Toward the Next Generation of Passive Micromixers: A Novel 3-D Design Approach

Abstract

1. Introduction

2. Governing Equations and Mathematical Methods

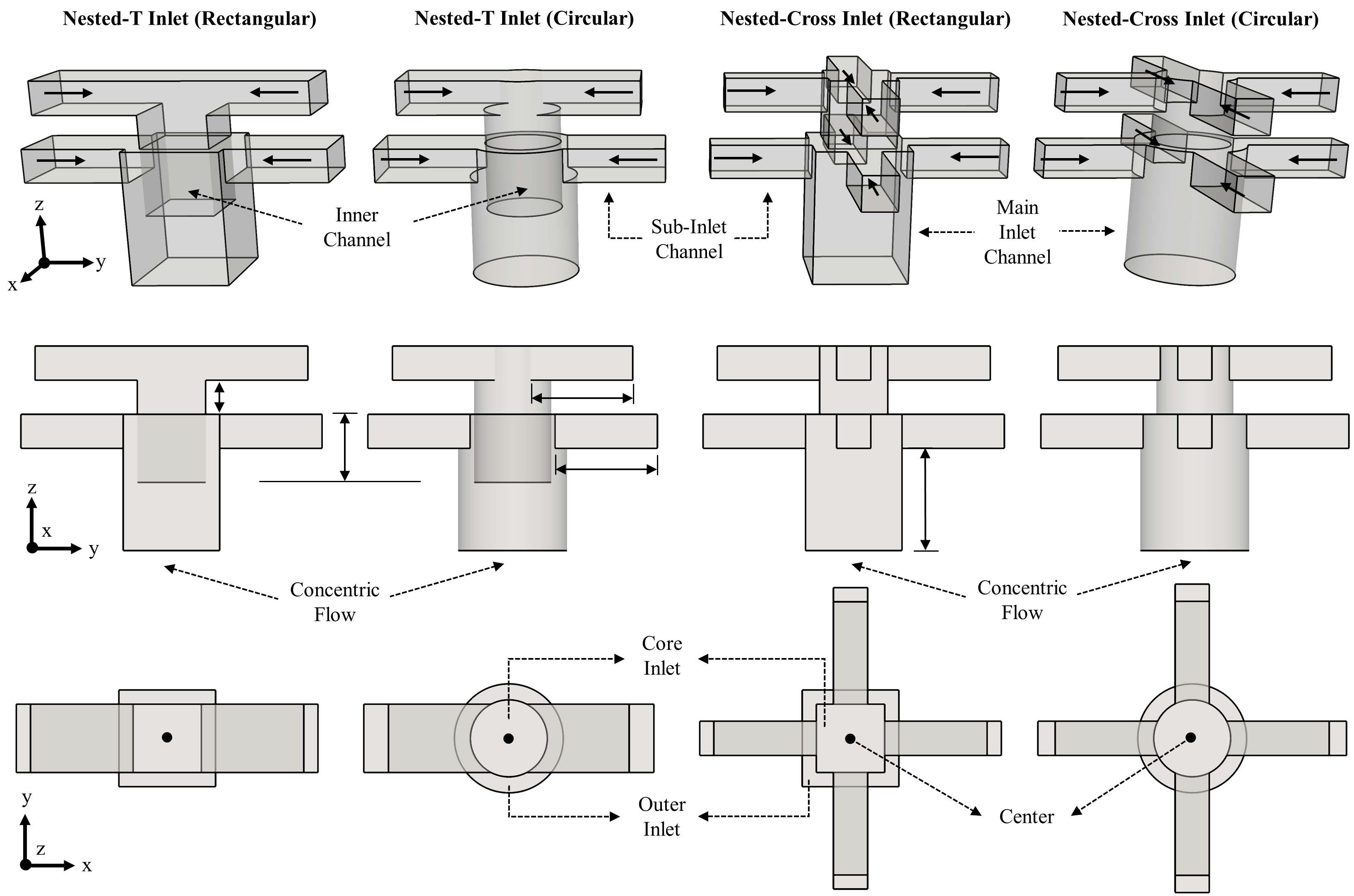

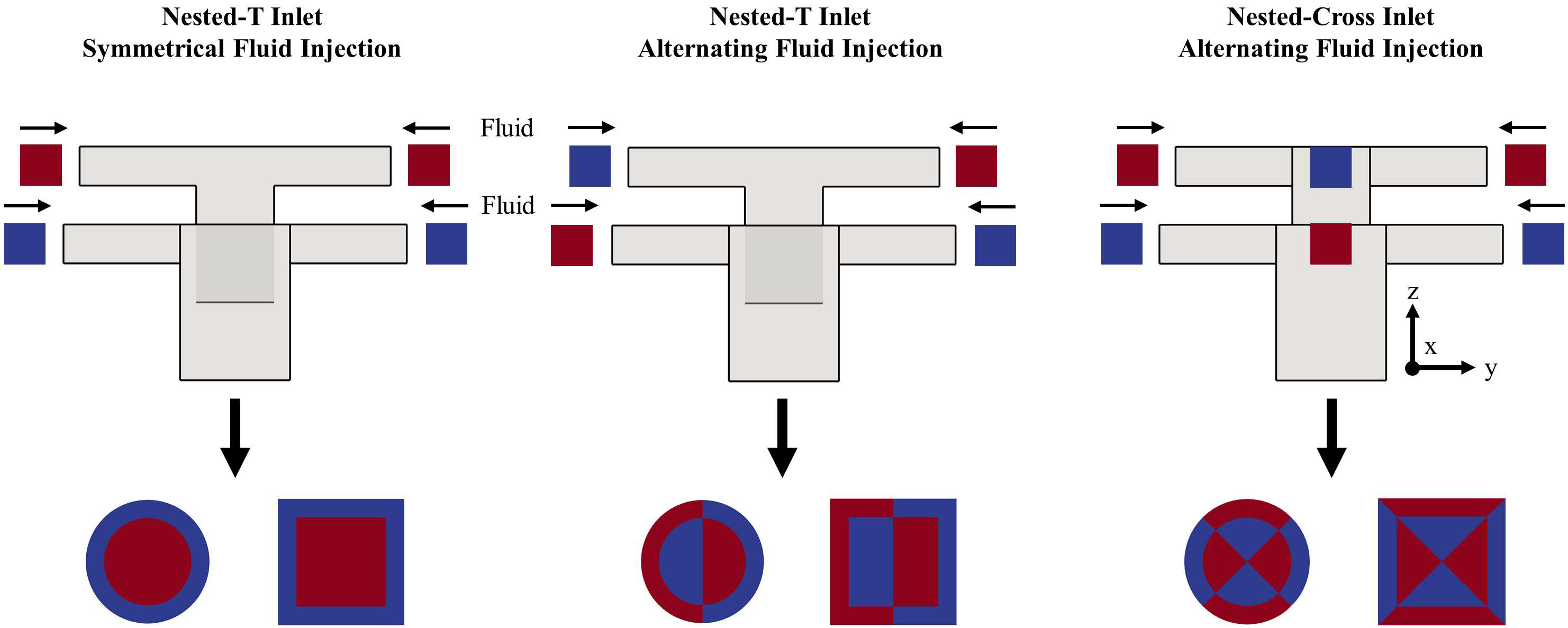

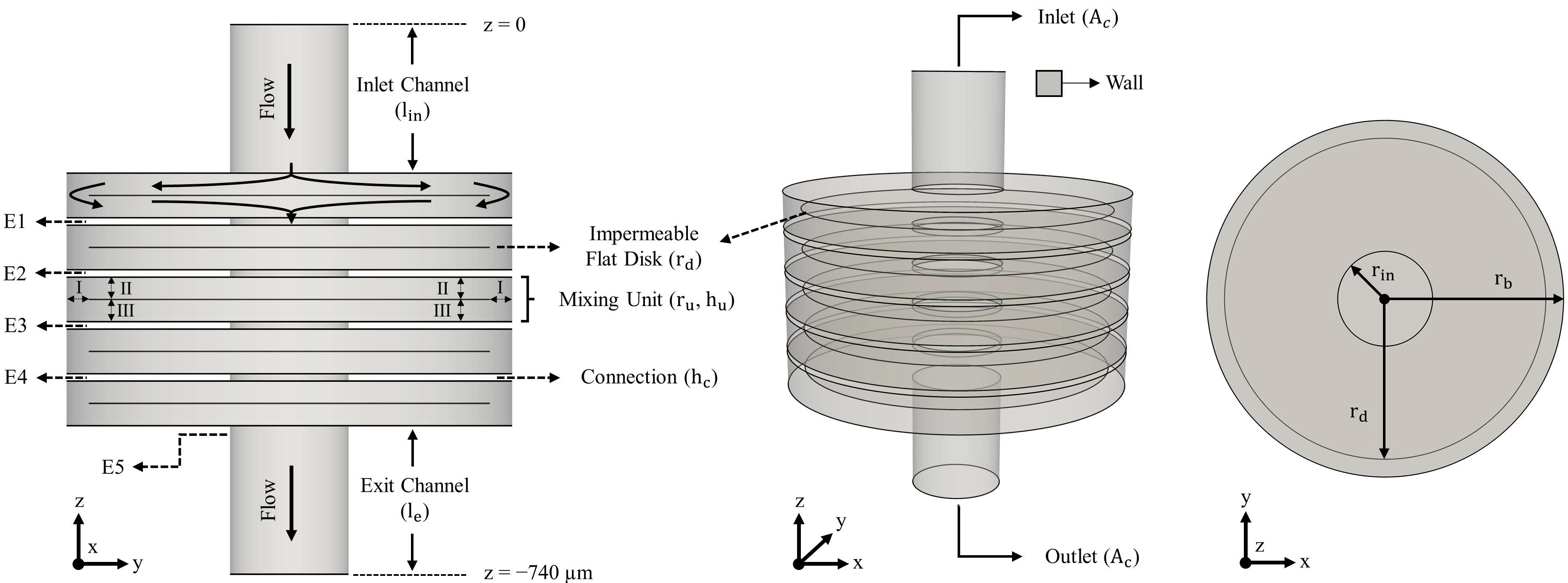

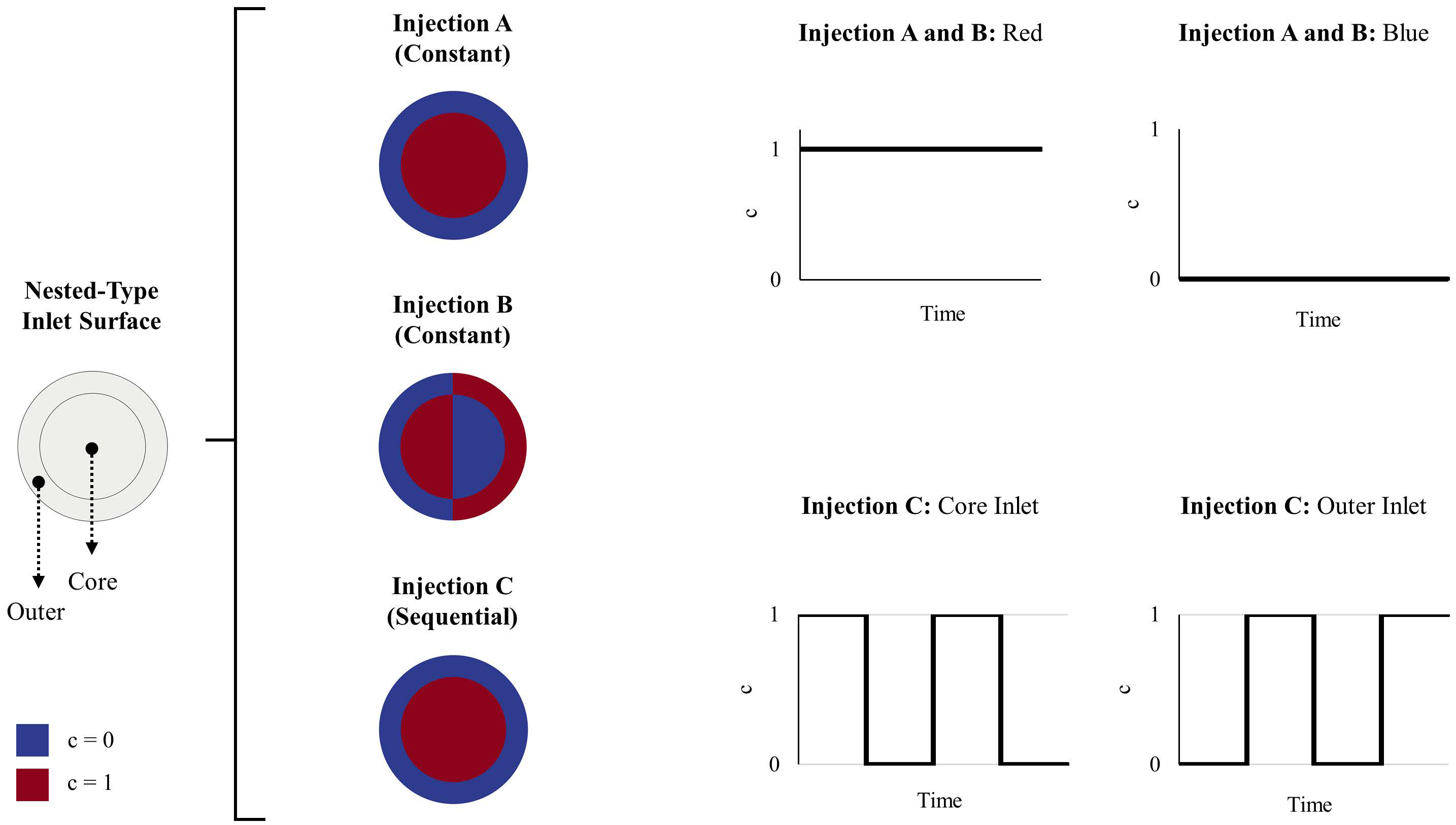

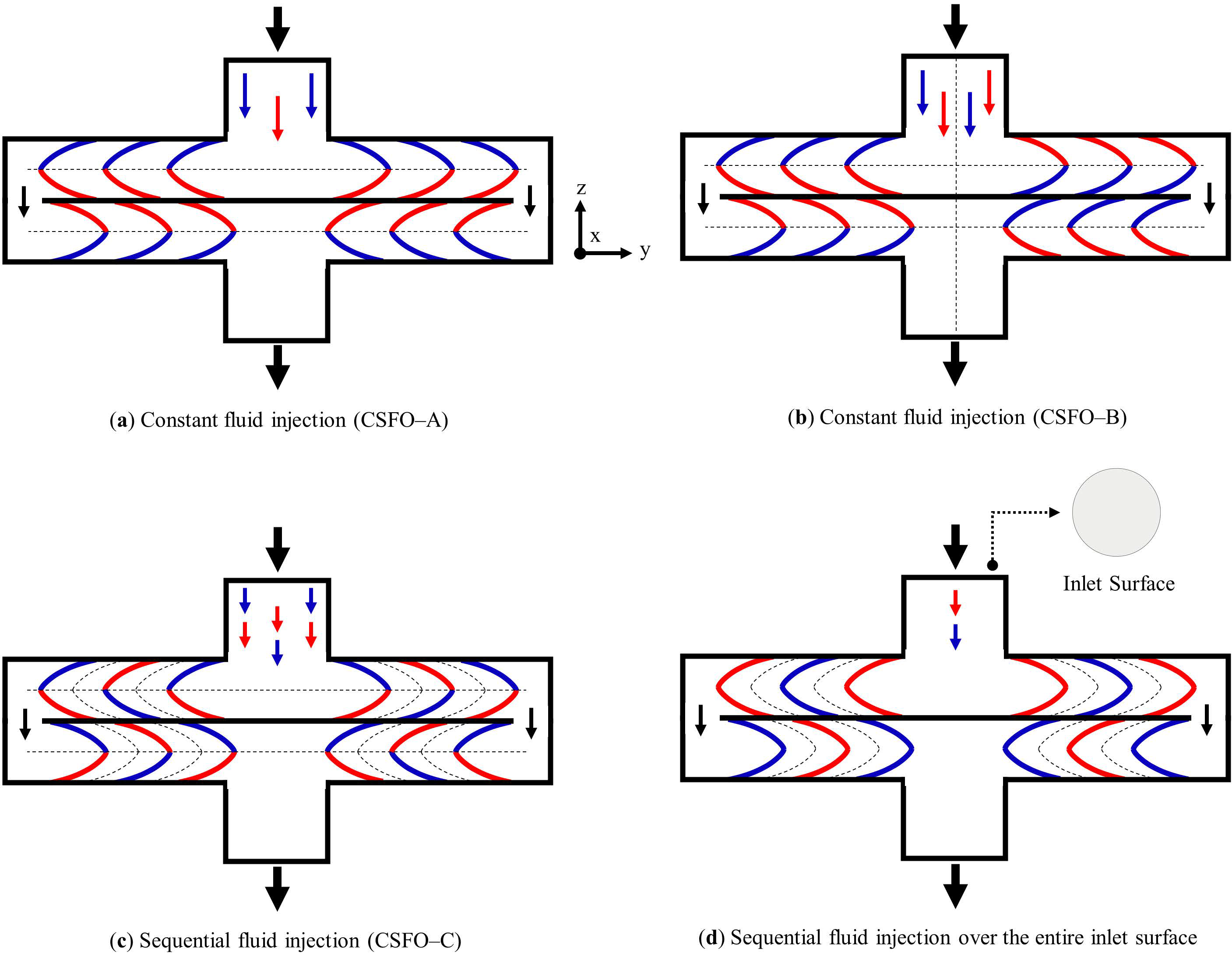

3. Micromixer Design and Simulation Setup

