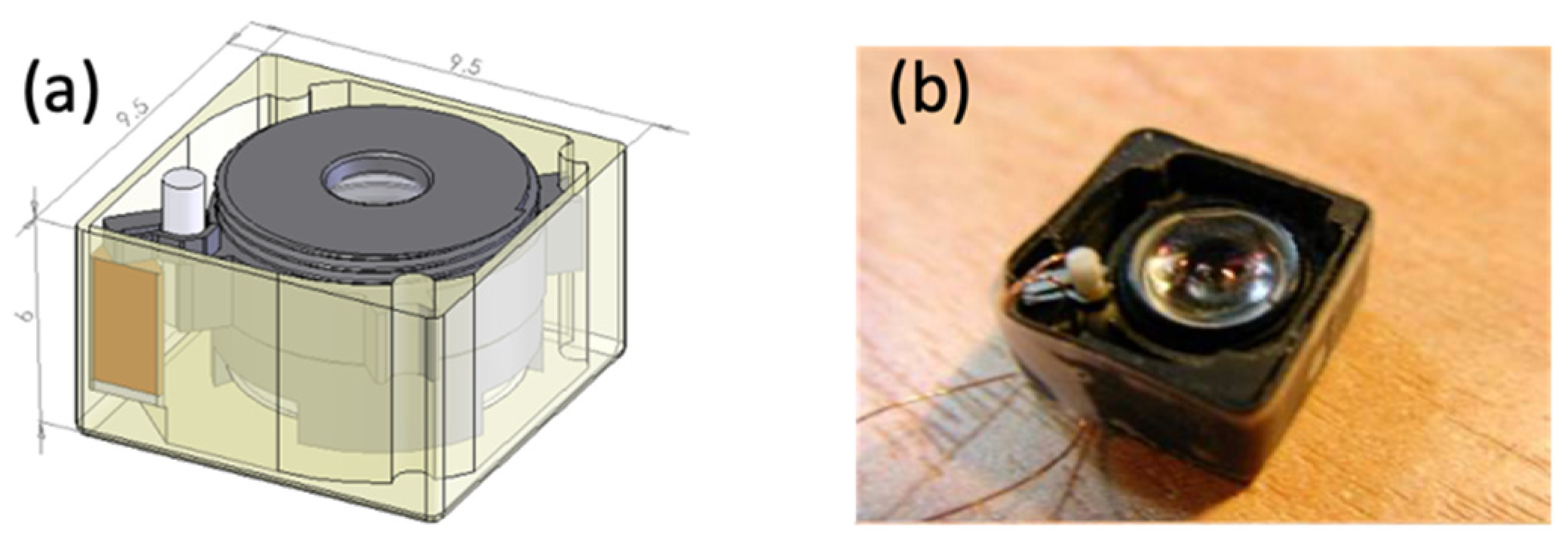

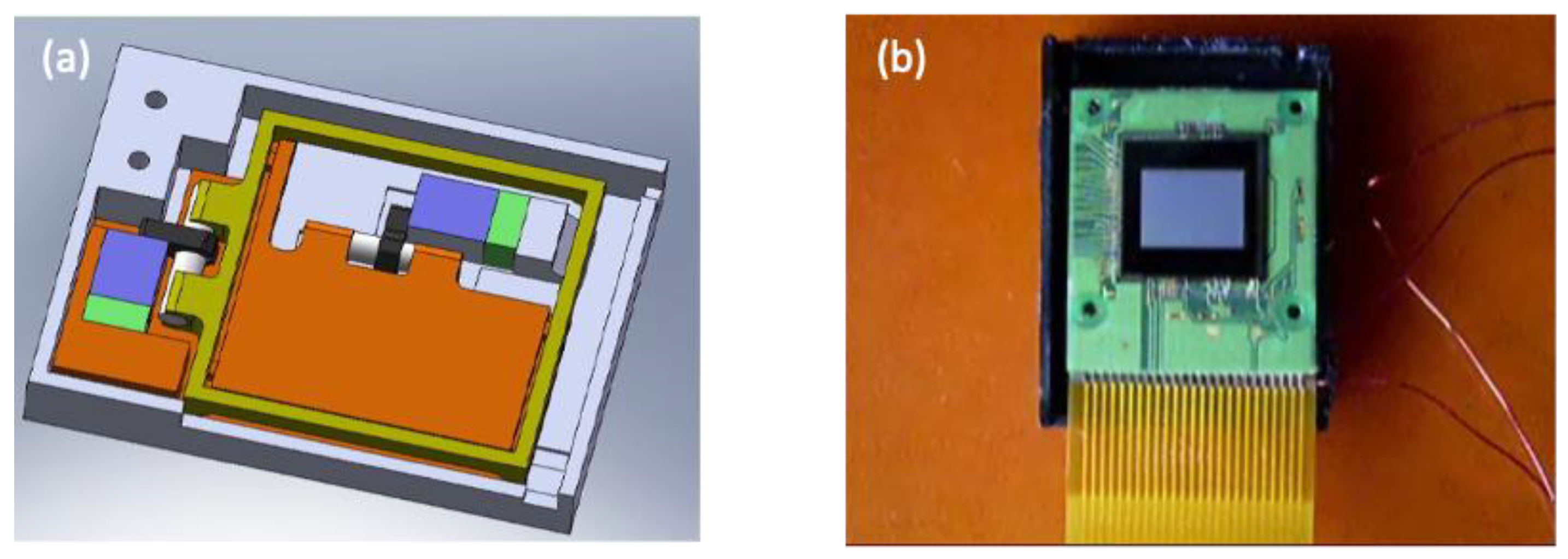

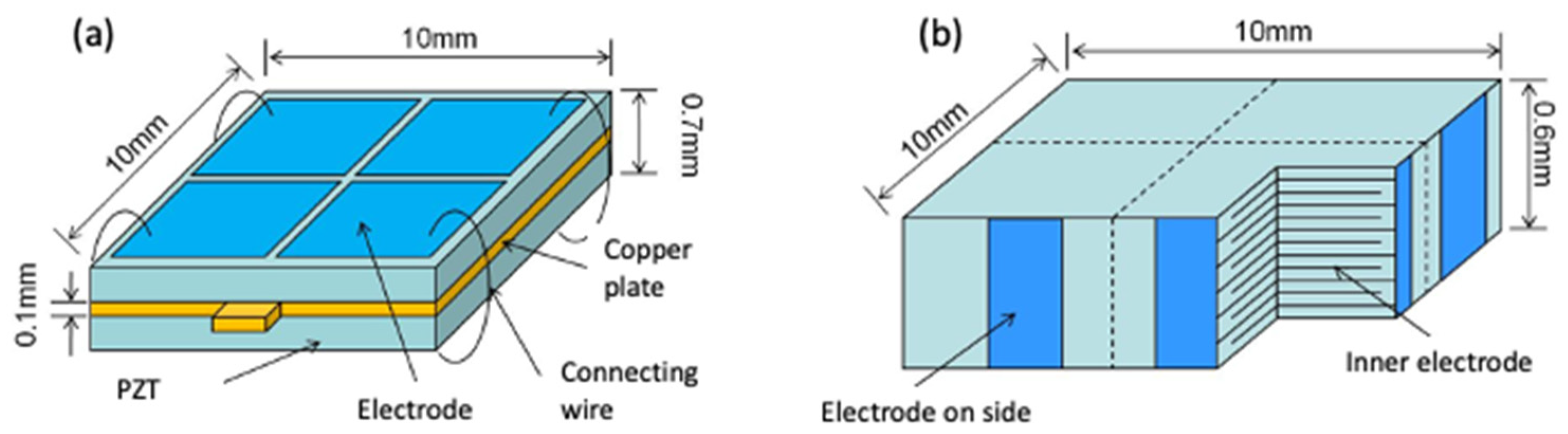

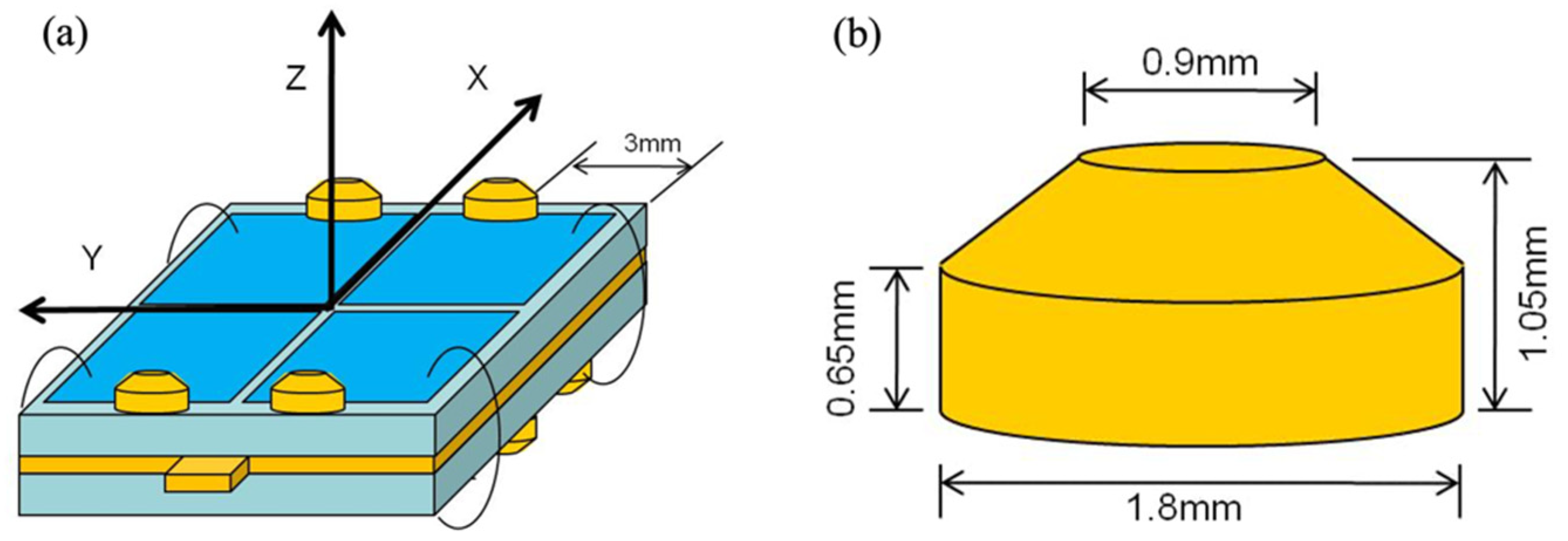

3.1. Design Concept

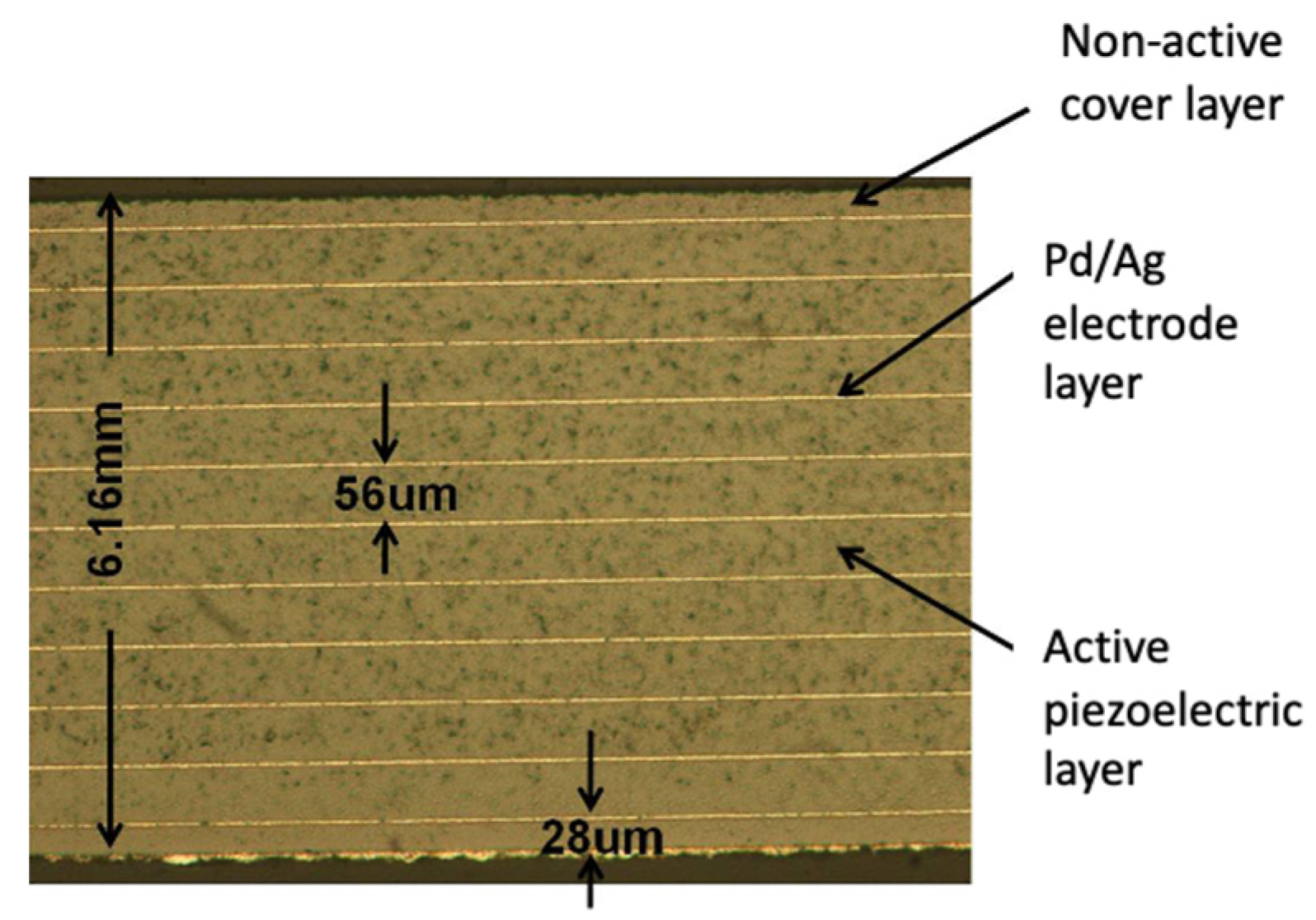

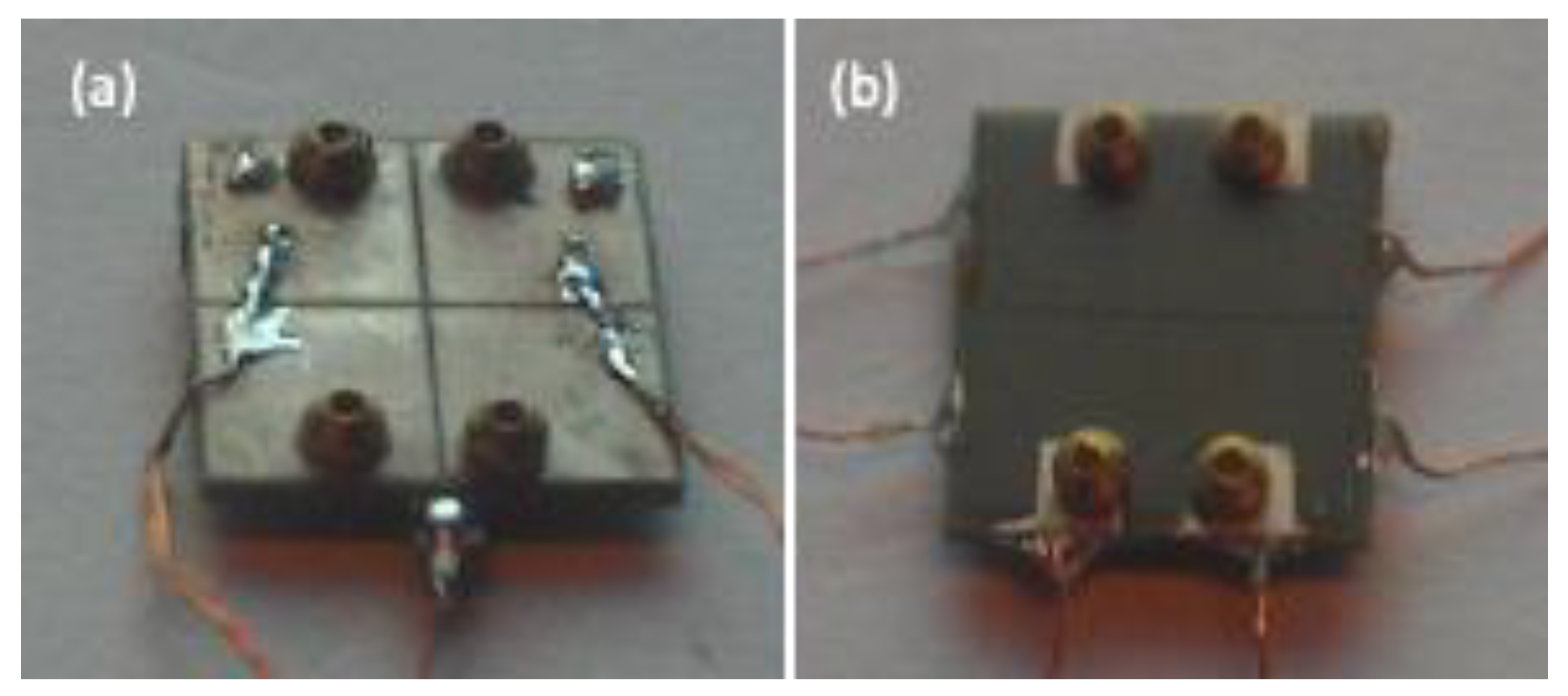

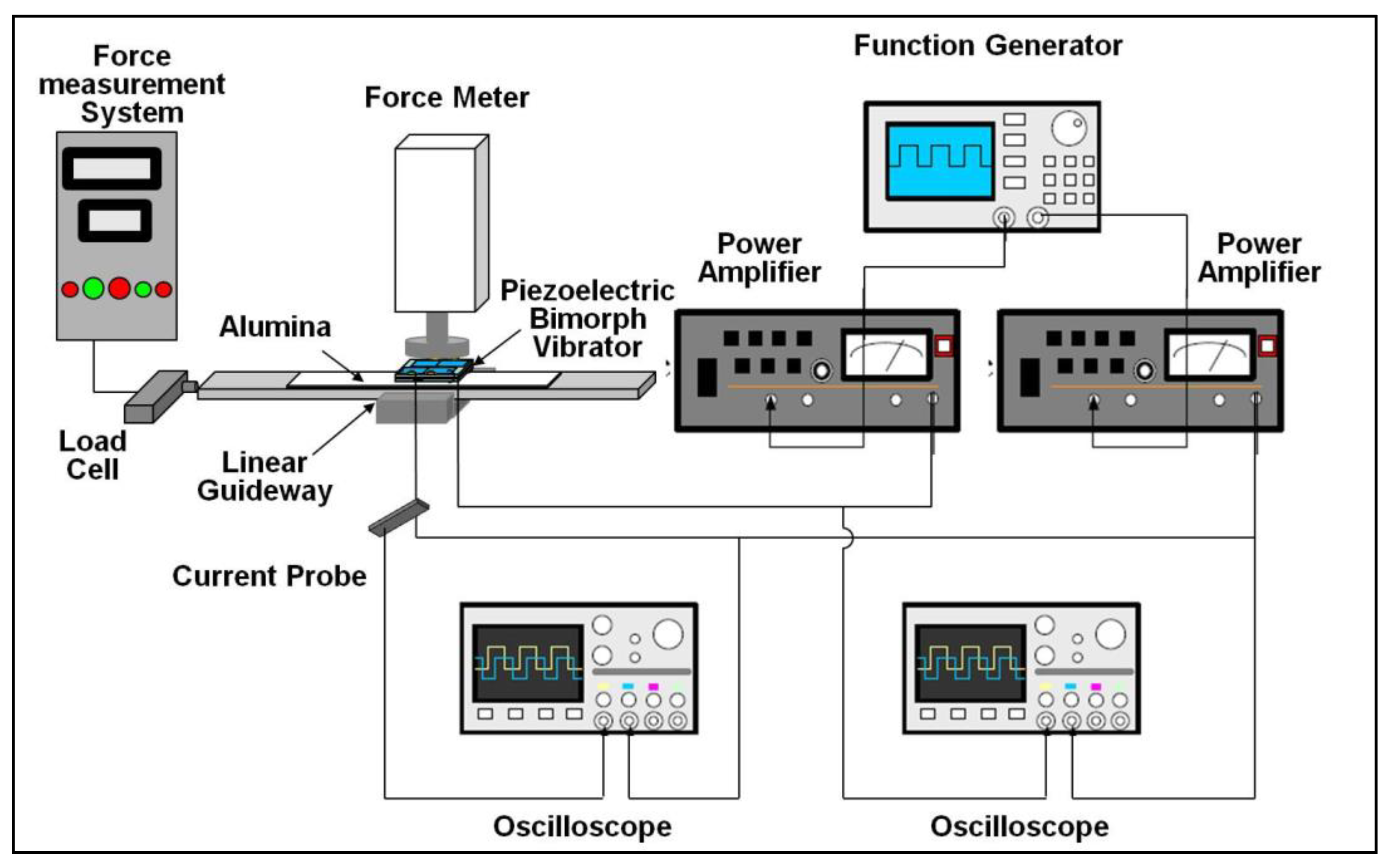

3.2. Fabrication and Assembly

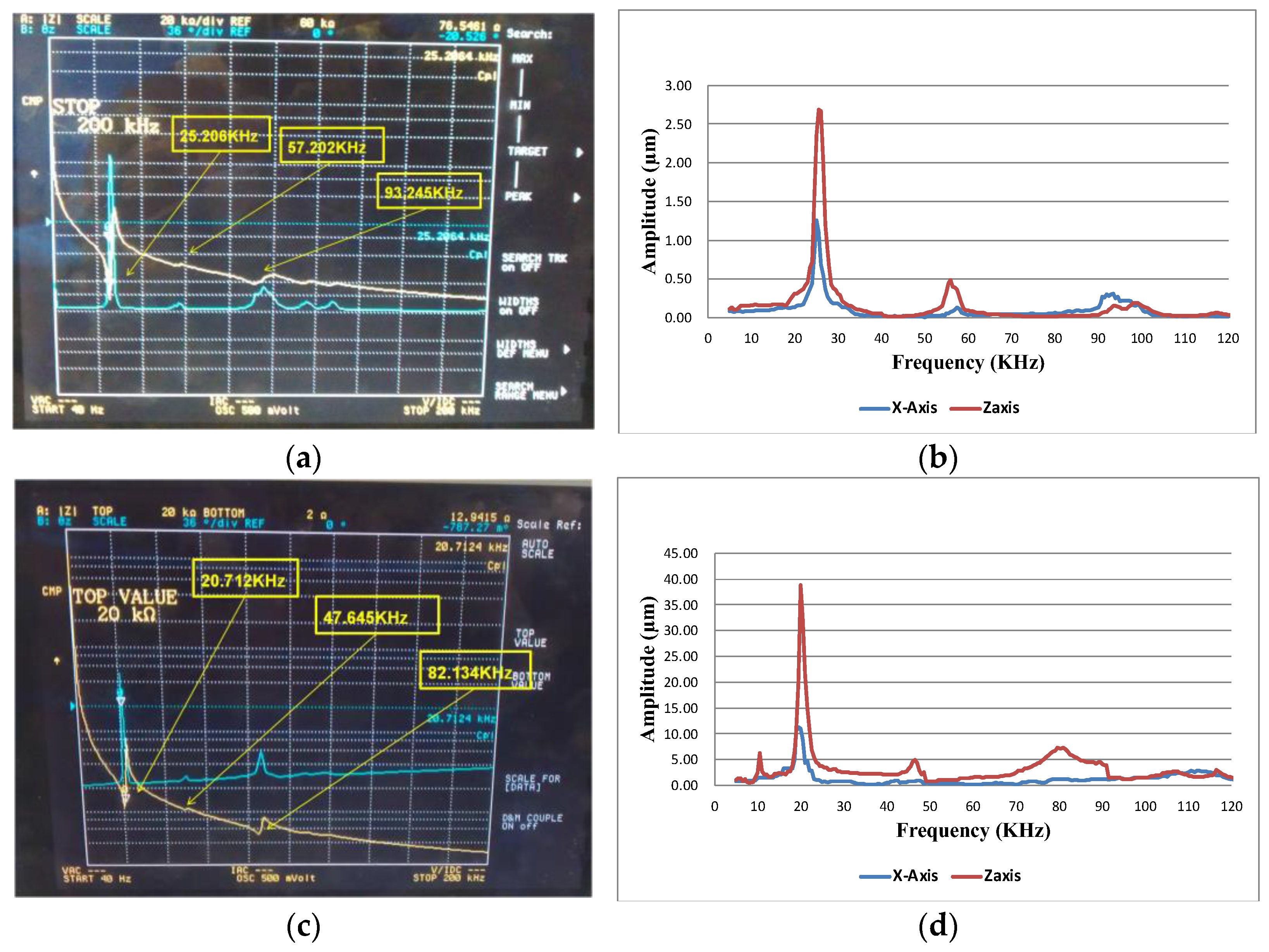

- (a)

- First of all, it can be noted that the first three fundamental bending modes were found in the finite element method simulation, impedance analyzer measurement and displacement amplitude measurement, which showed that the simulation and the actual measurement were related.

- (b)

- The measured results showed that both the simple bimorph stator and the multi-layer bimorph stator had a large displacement amplitude in the first mode; therefore, subsequent experiments can be performed in this mode.

