Simulation of Silicon Surface Barrier Detector with PN Junction Guard Rings to Improve the Breakdown Voltage

Abstract

1. Introduction

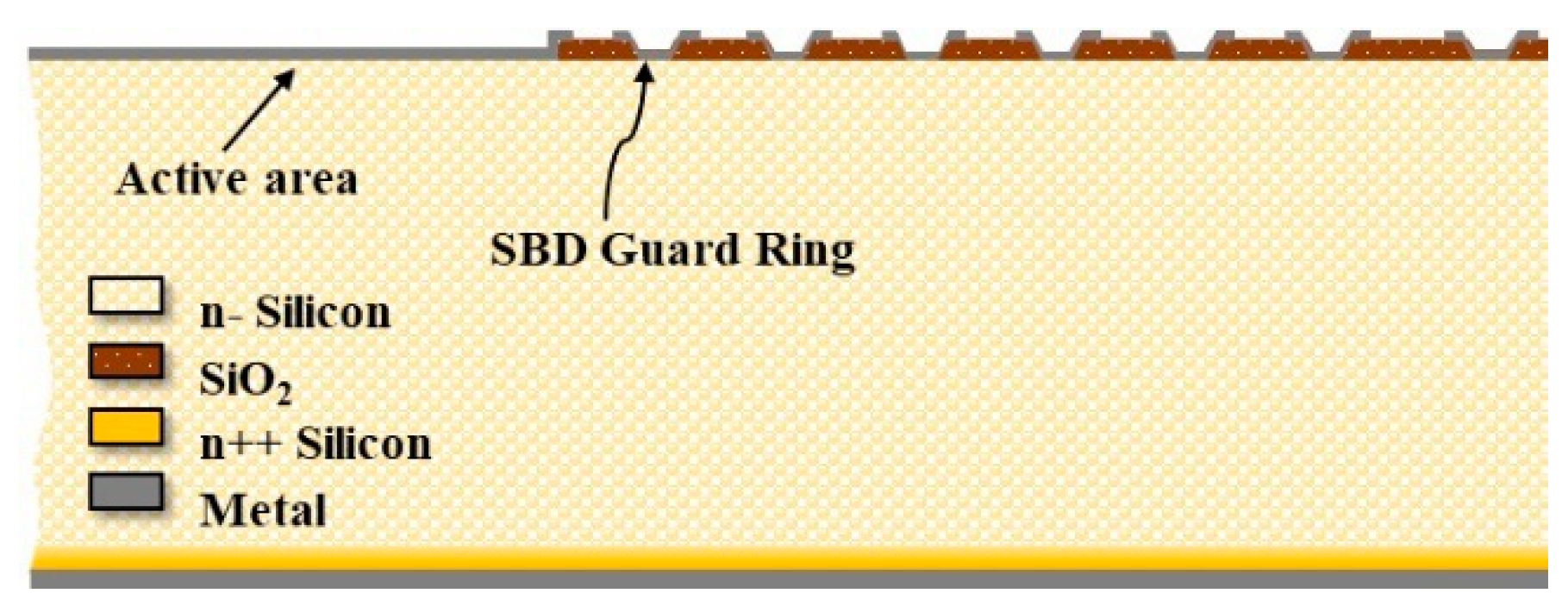

2. Device Structure and Simulation Method

3. Results and Discussion

3.1. c-SSBD and Hybrid-SSBD Performance Compared

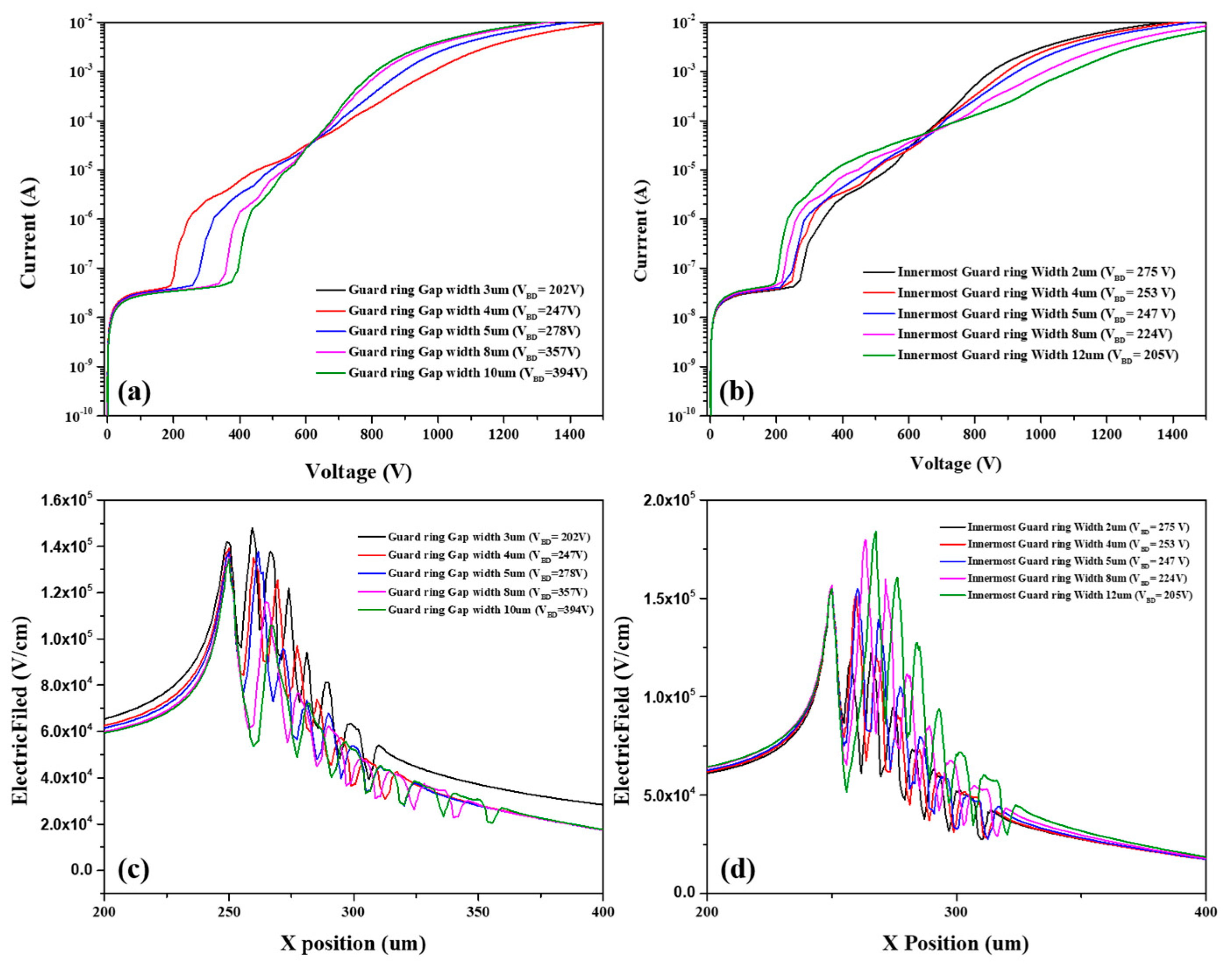

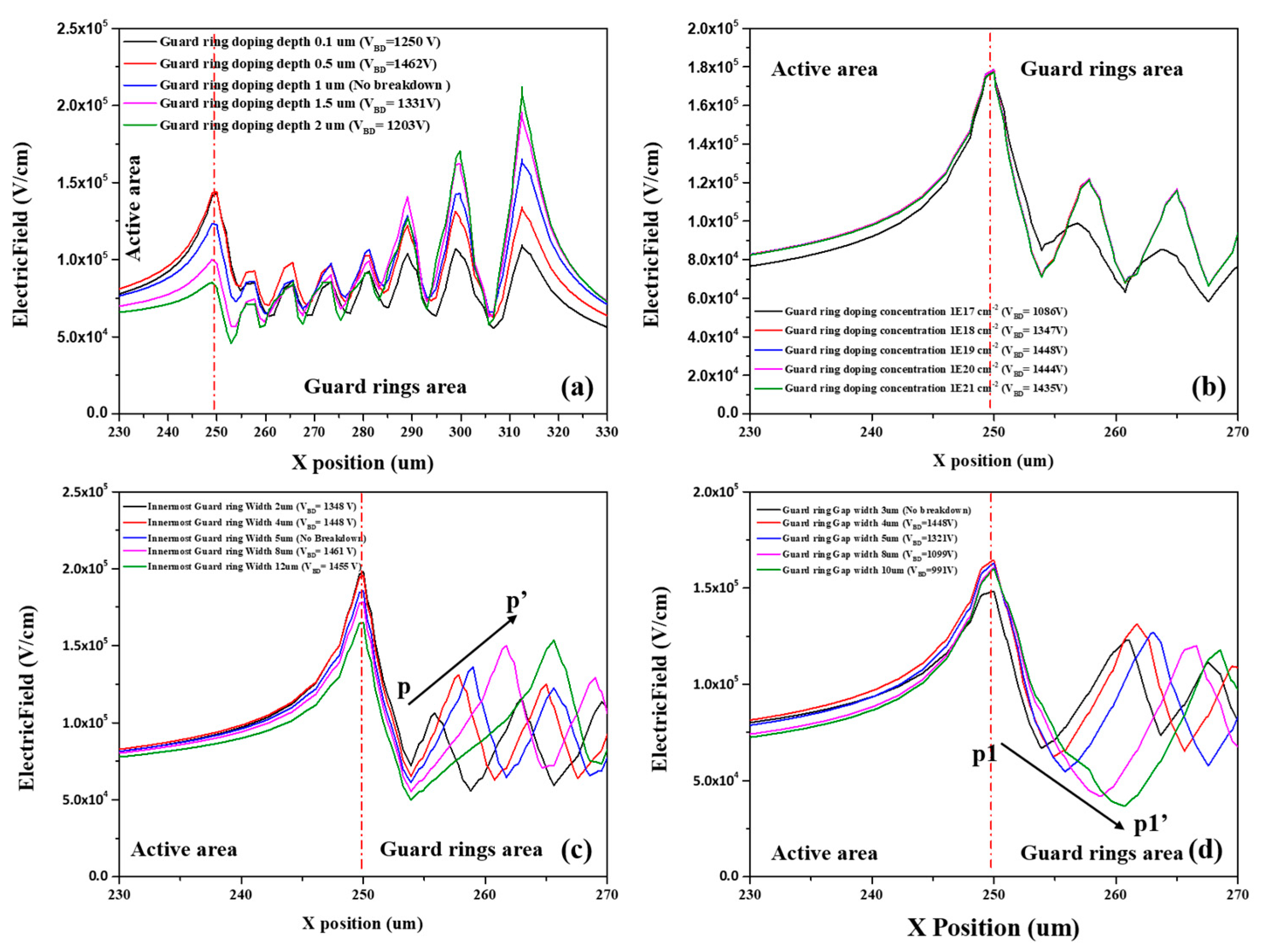

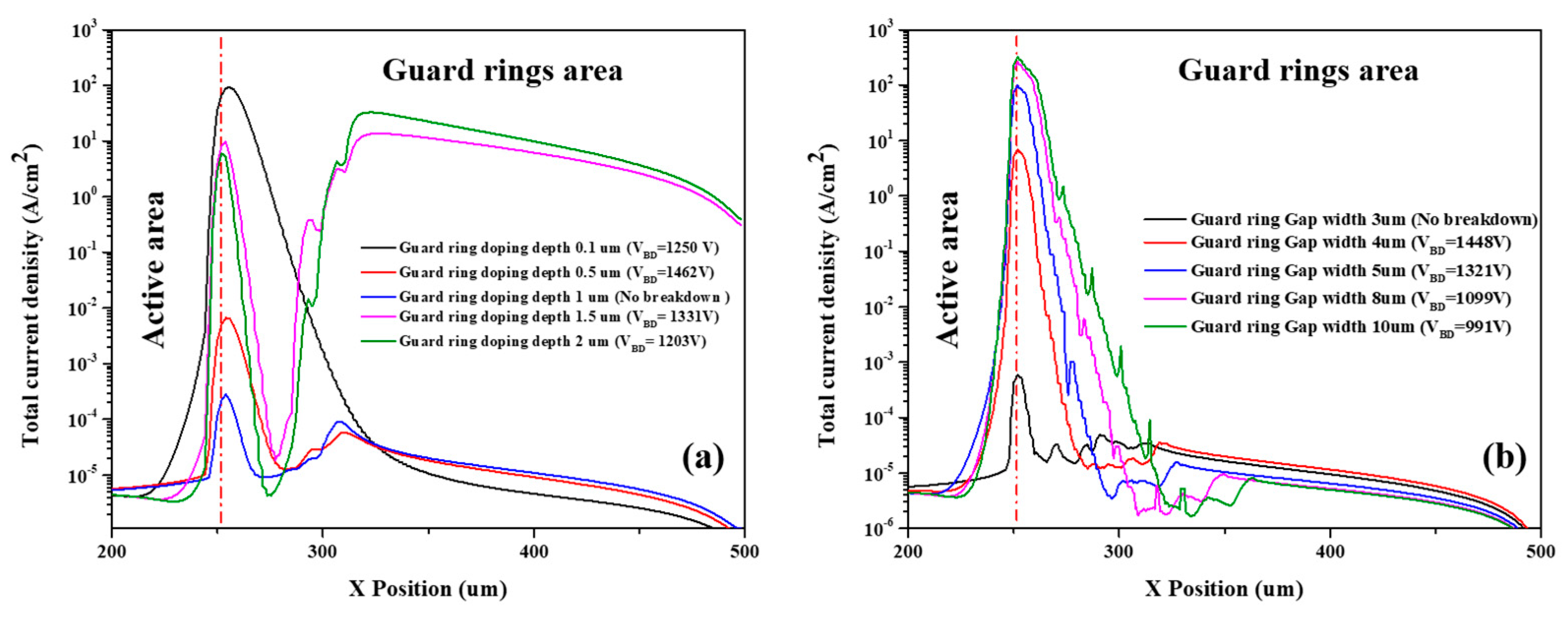

3.2. Effect of Guard Rings on Hybrid-SSBD Parameters