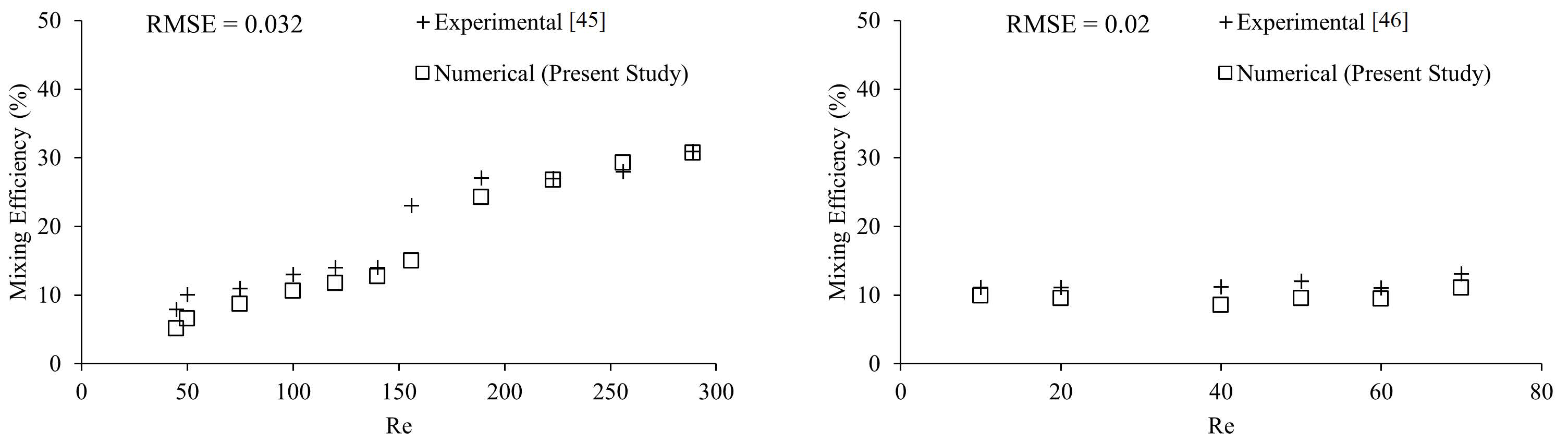

4. Mesh Study

5. Results

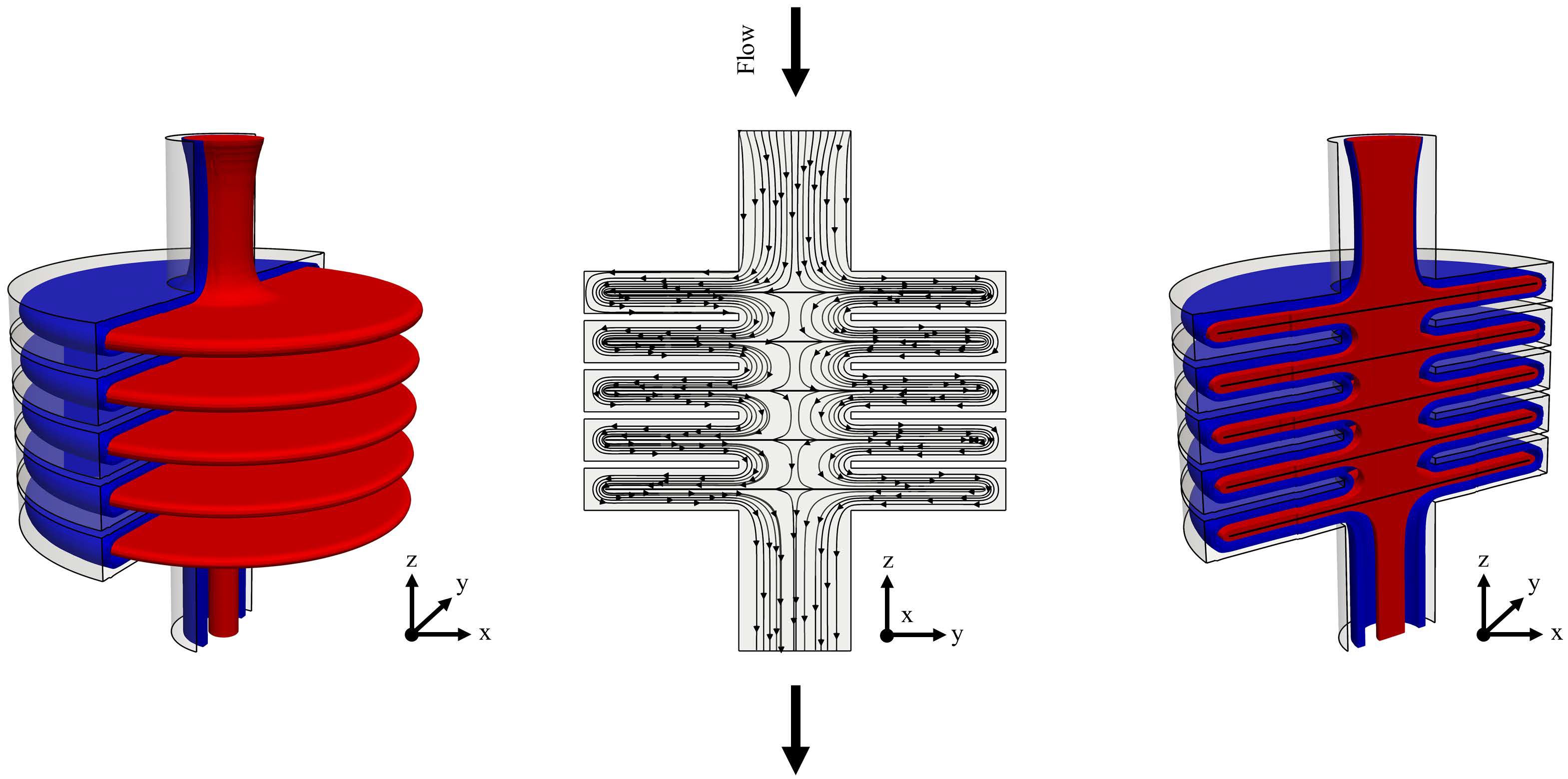

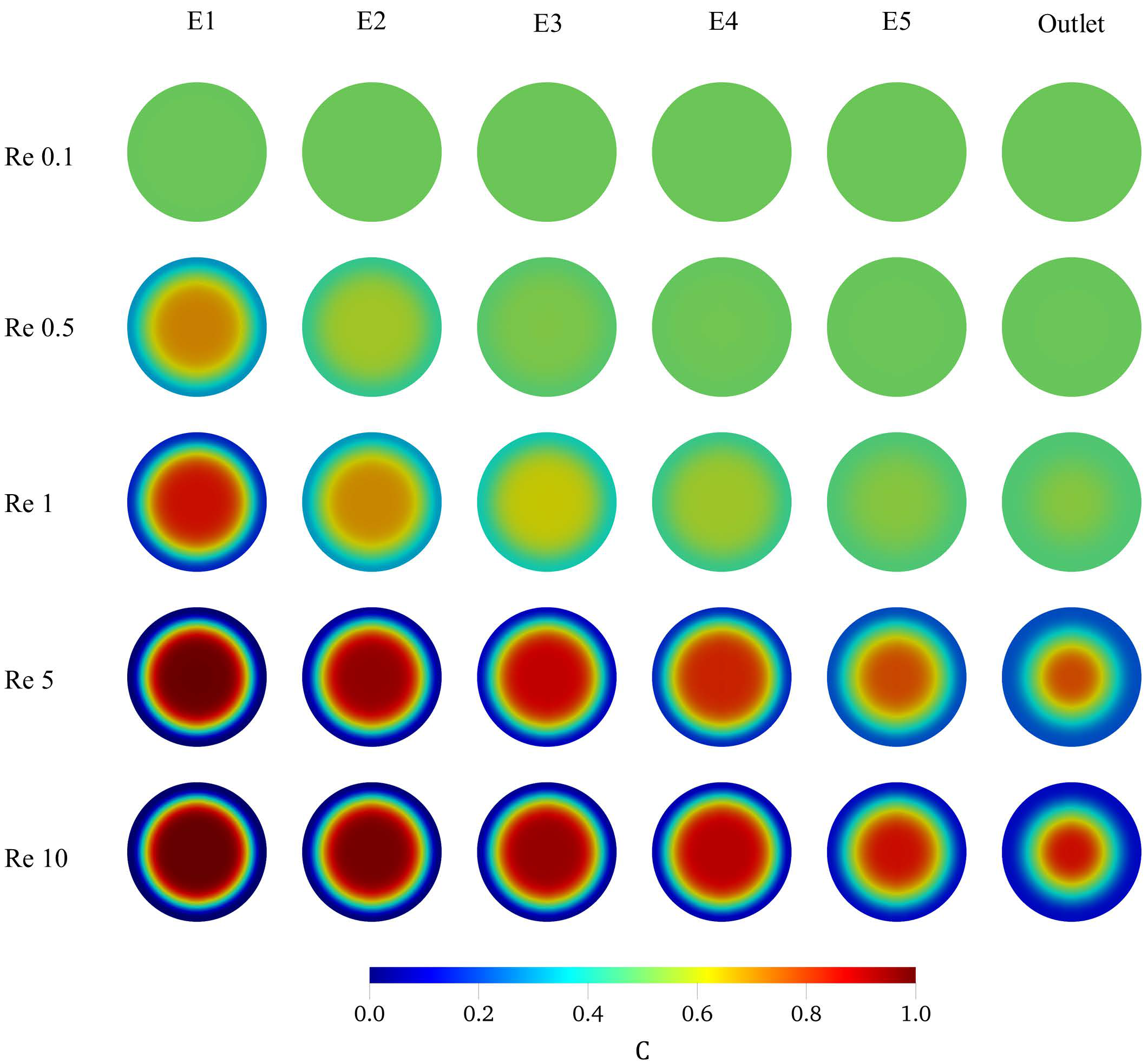

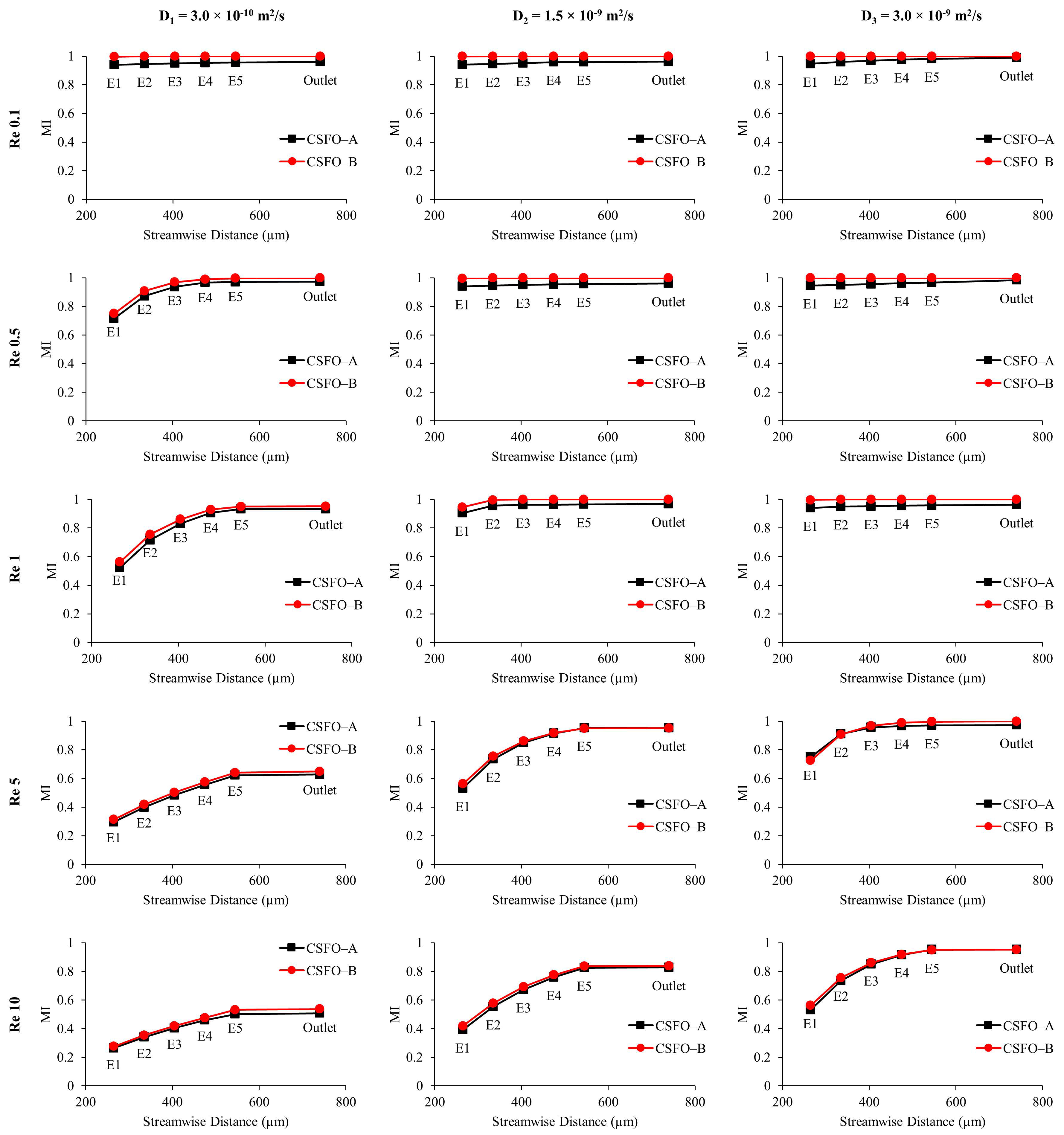

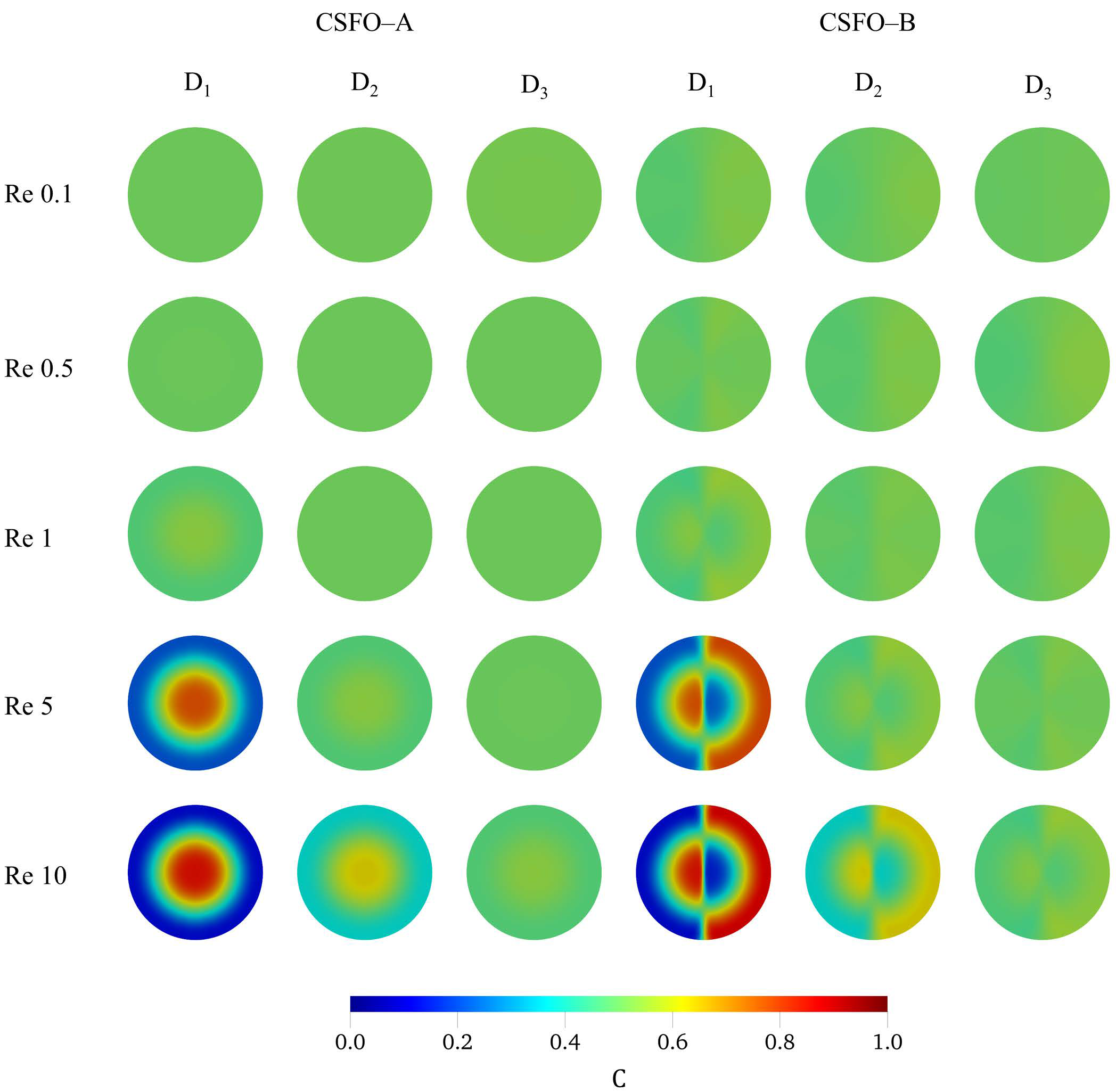

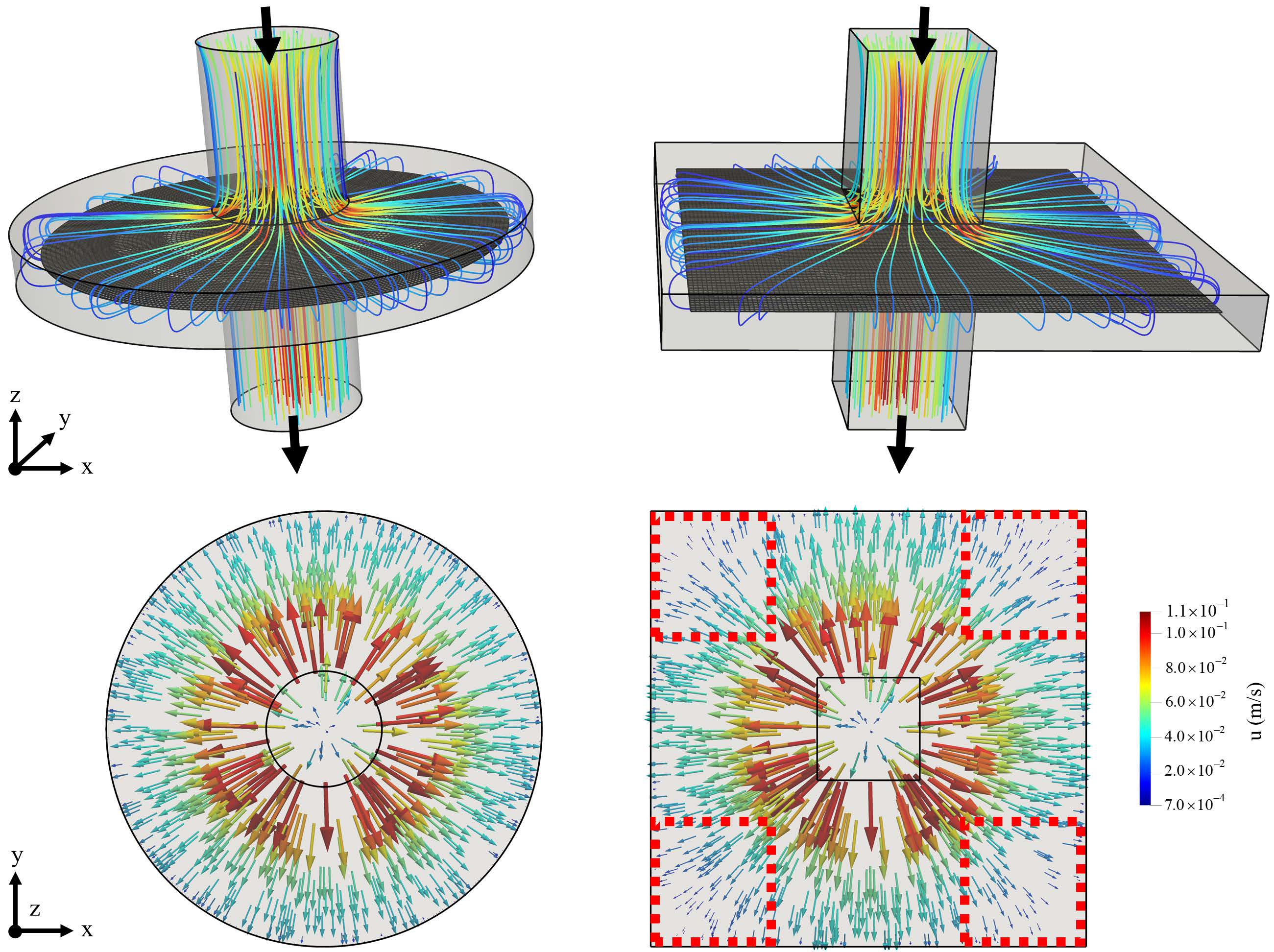

5.1. Fluid Mixing in the CSFO–A and CSFO–B Micromixer Configurations

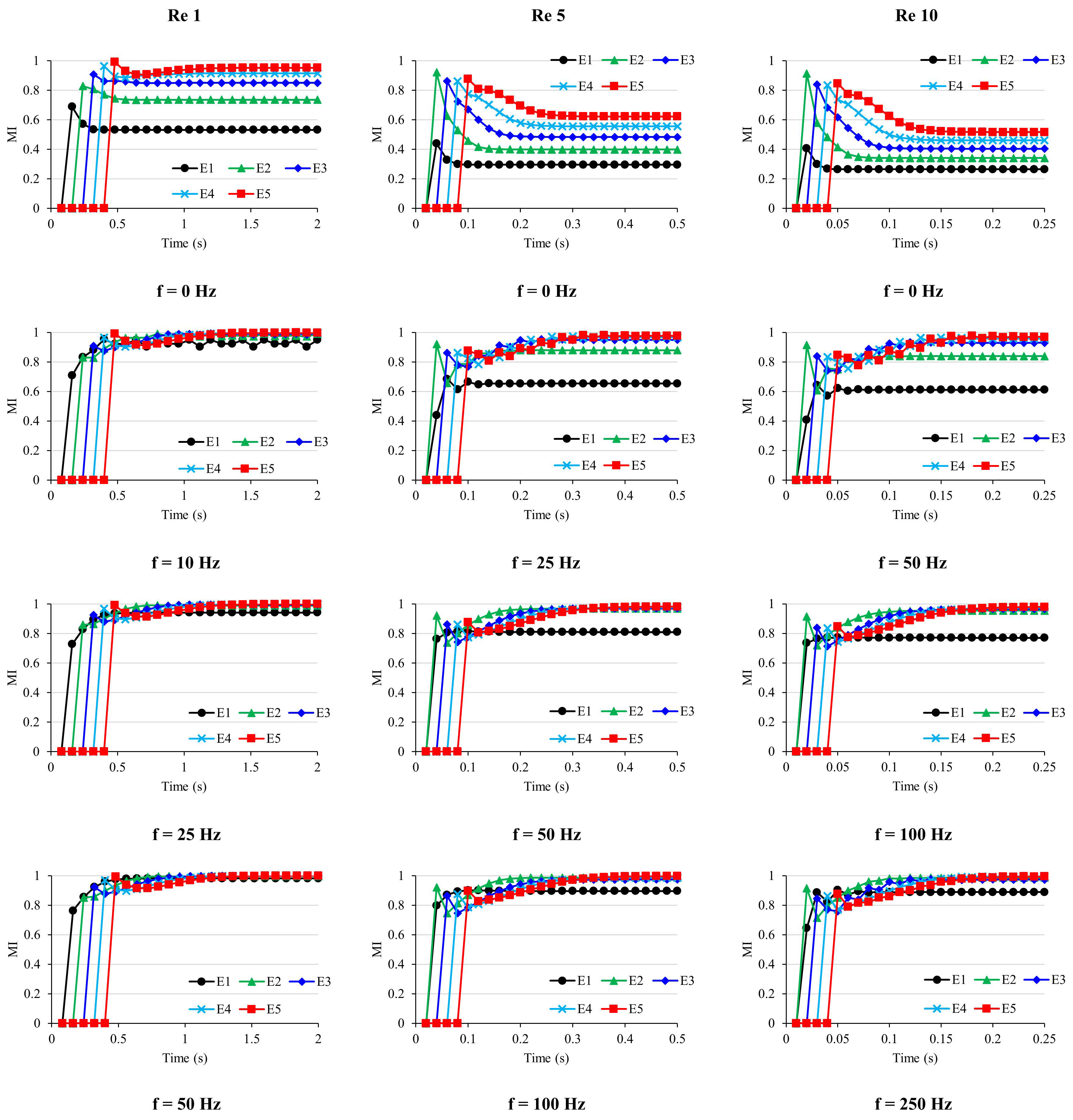

