Rapid Prototyping of Bio-Inspired Dielectric Resonator Antennas for Sub-6 GHz Applications

Abstract

:1. Introduction

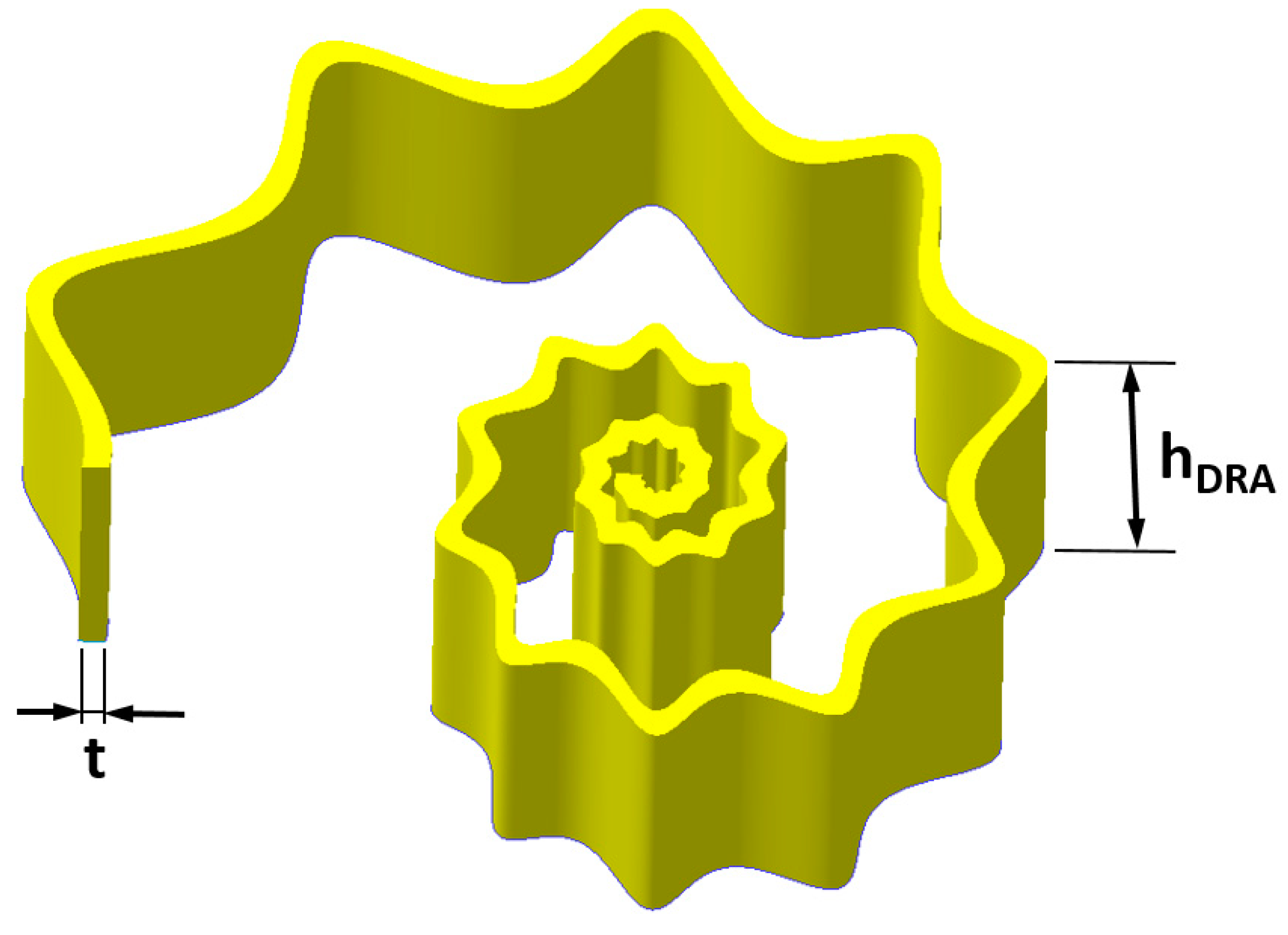

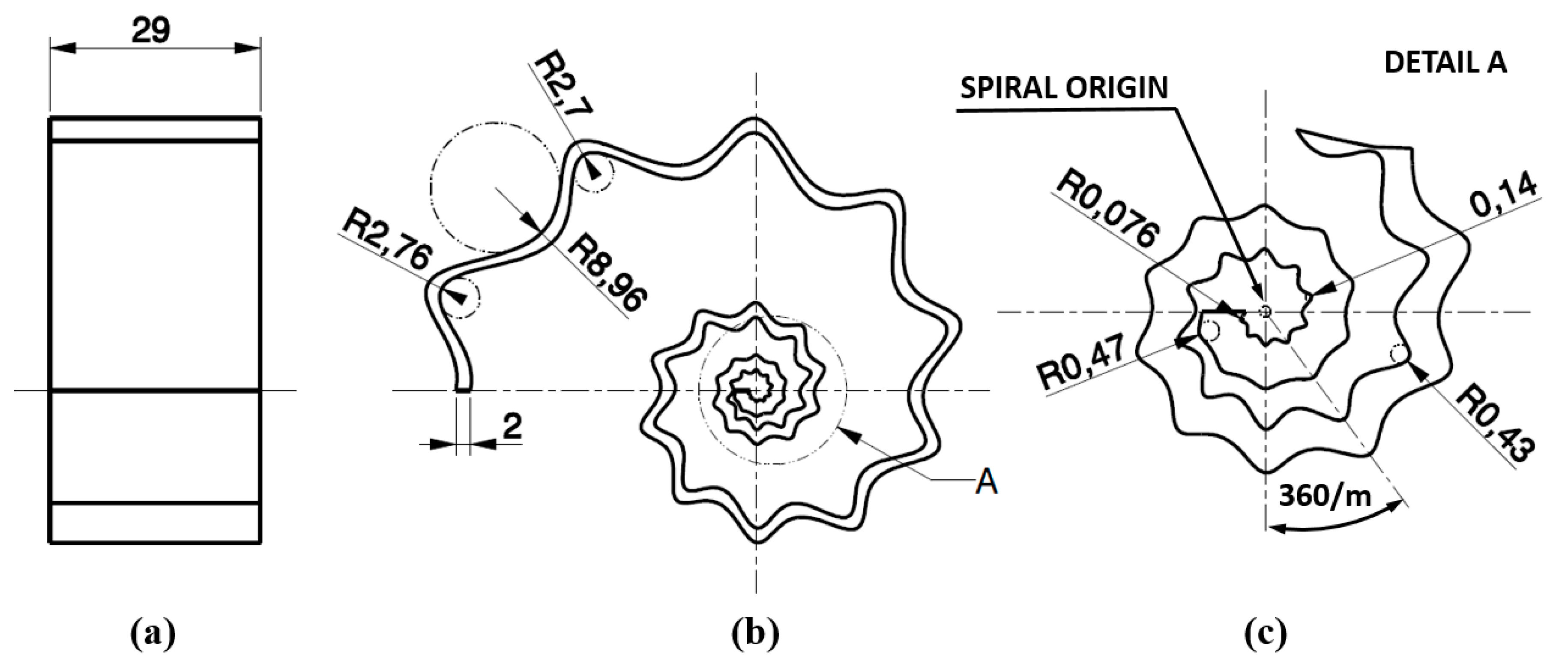

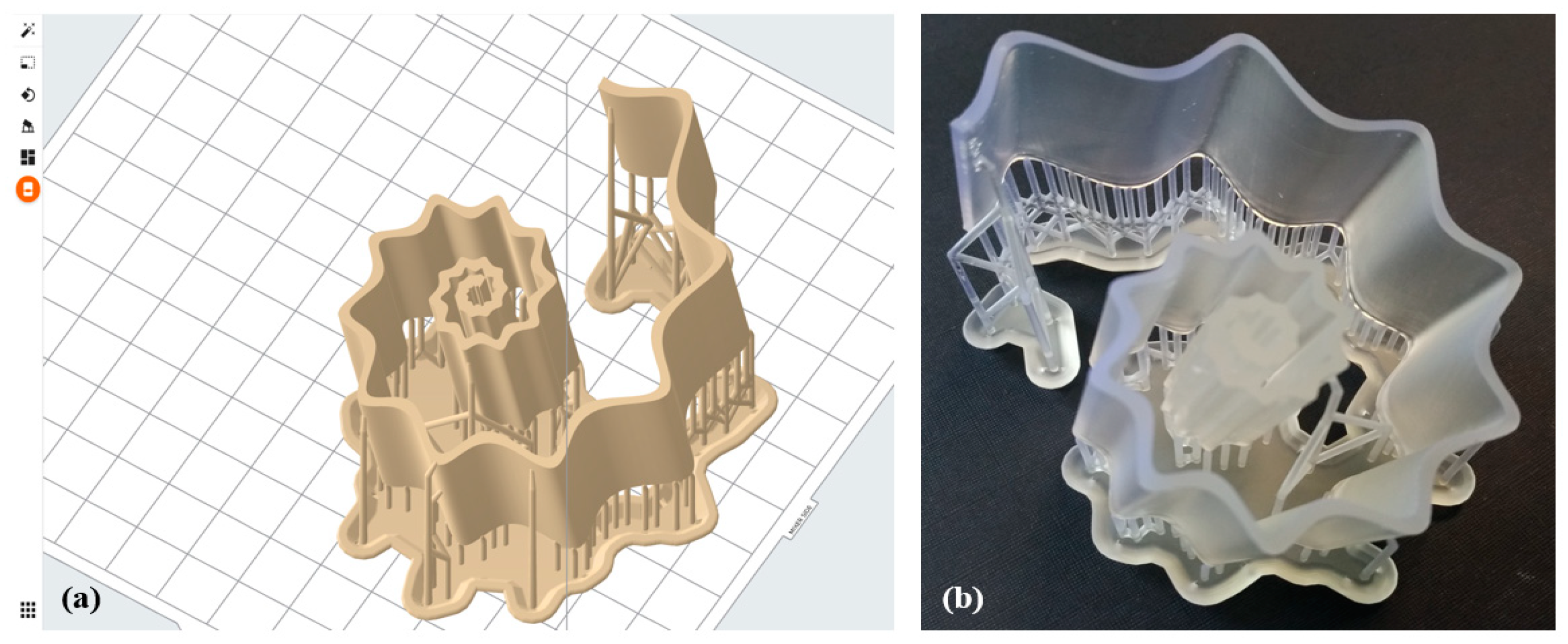

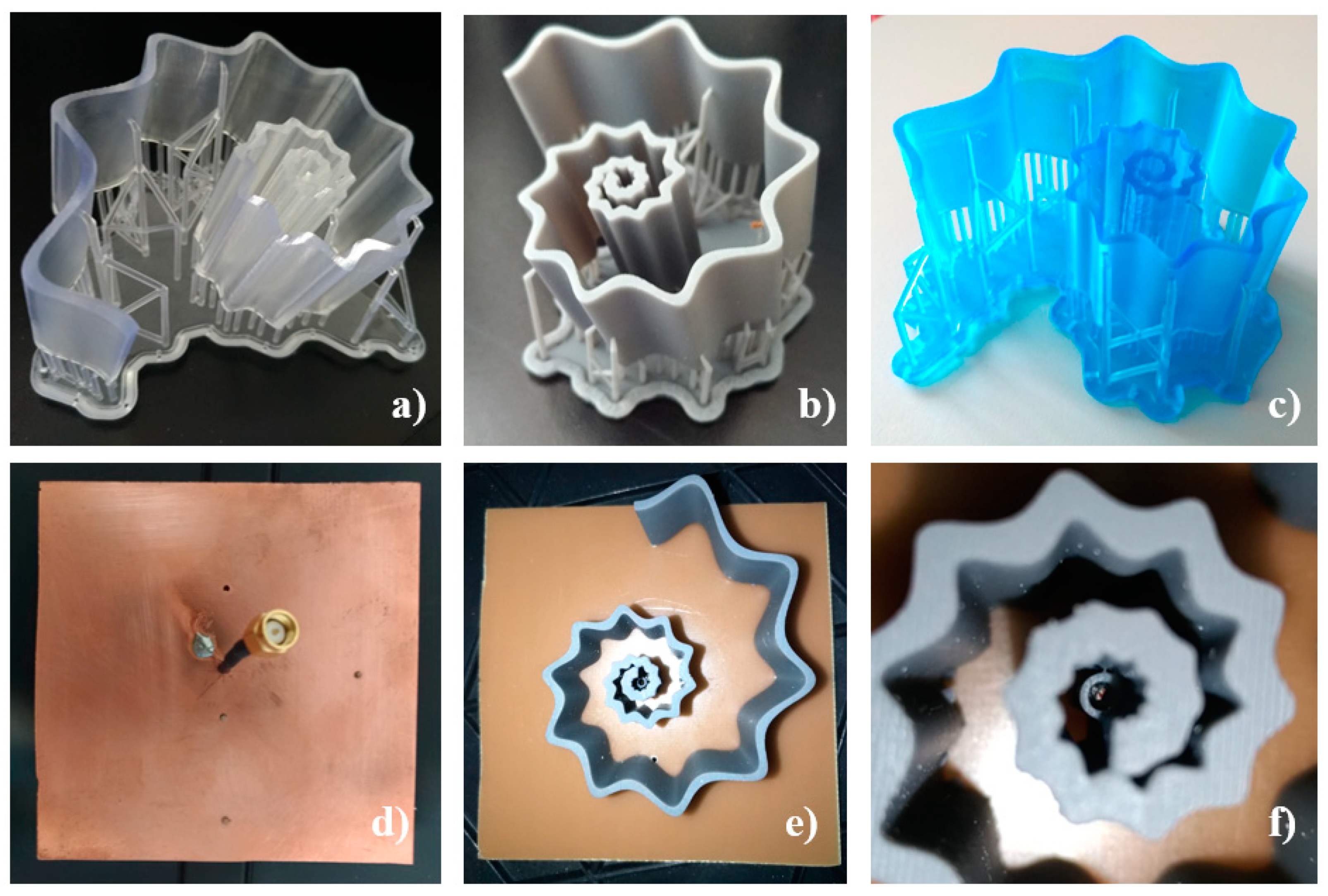

2. The Ggeometrical Modeling, Fabrication, and Geometrical Characterization of the SsDRA Prototypes

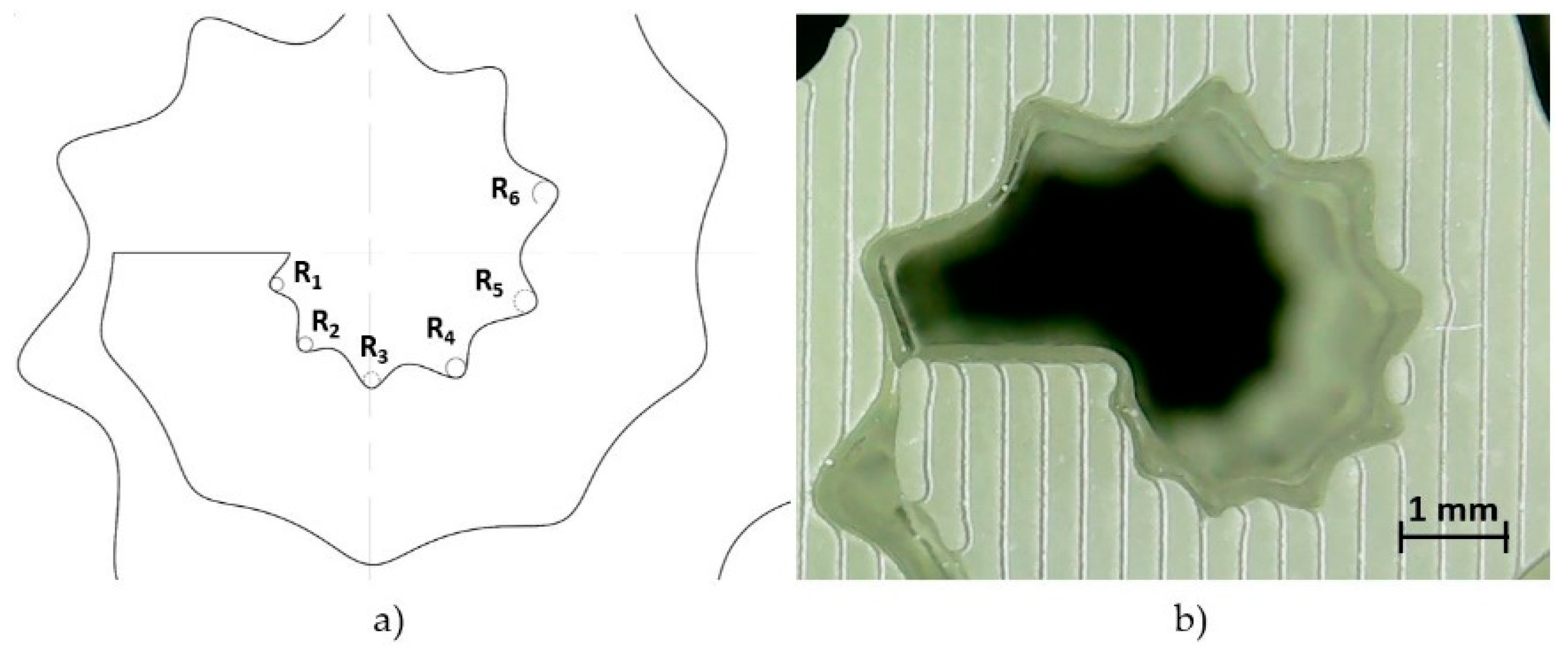

