1. Introduction

Micro-manipulation has been an active field of research for more than three decades [

1,

2]. We can distinguish two approaches to manipulate micro-objects. The first one is non-contact manipulation, where the forces (magnetic or electrostatic, for instance) are exerted at a certain distance from the manipulated objects [

3,

4]. This approach has many benefits such as direct action on specific objects (cells, etc.) from a certain distance, a short response time, and the capacity of using highly miniaturized objects as manipulators (particles, flagellates, etc.) However, non-contact manipulation suffers from some drawbacks such as low blocking forces, the sensitivity to the used material, and the fact that the produced forces are not localized, which might affect the other objects in the workspace. The other approach is contact manipulation, which is able to compensate for some of these drawbacks.

The most used physical architecture in micro-manipulation consists of a simple tweezers mounted on a serial or parallel robot [

5,

6]. This architecture is inspired by classical industrial robots and is not necessarily the most adequate for micro-manipulation. Indeed, the ratio between the robot’s size and manipulated object is much higher in micro-manipulation. For example, let us consider a compact robot of 10 cm side manipulating a 10

m cell. The ratio between the robot dimension and cell is about

. From the size ratio point of view, it is like manipulating a 10 cm side object with a robot which is 1 km large. We can thus see that any relative uncertainty in the mechanical structure of the robot has a huge impact on the precision and accuracy of the robot and the reliability of the performed task. In addition, any rotation of the object would require the rotation of the whole robot, which is unsuitable when manipulating in confined spaces such as inside Scanning Electron Microscopes [

7] or inside the human body [

8].

One way to avoid those issues is to perform local rotations through dexterous in-hand manipulation. Robotic dexterous manipulation has been an active field of research for more than three decades [

9,

10,

11]. Most research in this field is focused on grasping and manipulation of daily life objects using anthropomorphic hands [

12,

13]. The objective is to allow mobile manipulators and humanoid robots to manipulate arbitrary shaped objects typically made for humans. The problem consists in finding of the successive stable grasps able to reconfigure the position and orientation of the manipulated object. Several strategies are used to this end, such as rolling without sliding, finger gaiting, and others [

14].

The problem of in-hand manipulation of arbitrarily shaped objects is very complex. In [

15], a huge computation power composed of 384 workers (each worker has 16 core CPU) and 8 GPUs (NVIDIA V100) for policy training which results in the generation of 2 years of simulated experience per hour and a system with 32 CPU cores and 3 GPUs (NVIDIA P40) for vision model training were used to train the system to perform low accuracy manipulation operation using an anthropomorphic hand.

In industrial manipulation in general and micro-manipulation in particular, the problem of dexterous in-hand manipulation can be somehow simplified. Indeed, robot architecture and the shapes of the manipulated objects are usually known before manipulation, since they are parts of the manufacturing process. This allows us to perform pre-computation operations that are invariant with regard to the manipulating robot and properties of the manipulated object [

16].

In micro-manipulation, the kinematics for each probe (or finger) of the manipulating robot is usually simple, such as Cartesian architectures with pure translations are common [

17]. Those differences might help to reduce the complexity of dexterous in-hand manipulation, which also highly depends on the considered shapes and the number of possible contact points

c. Considering simple polyhedrons such as cuboids [

1,

18], tetrahedrons, or objects with a limited number of facets has already been resolved [

19,

20].

However, when the complexity of the shape increases because of curved surfaces, the problem becomes much more complex. In [

16,

21,

22], automatic 2-DoF manipulation of arbitrary shaped objects was accomplished by pre-computing a graph that represents all the stable grasps and the possible operations (rolling without sliding, finger gaiting, etc.) The proposed method was also able to take into account the adhesion forces that, on the one hand, improves the stability of the grasps but, on the other hand, disturbs the grasp when detaching one or several fingers. Extending those approaches from 2-D to 3-D induces a significant increase in complexity. Indeed, the number of potential contact points

c in 3-D (on object surface) is much higher than in 2-D (on curve). In addition, the number of DoF (3 to 6) as well as the number of fingers required for grasping and manipulating increases. All those parameters make the grasp space significantly bigger and the manipulation problem much more complex.

The contribution of this paper is thus to propose a 3-D dexterous in-hand micro-manipulation approach from a series of 2-D manipulation steps. Indeed, considering that all the fingers can only translate as it is the case in most multi-contact micro/nano-manipulation platforms; translating any object consists in synchronously translating all the fingers. When it comes to rotations, we know that any 3-D rotation can be decomposed into 3 successive rotations about 2 different axes in the current frame (XYX rotations, for instance). One can thus define two axes on the object to be considered for rotations. The normal plans to the two rotation axes intersect with the surface of the manipulated object and define two 2-D curves. Finally, rotating the object in 3-D consists in rotating it successively in 2-D considering the defined curves. The previously developed methods can thus be considered for 3-D manipulation. However, some key differences when switching from one rotation step to another must be considered to guarantee the continuity of the manipulation. These differences lead to new constraints when planning the manipulation that must be considered when formalizing the manipulation problem and proposing a solution for it.

In other words, this paper provides the first method to define 3-D finger trajectories enabling to perform in-hand 3-D rotations of a micro-object. The method is able to take into account some of the microscale specificities such as the adhesion.

The next section introduces the physical modeling for micro-manipulation in presence of adhesion forces.