- (c)

- The error between the simulation and the actual measurement expanded with the increase in the modal frequency, in particular, the errors of the third mode reached 14.96% (simple type) and 11.71% (multi-layer type), respectively. The main reason was that the friction tip was not added in the simulation, but the friction tip was added in the actual measurement. Although this error existed, it had no effect on the chosen first mode, and thus, related experiments can still be carried out.

- (d)

- In the displacement amplitude measurement of the laser interferometer, it was found that the resonant frequencies of the X-axis and Z-axis of each mode were sometimes slightly different, which may have been due to the measurement error or the selection of the measurement position.

- (e)

- The Z-axis displacement ratio of the multi-layer bimorph to the simple bimorph for the first, second and third modes were 14.42, 10.20 and 46.00, respectively. These ratios seem too high since the thickness-per-layer ratio of a simple bimorph to multi-layer bimorph was only 5.36. This meant that the electric field of the multi-layer bimorph should also be 5.36 times the simple bimorph under the same driving voltage. The reason may have come from the difference in the dimensions and structure of the two designs. The simple bimorph had a 0.1 mm copper layer and was also 0.1 mm thicker than the multi-layer bimorph; therefore, the simple bimorph was more structurally robust. Meanwhile, the X-axis displacement ratios were 9.02, 7.38 and 4.03, respectively.