5.2. Fluid Mixing in the CSFO–C Micromixer Configuration

6. Discussion

7. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

Appendix A

References

- Mansur, E.A.; Ye, M.; Wang, Y.; Dai, Y. A state-of-the-art review of mixing in microfluidic mixers. Chin. J. Chem. Eng. 2008, 16, 503–516. [Google Scholar] [CrossRef]

- Streets, A.M.; Huang, Y. Chip in a lab: Microfluidics for next generation life science research. Biomicrofluidics 2013, 7, 011302. [Google Scholar] [CrossRef] [PubMed]

- Park, J.M.; Seo, K.D.; Kwon, T.H. A chaotic micromixer using obstruction-pairs. J. Micromechanics Microengineering 2009, 20, 015023. [Google Scholar] [CrossRef]

- Reyes, D.R.; Iossifidis, D.; Auroux, P.-A.; Manz, A. Micro total analysis systems. 1. Introduction, theory, and technology. Anal. Chem. 2002, 74, 2623–2636. [Google Scholar] [CrossRef]

- Gambhire, S.; Patel, N.; Gambhire, G.; Kale, S. A review on different micromixers and its micromixing within microchannel. Int. J. Curr. Eng. Technol. 2016, 4, 409–413. [Google Scholar]

- Nguyen, N.-T.; Wu, Z. Micromixers—A review. J. Micromechanics Microengineering 2005, 15, R1–R16. [Google Scholar] [CrossRef]

- Suh, Y.K.; Kang, S. A review on mixing in microfluidics. Micromachines 2010, 1, 82–111. [Google Scholar] [CrossRef]

- Gidde, R.R.; Pawar, P.M.; Ronge, B.P.; Misal, N.D.; Kapurkar, R.B.; Parkhe, A.K. Evaluation of the mixing performance in a planar passive micromixer with circular and square mixing chambers. Microsyst. Technol. 2017, 24, 2599–2610. [Google Scholar] [CrossRef]