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Chabaud, V.; Dijkstra, H.; Gröne, M.; Flohr, M.; Horisberger, R.; Hubbeling, L.; Maehlum, G.; Peisert, A.; Sandvik, A.; Weilhammer, P.; et al. Beam test results from a prototype for the delphi microvertex detector. Nucl. Instrum. Meth. A 1990, 292, 75–80. [Google Scholar] [CrossRef][Green Version]

- Avdeichikov, V.V. Semiconductor Si(npn) detector with two surface−barrier junction. Nucl. Instrum. Meth. 1976, 138, 381. [Google Scholar] [CrossRef]

- Kimoto, T. Material science and device physics in SiC technology for high−voltage power devices. Jpn. J. Appl. Phys. 2015, 54, 040103. [Google Scholar] [CrossRef]

- Chen, X.; Xu, Y.; Zhou, D.; Yang, S.; Ren, F.-F.; Lu, H.; Tang, K.; Gu, S.; Zhang, R.; Zheng, Y.D.; et al. Solar−Blind Photodetector with High Avalanche Gains and Bias−Tunable Detecting Functionality Based on Metastable Phase alpha−Ga2O3/ZnO Isotype Heterostructures. ACS Appl. Mater. Interfaces 2017, 42, 36997–37005. [Google Scholar] [CrossRef] [PubMed]

- Hadjersi, T.; Cheraga, H.; Chergui, W. Surface barrier detectors made from ultra−high purity P−type silicon for beta and X−ray spectroscopy. Hard X-ray Gamma-ray Neutron Detect. Phys. 1999, 3768, 486–490. [Google Scholar] [CrossRef]

- Ray, A.; Das, T.N.; Betty, C.A.; Rao, T.V.C. Development of surface barrier detectors of low leakage current employing argon cold plasma assisted silicon surface cleaning prior to detector fabrication. J. Instrum. 2018, 13, P09019. [Google Scholar] [CrossRef]