Section 3 formalizes the problem of the complexity increase and the proposed approach to leverage its effect. The manipulation strategy based on a graph search algorithm is then presented in

Section 4. The simulation results are presented in

Section 5 followed by a discussion and conclusion section.

3. Problem Formalization

In order to perform fingers’ path planning, we assume that the object’s shape is known through its Computer-Aided Design model (CAD model). Considering the small size of the manipulated object, we also assume that the fingers are placed on their respective 3-D translation stages as it is widely done in robotic micromanipulation (e.g., in [

24]) and that the translation ranges are significantly larger than the object’s dimensions. We also consider only two and three fingers grasps. The admissible contact points (

c) on the object are obtained by sampling the object’s surface (see

Section 3.2).

To generate finger trajectories, we build a

, where each stable grasp is connected to its subsequent stable grasp(s). Each element of the graph is considered as a

which is connected by

to other nodes. Finding an optimal finger trajectory to rotate an object consists in finding a path in the

. Each

of the

is represented by four parameters, i.e.

where

i,

j, and

k define the indexes of contact points on the object of the first, second and third fingers respectively, and

l defines the index of angular position of the object. Considering that the index of a finger is 0 when the finger is not grasping the object, and

c is the number of contact points, the indexes

i,

j, and

k are integer between 0 and

c. The

represent the links between two subsequent stable grasps. It includes edges representing (i) rotation of the object taking into account the fingers’ rolling, (ii) a finger placement on the object, and (iii) a finger removal. The construction of the

has been discussed in detail in [

16]. Moreover, we also briefly describe the construction of the Graph in

Section 3.3 for its better understanding.

For fingers’ path planning, we use algorithm whose computational complexity is where b is the branching factor (average number of branches per node), and d is the depth (number of nodes to reach the goal). For branching factor b, there are two cases, the first case is when two fingers are in use, and the second is when three fingers are used. For the first case, when two fingers are already in contact with the object, the branching factor is the sum of operations: clockwise rotation, counter-clockwise rotation, and addition of the third finger over the remaining contact points. Whereas for the second case, when three fingers are in use, the branching factor is the sum of operations: clockwise rotation, counter-clockwise rotation, and detaching one of the fingers. For depth d, the total number of nodes are all the possible equilibrium grasps, which is the result of the number of contact points c of an object, the total number of fingers (F) being used to manipulate the object, and the number of possible angular positions/orientations () of the object. The higher the number of nodes, the more time the algorithm will take to find the trajectory. Thus, we propose to reduce the depth using Euler’s angles in order to reduce the computational complexity.

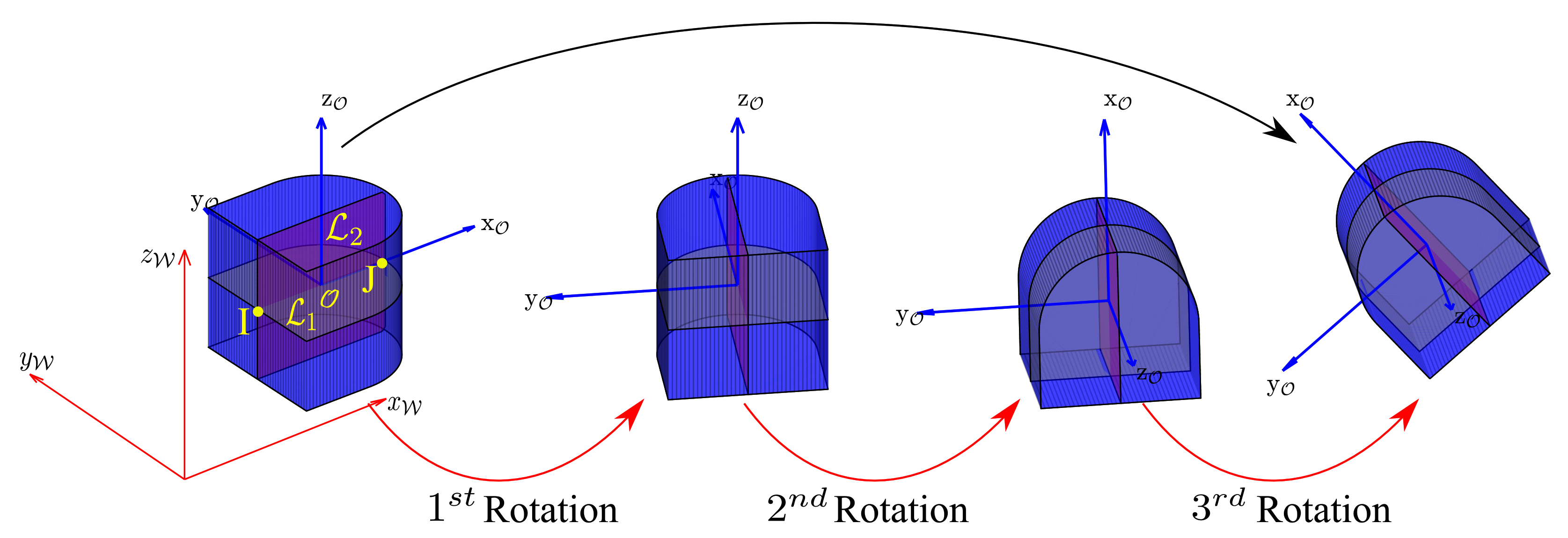

3.1. Reducing the Complexity Using Euler’s Angle

In planar (2-D) manipulation, where we consider manipulating an object in a single plane, the depth

d is computed as

Whereas to manipulate an object in spatial case (

), we imagine

number of planes over which the contact points are generated. In this case, the depth

d is computed as

From Equation (

6), we can conclude that the increase in depth exponentially increases the computational complexity. One of the challenges in 3-D manipulation is to leverage the complexity of the search algorithm. According to

