Sensitivity Analysis of a Portable Wireless PCB-MEMS Permittivity Sensor Node for Non-Invasive Liquid Recognition

Abstract

1. Introduction

2. Materials and Methods

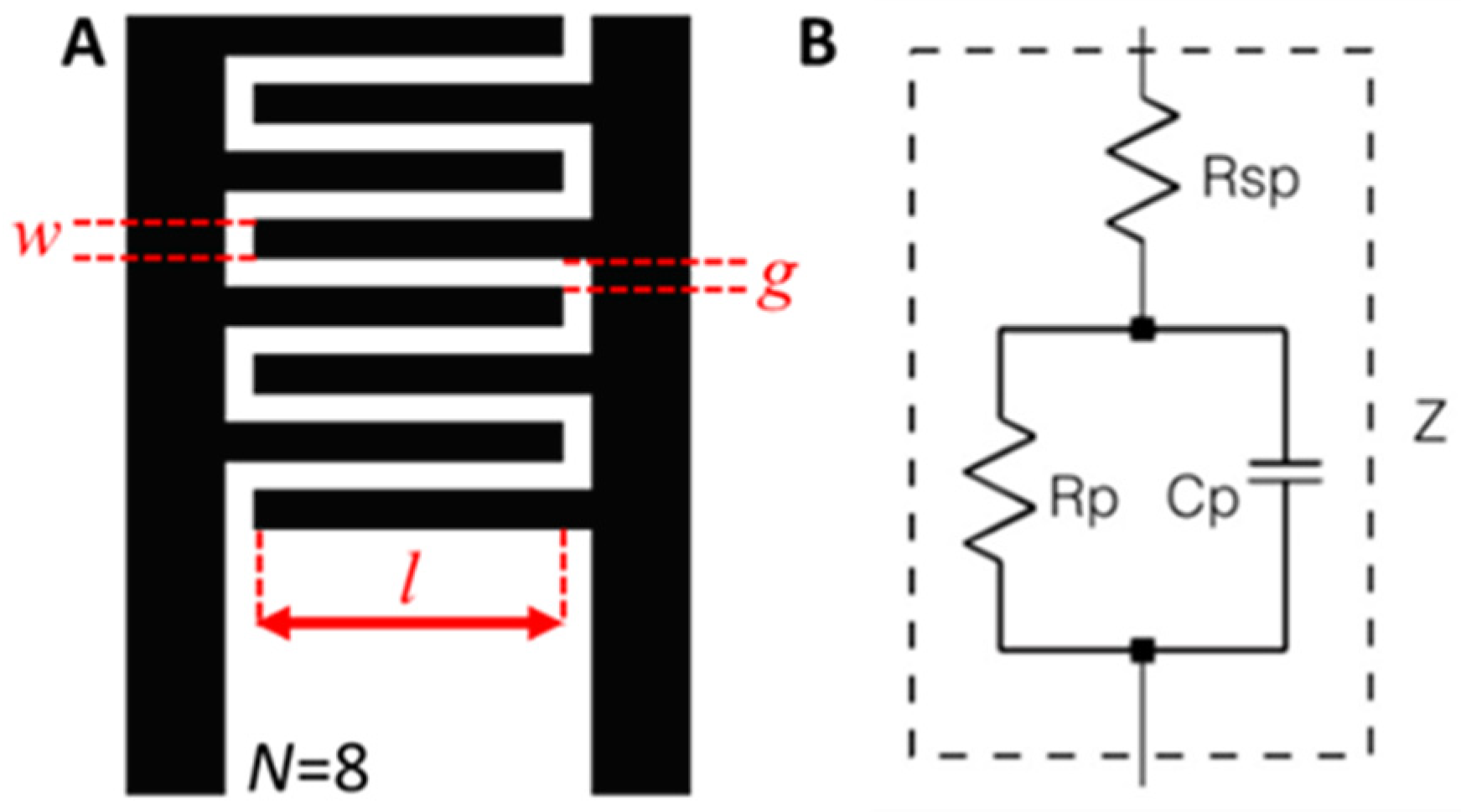

