Construction and Characterization of TiN/Si3N4 Composite Insulation Layer in TiN/Si3N4/Ni80Cr20 Thin Film Cutting Force Sensor

Abstract

:1. Introduction

2. Experimental Theory and Method

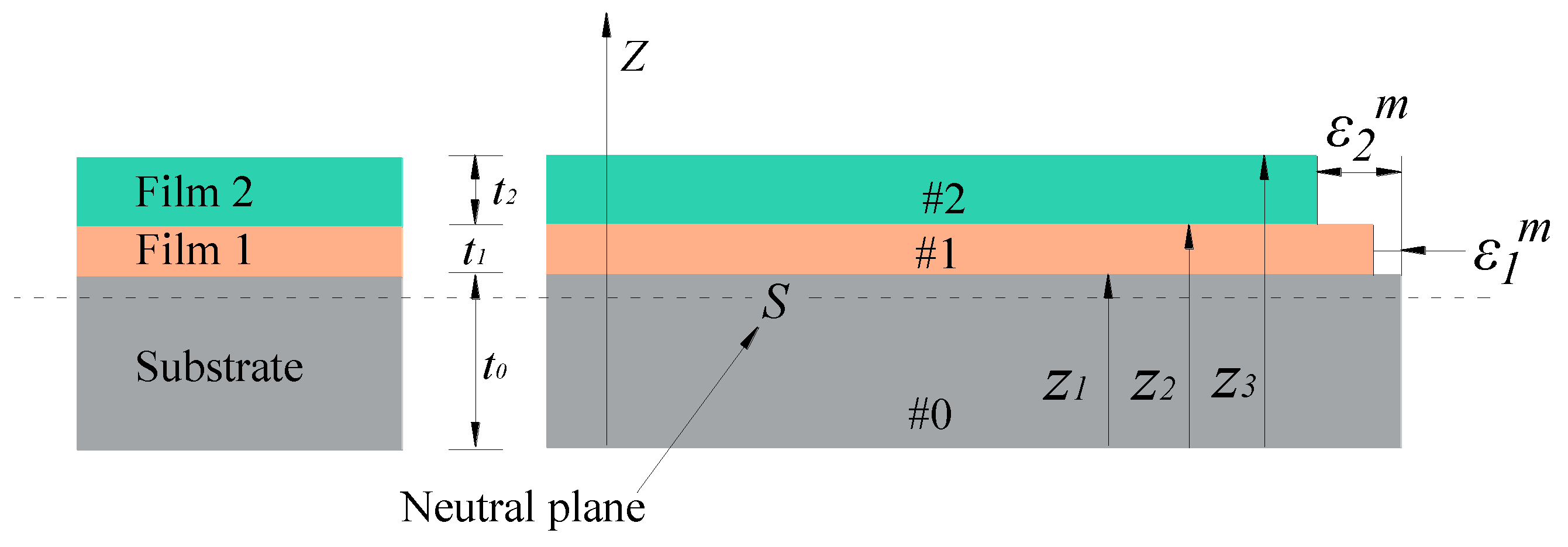

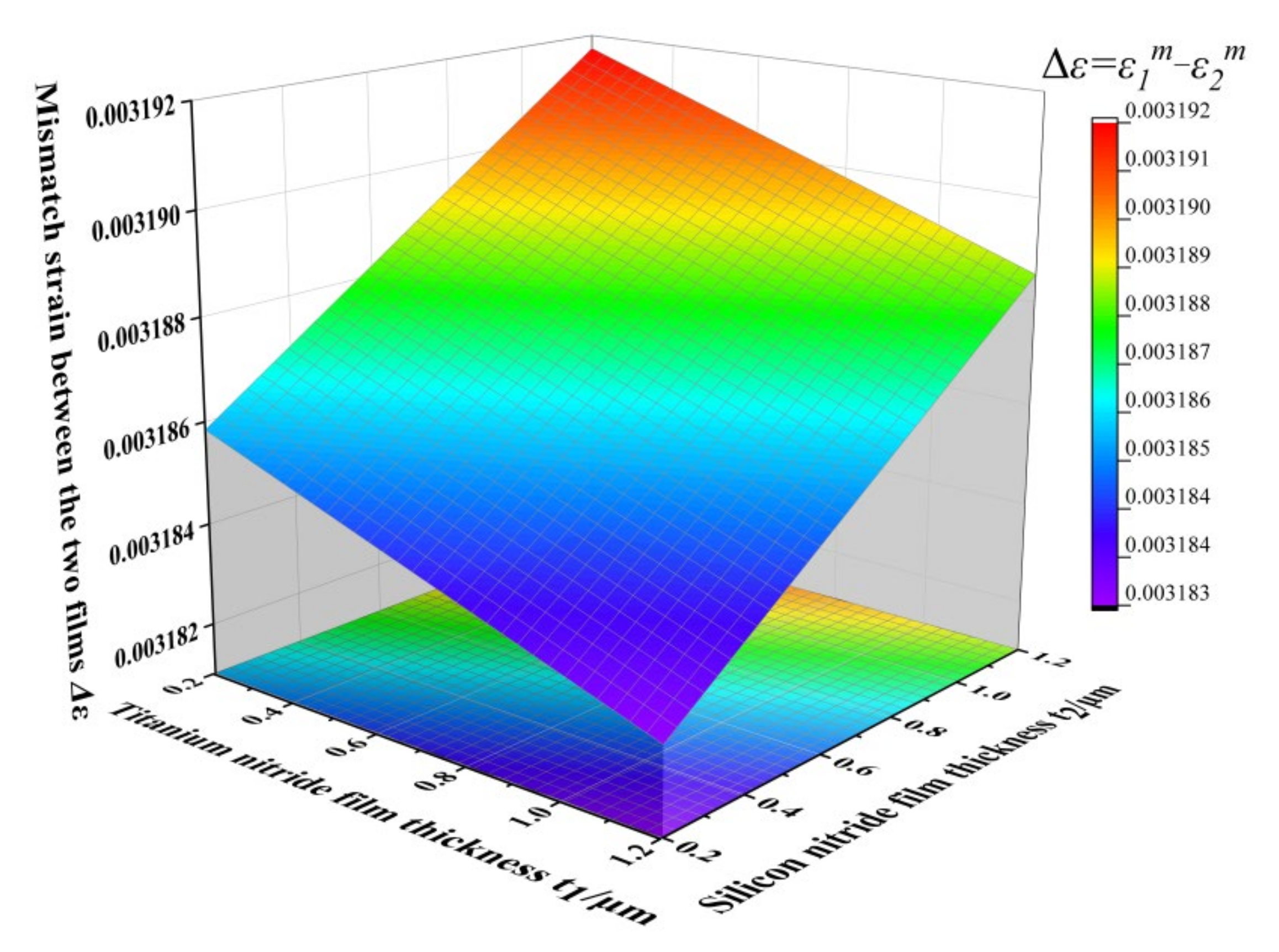

2.1. Mismatch Strain Analysis of Films by Stoney’s Classic Film Stress Formula

