Chemosensing on Miniaturized Plasmonic Substrates

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Cleaning Procedure of Coverslips

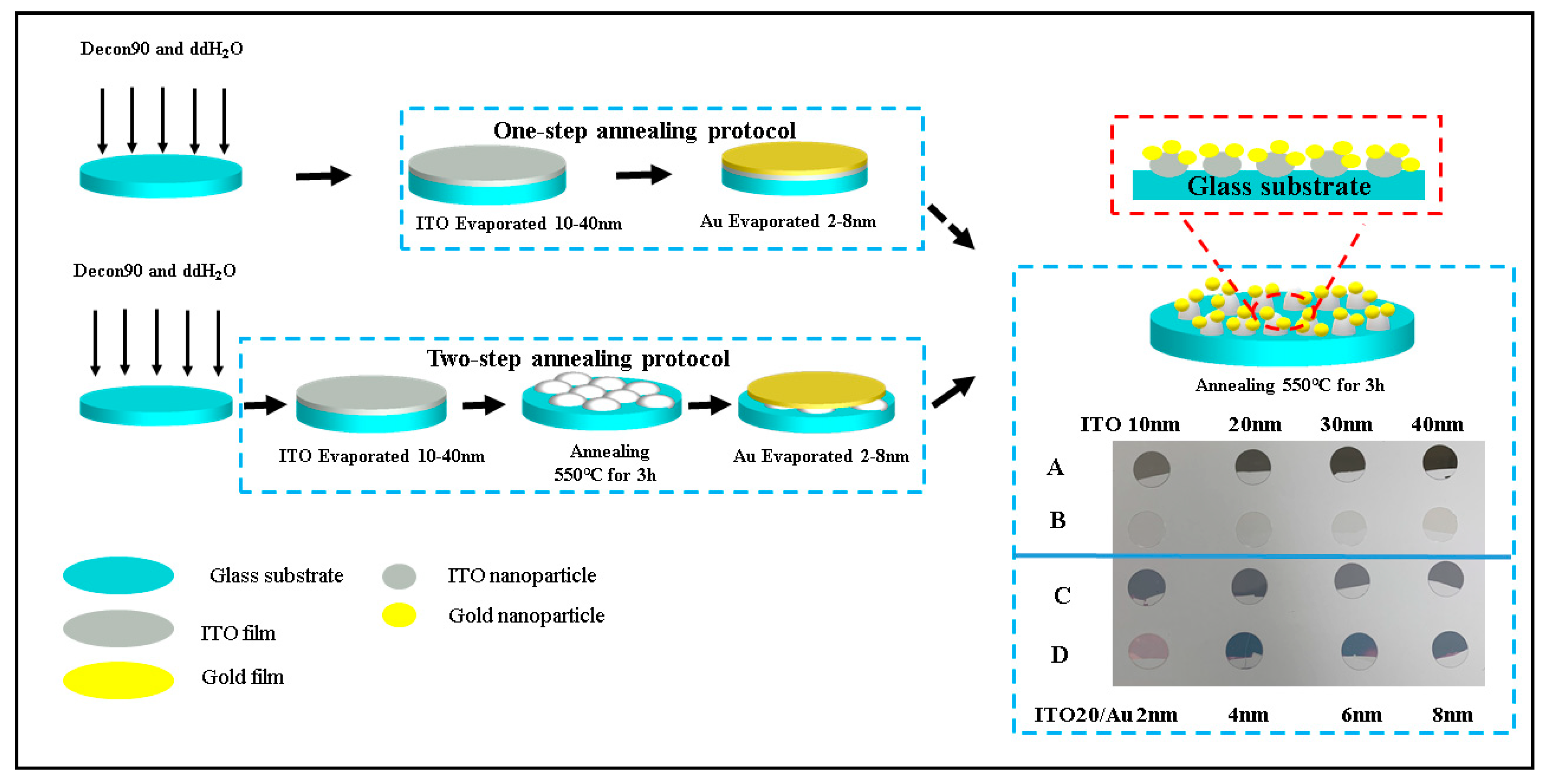

2.3. Evaporation of Gold and ITO on Glass Coverslips

2.4. Annealing of Gold- and ITO-Coated Coverslips

2.5. Instruments

2.6. Preparation of BPE Solutions

2.7. Statistical Analysis

3. Results

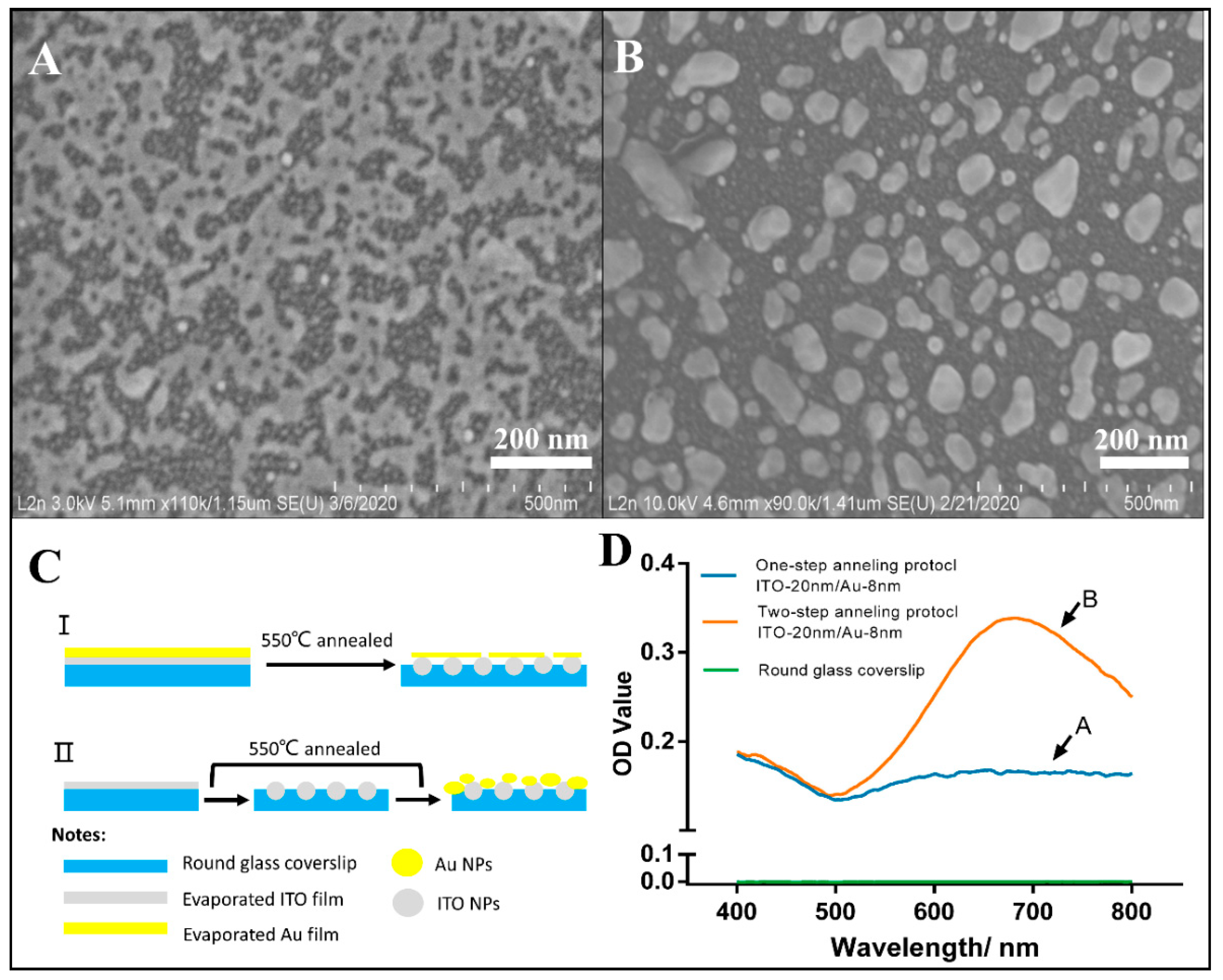

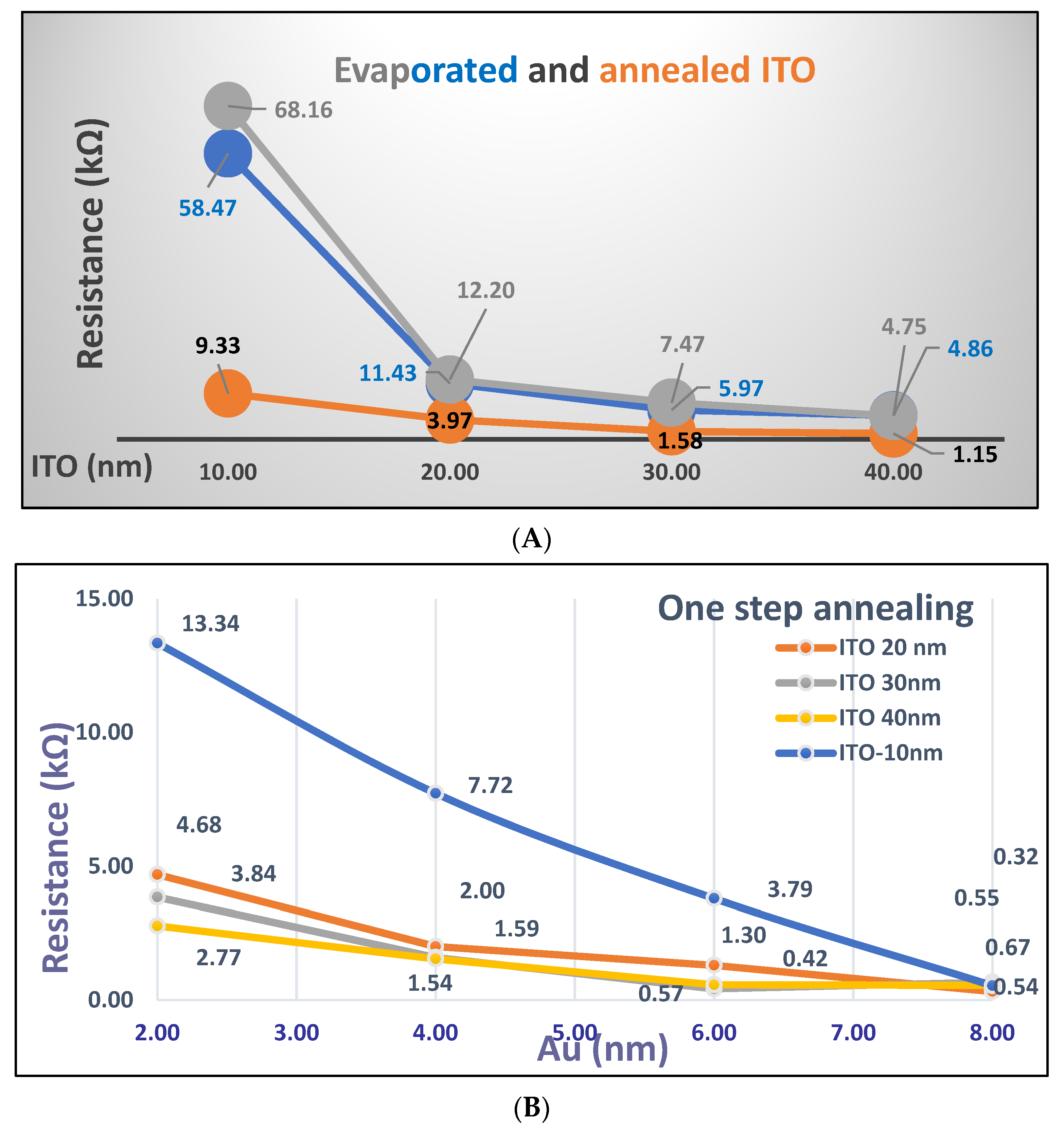

3.1. Optimization of the Annealing Process of Au/ITO Coated Coverslips

Electrical Measurements

3.2. AFM Characterization of Two-Steps Annealed Glass Surfaces

3.3. Optical Properties of Two-Steps Annealed Surfaces

