Scratch Morphology Transformation: An Alternative Method of Scratch Processing on Optical Surface

Abstract

:1. Introduction

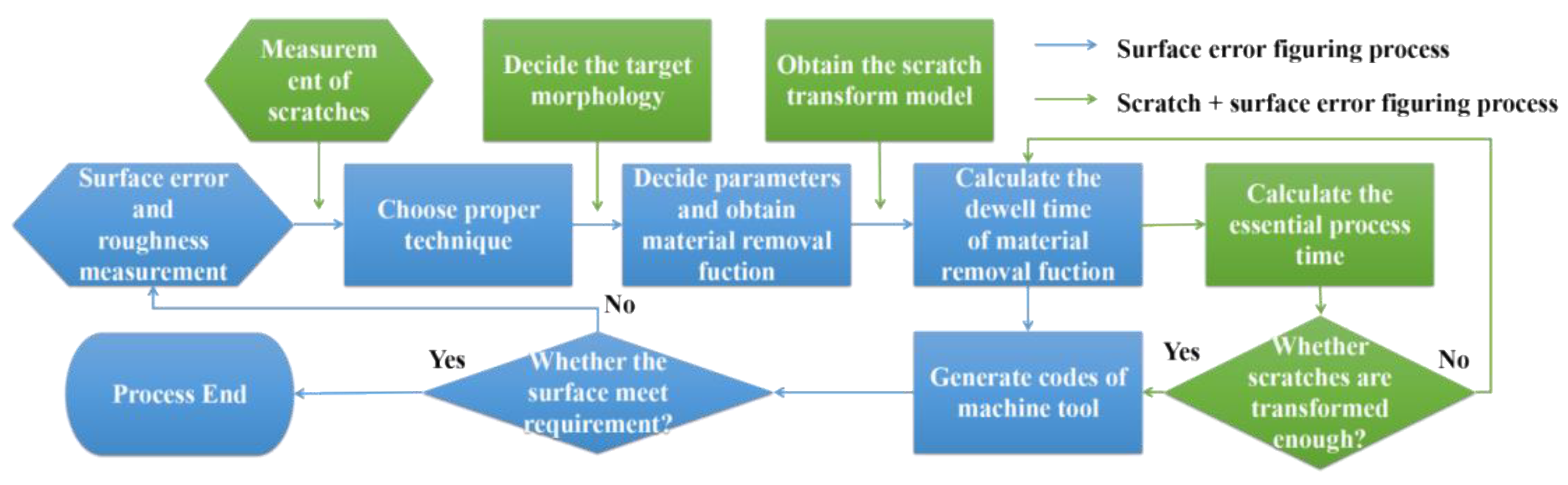

2. Scratch Morphology Transformation Examples of MRF and HF Etching

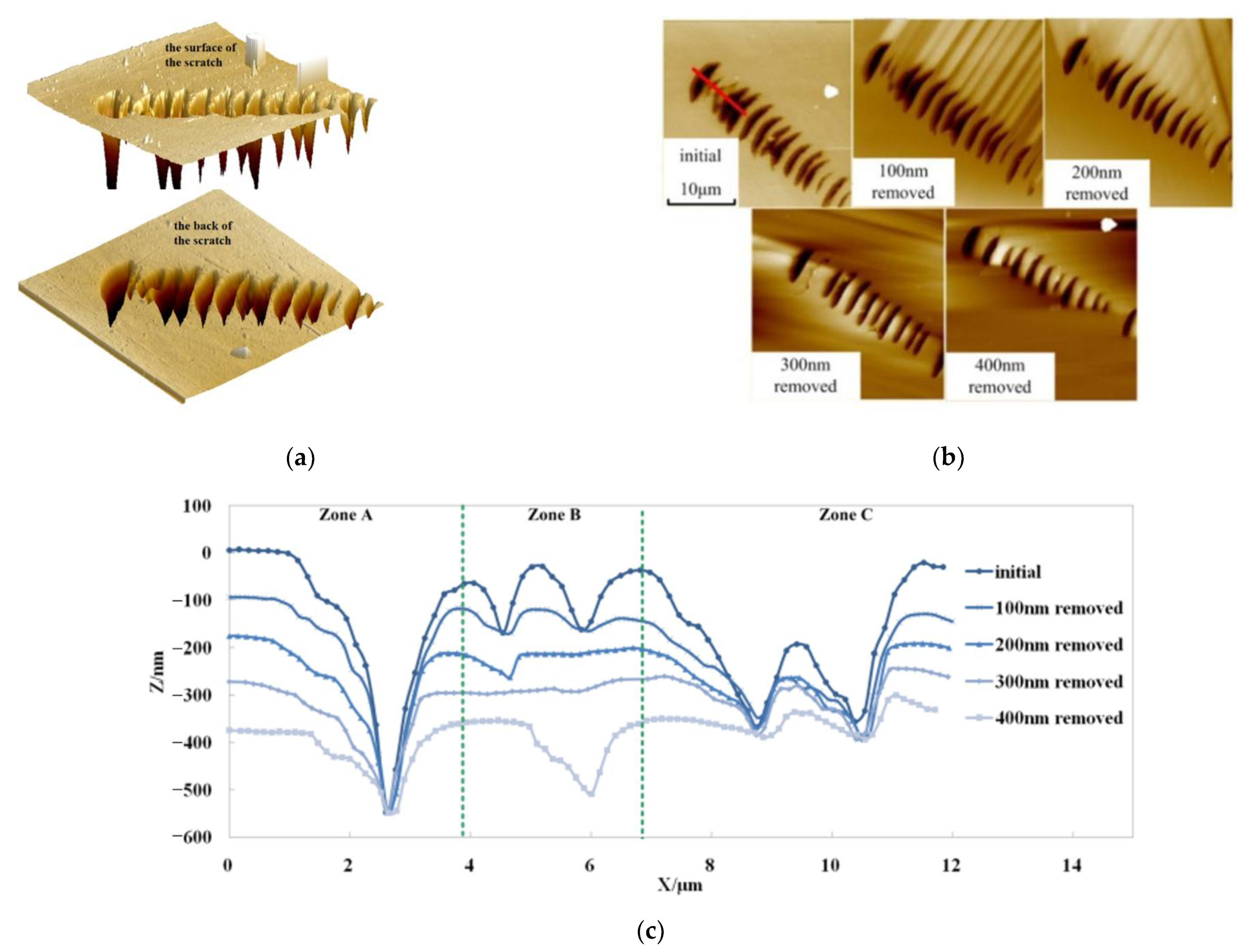