2.2. Deposition of Titanium Nitride Film

2.3. Characterization of Titanium Nitride Films

2.4. Preparation of Silicon Nitride Films and Nanoindentation Tests

3. Results and Discussions

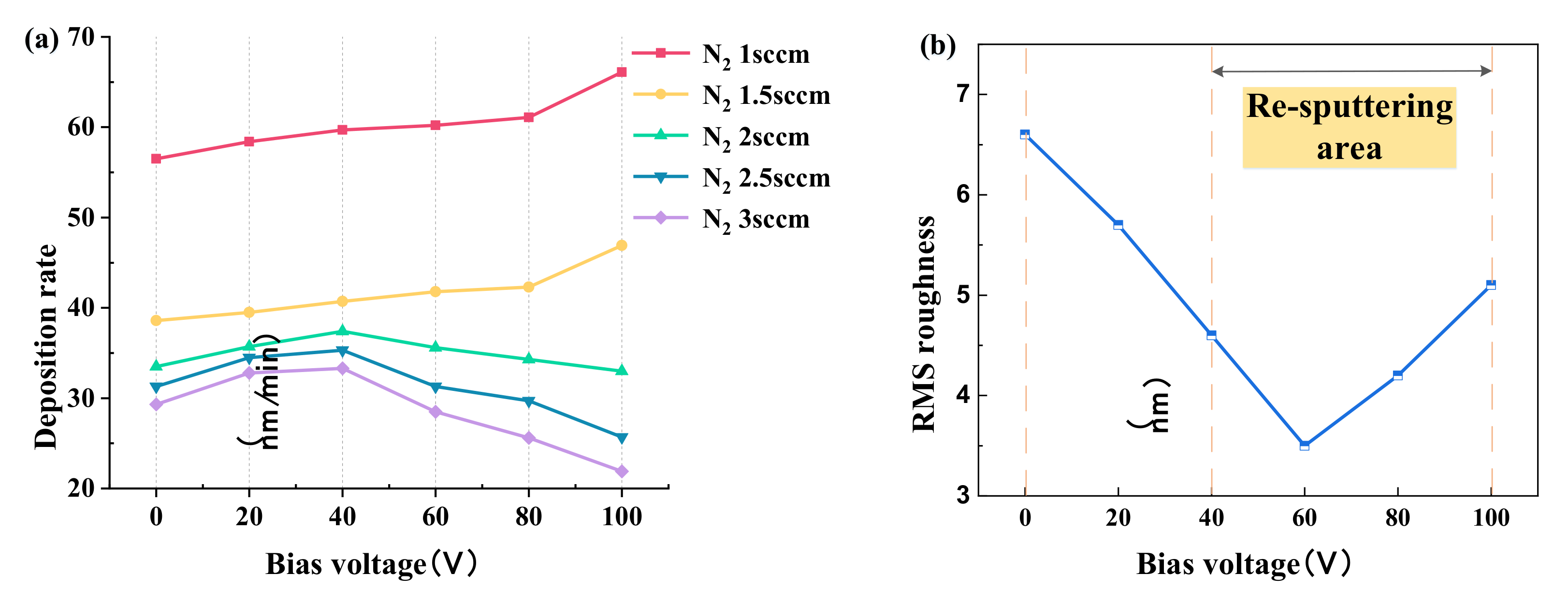

3.1. Effect of Substrate Negative Bias Voltage on Surface Morphology of TiN Films

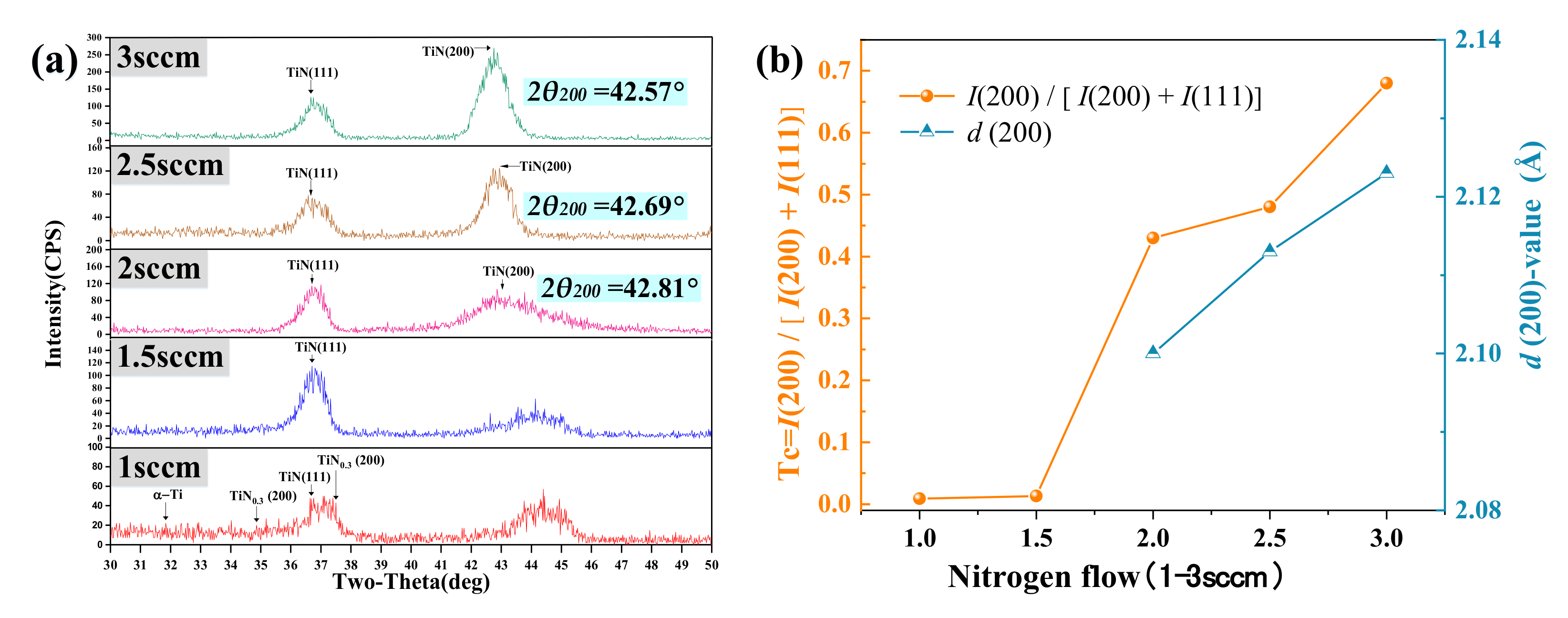