2.1. The Fabrication, Geometric Characterization, and Assembly of the SsDRA Prototypes

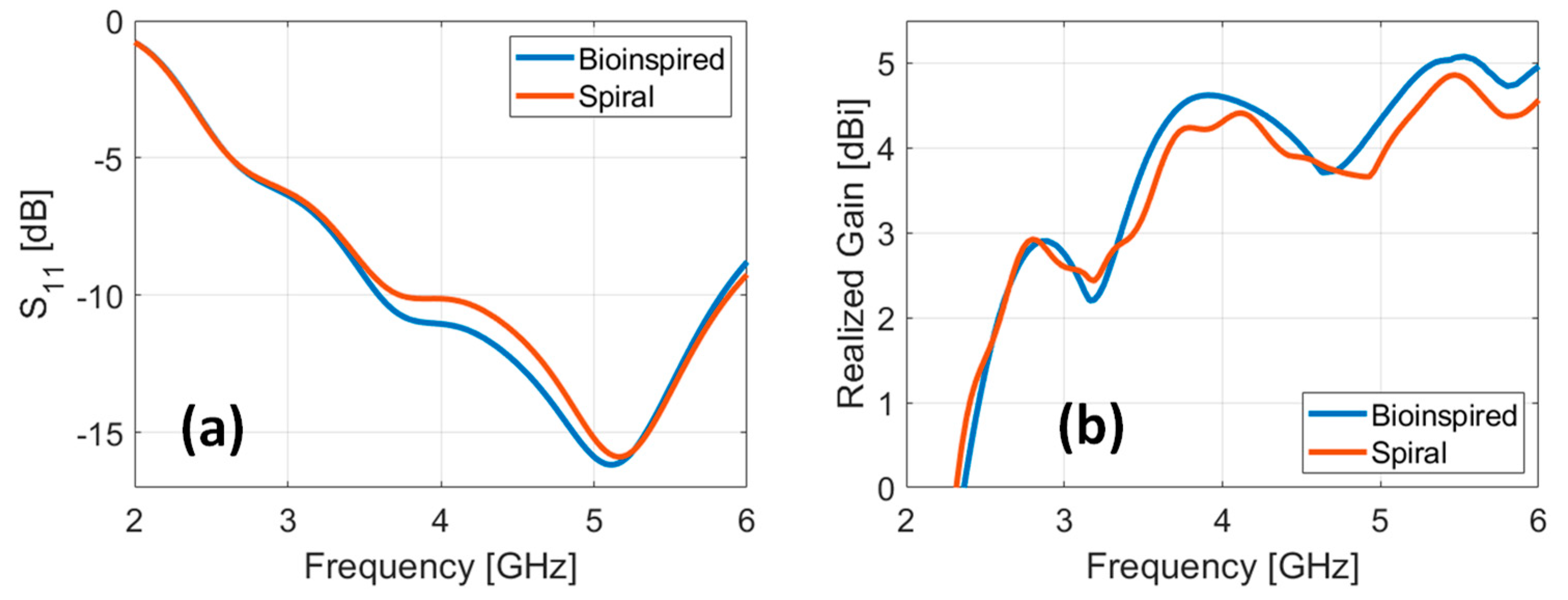

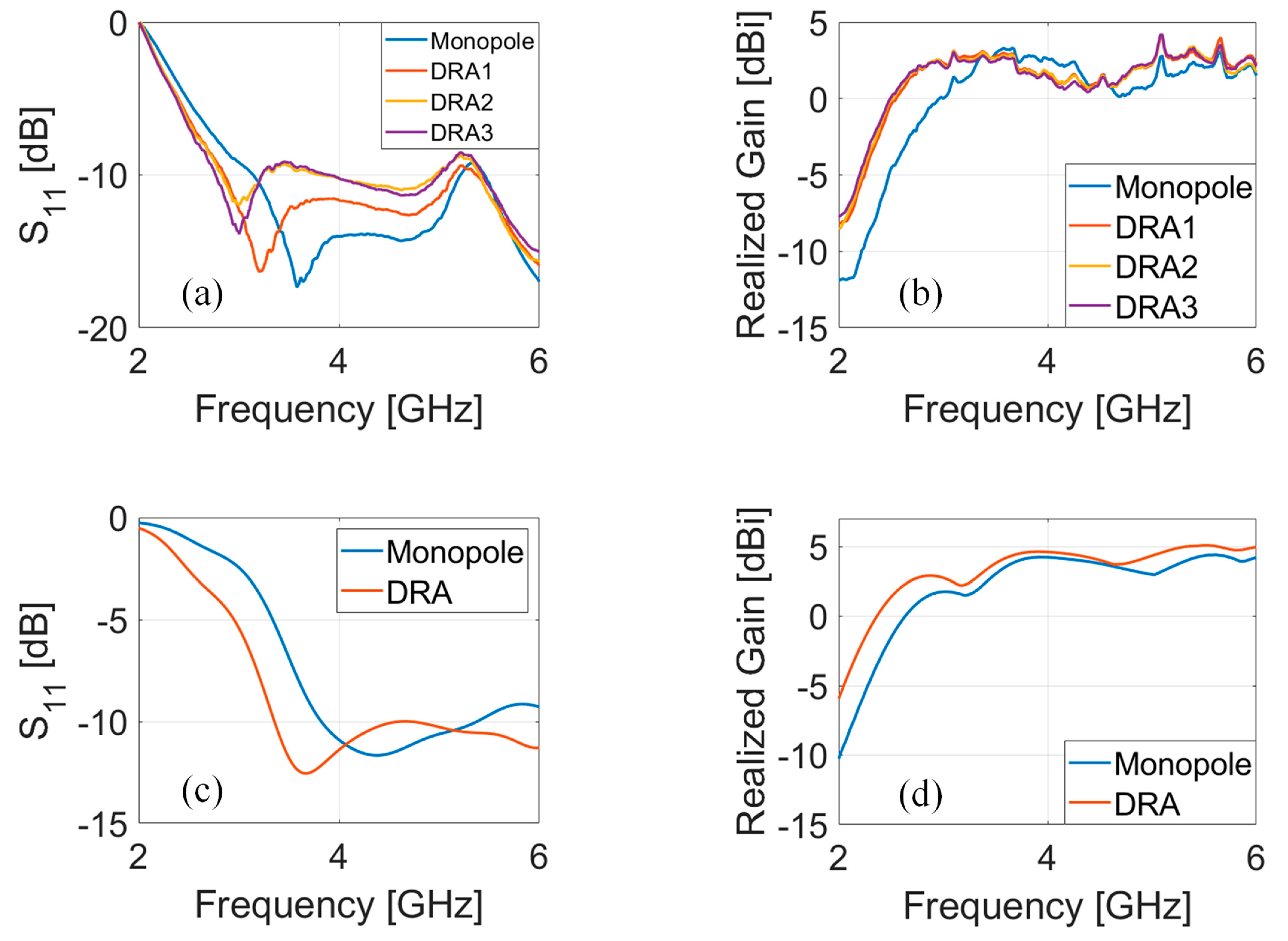

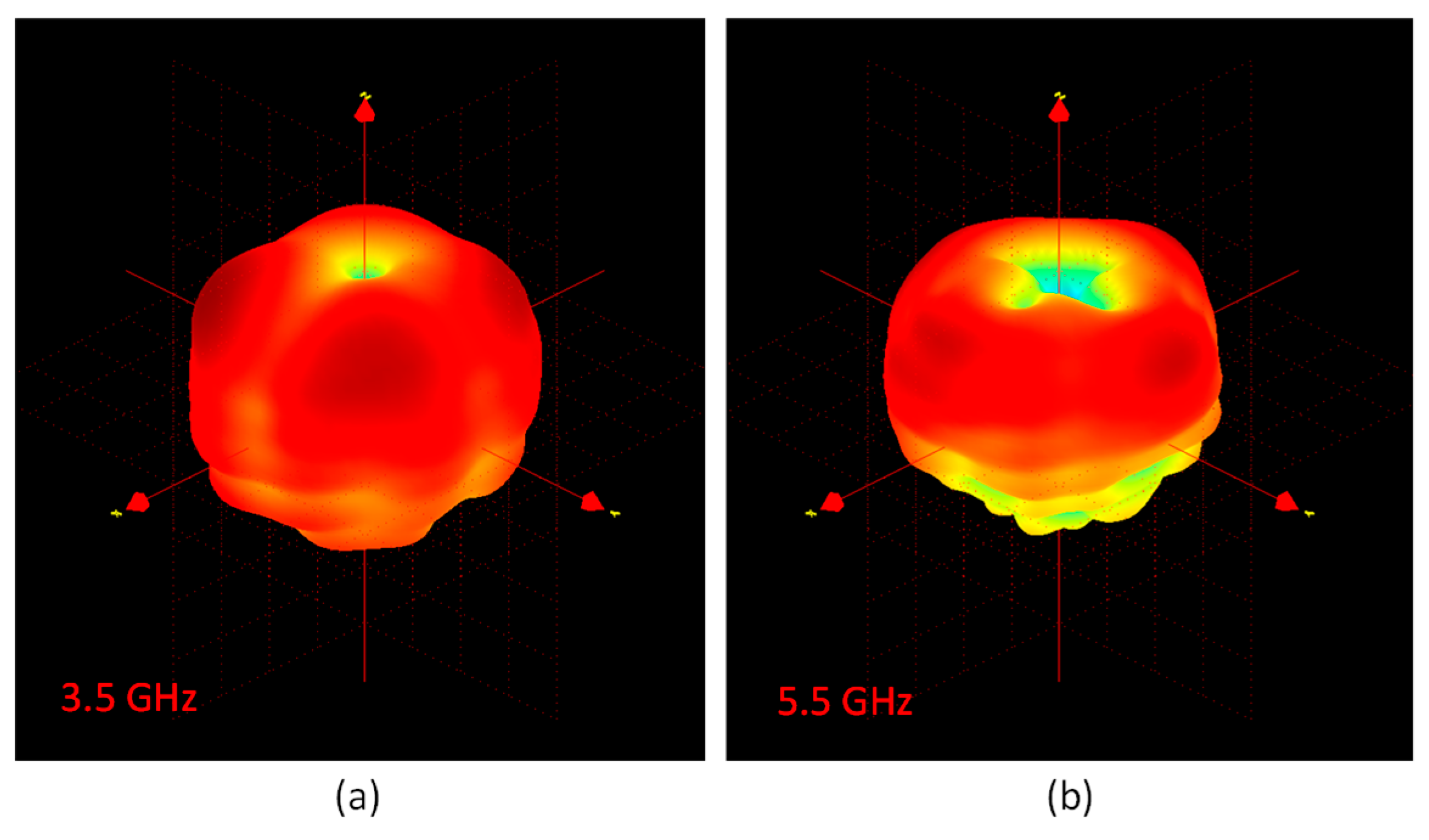

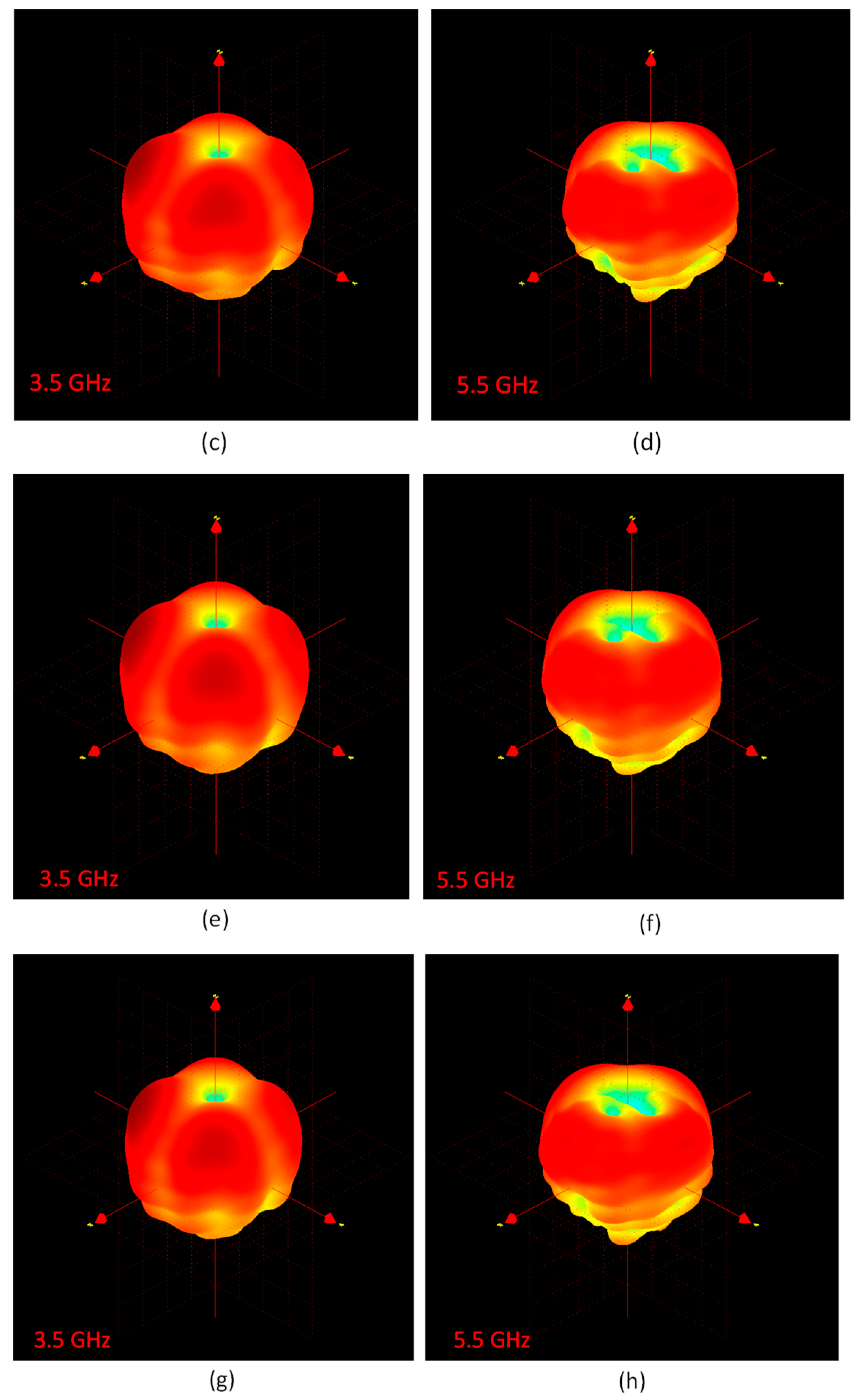

3. Measurements of the Scattering Parameter S11, Realized Gain, and 3D Radiation Patterns

4. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