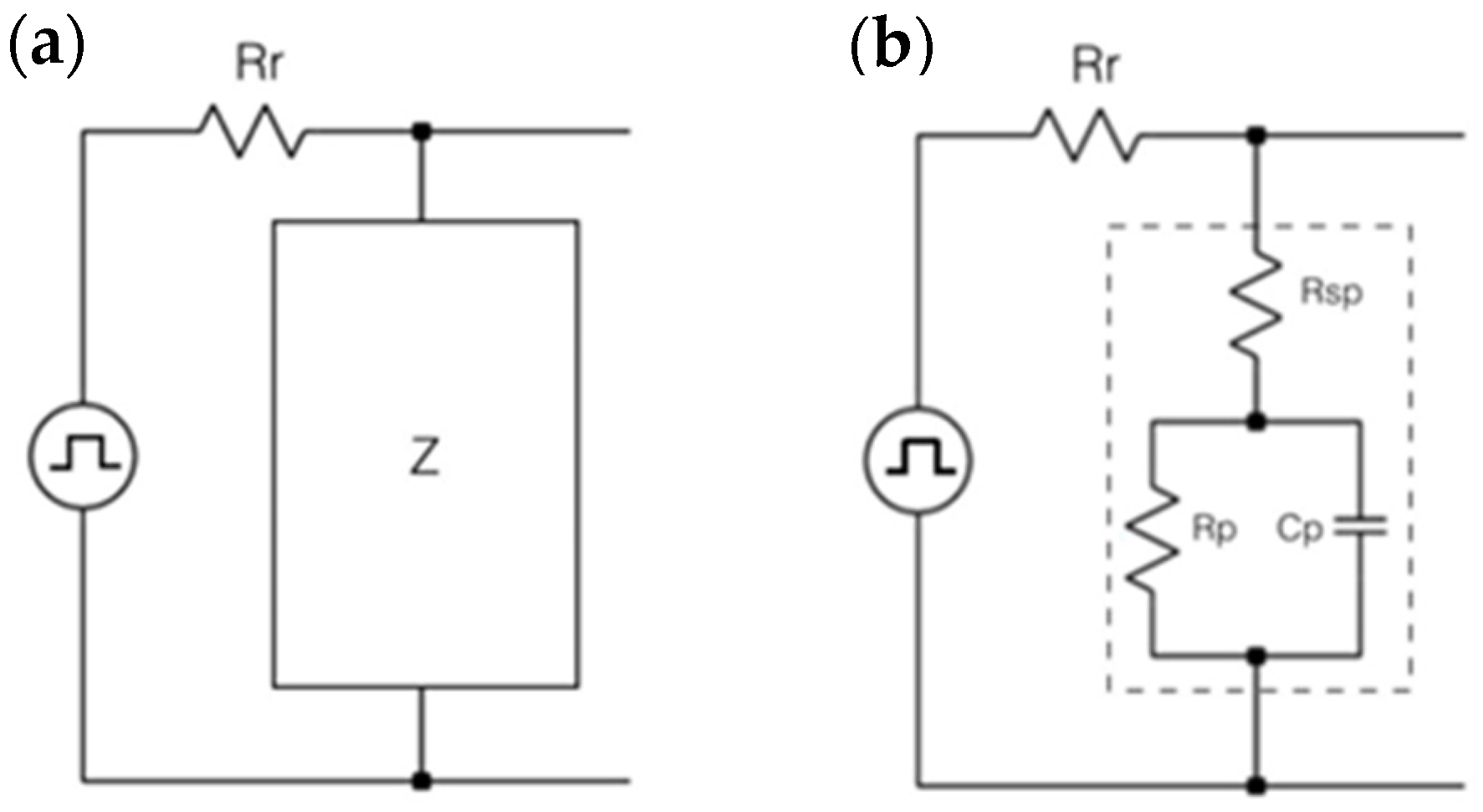

2.1. Transducer

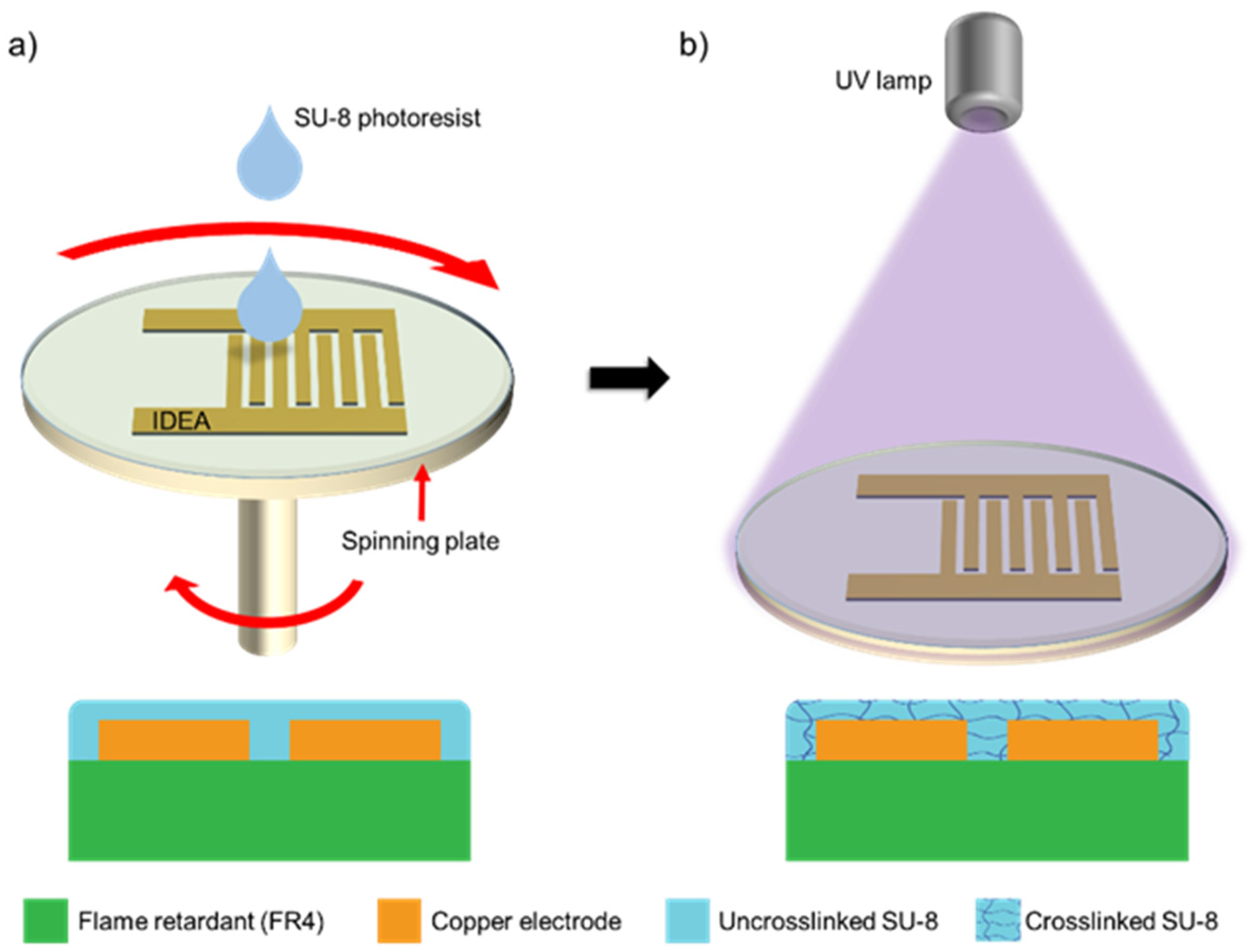

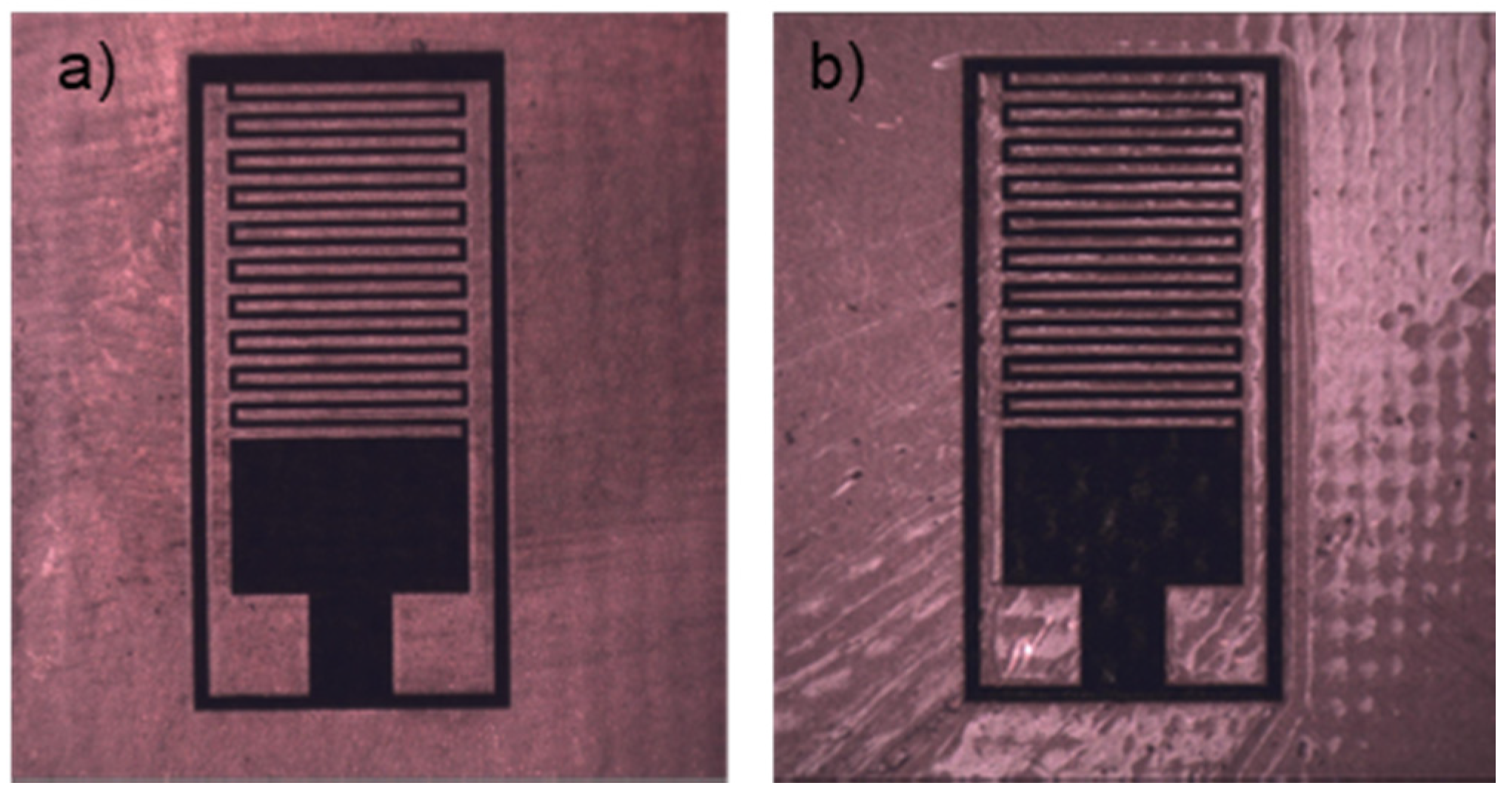

2.2. Fabrication Process

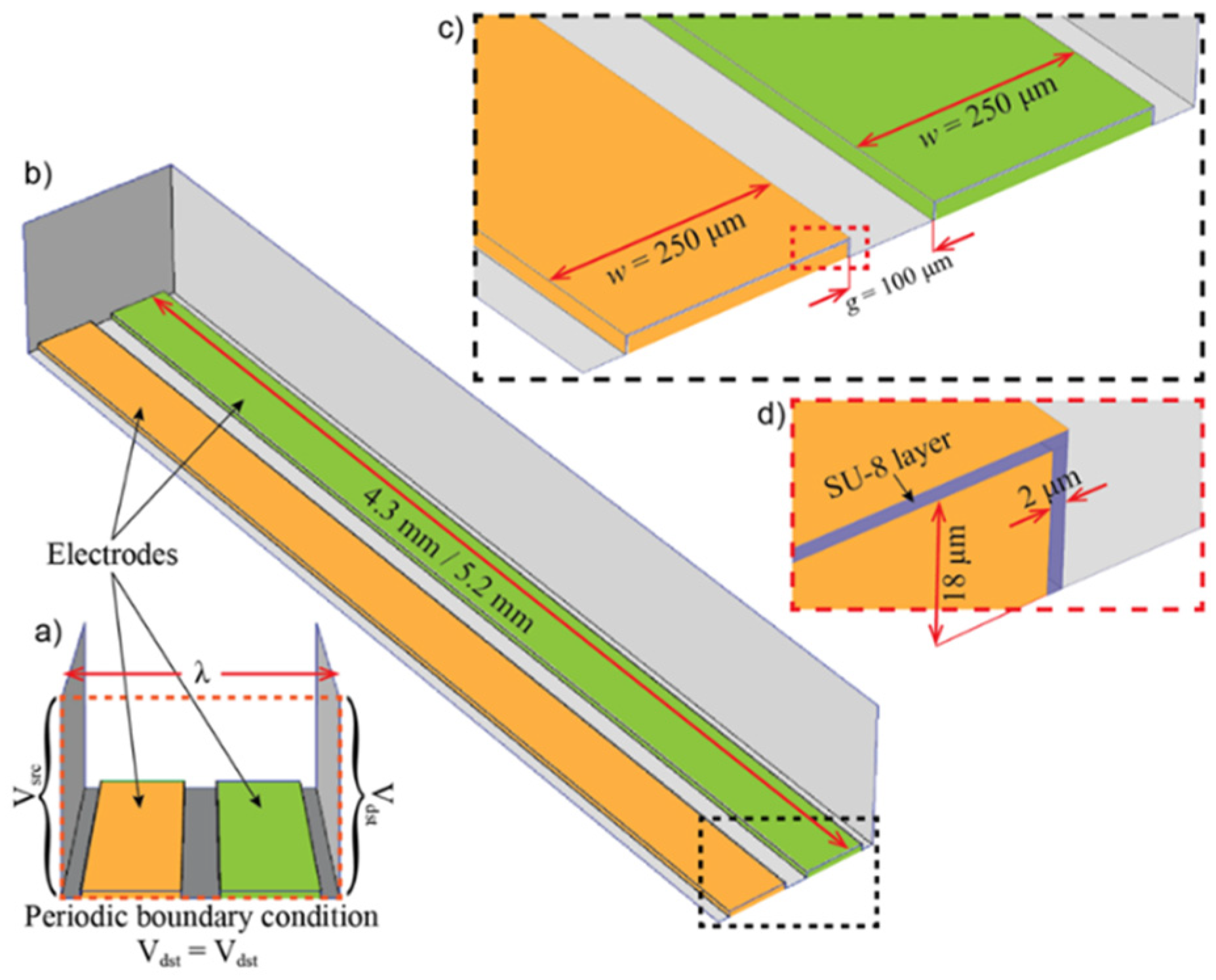

