Review of Microfluidic Methods for Cellular Lysis

Abstract

1. Introduction

2. Cell Lysis Methods

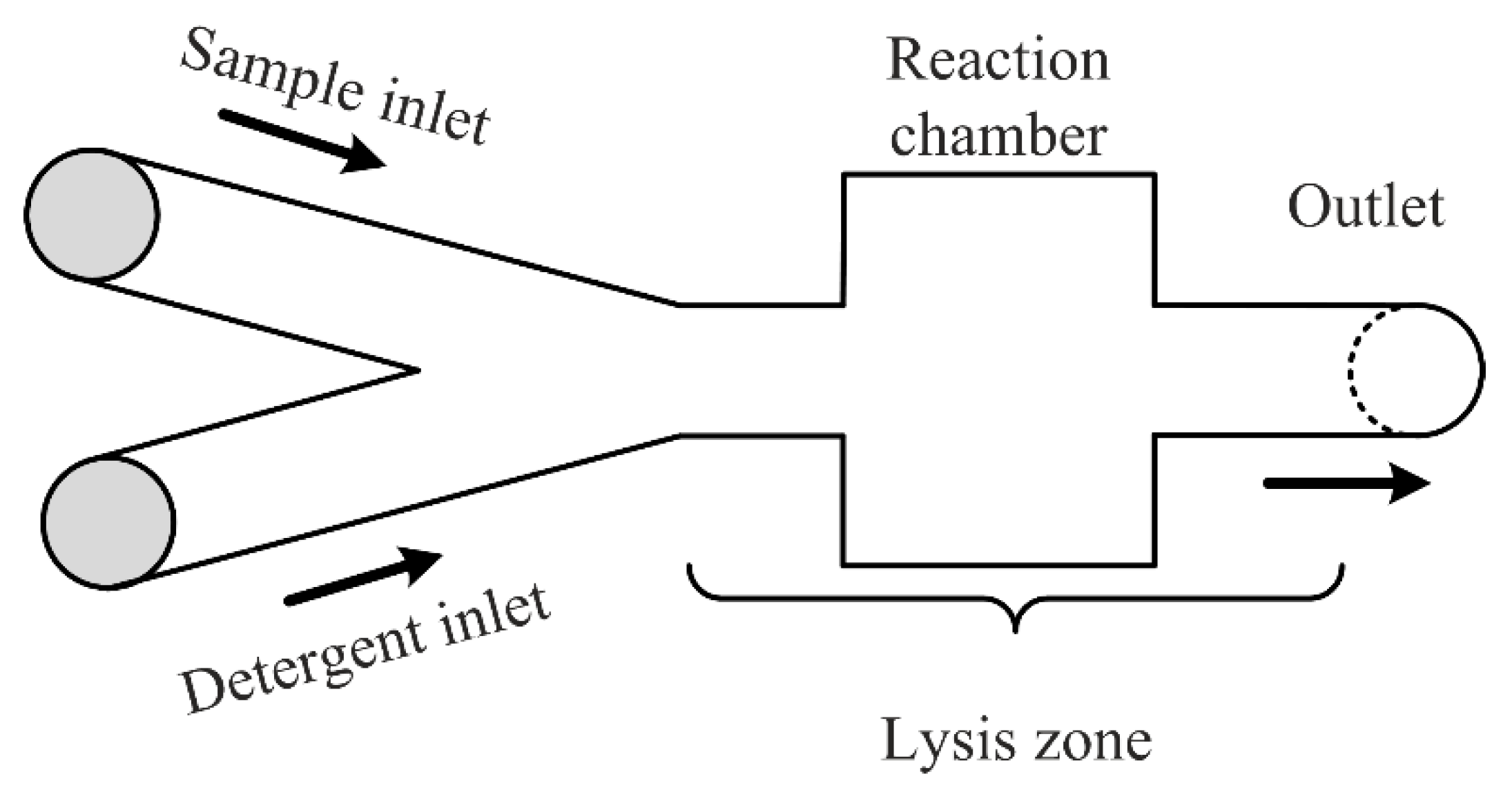

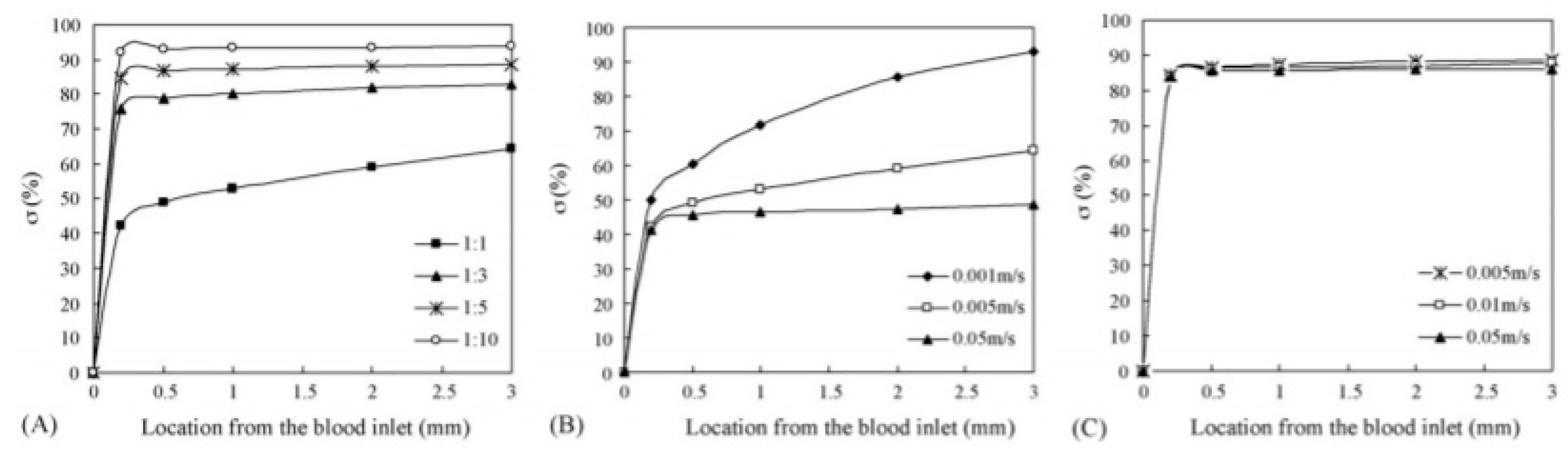

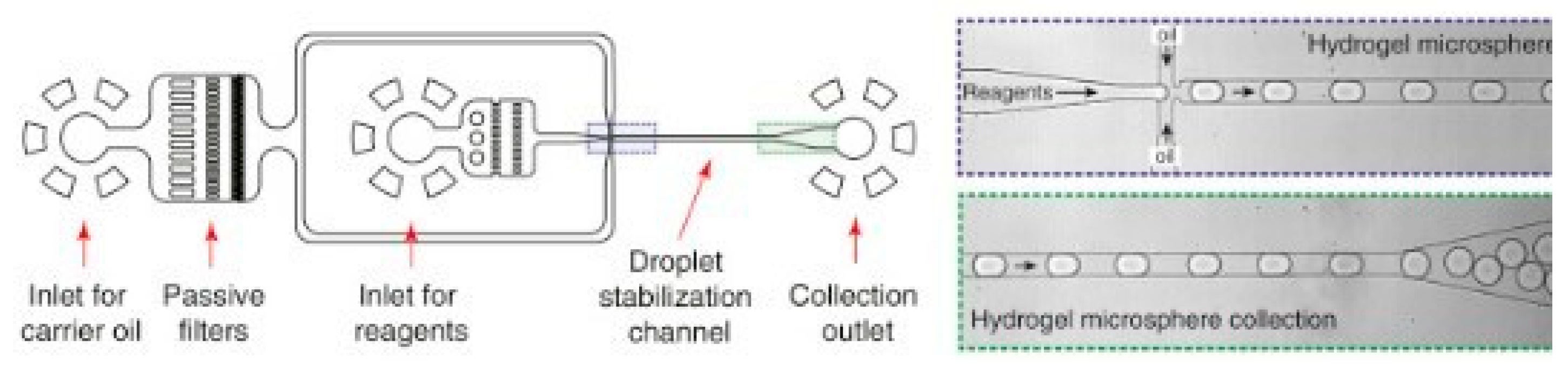

2.1. Chemical Lysis

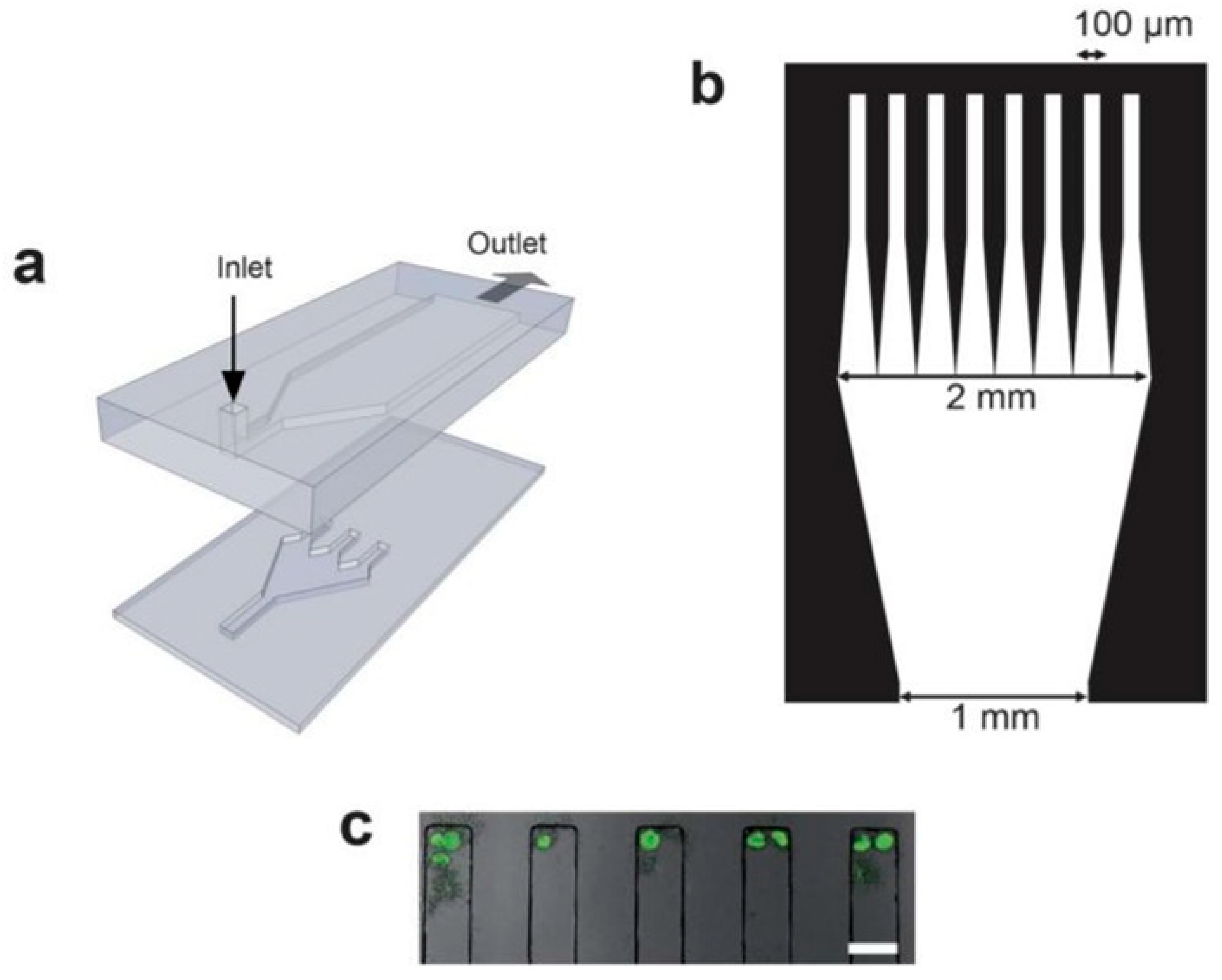