- Lee, C.Y.; Chang, C.L.; Wang, Y.N.; Fu, L.M. Microfluidic mixing: A review. Int. J. Mol. Sci. 2011, 12, 3263–3287. [Google Scholar] [CrossRef]

- Kumar, V.; Paraschivoiu, M.; Nigam, K.D.P. Single-phase fluid flow and mixing in microchannels. Chem. Eng. Sci. 2011, 66, 1329–1373. [Google Scholar] [CrossRef]

- Cai, G.; Xue, L.; Zhang, H.; Lin, J. A review on micromixers. Micromachines 2017, 8, 274. [Google Scholar] [CrossRef]

- Nguyen, N.-T. Chapter 1-introduction. In Micromixers, 2nd ed.; Nguyen, N.-T., Ed.; William Andrew Publishing: Oxford, UK, 2012; pp. 1–8. [Google Scholar]

- Chung, Y.-C.; Hsu, Y.-L.; Jen, C.-P.; Lu, M.-C.; Lin, Y.-C. Design of passive mixers utilizing microfluidic self-circulation in the mixing chamber. Lab A Chip 2004, 4, 70–77. [Google Scholar] [CrossRef]

- Alam, A.; Afzal, A.; Kim, K.-Y. Mixing performance of a planar micromixer with circular obstructions in a curved microchannel. Chem. Eng. Res. Des. 2014, 92, 423–434. [Google Scholar] [CrossRef]

- Capretto, L.; Cheng, W.; Hill, M.; Zhang, X. Micromixing within microfluidic devices. Top Curr. Chem. 2011, 304, 27–68. [Google Scholar]

- Le The, H.; Le Thanh, H.; Dong, T.; Ta, B.Q.; Tran-Minh, N.; Karlsen, F. An effective passive micromixer with shifted trapezoidal blades using wide reynolds number range. Chem. Eng. Res. Des. 2015, 93, 1–11. [Google Scholar] [CrossRef]

- Bhopte, S.; Sammakia, B.; Murray, B. Numerical study of a novel passive micromixer design. In Proceedings of the 2010 12th IEEE Intersociety Conference on Thermal and Thermomechanical Phenomena in Electronic Systems, Las Vegas, NV, USA, 2–5 June 2010; pp. 1–10. [Google Scholar]

- Okuducu, M.B.; Aral, M.M. Novel 3-d t-shaped passive micromixer design with helicoidal flows. Processes 2019, 7, 637. [Google Scholar] [CrossRef]

- Chen, X.; Li, T. A novel passive micromixer designed by applying an optimization algorithm to the zigzag microchannel. Chem. Eng. J. 2017, 313, 1406–1414. [Google Scholar] [CrossRef]

- Hossain, S.; Ansari, M.A.; Kim, K.-Y. Evaluation of the mixing performance of three passive micromixers. Chem. Eng. J. 2009, 150, 492–501. [Google Scholar] [CrossRef]

- Lin, C.-H.; Tsai, C.-H.; Fu, L.-M. A rapid three-dimensional vortex micromixer utilizing self-rotation effects under low reynolds number conditions. J. Micromechanics Microengineering 2005, 15, 935–943. [Google Scholar] [CrossRef]

- Tran-Minh, N.; Dong, T.; Karlsen, F. An efficient passive planar micromixer with ellipse-like micropillars for continuous mixing of human blood. Comput. Methods Programs Biomed. 2014, 117, 20–29. [Google Scholar] [CrossRef]

- Al-Halhouli, A.a.; Alshare, A.; Mohsen, M.; Matar, M.; Dietzel, A.; Büttgenbach, S. Passive micromixers with interlocking semi-circle and omega-shaped modules: Experiments and simulations. Micromachines 2015, 6, 953–968. [Google Scholar] [CrossRef]

- Bhagat, A.A.S.; Peterson, E.T.K.; Papautsky, I. A passive planar micromixer with obstructions for mixing at low reynolds numbers. J. Micromechanics Microengineering 2007, 17, 1017–1024. [Google Scholar] [CrossRef]

- Fang, Y.; Ye, Y.; Shen, R.; Zhu, P.; Guo, R.; Hu, Y.; Wu, L. Mixing enhancement by simple periodic geometric features in microchannels. Chem. Eng. J. 2012, 187, 306–310. [Google Scholar] [CrossRef]

- Ortega-Casanova, J.; Lai, C.H. Cfd study about the effect of using multiple inlets on the efficiency of a micromixer. Assessment of the optimal inlet configuration working as a microreactor. Chem. Eng. Process. Process Intensif. 2018, 125, 163–172. [Google Scholar] [CrossRef]

- Goullet, A.; Glasgow, I.; Aubry, N. Dynamics of microfluidic mixing using time pulsing. Discret. Contin. Dyn. Syst. 2005, 2005, 327–336. [Google Scholar]

- OpenFOAM. The Openfoam Foundation, Opencfd Ltd., v5; OpenFOAM: Bracknell, UK, 2015. [Google Scholar]

- Warming, R.F.; Beam, R.M. Upwind second-order difference schemes and applications in aerodynamic flows. AIAA J. 1976, 14, 1241–1249. [Google Scholar] [CrossRef]

- Wang, L.; Yang, J.-T.; Lyu, P.-C. An overlapping crisscross micromixer. Chem. Eng. Sci. 2007, 62, 711–720. [Google Scholar] [CrossRef]

- Moukalled, F.; Mangani, L.; Darwish, M. The Finite Volume Method in Computational Fluid Dynamics: An Advanced Introduction with Openfoam and Matlab; Springer Publishing Company Switzerland, Incorporated: Geneva, Switzerland, 2015; p. 791. [Google Scholar]

- Ansari, M.A.; Kim, K.Y.; Kim, S.M. Numerical and experimental study on mixing performances of simple and vortex micro t-mixers. Micromachines (Basel) 2018, 9, 204. [Google Scholar] [CrossRef]

- Roudgar, M.; Brunazzi, E.; Galletti, C.; Mauri, R. Numerical study of split t-micromixers. Chem. Eng. Technol. 2012, 35, 1291–1299. [Google Scholar] [CrossRef]

- Okuducu, M.B.; Aral, M.M. Performance analysis and numerical evaluation of mixing in 3-d t-shape passive micromixers. Micromachines 2018, 9, 210. [Google Scholar] [CrossRef]

- Zhang, M.; Wu, J.; Wang, L.; Xiao, K.; Wen, W. A simple method for fabricating multi-layer pdms structures for 3d microfluidic chips. Lab A Chip 2010, 10, 1199–1203. [Google Scholar] [CrossRef]

- Chen, X. Fabrication and performance evaluation of two multi-layer passive micromixers. Sens. Rev. 2018, 38, 321–325. [Google Scholar] [CrossRef]

- Branebjerg, J.; Gravesen, P.; Krog, J.P.; Nielsen, C.R. Fast mixing by lamination. In Proceedings of the Ninth International Workshop on Micro Electromechanical Systems, San Diego, CA, USA, 11–15 February 1996; pp. 441–446. [Google Scholar]

- Gray, B.L.; Jaeggi, D.; Mourlas, N.J.; van Drieënhuizen, B.P.; Williams, K.R.; Maluf, N.I.; Kovacs, G.T.A. Novel interconnection technologies for integrated microfluidic systems1paper presented as part of the ssaw-98 workshop.1. Sens. Actuators A Phys. 1999, 77, 57–65. [Google Scholar] [CrossRef]

