Theoretical Modeling Method for Material Removal Characteristics of Abrasive Water Jet Polishing under Rotating Oblique Incidence

Abstract

1. Introduction

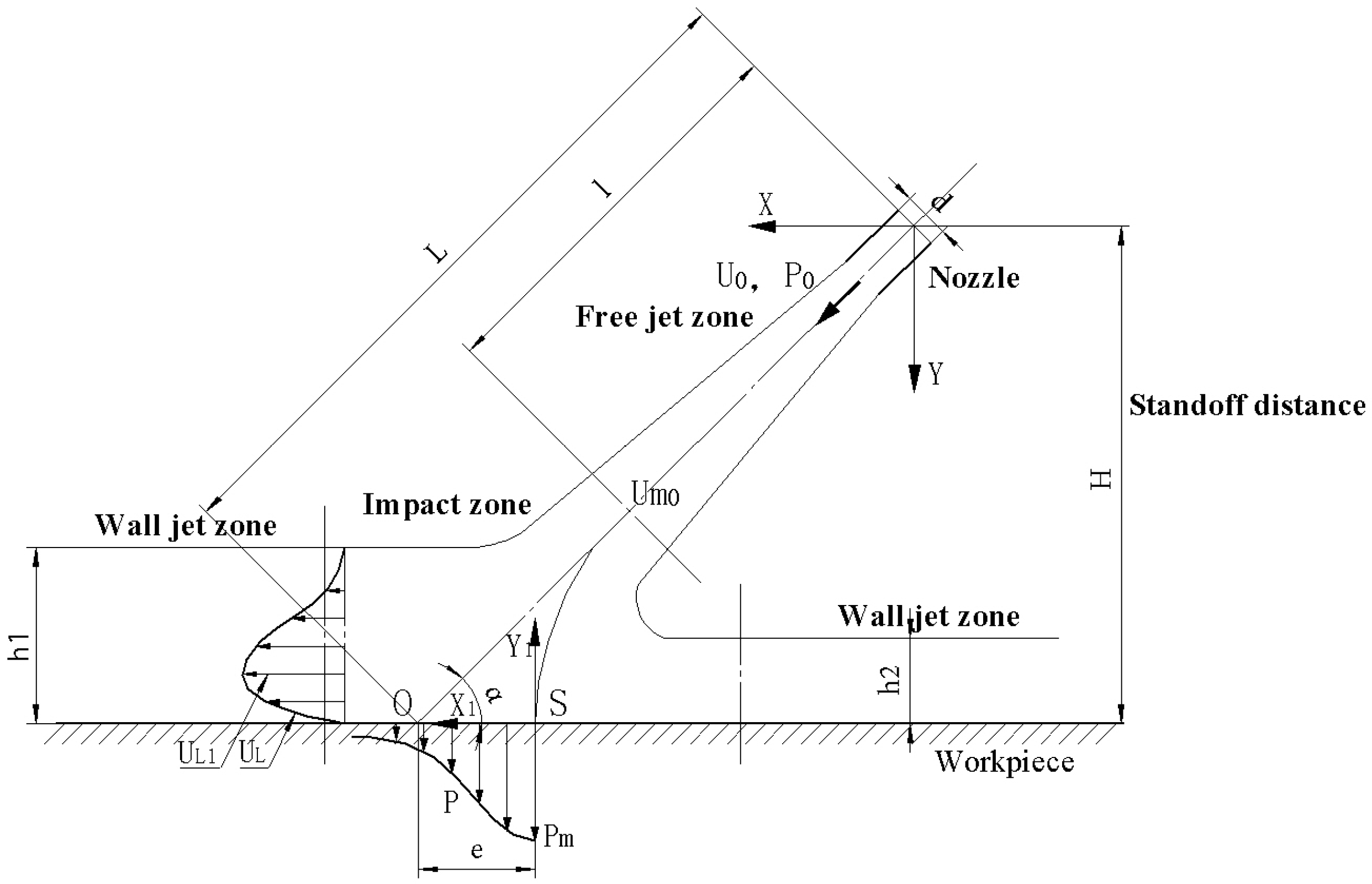

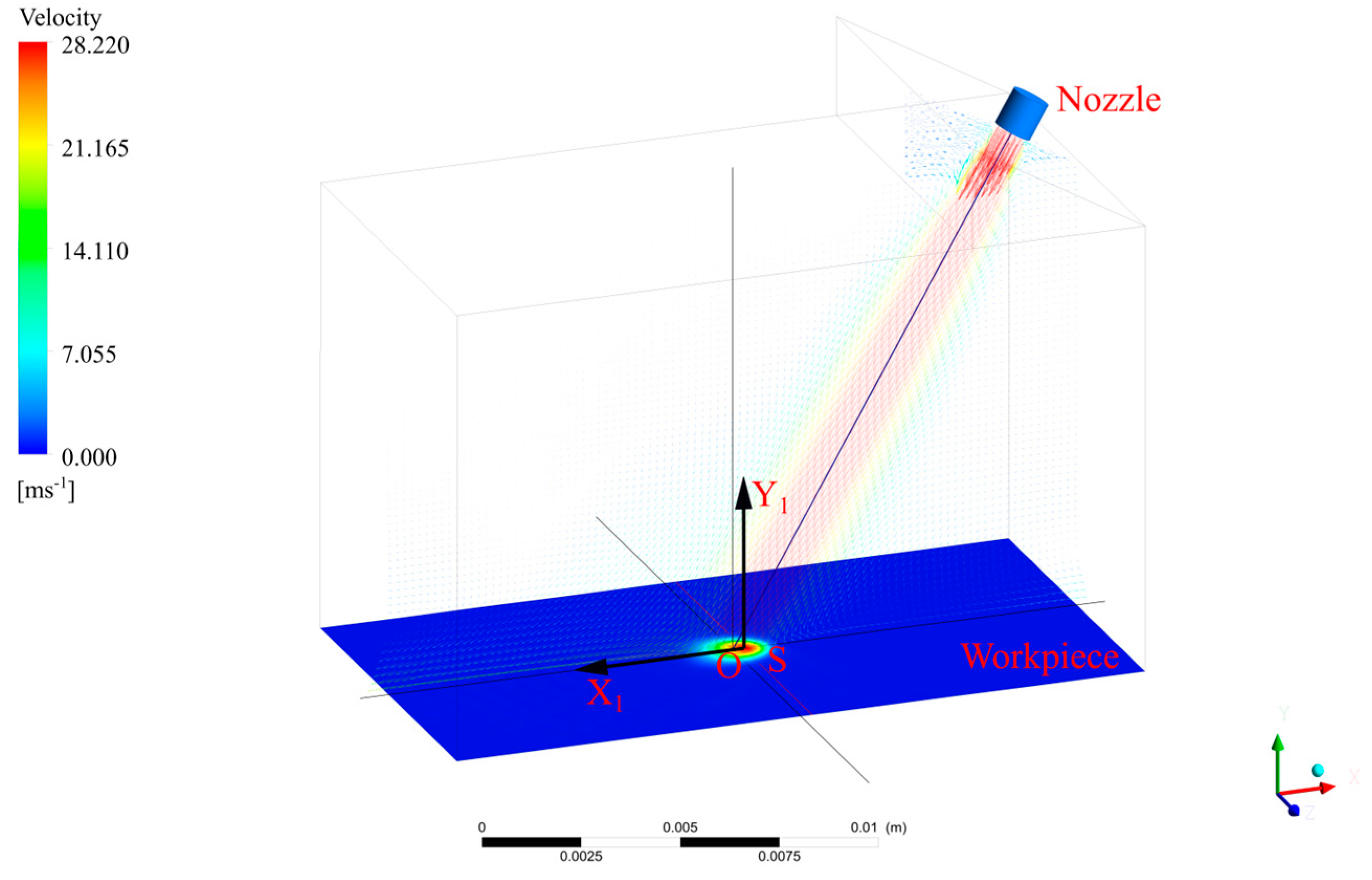

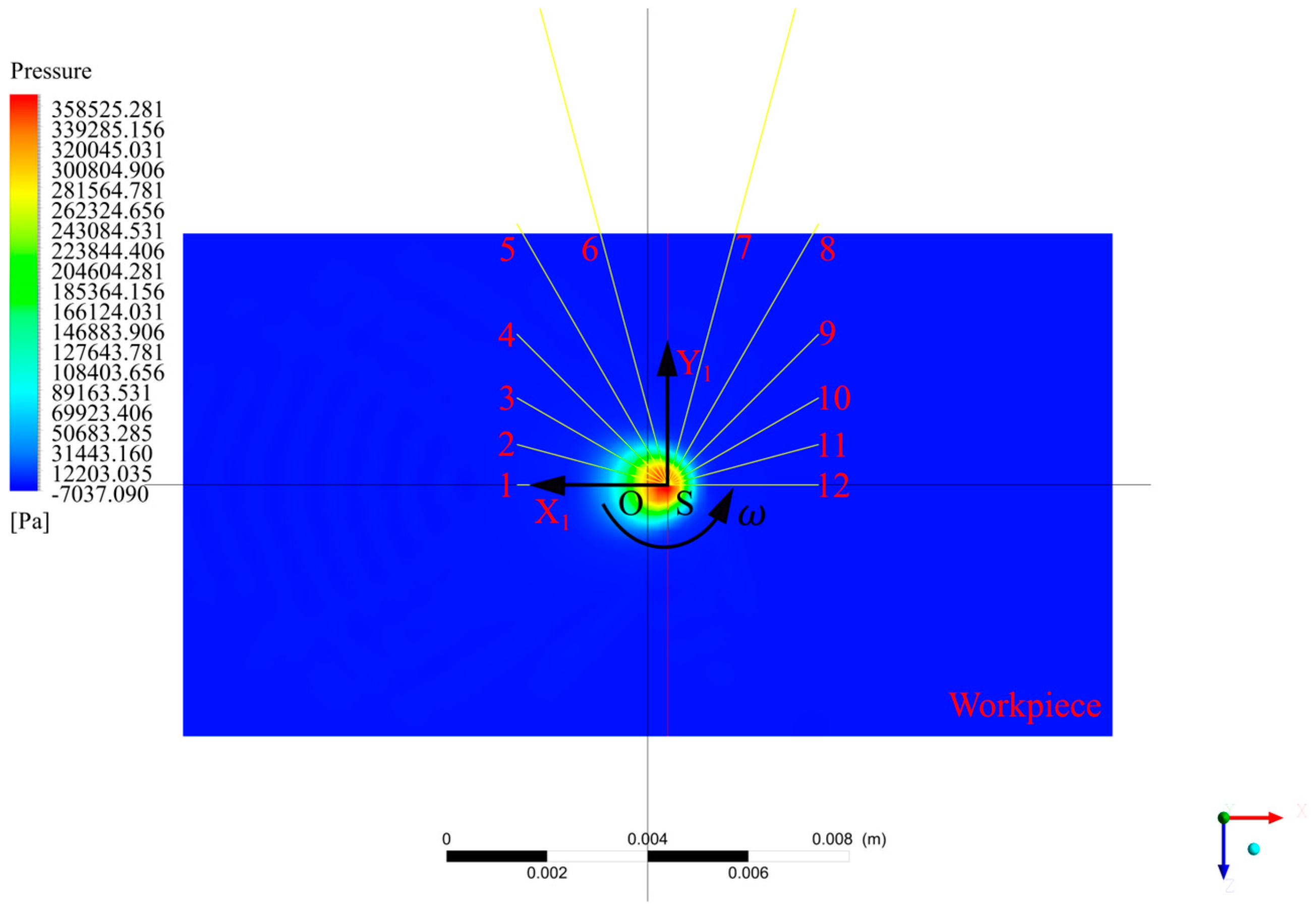

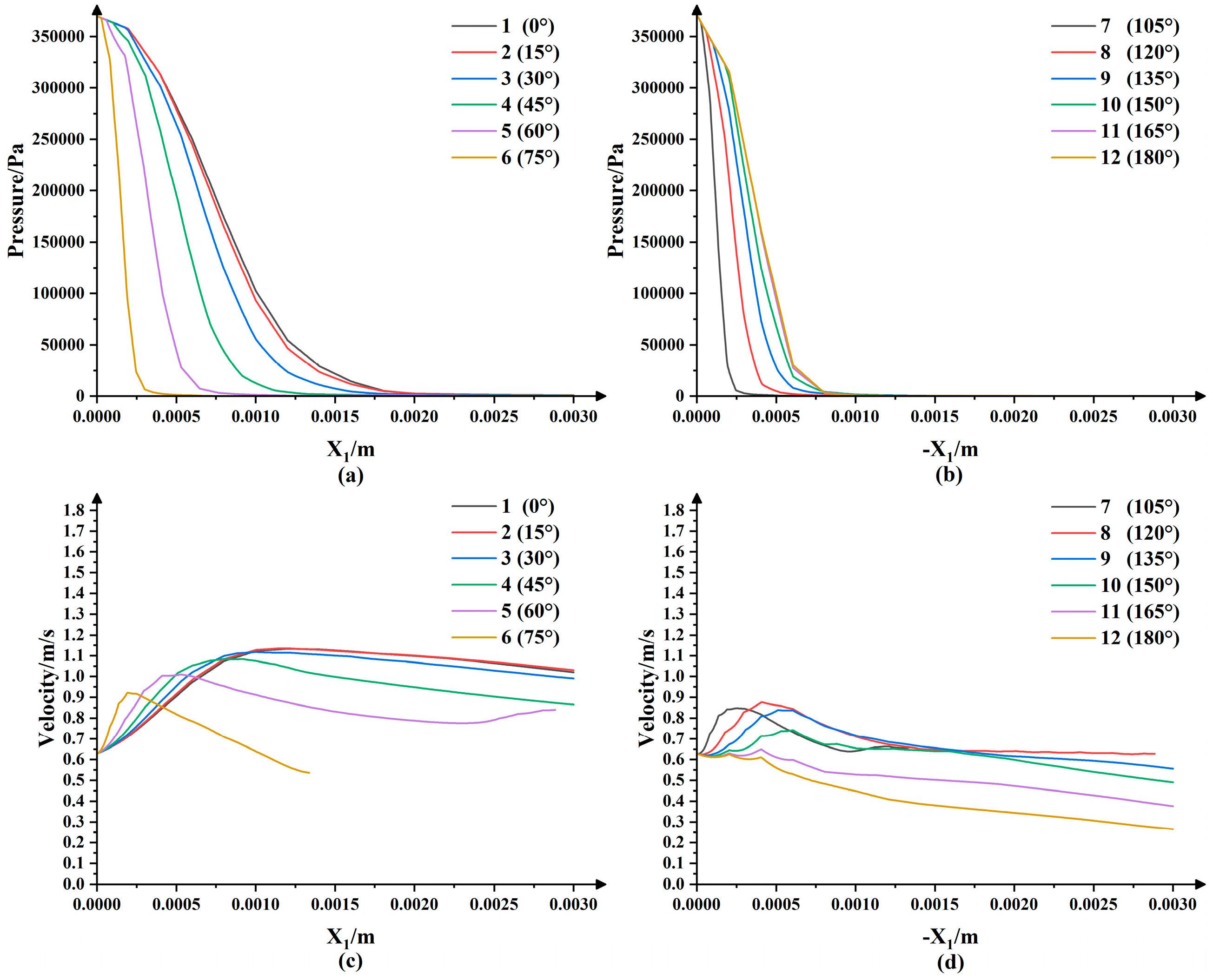

2. Theoretical TIF Modeling

2.1. Calculation of Material Removal Rate in a Single Abrasive Collision Process

- (1)

- Assume that the abrasive shape is spherical, its hardness is greater than the hardness of the workpiece and the deformation of the abrasive shape after the collision with the workpiece is negligible;

- (2)

- Assume that the abrasive particles are not embedded into the workpiece surface after collision but leave the workpiece at a certain speed;

- (3)

- Assume that the slurry medium is uniform;

- (4)

- Assume that there is no energy exchange between the abrasive particles.