Euler’s Angles, it is possible to decompose any 3-D rotation into three individual 2-D rotations along any two orthogonal axes [

25]. Thus, we define a frame defining the object position as

and propose to only retain two orthogonal planes

at

-axis and

at

-axis intersecting the object over lines

and

as illustrated in

Figure 1b. Since, the three individual 2-D rotations will be carried out in two different planes, we consider the two intersecting points

I and

J of lines

and

as a common link for these three individual rotations. The three individual rotations will be carried out as:

over

,

over

, and

over

, respectively, as represented in

Figure 2, which will limit the branching factor and reduce the number of grasps to the sum of grasping possibilities of each rotation carried out over these two planes as

The reduction of complexity introduced by two planes also reduces the genericity of our approach. Indeed, the considered objects should have a geometry in which both planes and can be defined. However, this is usually the case for micro-objects manufactured using the classical microfabrication methods.

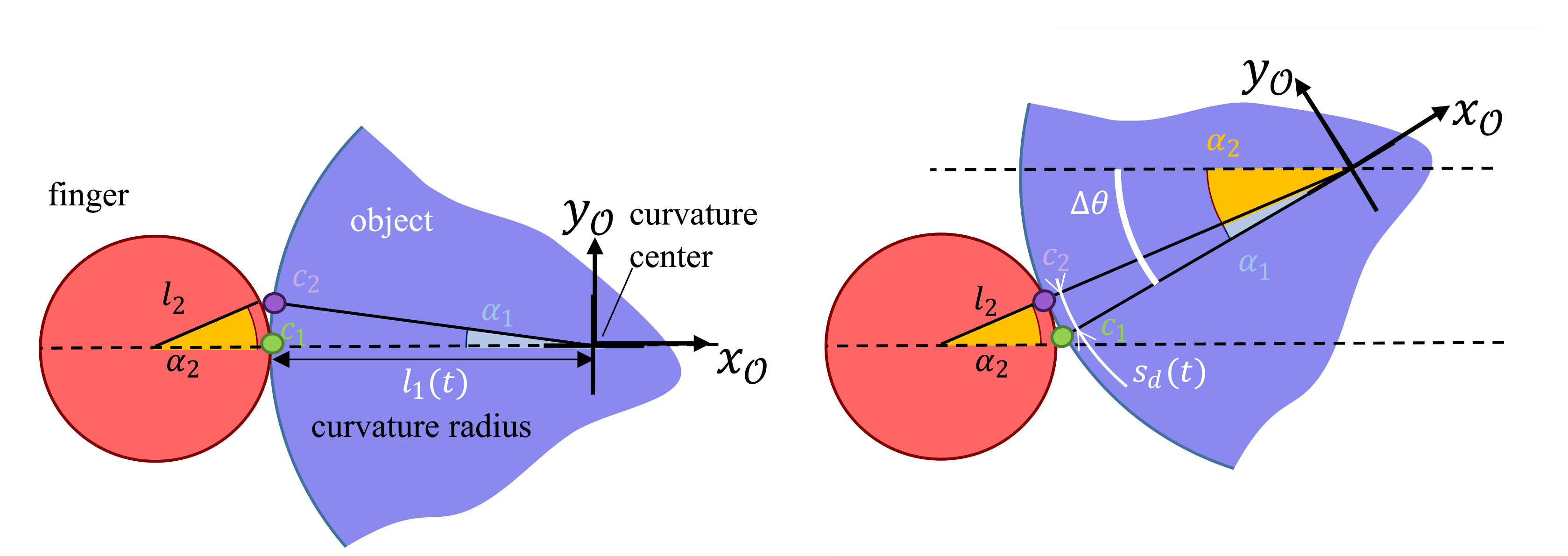

3.2. Sampling Strategy

As we consider that the object’s CAD model is known, we sample the manipulation lines and to generate contact points (c) for grasping. For sampling on the object, we consider that the rolling between two successive sample points corresponds to a pre-defined rotation of the object.

In that case, the distance

between two contact points is the function of finger radius

, the rotational step

, and the local curvature radius of the object

. To formulate the equation, we will refer to

Figure 3, where

is the contact point from where the object starts rotating around the finger, and

is the contact point where the rotation finishes. As the object’s total rotation (

) is the sum of the two angles

and

, and since both rolling distances

on the finger and

on the object are equal, we can determine the instantaneous curvilinear sampling distance

:

where the curvature radius of the object

on

-axis can be determined using the curvature formula defined for parametric equation:

where

,

,

, and

are the first and second derivatives of the parametric equation.

3.3. Graph G

The sampling strategy (Equation (

8)) enables to define the location and number of contact point along the lines lines

,

. Concretely, it means that we consider a discrete number (

c) of contact points and discrete rotations defined by the constant rotation step

. Parameters

i,

j,

k are integers in

(0 means that the finger is not used in the grasp), and parameter

l is integer in

meaning that the initial position

is defined by

. As an example,

means that the first finger is not used (

), the second and third fingers are respectively placed on contact position 2 and 5 (

,

), and that the current angular position of the object defined by (

) is

. The stability of each potential grasping is checked using the static equilibrium equation (Equation (

3)). Each stable configuration becomes a

in the

, in which a path represents a manipulation sequence. The Nodes (

n) are connected to the other to form the Graph

in the following way:

The 2-fingers grasps are respectively connected to (i) the 2-fingers grasp reachable by finger rolling following a clockwise rotation, (ii) the 2-fingers grasp reachable by finger rolling following a counter-clockwise rotation and (iii) to every 3-fingers grasps corresponding to a third finger addition.