3.3.1. Color Variation of the Coverslip Surface Versus Evaporated Gold Thickness

3.3.2. LSPR Characterization

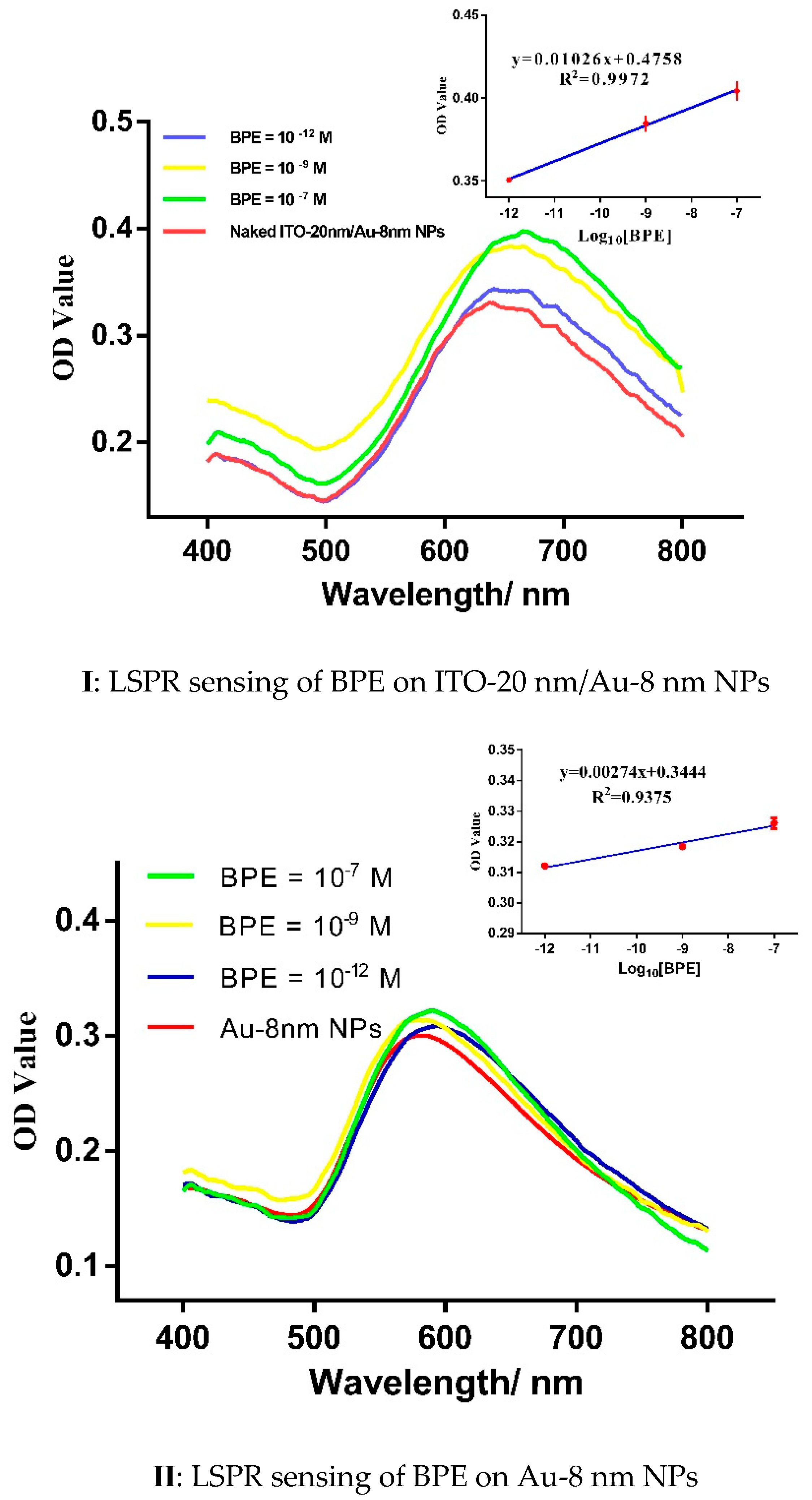

3.4. LSPR Chemosensing of BPE Traces on Two-Steps ITO/Au Annealed Coverslips

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Amendola, V.; Pilot, R.; Frasconi, M.; Maragò, O.M.; Iatì, M.A. Surface Plasmon Resonance in Gold Nanoparticles: A review. J. Phys. Condens. Matter. 2017, 29, 203002. [Google Scholar] [CrossRef] [PubMed]

- Petryayeva, E.; Krull, U.J. Localized Surface Plasmon Resonance: Nanostructures, Bioassays and Biosensing—A review. Anal. Chim. Acta 2011, 706, 8–24. [Google Scholar] [CrossRef]

