1. Introduction

Reliability of microelectromechanical system (MEMS) is one of the essential factors that determines the development time and time-to-market of the devices. Besides the design and the fabrication processes, environmental factors such as temperature, humidity and vibration are important aspects that influence the in-use reliability of MEMS devices [

1]. In addition, environmental factors are known acceleration factors for accelerated reliability test of MEMS. For instance, temperature is often used to accelerate creep, electrical short/open-circuit, charging and corrosion failures, humidity is commonly used to accelerate cyclic fatigue, stiction and charging failures, and vibration is usually used to accelerate stiction and shock/vibration failures [

1].

A great deal of work has been carried out to characterize MEMS reliability under different environmental conditions. For instance, Pustan et al. investigated the influence of temperature and humidity on the micromirror devices by using the combination of an Atomic Force Microscope and an environmental chamber [

2]. It was discovered that the stiffness of the micromirror is reduced by 46% in the temperature range of 20 °C to 140 °C. Zhang et al. used the standalone environmental chamber to study the influence of temperature and humidity on the linearity and sensitivity of RF MEMS power sensors [

3]. The test temperature and humidity ranges are 5 °C to 75 °C and 25% to 95% RH, respectively. Jan et al. proposed a test platform that combines a double-layer environmental chamber and a vibration shaker to study the effect of temperature and humidity on the resonant frequency of a CMOS-MEMS paddle resonator [

4]. Resonant frequency drops of 6.9 Hz and 1.3 Hz were observed in the temperature range of 25–80 °C and humidity range of 32–90% RH, respectively. The vibration is asserted to the device through a hole on the bottom of the environmental chamber, which creates inhomogeneity of temperature distribution within the chamber. Sivakumar et al. characterized the accrual rate of stiction and mechanical fatigue in a MEMS micromirror device within a temperature and humidity range of 25 °C to 90 °C and 20% to 80% RH, respectively [

5]. Lin et al. studied the RF MEMS switches performance and reliability under different temperatures [

6]. Under temperature aging, the calculated Mean Time to Failure (MTTF) for each condition is 985 h, 822 h and 751 h for the temperatures of 50 °C, 85 °C and 105 °C, respectively.

Despite the great need of studying the MEMS reliability under different environmental conditions, one of the major challenges is to conduct those tests with different environmental factors using standard MEMS testing equipment, such as interferometer, laser-Doppler vibrometer, vibration table (piezo shaker), and different microscopes, etc. Some of the MEMS testing equipment is too bulky to be operated in the commercially available environmental chambers or ovens, while some other equipment is highly sensitive to environmental factors such as the piezo shakers. Taking piezo shaker as an example, the performances of piezoelectric materials are strongly influenced by temperature, especially around the Curie temperature of the material [

7]. Therefore, it is difficult to use the piezo shaker within an oven. Meanwhile, most of the piezo shakers can generate very limited force, often in the range of tens of Newton, thus it is equivalently difficult to mount an oven, even the lightest one, on the piezo shaker. Such dilemma might be the detrimental factor for the lack of reliability of vibration energy harvesters (VEHs), in spite of a great deal of effort in developing various novel VEH devices [

8,

9,

10,

11].

Therefore, there is a strong need and market pull for standard generators of different environmental condition (environmental chambers), which can be integrated on different standard MEMS test equipment. For this purpose, the environmental chamber must be compact, lightweight and capable of generating a wide range of environmental conditions. Towards these goals, the major technical challenge is to integrate all functional elements within a rather small volume and not to exceed the mass and volume limitation. In addition, with miniaturized heating and humidifying elements, it is not easy to realize heating and humidifying functions with reasonable range and speed, compared to their macroscopic counterparts. Although control algorithms can be utilized to optimize the heating and humidifying process, most of the reported algorithms are developed for standard “big” environmental chambers [

12,

13,

14]. Their applicability on miniaturized systems still need to be investigated.