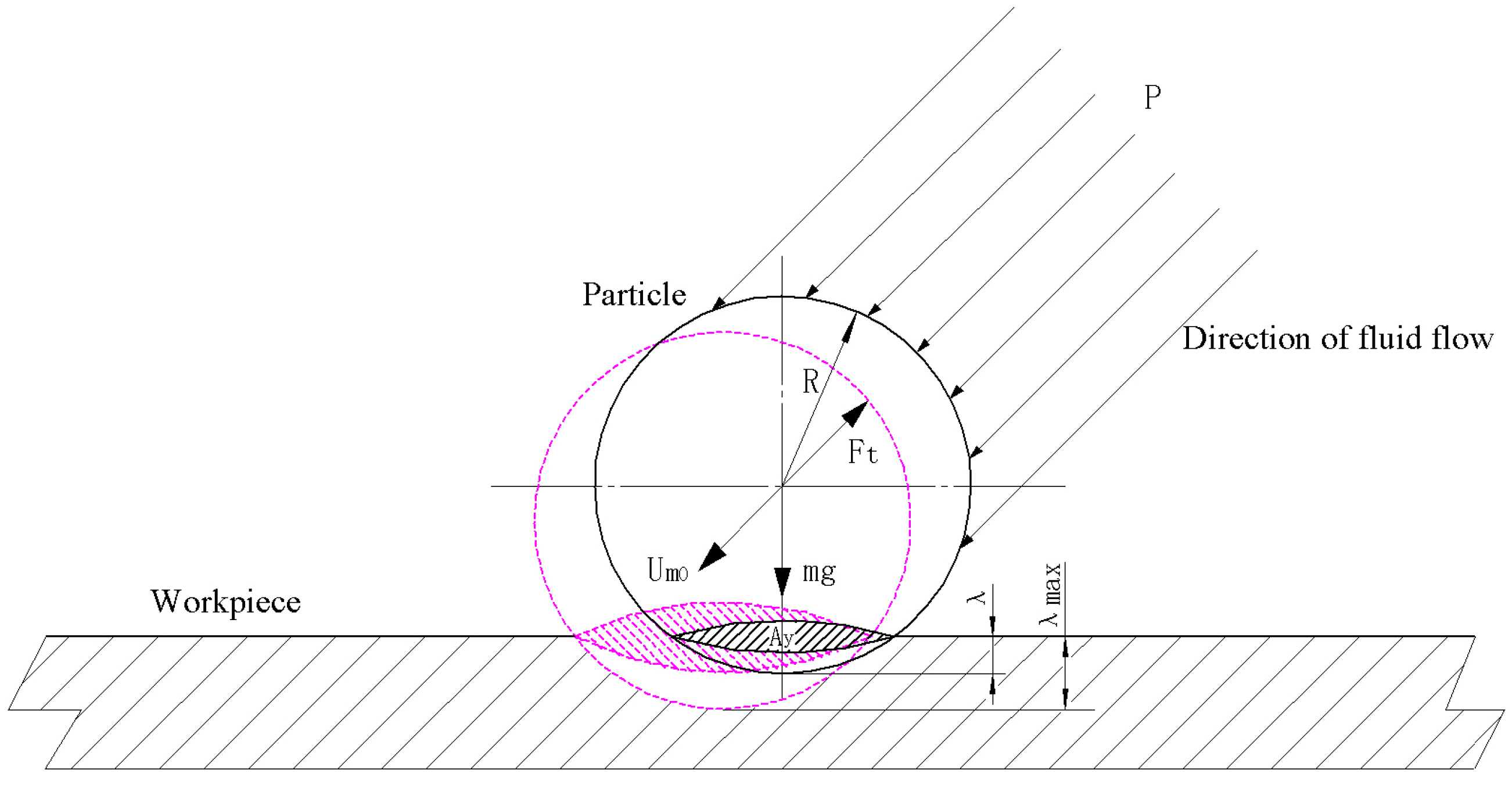

2.1.1. Calculation of Normal Material Removal Rate

Maximum Indentation Depth Caused by a Single Abrasive Particle during Collision

Material Removal Rate in the Normal Direction for a Single Abrasive Collision

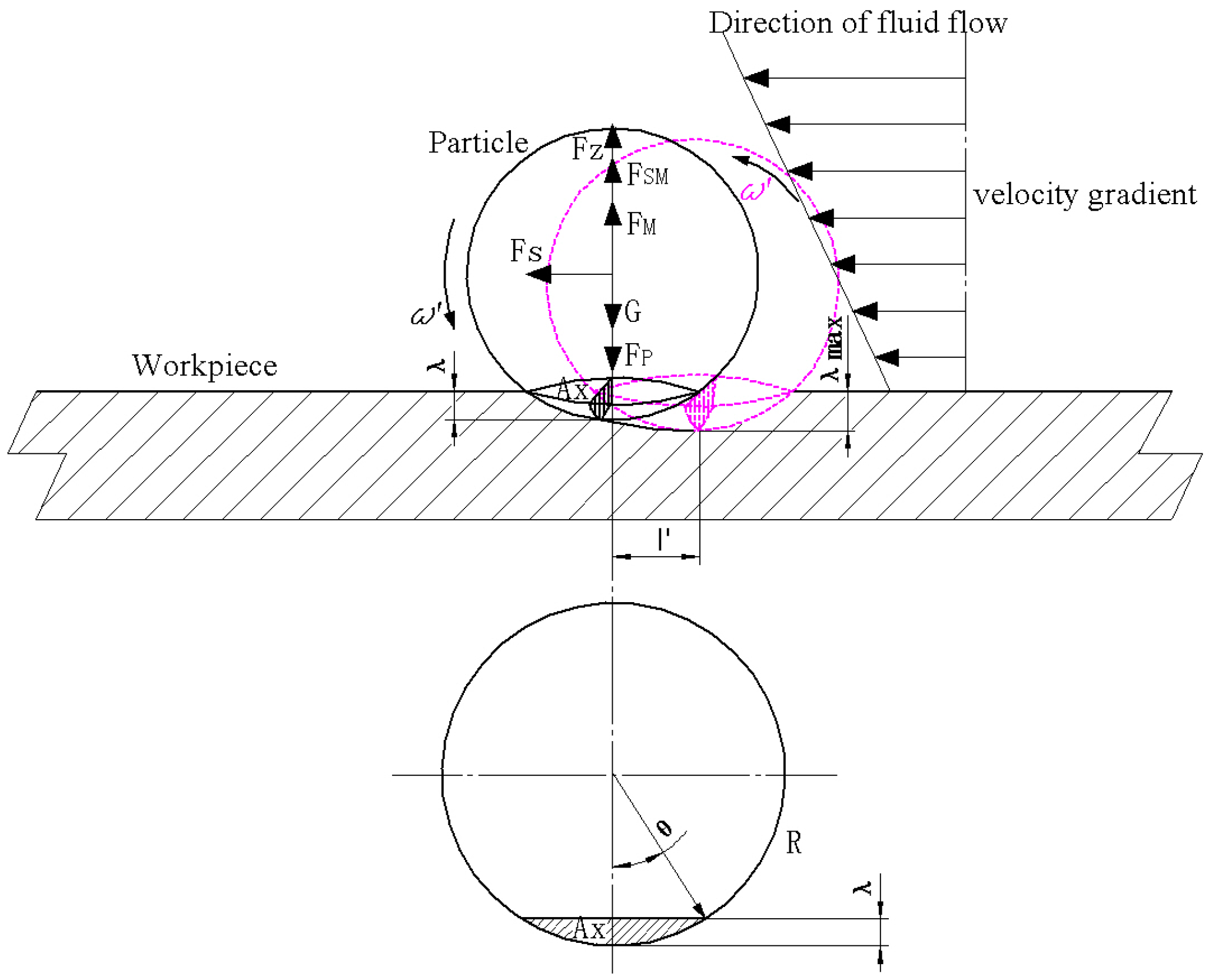

2.1.2. Calculation of Tangential Material Removal Rate

2.2. The Number of Abrasive Particles Colliding with a Workpiece Surface per Unit Time and Area

2.3. Distribution of Shear Stress on Workpiece Surfaces

3. Experimental Verification and Discussion

4. Conclusions

- (1)

