Effects of Thermal Annealing on Femtosecond Laser Micromachined Glass Surfaces

Abstract

1. Introduction

2. Results

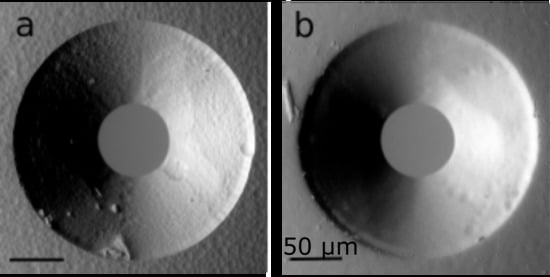

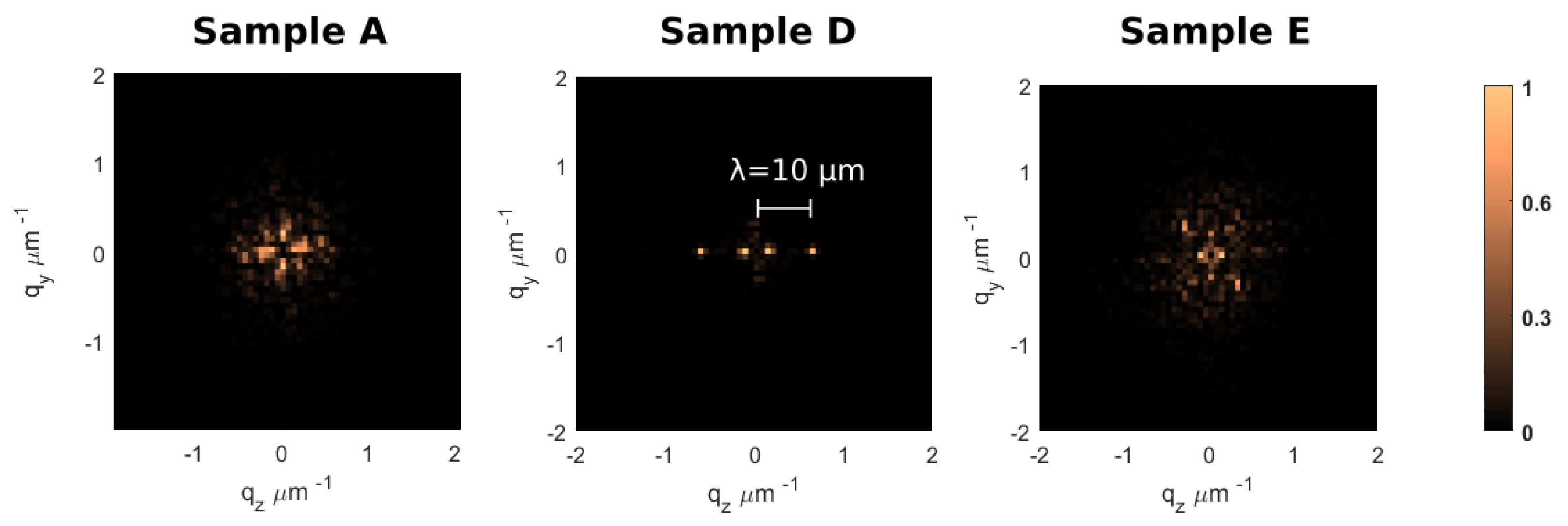

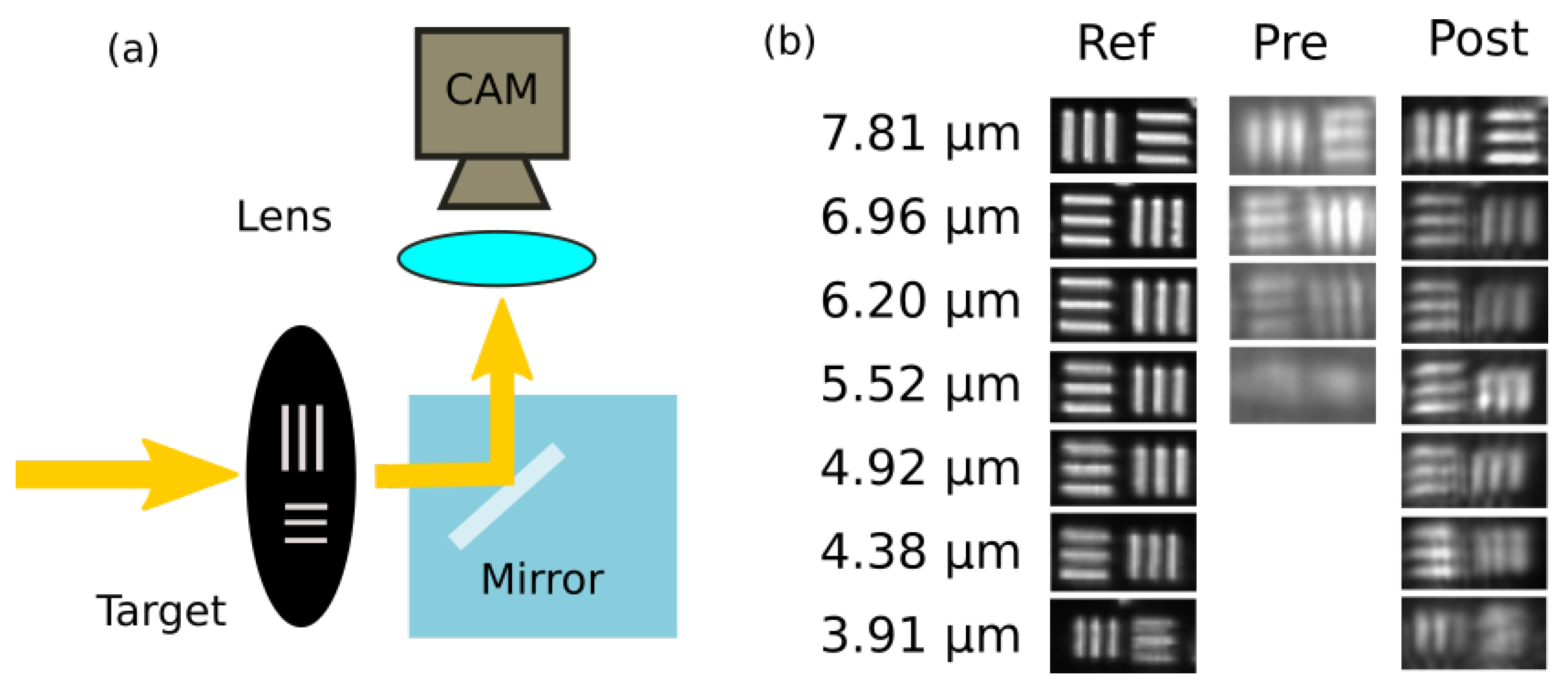

2.1. Optimization of Laser Irradiation

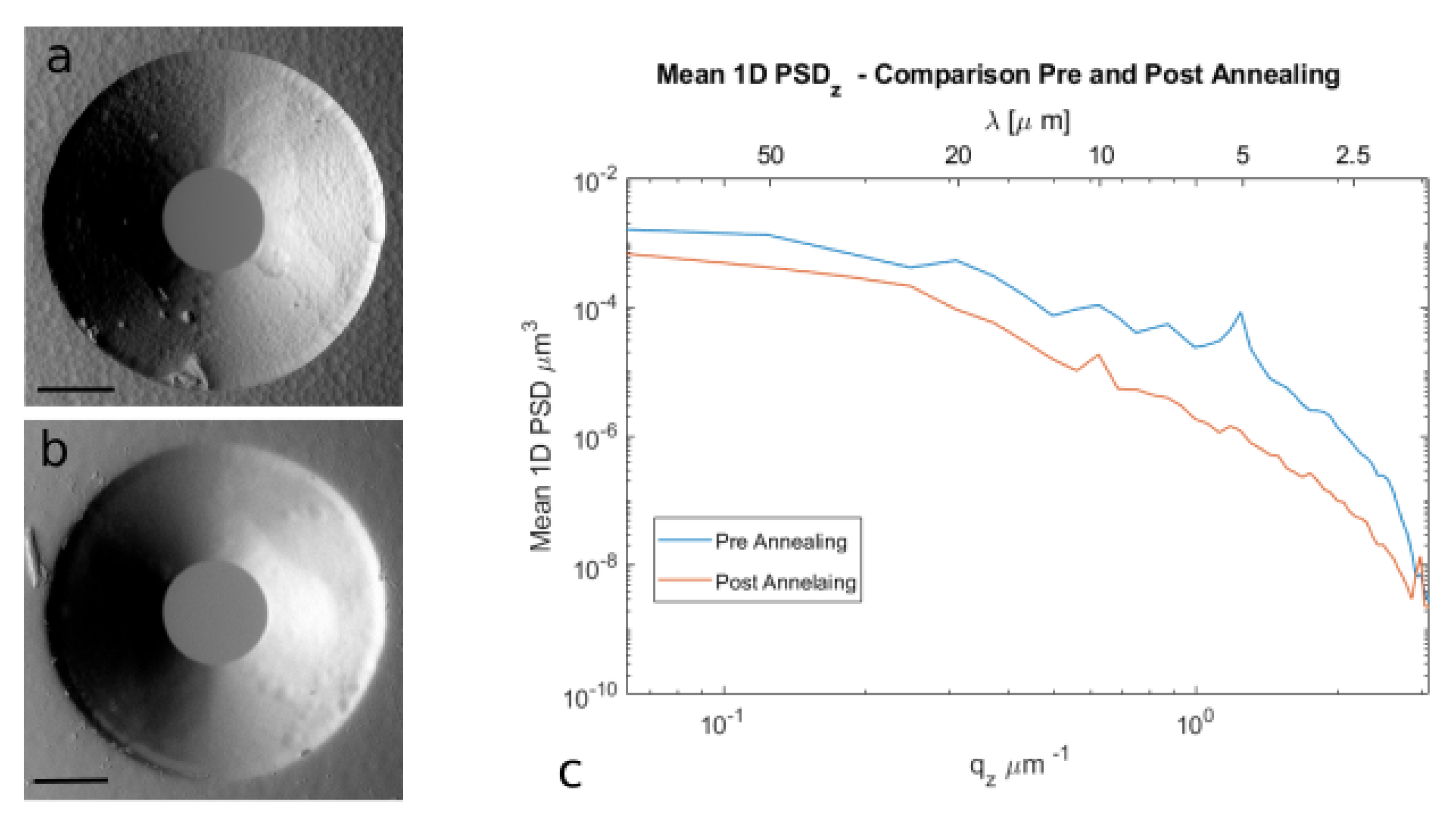

2.2. Thermal Annealing Characterization

3. Discussion

4. Materials and Methods

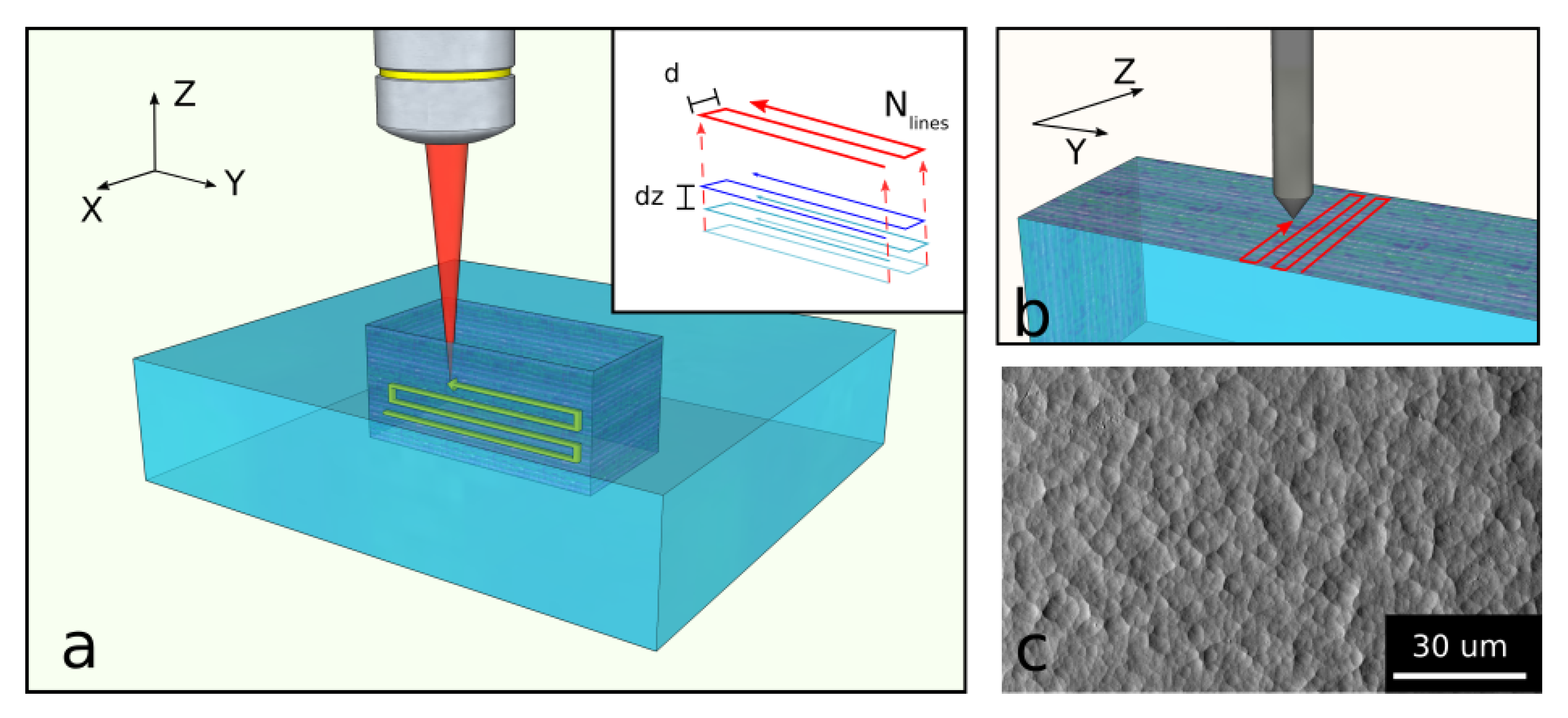

4.1. FLM Fabrication: Setup and Parameters

