A Pot-Like Vibrational Microfluidic Rotational Motor

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials

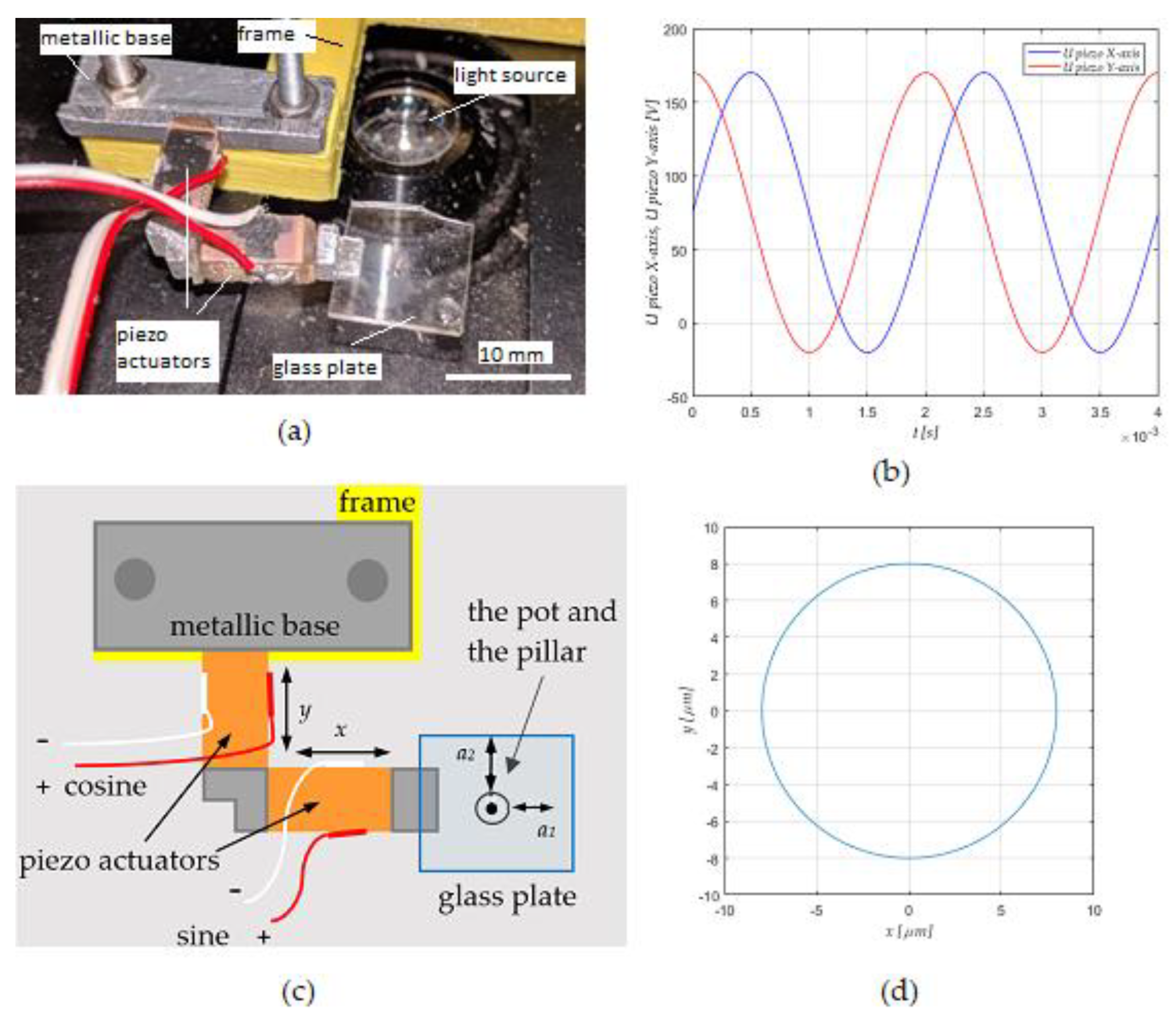

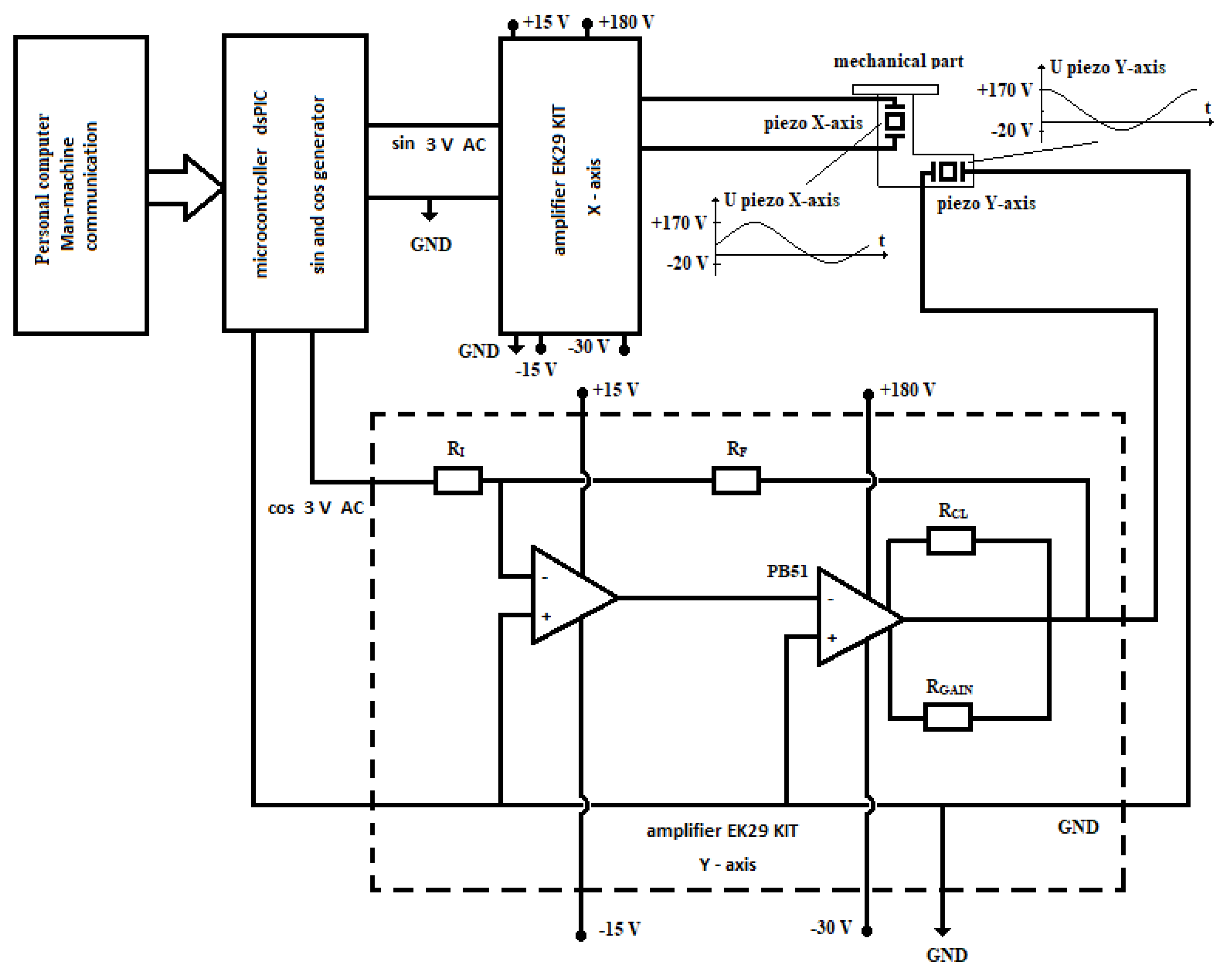

2.2. Laboratory Set-Up

2.3. Methods

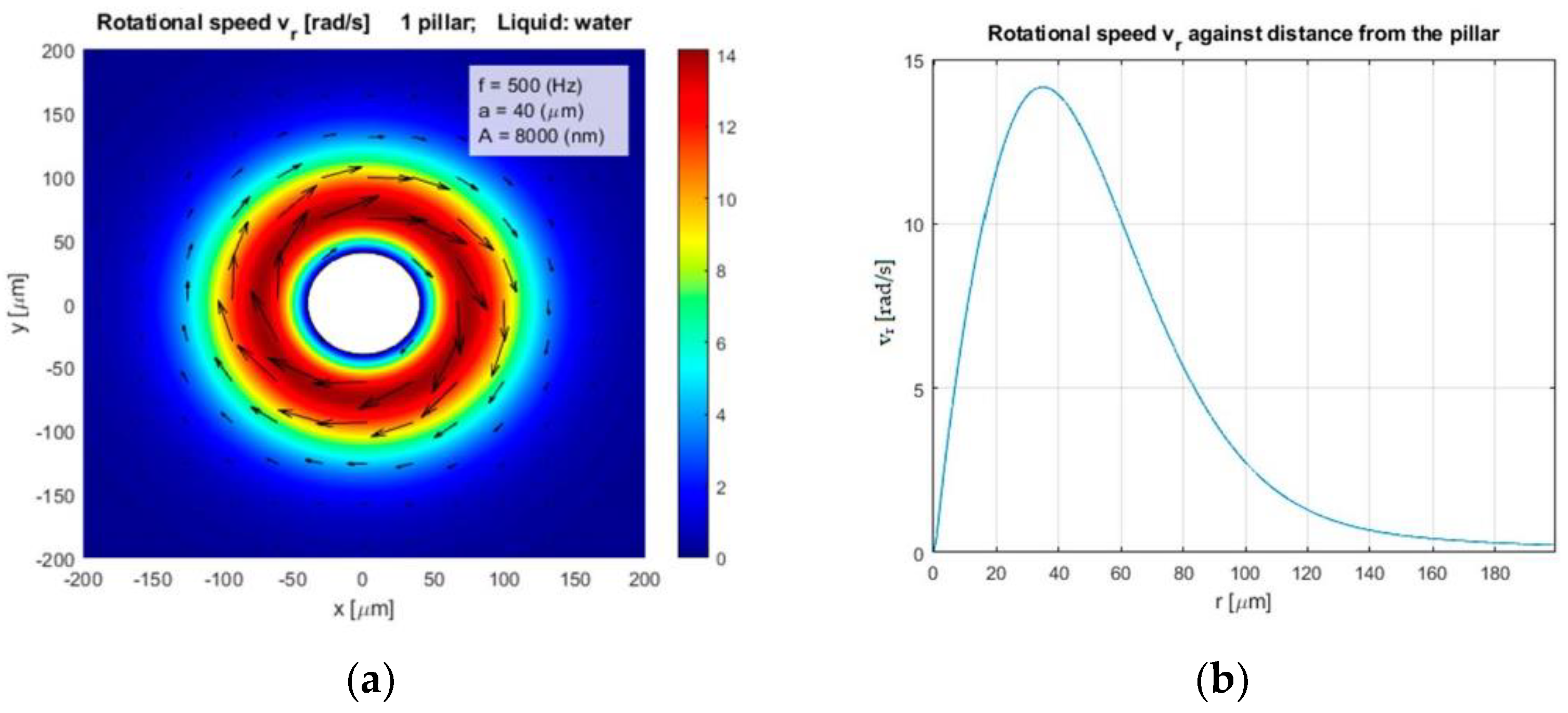

2.3.1. The Mathematical Model of the Microfluidic Streaming of Water around the Circular Vibrating Pillar

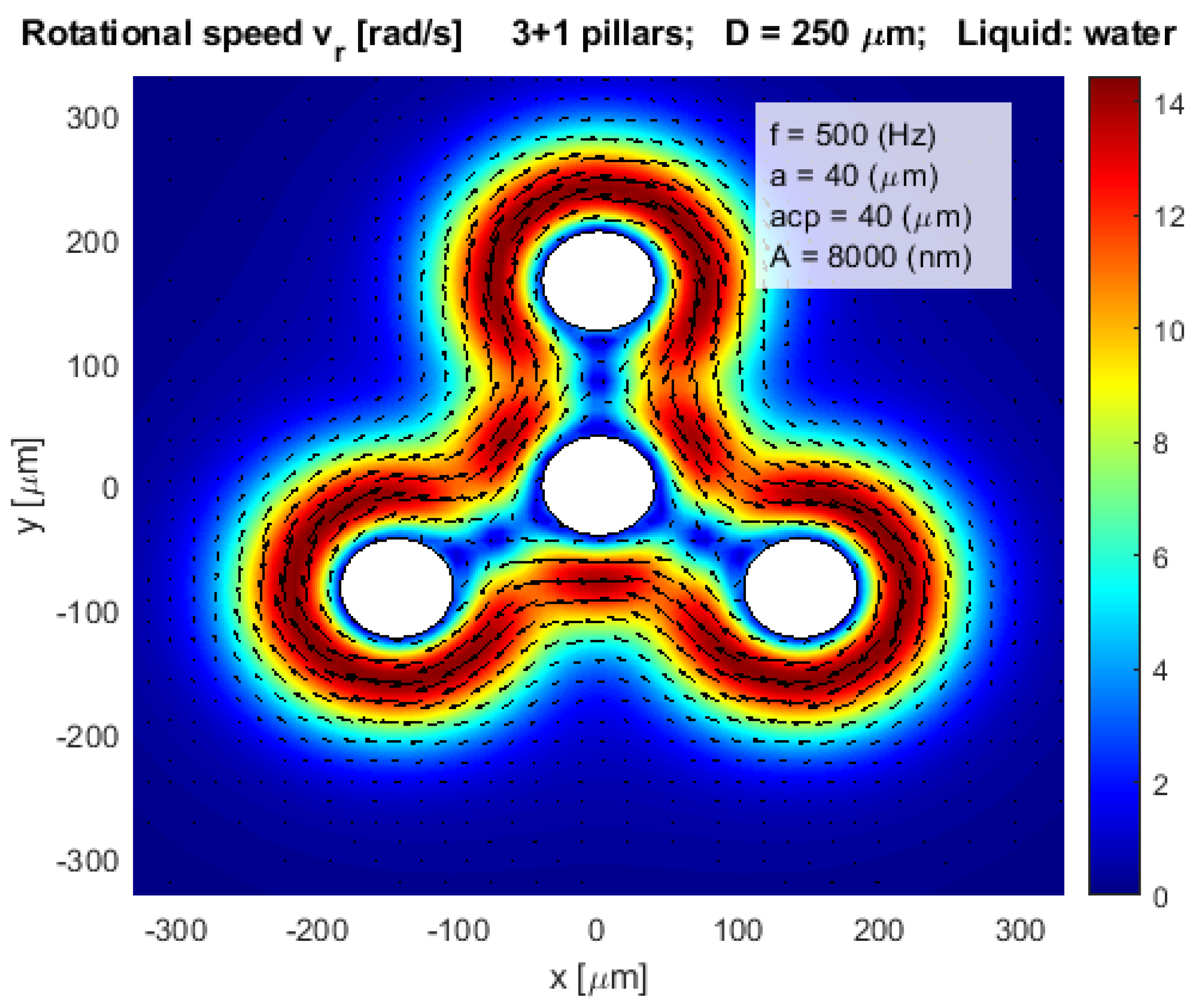