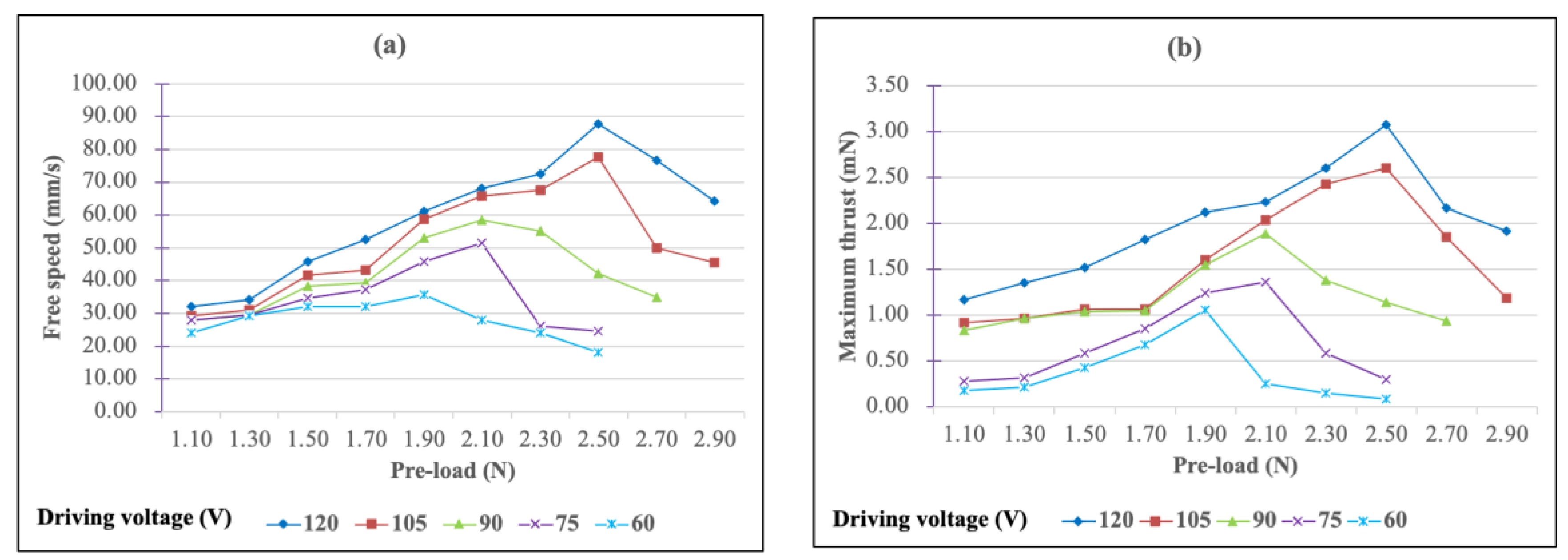

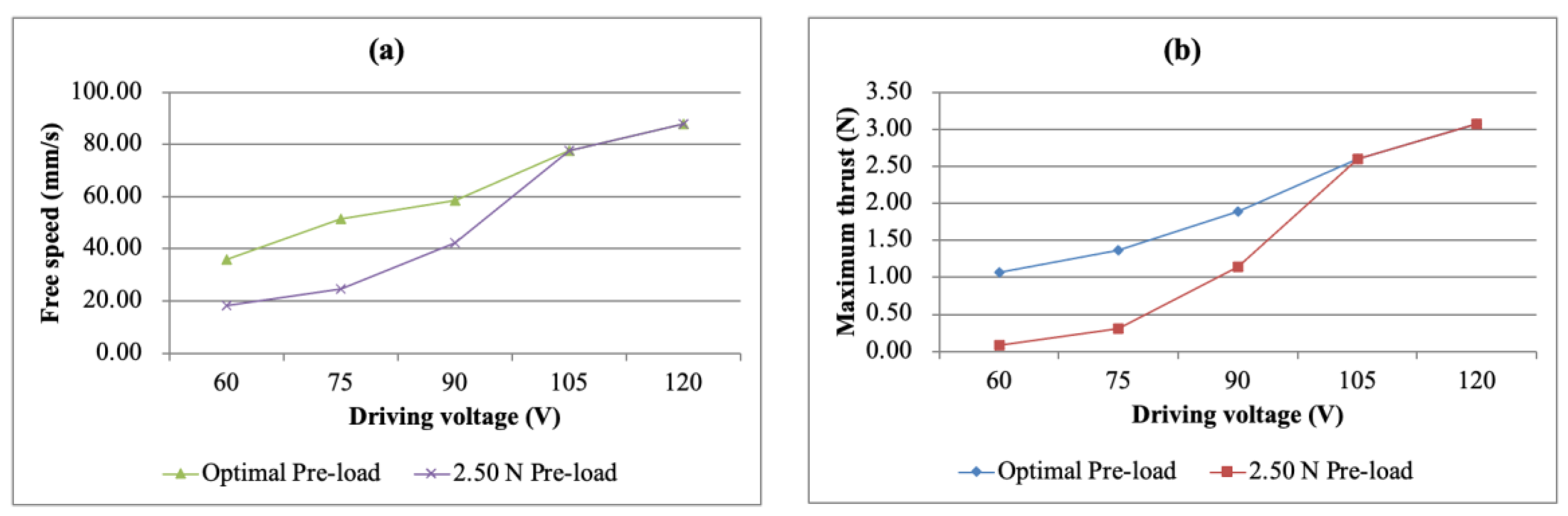

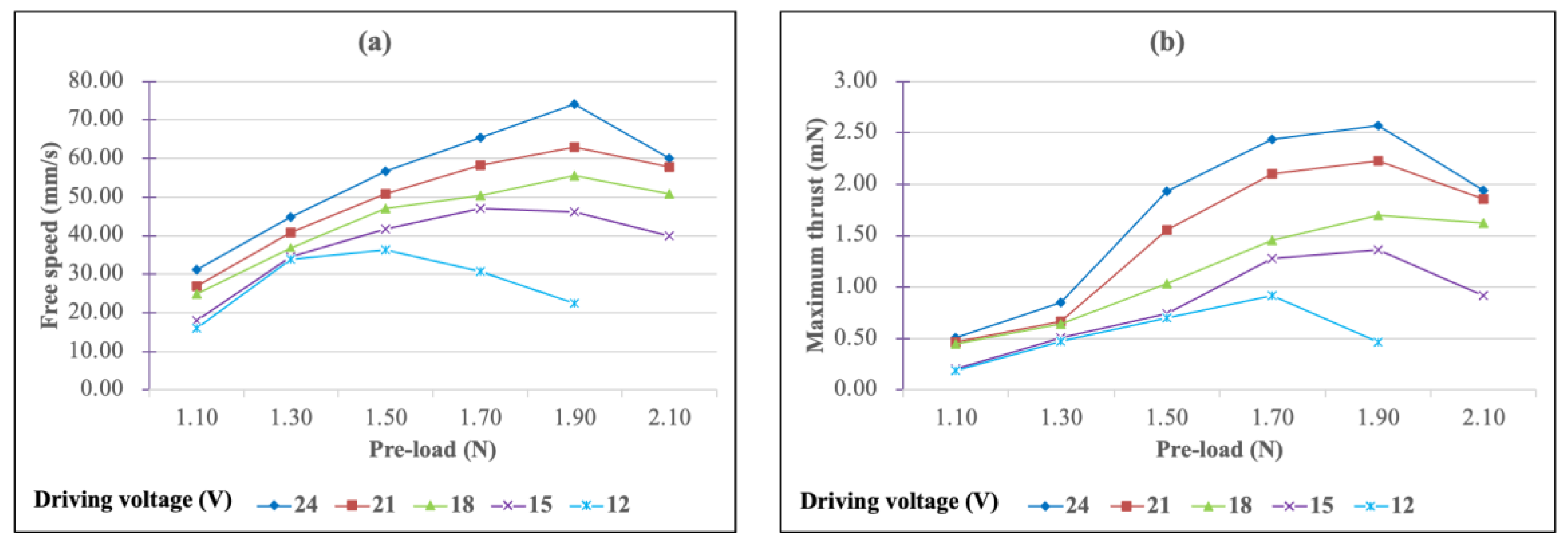

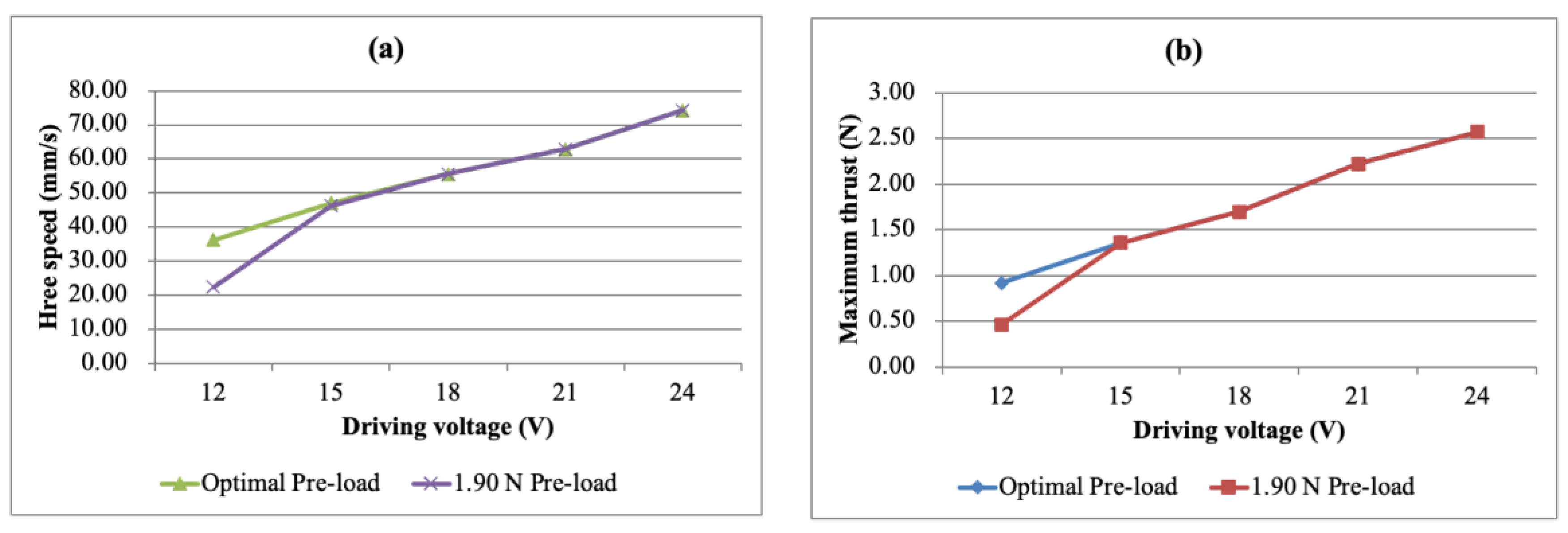

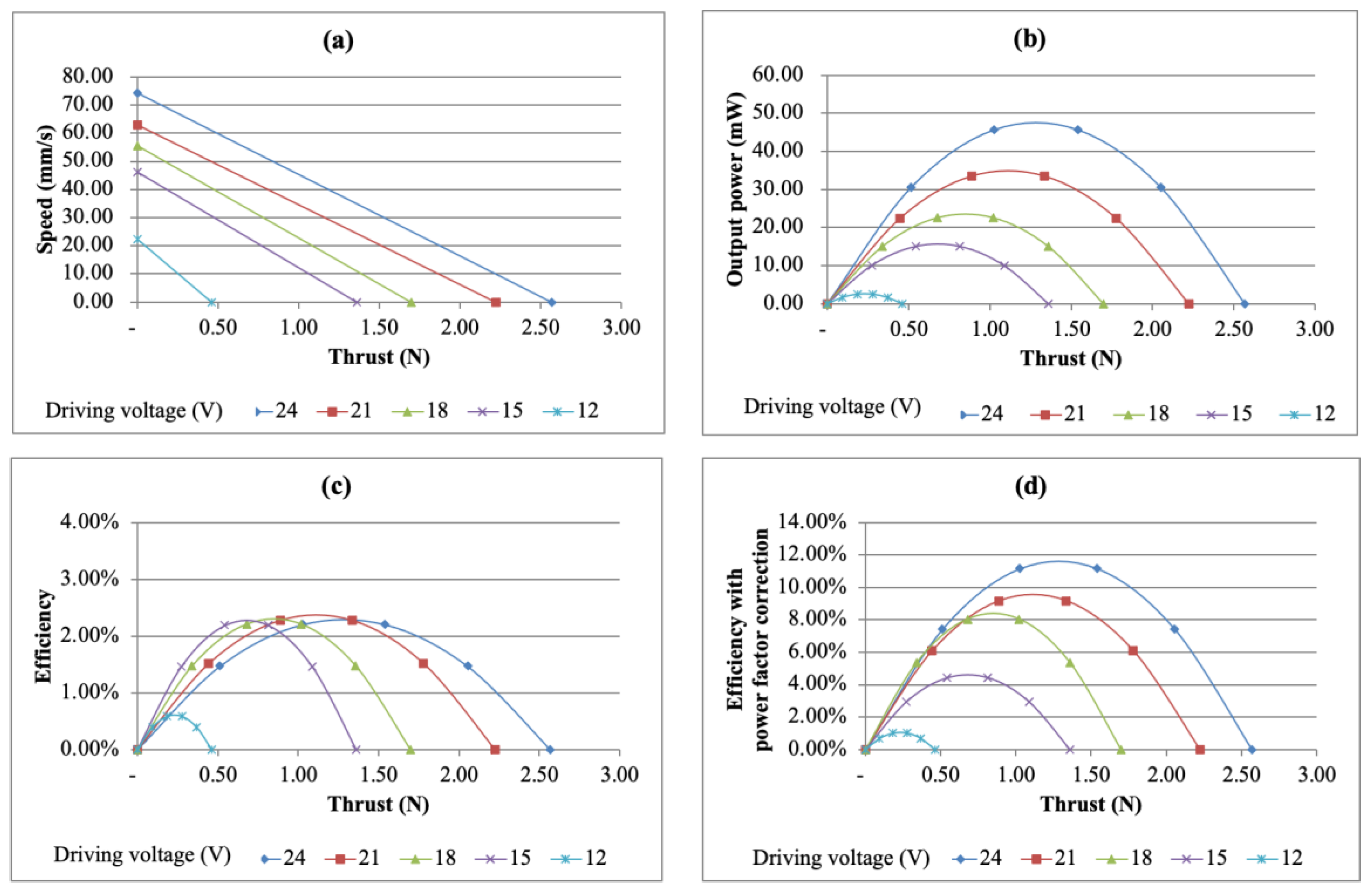

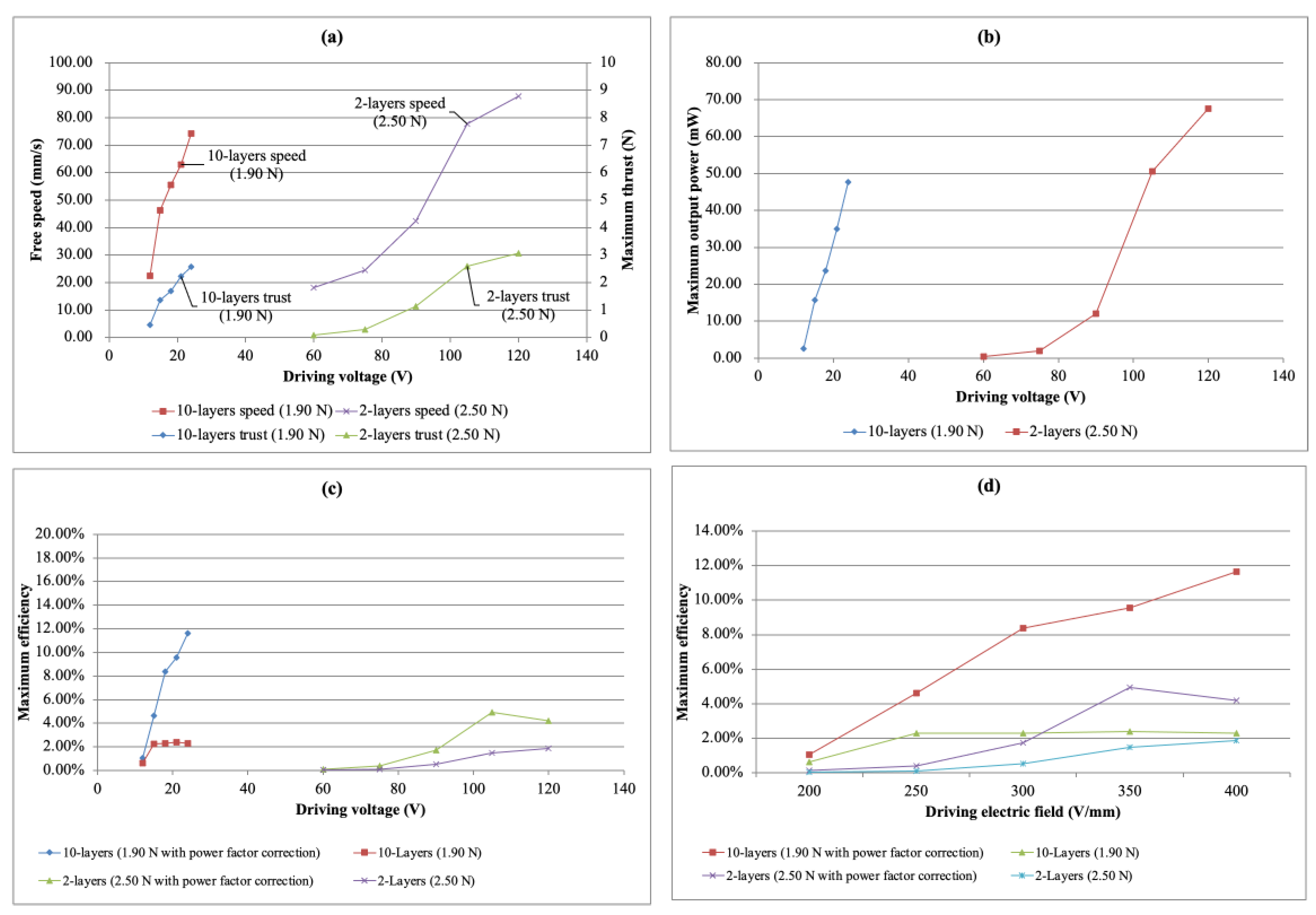

3.3. Testing and Performance Evaluation

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Yao, K.; Koc, B.; Uchino, K. Longitudinal-bending mode micromotor using multilayer piezoelectric actuator. IEEE Trans. Ultrason. Ferroelectr. Freq. Control 2001, 48, 1066–1071. [Google Scholar] [PubMed]