3.2. Effect of Nitrogen Gas Flow on Phase Composition and Microstructure of TiN

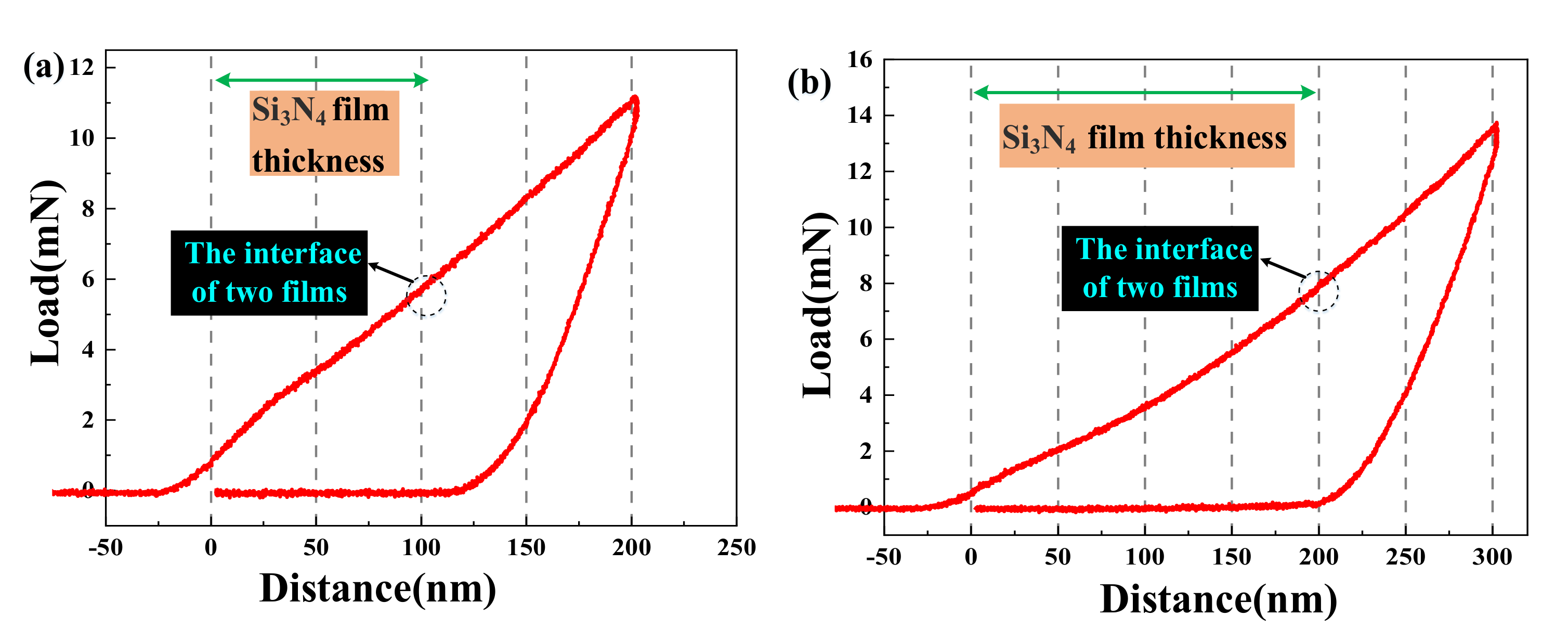

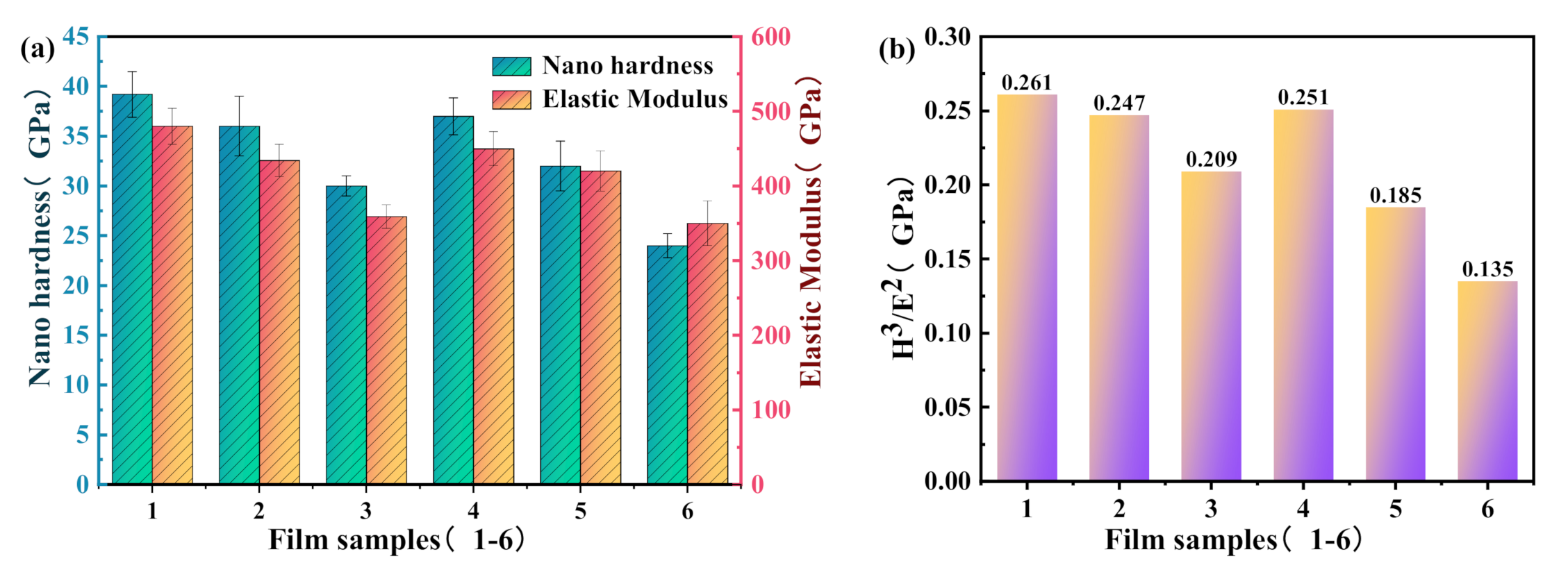

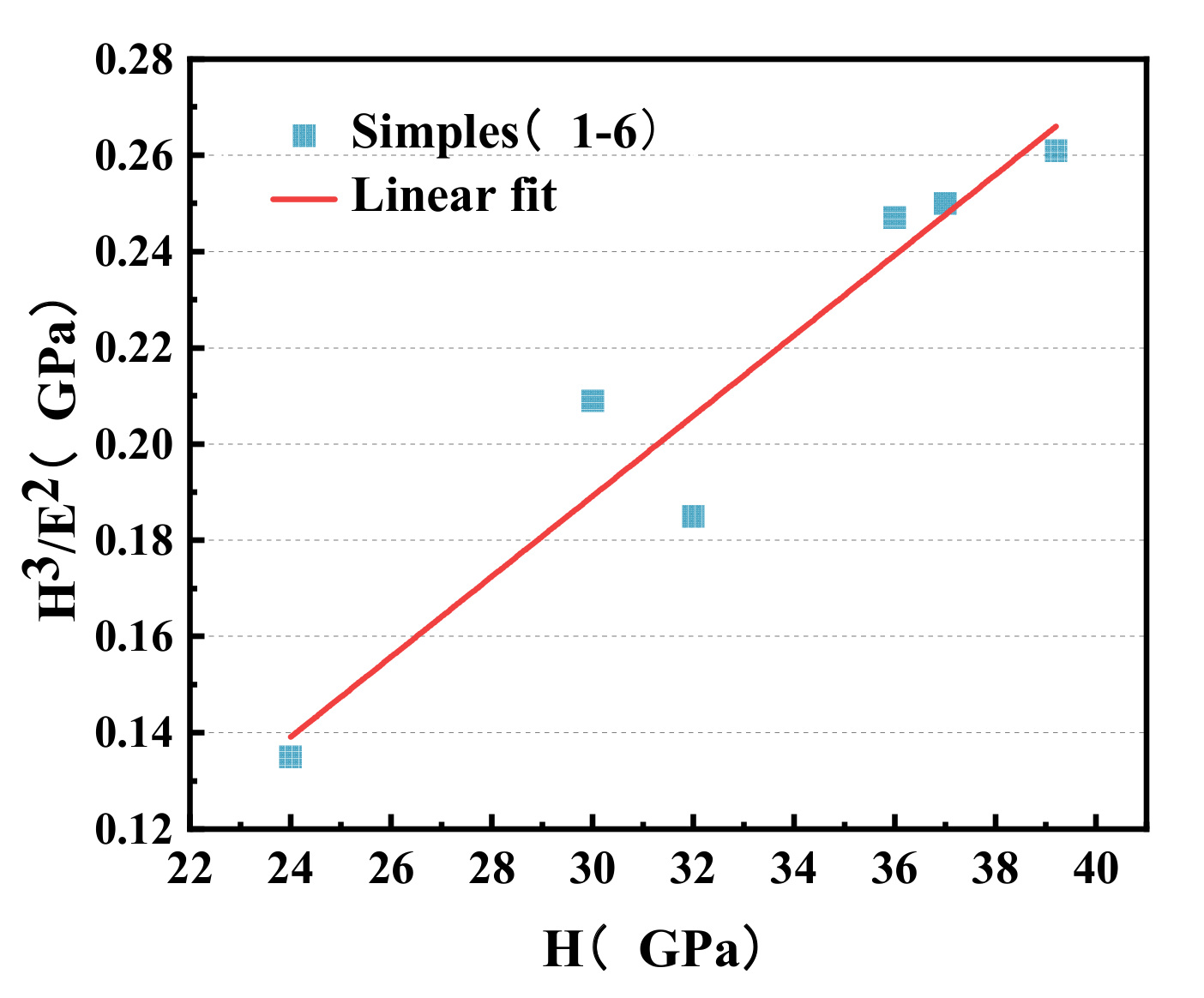

3.3. Film Thickness and Nano Indentation Experiment

4. Conclusions

- (1)

- The surface morphology and root mean square roughness of titanium nitride films under substrate negative bias voltage (0~−100 V) were revealed by atomic force microscope. The smoothest sample was obtained at −60 V bias and 3 sccm nitrogen flow, with an RMS of 3.5 nm. Then, with the increase of negative bias voltage, the surface smoothness of the film decreases, and the RMS increases to 5.1 nm at −100 V.

- (2)

- XRD analysis was carried out on the film (−60 V) with optimal smoothness. When the nitrogen flow rate is sufficient, the sample has a mixed phase of TiN(111) and (200). With the increase of nitrogen flow rate, the intensity of the TiN(200) phase increases continuously. It is observed by AFM that the smoothness of film samples becomes higher with the increase of TiN(200) peak orientation.

- (3)