- Boughedda, A.; Lakhdara, M.; Latreche, S.; Mendicino, R.; Betta, G.-F.D. Comparing different bulk radiation damage models in TCAD simulations of small−pitch 3D Si sensors. Micro Nano Lett. 2020, 10, 969. [Google Scholar] [CrossRef]

- Koybasi, O.; Bolla, G.; Bortoletto, D. Guard Ring Simulations for n−on−p Silicon Particle Detectors. IEEE. Trans. Nucl. Sci. 2010, 57, 2978–2986. [Google Scholar] [CrossRef][Green Version]

- Liou, B.W.; Lee, C.L. Characteristics of high breakdown voltage Schottky barrier diodes using p+−polycrystalline−silicon diffused−guard−ring. Solid−State Electron. 2000, 44, 631–638. [Google Scholar] [CrossRef]

- Yuan, H.; Tang, X.-Y.; Zhang, Y.-M.; Zhang, Y.-M.; Song, Q.-W.; Yang, F.; Wu, H. 4H−SiC Schottky barrier diodes with semi−insulating polycrystalline silicon field plate termination. Chin. Phys. B 2014, 23, 057102. [Google Scholar] [CrossRef]

- Casse, G.; Allport, P.P.; Turner, P.R.; Garcia, S.M.I.; Lozano, M. Performances of miniature microstrip detectors made on oxygen enriched p−type substrates after very high proton irradiation. Nucl. Instrum. Meth. A 2004, 535, 362–365. [Google Scholar] [CrossRef]

- Lin, C.-H.; Yuda, Y.; Wong, M.H.; Sato, M.; Takekawa, N.; Konishi, K.; Watahiki, T.; Yamamuka, M.; Murakami, H.; Kumagai, Y.; et al. Vertical Ga2O3 Schottky Barrier Diodes with Guard Ring Formed by Nitrogen−Ion Implantation. IEEE Electron Device Lett. 2019, 9, 1487–1490. [Google Scholar] [CrossRef]

- Fu, H.; Montes, J.; Deng, X.G.; Qi, X.; Goodnick, S.M.; Ponce, F.A.; Zhao, Y.J.; Fu, K.; Alugubelli, S.R.; Cheng, C.-Y.; et al. High Voltage Vertical GaN p−n Diodes with Hydrogen−Plasma Based Guard Rings. IEEE Electron Device Lett. 2020, 1, 127–130. [Google Scholar] [CrossRef]

- Driche, K.; Rugen, S.; Kaminski, N.; Umezawa, H.; Okumura, H.; Gheeraert, E. Electric field distribution using floating metal guard rings edge−termination for Schottky diodes. Diam. Relat. Mater. 2018, 82, 160–164. [Google Scholar] [CrossRef]

- Roy, S.; Bhattacharyya, A.; Krishnamoorthy, S. Design of a beta−Ga2O3 Schottky Barrier Diode With p−Type III−Nitride Guard Ring for Enhanced Breakdown. IEEE Trans. Electron Devices 2020, 11, 4842–4848. [Google Scholar] [CrossRef]

- Zhou, X.; Yue, R.; Zhang, J.; Dai, G.; Li, J.; Wang, Y. 4H−SiC Trench MOSFET with Floating/Grounded Junction Barrier−controlled Gate Structure. IEEE Trans. Electron Devices 2017, 11, 4568–4574. [Google Scholar] [CrossRef]

- Arbess, H.; Isoird, K.; Hamady, S.; Zerarka, M.; Planson, D. Original Field Plate to Decrease the Maximum Electric Field Peak for High−Voltage Diamond Schottky Diode. IEEE Trans. Electron Devices 2015, 9, 2945–2951. [Google Scholar] [CrossRef]

- Synopsys Inc. Synopsys TCAD Manuals. Available online: http://www.synopsys.com/products/tcad/tcad.html (accessed on 10 July 2022).