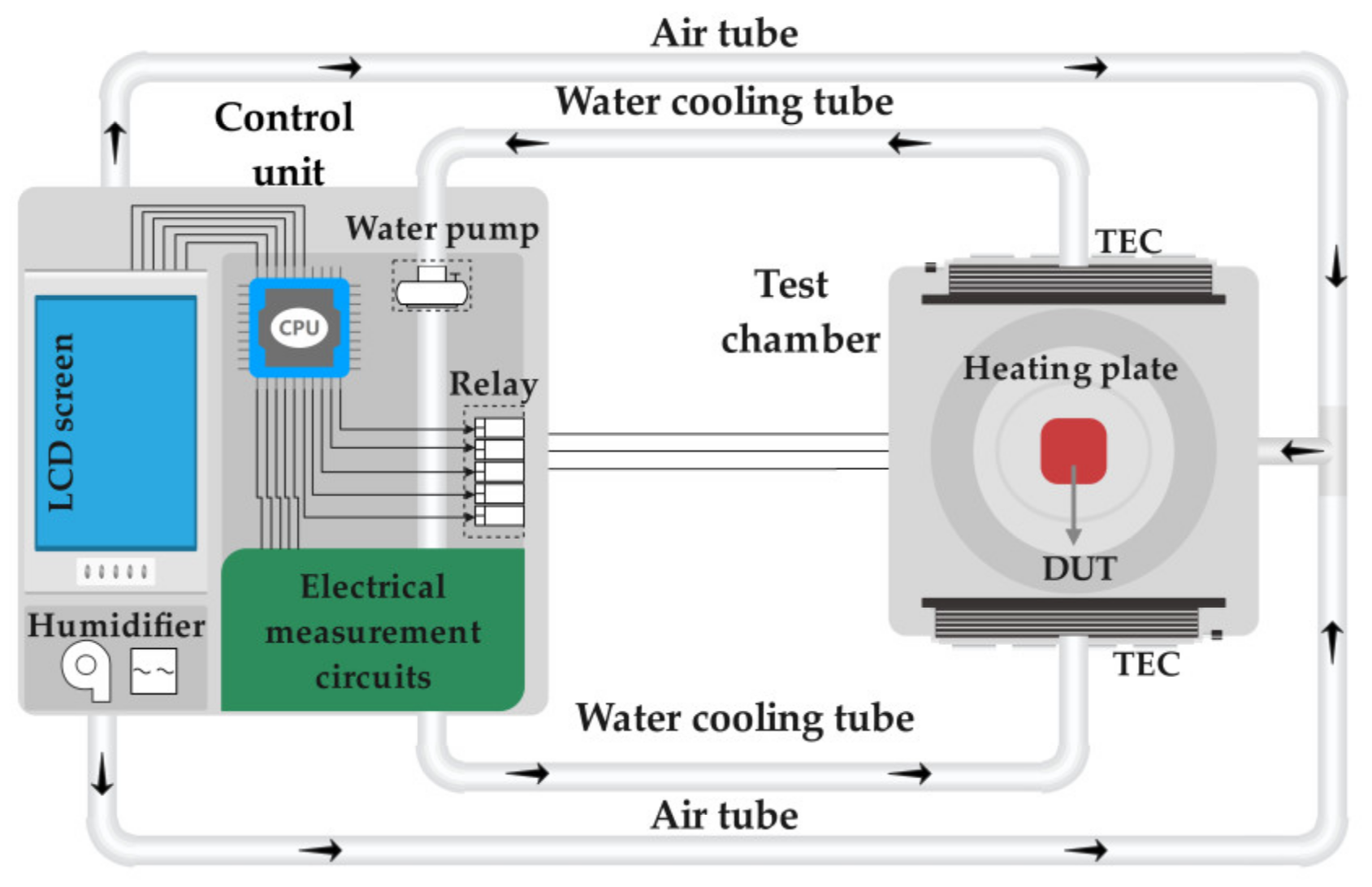

In this paper, we proposed a miniaturized reliability test system for microdevices with controlled environmental parameters, which has the advantages of lightweight, small volume, wide and stable range of controllable environmental parameters. The system can be integrated with the piezo shaker, white light interferometer and other equipment to complete the performance characterization of microdevices under different environmental conditions. The technical merits of the proposed system are to integrate all functional components within a very limited space, and fulfill all heating, humidifying and measurement functionalities comparable to bulky environmental systems. Although the test system in this paper is a specific system, it provides a technical platform for the reliability test of microdevices and can be widely used.