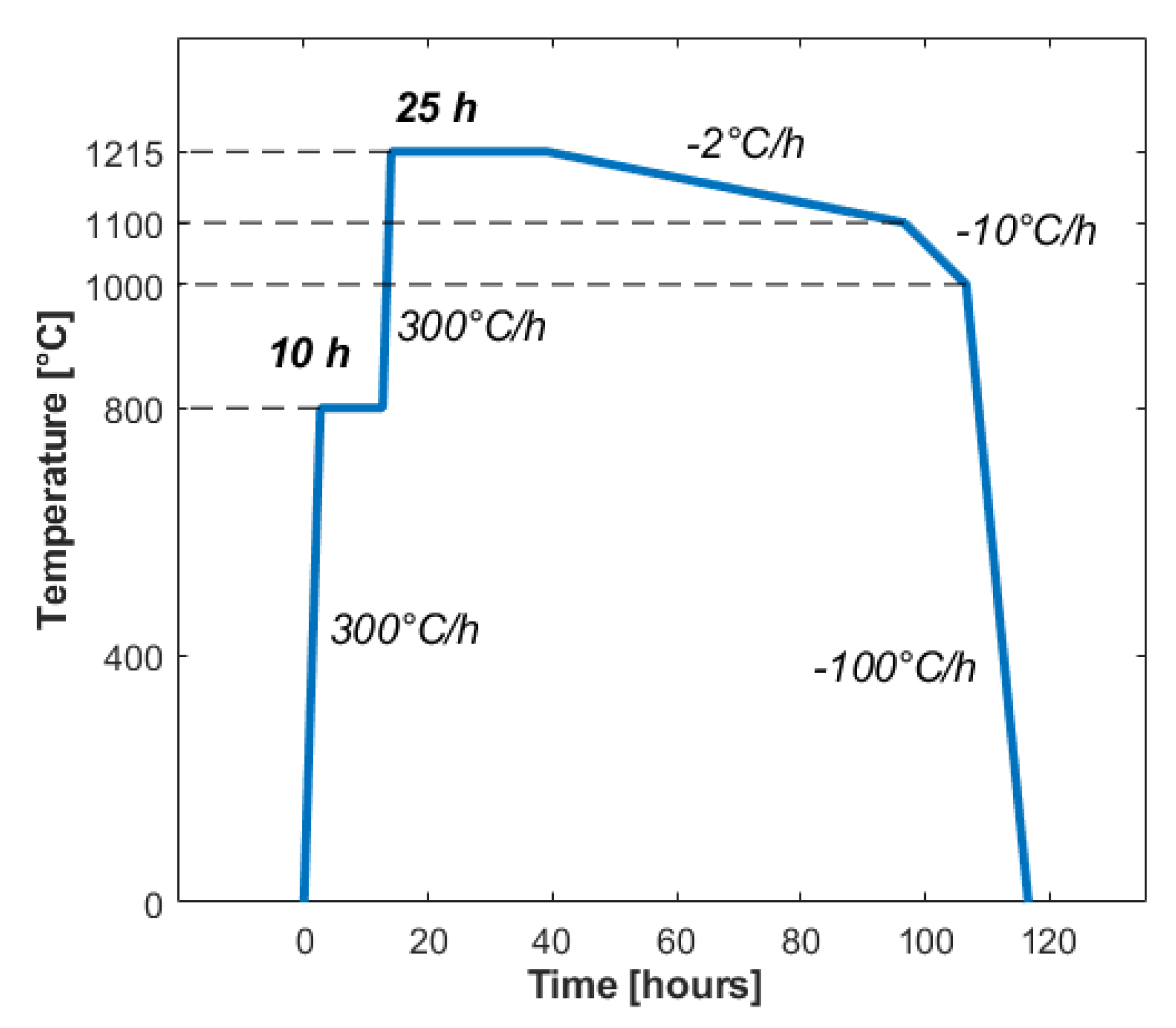

4.2. Thermal Smoothing

4.3. Roughness Analysis

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Della Valle, G.; Osellame, R.; Laporta, P. Micromachining of photonic devices by femtosecond laser pulses. J. Opt. A Pure Appl. Opt. 2009, 11, 013001. [Google Scholar] [CrossRef]

- Shimotsuma, Y.; Kazansky, P.G.; Qiu, J.; Hirao, K. Self-organized nanogratings in glass irradiated by ultrashort light pulses. Phys. Rev. Lett. 2003, 91, 1–4. [Google Scholar] [CrossRef]