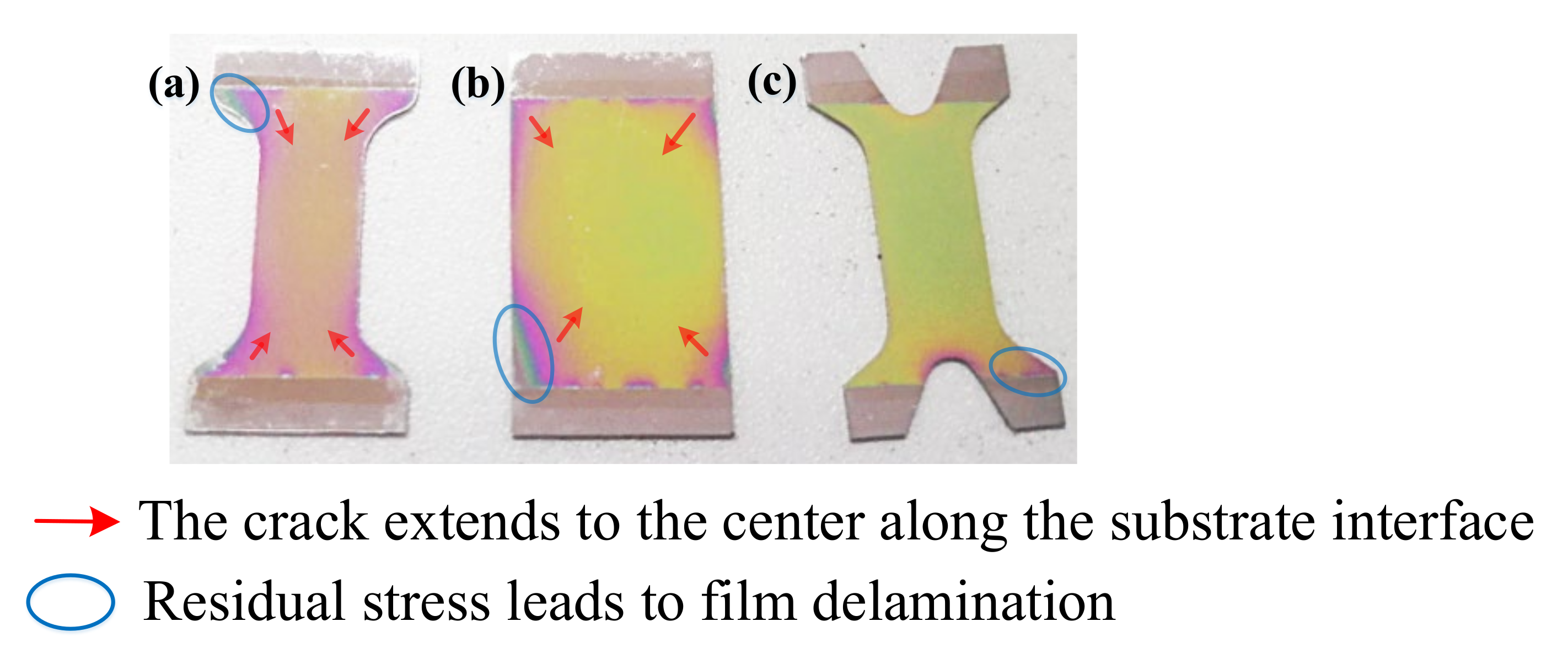

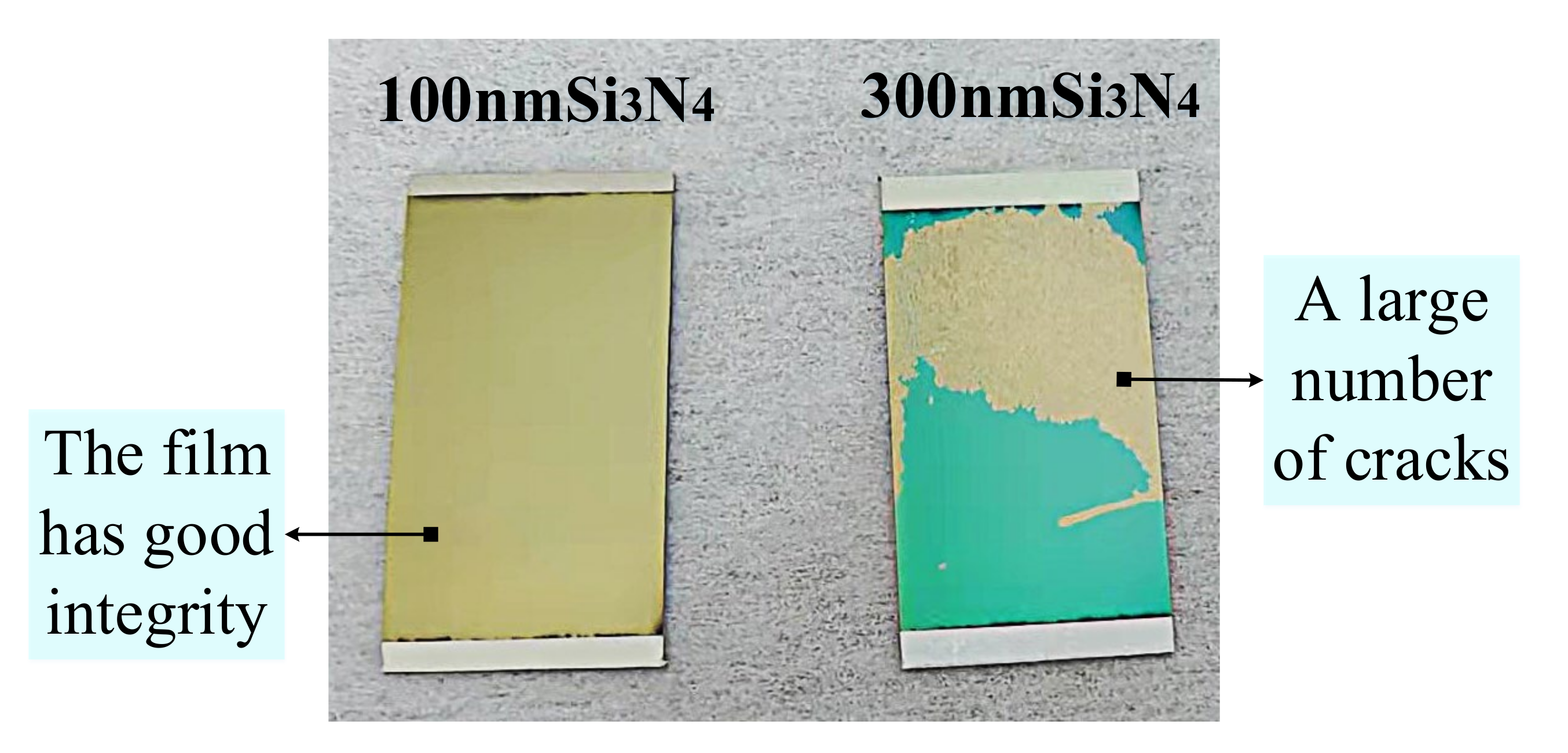

- A TiN/Si3N4 functional film system for cutting force measurement is established. In the nanoindentation experiment, the combination of 800 nm titanium nitride and 100 nm silicon nitride film showed the optimal hardness of 39.2 GPa, H3/E2 ratio of 0.261 GPa, and sound insulation performance. In high-speed machining, high enough hardness and toughness is not only the premise of accurate data acquisition but also a guarantee of service longevity.

- (4)

- TiN/Si3N4 films with greater hardness usually have a higher H3/E2 ratio. The subsequent increase in the thickness of silicon nitride film to 300 nm led to film cracking and sample failure. These observations, combined with the results of the nanoindentation experiment, verify our theoretical mismatch film-strain analysis.