The 3-fingers grasps are connected in a similar way to 3-fingers grasps (i) and (ii) and to (iii) three 2-fingers grasps considering each finger removing.

The next section defines the manipulation strategy including the cost and heuristic function to define an optimal path in the

, whose resolution using

will be presented in

Section 5.

4. In-Hand Manipulation Strategy

Given the number of fingers and object geometry, the finger trajectory generation is accomplished using two steps. The first step is to compute the stable grasps and generate the Graph (G) for each line and , while the second step is to define a path by traversing the graph(s) to achieve the desired configuration.

The object’s modeling is restricted only to two lines and and intersecting contact points I and J being the only common link, induces some constraints for successive rotations. These constraints are:

The first rotation should end at the intersecting points I and J.

The second rotation should start from these intersecting points I and J and end at the same intersecting points.

The third rotation should start from these intersecting points I and J.

In previous work, Seon et al. [

16] achieved only desired pose of object for planar manipulation, while to manipulate the object in 3-D, we need to comply with these constraints. Thus, we propose an original method to provide finger trajectories using

algorithm.

The

algorithm uses a heuristic for traversing the graph(s), while ensuring that it computes a path with minimum cost through the nodes

n. The algorithm optimizes the function

, which consists of the cost function

and heuristic function

as

Please note that in case of having two nodes with the same value of function , we chose a classical “Tie breaking" strategy consisting in exploring first the node having the minimal heuristic .

4.1. Cost Function

Cost function is the parameter which computes the cost of activity being performed to carry out the manipulation process from previous node () to current node (n). As per our strategy, there are two operations that can be performed for the manipulation task; (i) rolling of object and (ii) reconfiguration of fingers (finger gaiting):

The “rolling operation”, changes the orientation of object when 2 or 3 fingers are used, reaching to node

n from previous node

without any reconfiguration. Thus, we formalize the value of cost when a rolling operation is performed as

where

is the number of fingers used to roll the object, and

is the cost of the previous node.

When the “finger gaiting” operation is performed, either a finger is added or removed while the object remains in the same orientation; thus, the cost

is formalized as

where

is the reconfiguration cost. Concretely, we define the value of reconfiguration cost

at

. It means that we assume that a reconfiguration has a similar cost to a quarter-turn of rotation using two fingers (

).

4.2. Heuristic Function

In search algorithms, the heuristic function

estimates the minimum cost from the current node

to the goal node

. Please note that

,

or

means the first, second or third finger is respectively not used. In order to guarantee the convergence of the

algorithm, the heuristic must underestimate the remaining cost. To develop the heuristic function, we take into account all the parameters of a node (number of fingers being used, contact point on object, and angular position of object) as

where

is the difference between current orientation of object and goal orientation of object,

is the pre-defined rotational step, and

is the function of the non-ordered set

which provides the total number of estimated reconfigurations (addition/removal operation). Each element i.e.,

,

and

provides one of the four conditions in set

based on which fingers are used corresponding to

i,

j,

k indexes of

n and

respectively. The conditional output of

, or

is:

“” (not used), when the same finger is not used in current node and goal node (e.g., from to , finger 3 is not utilized in both nodes; in this case, the output of is “”).

“” (addition/removal), when the current node is using a finger while the goal node doesn’t and vice versa (e.g., from to , the position of finger-2 is at 20th contact point in n, while in finger 2 is not used; similarly finger 3 is not used in the n, while its position is at 25th contact point in . In this scenario, the output of and is “”).

“” (direct path), when the same finger is being used in both n and , and can directly reach from n to , by rolling only.

“” (indirect path), when the same finger is being used in n and , but can not directly reach from n to by rolling only.

The determination of the two last states “

” and “

” requires to check if the finger can directly go from

n to

by rolling only. In that way, we compute:

When , , or , it indicates respectively that the finger 1, 2 or 3 can move from current node to goal node directly by rolling. In such a case, the output of or is respectively “” (direct path). Otherwise, if the value is , , or it will need a reconfiguration; thus, the output of or will be “” (indirect path).

4.3. Calculation of Estimated Reconfigurations

To estimate the total number of reconfigurations, we compute the minimum reconfiguration operations

that are required to move from current node (

n) to goal node (

). The

Table 1 defines this value

for every possible cases considering a 2 fingers final grasp.

The examples described in

Table 1 enable to illustrate the general principle. Let us take the first data (a), i.e.,

, and

; for both used fingers (1 and 2), the output is “

”, and the third finger is not used in both current and final nodes (“

” case). We are going to show that this case requires at least 6 reconfiguration operations (

) as:

First, we have to add an unused finger, i.e., finger-3 to any admissible node going on to the case (b);

Then, remove finger-1 or finger-2, respectively, going on to case (c) or (c). We consider the first case in the following;

Then, place finger-1 in such a way a direct path is possible with this finger, going on to case (d) having = “”;

Then, remove finger-2, going on to the case (e);

Place finger-2 in such a way a direct path is possible with this finger, going on to case (f) having = “”;

At the end, remove finger-3 going on to the case (g) where the final node can be reached by rolling without reconfiguration.