- Okuto, Y.; Crowell, C.R. Threshold energy effect on avalanche breakdown voltage in semiconductor junctions. Solid−State Electron. 1975, 18, 161–168. [Google Scholar] [CrossRef]

- Moscatelli, F.; Passeri, D.; Morozzi, A.; Mendicino, R.; Betta, G.F.D.; Bilei, G.M. Combined Bulk and Surface Radiation Damage Effects at Very High Fluences in Silicon Detectors: Measurements and TCAD Simulations. IEEE Trans. Nucl. Sci. 2016, 63, 2716–2723. [Google Scholar] [CrossRef]

- Oussalah, S.; Mekheldi, M.; Filali, W.; Garoudja, E. Multi−guard ring TCAD simulations for different n−on−p planar silicon particle detectors. J. Instrum. 2021, 16, P02034. [Google Scholar] [CrossRef]

- Abderrezak, B.; Maya, L.; Saida, L.; Gian-Franco, D.B. Compact border termination for active−edge planar radiation detectors with enhanced breakdown voltage. Micro Nano Lett. 2020, 13, 969–971. [Google Scholar]

- Joo, M.H.; Park, K.M.; Choi, W.Y.; Song, J.H.; Im, S. Enhancing the breakdown voltages of Au/n−Si Schottky diodes by boron ion beam−induced edge termination. Nucl. Instrum. Meth. B 2000, 168, 399–403. [Google Scholar] [CrossRef]

- Bortoletto, D.; Bolla, G.; Guenther, M.; Grim, G.P.; Lander, R.L.; Willard, S.; Li, Z. Radiation damage studies of multi−guard ring p−type bulk diodes. Nucl. Instrum. Meth. A 1999, 435, 178–186. [Google Scholar] [CrossRef]

- Li, H.-G.; Guo, P.; Yuan, A.-B. Highly sensitive NIR PtSi/Si−nanostructure detectors. Infrared Technol. Appl. Robot. Sens. Adv. Control 2016, 10157, 50–56. [Google Scholar] [CrossRef]

- Semendy, F.; Singh, S.; Litz, M.; Wijewarnasuriya, P.; Blaine, K.; Dhar, N. Front and back side processed unintentionally doped GaAs Schottky detectors for X−ray detection. Solid−State Electron. 2010, 54, 1–3. [Google Scholar] [CrossRef]

| Reference | Sample Name | Substrate Resistance (Ω·cm) | Breakdown Voltage (V) |

|---|---|---|---|

| This work | c-SSBD | >10 k | <400 V |

| Hybrid-SSBD | >1500 V | ||

| B.W. Liou [9] | Schottky barrier diodes | 10 | 148 |

| A.Boughedda [22] | Planar radiation detectors | >10 k | <700 V |

| M.H. Joo [23] | Au/n−Si Schottky diode | 1 | <400 V |

| D. Bortoletto [24] | Multi−guard ring p−type bulk diodes | >10 k | <1000 V |

| H. G. Li [25] | PtSi/Si−nanostructure detectors | 20–30 | 100 V |

| F. Semendy [26] | Si−GaAs Schottky detectors | 6.9 × 107 | <1000 V |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wang, B.; Jia, R.; Li, X.; Tao, K.; Luo, W.; Wang, L.; Chen, J. Simulation of Silicon Surface Barrier Detector with PN Junction Guard Rings to Improve the Breakdown Voltage. Micromachines 2022, 13, 1811. https://doi.org/10.3390/mi13111811

Wang B, Jia R, Li X, Tao K, Luo W, Wang L, Chen J. Simulation of Silicon Surface Barrier Detector with PN Junction Guard Rings to Improve the Breakdown Voltage. Micromachines. 2022; 13(11):1811. https://doi.org/10.3390/mi13111811

Chicago/Turabian StyleWang, Bolong, Rui Jia, Xing Li, Ke Tao, Wei Luo, Longjie Wang, and Jiawang Chen. 2022. "Simulation of Silicon Surface Barrier Detector with PN Junction Guard Rings to Improve the Breakdown Voltage" Micromachines 13, no. 11: 1811. https://doi.org/10.3390/mi13111811

APA StyleWang, B., Jia, R., Li, X., Tao, K., Luo, W., Wang, L., & Chen, J. (2022). Simulation of Silicon Surface Barrier Detector with PN Junction Guard Rings to Improve the Breakdown Voltage. Micromachines, 13(11), 1811. https://doi.org/10.3390/mi13111811