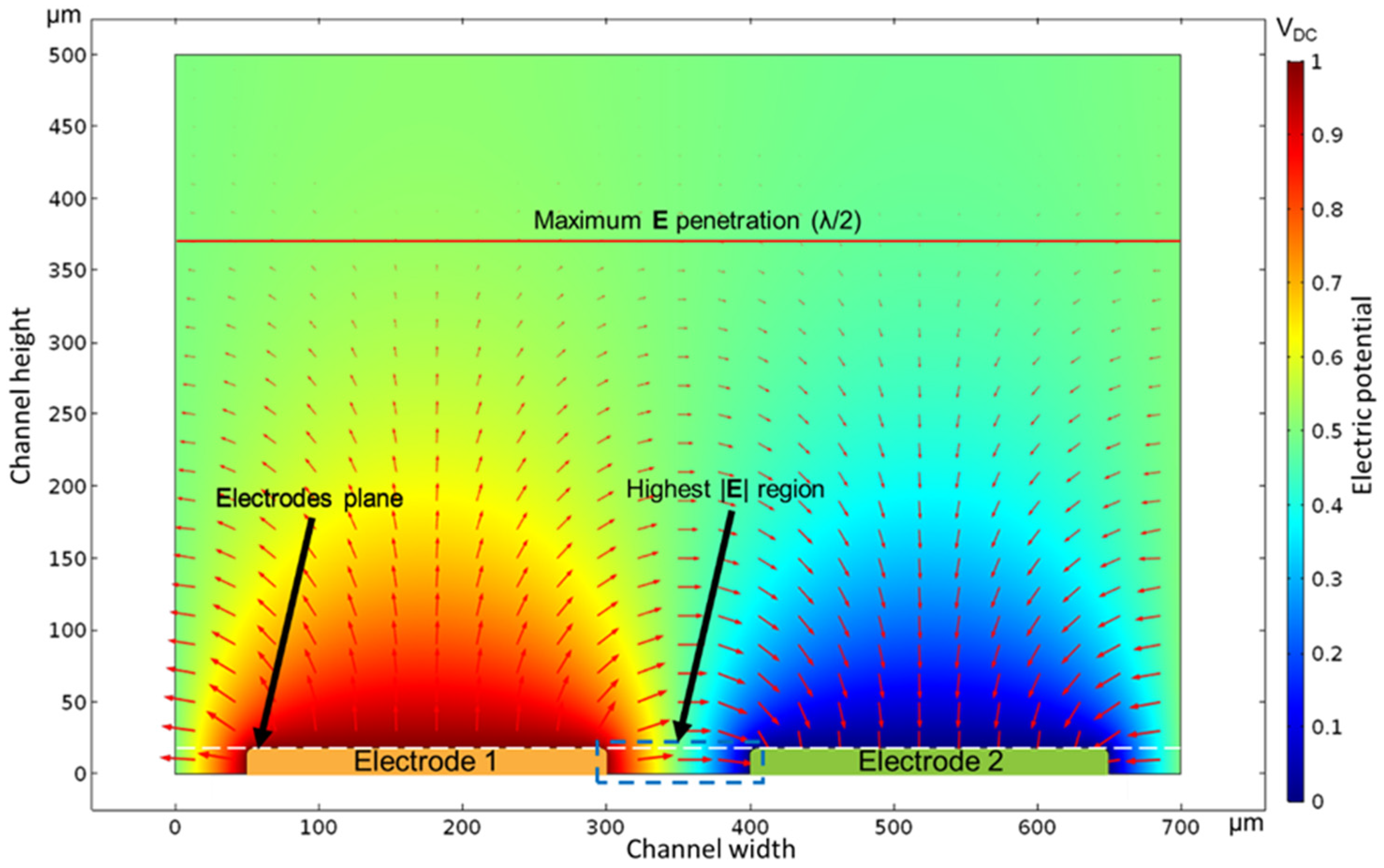

2.3. Finite Element Analysis

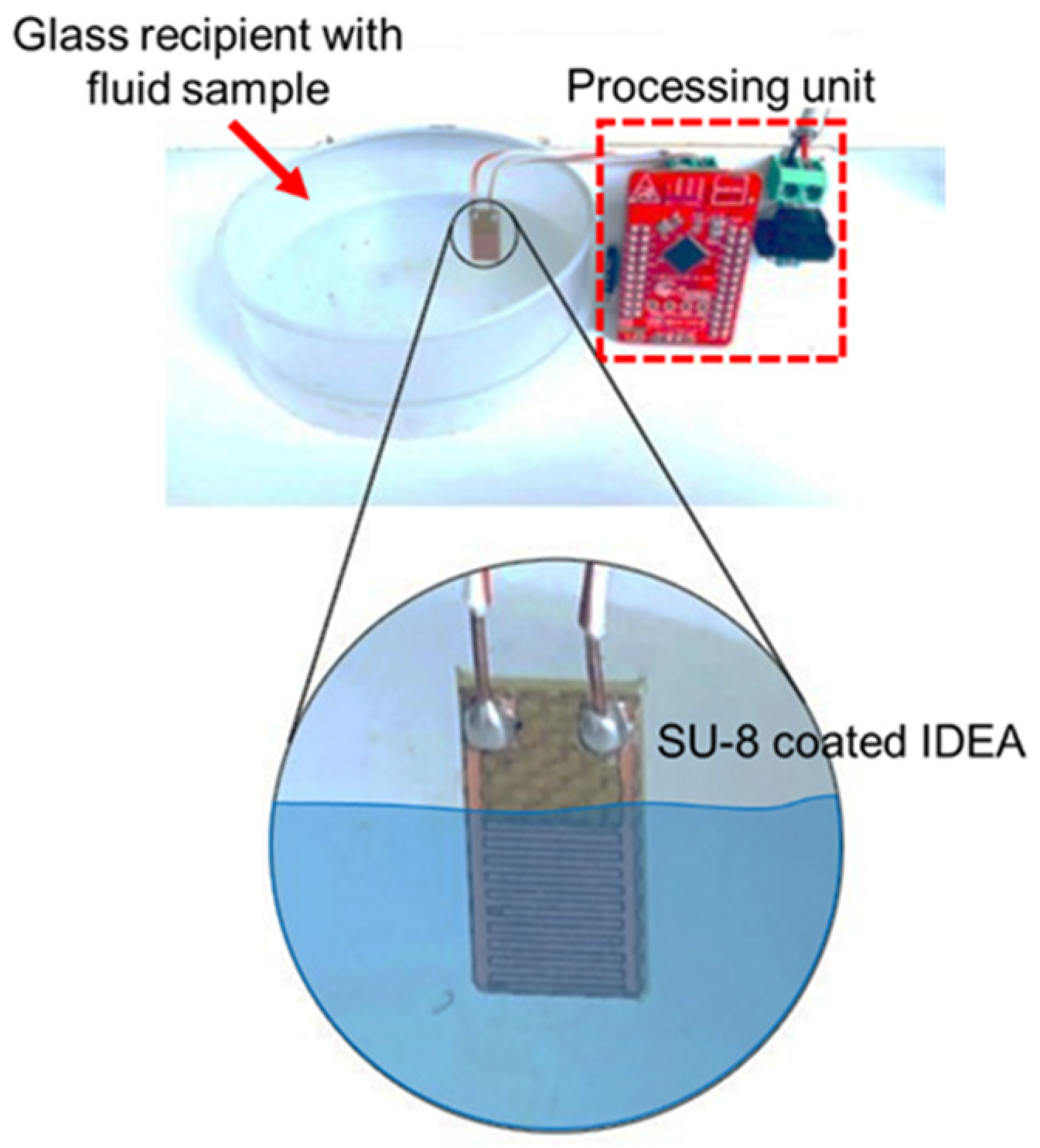

2.4. Experimental Setup

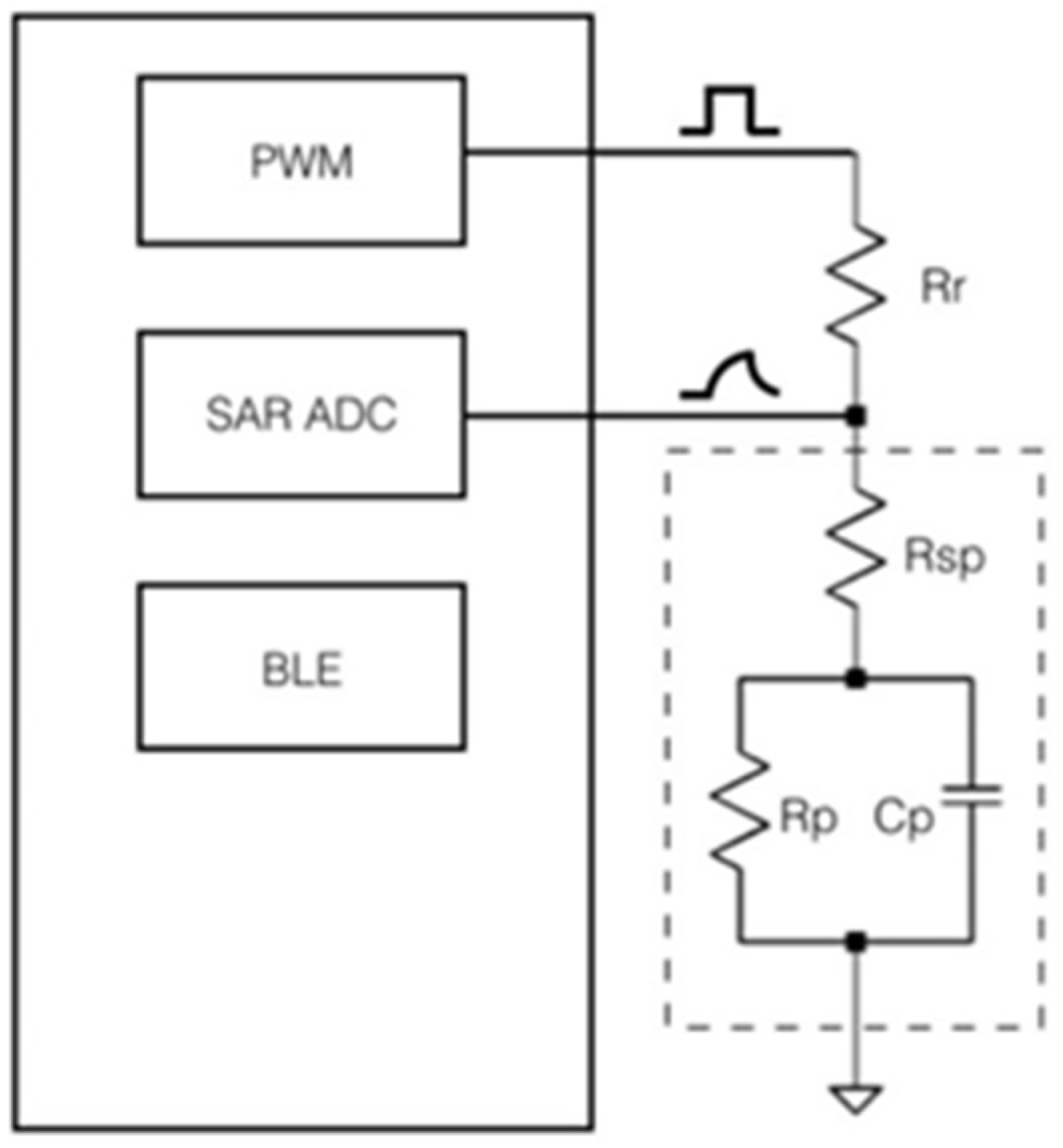

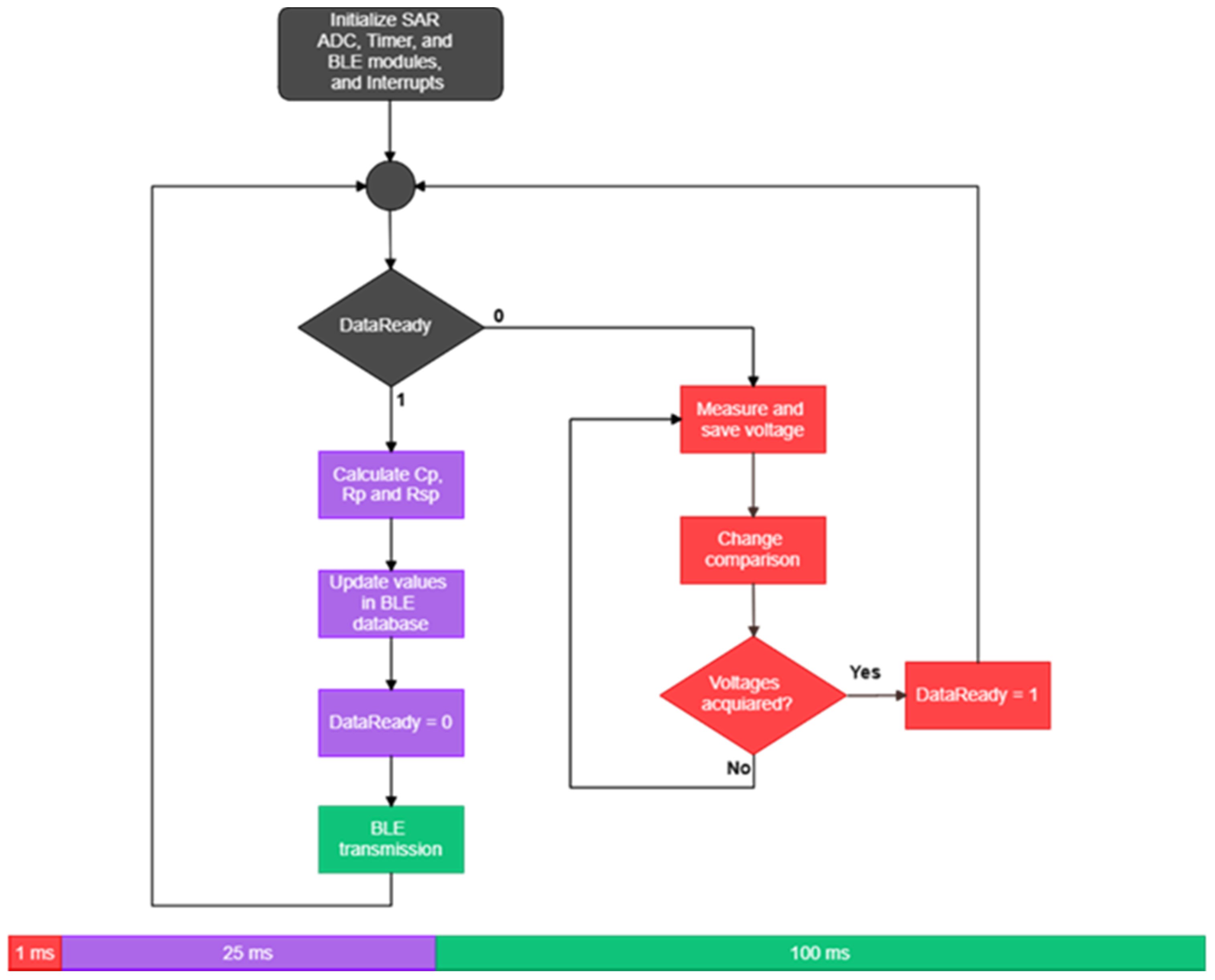