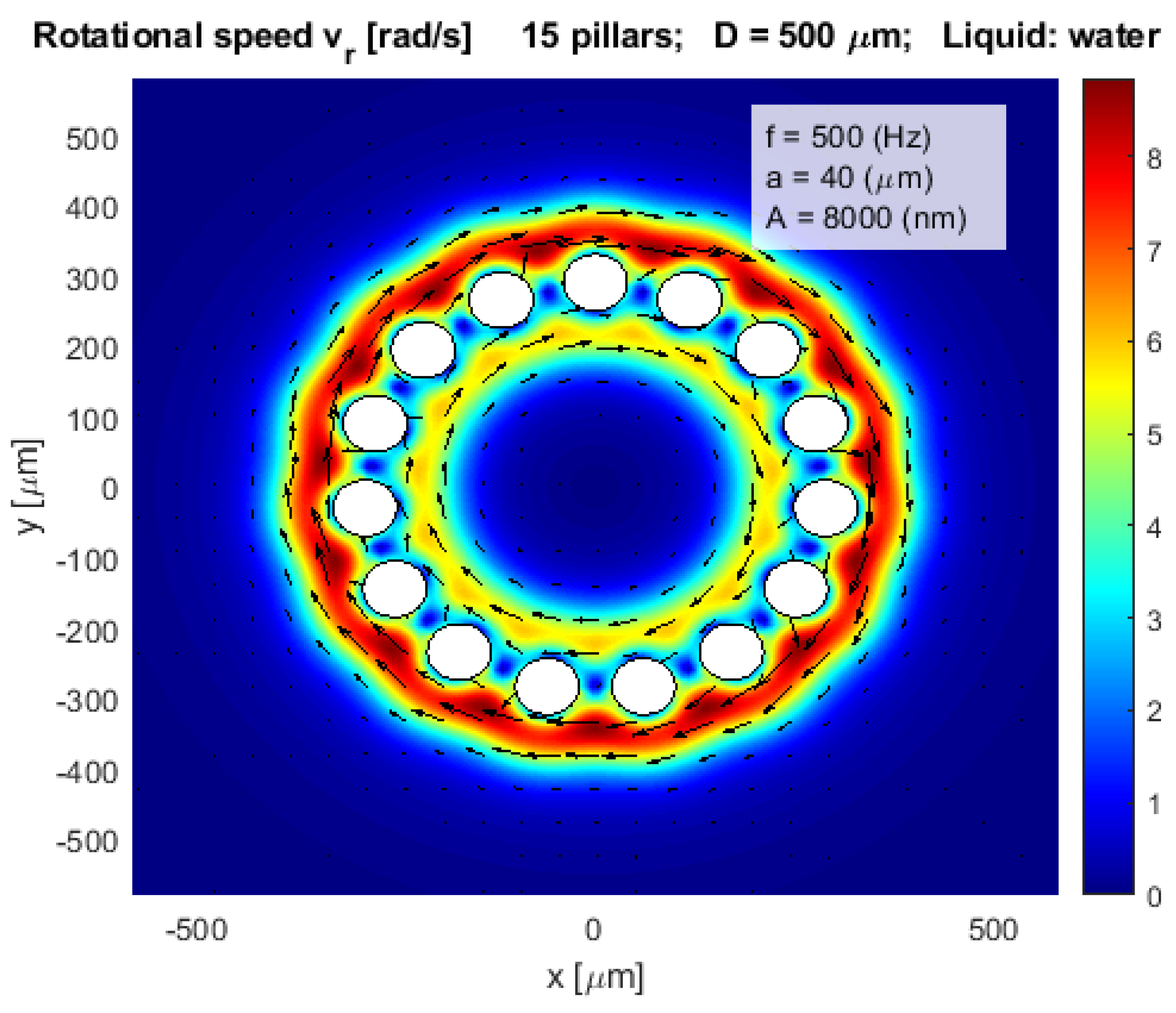

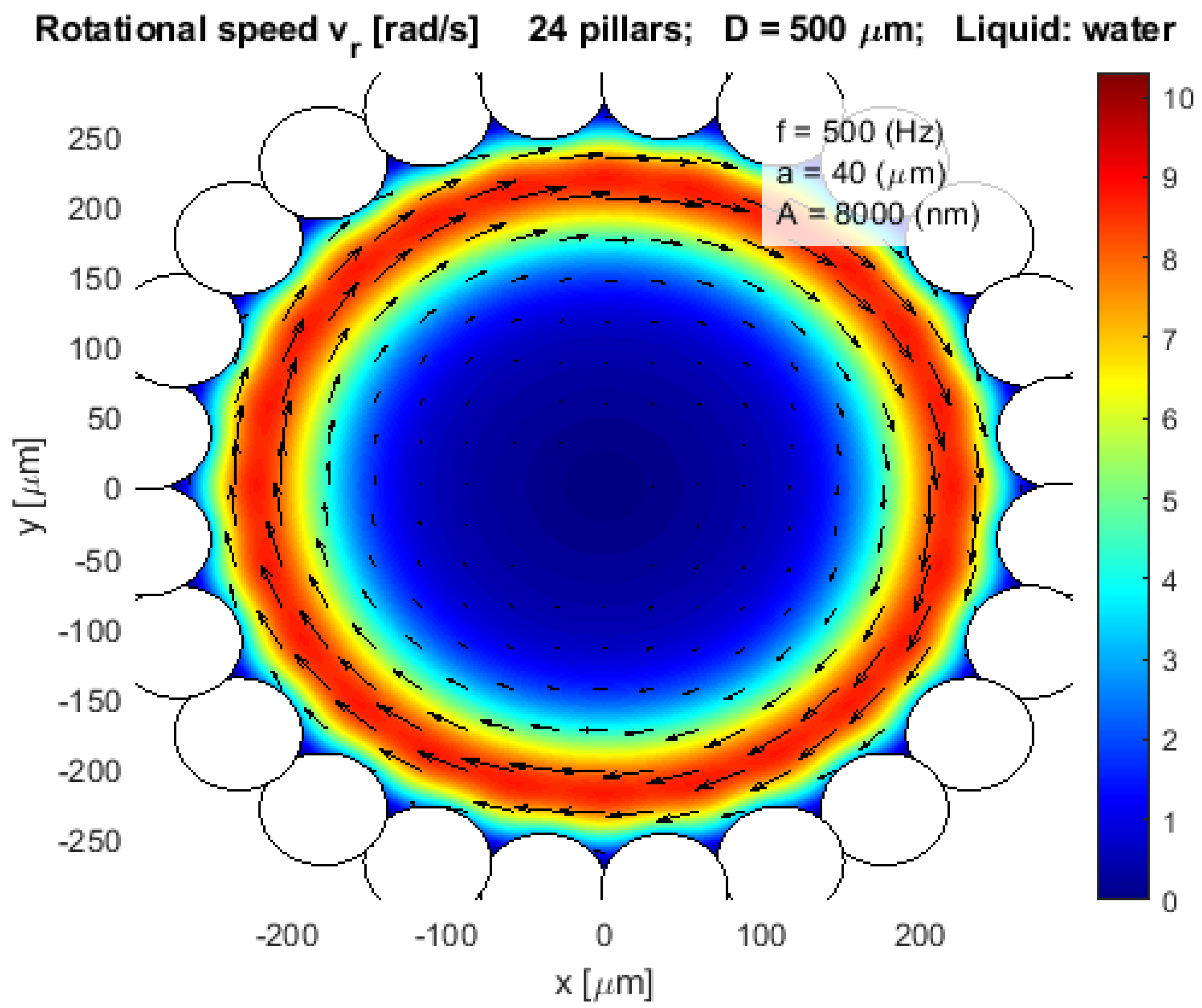

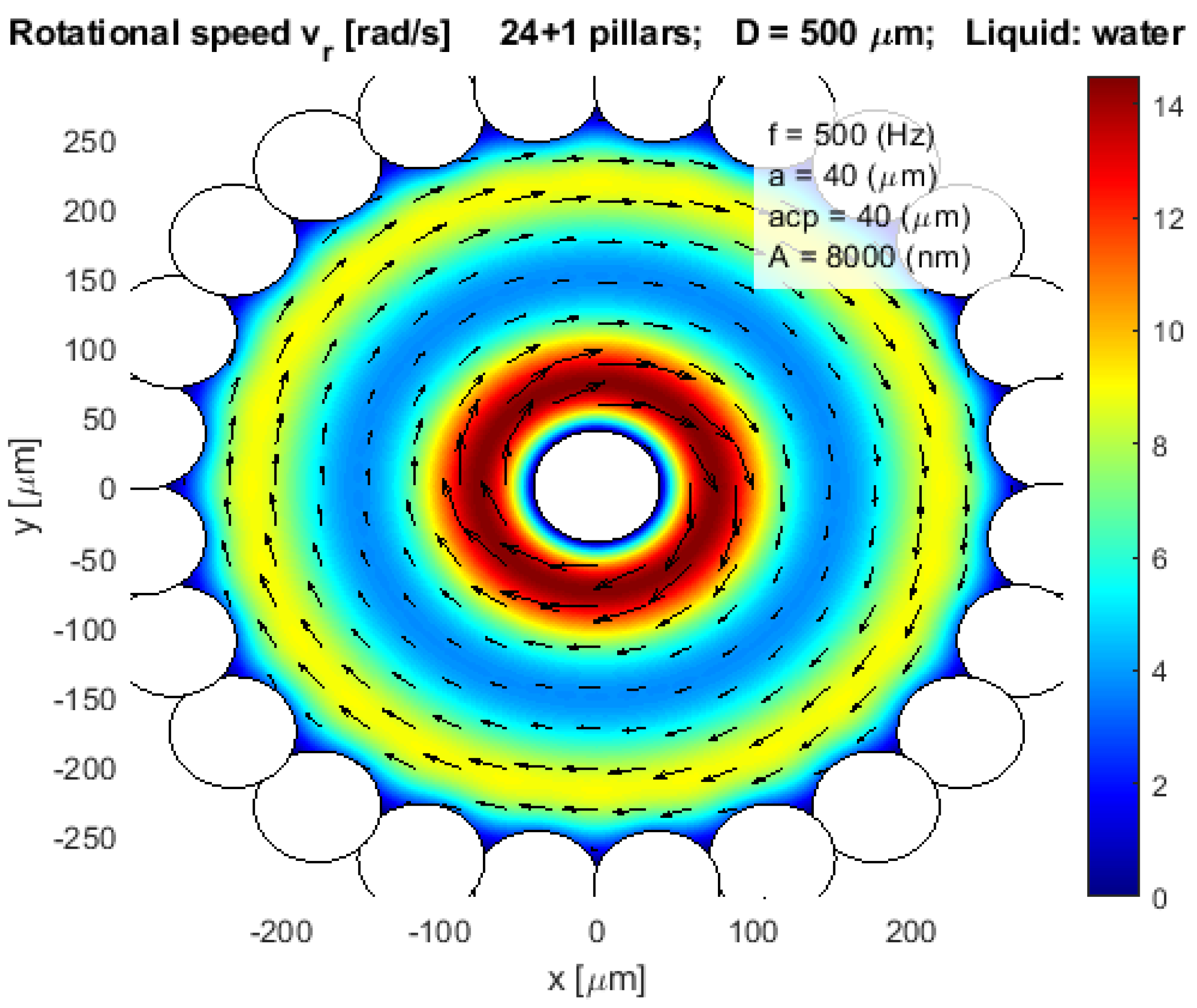

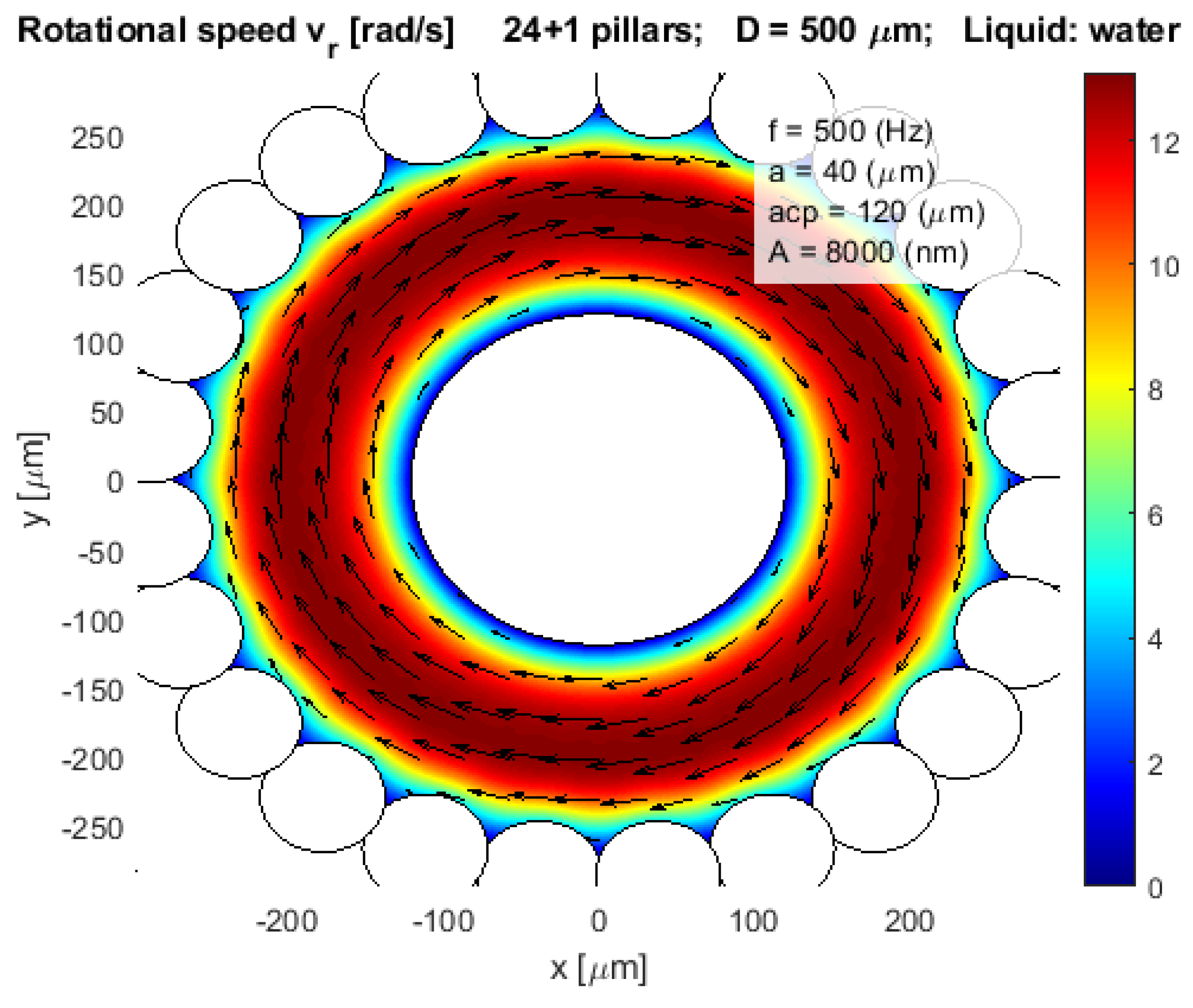

2.3.2. The Mathematical Model of Microfluidic Streaming of Water around Several Pillars

2.3.3. Mathematical Model of Microfluidic Streaming of Water in the Closed Pot-Like Configurations of Pillars

2.3.4. Presentation of the Pot-Like Microfluidic Rotational Vibrational Motor Types