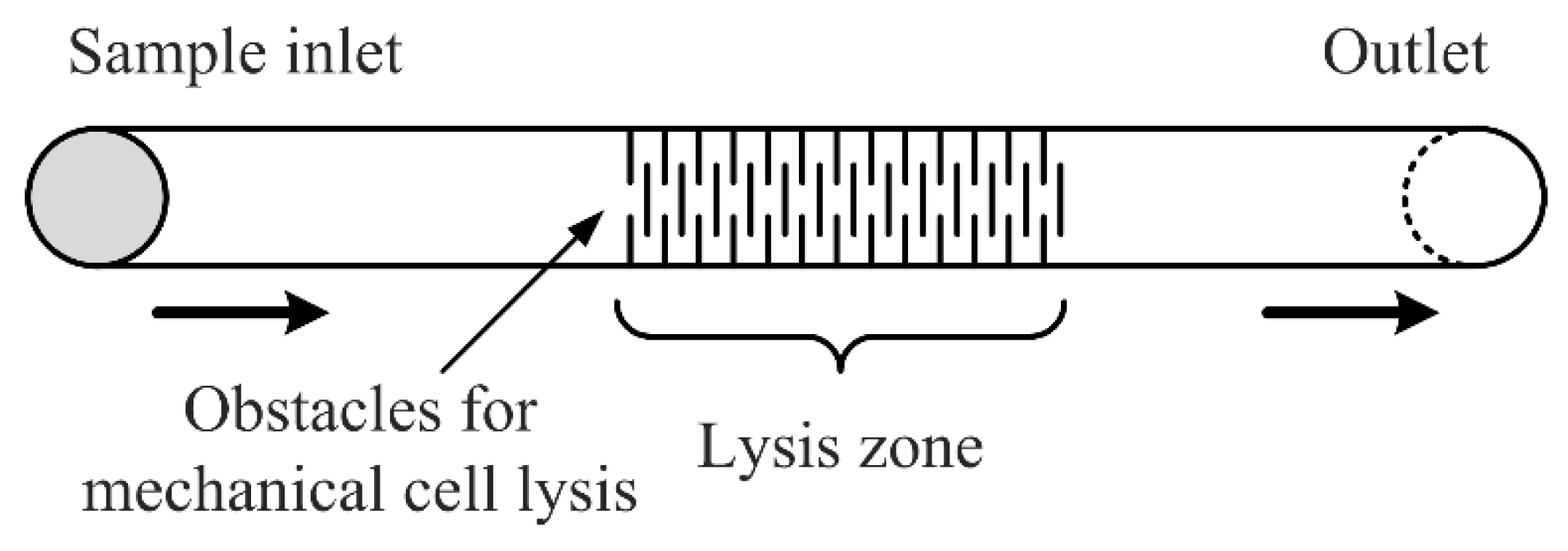

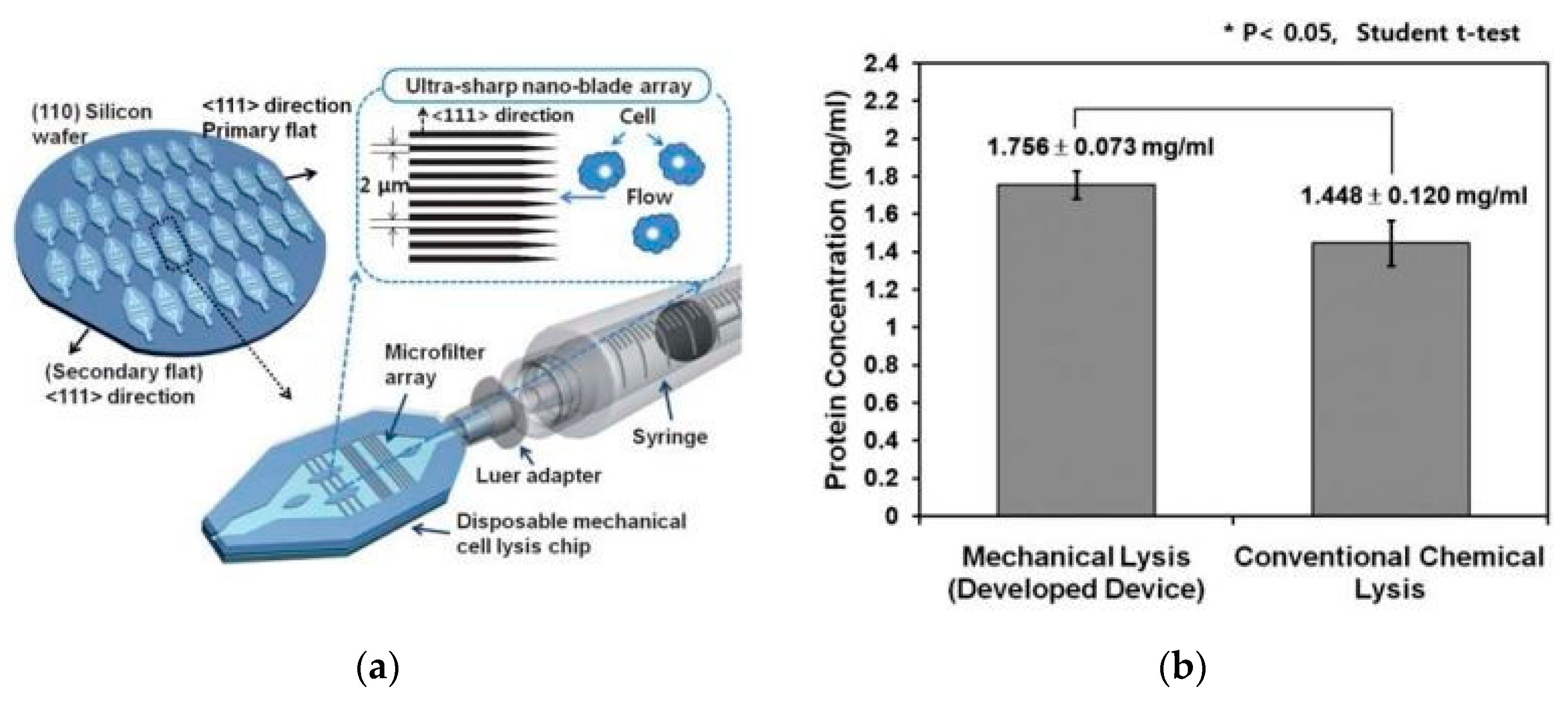

2.2. Mechanical Lysis

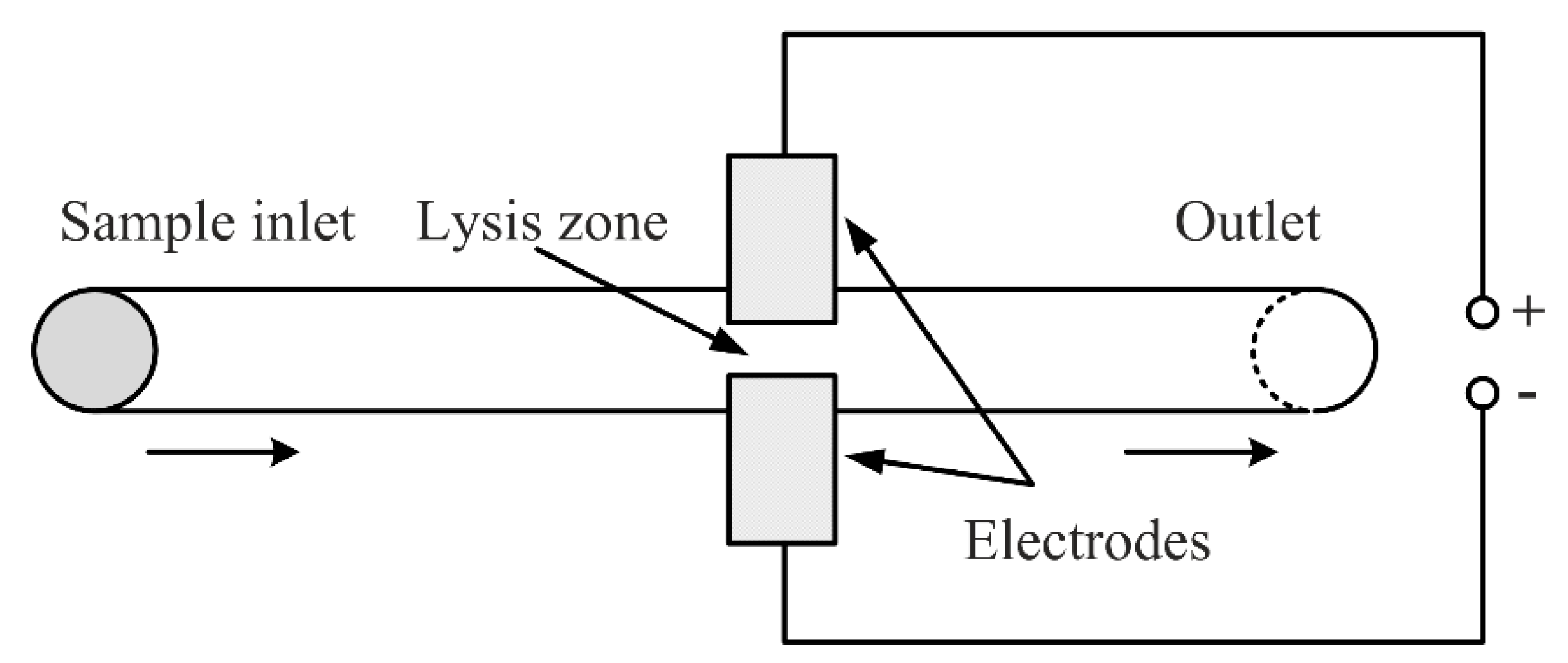

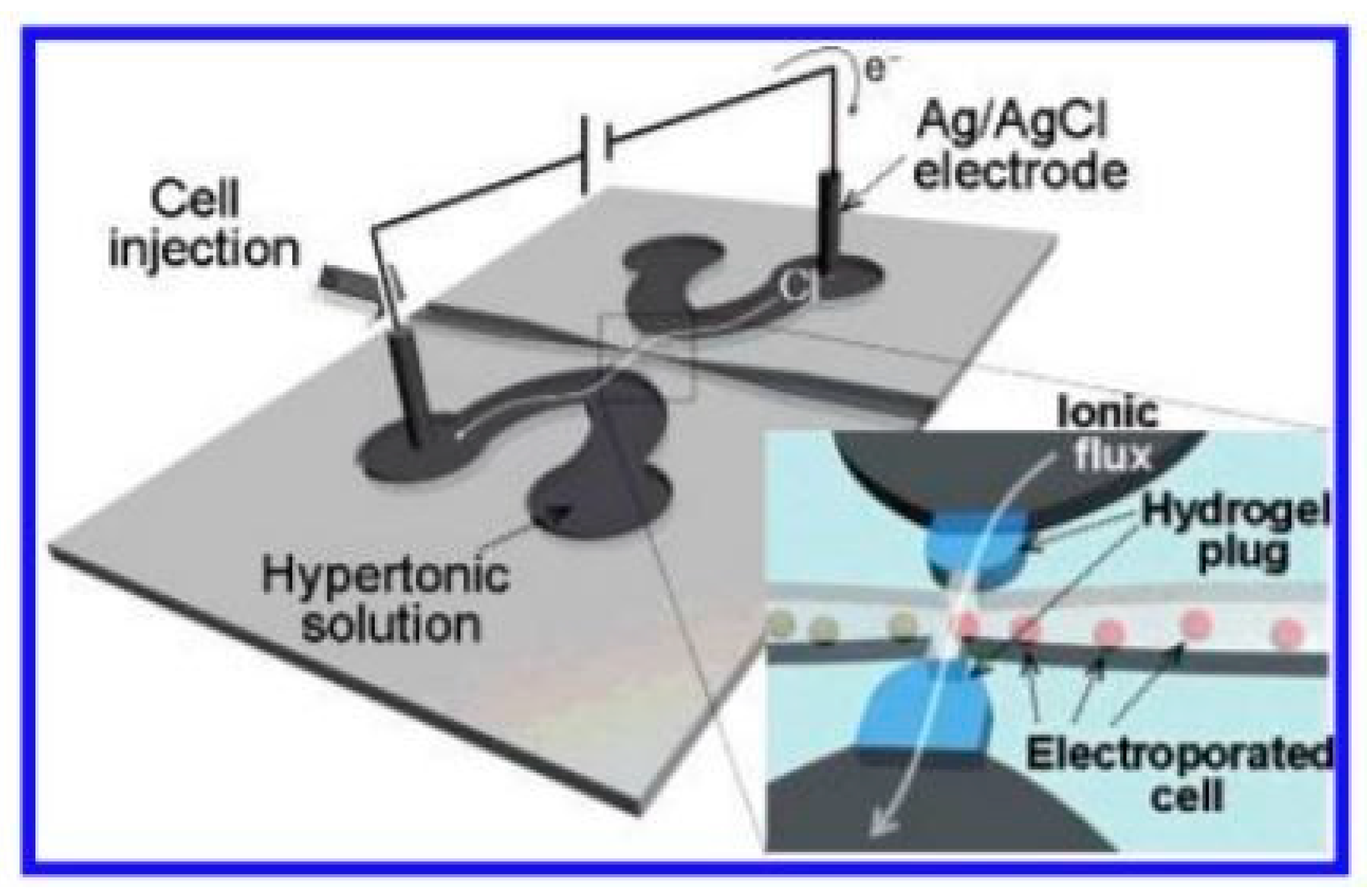

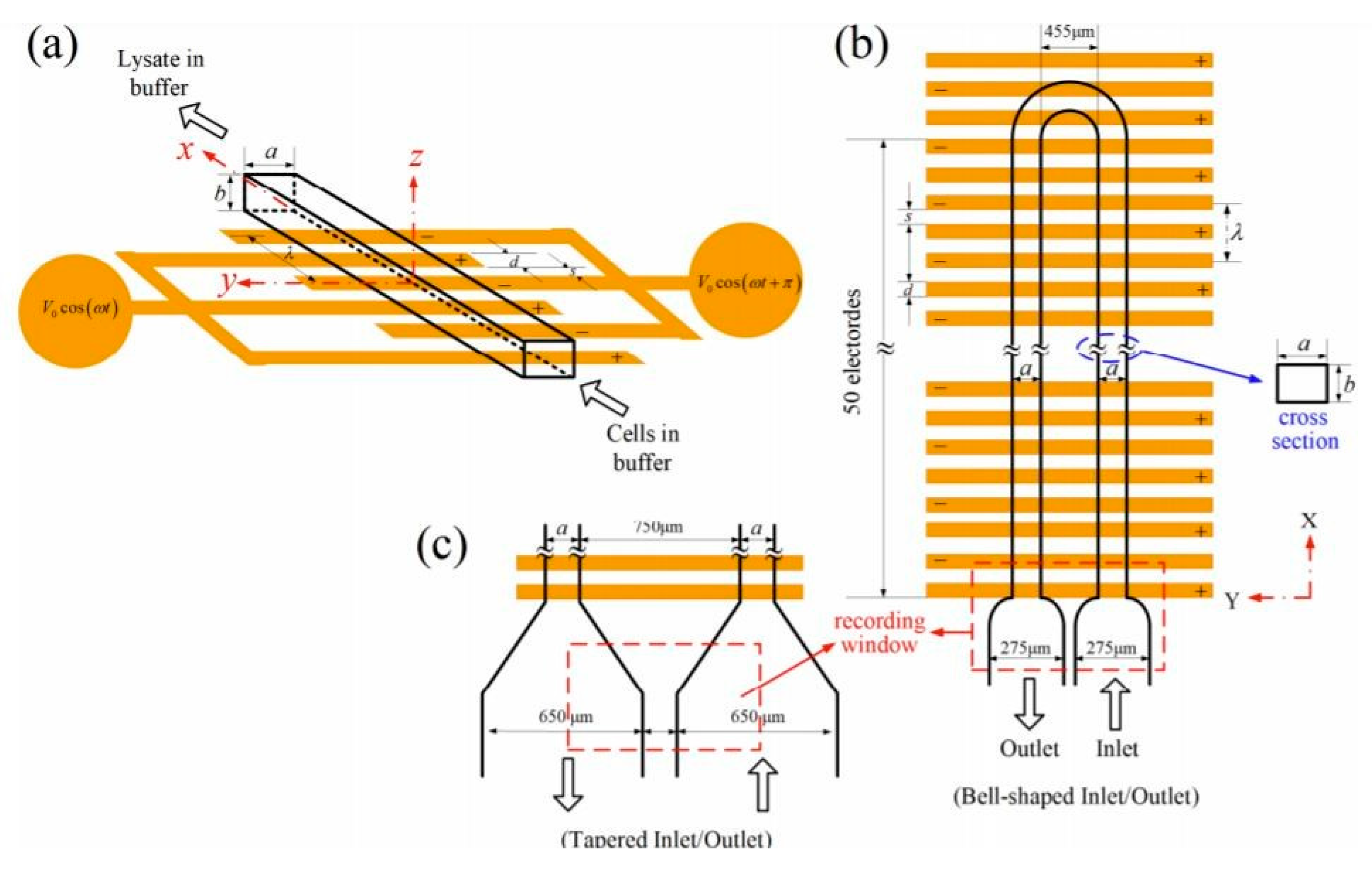

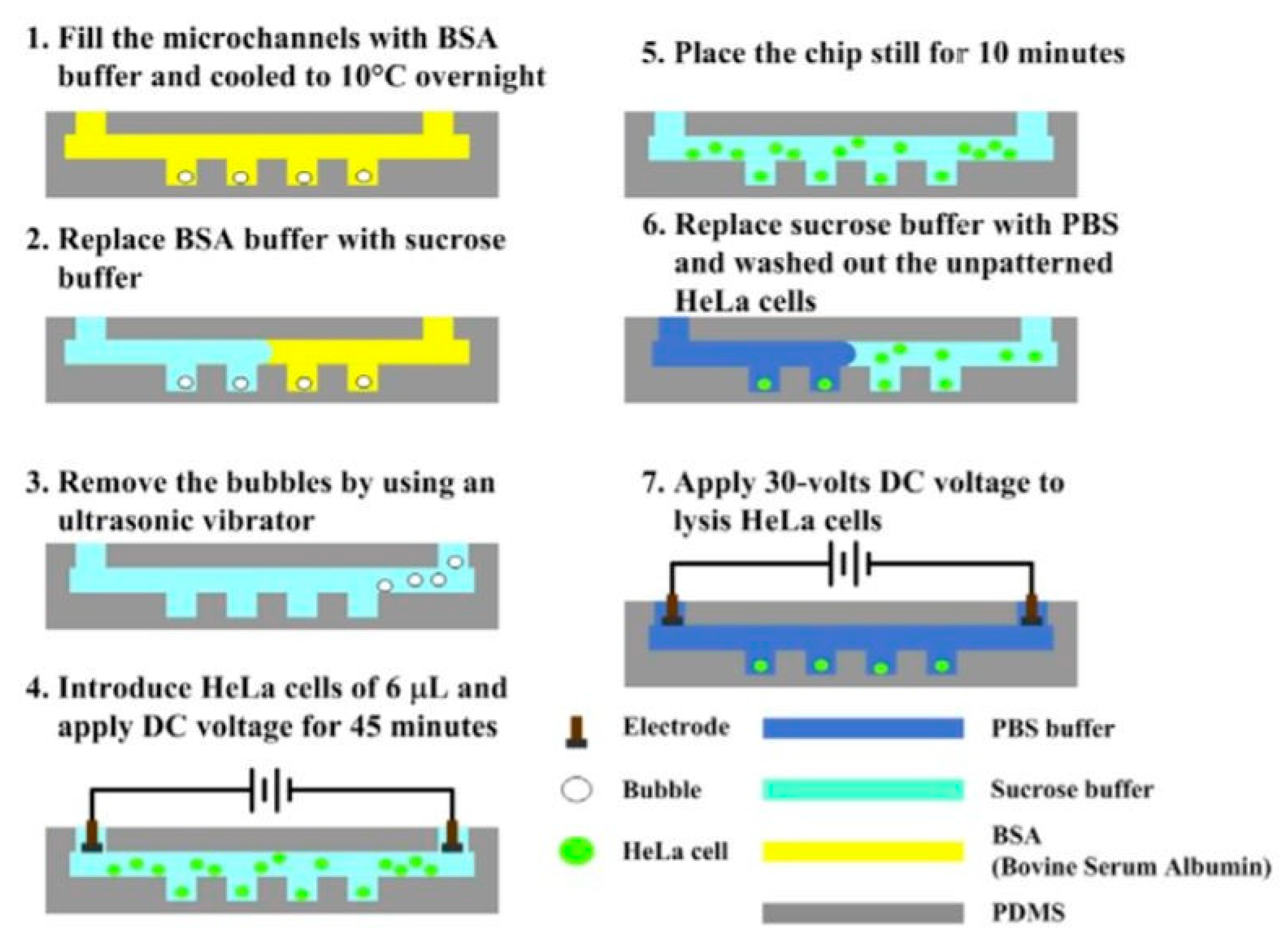

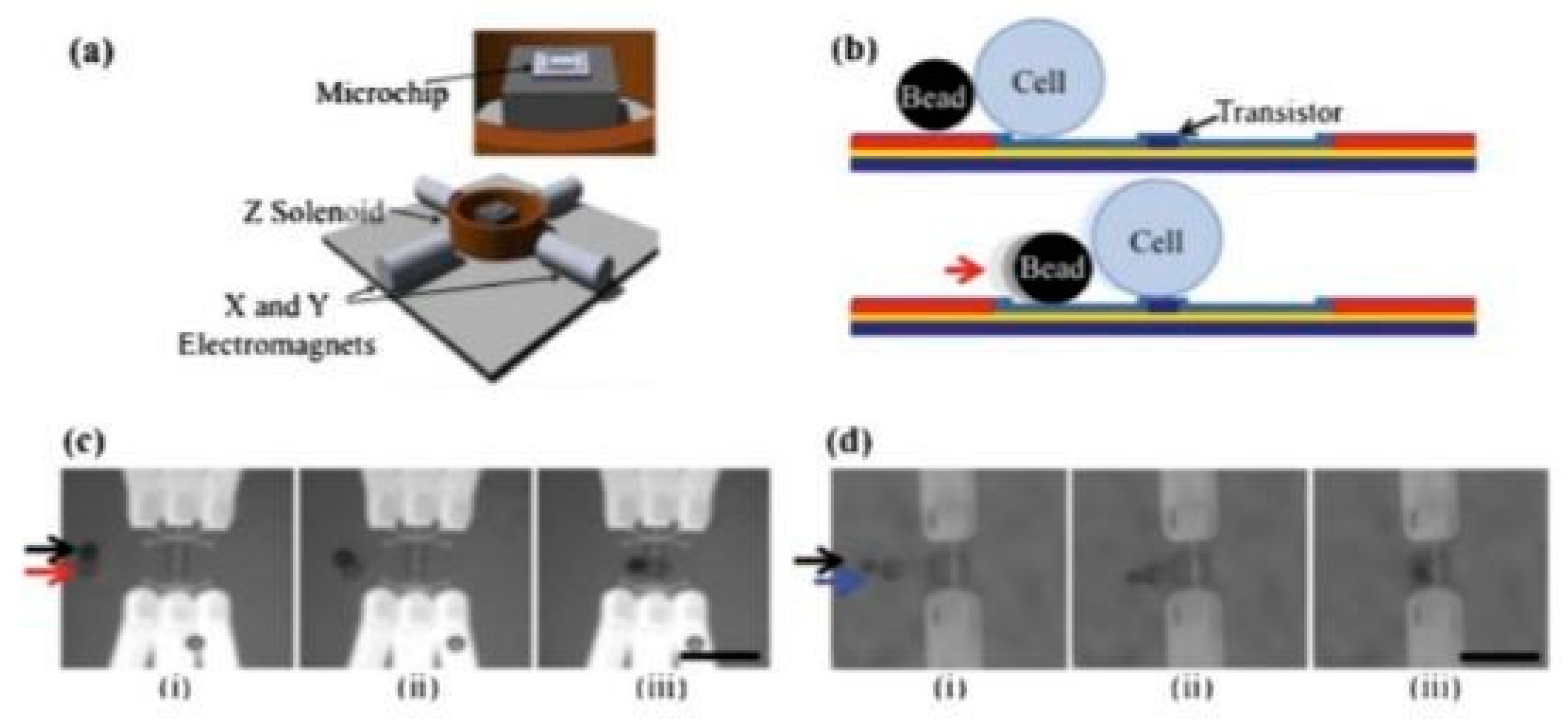