2.5. System Integration

3. Results and Discussion

3.1. Transducer Fabrication

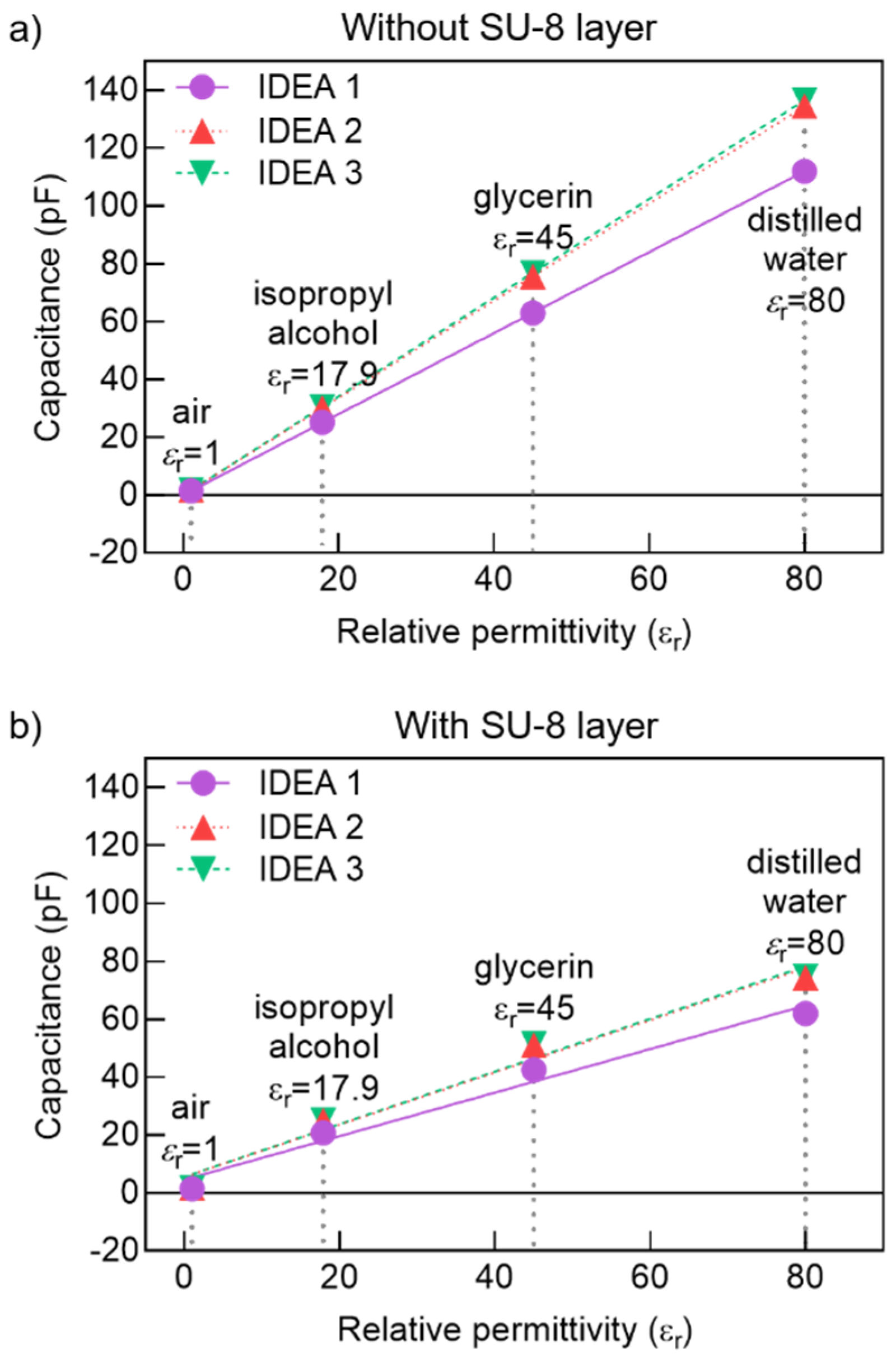

3.2. Capacitance Simulation

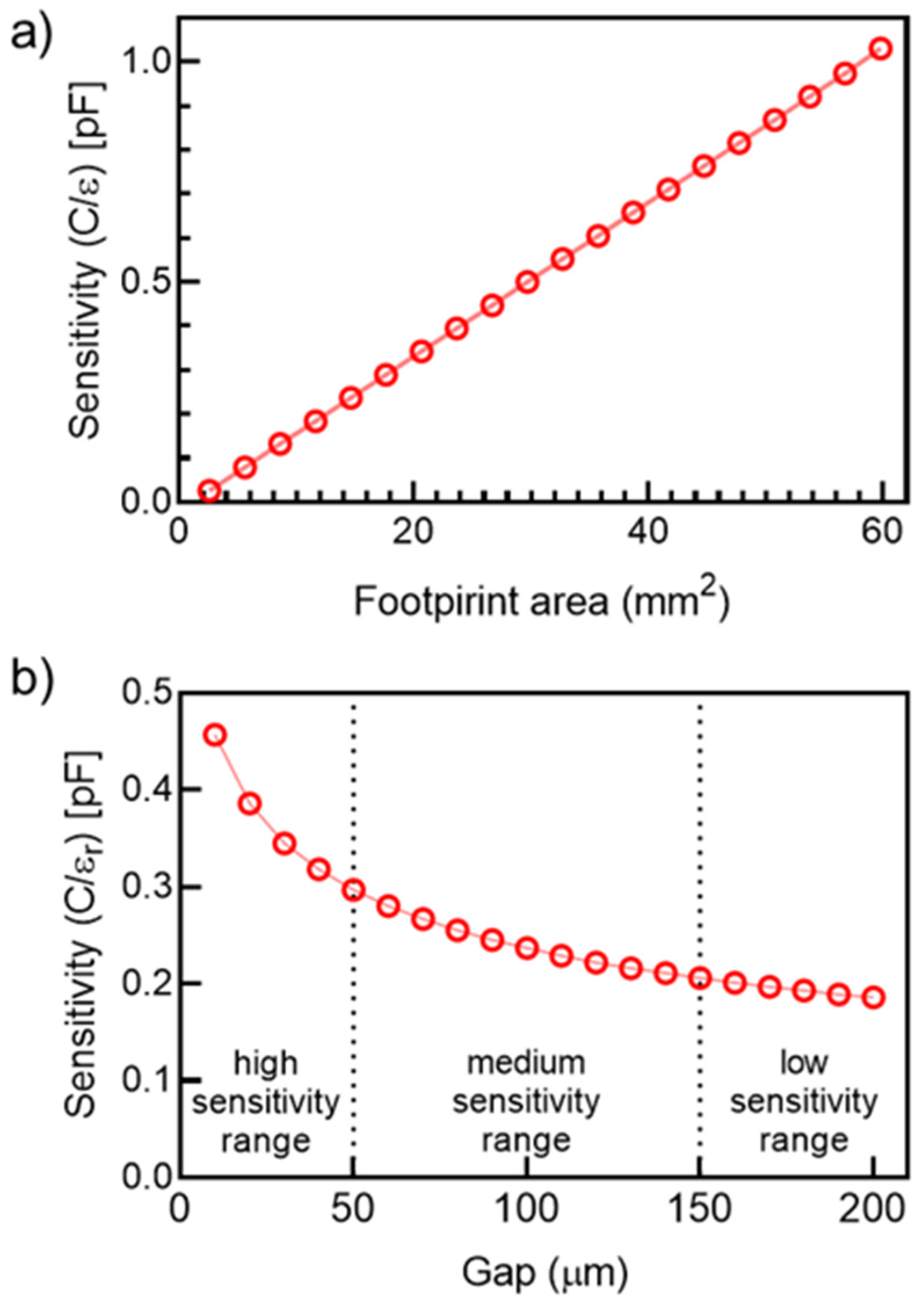