3. Results and Discussion

3.1. Manufacturing Results

The photos of the manufactured circuit board, control unit and test chamber are shown in

Figure 6. The temperature and humidity controllers are connected to the KF-2.54 terminal in the relay circuit. To drive multiple high-power devices at the same time, the PCBs in the system involve design with windowed topology and heat dissipation holes, in order to increase the heat dissipation capacity of the circuit board. The control unit is fabricated by 3D printing technology, and the upper cover is equipped with switch buttons, control buttons, an interaction interface, and a water inlet for the humidity regulator. An optical observation window is installed on the top surface of the test chamber to enable the optical measurements on the DUT. The housing of the test chamber is made of aluminum alloy with surface treatment of thick anodization, in order to enhance corrosion resistance. The test chamber has external dimensions of 9.2 cm × 9.2 cm × 7.2 cm and a weight of 1.07 kg. The control unit and the test chamber are connected through high-temperature aviation plugs for reliable electrical connections.

3.2. System Tuning

In order to solve the temperature and humidity model of the test chamber, the temperature and humidity open-loop response and the temperature and humidity open-loop coupling response of the test chamber are studied in time domain [

19].

Figure 7a, b show the temperature open-loop response of the test system to a 50% PWM duty-cycle step cooling signal and humidity open-loop coupling response of the test system to a 30% PWM duty-cycle step cooling signal, respectively (PWM cycle is 1 s). The 50% PWM duty-cycle step cooling signal is given at 0 s with a rise time of 20 ms. The temperature change of the test chamber delay is 44 s (warming up of the cooler), then rapidly from 44 s to 250 s (cooling process), and finally gradually between 250 s and 450 s. At the initial temperature of 20 °C, the maximum cooling rate is 0.075 °C per second at 80 s, and the temperature of the test chamber is finally stabilized at 9.3 °C under a 50% PWM duty-cycle step cooling signal. The open-loop coupling response of the humidity within the chamber follows a similar pattern. The 30% PWM duty-cycle step cooling signal is given at 0 s with a rise time of 20 ms. The humidity change of the test chamber delay is 28 s, then rapidly from 28 s to 200 s, and finally gradually between 200 s and 350 s. At the initial humidity of 76.8% RH, the maximum dehumidifying rate is 0.095% RH per second at 50 s, and the humidity of the test chamber is finally stabilized at 63.3% RH under a 30% PWM duty-cycle step cooling signal. The coupling of cooling and humidity is mainly caused by the sudden drop of temperature at the TEC cold end, which results in condensation of water vapor in the air. Similarly, we can get the open-loop response curve and open-loop coupling response curve of heating and humidifying, which will not be repeated here.

The two-point method was used to obtain the parameters of first-order delay models of the system, as given in

Table 1.

Through Equations (3) and (4), the parameters of the transfer functions of feed-forward decoupling factor are derived, as shown in

Table 2.

These parameters of transfer functions of the proposed system can be used to model the response of the control system. The analytical form of the model enabled the modeling process to be simple and accurate, where key design parameters can be tuned readily and conveniently.

The PID Tuner is utilized to solve the PID parameters in the system. The comparison between the system responses before and after the introduction of the feed-forward decoupling factor is shown in

Figure 8. The target temperature of 70 °C is realized within the time of 400 s in

Figure 8a and the target temperature of 5 °C is realized within the time of 200 s in

Figure 8b, both showing no overshoot or oscillation behavior. The temperature response curves before and after decoupling in

Figure 8a, b almost coincide, which means the feed-forward decoupling factor has almost no effect on the temperature regulation of the system. However, the feed-forward decoupling factor can obviously improve the humidity control of the system. In the heating-humidifying system of

Figure 8a, the target humidity of 90% RH is realized within the time of 100 s, showing no overshoot or oscillation behavior. However, when the system temperature reaches 45.6 °C at 146 s, the humidity of the system before decoupling decreases at the rate of 0.004% RH per second until 420 s, and then increases to 88.7% RH at 1000 s. Compared with before decoupling, the humidity of the system after decoupling is always stable at a target humidity of 90% RH. In the cooling-humidifying system in

Figure 8b, by introduction of the feed-forward decoupling factor, the regulating time decreases from 323 s to 108 s. To sum up, the simulation results show that the feed-forward decoupling factor has almost no effect on the temperature regulation of the system, but can obviously improve the humidity regulation.