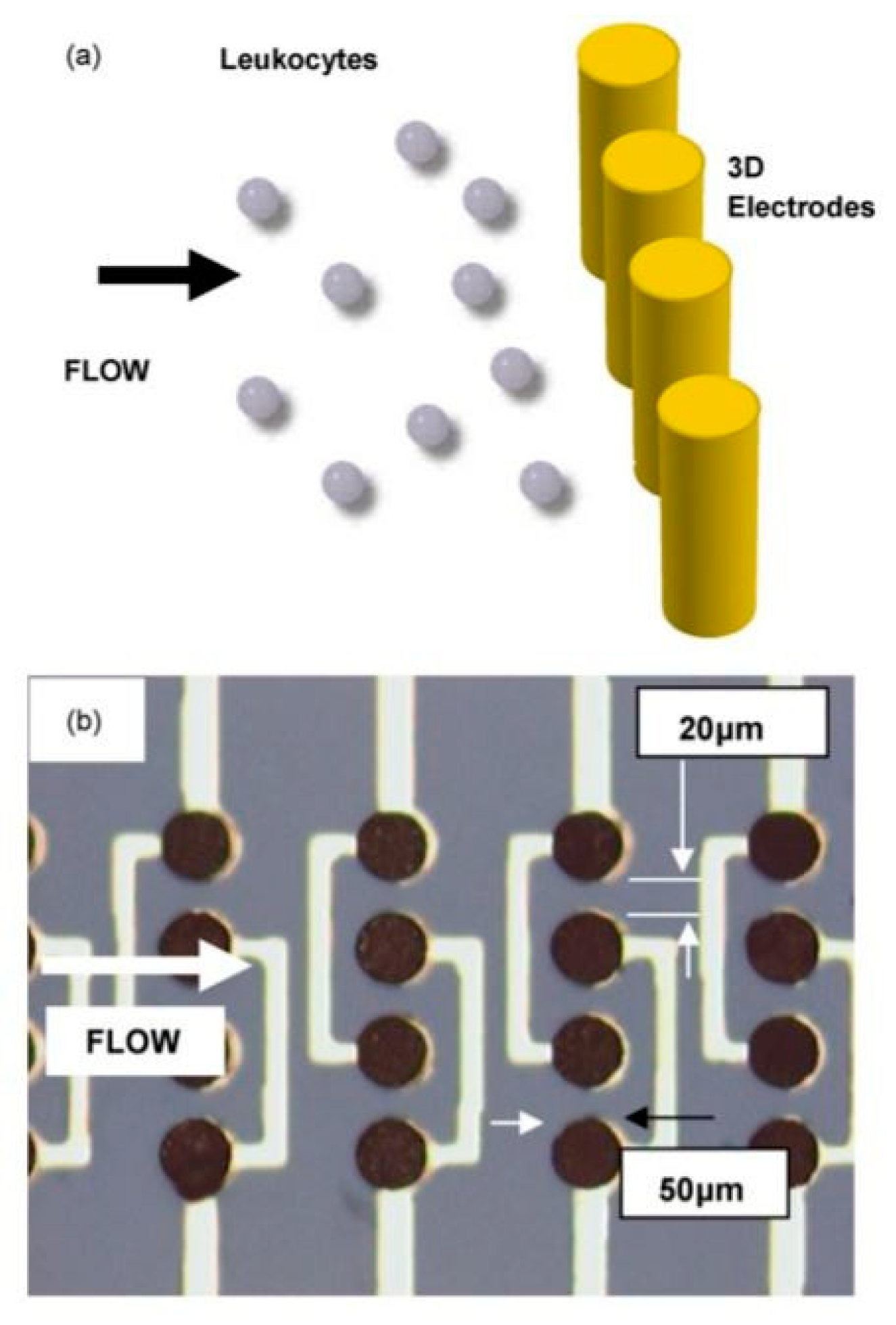

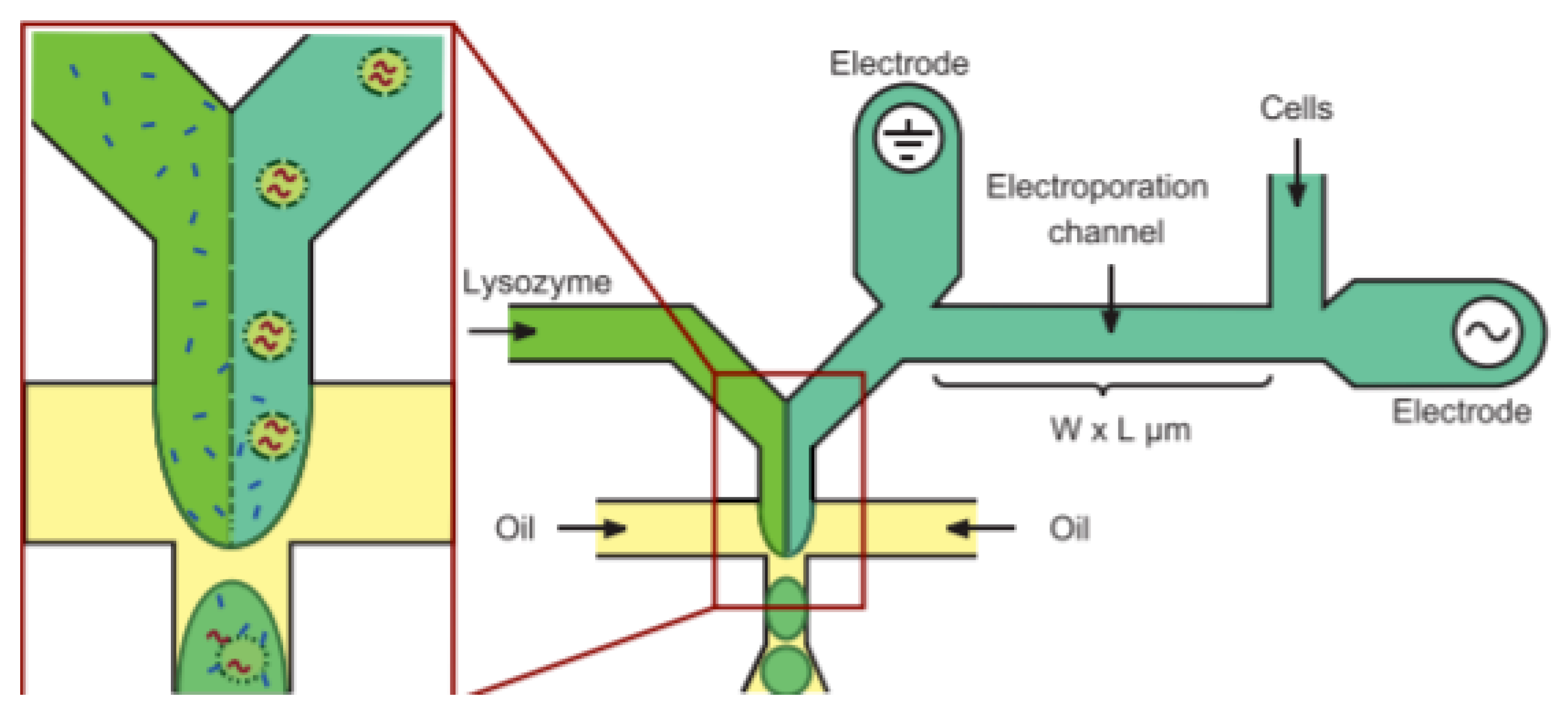

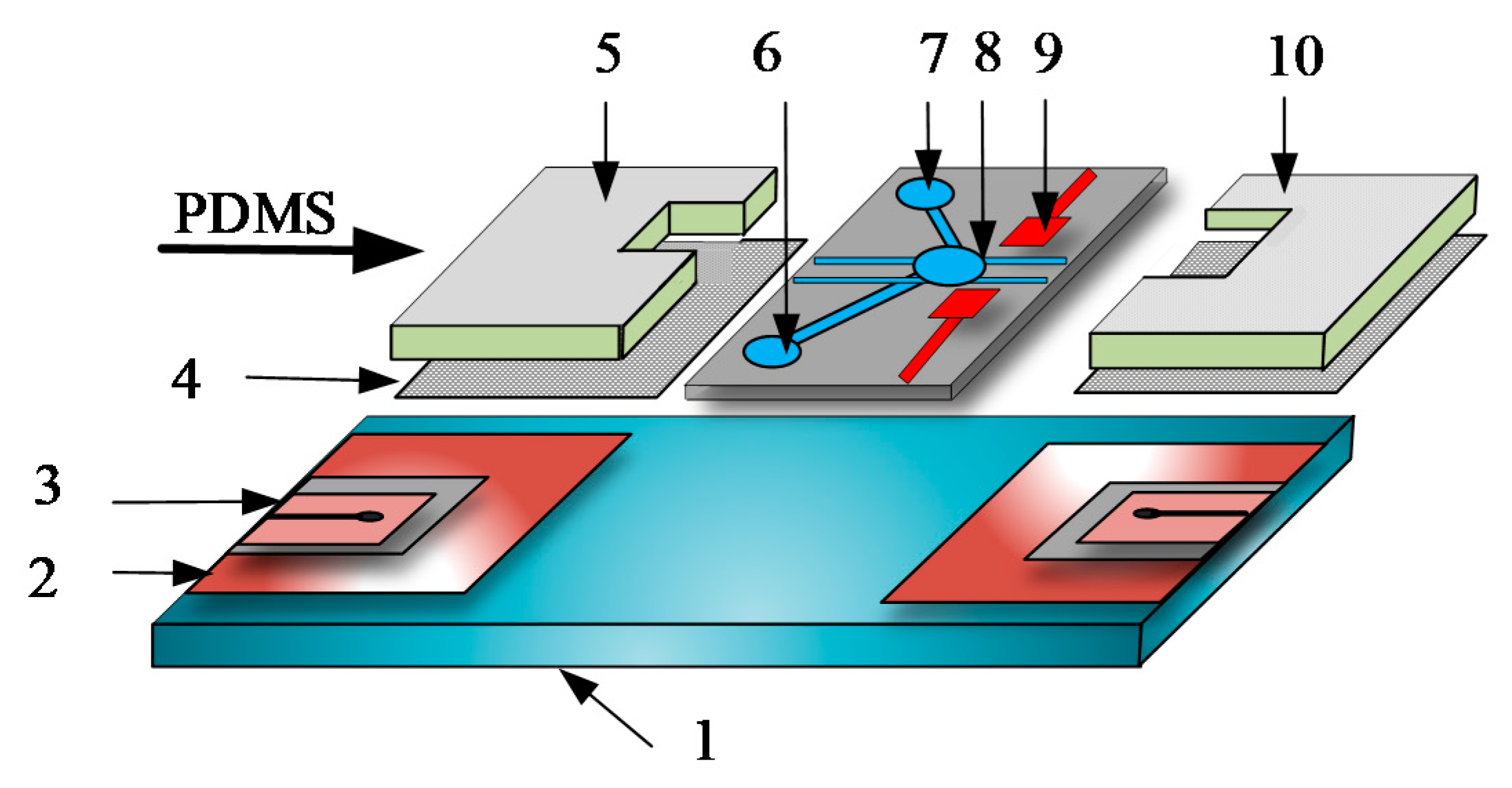

2.3. Electrical Methods

2.4. Laser Lysis

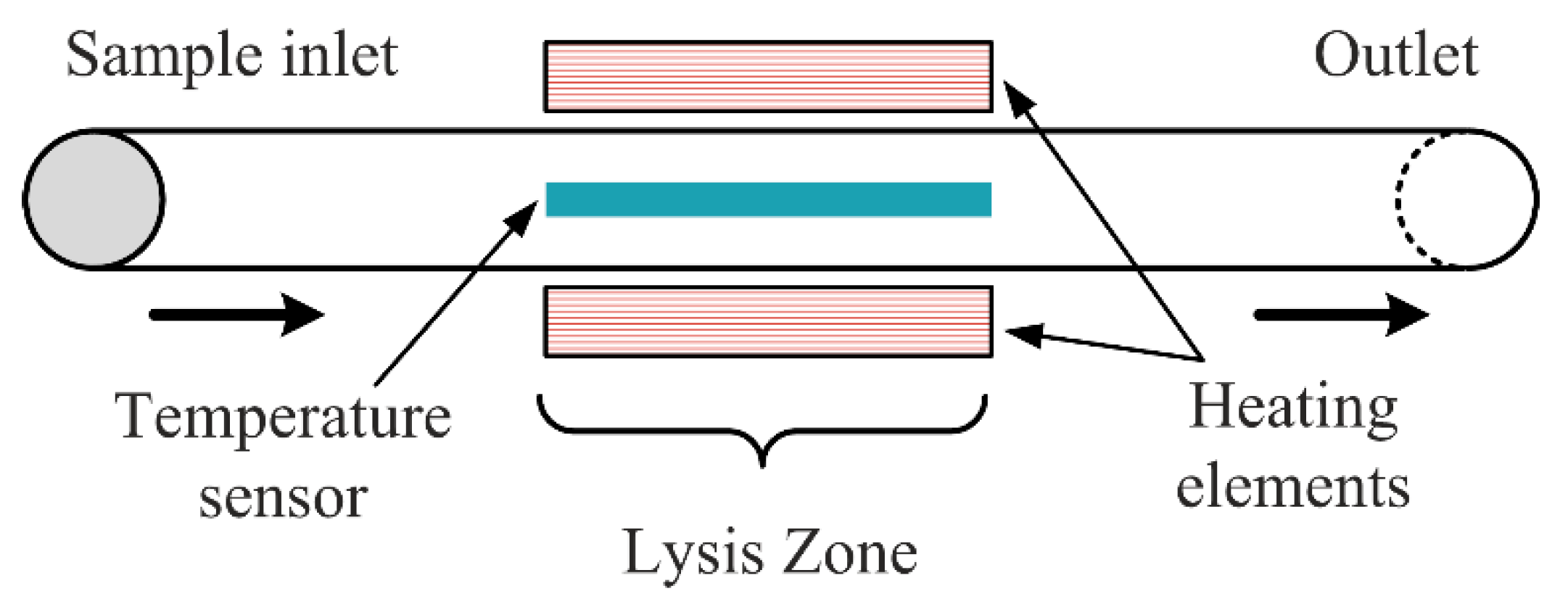

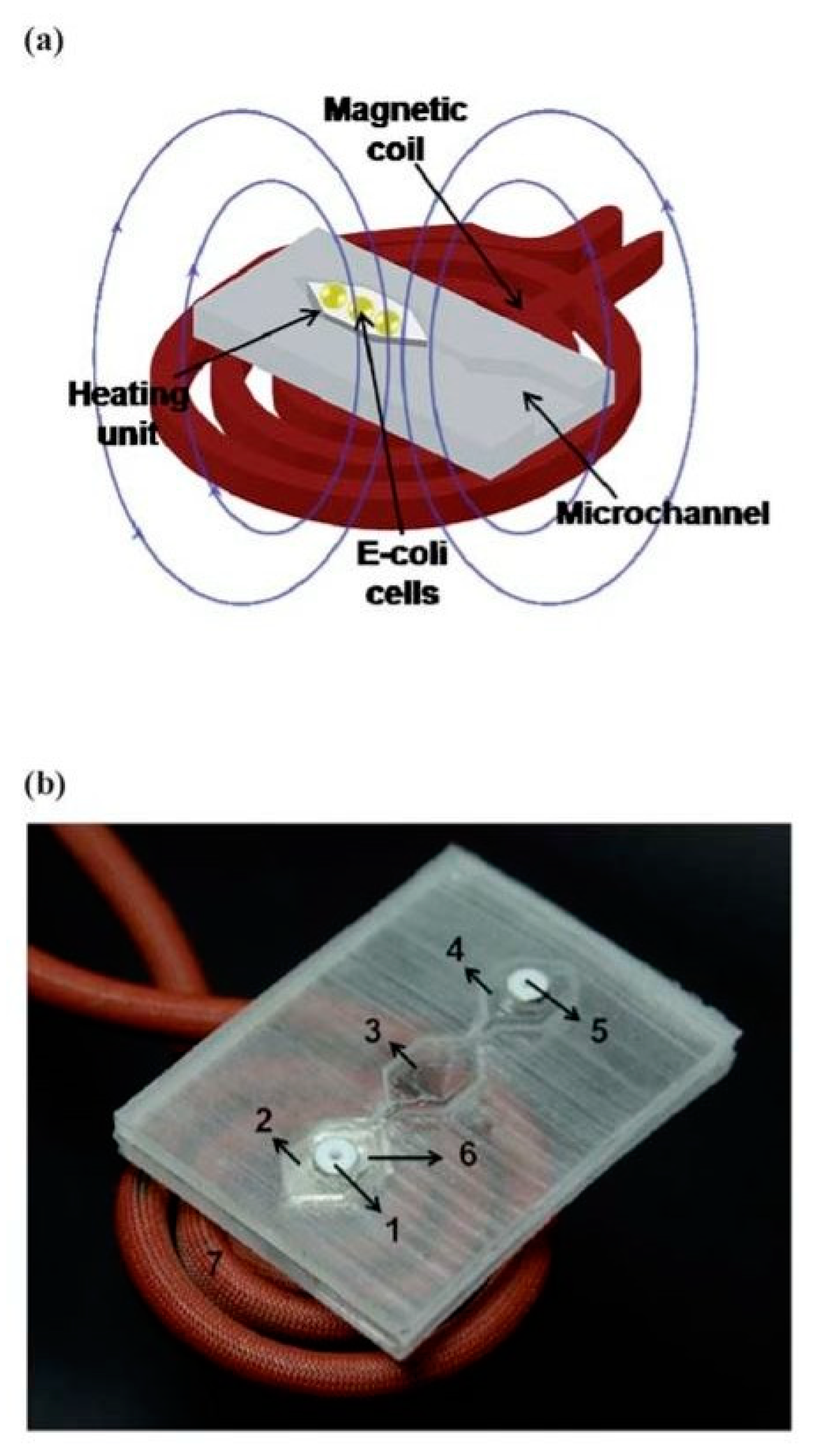

2.5. Thermal Lysis