This example illustrates the number of reconfigurations required for most of the cases described in

Table 1. The last case is the case (c

), where the first step is to add an unused finger, i.e., finger 3 to any admissible node, going on to the case (d) already mentioned above.

For all the possible nodes (

n), the

Table 1 enables to estimate the minimum number of reconfigurations

required from

n to

. The cost function and heuristic function are thus completely defined.

5. Results

In order to illustrate the behavior and properties of the proposed method, some examples are going to be considered. These examples defined in a first subsection use several geometries and are based on physical properties of micro-objects available in literature. The first analysis will highlight the impact of adhesion and friction on the size of the number of Nodes in the Graph (G) in a second subsection. As in the three planar rotations defined in finger planning, the second is the most constrained one; it will be carefully analyzed in a third subsection. The two last subsections will be dedicated to the finger trajectories to perform a complete 3-D rotation of micro-objects and to the computation time enabling to show the relevance of the proposed heuristic.

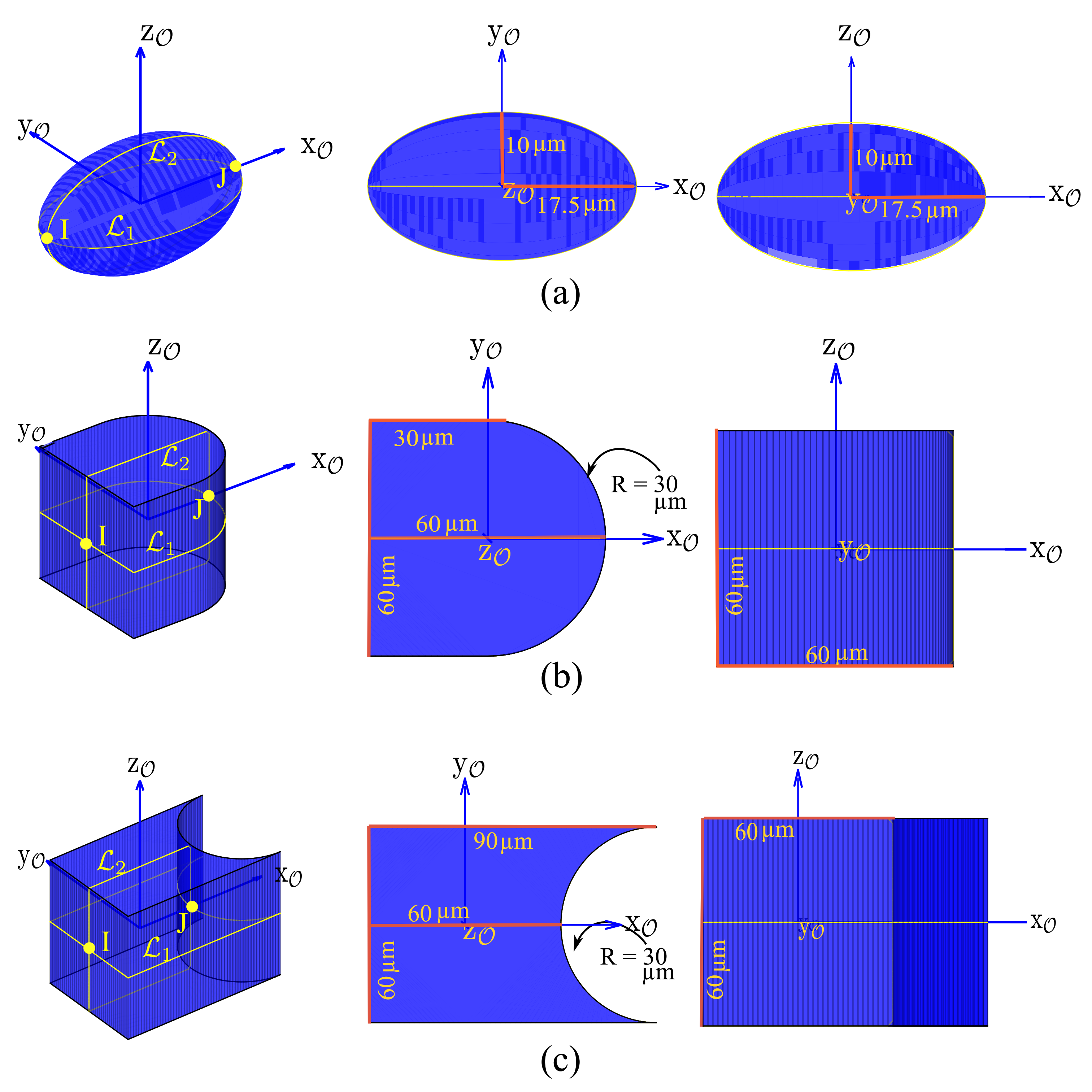

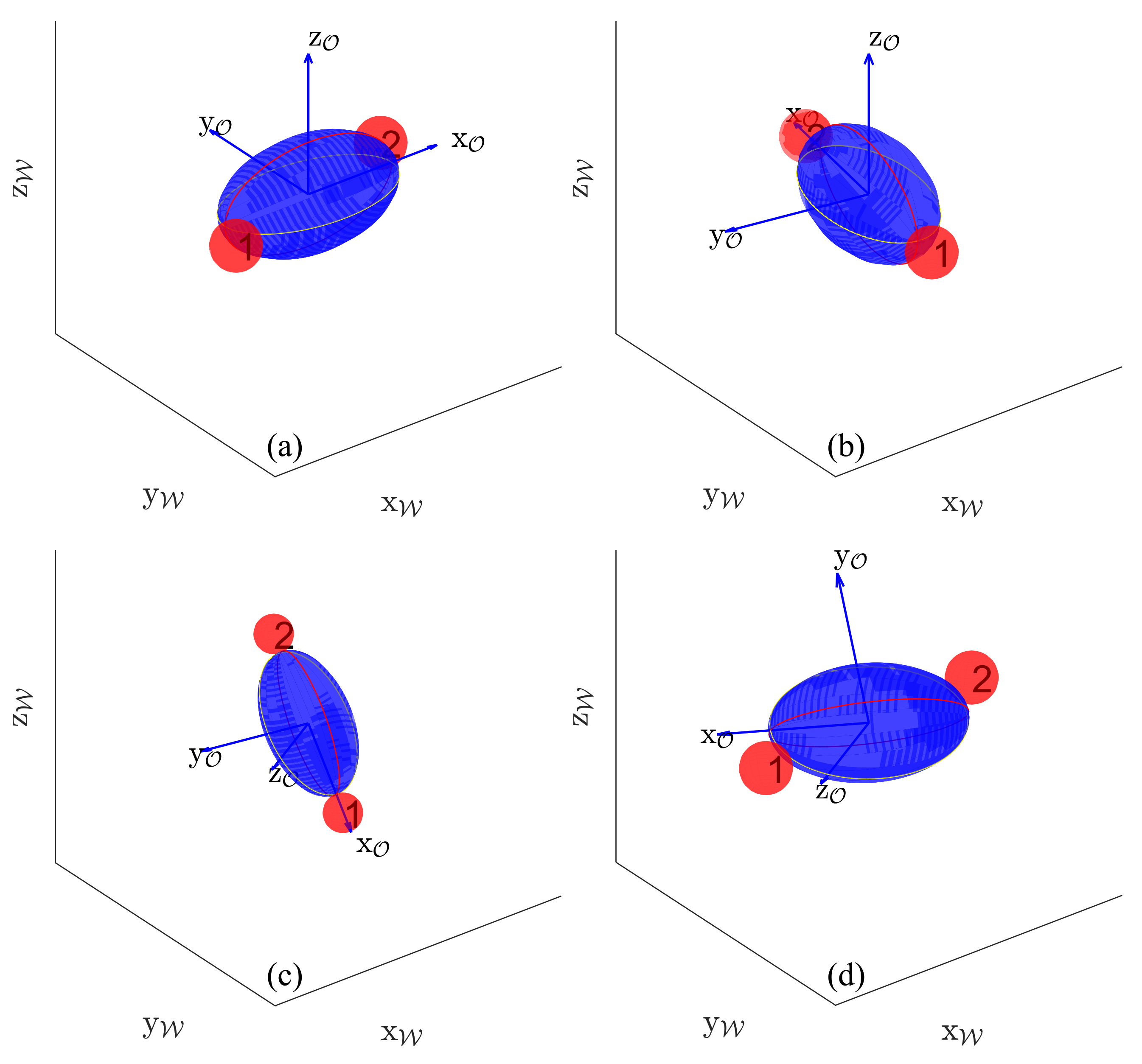

5.1. Parameters of the Examples

The proposed methodology presented in the previous sections has been simulated and implemented to generate the finger trajectories for three objects with different curvatures in 3-D space, i.e.,

Ellipsoid,