2.1. Morphyolog Evolution of MRF Transform

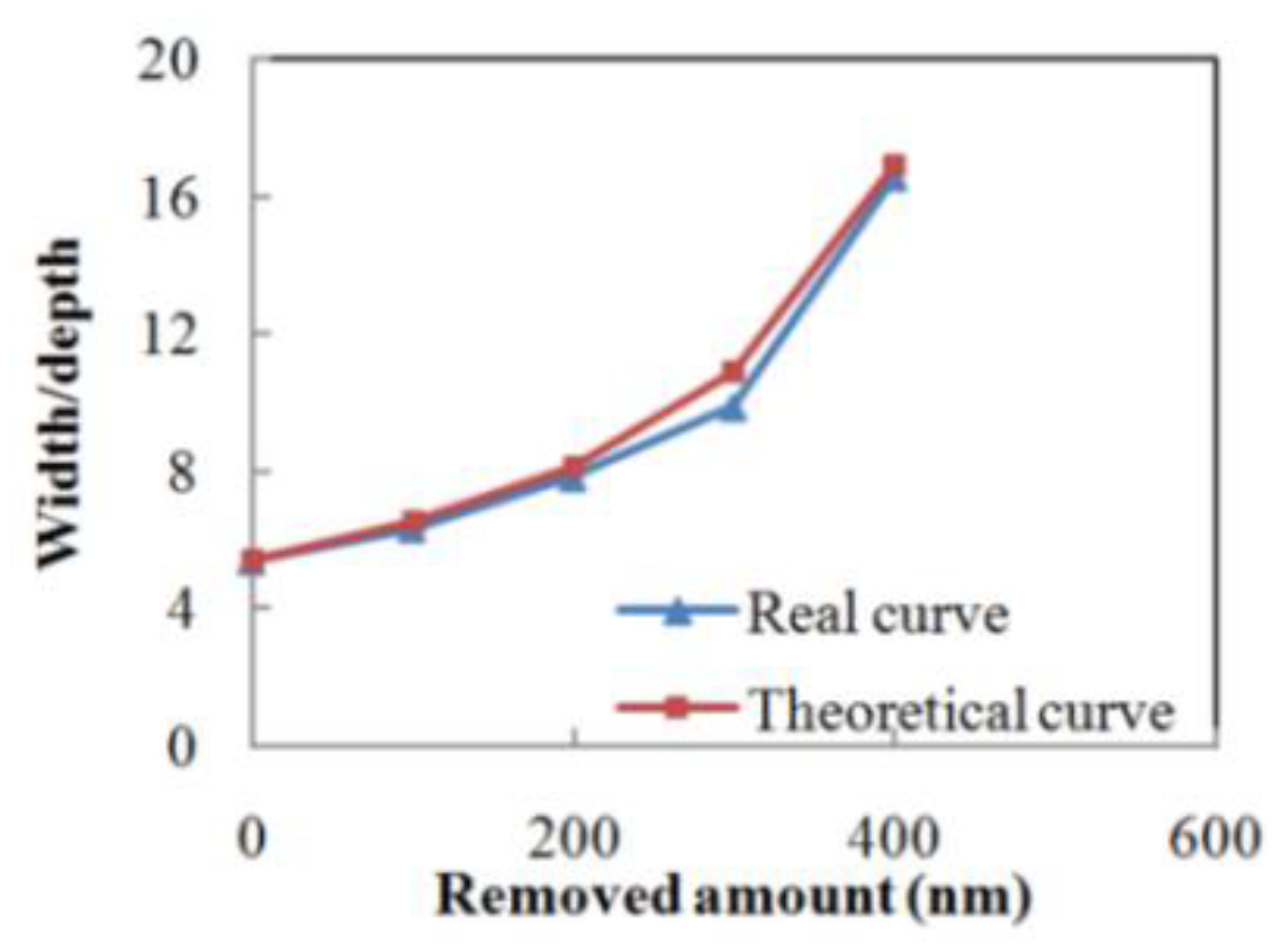

2.2. Analysis and Modeling of MRF

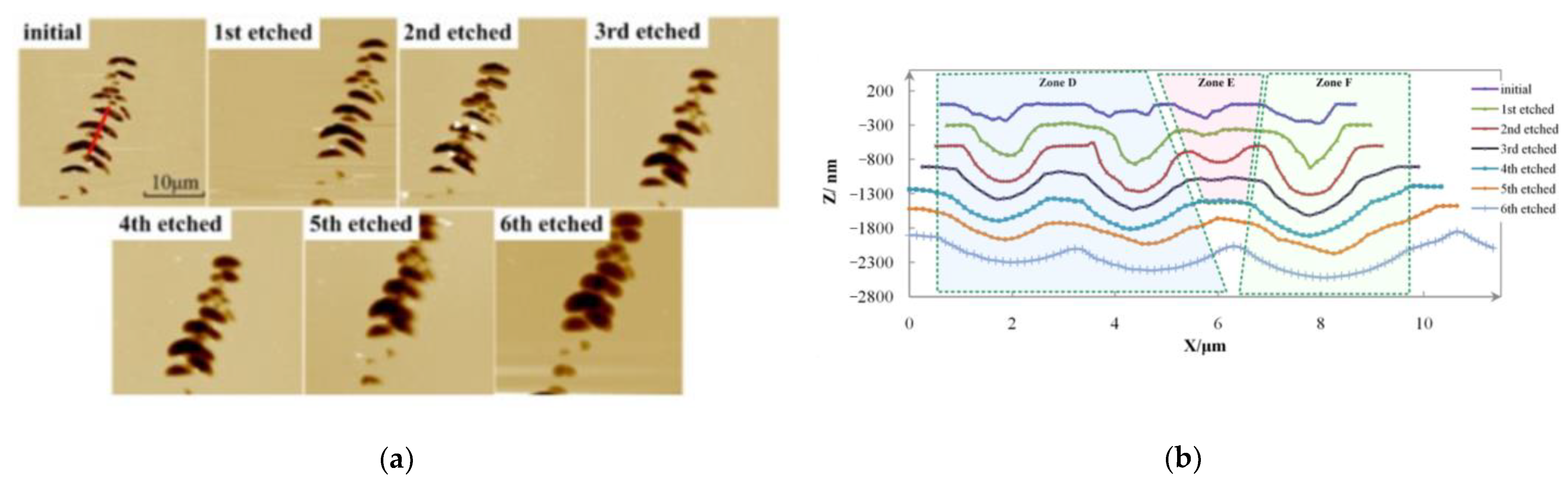