- Aoyagi, M.; Tomikawa, T.; Takano, T. A novel USM with a built-in clutch mechanism for a force-feed-back actuator. IEEE Ultrason. Symp. 2004, 3, 2239–2242. [Google Scholar]

- Toyama, S.; Sugitani, S.; Zhang, G.; Miyatani, Y.; Nakamura, K. Multi degree of freedom spherical USM. IEEE Int. Conf. Robot. Autom. 1995, 3, 2935–2940. [Google Scholar]

- Aoyagi, M.; Beeby, S.P.; White, N.M. A novel multi-degree-of-freedom thick-film USM. IEEE Trans. Ferroelectr. Freq. Control. Ultrason. 2002, 49, 151–158. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Takemura, K.; Ohno, Y.; Maeno, T. Design of a plate type multi-DOF USM and its driving characteristics. IEEE/ASME Int. Conf. Adv. Intell. Mechatron. Proc. 2003, 2, 1309–1314. [Google Scholar]

- Otokawa, K.; Maeno, T. Development of an arrayed-type multi-degree-of-freedom USM based on a selection of reciprocating vibration modes. IEEE Symp. Ultrason. 2004, 2, 1181–1184. [Google Scholar]

- Izuhara, S.; Mashimo, T. Linear piezoelectric motor using a hollow rectangular stator. Sens. Actuators A Phys. 2020, 309, 112002. [Google Scholar] [CrossRef]