Convex shaped object and

Concave shaped object provided in

Figure 4, using 3 fingers with 9

m diameter spherical tips. For the simulations, we have considered the physical properties of Silicon for all the fingers and the objects, a pull-off force of 1.5

N [

26], and a maximal grasping force of 30

N. As described in

Section 4, we propose to decompose the movement in 3 successive rotations as:

over

,

over

, and

over

, respectively. The sampling of the objects along

and

has been done using Equation (

8) considering

.

5.2. Impact of Adhesion and Friction on Graph (G)

Table 2 represents the impact of friction coefficient on the grasp stability (no. of nodes) when adhesion is considered and when it is ignored. The contact points are sampled on the lines

and

curves that represent the intersection of the object illustrated in

Figure 4 with the two considered rotation paths. The other parameters (finger radius, adhesion forces, and grasping forces) are constant.

We see that in the presence of adhesion forces, the number of nodes generated are the same for different values of friction coefficient. However, in the absence of adhesion forces, the friction coefficient plays an important role in the stability. Indeed, the higher the friction coefficient, the higher the grasping possibilities. In the rest of the paper, we are considering a friction coefficient of 0.3.

As a conclusion, taking into account the adhesion in microscale induces a graph G whose size is almost independent of the friction coefficient but whose size is significantly larger than without adhesion.