2.3. Morphology Evolution of HF Etching Transform

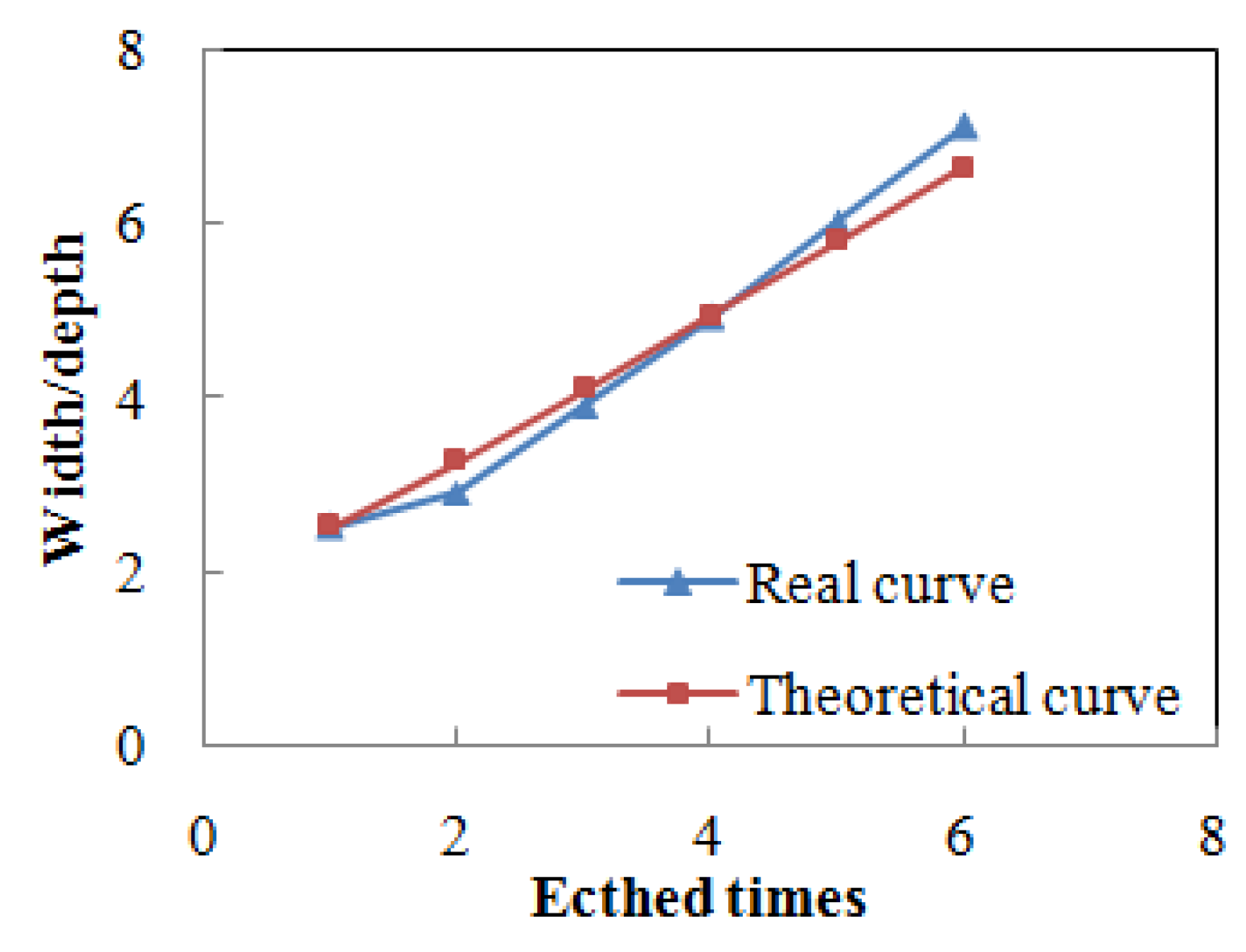

2.4. Analysis and Modeling of HF Etching

- (1)