- Richter, S.; Miese, C.; Döring, S.; Zimmermann, F.; Withford, M.J.; Tünnermann, A.; Nolte, S. Laser induced nanogratings beyond fused silica—Periodic nanostructures in borosilicate glasses and ULE. Opt. Mater. Express 2013, 3, 1161. [Google Scholar] [CrossRef]

- Zhang, F.; Zhang, H.; Dong, G.; Qiu, J. Embedded nanogratings in germanium dioxide glass induced by femtosecond laser direct writing. J. Opt. Soc. Am. B 2014, 31, 860. [Google Scholar] [CrossRef]

- Zimmermann, F.; Lancry, M.; Plech, A.; Richter, S.; Hari Babu, B.; Poumellec, B.; Tünnermann, A.; Nolte, S. Femtosecond laser written nanostructures in Ge-doped glasses. Opt. Lett. 2016, 41, 1161. [Google Scholar] [CrossRef]

- Fedotov, S.S.; Drevinskas, R.; Lotarev, S.V.; Lipatiev, A.S.; Beresna, M.; Čerkauskaitė, A.; Sigaev, V.N.; Kazansky, P.G. Direct writing of birefringent elements by ultrafast laser nanostructuring in multicomponent glass. Appl. Phys. Lett. 2016, 108, 071905. [Google Scholar] [CrossRef]

- Vishnubhatla, K.C.; Bellini, N.; Ramponi, R.; Cerullo, G.; Osellame, R. Shape control of microchannels fabricated in fused silica by femtosecond laser irradiation and chemical etching. Opt. Express 2009, 17, 8685–8695. [Google Scholar] [CrossRef] [PubMed]

- Rajesh, S.; Bellouard, Y. Towards fast femtosecond laser micromachining of glass, effect of deposited energy. In Proceedings of the Conference on Lasers and Electro-Optics, San Jose, CA, USA, 16–21 May 2010; p. JTuD18. [Google Scholar] [CrossRef]