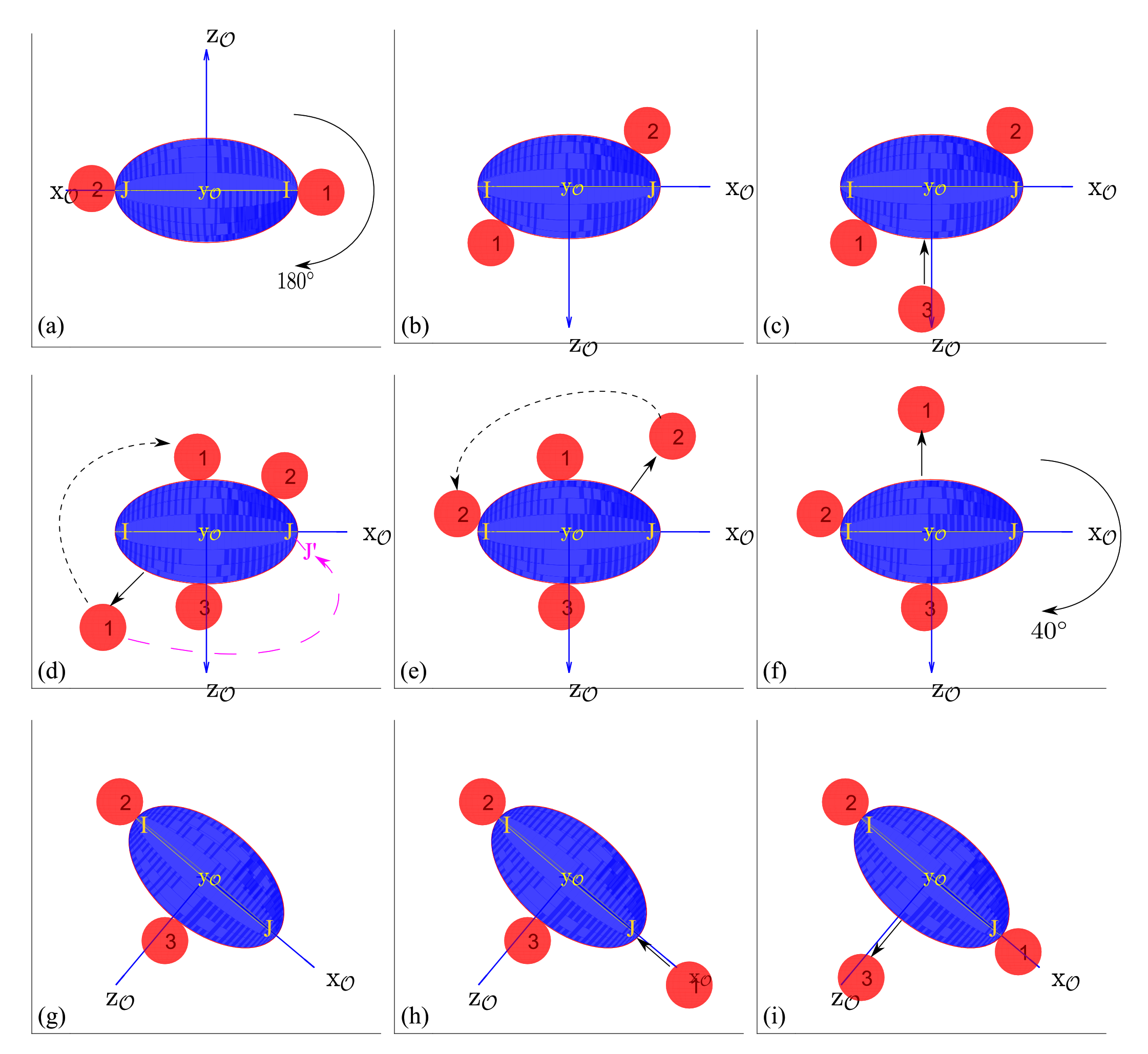

5.3. Analysis of the Second Rotation

As for rotations, the most challenging rotation to carry out is the intermediate one (2nd rotation), as the fingers’ positions need to start from and end at specific points (i.e., intersecting points I, J of orthogonal planes on the object). Due to this condition, the second rotation requires one or more reconfiguration, whereas for first and third rotations, they can directly be carried out by rolling most of the time.

As mentioned, the second rotation is the most challenging to carry out because of the constraints about the initial and final positions of the fingers on the object.

Figure 5 represents some steps involved in the second rotation, where the current node

(a), and goal node

(i). It means that we expect a rotation of

(going from 1 to 12 in the fourth coordinates) which represents

. In the initial configuration, finger-1 is placed on I (1 as the first coordinate of

n), finger-2 is placed on J (defined by 38 as the second coordinate of

n), and finger-3 is not used (defined by 0 as the third coordinate of

n). In the final configuration, finger-1 will be placed on point J, finger-2 will be placed on point I, and finger-3 will not be used.

Going from the initial configuration

Figure 5a to the final configuration

Figure 5i is performed in four major phases. The first phase is a half turn of the object, going from

Figure 5a to

Figure 5b, where the fingers are rolling on the object. The second phase is a sequence of finger gaiting in order to reach

Figure 5f. In the third phase, the object reaches the final orientation

Figure 5g in which finger-2 rolls to its final position I. The last phase is a second sequence of finger gaiting to place the finger-1 on point J and remove finger-3. This sequence is highly constrained by the adhesion. Indeed, in the case of 3 fingers grasping, when a finger is being removed, it pulls the object and may detach the object from the two other fingers. Concretely, only few configurations exist where a finger can be removed. This particularity of the micro-object’s behavior induces the original sequence of finger gaiting presented on

Figure 5c–i.

Typically, on

Figure 5d, we could expect that the finger-1 goes directly to the point J

, from where it could reach its final position by rolling. The algorithm makes another choice, because if finger-1 is directly placed on J

, then finger-2 will not be able to be removed in the next step, i.e.,

Figure 5e.