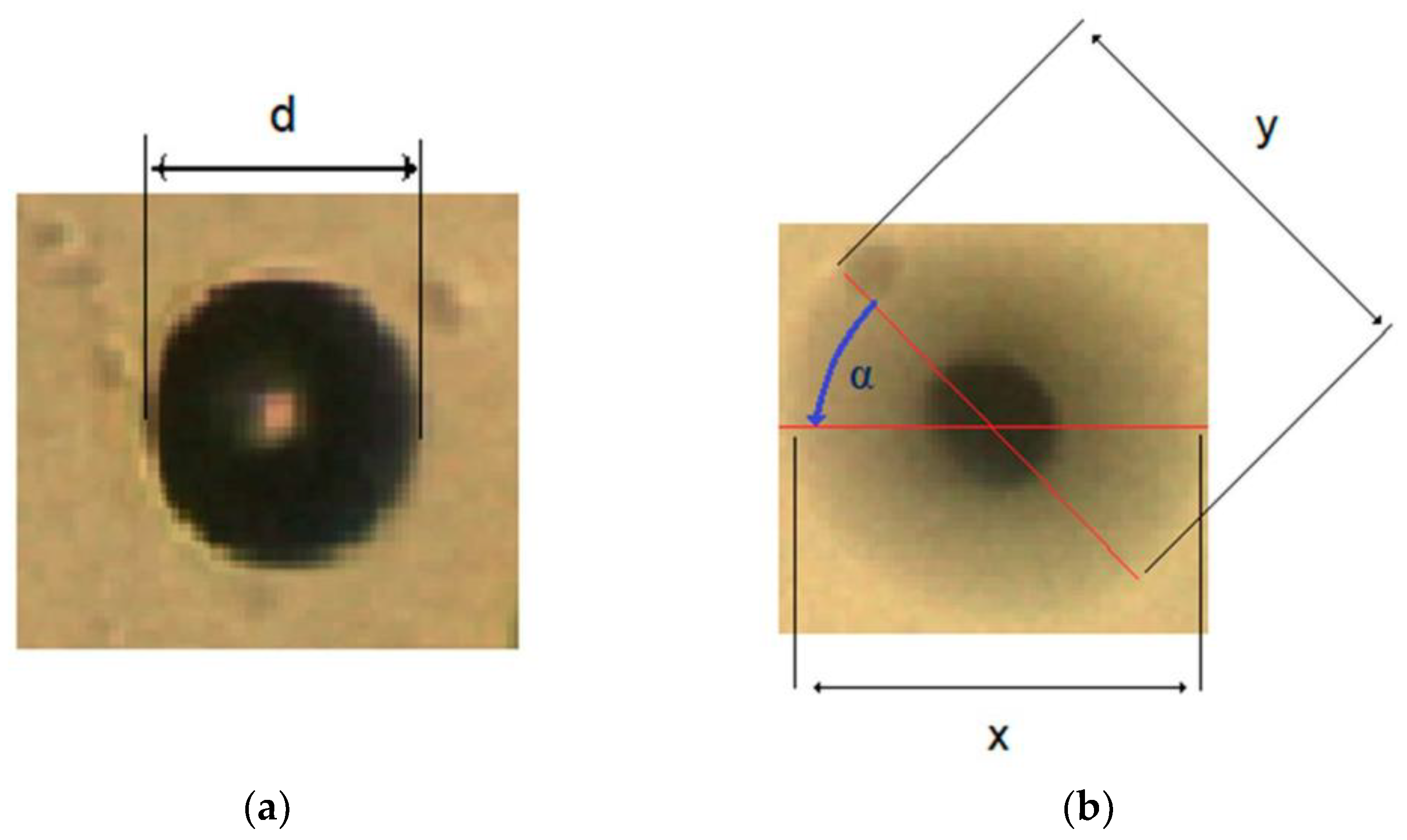

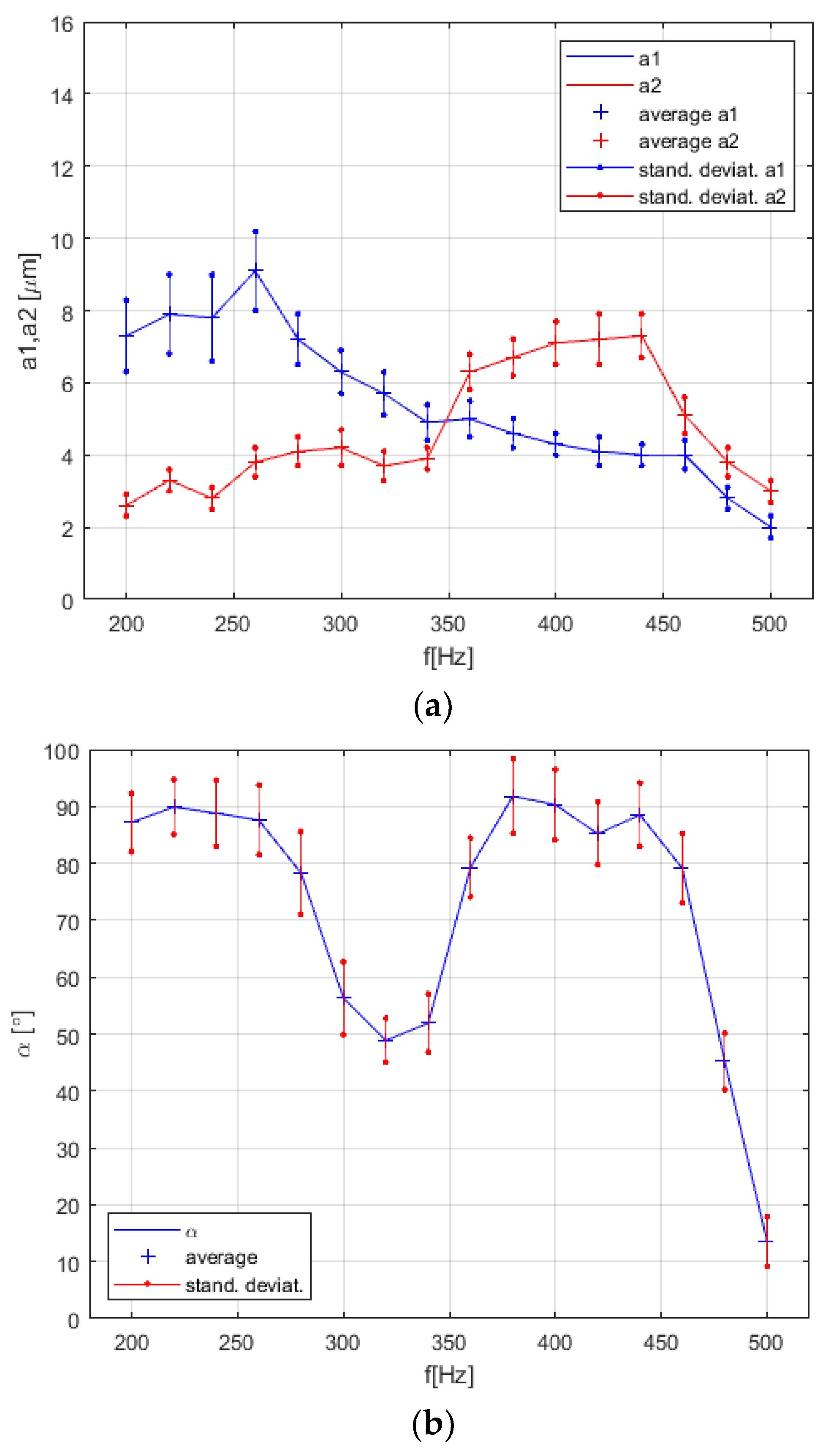

2.3.5. A Method for Measurement of the Amplitude and Phase Shift between Vibrations in Both x and y Directions

2.3.6. A Method for Measurement of the Rotational Speed of the Water Streaming in the Pot

3. Results

3.1. Vibrational Pot-Like Mechanism

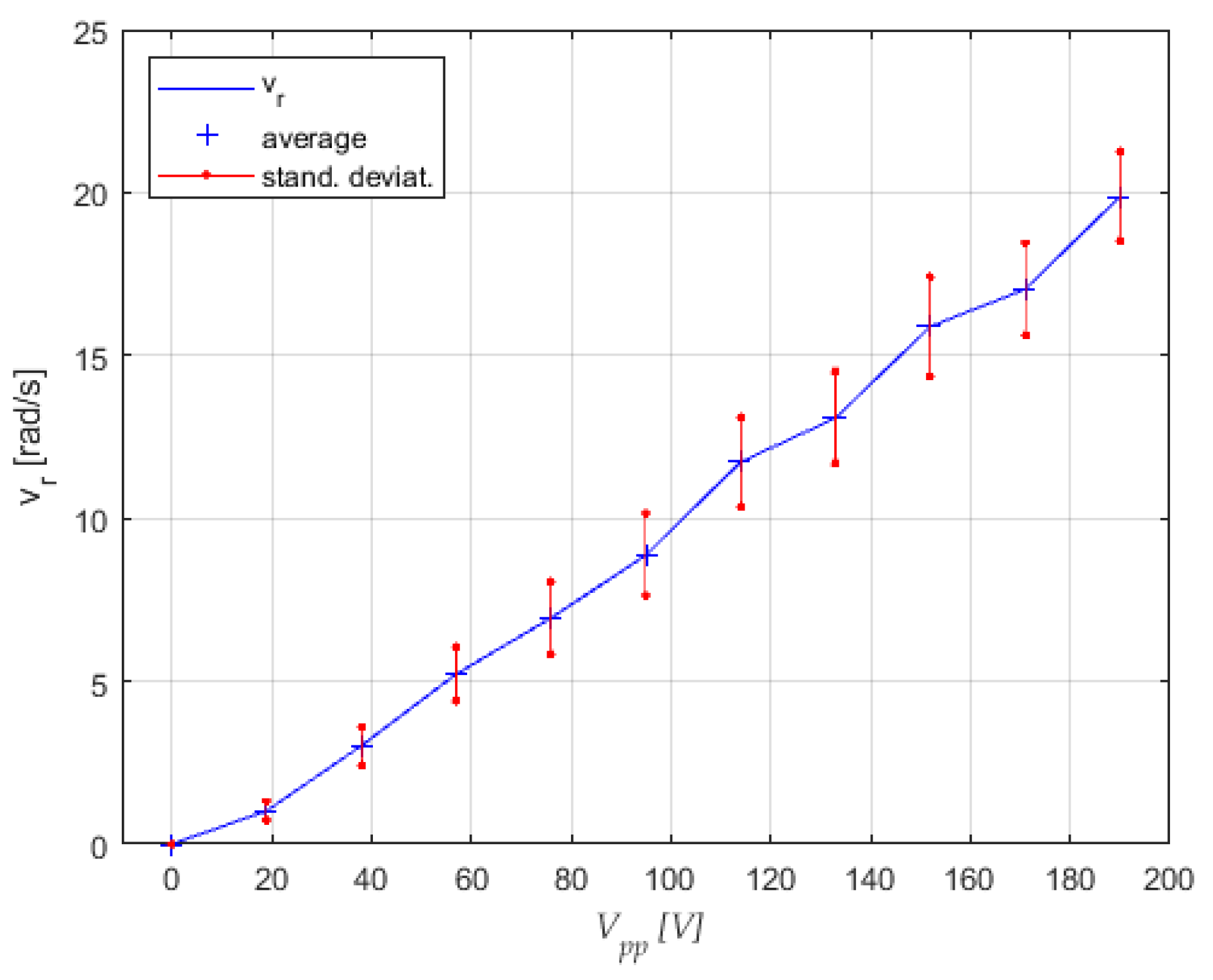

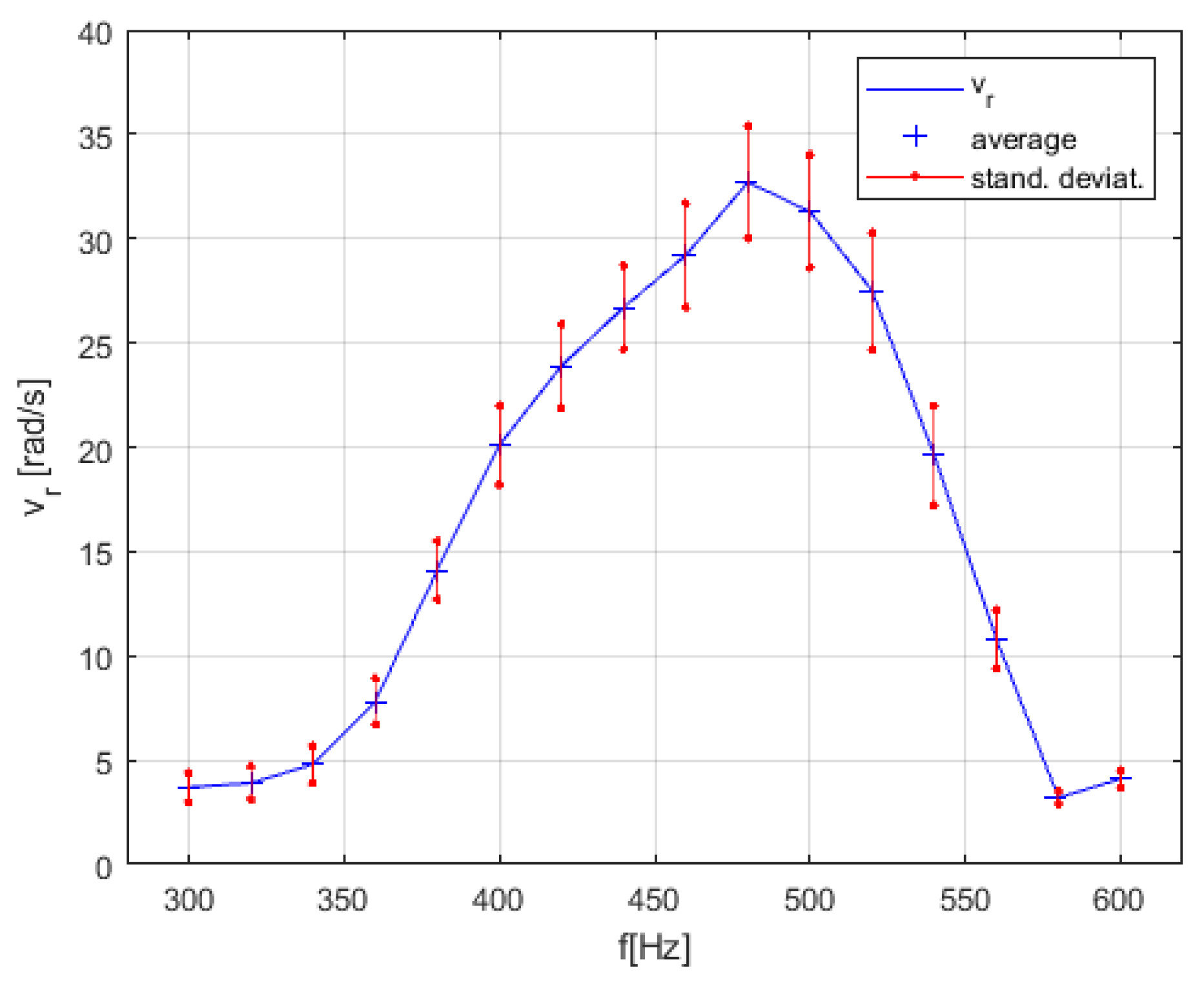

3.2. Free Floating Rotating Disc