3.3. System Characterization

From the simulation in the previous section, it can be seen that humidification has little effect on refrigeration and heating, so only feed-forward decoupling factors D12(s) and D32(s) are introduced in the system. In order to introduce the feed-forward decoupling factor into the control system, we need to carry out Z transformation on the feed-forward decoupling factors, and then they are transformed into difference equations, finally.

By introducing the difference equations into the control program, the feed-forward decoupling factor of the actual control system is added. The PID parameters obtained from the simulation are brought into the actual system, and then fine-tuning is carried out to obtain the temperature control effect of the system shown in

Figure 9a and the temperature and humidity decoupling control effect shown in

Figure 9b.

In order to characterize the heating dynamic adjustment performance of the system, a step temperature signal that has a target temperature of 60 °C is given at 100 s, as shown in

Figure 9a. The target temperature of 60 °C is realized within the time of 2023 s and the maximum overshoot is 2.5%. The system temperature differs from the target temperature by 0.1 °C within 700 s, and gradually stabilizes at 60 °C. The characterization of the cooling dynamic adjustment performance of the system within the chamber follows a similar pattern. A step temperature signal that has a target temperature of 10 °C is given at 1706 s, as shown in

Figure 9a. The temperature of the test chamber decreases rapidly from 1706 s to 2300 s (cooling process), and finally gradually between 2300 s and 2700 s (precise temperature control to avoid overshoot). The target temperature of 10 °C is realized within the time of 1080 s, showing no overshoot or oscillation behavior. The system temperature differs from the target temperature by 0.1 °C within 1124 s. The maximum temperature change rate is 0.2 °C/s for the heating process and −0.175 °C/s for the cooling process. Compared to the simulation, the actual temperature dynamic response of the system is slower because of the simplified first-order heating and cooling model, but can meet the requirements of most test devices.

The anti-disturbance test of the system is shown in

Figure 9b, and a step humidity signal that has a target humidity of 80% RH is given at 176 s. The target humidity of 80% RH is realized within the time of 234 s, and the maximum overshoot is 1%. The system humidity differs from the target humidity by 0.2% RH within 474 s. During the humidification process, the system temperature first gradually rises in 40–308 s, and stabilizes at 21.2 °C in 380–410 s, and then gradually returns to the initial value. The reason for this phenomenon is the temperature of the atomizing gas will be slightly higher than the temperature in the test chamber. A step temperature signal that has a target temperature of 30 °C is given at 1054 s. Due to the feedforward decoupling factor, the system humidity will increase in advance before being affected by temperature. Therefore, the system humidity will be higher than the set value of 80% RH in 1074–1126 s, and then as the temperature continues to rise to 31 °C, the system humidity gradually decreases to 54.3% RH. As the system temperature gradually stabilizes, the system humidity is also slowly increasing, and finally stabilizes at 80% ± 1% RH at 2182 s. Compared to the simulation, during the system temperature increase, the internal temperature of the test chamber does not reach complete consistency, which causes the system humidity to fail to maintain the set value.

In order to study the static tuning range of the system, the humidity is set to 100% RH and the temperature is increased from 0 °C to 120 °C, with a step of 10 °C. When the system is in steady state, the maximum humidity of the system is recorded. As a next step, the humidity is set to 0% RH and the temperature is decreased from 120 °C to 0 °C, with a step of 10 °C. When the system is in steady state, the minimum humidity of the system is recorded. The measured static tuning range of the system is shown in

Figure 10. In the temperature range of 0–40 °C, the maximum humidity that can be reached in the test chamber is 97% RH. The maximum humidity tuning range of 4.8–97% RH in the chamber is realized at a temperature of 40 °C. At elevated temperature, the maximum humidity within the chamber decreases. The measured maximum humidity is 70.3% RH at 60 °C, 40% RH at 90 °C and 9.3% RH at 120 °C.

The maximum humidity in the chamber decreases rapidly when the temperature increases, which can be attributed to the following reasons: As the temperature increases, the saturated vapor is capable of holding more liquid content. The maximum level of liquid content in the vapor generated by the humidifier (held at room temperature) cannot exceed the level of liquid content in the saturated vapor. The minimum humidity of the system is 0.5% RH at 120 °C and 23% RH at 0 °C, which because of the moisture content in saturated air will decrease as the temperature decreases. Considering the insufficiencies above, there is still space for improvements in the humidification system. For example, different humidification devices can be used at different temperature ranges, i.e., ultrasonic atomization device can be used to humidify the chamber at a low-temperature range, and thermal vaporization humidifier at a high-temperature range.