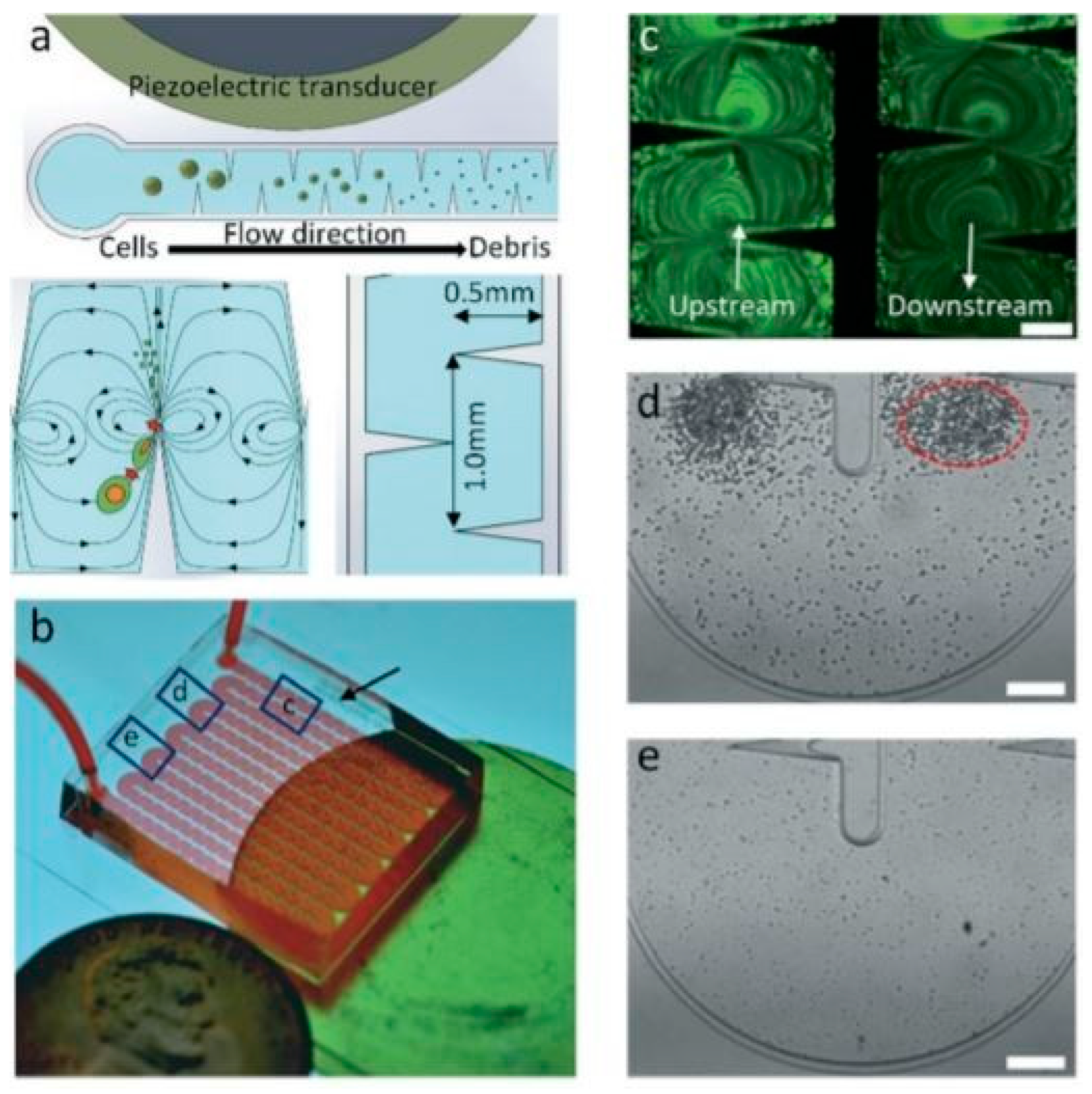

2.6. Acoustic and Electrochemical Methods

3. Discussion and Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Acknowledgments

Conflicts of Interest

Sample Availability

Abbreviations

| CFD | Computational fluid dynamics |

| SDS | Sodium dodecyl sulfate |

| DNA | Deoxyribonucleic acid |

| PCR | Polymerase chain reaction |

| CCO | Cell Crossover |

| E. coli | Escherichia coli |

References

- Nguyen, N.; Wereley, S. Fundamentals and Applications of Microfluidics; Artech House Publishing: Norwood, MA, USA, 2007. [Google Scholar]