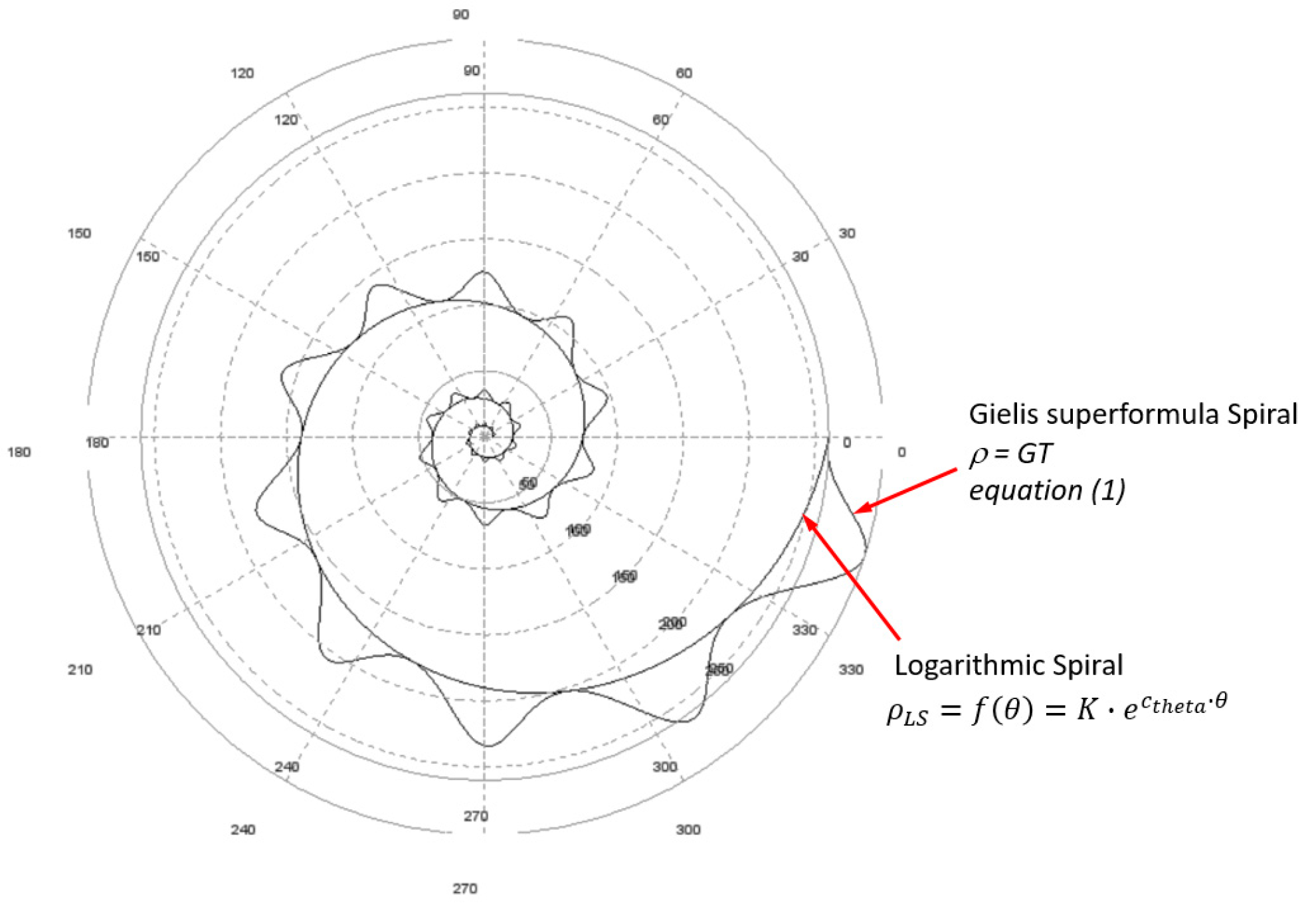

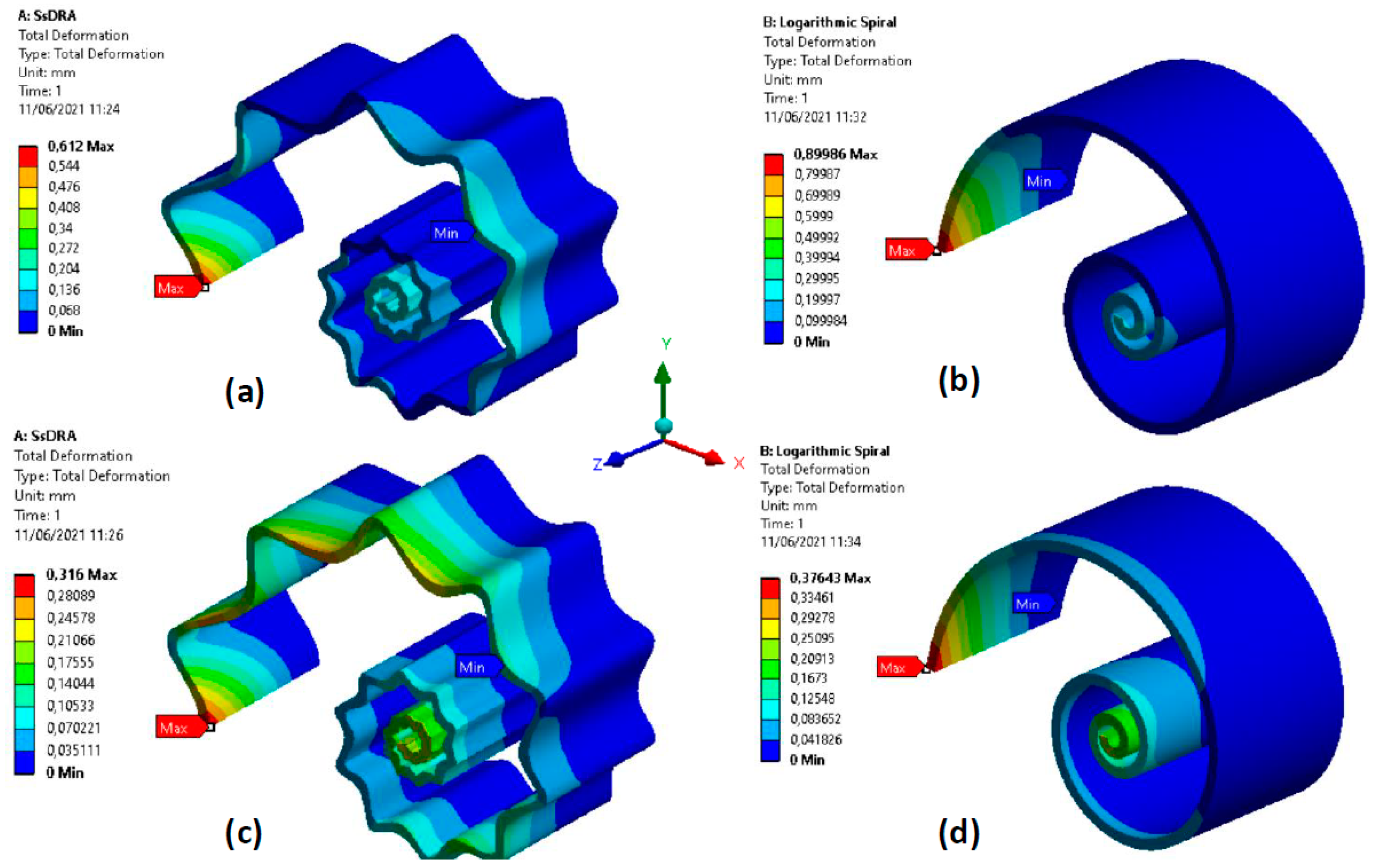

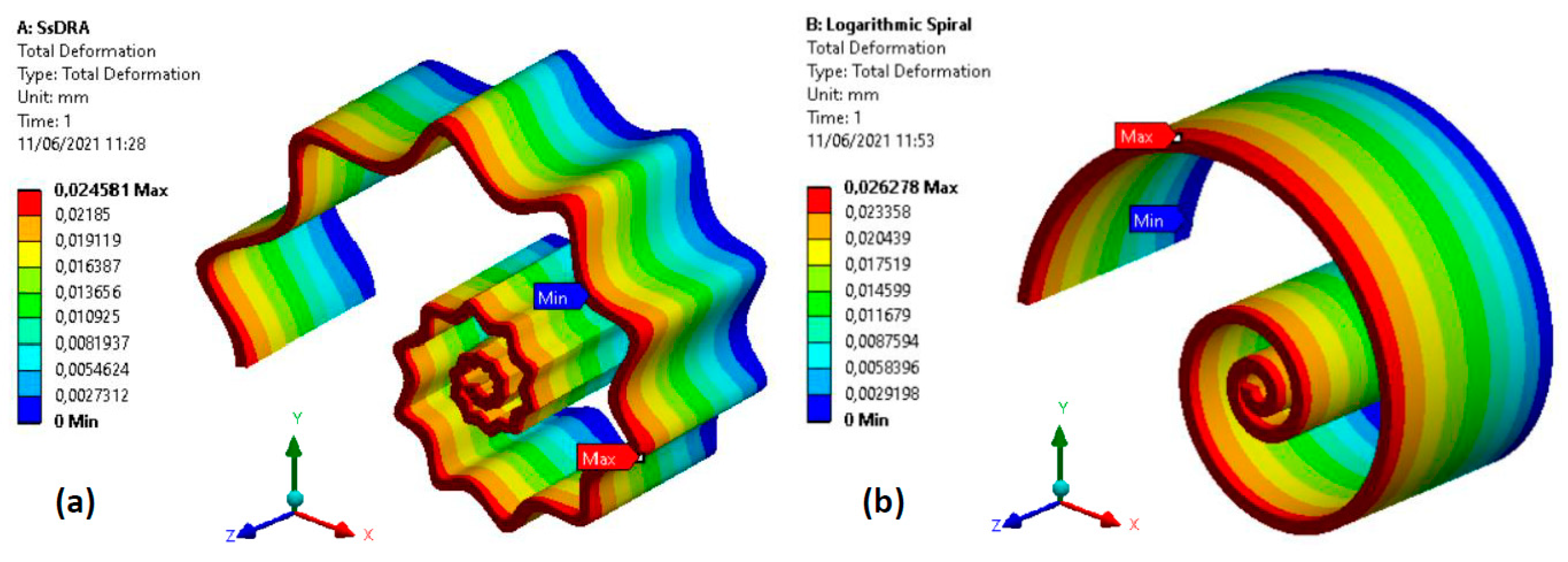

Appendix A. Supplementary Discussion: SsDRA vs. Logarithmic Spiral Shell DRA (LsDRA)—Antenna Performance and Structural Comparison

| Load Type | Configuration | Load | Max Displacement δMAX/Stiffnesses k | Variations | ||||

|---|---|---|---|---|---|---|---|---|