- Yang, J.; Qi, L.; Chen, Y.; Ma, H. Design and fabrication of a three dimensional spiral micromixer. Chin. J. Chem. 2013, 31, 209–214. [Google Scholar] [CrossRef]

- Galletti, C.; Roudgar, M.; Brunazzi, E.; Mauri, R. Effect of inlet conditions on the engulfment pattern in a t-shaped micro-mixer. Chem. Eng. J. 2012, 185–186, 300–313. [Google Scholar] [CrossRef]

- Wu, Z.; Nguyen, N.-T.; Huang, X. Nonlinear diffusive mixing in microchannels: Theory and experiments. J. Micromech. Microeng. 2004, 14, 604–611. [Google Scholar] [CrossRef]

- Holz, M.; Heil, S.; Sacco, A. Temperature-dependent self-diffusion coefficients of water and six selected molecular liquids for calibration in accurate 1h nmr pfg measurements. Phys. Chem. Chem. Phys. 2000, 2, 4740–4742. [Google Scholar] [CrossRef]

- Ansari, M.A.; Kim, K.-Y.; Anwar, K.; Kim, S.M. A novel passive micromixer based on unbalanced splits and collisions of fluid streams. J. Micromechanics Microengineering 2010, 20, 055007. [Google Scholar] [CrossRef]

- Izadpanah, E.; Hekmat, M.H.; Azimi, H.; Hoseini, H.; Babaie Rabiee, M. Numerical simulation of mixing process in t-shaped and dt-shaped micromixers. Chem. Eng. Commun. 2018, 205, 363–371. [Google Scholar] [CrossRef]

- Silva, J.P.; dos Santos, A.; Semiao, V. Experimental characterization of pulsed newtonian fluid flows inside t-shaped micromixers with variable inlets widths. Exp. Therm. Fluid Sci. 2017, 89, 249–258. [Google Scholar] [CrossRef]

- Ansari, M.A.; Kim, K.-Y.; Anwar, K.; Kim, S.M. Vortex micro t-mixer with non-aligned inputs. Chem. Eng. J. 2012, 181–182, 846–850. [Google Scholar] [CrossRef]

- Okuducu, M.B.; Aral, M.M. Computational evaluation of mixing performance in 3-d swirl-generating passive micromixers. Processes 2019, 7, 121. [Google Scholar] [CrossRef]

- Liu, M. Computational study of convective–diffusive mixing in a microchannel mixer. Chem. Eng. Sci. 2011, 66, 2211–2223. [Google Scholar] [CrossRef]

- Bailey, R.T. Managing false diffusion during second-order upwind simulations of liquid micromixing. Int. J. Numer. Methods Fluids 2017, 83, 940–959. [Google Scholar] [CrossRef]

- Tofteberg, T.; Skolimowski, M.; Andreassen, E.; Geschke, O. A novel passive micromixer: Lamination in a planar channel system. Microfluid. Nanofluidics 2009, 8, 209–215. [Google Scholar] [CrossRef]

- Hardt, S.; Schönfeld, F. Laminar mixing in different interdigital micromixers: Ii. Numerical simulations. AIChE J. 2003, 49, 578–584. [Google Scholar] [CrossRef]

- Sabry, M.N.; El-Emam, S.H.; Mansour, M.H.; Shouman, M.A. Development of an efficient uniflow comb micromixer for biodiesel production at low reynolds number. Chem. Eng. Process. Process Intensif. 2018, 128, 162–172. [Google Scholar] [CrossRef]

- Fujii, T.; Sando, Y.; Higashino, K.; Fujii, Y. A plug and play microfluidic device. Lab Chip 2003, 3, 193–197. [Google Scholar] [CrossRef]

- Nguyen, N.-T.; Huang, X. Mixing in microchannels based on hydrodynamic focusing and time-interleaved segmentation: Modelling and experiment. Lab on a chip 2005, 5, 1320–1326. [Google Scholar] [CrossRef]

- Nguyen, N.-T.; Huang, X. An analytical model for mixing based on time-interleaved sequential segmentation. Microfluid. Nanofluidics 2005, 1, 373–375. [Google Scholar] [CrossRef]

- Glasgow, I.; Lieber, S.; Aubry, N. Parameters influencing pulsed flow mixing in microchannels. Anal. Chem. 2004, 76, 4825–4832. [Google Scholar] [CrossRef]

- Alam, A.; Kim, K.-Y. Mixing performance of a planar micromixer with circular chambers and crossing constriction channels. Sens. Actuators B Chem. 2013, 176, 639–652. [Google Scholar] [CrossRef]

- Chung, C.K.; Shih, T.R. A rhombic micromixer with asymmetrical flow for enhancing mixing. J. Micromechanics Microengineering 2007, 17, 2495–2504. [Google Scholar] [CrossRef]

- Hossain, S.; Lee, I.; Kim, S.M.; Kim, K.-Y. A micromixer with two-layer serpentine crossing channels having excellent mixing performance at low reynolds numbers. Chem. Eng. J. 2017, 327, 268–277. [Google Scholar] [CrossRef]

- Sadegh Cheri, M.; Latifi, H.; Salehi Moghaddam, M.; Shahraki, H. Simulation and experimental investigation of planar micromixers with short-mixing-length. Chem. Eng. J. 2013, 234, 247–255. [Google Scholar] [CrossRef]

- Ansari, M.A.; Kim, K.-Y. Mixing performance of unbalanced split and recombine micomixers with circular and rhombic sub-channels. Chem. Eng. J. 2010, 162, 760–767. [Google Scholar] [CrossRef]

- Raza, W.; Hossain, S.; Kim, K.-Y. Effective mixing in a short serpentine split-and-recombination micromixer. Sens. Actuators B Chem. 2018, 258, 381–392. [Google Scholar] [CrossRef]

| Micromixer | Re | Mixing Efficiency (%) | Mixing Length (µm) | Reference |

|---|---|---|---|---|

| Crossing Channels | 0.1 | 88 | 6400 | [57] |

| Multi-Inlet | 0.1–0.29 | 90–80 | 5000 | [26] |

| Serpentine | 0.2 | 100 | 7500 | [59] |

| Baffled | 0.29 | 52 | 7200 | [25] |

| T-Shaped (f = 20 Hz) | 0.3 | 86.5 | 500 | [27] |

| T-Shaped (split inlet) | 0.5 | 42 | 2000 | [18] |

| Vortex | 0.5 | 50 | 1000 | [21] |

| Rhombic | 1 | 55 | 6000 | [58] |

| Obstructed Channels | 1 | 55 | 1180 | [60] |

| CSFO–A (D1) | 0.1 | 94 | 260 | Present study |

| 0.5 | 94 | 400 | ||

| 1 | 91 | 470 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Okuducu, M.B.; Aral, M.M. Toward the Next Generation of Passive Micromixers: A Novel 3-D Design Approach. Micromachines 2021, 12, 372. https://doi.org/10.3390/mi12040372

Okuducu MB, Aral MM. Toward the Next Generation of Passive Micromixers: A Novel 3-D Design Approach. Micromachines. 2021; 12(4):372. https://doi.org/10.3390/mi12040372

Chicago/Turabian StyleOkuducu, Mahmut Burak, and Mustafa M. Aral. 2021. "Toward the Next Generation of Passive Micromixers: A Novel 3-D Design Approach" Micromachines 12, no. 4: 372. https://doi.org/10.3390/mi12040372

APA StyleOkuducu, M. B., & Aral, M. M. (2021). Toward the Next Generation of Passive Micromixers: A Novel 3-D Design Approach. Micromachines, 12(4), 372. https://doi.org/10.3390/mi12040372