- Takemura, K.; Adegoke, O.; Suzuki, T.; Park, E.Y. A Localized Surface Plasmon Resonance-Amplified Immunofluorescence Biosensor for Ultrasensitive and Rapid Detection of Non-structural Protein 1 of Zika Virus. PLoS ONE 2019, 14, e0211517. [Google Scholar]

- Spackova, B.; Wrobel, P.; Bockova, M.; Homola, J. Optical Biosensors Based on Plasmonic Nanostructures: A Review. Proc. IEEE 2016, 104, 2380–2408. [Google Scholar] [CrossRef]

- Das, A.; Kumar, K.; Dhawan, A. Periodic Arrays of Plasmonic Crossed-bowtie Nanostructures Interspaced with Plasmonic Nanocrosses for Highly Sensitive LSPR based Chemical and Biological Sensing. RSC Adv. 2021, 11, 896–8106. [Google Scholar] [CrossRef]

- Chowdhury, A.D.; Nasrin, F.; Gangopadhyay, R.; Ganganboina, A.B.; Takemura, K.; Kozaki, I.; Honda, H.; Hara, T.; Park, S.; Suzuki, T.; et al. Controlling Distance, Size and Concentration of Nanoconjugates for Optimized LSPR based Biosensors. Biosens. Bioelectron. 2021, 170, 112657. [Google Scholar] [CrossRef]

- Romero, M.R.; Picchio, M.L. Biosensors based on Nanomaterials: Transducers and Modified Surfaces for Diagnostics. In Nanobiomaterial Enginnering: Concepts and Their Applications in Biomedicine and Diagnostics; Springer: Berlin/Heidelberg, Germany, 2020; pp. 15–47. [Google Scholar]

- Zopf, D.; Pittner, A.; Dathe, A.; Grosse, N.; Csaki, A.; Arstila, K.; Toppari, J.J.; Schott, W.; Dontsov, D.; Uhlrich, G.; et al. Plasmonic Nanosensor Array for Multiplexed dna-based Pathogen Detection. ACS Sens. 2019, 4, 335–343. [Google Scholar] [CrossRef]

- Mauriz, E. Clinical Applications of Visual Plasmonic Colorimetric Sensing. Sensors 2020, 20, 6214. [Google Scholar] [CrossRef]

- Zengin, A.; Tamer, U.; Caykara, T. SERS Detection of Hepatitis B virus DNA in a Temperature-Responsitive Sandwich Hybridization Assay. J. Raman Spectrosc. 2017, 48, 668–672. [Google Scholar] [CrossRef]

- Hu, J.; Fu, K.; Bohn, P.W. Whole-cell Pseudomonas Aeruginosa Localized Surface Plasmon Resonance Aptasensor. Anal. Chem. 2018, 90, 2326–2332. [Google Scholar] [CrossRef]