| SsDRA (1) Equation (1) Table 1 | LsDRA (2) Equation (1) Table 1 (ni = 1; mi = 0) | Δ12 % | ||||||

| δ MAX (mm) | k (N/mm) | δ MAX (mm) | k (N/mm) | ΔδMAX% | Δk% | |||

| Flexural along x | Cantilever | FX = 200N; FY = FZ = 0 | 0.612 | 326.80 | 0.900 | 222.22 | −32% | +47% |

| Flexural along y | Cantilever | FY = −200N; FX = FZ = 0 | 0.316 | 632.91 | 0.376 | 531.91 | −16% | +19% |

| Compression | Cantilever | FZ = −1000N; FX = FY = 0 | 0.024 | 41666.67 | 0.026 | 38461.54 | −8% | +8% |

References

- da Silva Júnior, P.F.; Carlos, R.; Freire, S.; René Serres, A.J.; da Fonseca Silva, P.H.; Costa Silva, J. Bio-Inspired Antenna for UWB Systems. In Proceedings of the 2016 1st International Symposium on Instrumentation Systems, Circuits and Transducers (INSCIT), Belo Horizonte, Brazil, 29 August–3 September 2016; p. 16408466. [Google Scholar] [CrossRef]

- Panda, R.A.; Kumari, P.; Naik, J.; Negi, P.; Mishra, D. Flower Shaped Patch with Circular Defective Ground Structure for 15 GHz Application. In Innovations in Bio-Inspired Computing and Applications; IBICA 2019, Advances in Intelligent Systems and Computing, 1180; Abraham, A., Panda, M., Pradhan, S., Garcia-Hernandez, L., Ma, K., Eds.; Springer: Berlin/Heidelberg, Germany, 2019. [Google Scholar] [CrossRef]