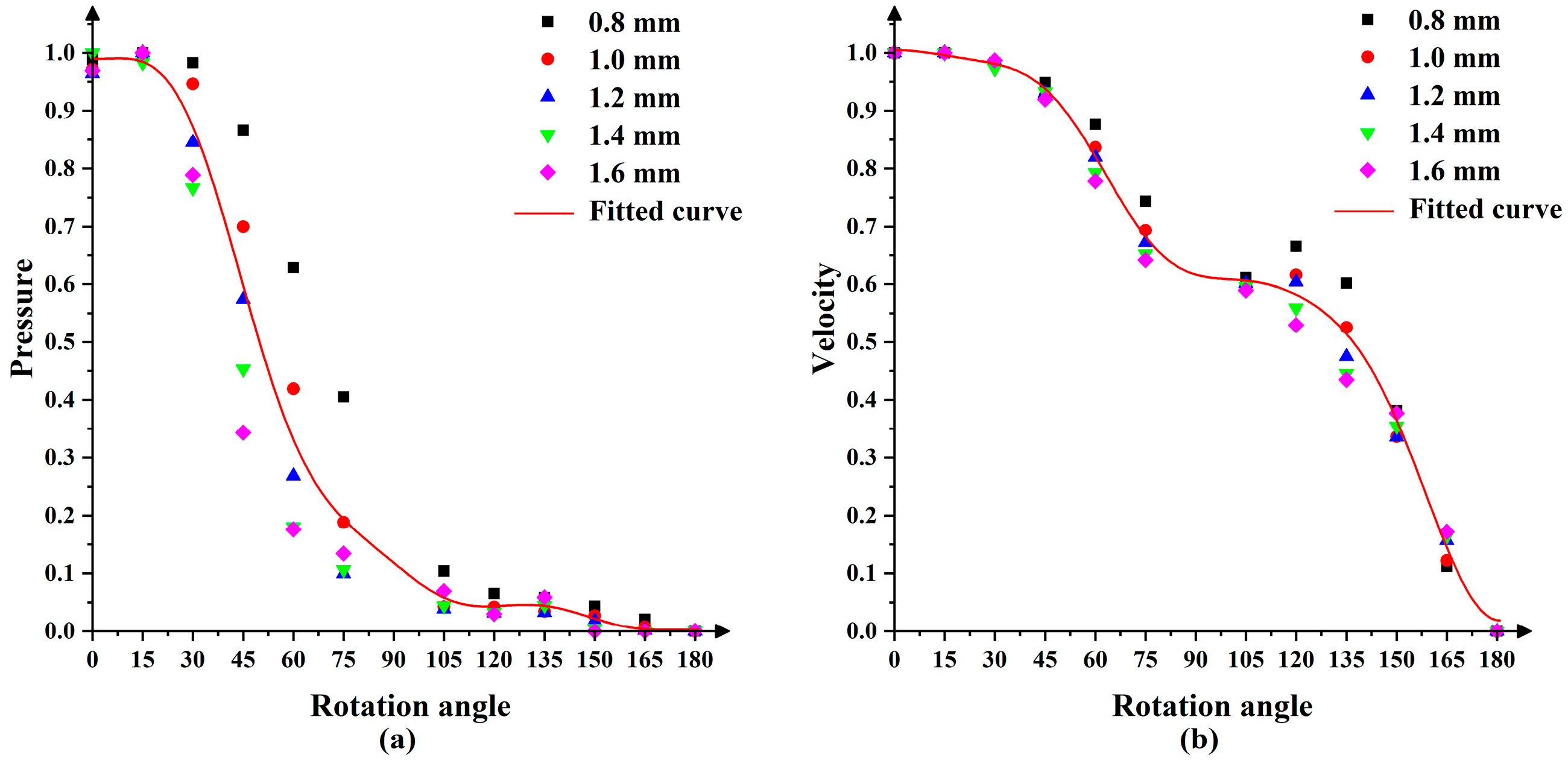

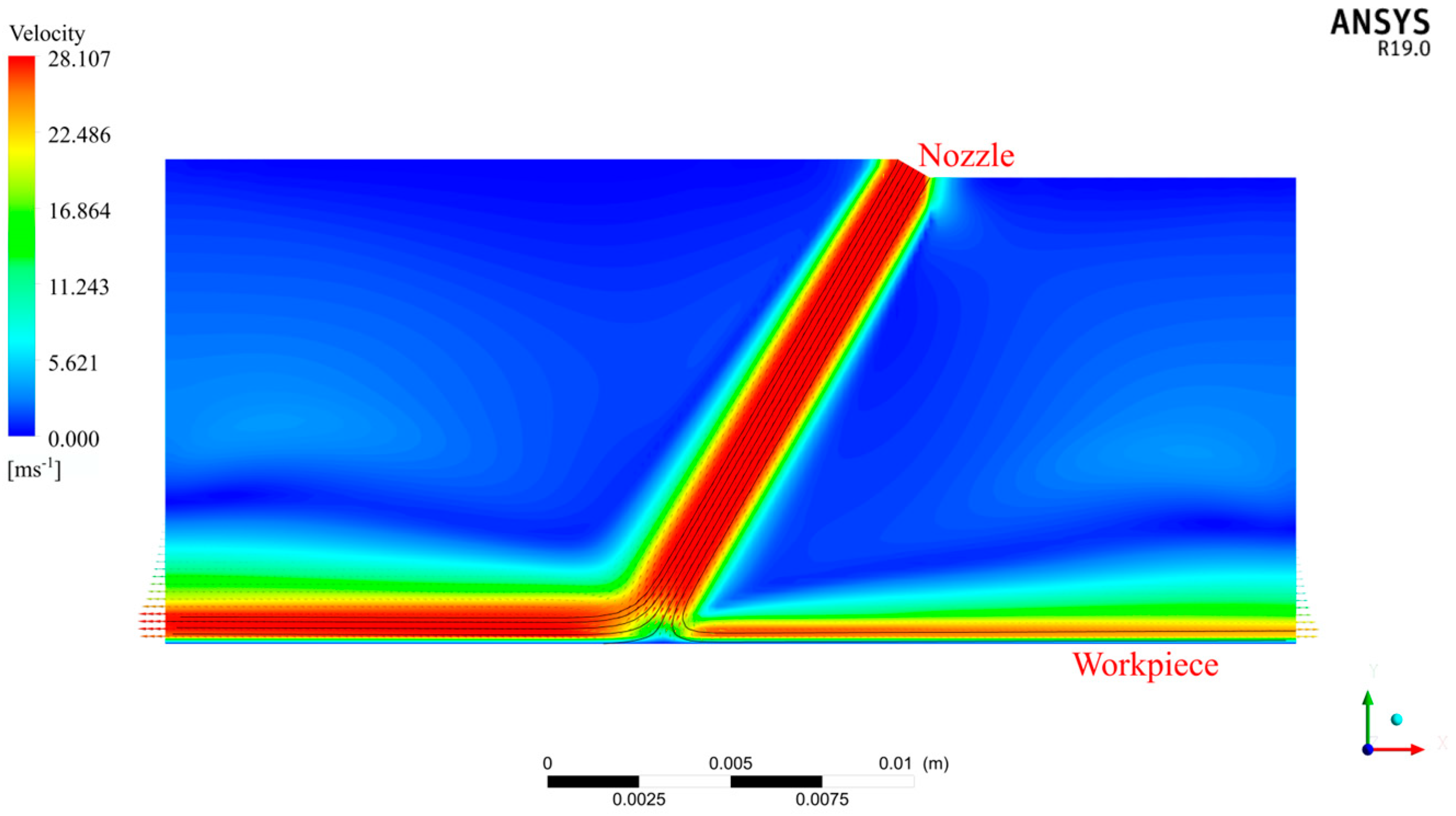

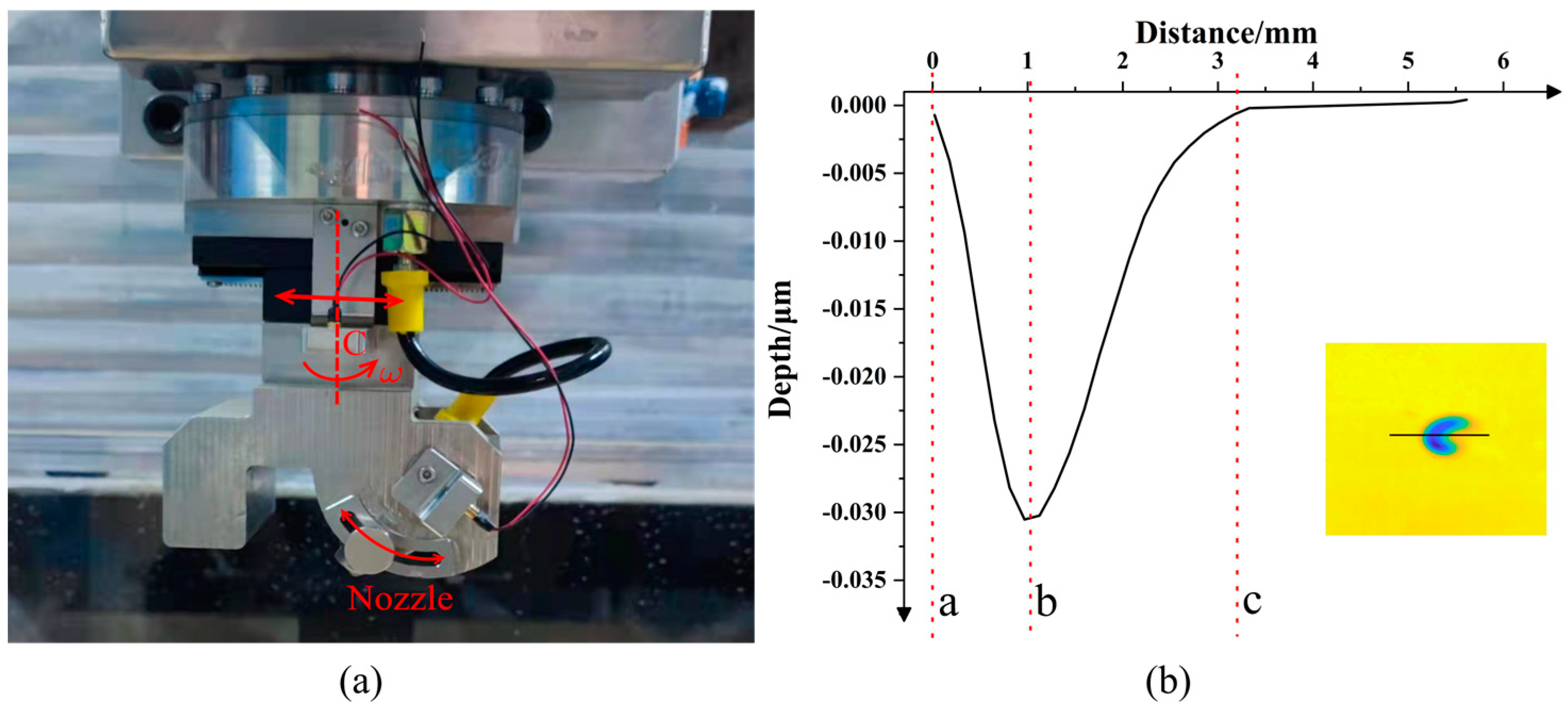

- By using FLUENT simulation software to analyze the velocity and pressure distributions on a workpiece surface when a nozzle was at rest and under oblique incidence processing, the variation rule for time when the nozzle rotated at a certain angular velocity could be obtained, according to the symmetry of the distribution. At the same time, by discretizing the time and distance, the material removal depth at any position and any time in the impact zone could also be quantitatively analyzed.

- (2)

- By comparing and analyzing experimental TIF curves and theoretical TIF curves, it was verified that the model could effectively predict the contours of the TIF and the maximum material removal depth obtained when the nozzle was under the condition of rotating oblique incidence. It is worth noting that there were certain deviations between the theoretical TIF curves and the experimental TIF curves, which might have been caused by fluctuations in slurry pressure, the instability of the slurry concentration and abrasive uniformity or the tilt of the workpiece surface, among other options.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Jiang, X.W.; Long, X.W.; Tan, Z.Q. A Review of Material Removal Mechanism in Ultra-Precision Polishing of Optical Glass. Chin. J. Lasers 2021, 48, 236–253. [Google Scholar]