- Schmid, G. Physical and Chemical Consequences of Size-Reduction of Gold: Bioresponse and Biodistribution. J. Clust. Sci. 2014, 25, 29–49. [Google Scholar] [CrossRef]

- Jia, K.; Khaywah, M.Y.; Li, Y.; Bijeon, J.L.; Adam, P.M.; Déturche, R.; Guelorget, B.; François, M.; Louarn, G.; Ionescu, R.E. Strong Improvements of Localized Surface Plasmon Resonance Sensitivity by Using Au/Ag Bimetallic Nanostructures Modified with Polydopamine Films. ACS Appl. Mater. Interfaces 2014, 6, 219–227. [Google Scholar] [CrossRef]

- Hurst, S.J.; Lytton-Jean, A.K.R.; Mirkin, C.A. Maximizing DNA Loading on a Range of Gold Nanoparticle Sizes. Anal. Chem. 2006, 78, 8313–8318. [Google Scholar] [CrossRef] [PubMed]

- Zhou, N.; Ye, C.; Polavarapu, L.; Xu, Q.-H. Controlled Preparation of Au/Ag/SnO 2 Core–Shell Nanoparticles using a Photochemical Method and Applications in LSPR based Sensing. Nanoscale 2015, 7, 9025–9032. [Google Scholar] [CrossRef]

- Liu, J.; Jalali, M.; Mahshid, S.; Wachsmann-Hogiu, S. Are Plasmonic Optical Biosensors Ready for Use in Point-of-Need Applications? Analyst 2020, 145, 364–384. [Google Scholar] [CrossRef] [PubMed]

- Widayanti; Abraha, K. Study on the Effect of Nanoparticle Bimetallic Coreshell Au-Ag for Sensitivity Enhancement of Biosensor Based on Surface Plasmon Resonance. J. Phys. Conf. Ser. 2016, 694, 012075. [Google Scholar] [CrossRef]

- Yu, T.; Geng, Z. Strategies to Improve Performances of LSPR Biosensing: Structure, Materials, and Interface Modification. Biosens. Bioelectron. 2021, 174, 112850. [Google Scholar]

- Koirala, K.P.; Ge, J.; Kalyanaraman, R.; Duscher, G. Direct Detection of Highly Localized Metal-Metal Interface Plasmons from Bimetallic Nanoparticles. Plasmonics 2021, 1–8. [Google Scholar] [CrossRef]

- Liao, J.; Zhan, Y.; Liu, Q.; Hong, R.; Tao, C.; Wang, Q.; Lin, H.; Han, Z.; Zhang, D. Tunable Surface Plasmon Resonance of Al-Cu Bimetallic Nanoparticles Thin Films Induced by Pulsed-laser. Appl. Surf. Sci. 2021, 540, 148397. [Google Scholar] [CrossRef]

- Yang, C.-S.; Chang, C.-M.; Chen, P.-H.; Yu, P.; Pan, C.-L. Broadband Terahertz Conductivity and Optical Transmission of Indium-Tin-Oxide (ITO) Nanomaterials. Opt. Express 2013, 21, 16670. [Google Scholar] [CrossRef] [PubMed]

- Mryasov, O.; Freeman, A. Electronic Band Structure of Indium Tin Oxide and Criteria for Transparent Conducting Behavior. Phys. Rev. B 2001, 64, 233111. [Google Scholar] [CrossRef]

- Li, W.-C.; Lee, S.-W. The Characteristic Self-Assembly of Gold nanoparticles over Indium Tin Oxide (ITO) Substrate. Bull. Korean Chem. Soc. 2011, 32, 1133–1137. [Google Scholar] [CrossRef][Green Version]

- Lee, J.-H.; Mim, B.-C.; Oh, B.-K.; Choi, J.-W. Rapid and Sensitive Determination of HIV-1 Virus Based on Surface Enhanced Raman Spectroscopy. J. Biomed. Nanotechnol. 2015, 11, 2223–2230. [Google Scholar] [CrossRef] [PubMed]