- Islam, M.S.; Aryasomayajula, T.A.; Selvaganapathy, P.R. A Review on Macroscale and Microscale Cell Lysis Methods. Micromachines 2017, 8, 83. [Google Scholar] [CrossRef]

- Gao, D.; Jin, F.; Zhou, M.; Jiang, M. Recent advances in single-cell manipulation and biochemical analysis on microfluidics. Analyst 2019, 17, 1533–1547. [Google Scholar] [CrossRef] [PubMed]

- Nandagopal, M.S.G.; Nakkeeran, E.; Prasanna, V.R.; Selvaraju, N.N. Advance Microfluidic Approach over Conventional Batch and CTR for Improving the Efficiency of E-coli Cell Lysis by CuO Nanoparticles. Int. J. Chem. React. Eng. 2016, 15, 20160105. [Google Scholar] [CrossRef]

- Yu, F.; Hunziker, W.W.; Choudhury, D. Engineering Microfluidic Organoid-on-a-Chip Platforms. Micromachines 2019, 10, 165. [Google Scholar] [CrossRef] [PubMed]

- Nan, L.; Jiang, Z.; Wei, X. Emerging microfluidic devices for cell lysis: A review. Lab Chip 2014, 14, 83. [Google Scholar] [CrossRef] [PubMed]

- Kotlowski, R.; Martin, A.; Ablordey, A.; Chemlal, K.; Fonteyne, P.A.; Portaels, F. One-tube cell lysis and DNA extraction procedure for PCR-based detection of Mycobacterium ulcerans in aquatic insects, mollusks, and fish. J. Med. Microbiol. 2004, 53, 927–933. [Google Scholar] [CrossRef]

- Sharma, R.; Dill, B.D.; Chourey, K.; Shah, M.; VerBerkmoes, N.C.; Hettich, R.L. Coupling a Detergent Lysis/Cleanup Methodology with Intact Protein Fractionation for Enhanced Proteome Characterization. J. Proteome Res. 2012, 11, 6008–6018. [Google Scholar] [CrossRef]

- Brown, R.B.; Audet, J. Current techniques for single-cell lysis. J. R. Soc. Interface 2008, 5, 131–138. [Google Scholar] [CrossRef]

- Ward, K.; Fan, Z.H. Mixing in microfluidic devices and enhancement methods. J. Micromech. Microeng 2015, 76925, 094001. [Google Scholar] [CrossRef]

- Chen, X.; Dafu, C.; Changchun, L.; Haoyuan, C. Microfluidic Biochip for Blood Cell Lysis. Chin. J. Anal. Chem. 2006, 34, 1656–1660. [Google Scholar] [CrossRef]

- Chen, X.; Cui, D.; Liu, C.; Li, H.; Chen, J. Continuous flow microfluidic device for cell separation, cell lysis, and DNA purification. Anal. Chim. Acta 2007, 584, 237–243. [Google Scholar] [CrossRef]

- Erickson, D.; Li, D. Influence of Surface Heterogeneity on Electrokinetically-driven Microfluidic Mixing. Langmuir 2002, 18, 1883–1892. [Google Scholar] [CrossRef]

- Santillo, M.F.; Heien, M.L.; Ewing, A.G. Temporal analysis of protozoan lysis in a microfluidic device. Lab Chip 2009, 9, 2796–2802. [Google Scholar] [CrossRef]

- Greenleaf, J. Orthostatic Intolerance after Artificial Heat Acclimatization in Physically fit subjects. Nature 1969, 222, 891–892. [Google Scholar] [CrossRef]

- PanReac AppliChem. Detergents–More than Foam! Available online: https://www.applichem.com/en/literature/brochures/brochures-biochemical-support/detergents/ (accessed on 27 March 2021).

- Shamloo, A.; Hassani-Gangaraj, M. Investigating the effect of reagent parameters on the efficiency of cell lysis within droplets. Anal. Chim. Acta 2020, 32, 062002. [Google Scholar]

- Fradique, R.; Azevedo, A.M.; Chu, V.; Conde, J.P.; Aires-Barros, M.R. Microfluidic platform for rapid screening of bacterial cell lysis. J. Chromatogr. A 2019, 14, 55. [Google Scholar] [CrossRef] [PubMed]

- Su, W.; Yu, H.; Jiang, L.; Chen, W.; Li, H.; Qin, J. Integrated Microfluidic Device for Enrichment and Identification of Circulating Tumor Cells from the Blood of Patients with Colorectal Cancer. Hindawi 2019, 6, 8945974. [Google Scholar] [CrossRef] [PubMed]

- Ocvirk, G.; Moosavi, H.S.; Szarka, R.J. Arriaga Beta-Galactosidase Assays of Single-Cell Lysates on a Microchip: A Complementary Method for Enzymatic Analysis of Single Cells. Proc. 2004, 53792, 115–125. [Google Scholar]

- Mahalanabis, M.; Al-Muayad, H.; Kulinski, M.D.; Altmanb, D.; Klapperich, C.M. Cell lysis and DNA extraction of gram-positive and gram-negative bacteria from whole blood in a disposable microfluidic chip. Lab Chip 2009, 19, 2811–2817. [Google Scholar] [CrossRef] [PubMed]

- Sauer-Budge, A.F.; Mirer, P.; Chatterjee, A.; Klapperich, C.M.; Chargina, D.; Sharon, A. Low cost and manufacturable complete microTAS for detecting bacteria. Lab Chip 2009, 9, 2803–2811. [Google Scholar] [CrossRef]

- Liu, Y.; Schulze-Makuch, D.; Vera, J.P.; Cockell, C.; Leya, T.; Baqué, M.; Walther-Antonio, M. The Development of an Effective Bacterial Single-Cell Lysis Method Suitable for Whole Genome Amplification in Microfluidic Platforms. Micromachines 2018, 9, 367. [Google Scholar] [CrossRef] [PubMed]

- Wu, X.; Zarka, A.; Boussiba, S. A Simplified Protocol for Preparing DNA from Filamentous Cyanobacteria. J. Biol. Eng. 2000, 18, 385–392. [Google Scholar] [CrossRef]

- Mehta, K.; Evitt, N.; Swartz, J.R. Chemical lysis of cyanobacteria. J. Biol. Eng. 2015, 9, 26110017. [Google Scholar] [CrossRef]

- Mun, B.P.; Jung, S.M.; Yoon, S.Y.; Kim, S.H.; Lee, J.H.; Yang, S. Continuous cell cross over and lysis in a microfluidic device. Microfluid. Nanofluid. 2010, 8, 695–701. [Google Scholar] [CrossRef]

- Irimia, D.; Tompkins, R.G.; Toner, M. Single-cell chemical lysis in picoliter-scale closed volumes using a microfabricated device. Anal. Chem. 2004, 76, 6137–6143. [Google Scholar] [CrossRef]

- Jen, C.; Hsiao, J.H.; Maslov, N.A. Single-Cell Chemical Lysis on Microfluidic Chips with Arrays of Microwells. Rev. Sci. Instrum. 2012, 12, 347–358. [Google Scholar] [CrossRef]

- Sasuga, Y.; Iwasawa, T.; Terada, K.; Oe, Y.; Sorimachi, H.; Ohara, O.; Harada, Y. Single-Cell Chemical Lysis Method for Analyses of Intracellular Molecules Using an Array of Picoliter-Scale Microwells. Anal. Chem. 2008, 80, 9141–9149. [Google Scholar] [CrossRef]

- SooHoo, J.; Herr, J.; Ramsey, J.M.; Walker, G.M. Microfluidic Cytometer for the Characterization of Cell Lysis. Anal. Chem. 2012, 84, 21952201. [Google Scholar] [CrossRef] [PubMed]

- Shinde, P.; Mohan, L.; Kumar, A.; Dey, K.; Maddi, A.; Patananan, A.N.; Tseng, F.G.; Chang, H.Y.; Nagai, M.; Santra, T.S. Current Trends of Microfluidic Single-Cell Technologies. Int. J. Sci. 2018, 222, 3143. [Google Scholar] [CrossRef]

- Ramji, R.; Xiang, A.C.; Ying, N.J.; Teck, L.C.; Hung, C.C. Microfluidic Single Mammalian Cell Lysis in Picolitre Droplets. J. Biosens. Bioelectron. 2013, 222, S1:001. [Google Scholar] [CrossRef]

- Klein, A.; Mazutis, L.; Weitz, D.A.; Kirschner, M.W. Droplet Barcoding for Single-Cell Transcriptomics Applied to Embryonic Stem Cells. Cell. 2015, 161, 1187–1201. [Google Scholar] [CrossRef]

- Kim, S.; Clark, I.C.; Shahi, P.; Abate, A.R. Single-cell RT-PCR in microfluidic droplets with integrated chemicallysis. Anal. Chem. 2018, 90, 1273–1279. [Google Scholar] [CrossRef] [PubMed]

- Matuła, K.; Rivello, F.; Huck, T.S. Single-Cell Analysis Using Droplet Microfluidics. Cell 2020, 4, 1900188. [Google Scholar] [CrossRef] [PubMed]

- Hosokawa, M.; Nishikawa, Y.; Kogawa, M.; Takeyama, H. Massively parallel whole genome amplification for single-cell sequencing using droplet microfluidics. Nature 2017, 7, 5199. [Google Scholar] [CrossRef]

- Olanrewaju, A.; Beaugrand, M.; Yafia, M.; Juncker, D. Capillary microfluidics in microchannels: From microfluidic networks to capillaric circuit. Lab Chip 2018, 18, 2323–2347. [Google Scholar] [CrossRef] [PubMed]

- Carlo, D.; Jeong, K.H.; Lee, L.P. Reagentless mechanical cell lysis by nanoscale barbs in microchannels for sample preparation. Lab Chip 2003, 3, 287–291. [Google Scholar] [CrossRef] [PubMed]