- Prabhat, K.B.; Khushwant, S.G.; Gufran, S.K.; Raj, K. Line contact ring magnetorheological finishing process polishing of optics. Appl. Opt. 2022, 61, 2582–2590. [Google Scholar]

- Bauer, J.; Frost, F.; Lehmann, A.; Ulitschka, M.; Yaguo, L.; Arnold, T. Finishing of metal by ion beam technologies. Opt. Eng. 2019, 58, 092612. [Google Scholar] [CrossRef]

- Takahiro, H.; Yoshinori, T.; Hidekazu, M. Machining Property in Smoothing of Steeply Curved Surfaces by Elastic Emission Machining. Procedia CIRP 2014, 13, 198–202. [Google Scholar]

- Fahnle, O.W.; Brug, H.V.; Frankena, H.J. Fluid jet polishing of optical surfaces. Appl. Opt. 1998, 37, 6771–6773. [Google Scholar] [CrossRef]

- Fang, H.; Guo, P.J.; Yu, J.C. Research on material removal mechanism of fluid jet polishing. Opt. Tech. 2004, 248–251. [Google Scholar] [CrossRef]

- Lin, L.; He, Z.W.; Hu, T.; You, H. Review on Technology of Abrasive Water Jet Polishing. Chin. Hydraul. Pneum. 2022, 46, 74–91. [Google Scholar]