3.3. Theoretical Sensitivity Analysis

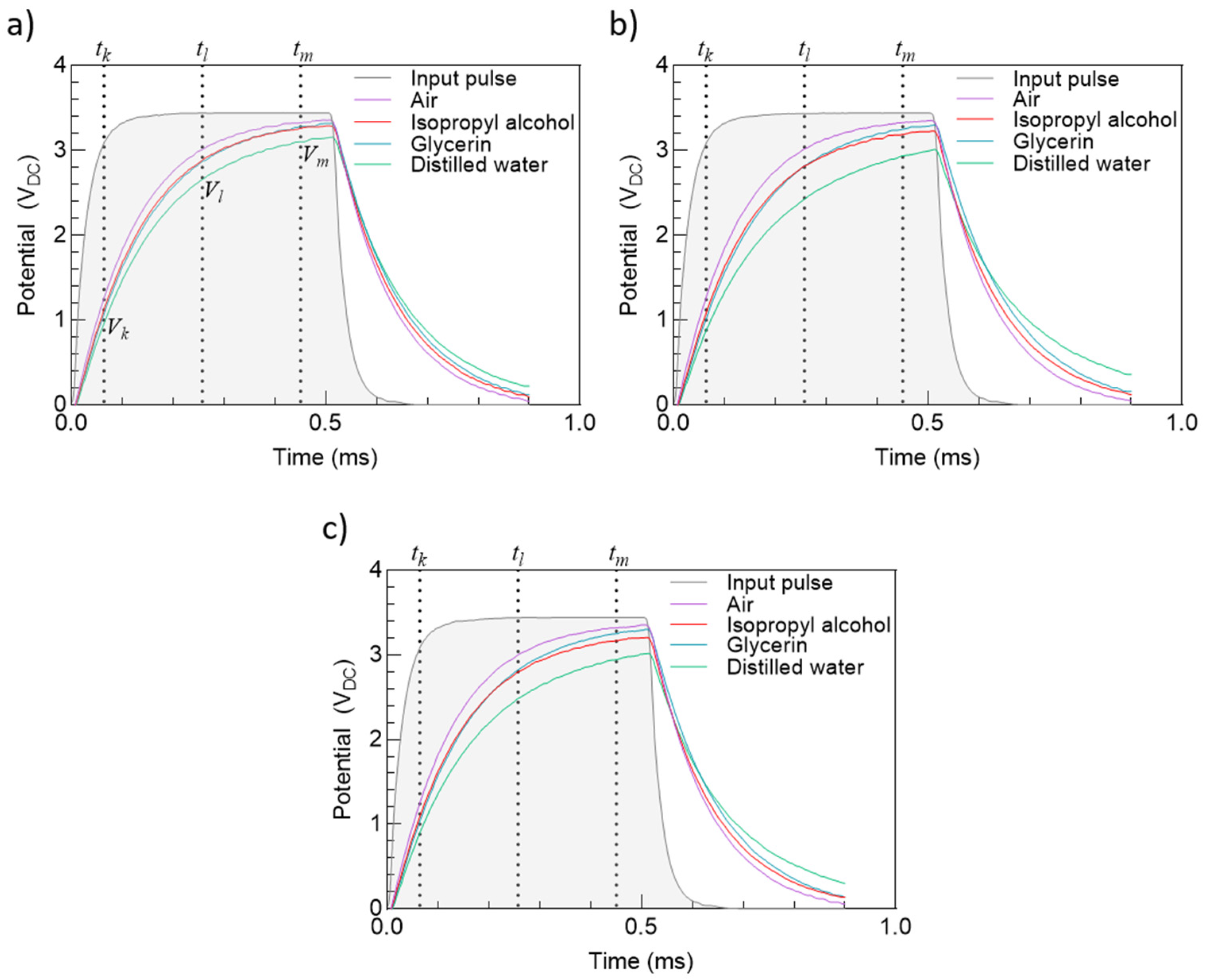

3.4. Experimental Tests

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Chen, T.; Dubuc, D.; Poupot, M.; Fournie, J.-J.; Grenier, K. Accurate Nanoliter Liquid Characterization Up to 40 GHz for Biomedical Applications: Toward Noninvasive Living Cells Monitoring. IEEE Trans. Microw. Theory Technol. 2012, 60, 4171–4177. [Google Scholar] [CrossRef]