- Han, J.Y.; Wiederoder, M.; DeVoe, D.L. Isolation of intact bacteria from the blood by selective cell lysis in a microfluidic porous silica monolith. Microsyst. Nanoeng. 2019, 5, 30. [Google Scholar] [CrossRef] [PubMed]

- Yun, S.S.; Yoon, S.Y.; Song, M.K.; Im, S.M.; Kim, S.; Lee, J.H.; Yang, S. Handheld mechanical cell lysis chip with ultra-sharp silicon nano-blade arrays for rapid intracellular protein extraction. Lab Chip 2010, 3, 1442–1446. [Google Scholar] [CrossRef] [PubMed]

- Huang, X.; Xing, X.; Ng, C.N.; Yobas, L. Single-Cell Point Constrictions for Reagent-Free High-Throughput Mechanical Lysis and Intact Nuclei Isolation. Micromachines 2019, 10, 488. [Google Scholar] [CrossRef] [PubMed]

- Yasui, T.; Yanagida, T.; Shimada, T.; Otsuka, K.; Takeuchi, M.; Nagashima, K.; Rahong, S.; Naito, T.; Takeshita, D.; Yonese, A.; et al. Massively parallel whole genome amplification for single-cell sequencing using droplet microfluidics. ACS Nano 2019, 13, 2262–2273. [Google Scholar]

- So, H.; Lee, K.; Seo, Y.H.; Murthy, N.; Pisano, A.P. Hierarchical Silicon Nanospikes Membrane for Rapid and High-Throughput Mechanical Cell Lysis. ACS Appl. Mater. Interfaces 2014, 6, 6993–6997. [Google Scholar] [CrossRef] [PubMed]

- So, H.; Lee, K.; Seo, Y.H.; Murthy, N.; Pisano, A.P. All-in-One Nanowire-Decorated Multifunctional Membrane for Rapid Cell Lysis and Direct DNA Isolation. ACS Appl. Mater. Interfaces 2014, 6, 20693–20699. [Google Scholar] [CrossRef] [PubMed]

- Tavakoli, H.; Zhou, W.; Ma, L.; Perez, S.; Ibarra, A.; Xu, F.; Zhan, S.; Li, X. Recent advances in microfluidic platforms for single-cell analysis in cancer biology, diagnosis and therapy. Trends Anal. Chem. 2019, 117, 13–26. [Google Scholar] [CrossRef]

- Kim, Y.; Kang, J.; Park, S.J.; Yoon, E.S.; Park, J.K. Microfluidic biomechanical device for compressive cell stimulation and lysis. Sens. Actuators B 2007, 128, 108–116. [Google Scholar] [CrossRef]

- Kido, H.; Micic, M.; Smith, D.; Zoval, J.; Norton, J.; Madou, M. A novel, compact disk-like centrifugal microfluidic system for cell lysis and sample homogenization. Colloids Surf. B Biointerfaces 2007, 58, 44–51. [Google Scholar] [CrossRef] [PubMed]

- Siergist, J.; Gorkin, R.; Bastien, M.; Stewart, G.; Peytavi, R.; Kido, H.; Bergeronb, M. Validation of a centrifugal microfluidic sample lysis and homogenization platform for nucleic acid extraction with clinical samples. Lab Chip 2010, 58, 363–371. [Google Scholar]

- Vandeventer, P.E.; Weigel, K.M.; Salazar, J.; Erwin, B.; Irvine, B.; Doebler, R.; Nadim, A.; Cangelosi, G.A.; Niemz, A. Disruption of Lysis-Resistant Bacterial Cells by Use of a Miniature, Low-Power, Disposable Device. J. Clin. Microbiol. 2011, 49, 2533–2539. [Google Scholar] [CrossRef] [PubMed]

- Cheng, Y.; Wang, Y.; Wang, Z.; Huang, L.; Bi, M.; Xu, W.; Wang, W.; Ye, X. A mechanical cell disruption microfluidic platform based on an on-chip micropump. Biomicrofluidics 2017, 11, 024112. [Google Scholar] [CrossRef]

- Berasaluce, A.; Matthys, L.; Mujika, J.; Antonana-Dıez, M.; Valeroa, A.; Agirregabiria, M. Bead beating-based continuous flow cell lysis in a microfluidic device. RSC Adv. 2015, 5, 22350. [Google Scholar] [CrossRef]

- Lee, D.J.; Mai, J.; Huang, T.J.; Agirregabiria, M. Microfluidic approaches for cell-based molecular diagnosis. Biomicrofluidics 2018, 12, 051501. [Google Scholar] [CrossRef]

- Baek, C.; Min, J. Microvalve-assisted Bead-beating System for Selective Nucleic Acid Preparation from Bacteria and Viruses. BioChip J. 2015, 9, 332–338. [Google Scholar] [CrossRef]

- Hwang, K.W.; Kwon, S.H.; Jung, S.O.; Lim, H.K.; Jung, W.J.; Park, C.S.; Kim, J.H.; Suh, K.Y.; Huh, N. Miniaturized bead-beating device to automate full DNA sample preparation processes for Gram-positive bacteria. Lab Chip 2011, 11, 3649. [Google Scholar] [CrossRef] [PubMed]

- Flaender, M.; Dulk, R.; Ventosa, J.; Flegeau, V. Grinding Lysis (GL): A microfluidic device for sample enrichment and mechanical lysis in one. Sens. Actuators B 2018, 258, 148–155. [Google Scholar] [CrossRef]

- Wang, Z.; Huang, P.H.; Chen, C.; Bachman, H.; Zhao, S.; Yang, S.; Huang, T.J. Cell lysis via acoustically oscillating sharp edges. Lab Chip 2019, 19, 4021. [Google Scholar] [CrossRef]

- Jiang, F.; Chen, J.; Yu, J. Design and application of a microfluidic cell lysis microelectrode chip. Instrum. Sci. Technol. 2015. [Google Scholar] [CrossRef]

- Geng, T.; Lu, C. Microfluidic Electroporation for Cellular Analysis and Delivery. Lab Chip 2013, 13, 3803–3821. [Google Scholar] [CrossRef] [PubMed]

- Sedgwick, H.; Caron, F.; Monaghan, P.B.; Kolch, W.; Cooper, J.M. Lab-on-a-chip technologies for proteomic analysis from isolated cells. J. R. Soc. Interface 2008, 5, S123. [Google Scholar] [CrossRef] [PubMed]

- Islam, M.I.; Kuryllo, K.; Selvaganapathy, P.R.; Li, Y.; Deen, M.J. A Microfluidic Sample Preparation device for Pre-Concentration and Cell Lysis Using A Nanoporous Membrane. In Proceedings of the 17th International Conference on Miniaturized Systems for Chemistry and Life Sciences, Freiburg, Germany, 27–31 October 2013. [Google Scholar]

- Fox, M.B.; Esveld, D.C.; Valero, A.; Luttge, R.; Mastwijk, H.C.; Bartels, P.V.; Boom, R.M. Electroporation of cells in microfluidic devices: A review. Anal. Bioanal. Chem. 2006, 385, 474–485. [Google Scholar] [CrossRef]

- Jeon, H.; Kim, S.; Lim, G.M. Electrical force-based continuous cell lysis and sample separation techniques for development of integrated microfluidic cell analysis system: A review, Microelectronic Engineering. Microelectron. Eng. 2018, 10, 55–72. [Google Scholar] [CrossRef]

- Mernier, G.; Piacentini, N.; Braschler, T.; Demierre, N.; Renauda, P. Continuous-flow electrical lysis device with integrated control by dielectrophoretic cell sorting. Lab Chip 2010, 10, 2077–2082. [Google Scholar] [CrossRef]

- Ziv, R.; Steinhardt, R.; Pelled, G.; Gazit, D.; Rubinsky, B. Micro-electroporation of mesenchymal stem cells with alternating electrical current pulses. Biomed Microdevices 2009, 11, 95–101. [Google Scholar] [CrossRef]

- Kim, K.S.; Kim, J.H.; Kim, K.P.; Chung, T.D. Continuous Low-Voltage dc Electroporation on a Microfluidic Chip with Polyelectrolytic Salt Bridges. Anal. Chem. 2007, 79, 7761–7766. [Google Scholar] [CrossRef]

- Wei, X.; Li, J.; Wang, L.; Yang, F. Low-voltage electrical cell lysis using a microfluidic device. Biomed. Microdevices 2019, 22, 1–9. [Google Scholar] [CrossRef]

- Lo, Y.J.; Lei, U. A Continuous Flow-through Microfluidic Device for Electrical Lysis of Cells. Micromachines 2019, 10, 247. [Google Scholar] [CrossRef]

- Church, C.; Zhu, J.; Huang, G.; Tzeng, T. Integrated electrical concentration and lysis of cells in a microfluidic chip. Biomicrofluidics 2010, 4, 044101. [Google Scholar] [CrossRef]

- Jen, C.P.; Amstislavskaya, T.G.; Liu, Y.H.; Hsiao, J.H.; Chen, Y.H. Single-Cell Electric Lysis on an Electroosmotic-Driven Microfluidic Chip with Arrays of Microwells. Sensors 2012, 12, 6967–6977. [Google Scholar] [CrossRef] [PubMed]

- Ramadan, Q.; Samper, V.; Poenar, D.; Liang, Z.; Chen, Y.; Lim, T.D. Simultaneous cell lysis and bead trapping in a continuous flow microfluidic device. Sens. Actuators B 2006, 113, 944–955. [Google Scholar] [CrossRef]

- Bao, N.; Lu, C. A microfluidic device for physical trapping and electrical lysis of bacterial cells. Appl. Phys. Lett. 2008, 92, 214103. [Google Scholar] [CrossRef]

- Jokilaakso, N.; Salm, E.; Chen, A.; Millet, L.; Guevara, C.D.; Dorvel, B.; Reddy, B., Jr.; Karlstrom, A.E.; Chen, Y.; Ji, H.; et al. Ultra-localized single-cell electroporation using silicon nanowires. Lab Chip 2013, 13, 336. [Google Scholar] [CrossRef] [PubMed]

- Hung, M.S.; Chang, Y.T. Single-cell lysis and DNA extending using electroporation microfluidic device. BioChip J. 2012, 6, 84–90. [Google Scholar] [CrossRef]

- De Lange, N.; Tran, T.M.; Abate, A.R. Electrical lysis of cells for detergent-free droplet assays. Biomicrofluidics 2016, 10, 024114. [Google Scholar] [CrossRef] [PubMed]

- Lu, K.; Wo, A.; Lo, Y.; Chen, K.C.; Lin, C.M.; Yang, C.R. Three dimensional electrode array for cell lysis via electroporation. Biosens. Bioelectron. 2006, 22, 568–574. [Google Scholar] [CrossRef] [PubMed]

- Lu, H.; Schmidt, M.A.; Jensen, K.F. A microfluidic electroporation device for cell lysis. Lab Chip 2005, 5, 23–29. [Google Scholar] [CrossRef] [PubMed]

- Thompson, A.; Paguirigan, A.L.; Kreutz, J.E.; Radich, J.P.; Chiu, D.T. Microfluidics for Single-Cell Genetic Analysis. Lab Chip 2013, 14, 3135–3142. [Google Scholar] [CrossRef]

- Wang, S.; Zhang, X.; Wang, W.; Lee, L.J. Semicontinuous Flow Electroporation Chip for High-Throughput Transfection on Mammalian Cells. Anal. Chem. 2009, 81, 4414–4421. [Google Scholar] [CrossRef] [PubMed][Green Version]

- Dalmay, C.; Villemejanea, J.; Joubert, V.; Silve, A.; Arnaud-Cormos, D.; Francais, O.; Mir, L.M.; Leveque, P.; Le Pioufle, B. A microfluidic biochip for the nanoporation of living cells. Biosens. Bioelectron. 2011, 26, 4649–4655. [Google Scholar] [CrossRef]