- Mesquita, M.D.S.; D’Assunção, A.G.; Oliveira, J.B.L.; Batista, Y.M.V. A New Conductive Ink for Microstrip Antenna and Bioinspired FSS Designs on Glass and Fiberglass Substrates. J. Microw. Optoelectron. Electromagn. Appl. 2019, 18, 227–245. [Google Scholar] [CrossRef]

- Abolade, J.O.; Konditi, D.B.O.; Dharmadhikary, V.M. Bio-inspired wideband antenna for wireless applications based on perturbation technique. Heliyon 2020, 6, e04282. [Google Scholar] [CrossRef] [PubMed]

- Singh, P.; Ray, K.; Rawat, S. Analysis of Sun Flower Shaped Monopole Antenna. Wirel. Pers. Commun. 2019, 104, 881–894. [Google Scholar] [CrossRef]

- Malik, R.; Singh, P.; Ali, H.; Goel, T. A Star Shaped Superwide Band Fractal Antenna for 5G Applications. In Proceedings of the 2018 3rd International Conference for Convergence in Technology (I2CT), Pune, India, 6–8 April 2018; pp. 1–6. [Google Scholar] [CrossRef]

- Anguera, J.; Puente, C.; Borja, C.; Soler, J. Fractal-Shaped Antennas: A Review. In Wiley Encyclopedia of RF and Microwave Engineering; Chang, K., Ed.; John Wiley & Sons, Inc.: New York, NY, USA, 2005; Volume 2, pp. 1620–1635. [Google Scholar]

- Song, C.T.P.; Hall, P.S.; Ghafouri-Shiraz, H.; Wake, D. Sierpinski Monopole Antenna with Controlled Band Spacing and Input Impedance. IEE Electron. Lett. 1999, 35, 1036–1037. [Google Scholar] [CrossRef]

- Jayasinghe, J.W.; Anguera, J.; Uduwawala, D.N. A High-Directivity Microstrip Patch Antenna Design by Using Genetic Algorithm Optimization. Prog. Electromagn. Res. C 2013, 37, 131–144. [Google Scholar] [CrossRef] [Green Version]

- de Oliveira, M.A.; da Costa, A.P.; Forte, G.G.S.; de Melo, P.-K.P.; Fontgalland, G.; Silva, P.-H.F.; Fontgalland, I.L. Using polar transformation to design a dissimilar antenna array inspired on four-leaf clover. In Proceedings of the 2018 IEEE Radio and Wireless Symposium (RWS), Anaheim, CA, USA, 15–18 January 2018; pp. 228–230. [Google Scholar] [CrossRef]

- Gielis, J. A generic geometric transformation that unifies a wide range of natural and abstract shapes. Am. J. Bot. 2003, 90, 333–338. [Google Scholar] [CrossRef]

- Gielis, J. Method and Apparatus for Synthesizing and Analyzing Patterns Utilizing Novel “Super-Formula” Operator. U.S. Patent US7620527B1, 17 November 2009. [Google Scholar]

- Poordaraee, M.; Oraizi, H.; Khajevandi, S.; Glazunov, A.A. Systematic Design of a Circularly Polarized Microstrip Antenna Using a Shape Super-Formula and the Characteristic Mode Theory. In Proceedings of the 2018 18th Mediterranean Microwave Symposium (MMS), Istanbul, Turkey, 31 October–2 November 2018; pp. 47–50. [Google Scholar] [CrossRef]

- Omar, A.A.; Naser, S.; Hussein, M.; Dib, N.; Rashad, M.W. Superformula-Based Compact UWB CPW-Fed-Patch Antenna With and Without Dual Frequency Notches. ACES J. 2017, 32, 979–986. [Google Scholar]

- Naser, S.; Dib, N. Design and analysis of super-formula-based UWB monopole antenna. In Proceedings of the 2016 IEEE International Symposium on Antennas and Propagation (APSURSI), Fajardo, Puerto Rico, 26 June–1 July 2016; pp. 1785–1786. [Google Scholar] [CrossRef]

- de Jong van Coevorden, C.M.; Gielis, J.; Caratelli, D. Application of Gielis transformation to the design of metamaterial structures. J. Phys. Conf. Ser. 2018, 963, 012008. [Google Scholar] [CrossRef]

- Zarghooni, B.; Dadgarpour, A.; Pourahmadazar, J.; Denidni, T.A. Supershaped metamaterial unit-cells using the gielis formula. In Proceedings of the 2015 IEEE International Symposium on Antennas and Propagation & USNC/URSI National Radio Science Meeting, Vancouver, BC, Canada, 19–24 July 2015; pp. 458–459. [Google Scholar] [CrossRef]

- Khajevandi, S.; Oraizi, H.; Poordaraee, M. Design of Planar Dual-Bandstop FSS Using Square-Loop-Enclosing Superformula Curves. IEEE Antennas Wirel. Propag. Lett. 2018, 17, 731–734. [Google Scholar] [CrossRef]

- Martínez-Dueñas, E.R.; de Jong van Coevorden, C.M.; Caratelli, D. Supershaped complementary split-ring resonators. In Proceedings of the 2017 USNC-URSI Radio Science Meeting (Joint with AP-S Symposium), San Diego, CA, USA, 9–14 July 2017; pp. 43–44. [Google Scholar] [CrossRef]

- Rubio, M.; Dueñas, E.J.; de Jong van Coevorden, C.M.; Stukach, O.V.; Panokin, N.V.; Gielis, J.; Caratelli, D. Electromagnetic modeling and design of a novel class of complementary split? Ring Reson. 2019, 29, e21582. [Google Scholar] [CrossRef]

- Petosa, A.; Ittipiboon, A. Dielectric resonator Antennas: A historical review and the current state of the art. IEEE Antennas Propag. Mag. 2010, 52, 91–116. [Google Scholar] [CrossRef]

- Keyrouz, S.; Caratelli, D. Dielectric Resonator Antennas: Basic Concepts, Design Guidelines, and Recent Developments at Millimeter-Wave Frequencies. Int. J. Antennas Propag. 2016, 2016, 1–20. [Google Scholar] [CrossRef]

- Kumar, P.; Dwari, S.; Singh, S.; Kumar, J. Investigation and Development of 3D Printed Biodegradable PLA as Compact Antenna for Broadband Applications. IETE J. Res. 2018, 66, 53–64. [Google Scholar] [CrossRef]

- Kumar, P.; Dwari, S.; Kumar, J. Design of Biodegradable Quadruple-shaped DRA for WLAN/Wi-Max applications. J. Microw. Optoelectron. Electromagn. Appl. 2017, 16, 867–880. [Google Scholar] [CrossRef] [Green Version]

- Marrocco, V.; Basile, V.; Fassi, I.; Grande, M.; Laneve, D.; Prudenzano, F.; D’Orazio, A. Dielectric Resonant Antennas via Additive Manufacturing for 5G Communications. In Proceedings of the PIERS 2019, Rome, Italy, 17–20 June 2019. [Google Scholar]

- Basile, V.; Grande, M.; Marrocco, V.; Laneve, D.; Petrignani, S.; Prudenzano, F.; Fassi, I. Design and Manufacturing of Super-Shaped Dielectric Resonator Antennas for 5G Applications Using Stereolithography. IEEE Access 2020, 8, 82929–82937. [Google Scholar] [CrossRef]

- Petrignani, S.; D’Orazio, A.; Grande, M.; Marrocco, V.; Basile, V.; Fassi, I. Supershaped dielectric resonator antenna for 5G applications. In Proceedings of the Antennas and Propagation Conference 2019 (APC-2019), Birmingham, UK, 11–12 November 2019; pp. 1–4. [Google Scholar] [CrossRef]