Author Contributions

Funding

Conflicts of Interest

References

- Zhao, Y.; Zhao, Y.; Ge, X. The Development of a Triaxial Cutting Force Sensor Based on a MEMS Strain Gauge. Micromachines 2018, 9, 30. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Li, T.; Shi, T.; Tang, Z.; Liao, G.; Duan, J.; Han, J.; He, Z. Real-time tool wear monitoring using thin-film thermocouple. J. Mater. Process. Technol. 2021, 288, 116901. [Google Scholar] [CrossRef]

- Gong, T.; Zhao, Y. Design and Manufacturing of a High-Sensitivity Cutting Force Sensor Based on AlSiCO Ceramic. Micromachines 2021, 12, 63. [Google Scholar] [CrossRef]

- Rehorn, A.G.; Jiang, J.; Orban, P.E.; Bordatchev, E.V. State-of-the-art methods and results in tool condition monitoring: A review. Int. J. Adv. Manuf. Technol. 2005, 26, 693–710. [Google Scholar] [CrossRef]

- Mohanraj, T.; Shankar, S.; Rajasekar, R.; Sakthivel, N.R.; Pramanik, A. Tool condition monitoring techniques in milling process—A review. Prog. Artif. Intell. 2020, 9, 1032–1042. [Google Scholar] [CrossRef]

- Zhang, Y.; Wu, W.; Han, Y.; Wen, H.; Cheng, Y.; Liu, L. Design and Analysis of a Turning Dynamometer Embedded in Thin-Film Sensor. Micromachines 2019, 10, 210. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Ting, Y.; Chen, H.-Y. Design and performance evaluation of a multi-axis thin-film sensor for milling process measurement. Sens. Actuators A Phys. 2021, 332, 113147. [Google Scholar] [CrossRef]

- Veprek, S.; Reiprich, S.; Shizhi, L. Superhard nanocrystalline composite materials: The TiN/Si3N4 system. Appl. Phys. Lett. 1995, 66, 2640–2642. [Google Scholar] [CrossRef] [Green Version]

- Veprek, S.; Argon, A. Towards the understanding of mechanical properties of super- and ultrahard nanocomposites. J. Vac. Sci. Technol. B Microelectron. Nanometer Struct. Process. Meas. Phenom. 2002, 20, 650–664. [Google Scholar] [CrossRef] [Green Version]

- Chawla, V.; Jayaganthan, R.; Chandra, R. Microstructural and mechanical properties of sputter deposited TiN/SiNx multilayer thin films. Mater. Chem. Phys. 2010, 122, 424–430. [Google Scholar] [CrossRef]

- An, T.; Tian, H.W.; Wen, M. Structures and mechanical properties of TiN/SiNx multilayer films deposited by magnetron sputtering at different N2/Ar gas flow ratios. Vacuum 2008, 82, 1187–1190. [Google Scholar] [CrossRef]

- Soderberg, H.; Oden, M.; Flink, A. Growth and characterization of TiN/SiN (001) superlattice films. J. Mater. Res. 2007, 22, 3255–3264. [Google Scholar] [CrossRef] [Green Version]

- Veprek, S.; Niederhofer, A.; Moto, K.; Bolom, T.; Männling, H.-D.; Nesladek, P.; Dollinger, G.; Bergmaier, A. Composition nanostructure and origin of the ultrahardness in nc-TiN/a-Si3N4/a-and nc-TiSi2 nanocomposites with HV = 80 to ≥105 GPa. Surf. Coat. Technol. 2000, 133–134, 152–159. [Google Scholar] [CrossRef]

- Sperr, M.; Zhang, Z.L.; Ivanov, Y.P.; Mayrhofer, P.H.; Bartosik, M. Correlating elemental distribution with mechanical properties of TiN/SiNx nanocomposite coatings. Scr. Mater. 2019, 170, 20–23. [Google Scholar] [CrossRef]

- Kauffmann, F.; Dehm, G.; Schier, V.; Schattke, A.; Beck, T.; Lang, S.; Arzt, E. Microstructural size effects on the hardness of nanocrystalline TiN/amorphous-SiNx coatings prepared by magnetron sputtering. Thin Solid Film. Int. J. Sci. Technol. Thin Thick Film. 2005, 473, 114–122. [Google Scholar] [CrossRef]

- An, T.; Wen, M.; Hu, C.Q.; Tian, H.W.; Zheng, W.T. Interfacial fracture for TiN/SiNx nano-multilayer coatings on Si(111) characterized by nanoindentation experiments. Mater. Sci. Eng. A Struct. Mater. Prop. Misrostructure Process. 2008, 494, 324–328. [Google Scholar] [CrossRef]

- Phinichka, N.; Chandra, R.; Barbe, Z.H. Ionized magnetron sputter deposition of hard nanocomposite TiN/amorphous-silicon nitride films. J. Vac. Sci. Technol. A Vac. Surf. Film. 2004, 22, 477–481. [Google Scholar] [CrossRef]

- Schmidt, S.; Hanninen, T.; Wissting, J.; Hultman, L.; Goebbels, N.; Santana, A.; Tobler, M.; Högberg, H. SiNx coatings deposited by reactive high power impulse magnetron sputtering: Process parameters influencing the residual coating stress. J. Appl. Phys. 2017, 121, 171904. [Google Scholar] [CrossRef] [Green Version]

- Djaziri, S.; Renault, P.-O.; Le Bourhis, E.; Goudeau, P.; Faurie, D.; Geandier, G.; Mocuta, C.; Thiaudière, D. Comparative study of the mechanical properties of nanostructured thin films on stretchable substrates. J. Appl. Phys. 2014, 116, 093504. [Google Scholar] [CrossRef]

- Suo, Z.G.; Hutchinson, J.W. Interface crack between two elastic layers. Int. J. Fract. 1990, 43, 1–18. [Google Scholar] [CrossRef]

- Mu, Q. Analysis of substrate curvature and film stress through a reformed mathematical description on mismatch strain. AIP Adv. 2018, 8, 65224. [Google Scholar] [CrossRef]