- at the beginning, the initial depth is unreliable, since the defect pits are too narrow to be detected by the AFM probe;

- (2)

- after the first etching, pit valleys are partly opened, so the detected depth increases. Besides, those sharp edges and angles become blunt and rounded. The second etching opens the defects further and the depths keep the same in following measurements;

- (3)

- the fifth and sixth measurements show the depth shrinks since the boarders of nearby pit cross and the partition disappears. This phenomenon exists only for pit arrays;

- (4)

- in contrast to depth, the width increases constantly, so the W/D keeps increasing.

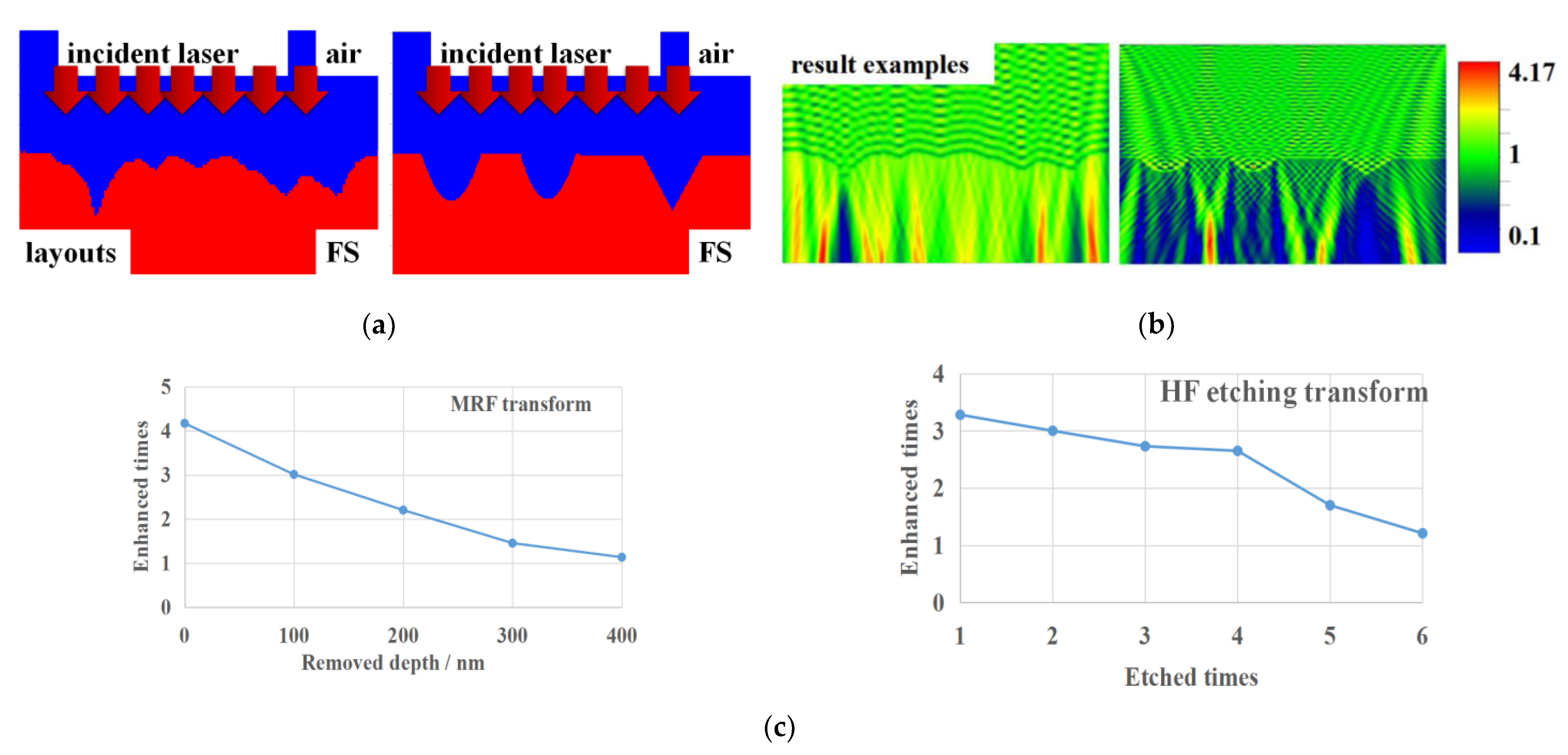

3. The Effect of Transformation

3.1. Light Field Enhancement Decreasing after Transform

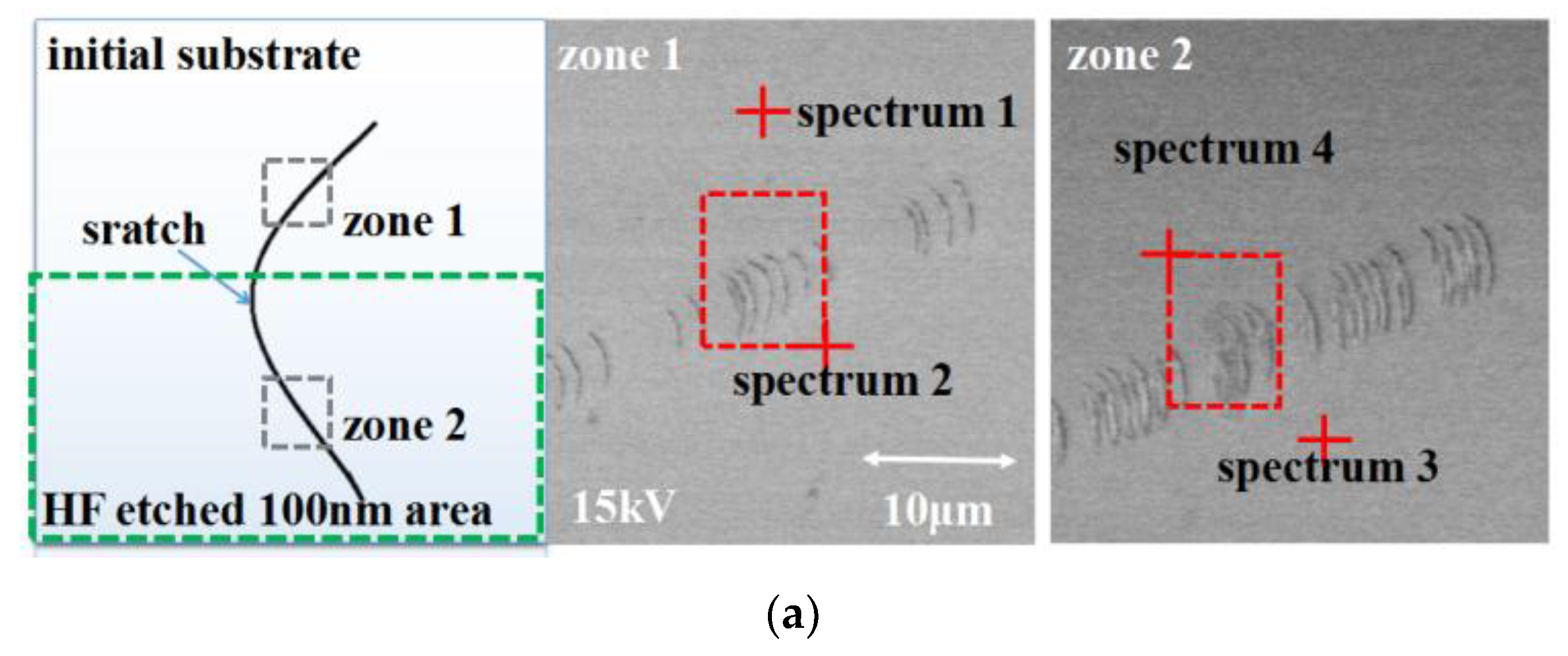

3.2. Chemical Impurity Cleaning after HF Transform

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Conflicts of Interest

References

- Danson, C.N.; Haefner, C.; Bromage, J.; Butcher, T.; Chanteloup, J.-C.F.; Chowdhury, E.A.; Galvanauskas, A.; Gizzi, L.A.; Hein, J.; Hillier, D.I.; et al. Petawatt and exawatt class lasers worldwide. High Power Laser Sci. Eng. 2019, 7. [Google Scholar] [CrossRef]