3.4. System Functionality Verification

Figure 11a shows a photo of the miniaturized reliability test system integrated with a piezo shaker. Such experimental configuration enables the reliability test of micro-energy harvesters, which have not been reported due to the incompatibility between the piezo shaker and environmental chambers (e.g., a convection oven). The shaker used in this study is a model JZK-20 piezo shaker from Sinocera Corporation, which is capable of generating a maximum excitation force of 200 N. The DUT is mounted on a customized sample stage with electrical connections to the feedthrough on the sidewall of the chamber, as shown in

Figure 11b. The sample stage can be readily exchanged to adapt to different types of device connections. A second temperature sensor is mounted above the sample stage next to the DUT in order to monitor the actual temperature around the DUT. The DUT is a customized electromagnetic vibration energy harvester fabricated by the authors for the verification of the proposed test system. It is based on a flex-rigid structure, in which an NdFeB disc magnet is suspended over a winded coil, by four polyimide springs. The key geometric parameters of the device are shown in

Table 3. The working principle of the energy harvester is to convert the movement between the coil and the magnet into an induced voltage in the coil. When the resonant frequency of the energy harvester is matched with the external vibration frequency, the output voltage of the energy harvester reaches the maximum. Due to the complex rigid-flex structure and the polymer nature of the springs, it is very interesting to study the reliability of the energy harvester in different environmental conditions. Therefore, the energy harvester is selected as a typical scenario to verify the functionality of the system. As a proof-of-concept experiment, only simple behavioral tests of the energy harvester at different temperature and humidity were conducted.

Firstly, the effect of temperature on the dynamic response of the energy harvester is studied. The humidity inside the chamber is set to be 40% RH, and the temperature is set to 10 °C, 30 °C, 50 °C and 70 °C, respectively. The output voltage is measured by exciting the energy harvester with a sinusoidal acceleration of 0.3 g (±0.15 g). The influence of temperature on the output voltage and resonant frequency of the energy harvester is shown in

Figure 12a. The horizontal axis represents the vibration frequency of the piezo shaker, and the vertical axis represents the peak-to-peak voltage of the energy harvester. It can be seen that when the temperature increases, the resonance frequency of the energy harvester shifts towards the low-frequency regime, as a result of the reduced spring stiffness of the polyimide at increased temperature values. The humidity in the test chamber is held constant at 40% RH throughout the experiments. For the temperature of 10 °C, the maximum output voltage of the energy harvester is 66.6 mV at 22.0 Hz. For the temperature of 30 °C, the maximum output voltage of the energy harvester is 78.1 mV at 19.9 Hz. For the temperature of 50 °C, the maximum output voltage of the energy harvester is 73.4 mV at 18.6 Hz. For the temperature of 70 °C, the maximum output voltage of the energy harvester is 63.9 mV at 17.3 Hz. In theory, the output voltage of the energy harvester should increase once the spring stiffness decreases. However, an increase of the output voltage is firstly observed from 10 °C to 30 °C, followed by a decrease of the output voltage firstly observed from 30 °C to 70 °C. This behavior is repeatedly observed in the experiments, but has not been sufficiently explained yet. More thorough study will be conducted to understand this phenomenon in the future.

Secondly, the effect of humidity on the dynamic response of the energy harvester is studied. The temperature in the chamber is set to 30 °C, and the humidity is set to 40%, 65% and 90% RH, respectively. The output voltage is measured by exciting the energy harvester with a sinusoidal acceleration of 0.3 g (±0.15 g). The influence of humidity on the output voltage and resonance frequency of the energy harvester is measured, after maintaining the temperature and humidity at constant value for one hour, as shown in

Figure 12b. For the temperature of 30 °C, the resonance frequency of the harvester is decreased by 0.3 Hz in the humidity range of 40–90% RH. This is induced by the slight mass enhancement of the magnet due to the condensation of water vapor in a high relative humidity environment. The experimental results show that at a temperature of 30 °C, humidity has little effect on the output performance of the energy harvester in a short period of time. This is due to the excellent water-resistant properties of the polyimide springs. Under high-temperature and long-term conditions, the effect of different humidity on the output performance of the energy harvester needs to be further investigated.