- Ryndzionek, R.; Sienkiewicz, L. A review of recent advances in the single- and multi-degree-of-freedom ultrasonic piezoelectric motors. Ultrasonics 2021, 116, 106471. [Google Scholar] [CrossRef]

- Zhou, X.; Chen, W.; Liu, J. Novel 2-DOF Planar Ultrasonic Motor with Characteristic of Variable Mode Excitation. IEEE Trans. Ind. Electron. 2016, 63, 6941–6948. [Google Scholar] [CrossRef]

- Li, X.; Chen, Z.; Dong, S. A Double B1-Mode 4-Layer Laminated Piezoelectric Linear Motor. IEEE Trans. Ultrason. Ferroelectr. Freq. Control 2012, 59, 2752–2757. [Google Scholar]

- Li, X.; Ci, P.; Liu, G.; Dong, S. A two-layer linear piezoelectric micromotor. IEEE Trans. Ultrason. Ferroelectr. Freq. Control 2015, 62, 405–411. [Google Scholar] [CrossRef] [PubMed]

- Chen, Z.J.; Li, X.T.; Ci, P.H.; Liu, G.X.; Dong, S.X. A standing wave linear ultrasonic motor operating in in-plane expanding and bending modes. Rev. Sci. Instrum. 2015, 86, 035002. [Google Scholar] [CrossRef] [PubMed]

- Ci, P.H.; Liu, G.X.; Chen, Z.J.; Dong, S.X. A standing wave linear ultrasonic motor operating in face-diagonal-bending mode. Appl. Phys. Lett. 2013, 103, 102904. [Google Scholar] [CrossRef]

- Henderson, D.A. Simple ceramic motor…inspiring smaller products. In Proceedings of the 10th International Conference on New Actuator, Bremen, Germany, 14–16 June 2006; pp. 1–4. [Google Scholar]

- Miniswys, S.A. Available online: https://www.miniswys.com/ (accessed on 18 November 2022).

- Paik, D.S.; Yoo, K.H.; Kang, C.Y.; Cho, B.H.; Nam, S.; Yoon, S.J. Multilayer piezoelectric linear ultrasonic motor for camera module. J. Electroceramics 2009, 22, 346–351. [Google Scholar] [CrossRef]

- Lee, W.H.; Kang, C.Y.; Paik, D.S.; Ju, B.K.; Yoon, S.J. Butterfly shaped ultra slim piezoelectric ultrasonic linear motor. Sens. Actuators A Phys. 2011, 168, 127–130. [Google Scholar] [CrossRef]

- Li, S.Y.; Jiang, W.H.; Zheng, L.M.; Cao, W.W. A face-shear mode single crystal ultrasonic motor. Appl. Phys. Lett. 2013, 102, 183512. [Google Scholar] [CrossRef] [Green Version]

- Wischnewski, M.; Delibas, B.; Wischnewski, A.; Pertsch, P. Microscale Monocrystal Ultrasonic Actuators for Miniature Optical Systems. In Proceedings of the ACTUATOR 2022, International Conference and Exhibition on New Actuator Systems and Applications, Mannheim, Germany, 29–30 June 2022. [Google Scholar]

- Chen, Z.; Li, X.; Liu, G.; Dong, S. A two degrees-of-freedom piezoelectric single-crystal micromotor. J. Appl. Phys. 2014, 116, 224101. [Google Scholar] [CrossRef]

- Izuhara, S.; Mashimo, T. Design and characterization of a thin linear ultrasonic motor for miniature focus systems. Sens. Actuators A Phys. 2021, 329, 112797. [Google Scholar] [CrossRef]

- Mashimo, T.; Izuhara, S. Review: Recent advances in micromotors. IEEE Access 2020, 8, 213489–213501. [Google Scholar] [CrossRef]

- Mukhopadhyay, S.; Behera, B.; Kumar, J. A brief review on the recent evolution in piezoelectric linear ultrasonic Motors. Eng. Res. Express 2021, 3, 042003. [Google Scholar] [CrossRef]

- Li, X.; Wen, Z.; Jia, B.; Cao, T.; Yu, D.; Wu, D. A Review of Application and Development Trends in Ultrasonic Motors. ES Mater. Manuf. 2021, 12, 3–16. [Google Scholar] [CrossRef]

- Pearce, D.; Hooley, A.; Button, T. On Piezoelectric super-helix actuators. Sens. Actuators A 2002, 100, 281–286. [Google Scholar] [CrossRef]

- Uchino, K. Piezoelectric motors for camera modules. In Proceedings of the 11th International Conference and Exhibition on New Actuator Systems and Applications, Bremen, Germany, 9–11 June 2008; p. 157. [Google Scholar]

- Lee, C.; Huang, C.; Shih, T. Lens Actuating Device. US Patent No. 7446963, 4 November 2008. [Google Scholar]

- Okamoto, Y.; Yoshida, R.; Sueyoshi, H. The development of a smooth impact drive mechanism (SIDM) using a piezoelectric element. Konica Minolta Technol. Rep. 2004, 1, 23–26. [Google Scholar]

- Available online: http://piezo-tech.com/product_info/tula/?lang=en (accessed on 31 October 2022).

| Items | First Mode | Second Mode | Third Mode |

|---|---|---|---|

| Simulation frequency (kHz) | 24.60 | 59.61 | 109.64 |

| Impedance analyzer measurement frequency (kHz) | 25.21 | 57.20 | 93.25 |

| X-axis laser interferometer measurement frequency (kHz) | 25.00 | 57.50 | 93.50 |

| X-axis displacement (µm@10V) | 1.26 | 0.13 | 0.31 |

| Z-axis laser interferometer measurement frequency (kHz) | 25.00 | 56.00 | 93.50 |

| Z-axis displacement (µm@10V) | 2.69 | 0.49 | 0.16 |

| Difference between impedance analyzer measurement frequency and simulation frequency | 2.47% | 4.03% | 14.96% |

| Measurement frequency difference between impedance analyzer and laser interferometer (X-axis) | 0.82% | 0.52% | 0.27% |

| Measurement frequency difference between impedance analyzer and laser interferometer (Z-axis) | 0.82% | 2.10% | 0.27% |

| Items | First Mode | Second Mode | Third Mode |

|---|---|---|---|

| Simulation frequency (kHz) | 20.71 | 49.87 | 93.03 |

| Impedance analyzer measurement frequency (kHz) | 20.71 | 47.65 | 82.13 |

| X-axis laser interferometer measurement frequency (kHz) | 19.50 | 47.20 | 81.00 |

| X-axis displacement (µm@10V) | 11.37 | 0.96 | 1.25 |

| Z-axis laser interferometer measurement frequency (kHz) | 20.00 | 46.70 | 81.00 |

| Z-axis displacement (µm@10V) | 38.79 | 5.00 | 7.36 |

| Difference between impedance analyzer measurement frequency and simulation frequency | 0.02% | 4.47% | 11.71% |

| Measurement frequency difference between impedance analyzer and laser interferometer (X-axis) | 5.85% | 0.93% | 1.38% |

| Measurement frequency difference between impedance analyzer and laser interferometer (Z-axis) | 3.44% | 1.92% | 1.38% |