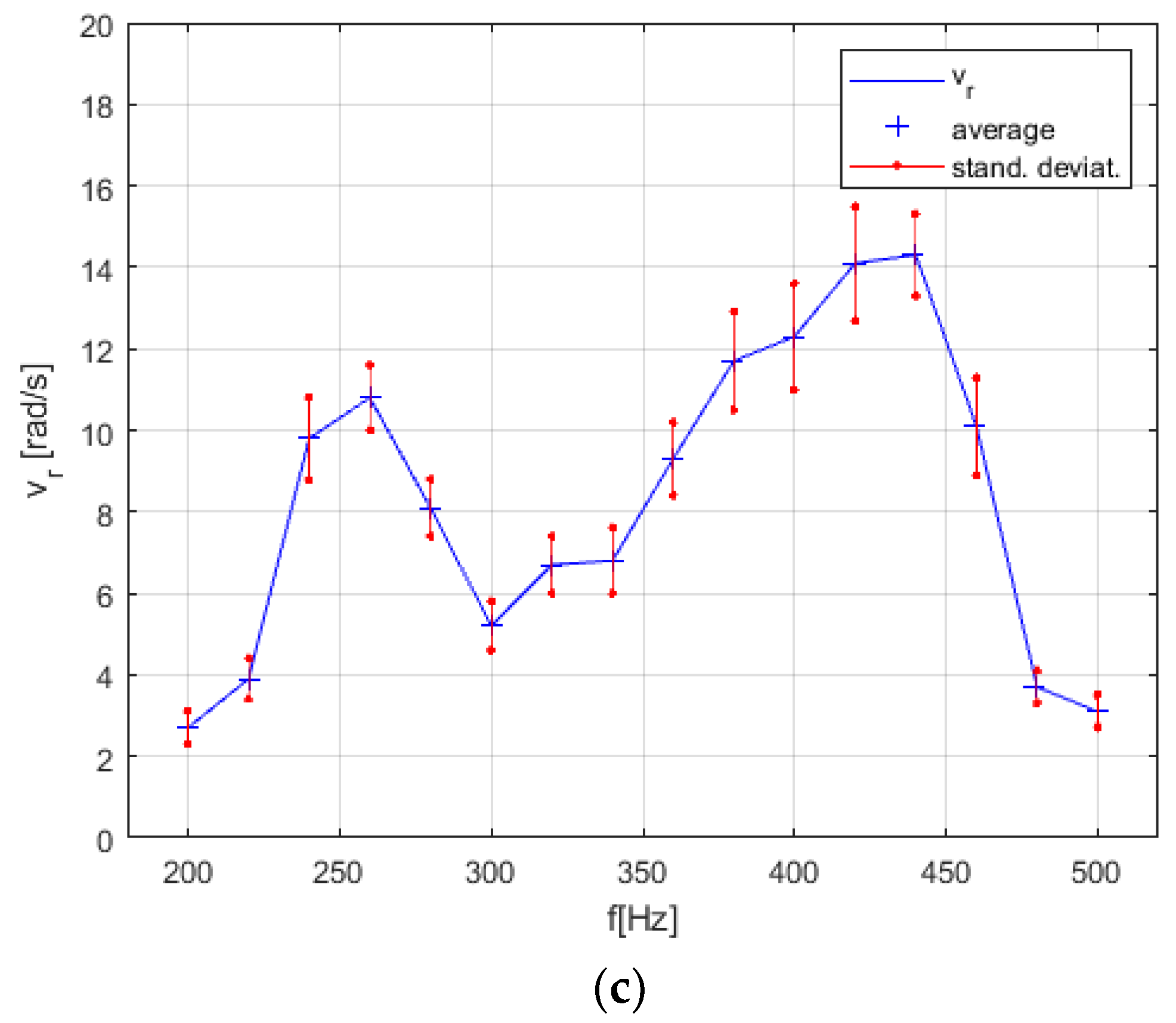

3.3. Pot-Like Microfluidic Rotational Vibrational Motor with Concave Shape of the Water’s Surface

3.4. Pot-Like Microfluidic Rotational Vibrational Motor with Centrally Mounted Floating Disc on the Central Pillar with Radius 40 µm

3.5. Pot-Like Microfluidic Rotational Vibrational Motor with Rigidly Attached Disc to the Rotating Axis

4. Discussion

4.1. Understanding the Changes of the Resonant Peak

4.2. Estimation of Motor Maximum Torque of the Two Types of Microfluidic Motor

4.3. Stability of Rotational Speed

4.4. Possible Improvements

- Prevent the evaporation of the liquid from the pot: using low evaporation rate solvents (Cyclohexanol, Eastman 2-ethylhexanol, …), and/or make better (more sealed) upper bearings. We experimented by putting a small drop of lubricant on the place of the upper bearings’ hole through the upper plastic foil in the case of the microfluidic motor with the submerged disc fixed on the axis (see Figure 10g). In this case, we achieved a slightly higher rotational speed at the beginning of the experiment, due to reducing the friction in the upper bearings, and also lowered the rate of evaporation. We prolonged the non-stop operation of the microfluidic motor from about 9 h, let us say to about 10 h. We would probably need more viscous lubricant to prolong the working time. Our type of lubricant somehow penetrated through the upper bearings, due to vibrations, and polluted the water in the pot. Due to the increased kinematic viscosity of the polluted water, the maximal rotational speed was reduced after 4–5 h of working time by about 10–15%.

- More quality bearings with smaller and a smoother hole in the bearings and lubricant in the bearings, should be used to prevent the axis wobbling.