- Ray, N.J.; Yoo, J.H.; McKeown, J.T.; Elhadj, S.; Baxamusa, S.H.; Johnson, M.A.; Nguyen, H.T.; Steele, W.A.; Chesser, J.M.; Matthews, M.J.; et al. Enhanced Tunability of Gold Nanoparticle Size, Spacing, and Shape for Large-Scale Plasmonic Arrays. ACS Appl. Nano Mater. 2019, 2, 4395–4401. [Google Scholar] [CrossRef]

- Jung, L.S.; Campbell, C.T.; Chinowsky, T.M.; Mar, M.N.; Yee, S.S. Quantitative Interpretation of the Response of Surface Plasmon Resonance Sensors to Adsorbed Films. Langmuir 1998, 14, 5636–5648. [Google Scholar] [CrossRef]

- Jones, M.R.; Osberg, K.D.; Macfarlane, R.J.; Langille, M.R.; Mirkin, C.A. Templated Techniques for the Synthesis and Assembly of Plasmonic Nanostructures. Chem. Rev. 2011, 111, 3736–3827. [Google Scholar] [CrossRef]

- Wang, D.; Schaaf, P. Thermal Dewetting of Thin Au Films Deposited onto Line-Patterned Substrates. J. Mater. Sci. 2012, 47, 1605–1608. [Google Scholar] [CrossRef]

- Mansourian, A.; Nasir, M.; Dickson, W.; O’Connor, D.; McCarron, R.; Wurtz, G.; Zayats, A.V. Fabrication and Effect of Annealing on Optical Properties of Single and Bimetallic Periodic Array of Different Noble Metals. In Proceedings of the 2012 12th IEEE International Conference on Nanotechnology (IEEE-NANO), Birmingham, UK, 20–23 August 2012. [Google Scholar]

- Jia, K.; Bijeon, J.L.; Adam, P.M.; Ionescu, R.E. Sensitive Localized Surface Plasmon Resonance Multiplexing Protocols. Anal. Chem. 2012, 84, 8020–8027. [Google Scholar] [CrossRef]

- Karakouz, T.; Maoz, B.M.; Lando, G.; Vaskevich, A.; Rubinstein, I. Stabilization of Gold Nanoparticle Films on Glass by Thermal Embedding. ACS Appl. Mater. Interfaces 2011, 3, 978–987. [Google Scholar] [CrossRef]

| Type of Substrate | λmax (nm) | Maximum Optical Density | ODmax/fwhm a (10−3) |

|---|---|---|---|

| ITO-20 nm/Au-2 nm | 578 | 0.119 | 1.05 |

| ITO-20 nm/Au-4 nm | 623 | 0.233 | 1.52 |

| ITO-20 nm/Au-6 nm | 653 | 0.285 | 1.72 |

| ITO-20 nm/Au-8 nm | 669 | 0.342 | 2.33 |

| ITO-10 nm/Au-8 nm | 650 | 0.307 | 2.19 |

| ITO-20 nm/Au-8 nm | 653 | 0.342 | 2.33 |

| ITO-30 nm/Au-8 nm | 650 | 0.323 | 2.29 |

| ITO-40 nm/Au-8 nm | 648 | 0.291 | 1.58 |

| Au-8 nm | 581 | 0.290 | 2.20 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wang, P.; Ionescu, R.E. Chemosensing on Miniaturized Plasmonic Substrates. Micromachines 2021, 12, 275. https://doi.org/10.3390/mi12030275

Wang P, Ionescu RE. Chemosensing on Miniaturized Plasmonic Substrates. Micromachines. 2021; 12(3):275. https://doi.org/10.3390/mi12030275

Chicago/Turabian StyleWang, Pengcheng, and Rodica Elena Ionescu. 2021. "Chemosensing on Miniaturized Plasmonic Substrates" Micromachines 12, no. 3: 275. https://doi.org/10.3390/mi12030275

APA StyleWang, P., & Ionescu, R. E. (2021). Chemosensing on Miniaturized Plasmonic Substrates. Micromachines, 12(3), 275. https://doi.org/10.3390/mi12030275