- Zeng, X.; Zhou, K.; Zuo, Y.; Zhu, Q.; Su, J.; Wang, X.; Wang, X.; Huang, X.; Jiang, X.; Jiang, D.; et al. Multi-petawatt laser facility fully based on optical parametric chirped-pulse amplification. Opt. Lett. 2017, 42, 2014–2017. [Google Scholar] [CrossRef] [PubMed]

- Bloembergen, N. Role of Cracks, Pores, and Absorbing Inclusions on Laser Induced Damage Threshold at Surfaces of Transparent Dielectrics. Appl. Opt. 1973, 12, 661. [Google Scholar] [CrossRef]

- Miller, P.E.; Bude, D.; Suratwala, T.I.; Shen, N.; Laurence, T.A. Fracture-induced subbandgap absorption as a precursor to optical damage on fused silica surfaces. Opt. Lett. 2010, 35, 2702–2704. [Google Scholar] [CrossRef]

- Mori, Y.; Yamamura, K.; Endo, K.; Yamauchi, K.; Yasutake, K.; Goto, H.; Kakiuchi, H.; Sano, Y.; Mimura, H. Creation of perfect surfaces. J. Cryst. Growth 2005, 275, 39–50. [Google Scholar] [CrossRef]

- Ming, L.; Guo, X.; Zhai, R.; Luo, X.; Kang, R.; Jin, Z.; Guo, D. Study on the subsurface damage mechanism of optical quartz glass during single grain scratching. Ceram. Int. 2020, 47, 7683–7691. [Google Scholar] [CrossRef]

- Kordonski, W.; Gorodkin, S. Material removal in magnetorheological finishing of optics. Appl. Opt. 2011, 50, 1984–1994. [Google Scholar] [CrossRef]

- Church, E.L.; Takacs, P.Z. Specification of surface figure and finish in terms of system performance. Appl. Opt. 1993, 32, 3344–3353. [Google Scholar] [CrossRef] [PubMed]

- Kim, D.W.; Park, W.H.; Kim, S.-W.; Burge, J.H. Parametric modeling of edge effects for polishing tool influence functions. Opt. Express 2009, 17, 5656–5665. [Google Scholar] [CrossRef] [PubMed]

- Xiao, H.; Dai, Y.; Duan, J.; Tian, Y.; Li, J. Material removal and surface evolution of single crystal silicon during ion beam polishing. Appl. Surf. Sci. 2021, 544, 148954. [Google Scholar] [CrossRef]

- Bigerelle, M.; Gautier, A.; Iost, A. Roughness characteristic length scales of micro-machined surfaces: A multi-scale modelling. Sens. Actuators B Chem. 2007, 126, 126–137. [Google Scholar] [CrossRef]

- Suratwala, T.I.; Miller, P.E.; Bude, J.D.; Steele, W.A.; Shen, N.; Monticelli, M.V.; Feit, M.D.; Laurence, T.A.; Norton, M.A.; Carr, C.W.; et al. HF-Based Etching Processes for Improving Laser Damage Resistance of Fused Silica Optical Surfaces. J. Am. Ceram. Soc. 2011, 94, 416–428. [Google Scholar] [CrossRef] [Green Version]

- Rubenchik, A.M.; Feit, M.D. Initiation, growth, and mitigation of UV-laser-induced damage in fused silica. Proc. SPIE Int. Soc. Opt. Eng. 2002, 4679, 79–95. [Google Scholar] [CrossRef] [Green Version]

- Shi, F.; Tian, Y.; Peng, X.; Dai, Y. Combined technique of elastic magnetorheological finishing and HF etching for high-efficiency improving of the laser-induced damage threshold of fused silica optics. Appl. Opt. 2014, 53, 598–604. [Google Scholar] [CrossRef]