- Messelink, W.A.C.M.; Faehnle, O.W. Exploiting the Process Stability of Fluid Jet Polishing. In Optical Fabrication and Testing; Rochester: New York, NY, USA, 2008. [Google Scholar]

- Booij, S.M. Fluid Jet Polishing: Possibilities and Limitations of a New Fabrication Technique. Ph.D. Thesis, Technical University of Delft, Delft, The Netherlands, 2003. [Google Scholar]

- Cao, Z.; Cheung, C.F. Theoretical modelling and analysis of the material removal characteristics in fluid jet polishing. Int. J. Mech. Sci. 2014, 89, 158–166. [Google Scholar] [CrossRef]

- Lü, L.; Ma, P.; Zhu, H.; Huang, J.Y.; Wang, G. Effect of Material Removal Function on Surface Shape Error Correction in Fluid Jet Polishing. Chin. J. Lasers 2016, 43, 245–252. [Google Scholar]

- Horiuchi, O.; Ikeno, J.; Shibutani, H.; Suzuki, H.; Mizukami, Y. Nano-abrasion machining of brittle materials and its application to corrective figuring. Precis. Eng. 2007, 31, 47–54. [Google Scholar] [CrossRef]

- Fang, H.; Guo, P.J.; Yu, J.C. Optimization of the material removal in fluid jet polishing. Opt. Eng. 2006, 45, 053401. [Google Scholar] [CrossRef]

- Wang, T.; Cheng, H.B.; Dong, Z.C.; Tam, H.Y. Removal character of vertical jet polishing with eccentric rotation motion using magnetorheological fluid. J. Mater. Process Tech. 2013, 213, 1532–1537. [Google Scholar] [CrossRef]