4.5. Endurance Test

Supplementary Materials

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Field, L.A.; White, R.M.; Pisano, A.P. Fluid-Powered Rotary Gears and Micro-Flow Channels. In Proceedings of the TRANSDUCERS ’91: International Conference on Solid-State Sensors and Actuators, San Francisco, CA, USA, 24–27 June 1991; pp. 1033–1036. [Google Scholar] [CrossRef]

- Takei, A.; Matsumoto, K.; Shomoyama, I. Capillary motor driven by electrowetting. Lab Chip 2010, 10, 1781–1786. [Google Scholar] [CrossRef] [PubMed]

- Amjadi, A.; Shirsavar, R.; Hamedani Radja, N.; Ejtehadi, M.R. A liquid film motor. Microfluid. Nanofluid. 2009, 6, 711–715. [Google Scholar] [CrossRef]

- Shilton, R.J.; Glass, N.R.; Chan, P.; Yeo, L.Y.; Friend, J.R. Rotational microfluidic motor for on-chip microcentrifugation. Appl. Phys. Lett. 2011, 98, 254103. [Google Scholar] [CrossRef]

- Shilton, R.J.; Glass, N.; Langelier, S.; Chan, P.; Yeo, L.Y.; Friend, J.R. On-chip surface acoustic wave driven microfluidic motors. In Smart Nano-Micro Materials and Devices, Proceedings of the SPIE, Melbourne, Australia, 23 December 2011; Juodkazis, S., Gu, M., Eds.; SPIE: Bellingham, WA, USA, 2011; Volume 8204. [Google Scholar] [CrossRef]

- Yeo, L.Y.; Friend, J.R. Surface Acoustic Wave Microfluidics. Annu. Rev. Fluid Mech. 2014, 46, 379–406. [Google Scholar] [CrossRef]

- Kaynak, M.; Ozcelik, A.; Nama, N.; Nourhani, A.; Lammert, P.E.; Crespi, V.H.; Huang, T.J. Acoustofluidic actuation of in situ fabricated microrotor. Lab Chip 2016, 16, 3532–3537. [Google Scholar] [CrossRef]

- Feng, L.; Song, B.; Zhang, D.; Jiang, Y.; Arai, F. On-Chip Tunable Cell Rotation Using Acoustically Oscillating Asymmetrical Microstructures. Micromachines 2018, 9, 596. [Google Scholar] [CrossRef] [PubMed]

- Li, Z.; Li, Z.; Xie, Z.; Mei, Y.; Wang, Y.; Huang, G.; Liu, Y. A simple method to fabricate metal-oil micromachines. SN Appl. Sci. 2020, 2, 746. [Google Scholar] [CrossRef]

- Wang, X.; Attinger, D.; Moraga, F. A Micro-Rotor Driven by an Acoustic Bubble. Nanoscale Microscale Thermophys. Eng. 2006, 10, 379–385. [Google Scholar] [CrossRef]

- Kao, J.; Wang, X.; Warren, J.; Xu, J. A bubble-powered micro-rotor: Conception, manufacturing, assembly and characterization. J. Micromech. Microeng. 2007, 17, 2454. [Google Scholar] [CrossRef]

- Hayakawa, T.; Sakuma, S.; Fukuhara, T.; Yokoyama, Y. A single cell extraction chip using vibration-induced whirling flow and a thermo-responsive gel pattern. Micromachines 2014, 5, 681–696. [Google Scholar] [CrossRef]

- Hayakawa, T.; Sakuma, S.; Arai, F. On-chip 3D rotation of oocyte based on a vibration-induced local whirling flow. Microsyst. Nanoeng. 2015, 1, 15001. [Google Scholar] [CrossRef]

- Zhang, J.; Yang, S.; Chen, C.; Hartman, J.H.; Huang, P.H.; Wang, L.; Tian, Z.; Zhang, P.; Faulkenberry, D.; Meyer, J.N.; et al. Surface acoustic waves enable rotational manipulation of Caenorhabditis elegans. Lab Chip 2019, 19, 984–992. [Google Scholar] [CrossRef] [PubMed]

- Tan, M.K.; Siddiqi, A.; Yeo, L.Y. A Facile and Flexible Method for On-Demand Directional Speed Tunability in the Miniaturised Lab-on-a-Disc. Sci. Rep. 2017, 7, 6652. [Google Scholar] [CrossRef] [PubMed]

- Lu, X.; Zhao, K.; Peng, H.; Li, H.; Liu, W. Local Enhanced Microstreaming for Controllable High-Speed Acoustic Rotary Microsystems. Phys. Rev. Appl. 2019, 11, 044064. [Google Scholar] [CrossRef]

- Uran, S.; Bratina, B.; Šafarič, R. A Microfluidic Rotational Motor Driven by Circular Vibrations. Micromachines 2019, 10, 809. [Google Scholar] [CrossRef] [PubMed]

- Ahmed, H.; Ramesan, S.; Lee, L.; Rezk, A.R.; Yeo, L.Y. On-Chip Generation of Vortical Flows for Microfluidic Centrifugation. Nano-Micro Small 2019, 16, 1903605. [Google Scholar] [CrossRef] [PubMed]

- Jalal, J.; Leong, T.S.H. Microstreaming and Its Role in Applications: A Mini-Review. Fluids 2018, 3, 93. [Google Scholar] [CrossRef]

- Holtsmark, J.; Johnsen, I.; Sikkeland, T.; Skavlem, S. Boundary layer flow near a cylindrical obstacle in an oscillating, incompressible fluid. J. Acoust. Soc. Am. 1954, 26, 26–39. [Google Scholar] [CrossRef]

| Ref. | Type | Rotor Size Diameter [µm] | Speed [rad/s] | Torque [pNm] | Controllability in Both Directions | Transfer of Mechanical Energy Out of the Motor |

|---|---|---|---|---|---|---|

| [1] | Microfluidic driven motor in the channel | 60–1600 | 390 | 8.7 | No | No |

| [2] | Electro-wetting micromotor | 2000 | 18 | - | Yes | No |

| [3] | Rotating the thin layer of liquid | - | 9 | - | Yes | No |

| [4,5,6] | Surface acoustic waves motor | 5000 | 235 | 6 × 104 | Yes | No |

| [7] | Microfluidic motor with edges | 600 | 125 | - | No | Yes |

| [9] | Rotational Janus micromachine | 100 | 0.6 | - | No | No |

| [10,11] | Bubble-Powered Micro-Rotor | 65–100 | 65–70 | No | No | |

| [17] | Microfluidic motor with central pillar | 350 | 26 | 0.2 | Yes | No |

| Our pot-like microfluidic motor | 350 | 15 | 0.1 | Yes | Yes |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Uran, S.; Malok, M.; Bratina, B.; Šafarič, R. A Pot-Like Vibrational Microfluidic Rotational Motor. Micromachines 2021, 12, 177. https://doi.org/10.3390/mi12020177

Uran S, Malok M, Bratina B, Šafarič R. A Pot-Like Vibrational Microfluidic Rotational Motor. Micromachines. 2021; 12(2):177. https://doi.org/10.3390/mi12020177

Chicago/Turabian StyleUran, Suzana, Matjaž Malok, Božidar Bratina, and Riko Šafarič. 2021. "A Pot-Like Vibrational Microfluidic Rotational Motor" Micromachines 12, no. 2: 177. https://doi.org/10.3390/mi12020177

APA StyleUran, S., Malok, M., Bratina, B., & Šafarič, R. (2021). A Pot-Like Vibrational Microfluidic Rotational Motor. Micromachines, 12(2), 177. https://doi.org/10.3390/mi12020177