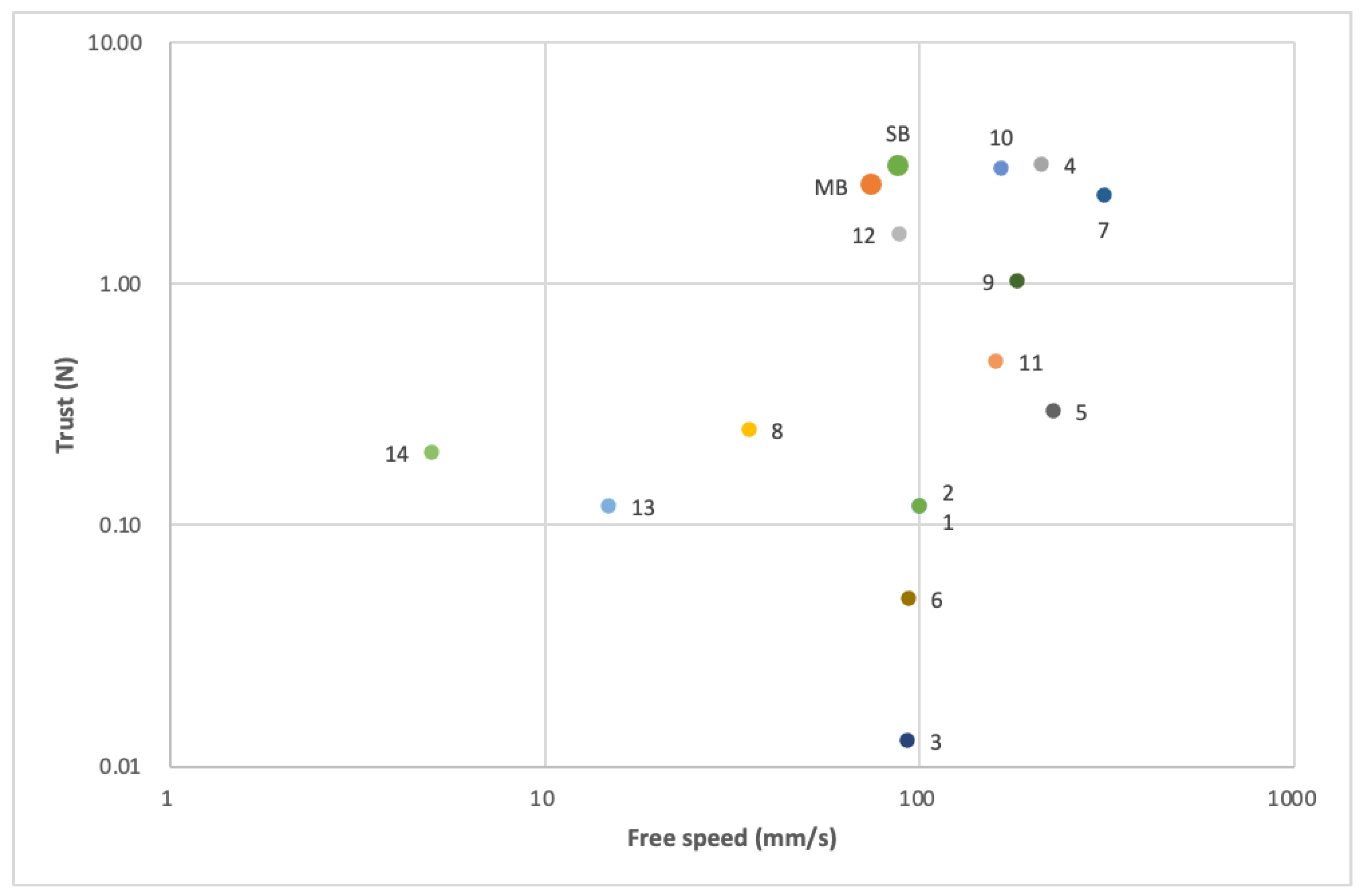

| USM Code | Reference | Year | Type | DOF | Dimension mmL × mmW × mmt | Volume (mm3) | Voltage of the Max. Free Speed (V) | Free Speed (mm/s) | Voltage of the Max. Thrust (V) | Thrust (N) | Free Speed /Volume {(mm/s)/mm3} | Thrust /Volume (N/mm3) |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| SB | This study | 2022 | Simple Bimorph | 2 | 10 × 10 × 0.7 | 70.00 | 120.00 | 87.75 | 120.00 | 3.08 | 1253.57 | 0.0440 |

| MB | This study | 2022 | Multi-Layer bimorph | 2 | 10 × 10 × 0.6 | 60.00 | 24.00 | 74.23 | 24.00 | 2.57 | 1237.17 | 0.0428 |

| 1 | [19] | 2022 | PZT | 1 | 6.7 × 4.2 × 0.5 | 14.07 | 22.62 | 100.00 | 22.62 | 0.12 | 7107.32 | 0.0085 |

| 2 | [19] | 2022 | Single crystal | 1 | 6.7 × 4.2 × 0.5 | 14.07 | 28.28 | 100.00 | 28.28 | 0.12 | 7107.32 | 0.0085 |

| 3 | [21] | 2021 | PZT | 1 | 4.5 × 4.5 × 0.9 | 18.23 | 100.00 | 92.80 | 100.00 | 0.01 | 5091.91 | 0.0007 |

| 4 | [9] | 2016 | PZT | 2 | 63 × 10 × 10 | 6300.00 | 400.00 | 211.30 | 400.00 | 3.15 | 33.54 | 0.0005 |

| 5 | [11] | 2015 | PZT, Traveling wave | 1 | 5 × 2 × 2 | 20.00 | 70.00 | 227.00 | 80.00 | 0.30 | 11,350.00 | 0.0150 |

| 6 | [11] | 2015 | PZT, Standing wave | 1 | 5 × 2 × 2 | 20.00 | 80.00 | 93.00 | 80.00 | 0.05 | 4650.00 | 0.0025 |

| 7 | [12] | 2015 | PZT | 1 | 15 × 15 × 2 | 450.00 | 150.00 | 310.00 | 150.00 | 2.35 | 688.89 | 0.0052 |

| 8 | [20] | 2014 | Single crystal | 2 | 9 × 2 × 2 | 36.00 | 80.00 | 35.00 | 80.00 | 0.25 | 972.22 | 0.0069 |

| 9 | [18] | 2013 | Single crystal | 1 | 9.6 × 9.6 × 2.5 | 230.40 | 50.00 | 182.50 | 50.00 | 1.03 | 792.10 | 0.0045 |

| 10 | [13] | 2013 | PZT | 1 | 15 × 15 × 2 | 450.00 | 150.00 | 165.00 | 150.00 | 3.00 | 366.67 | 0.0067 |

| 11 | [10] | 2012 | PZT | 1 | 12 × 4 × 4 | 192.00 | 40.00 | 160.00 | 40.00 | 0.48 | 833.33 | 0.0025 |

| 12 | [17] | 2011 | PZT | 1 | 9 × 8 × 1 | 72.00 | 88.00 | 1.62 | 1222.22 | 0.0225 | ||

| 13 | [16] | 2009 | PZT | 1 | 11 × 4 × 2.5 | 110.00 | 12.00 | 14.80 | 12.00 | 0.12 | 134.55 | 0.0011 |

| 14 | [14] | 2006 | PZT | 1 | 6 × 1.5 × 1.5 | 13.50 | 40.00 | 5.00 | 40.00 | 0.20 | 370.37 | 0.0148 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Lee, C.-P.; Tsai, M.-C.; Fuh, Y.-K. Tiny Piezoelectric Multi-Layered Actuators with Application in a Compact Camera Module—Design, Fabrication, Assembling and Testing Issues. Micromachines 2022, 13, 2126. https://doi.org/10.3390/mi13122126

Lee C-P, Tsai M-C, Fuh Y-K. Tiny Piezoelectric Multi-Layered Actuators with Application in a Compact Camera Module—Design, Fabrication, Assembling and Testing Issues. Micromachines. 2022; 13(12):2126. https://doi.org/10.3390/mi13122126

Chicago/Turabian StyleLee, Chao-Ping, Mi-Ching Tsai, and Yiin-Kuen Fuh. 2022. "Tiny Piezoelectric Multi-Layered Actuators with Application in a Compact Camera Module—Design, Fabrication, Assembling and Testing Issues" Micromachines 13, no. 12: 2126. https://doi.org/10.3390/mi13122126

APA StyleLee, C.-P., Tsai, M.-C., & Fuh, Y.-K. (2022). Tiny Piezoelectric Multi-Layered Actuators with Application in a Compact Camera Module—Design, Fabrication, Assembling and Testing Issues. Micromachines, 13(12), 2126. https://doi.org/10.3390/mi13122126