- Marrocco, V.; Basile, V.; Grande, M.; Prudenzano, F.; D’Orazio, A.; Fassi, I. Additive Manufacturing for 5G Antennas: How Technologies and Materials Impact on Design. In Proceedings of the (2020) 22nd International Conference on Transparent Optical Networks (ICTON) 2020, Bari, Italy, 19–23 July 2020. [Google Scholar]

- Simeoni, M.; Cicchetti, R.; Yaravoy, A.; Caratelli, D. Plastic-based supershaped dielectric Resonator antennas for wide-band Applications. IEEE Trans. Antennas Propag. 2011, 59, 4820–4825. [Google Scholar] [CrossRef]

- Kanth, V.; Raghavan, S. Hybrid Complementary FSS Element based on Fibonacci Spiral for Triple-band EMI Shielding Application. In Proceedings of the 2019 IEEE 5th Global Electromagnetic Compatibility Conference (GEMCCON), Bangalore, India, 6–8 November 2019; pp. 1–4. [Google Scholar] [CrossRef]

- Varikuntla, K.K.; Singaravelu, R. Design of a Novel 2.5D Frequency Selective Surface Element Using Fibonacci Spiral for Radome Application. In Proceedings of the 2018 Asia-Pacific Microwave Conference (APMC), Kyoto, Japan, 6–9 November 2018; p. FR3-D5. [Google Scholar] [CrossRef]

- Sharma, C.; Vishwakarma, D.K. Miniaturization of Spiral Antenna Based on Fibonacci Sequence Using Modified Koch Curve. IEEE Antennas Wirel. Propag. Lett. 2016, 16, 932–935. [Google Scholar] [CrossRef]

- Yang, N.; Leung, K.W.; Lu, K.; Wu, N. Omnidirectional Circularly Polarized Dielectric Resonator Antenna With Logarithmic Spiral Slots in the Ground. IEEE Trans. Ant. Propag. 2017, 65, 839–844. [Google Scholar] [CrossRef]

- Melchiorre, L.; Marasco, I.; Niro, G.; Basile, V.; Marrocco, V.; D’Orazio, A.; Grande, M. Bio-Inspired Dielectric Resonator Antenna for Wideband Sub-6 GHz Range. Appl. Sci. 2020, 10, 8826. [Google Scholar] [CrossRef]

- Yu, Z.; Guo, N.; Fan, J. Water Spiral Dielectric Resonator Antenna for Generating Multimode OAM. IEEE Ant. Wireless Propag. Lett. 2020, 19, 601–605. [Google Scholar] [CrossRef]

- Gielis, J.; Caratelli, D.; Peijian, S.; Ricci, P.E. A Note on Spirals and Curvature. Growth and Form. 2020, 1, 1–8. [Google Scholar] [CrossRef] [Green Version]

- Gibson, I.; Rosen, D.; Stucker, B.; Khorasani, M. Additive Manufacturing Technologies; Springer: New York, NY, USA, 2014; Volume 17, p. 195. [Google Scholar] [CrossRef]

- Basile, V.; Modica, F.; Fassi, I. Analysis and modeling of defects in unsupported overhanging features in micro-stereolithography. In Proceedings of the International Design Engineering Technical Conferences & Computers and Information in Engineering Conference (IDETC/CIE), Charlotte, NC, USA, 21–24 August 2016; ASME: New York, NY, USA. [Google Scholar] [CrossRef]

- Formlabs Materials. Available online: https://formlabs.com/it/materials/ (accessed on 28 August 2021).

- Modica, F.; Basile, V.; Ruggeri, S.; Fontana, G.; Fassi, I. Can a low-cost sensing system be exploited for high precision machining? Proced. CIRP 2018, 75, 391–396. [Google Scholar] [CrossRef]

- Collins, T.J. ImageJ for microscopy. BioTechniques 2007, 43, S25–S30. [Google Scholar] [CrossRef] [PubMed]

| f(θ) | K | ctheta | a | b | m1 | m2 | n1 | n2 | n3 |

|---|---|---|---|---|---|---|---|---|---|

| 6 | 0.2 | 1 | 1 | 10 | 10 | 5 | 5 | 5 |

| SsDRA | Material | Color | Time (min) | Temperature (°C) |

|---|---|---|---|---|

| DRA1 | Clear V04 | Transparent | 15 | 60 |

| DRA2 | Grey V04 | Grey | 30 | 60 |

| DRA3 | Tough V05 | Blue | 60 | 60 |

| Dimension | Nominal Value | Measured Value | Deviation | ||

|---|---|---|---|---|---|

| [µm] | [pixels] | [µm] | [µm] | [%] | |

| R1 | 76 | 7.252 | 83.0 | 7.0 | 9% |

| R2 | 101 | 8.752 | 100.2 | −0.8 | −1% |

| R3 | 94 | 7.752 | 88.7 | −5.3 | −6% |

| R4 | 104 | 9.500 | 108.7 | 4.7 | 5% |

| R5 | 121 | 11.500 | 131.6 | 10.6 | 9% |

| R6 | 131 | 12.005 | 137.4 | 6.4 | 5% |

| Ultra Wideband Antennas | Resonant Frequency (GHz) | Bandwidth (GHz) (Up to 6 GHz) | Gain (dB) (Up to 6 GHz) |

|---|---|---|---|

| Circular monopole patch [1] | 2.81 | 2.9 | NA |

| Jasmine Flower patch [1] | 3.75 | 2.25 | NA |

| Rectangular Cu Patch [3] | 2.50, 3.85 | 0.07@2.5, 0.105@3.85 | NA |

| Rectangular Silver Patch [3] | 2.42, 3.77 | 0.11@2.42, 0.12@3.77 | NA |

| C-DRA [26] | 3.5 | 1.28 | 4.4 |

| R-DRA [26] | 3.5 | 1.16 | 4.4 |

| S-DRA [26] | 3.3 | 1.32 | 4.3 |

| Bio-inspired SsDRA | 3.3, 5.3 | 2 | 3.5, 4.0 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Marrocco, V.; Basile, V.; Marasco, I.; Niro, G.; Melchiorre, L.; D’Orazio, A.; Grande, M.; Fassi, I. Rapid Prototyping of Bio-Inspired Dielectric Resonator Antennas for Sub-6 GHz Applications. Micromachines 2021, 12, 1046. https://doi.org/10.3390/mi12091046

Marrocco V, Basile V, Marasco I, Niro G, Melchiorre L, D’Orazio A, Grande M, Fassi I. Rapid Prototyping of Bio-Inspired Dielectric Resonator Antennas for Sub-6 GHz Applications. Micromachines. 2021; 12(9):1046. https://doi.org/10.3390/mi12091046

Chicago/Turabian StyleMarrocco, Valeria, Vito Basile, Ilaria Marasco, Giovanni Niro, Luigi Melchiorre, Antonella D’Orazio, Marco Grande, and Irene Fassi. 2021. "Rapid Prototyping of Bio-Inspired Dielectric Resonator Antennas for Sub-6 GHz Applications" Micromachines 12, no. 9: 1046. https://doi.org/10.3390/mi12091046

APA StyleMarrocco, V., Basile, V., Marasco, I., Niro, G., Melchiorre, L., D’Orazio, A., Grande, M., & Fassi, I. (2021). Rapid Prototyping of Bio-Inspired Dielectric Resonator Antennas for Sub-6 GHz Applications. Micromachines, 12(9), 1046. https://doi.org/10.3390/mi12091046