- Liao, D.; Zhang, F.; Xie, R.; Zhao, S.; Wang, J.; Xu, Q. Deterministic control of material removal distribution to converge surface figure in full-aperture polishing. J. Manuf. Process. 2020, 53, 144–152. [Google Scholar] [CrossRef]

- Jones, R.A. Grinding and Polishing with Small Tools under Computer Control. Opt. Eng. 1979, 18, 102–107. [Google Scholar] [CrossRef]

- Suratwala, T.I.; Miller, P.E.; Feit, M.D.; Menapace, J.A. Scratch Forensics. Opt. Photonics News 2008, 19, 12–15. [Google Scholar]

- Mikosza, A.G. Section-and-Etch Study of Hertzian Fracture Mechanics. J. Appl. Phys. 1971, 42, 5540–5545. [Google Scholar] [CrossRef] [Green Version]

- Hu, H.; Dai, Y.; Peng, X.; Wang, J. Research on reducing the edge effect in magnetorheological finishing. Appl. Opt. 2011, 50, 1220–1226. [Google Scholar] [CrossRef]

- Wong, L.; Suratwala, T.; Feit, M.D.; Miller, P.E.; Steele, R. The effect of HF/NH4F etching on the morphology of surface fractures on fused silica. J. Non-Cryst. Solids 2009, 355, 797–810. [Google Scholar] [CrossRef]

- Chai, Y.; Zhu, M.; Wang, H.; Xing, H.; Cui, Y.; Sun, J.; Yi, K.; Shao, J. Laser-resistance sensitivity to substrate pit size of multilayer coatings. Sci. Rep. 2016, 6, 27076. [Google Scholar] [CrossRef] [PubMed] [Green Version]

| Removed Amount | Width (μm) | Depth (nm) | Width/Depth |

|---|---|---|---|

| 0 | 2.955 | 548.61 | 5.39 |

| 100 nm | 2.865 | 451.65 | 6.34 |

| 200 nm | 2.913 | 371.91 | 7.83 |

| 300 nm | 2.733 | 276.61 | 9.88 |

| 400 nm | 2.814 | 169.71 | 16.58 |

| State | Width/nm | Depth/nm | W/D |

|---|---|---|---|

| initial | 1380 | 272 | 5.1 |

| 1st etched | 1500 | 611 | 2.5 |

| 2nd etched | 2040 | 711 | 2.9 |

| 3rd etched | 2750 | 713 | 3.9 |

| 4th etched | 3250 | 713 | 4.9 |

| 5th etched | 4160 | 693 | 6.0 |

| 6th etched | 4760 | 670 | 7.1 |

| Parameters | Value |

|---|---|

| Simulation area | 12 μm × 6 μm |

| Discrete space interval | 10 nm |

| Discrete time interval | 5 × 10−17 s |

| Time length | 10−13 s |

| Boundary condition | PML |

| Steps | 2000 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhou, G.; Tian, Y.; Shi, F.; Song, C.; Tie, G.; Liu, S.; Zhou, G.; Shao, J.; Wu, Z. Scratch Morphology Transformation: An Alternative Method of Scratch Processing on Optical Surface. Micromachines 2021, 12, 1030. https://doi.org/10.3390/mi12091030

Zhou G, Tian Y, Shi F, Song C, Tie G, Liu S, Zhou G, Shao J, Wu Z. Scratch Morphology Transformation: An Alternative Method of Scratch Processing on Optical Surface. Micromachines. 2021; 12(9):1030. https://doi.org/10.3390/mi12091030

Chicago/Turabian StyleZhou, Guangqi, Ye Tian, Feng Shi, Ci Song, Guipeng Tie, Shijie Liu, Gang Zhou, Jianda Shao, and Zhouling Wu. 2021. "Scratch Morphology Transformation: An Alternative Method of Scratch Processing on Optical Surface" Micromachines 12, no. 9: 1030. https://doi.org/10.3390/mi12091030

APA StyleZhou, G., Tian, Y., Shi, F., Song, C., Tie, G., Liu, S., Zhou, G., Shao, J., & Wu, Z. (2021). Scratch Morphology Transformation: An Alternative Method of Scratch Processing on Optical Surface. Micromachines, 12(9), 1030. https://doi.org/10.3390/mi12091030