- Bellouard, Y.; Said, A.A.; Bado, P. Integrating optics and micro-mechanics in a single substrate: A step toward monolithic integration in fused silica. Opt. Express 2005, 13, 6635. [Google Scholar] [CrossRef]

- Osellame, R.; Hoekstra, H.J.; Cerullo, G.; Pollnau, M. Femtosecond laser microstructuring: An enabling tool for optofluidic lab-on-chips. Laser Photonics Rev. 2011, 5, 442–463. [Google Scholar] [CrossRef]

- Sala, F.; Castriotta, M.; Paiè, P.; Farina, A.; D’Annunzio, S.; Zippo, A.; Osellame, R.; Bragheri, F.; Bassi, A.; Osellame, R.; et al. High-throughput 3D imaging of single cells with light-sheet fluorescence microscopy on chip. Biomed. Opt. Express 2020, 11, 4397. [Google Scholar] [CrossRef]

- Paiè, P.; Zandrini, T.; Vázquez, R.M.; Osellame, R.; Bragheri, F. Particle manipulation by optical forces in microfluidic devices. Micromachines 2018, 9, 200. [Google Scholar] [CrossRef]

- Cheng, Y.; Sugioka, K.; Midorikawa, K.; Masuda, M.; Toyoda, K.; Kawachi, M.; Shihoyama, K. Three-dimensional micro-optical components embedded in photosensitive glass by a femtosecond laser. Opt. Lett. 2003, 28, 1144. [Google Scholar] [CrossRef] [PubMed]

- Cheng, Y.; Sugioka, K.; Midorikawa, K. Microfluidic laser embedded in glass by three-dimensional femtosecond laser microprocessing. Opt. Lett. 2004, 29, 2007–2009. [Google Scholar] [CrossRef]

- Wang, Z.; Sugioka, K.; Midorikawa, K. Three-dimensional integration of microoptical components buried inside photosensitive glass by femtosecond laser direct writing. Appl. Phys. A Mater. Sci. Process. 2007, 89, 951–955. [Google Scholar] [CrossRef]

- Simoni, F.; Bonfadini, S.; Spegni, P.; Lo Turco, S.; Lucchetta, D.; Criante, L. Low threshold Fabry-Perot optofluidic resonator fabricated by femtosecond laser micromachining. Opt. Express 2016, 24, 17416. [Google Scholar] [CrossRef] [PubMed]

- He, F.; Cheng, Y.; Qiao, L.; Wang, C.; Xu, Z.; Sugioka, K.; Midorikawa, K.; Wu, J. Two-photon fluorescence excitation with a microlens fabricated on the fused silica chip by femtosecond laser micromachining. Appl. Phys. Lett. 2010, 96, 041108. [Google Scholar] [CrossRef]

- Paiè, P.; Bragheri, F.; Claude, T.; Osellame, R. Optofluidic light modulator integrated in lab-on-a-chip. Opt. Express 2017, 25, 7313. [Google Scholar] [CrossRef]

- Watanabe, W.; Kuroda, D.; Itoh, K.; Nishii, J. Fabrication of Fresnel zone plate embedded in silica glass by femtosecond laser pulses. Opt. Express 2002, 10, 978. [Google Scholar] [CrossRef]

- Nieto-Vesperinas, M.; Sánchez-Gil, J.A. Light scattering from a random rough interface with total internal reflection. J. Opt. Soc. Am. A 2008, 9, 424. [Google Scholar] [CrossRef]

- Lo Turco, S.; Di Donato, A.; Criante, L. Scattering effects of glass-embedded microstructures by roughness controlled fs-laser micromachining. J. Micromech. Microeng. 2017, 27, 65007. [Google Scholar] [CrossRef]

- Dogan, Y.; Madsen, C.K. Optimization of ultrafast laser parameters for 3D micromachining of fused silica. Opt. Laser Technol. 2019, 123, 105933. [Google Scholar] [CrossRef]

- Ho, S.; Herman, P.R.; Aitchison, J.S. Single- and multi-scan femtosecond laser writing for selective chemical etching of cross section patternable glass micro-channels. Appl. Phys. A Mater. Sci. Process. 2012. [Google Scholar] [CrossRef]