At the end, because of the constraint of the finger removing, the final configuration is reached after 4 finger-placements and 4 finger-removals, a total of 8 reconfiguration operations. As per the estimated reconfigurations table (

Table 1), the heuristic function expects to have only 6 reconfigurational operations (

is “

”,

is “

”, and

is “

”). However, the optimal path contains 8 operations to carry out this second rotation.

As mentioned above, the second rotation starts and finishes with a two fingers grasp. Concretely, there are 6 combinations due to fingers’ permutation (

P

= 6) which have to be evaluated. We compute all the six trajectories for second rotation and choose the optimal one.

Table 3 provides an example of the cost and time computation obtained on the six possible trajectories for the second rotation. It shows that each of 6 combinations provides different number of executed reconfigurations

and a different computation time.

As we can see in

Table 3, the higher the number of required reconfigurations, the higher the global cost and the computation time. In this example, the fourth case, i.e.,

and

, which has the lowest cost, will be retained for the simulation purpose. This case is described in detail in

Figure 5.

5.4. Analysis of the Whole 3-D Rotation

Our goal is to achieve 3-D manipulation of a micro-object. To manipulate a micro-object in 3-D, we proposed to decompose the 3-D rotation into three 2-D rotations and then combine them through

Euler’s Angles as described in

Section 3.1. All three individual rotations have been carried out in their object frame

; thus, for all the three individual rotations, the transformation matrix from 3rd rotation to world frame

i.e.,

is

Figure 6 shows the complete 3-D rotation of an ellipsoid object.

Figure 6a,b represent the initial grasp of the object by finger-1 and finger-2, and its rotation on the object’s

z-axis of

placing the finger-1 and finger-2 at intersecting points of

and

.

Figure 6c represents the second rotation of

on the object’s

y-axis initializing from desired fingers grasp (intersecting points of

and

) encompassing all the reconfigurational steps (some steps represented in

Figure 5) to reach another desired fingers grasp with finger-1 and finger-2.

Figure 6d represents the last rotation of

on the object’s

z-axis starting from desired finger grasp. It is to be noted that in this example (ellipsoid object), the first and third rotations are executed directly by rolling (without any reconfiguration). We have also provided the

Supplementary Video S1 of combined 3-D rotation, the link can be found at the end of paper in

Supplementary Materials section.

5.5. Computation Time

The last performance analyzed in this paper is the computation time which is one way to evaluate the relevance of the proposed heuristic.

Table 4 presents the computation time for three examples using the three objects’ geometries described in

Figure 4 and considering both cases with or without adhesion. The ellipsoid case shows an example where the required rotations can be reached with adhesion and cannot be reached without adhesion. In such a case, the friction coefficient

is not sufficiently large to provide a sufficient number of stable grasps to connect the initial node and final node in the

. It means that it is not physically possible to find a succession of stable grasps to perform the rotations. In the two other cases, the total computation times of both cases of adhesion have a similar order of magnitude (5 to 10.5 s). This example describes a global trend regarding the impact of adhesion on the number of reconfigurations. As presented in the two last examples, in most of the cases, the number of reconfigurations is higher without adhesion than with adhesion. Indeed, without adhesion, the reachable rotation with a grasping is limited by the friction cone and possible collision between fingers, when with adhesion the rotation is only limited by the second constraint.

6. Discussion and Conclusions

6.1. Discussions

Regarding the computation time, the current results were simulated using MATLAB ® with core programming, where the specifics of systems are: Intel Core i7-9750H (6 core CPU), 24-GB RAM. The computation time is also impacted by the sampling strategy defined by the parameter . A smaller will enable to consider more values of rotations but will increase the number of Nodes and thus the computation time.

In the simulations of “with adhesion cases”, we consider a constant value of pull-off force representing the force required to remove a finger from the object. Concretely, this force is highly dependent on the surface properties of both the object and the finger (local oxidation, local roughness, etc.) and may vary along the trajectory. We can show that until the pull-off force is significantly larger than the weight, the and thus the optimal trajectory are independent of the exact value of the pull-off force. Thus, the obtained trajectory described in this paper is robust to pull-off force variation along the trajectory.

The current simulation takes into account the adhesion phenomena, the friction force, the object geometry and the collision between the fingers considered as spheres. Concretely, the fingers should be placed on supports linked to translation micro-actuators. The optimal shape of the supports in order to reduce their collisions and the impact of these potential collisions on the finger trajectories will be studied in future works.

6.2. Conclusions

In this paper, we proposed a new method to perform finger path planning for 3-D dexterous manipulation of micro-objects. To leverage the complexity of 3-D dexterous manipulation, we proposed to carry out three planar rotations about two orthogonal axes. We also proposed an algorithm to cope with the constraints to starting and/or ending the rotation with predefined finger positions on the object and to ensure the continuity of the manipulation process over three successive angles. Moreover, we formalized the sampling strategy to sample contact points on the object which takes into account the finger radius, object geometry, and the rotational step. The simulation results show that the desired 3-D manipulation of micro-objects can be carried out by performing three 2-D rotations with large rotation angles. Currently, the time to compute fingers’ trajectories for first and third rotations is a few seconds, while it is a few minutes for the second rotation, which is in acceptable range for various applications. We also conclude that the presence of adhesion forces enables more feasible trajectories in contrast to the absence of adhesion forces, as the number of equilibrium grasp is higher.