- Peng, W.Q.; Yin, S.H. Material Removal Optimization of Jet Polishing Based on Slit Nozzle. Aviat. Precis. Manuf. Technol. 2019, 55, 1–4. [Google Scholar]

- Li, Z.Z. Study on Abrasive Jet Polishing Technology. Ph.D. Thesis, National University of Defense Technology, Changsha, China, 2011. [Google Scholar]

- Li, J.; Zhang, L.X.; Sun, P.F.; Wang, Z.Y.; Ke, R. Fast Generation Method of Gaussian-Shaped Removal Function of Fluid Jet Polishing. Acta Opt. Sin. 2018, 38, 272–280. [Google Scholar]

- Wang, Z.Y.; Zhang, L.X.; Sun, P.F.; Li, J.; Yin, C.Z. Mathematical Modeling Method for Generation of Gaussian-Type Removal Function in Fluid Jet Polishing. Acta Opt. Sin. 2018, 38, 302–309. [Google Scholar]

- Zhou, S.Z. Numerical Modeling and Experimental Research on Removal Characteristics in Multi-Nozzle Abrasive Water Jet. Master’s Thesis, Hunan University, Changsha, China, 2020. [Google Scholar]

- Wang, C.J.; Cheung, C.F.; Liu, M.Y. Numerical modeling and experimentation of three dimensional material removal characteristics in fluid jet polishing. Int. J. Mech. Sci. 2017, 133, 568–577. [Google Scholar] [CrossRef]

- Christina, S.; Kent, P.; Maria, L.; Anders, J. Fluid jet polishing of planar flat glass surfaces and within holes. Glass Technol. Eur. J. Glass Sci. Technol. A 2014, 55, 49–54. [Google Scholar]

- Preston, F. The theory and design of plate glass polishing machines. J. Soc. Glass Technol. 1927, 9, 214–256. [Google Scholar]

- Zhou, Y.; Liang, D.P. Study on the Theoretic Model of Ultrasonic Polishing. China Mech. Eng. 2005, 16, 664–666. [Google Scholar]

- Dong, Z.Y. Jet Mechanics, 1st ed.; Science Press: Beijing, China, 2005; pp. 33–83. [Google Scholar]

- Luo, Y.C.; Li, X.L.; Zhang, Y.; Zhang, R.Z.; Yang, L.M. Analysis of flow field characteristics in fluid jet polishing. Opt. Tech. 2014, 40, 376–380. [Google Scholar]

- Shi, C.Y.; Yuan, J.H.; Wu, F.; Wan, Y.J. Influence of standoff distance on material removal function in fluid jet polishing. Infrared Laser Eng. 2011, 40, 685–689. [Google Scholar]

- Peng, W.Q. Study on the Key Technology of Ultrasmooth Surface Fabrication Based on the Material Removal in Elastic mode. Ph.D. Thesis, National University of Defense Technology, Changsha, China, 2014. [Google Scholar]

- Zou, Z.L. Study on Mechanism of abrasive water jet cutting coal and rock. COAL 1996, 2, 51–53. [Google Scholar]

- Hutchings, I.M. A model for the erosion of metals by spherical particles at normal incidence. WEAR 1980, 70, 269–281. [Google Scholar] [CrossRef]

- Guo, J.L. Two Phase Flow & Multiphase Flow Mechanics, 1st ed.; Xi’an Jiaotong University Press: Xi’an, China, 2002; pp. 340–360. [Google Scholar]

- Wang, M.B.; Wang, R.H. Analysis of forces acting on abrasive particles in abrasive water jet. J. China Univ. Pet. 2006, 30, 47–49+74. [Google Scholar]

- Shi, C.Y. Study on Key Problems of Fluid Jet Polishing. Ph.D. Thesis, University of Chinese Academy of Sciences, Beijing, China, 2011. [Google Scholar]

- Feng, J.M. Fluid Mechanics, 1st ed.; Huazhong University of science and Technology Press: Wuhan, China, 2010; pp. 140–163. [Google Scholar]

- Mi, S.G.; Luo, Y.C.; Li, F.Y.; Zhang, R.Z. Analysis of jet velocity and impinging angle on material removal characteristic in fluid jet polishing. Opt. Tech. 2016, 42, 161–165. [Google Scholar]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhang, Z.; Song, C.; Shi, F.; Tie, G.; Zhang, W.; Wang, B.; Tian, Y.; Hou, Z. Theoretical Modeling Method for Material Removal Characteristics of Abrasive Water Jet Polishing under Rotating Oblique Incidence. Micromachines 2022, 13, 1690. https://doi.org/10.3390/mi13101690

Zhang Z, Song C, Shi F, Tie G, Zhang W, Wang B, Tian Y, Hou Z. Theoretical Modeling Method for Material Removal Characteristics of Abrasive Water Jet Polishing under Rotating Oblique Incidence. Micromachines. 2022; 13(10):1690. https://doi.org/10.3390/mi13101690

Chicago/Turabian StyleZhang, Zhiqiang, Ci Song, Feng Shi, Guipeng Tie, Wanli Zhang, Bo Wang, Ye Tian, and Zhanqiang Hou. 2022. "Theoretical Modeling Method for Material Removal Characteristics of Abrasive Water Jet Polishing under Rotating Oblique Incidence" Micromachines 13, no. 10: 1690. https://doi.org/10.3390/mi13101690

APA StyleZhang, Z., Song, C., Shi, F., Tie, G., Zhang, W., Wang, B., Tian, Y., & Hou, Z. (2022). Theoretical Modeling Method for Material Removal Characteristics of Abrasive Water Jet Polishing under Rotating Oblique Incidence. Micromachines, 13(10), 1690. https://doi.org/10.3390/mi13101690