- Zhou, Y.; Basu, S.; Laue, E.D.; Seshia, A.A. Dynamic monitoring of single-cell lysis in an impedance-based microfluidic device. Biomed. Microdevices 2016, 18, 56. [Google Scholar] [CrossRef]

- Hiramoto, K.; Ino, K.; Nashimoto, Y.; Ito, K.; Shiku, H. Electric and Electrochemical Microfluidic Devices for Cell Analysis. Front. Chem. 2019, 7, 396. [Google Scholar] [CrossRef]

- Zhou, Y.; Wang, J.; Bao, N.; Lu, C. Dynamic monitoring of single-cell lysis in an impedance-based microfluidic device. Anal. Chem. 2009, 81, 2027–2031. [Google Scholar] [CrossRef]

- Qu, B.; Eu, Y.J.; Jeong, W.J.; Kim, D.P. Droplet electroporation in microfluidics for efficient cell transformation with or without cell wall removal. Lab Chip. 2012, 81, 2027–2031. [Google Scholar] [CrossRef]

- Yoo, B.S.; Im, D.J.; Ahn, M.M.; Park, S.J.; Kim, Y.H.; Kang, I.S. A continuous droplet electroporation system for high throughput processing. Analyst 2018, 143, 57852. [Google Scholar] [CrossRef]

- Movahed, S.; Li, D. Microfluidics cell electroporation. Microfluid. Nanofluid. 2011, 10, 703–734. [Google Scholar] [CrossRef]

- Kurita, H.; Takahashi, S.; Asada, A.; Matsuo, M.; Kishikawa, K.; Mizuno, A.; Numano, R. Parallelized Electroporation by Electrostatic Manipulation of a Water-in-Oil Droplet as a Microreactor. PLoS ONE 2015, 10, e0144254. [Google Scholar]

- Kremer, C.; Witte, C.; Neale, S.L.; Reboud, J.; Barrett, M.P.; Cooper, J.M. Shape-Dependent Optoelectronic Cell Lysis. Angew. Chem. Int. Ed. 2015, 53, 842–846. [Google Scholar] [CrossRef]

- Magidson, V.; Loncarek, J.; Hergert, P.; Rieder, C.L.; Khodjakov, A. Laser Microsurgery in the GFP Era: A Cell Biologist’s Perspective. Methods Cell Biol. 2007, 82, 239–266. [Google Scholar]

- Rau, K.; Quinto-Su, P.A.; Hellman, A.N.; Venugopalan, V. Pulsed Laser Microbeam-Induced Cell Lysis: Time-Resolved Imaging and Analysis of Hydrodynamic Effects. Biophys. J. 2007, 91, 317–329. [Google Scholar] [CrossRef]

- Hellman, A.N.; Rau, K.R.; Yoon, H.H.; Venugopalan, V. Biophysical response to pulsed laser microbeam-induced cell lysis and molecular delivery. J. Biophoton. 2008, 1, 24–35. [Google Scholar] [CrossRef] [PubMed]

- Dhawan, M.D.; Wise, F.; Baeumner, A.J. Development of a laser-induced cell lysis system. Anal. Bioanal. Chem. 2002, 374, 421–426. [Google Scholar] [CrossRef] [PubMed]

- Wan, W.; Yeow, J.T.W. Study of a novel cell lysis method with titanium dioxide for Lab-on-a-Chip devices. Biomed. Microdevices 2011, 13, 527–532. [Google Scholar] [CrossRef]

- Huang, S.H.; Hung, L.Y.; Lee, G.B. Continuous Nucleus Extraction by Optically-Induced Cell Lysis on a Batch-type Microfluidic Platform. Lab Chip 2015, 16, 1447–1456. [Google Scholar] [CrossRef]

- Gorgannezhad, L.; Stratton, H.; Nguyen, N.T. Microfluidic-Based Nucleic Acid Amplification Systems in Microbiology. Micromachines 2019, 10, 408. [Google Scholar] [CrossRef]

- Lee, C.Y.; Lee, G.B.; Lin, L.; Huang, F.C.; Liao, C.J. Integrated microfluidic systems for cell lysis, mixing/pumping, and DNA amplification. J. Micromech. Microeng. 2005, 15, 1215–1223. [Google Scholar] [CrossRef]

- Packard, M.M.; Wheeler, E.K.; Alocilja, E.C.; Shusteff, M. Performance Evaluation of Fast Microfluidic Thermal Lysis of Bacteria for Diagnostic Sample Preparation. Diagnostics 2013, 3, 105–116. [Google Scholar] [CrossRef] [PubMed]

- Privorotskaya, N.; Liu, Y.S.; Lee, J.; Zeng, Z.; Carlisle, J.A.; Radadia, A.; Millet, L.; Bashir, R.; King, W.P. Rapid thermal lysis of cells using silicon–diamond microcantilever heaters. Lab Chip 2010, 10, 1135–1141. [Google Scholar] [CrossRef] [PubMed]

- Burklund, A.; Petryk, J.D.; Hoopes, P.J.; Zhang, J.X. Microfluidic enrichment of bacteria coupled to contact-free lysis on a magnetic polymer surface for downstream molecular detection. Biomicrofluidics 2020, 3, 034115. [Google Scholar] [CrossRef] [PubMed]

- Cheong, K.; Yi, D.; Lee, J.G.; Park, J.M.; Kim, M.J.; Edel, J.B.; Ko, C. Gold nanoparticles for one-step DNA extraction and real-time PCR of pathogens in a single chamber. Lab Chip 2008, 8, 810–813. [Google Scholar] [CrossRef] [PubMed]

- Tsougeni, P.; Papadakis, G.; Gianneli, M.; Grammoustianou, A.; Dupuy, B.; Petrou, P.N.; Kakabakos, S.E.; Tserepi, A.; Gizeli, E.; Gogolides, E. Plasma nanotextured polymeric lab-on-a-chip for 1 highly efficient bacteria capture and lysis. Lab Chip 2016, 16, 120–131. [Google Scholar] [CrossRef] [PubMed]

- Baek, S.; Min, J.; Park, J.P. Wireless induction heating in a microfluidic device for cell lysis. Lab Chip 2010, 10, 909–917. [Google Scholar] [CrossRef] [PubMed]

- Wang, Z.; Zhe, J. Recent advances in particle and droplet manipulation for lab-on-a-chip devices based on surface acoustic waves. Lab Chip 2019, 19, 1280. [Google Scholar] [CrossRef]

- Ding, X.; Li, P.; Lin, S.; Huang, T.J.; Constanzo, F.; Shi, J.; Mao, X.; Slotcavage, D. Surface acoustic wave microfluidics. Lab Chip 2013, 13, 3626–3649. [Google Scholar] [CrossRef]

- Lu, H.; Mutafopulos, K.; Heyman, J.A.; Spink, P.; Shen, L.; Wang, C.; Franke, T.; Weitz, D.A. Rapid additive-free bacteria lysis using traveling surface acoustic waves in microfluidic channels. Lab Chip 2019, 19, 4064. [Google Scholar] [CrossRef]

- Reboud, J.; Bourquin, Y.; Wilson, R.; Pall, G.; Jiwaji, M.; Pitt, A.; Graham, A.; Waters, A.; Cooper, J. Shaping acoustic fields as a toolset for microfluidic manipulations in diagnostic technologies. Proc. Natl. Acad. Sci. USA 2012, 109, 15162–15167. [Google Scholar] [CrossRef] [PubMed]

- Taller, D.; Richards, K.; Slouka, Z.; Senapati, S.; Hill, R.; Go, D.; Chang, H. On-Chip Surface Acoustic Wave Lysis and Ion-Exchange Nanomembrane Detection of Exosomal RNA for Pancreatic Cancer Study and Diagnosis. Lab Chip 2015, 15, 1656–1666. [Google Scholar] [CrossRef] [PubMed]

- Tandiono, T.; Ow, D.; Driessen, L.; Chin, C.; Klaseboer, E.; Choo, A.; Ohl, S.; Ohla, C. Sonolysis of Escherichia coli and Pichia pastoris in microfluidics. Lab Chip 2012, 12, 780. [Google Scholar] [CrossRef]

- Marenits, T.; Kusler, B.; Yaralioglu, G.; Liu, S.; Yakub, E.; HÆggström, A.; Ohl, S.; Ohla, C. Microfluidic Sonicator for Real-Time Disruption of Eukaryotic Cells and Bacterial Spores for DNA Analysis. Ultrasound Med. Biol. 2005, 31, 1265–1277. [Google Scholar] [CrossRef]

- Lee, H.; Kim, J.; Lim, H.; Cho, E.; Huh, N.; Ko, C.; Park, J.; Choi, J.; Lee, S. Electrochemical cell lysis device for DNA extraction. Lab Chip 2010, 10, 626–633. [Google Scholar] [CrossRef] [PubMed]

- Di Carlo, D.; Zanetti, C.; Zhang, Y.; Hung, P.; Lee, L. On-chip cell lysis by local hydroxide generation. Lab Chip 2005, 10, 171–178. [Google Scholar]

- Chen, Y.; Chen, L.; Chen, S.; Chang, M.; Chen, T. A modified osmotic shock for periplasmic release of a recombinant creatinase from Escherichia coli. Biochem. Eng. J. 2004, 19, 211–215. [Google Scholar] [CrossRef]

- Zhu, K.; Jin, H.; He, Z.; Zhu, Q.; Wang, B. A continuous method for the large-scale extraction of plasmid DNA by modified boiling lysis. Nat. Protoc. 2006, 1, 3089–3093. [Google Scholar] [CrossRef]

- McIntyre, D.; Lashkaripour, A.; Densmore, D. Rapid and Inexpensive Microfluidic Electrode Integration with Conductive Ink. Lab Chip 2020, 20, 3690–3695. [Google Scholar] [CrossRef]

- Funk, C.; Chan, S.; Wu, A. Microfluidic single-cell analysis–Toward integration and total on-chip analysis. Biomicrofluidics 2020, 14, 021502. [Google Scholar] [CrossRef] [PubMed]

| Lysis Type | Efficiency | Lysis Time | Technical Difficulty | Cost |

|---|---|---|---|---|

| Chemical | High | Slow/Moderate | Low | Low |

| Mechanical | Medium | Moderate | Medium | Medium |

| Electrical methods | High | Fast | High | High |

| Thermal | Medium | Moderate | Medium | Medium |

| Laser | High | Very Fast | Very High | Very High |

| Acoustic | High | Very Fast | High | High |

| Electrochemical | Medium | Moderate | High | Moderate |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Grigorov, E.; Kirov, B.; Marinov, M.B.; Galabov, V. Review of Microfluidic Methods for Cellular Lysis. Micromachines 2021, 12, 498. https://doi.org/10.3390/mi12050498

Grigorov E, Kirov B, Marinov MB, Galabov V. Review of Microfluidic Methods for Cellular Lysis. Micromachines. 2021; 12(5):498. https://doi.org/10.3390/mi12050498

Chicago/Turabian StyleGrigorov, Emil, Boris Kirov, Marin B. Marinov, and Vassil Galabov. 2021. "Review of Microfluidic Methods for Cellular Lysis" Micromachines 12, no. 5: 498. https://doi.org/10.3390/mi12050498

APA StyleGrigorov, E., Kirov, B., Marinov, M. B., & Galabov, V. (2021). Review of Microfluidic Methods for Cellular Lysis. Micromachines, 12(5), 498. https://doi.org/10.3390/mi12050498