- Oliinyk, B.V.; Isaieva, K.; Manilov, A.I.; Nychyporuk, T.; Geloen, A.; Joffre, F.; Skryshevsky, V.A.; Litvinenko, S.V.; Lysenko, V. Silicon-Based Optoelectronic Tongue for Label-Free and Nonspecific Recognition of Vegetable Oils. ACS Omega 2020, 5, 5638–5642. [Google Scholar] [CrossRef] [PubMed]

- Jiang, X.; Yang, T.; Li, C.; Zhang, R.; Zhang, L.; Zhao, X.; Zhu, H. Rapid Liquid Recognition and Quality Inspection with Graphene Test Papers. Glob. Chall. 2017, 1, 1700037. [Google Scholar] [CrossRef] [PubMed]

- ITU. ITU Internet Reports. The Internet of Things; ITU: Geneva, Switzerland, 2005. [Google Scholar]

- Bhatnagar, P.; Beyette, F. Microcontroller-based Electrochemical Impedance Spectroscopy for wearable health monitoring systems. In Proceedings of the 2015 IEEE 58th International Midwest Symposium on Circuits and Systems (MWSCAS), Fort Collins, CO, USA, 2–5 August 2015; pp. 1–4. [Google Scholar]

- Lario-García, J.; Pallas-Areny, R. Measurement of three independent components in impedance sensors using a single square wave. Sens. Actuators A Phys. 2004, 110, 164–170. [Google Scholar] [CrossRef][Green Version]

- Min, J.; Park, S.; Yun, C.-B.; Lee, C.-G.; Lee, C. Impedance-based structural health monitoring incorporating neural network technique for identification of damage type and severity. Eng. Struct. 2012, 39, 210–220. [Google Scholar] [CrossRef]

- Tozlu, S.; Senel, M.; Mao, W.; Keshavarzian, A. Wi-Fi enabled sensors for internet of things: A practical approach. IEEE Commun. Mag. 2012, 50, 134–143. [Google Scholar] [CrossRef]

- Kaur, N.; Sood, S.K. An Energy-Efficient Architecture for the Internet of Things (IoT). IEEE Syst. J. 2017, 11, 796–805. [Google Scholar] [CrossRef]

- Ruan, T.; Chew, Z.J.; Zhu, M. Energy-Aware Approaches for Energy Harvesting Powered Wireless Sensor Nodes. IEEE Sens. J. 2017, 17, 2165–2173. [Google Scholar] [CrossRef]

- Gomes, R.D.; Queiroz, D.V.; Lima-Filho, A.; Fonseca, I.E.; Alencar, M.S. Real-time link quality estimation for industrial wireless sensor networks using dedicated nodes. Ad Hoc Netw. 2017, 59, 116–133. [Google Scholar] [CrossRef]

- Parkinson, G.; Crutchley, D.; Green, P.M.; Antoniou, M.; Boon, M.; Green, P.N.; Green, P.R.; Sloan, R.; York, T. Environmental monitoring in grain. In Proceedings of the 2010 IEEE Instrumentation & Measurement Technology Conference Proceedings, Austin, TX, USA, 3–6 May 2010; pp. 939–943. [Google Scholar]

- Sulaiman, S.; Manut, A.; Firdaus, A.N. Design, Fabrication and Testing of Fringing Electric Field Soil Moisture Sensor for Wireless Precision Agriculture Applications. In Proceedings of the 2009 International Conference on Information and Multimedia Technology, Jeju Island, Korea, 16–18 December 2009; pp. 513–516. [Google Scholar] [CrossRef]

- Ojha, T.; Misra, S.; Raghuwanshi, N.S. Wireless sensor networks for agriculture: The state-of-the-art in practice and future challenges. Comput. Electron. Agric. 2015, 118, 66–84. [Google Scholar] [CrossRef]

- Raza, S.; Misra, P.; He, Z.; Voigt, T. Building the Internet of Things with bluetooth smart. Ad Hoc Netw. 2017, 57, 19–31. [Google Scholar] [CrossRef]

- Tsamis, E.; Avaritsiotis, J. Design of planar capacitive type sensor for “water content” monitoring in a production line. Sens. Actuators A Phys. 2005, 118, 202–211. [Google Scholar] [CrossRef]

- Demo, J.; Steiner, A.; Friedersdorf, F.; Putic, M. Development of a wireless miniaturized smart sensor network for aircraft corrosion monitoring. In Proceedings of the 2010 IEEE Aerospace Conference, Big Sky, MT, USA, 6–13 March 2010; pp. 1–9. [Google Scholar]

- Su, W.; Tentzeris, M.M. Smart Test Strips: Next-Generation Inkjet-Printed Wireless Comprehensive Liquid Sensing Platforms. IEEE Trans. Ind. Electron. 2017, 64, 7359–7367. [Google Scholar] [CrossRef]

- Manjakkal, L.; Cvejin, K.; Kulawik, J.; Zaraska, K.; Szwagierczak, D. Electrochemical interdigitated conductimetric ph sensor based on RuO2 thick film sensitive layer. In Proceedings of the 2014 International Conference and Exposition on Electrical and Power Engineering (EPE), Iasi, Romania, 16–18 October 2014; pp. 797–800. [Google Scholar]

- Lobato-Morales, H.; Corona-Chávez, A.; Olvera-Cervantes, J.L. Planar Sensors for RFID Wireless Complex-Dielectric-Permittivity Sensing of Liquids. In Proceedings of the 2013 IEEE MTT-S International Microwave Symposium Digest (MTT), Seattle, WA, USA, 2–7 June 2013; pp. 2–4. [Google Scholar]

- Harraz, F.A. Porous silicon chemical sensors and biosensors: A review. Sens. Actuators B Chem. 2014, 202, 897–912. [Google Scholar] [CrossRef]

- RoyChaudhuri, C. A review on porous silicon based electrochemical biosensors: Beyond surface area enhancement factor. Sens. Actuators B Chem. 2015, 210, 310–323. [Google Scholar] [CrossRef]

- Contreras-Saenz, M.; Hassard, C.; Vargas-Chacon, R.; Gordillo, J.L.; Camacho-Leon, S. Maskless fabrication of a microfluidic device with interdigitated electrodes on PCB using laser ablation. In Microfluidics, BioMEMS, and Medical Microsystems XIV; SPIE: Bellingham, WA, USA, 2016; Volume 9705, p. 97050N. [Google Scholar] [CrossRef]

- Contreras-Saenz, M.; Vargas-Chacon, R.M.; Rodriguez-Delgado, J.M.; Camacho-Leon, S. PCB-MEMS: Fabrication of Active Microfluidic Devices by Laser Ablation. In Laser Ablation: Advances in Research and Applications; Nova Science Publishers: Hauppage, NY, USA, 2017. [Google Scholar]

- Rukavina, A.V. Non-invasive liquid recognition based on interdigital capacitor. Sens. Actuators A Phys. 2015, 228, 145–150. [Google Scholar] [CrossRef]

- Czaja, Z. A microcontroller system for measurement of three independent components in impedance sensors using a single square pulse. Sens. Actuators A Phys. 2012, 173, 284–292. [Google Scholar] [CrossRef]

- Randles, J.E.B. Kinetics of rapid electrode reactions. Discuss. Faraday Soc. 1947, 1, 11–19. [Google Scholar] [CrossRef]

- Olthuis, W.; Streekstra, W.; Bergveld, P. Theoretical and experimental determination of cell constants of planar-interdigitated electrolyte conductivity sensors. Sens. Actuators B Chem. 1995, 24, 252–256. [Google Scholar] [CrossRef]