- Ross, C.; Maclachlan, D.G.; Choudhury, D.; Thomson, R.R. Towards optical quality micro-optic fabrication by direct laser writing and chemical etching. Front. Ultrafast Opt. Biomed. Sci. Ind. Appl. XVII 2017, 10094, 100940V. [Google Scholar] [CrossRef]

- He, F.; Cheng, Y.; Xu, Z.; Liao, Y.; Xu, J.; Sun, H.; Wang, C.; Zhou, Z.; Sugioka, K.; Midorikawa, K.; et al. Direct fabrication of homogeneous microfluidic channels embedded in fused silica using a femtosecond laser. Opt. Lett. 2010, 35, 282–284. [Google Scholar] [CrossRef]

- Lin, J.; Yu, S.; Ma, Y.; Fang, W.; He, F.; Qiao, L.; Tong, L.; Cheng, Y.; Xu, Z. On-chip three-dimensional high-Q microcavities fabricated by femtosecond laser direct writing. Opt. Express 2012, 20, 10212. [Google Scholar] [CrossRef]

- Jung, S.; Lee, P.A.; Kim, B.H. Surface polishing of quartz-based microfluidic channels using CO2 laser. Microfluid. Nanofluid. 2016, 20, 84. [Google Scholar] [CrossRef]

- Serhatlioglu, M.; Ortaç, B.; Elbuken, C.; Biyikli, N.; Solmaz, M.E. CO2 laser polishing of microfluidic channels fabricated by femtosecond laser assisted carving. J. Micromech. Microeng. 2016, 26. [Google Scholar] [CrossRef]

- Weingarten, C.; Steenhusen, S.; Hermans, M.; Willenborg, E.; Schleifenbaum, J.H. Laser polishing and 2PP structuring of inside microfluidic channels in fused silica. Microfluid. Nanofluid. 2017, 21, 165. [Google Scholar] [CrossRef]

- He, F.; Lin, J.; Cheng, Y. Fabrication of hollow optical waveguides in fused silica by three-dimensional femtosecond laser micromachining. Appl. Phys. B Lasers Opt. 2011, 105, 379–384. [Google Scholar] [CrossRef]

- Feit, M.D.; Suratwala, T.I.; Wong, L.L.; Steele, W.A.; Miller, P.E.; Bude, J.D. Modeling wet chemical etching of surface flaws on fused silica. Proc. SPIE 2009, 7504, 75040L. [Google Scholar] [CrossRef]

- Bhushan, B. Surface roughness analysis and measurement techniques. Mod. Tribol. Handb. Vol. One Princ. Tribol. 2000, 1, 49–119. [Google Scholar] [CrossRef]

| Sample | N | dz | Pol | |

|---|---|---|---|---|

| A | 6 lines | 2 m | ⊥ | 43 nm |

| B | single line | 2 m | ⊥ | 57 nm |

| C | 6 lines | 5 m | ⊥ | 28 nm |

| D | 6 lines | 10 m | ⊥ | 35 nm |

| E | 6 lines | 2 m | ‖ | 63 nm |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Sala, F.; Paié, P.; Martínez Vázquez, R.; Osellame, R.; Bragheri, F. Effects of Thermal Annealing on Femtosecond Laser Micromachined Glass Surfaces. Micromachines 2021, 12, 180. https://doi.org/10.3390/mi12020180

Sala F, Paié P, Martínez Vázquez R, Osellame R, Bragheri F. Effects of Thermal Annealing on Femtosecond Laser Micromachined Glass Surfaces. Micromachines. 2021; 12(2):180. https://doi.org/10.3390/mi12020180

Chicago/Turabian StyleSala, Federico, Petra Paié, Rebeca Martínez Vázquez, Roberto Osellame, and Francesca Bragheri. 2021. "Effects of Thermal Annealing on Femtosecond Laser Micromachined Glass Surfaces" Micromachines 12, no. 2: 180. https://doi.org/10.3390/mi12020180

APA StyleSala, F., Paié, P., Martínez Vázquez, R., Osellame, R., & Bragheri, F. (2021). Effects of Thermal Annealing on Femtosecond Laser Micromachined Glass Surfaces. Micromachines, 12(2), 180. https://doi.org/10.3390/mi12020180