- Gunnars, J.; Wiklund, U. Determination of growth-induced strain and thermo-elastic properties of coatings by curvature measurements. Mater. Sci. Eng. A Struct. Mater. Prop. Misrostructure Process. 2002, 336, 7–21. [Google Scholar] [CrossRef]

- Injeti, S.S.; Annabattula, R.K. Extending Stoney’s equation to thin, elastically anisotropic substrates and bilayer films. Thin Solid Film. Int. J. Sci. Technol. Thin Thick Film. 2016, 598, 252–259. [Google Scholar] [CrossRef]

- Barmak, K.; Coffey, K.R. Metallic Films for Electronic, Optical and Magnetic Applications: Structure, Processing and Properties; Woodhead Publishing: Sawston, UK, 2014. [Google Scholar]

- Mayrhofer, P.H.; Mitterer, C.; Hultman, L.; Clemens, H. Microstructural design of hard coatings. Prog. Mater. Sci. 2006, 51, 1032–1114. [Google Scholar] [CrossRef]

- Hsu, C.-Y.; Chiang, C.-C.; Hsieh, T.-S.; Hsu, H.-C.; Tsai, L.; Hou, C.-H. Study of fiber Bragg gratings with TiN-coated for cryogenic temperature measurement. Opt. Laser Technol. 2021, 136, 106768. [Google Scholar] [CrossRef]

- Habermehl, S. Coefficient of thermal expansion and biaxial Young’s modulus in Si-rich silicon nitride thin films. J. Vac. Sci. Technol. A Vac. Surf. Film. 2018, 36, 021517. [Google Scholar] [CrossRef]

- Cen, Z.H.; Xu, B.X.; Hu, J.F.; Ji, R.; Toh, Y.T.; Ye, K.D.; Hu, Y.F. Temperature effect on titanium nitride nanometer thin film in air. J. Phys. D Appl. Phys. 2017, 50, 75105. [Google Scholar] [CrossRef]

- Qi, R.; Pan, L.; Feng, Y.; Wu, J.; Li, W.; Wang, Z. Evolution of chemical, structural, and mechanical properties of titanium nitride thin films deposited under different nitrogen partial pressure. Results Phys. 2020, 19, 103416. [Google Scholar] [CrossRef]

- Chen, Q.; Li, A.; Wu, G.; Lu, Z.; Zhang, G.; Tian, G. Structure vs chemistry: Tribological behavior of TiN films in the nitrogen atmosphere. Ceram. Int. 2020, 46, 28053–28063. [Google Scholar] [CrossRef]

- Zhang, R.F.; Argon, A.S.; Veprek, S. Understanding why the thinnest SiNx interface in transition-metal nitrides is stronger than the ideal bulk crystal. Phys. Rev. B 2010, 81, 245418. [Google Scholar] [CrossRef]

- Ivashchenko, V.I.; Veprek, S.; Argon, A.S.; Turchi, P.E.A.; Gorb, L.; Hill, F.; Leszczynski, J. First-principles quantum molecular calculations of structural and mechanical properties of TiN/SiNx heterostructures, and the achievable hardness of the nc-TiN/SiNx nanocomposites. Thin Solid Film. 2015, 578, 83–92. [Google Scholar] [CrossRef] [Green Version]

- Kong, M.; Zhao, W.; Wei, L.; Li, G. Investigations on the microstructure and hardening mechanism of TiN/Si3N4 nanocomposite coatings. J. Phys. D Appl. Phys. A Europhys. J. 2007, 40, 2858–2863. [Google Scholar] [CrossRef]

- Musil, J.; Kunc, F.; Zeman, H.; Polakova, H. Relationships between hardness, Young’s modulus and elastic recovery in hard nanocomposite coatings. Surf. Coat. Technol. 2002, 154, 304–313. [Google Scholar] [CrossRef]

| Material | Elastic Modulus (GPa) | Poisson’s Ratio | Thermal Expansion Coefficient (10−6/K) |

|---|---|---|---|

| 304SS | 195 | 0.25 | 17.2 |

| TiN Film1 | 279 | 0.25 | 7.4 |

| Si3N4 Film2 | 304 | 0.24 | 2.45 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ma, R.; Wu, W.; He, Z.; Cheng, Y.; Liu, L.; Zhao, Y. Construction and Characterization of TiN/Si3N4 Composite Insulation Layer in TiN/Si3N4/Ni80Cr20 Thin Film Cutting Force Sensor. Micromachines 2021, 12, 1476. https://doi.org/10.3390/mi12121476

Ma R, Wu W, He Z, Cheng Y, Liu L, Zhao Y. Construction and Characterization of TiN/Si3N4 Composite Insulation Layer in TiN/Si3N4/Ni80Cr20 Thin Film Cutting Force Sensor. Micromachines. 2021; 12(12):1476. https://doi.org/10.3390/mi12121476

Chicago/Turabian StyleMa, Ruyuan, Wenge Wu, Zhenyu He, Yunping Cheng, Lijuan Liu, and Yongjuan Zhao. 2021. "Construction and Characterization of TiN/Si3N4 Composite Insulation Layer in TiN/Si3N4/Ni80Cr20 Thin Film Cutting Force Sensor" Micromachines 12, no. 12: 1476. https://doi.org/10.3390/mi12121476

APA StyleMa, R., Wu, W., He, Z., Cheng, Y., Liu, L., & Zhao, Y. (2021). Construction and Characterization of TiN/Si3N4 Composite Insulation Layer in TiN/Si3N4/Ni80Cr20 Thin Film Cutting Force Sensor. Micromachines, 12(12), 1476. https://doi.org/10.3390/mi12121476