- Vázquez-Piñón, M.; Pramanick, B.; Ortega-Gama, F.; Perez-Gonzalez, V.H.; Kulinsky, L.; Madou, M.J.; Hwang, H.; Martinez-Chapa, S. Hydrodynamic channeling as a controlled flow reversal mechanism for bidirectional AC electroosmotic pumping using glassy carbon microelectrode arrays. J. Micromech. Microeng. 2019, 29, 075007. [Google Scholar] [CrossRef]

| Geometric Feature | IDEA 1 | IDEA 2 | IDEA 3 |

|---|---|---|---|

| Finger width (w) | 250 µm | 250 µm | 250 µm |

| Gap between fingers (g) | 100 µm | 100 µm | 100 µm |

| Finger length (l) | 4.3 mm | 4.3 mm | 5.2 mm |

| Finger count (N) | 20 | 24 | 20 |

| Footprint area (A) | 30.1 mm2 | 36.1 mm2 | 36.4 mm2 |

| Geometric Feature | CAD Design | PCB Device Mean (SD) | RPE |

|---|---|---|---|

| [µm] | 250 | 235.40 (9.7) | 6.201% |

| [mm] | 4.3 | 4.36 (12.7) | 1.578% |

| [µm] | 100 | 112.13 (9.5) | 10.814% |

| [mm2] | 30.1 | 30.4 (1.7) | 0.878% |

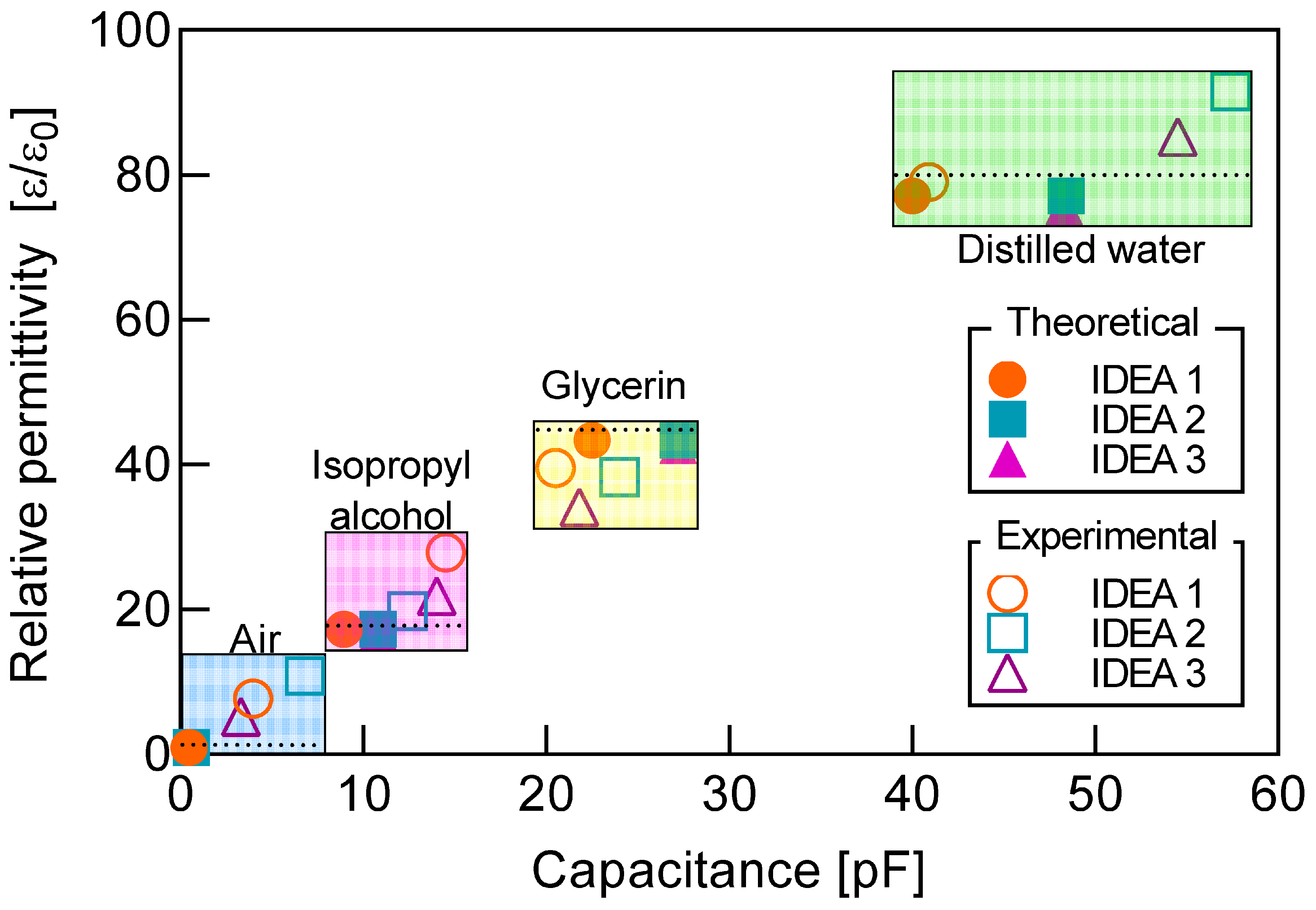

| Transducer | Air | Isopropyl Alcohol | Glycerin | Distilled Water | ||||

|---|---|---|---|---|---|---|---|---|

| Theoretical | Experimental | Theoretical | Experimental | Theoretical | Experimental | Theoretical | Experimental | |

| IDEA 1 | 0.49 | 3.98 | 8.94 | 14.5 | 22.48 | 20.5 | 39.97 | 40.9 |

| IDEA 2 | 0.60 | 6.82 | 10.82 | 12.4 | 27.22 | 24.0 | 48.39 | 57.4 |

| IDEA 3 | 0.60 | 3.32 | 10.81 | 14.0 | 27.19 | 21.8 | 48.34 | 54.5 |

| Transducer | Footprint Area, mm2 | Sensitivity, pF/εr | ||

|---|---|---|---|---|

| Theoretical | Experimental | RPE | ||

| IDEA 1 | 30.1 | 0.5186 | 0.5181 | 0.10% |

| IDEA 2 | 36.1 | 0.6274 | 0.6272 | 0.04% |

| IDEA 3 | 36.4 | 0.6382 | 0.6390 | 0.12% |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Meléndez-Campos, J.; Vázquez-Piñón, M.; Camacho-Leon, S. Sensitivity Analysis of a Portable Wireless PCB-MEMS Permittivity Sensor Node for Non-Invasive Liquid Recognition. Micromachines 2021, 12, 1068. https://doi.org/10.3390/mi12091068

Meléndez-Campos J, Vázquez-Piñón M, Camacho-Leon S. Sensitivity Analysis of a Portable Wireless PCB-MEMS Permittivity Sensor Node for Non-Invasive Liquid Recognition. Micromachines. 2021; 12(9):1068. https://doi.org/10.3390/mi12091068

Chicago/Turabian StyleMeléndez-Campos, Javier, Matias Vázquez-Piñón, and Sergio Camacho-Leon. 2021. "Sensitivity Analysis of a Portable Wireless PCB-MEMS Permittivity Sensor Node for Non-Invasive Liquid Recognition" Micromachines 12, no. 9: 1068. https://doi.org/10.3390/mi12091068

APA StyleMeléndez-Campos, J., Vázquez-Piñón, M., & Camacho-Leon, S. (2021). Sensitivity Analysis of a Portable Wireless PCB-MEMS Permittivity Sensor Node for Non-Invasive Liquid Recognition. Micromachines, 12(9), 1068. https://doi.org/10.3390/mi12091068