Phase-Type Fresnel Zone Plate with Multi-Wavelength Imaging Embedded in Fluoroaluminate Glass Fabricated via Ultraviolet Femtosecond Laser Lithography

Abstract

:1. Introduction

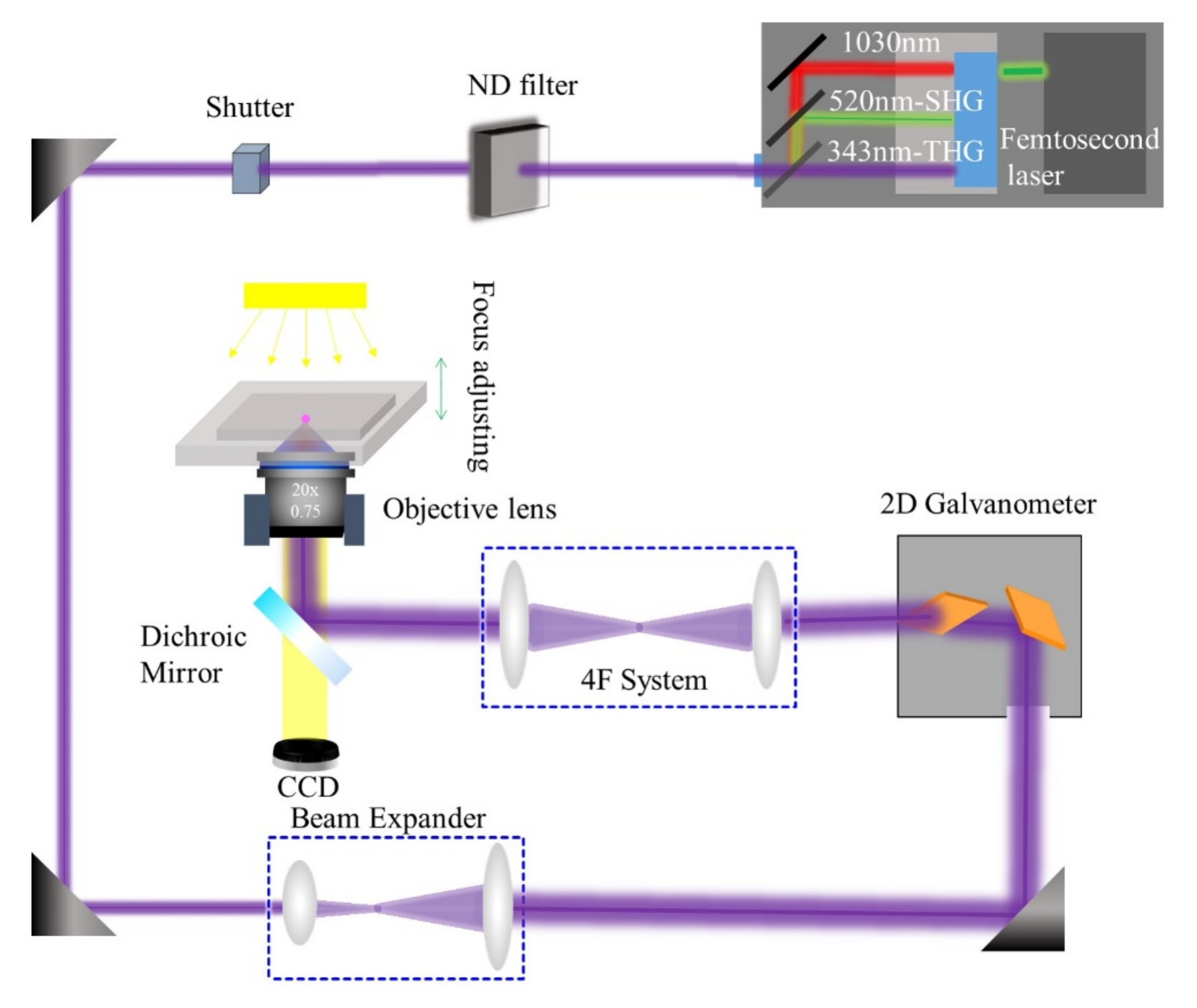

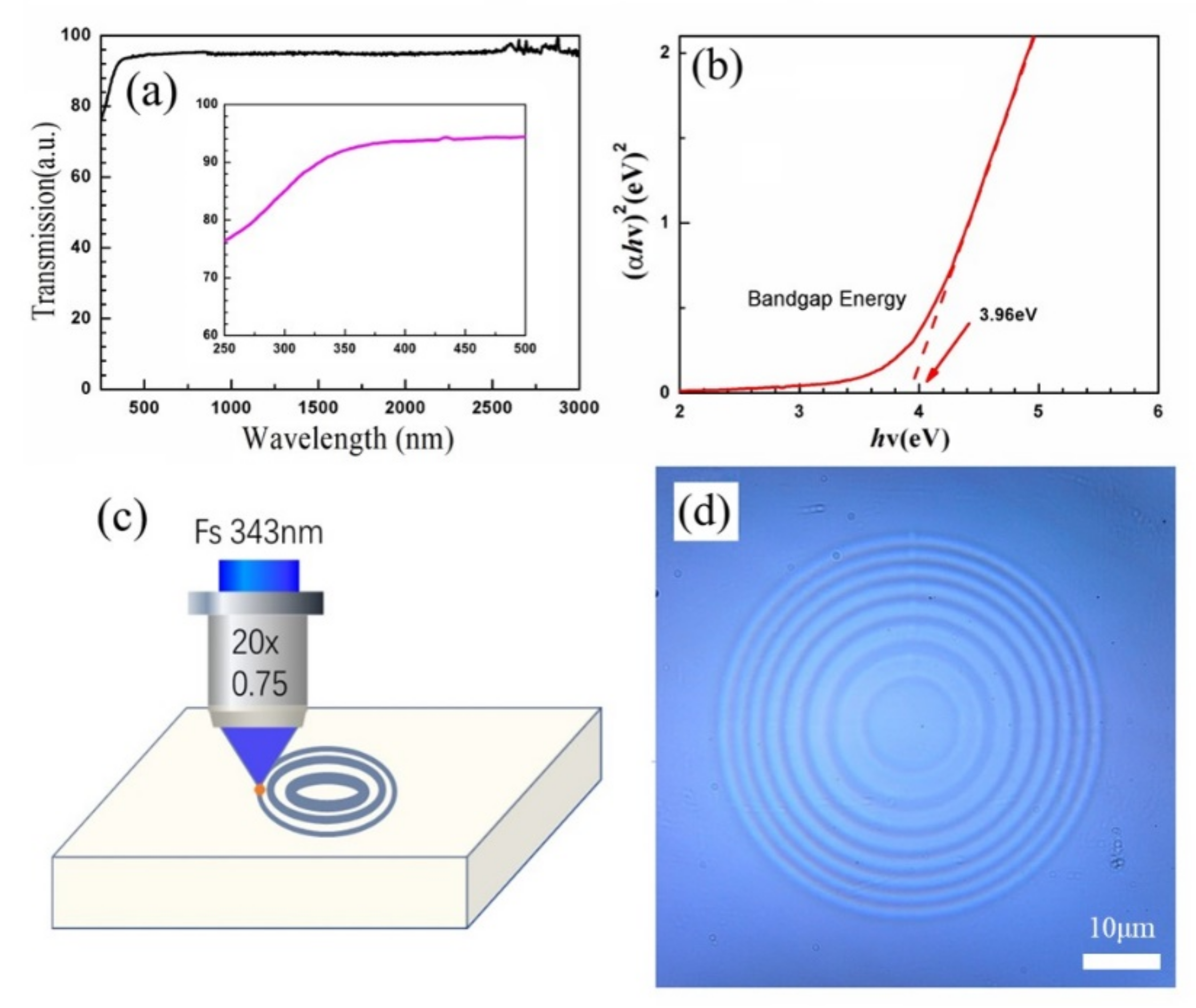

2. Materials and Methods

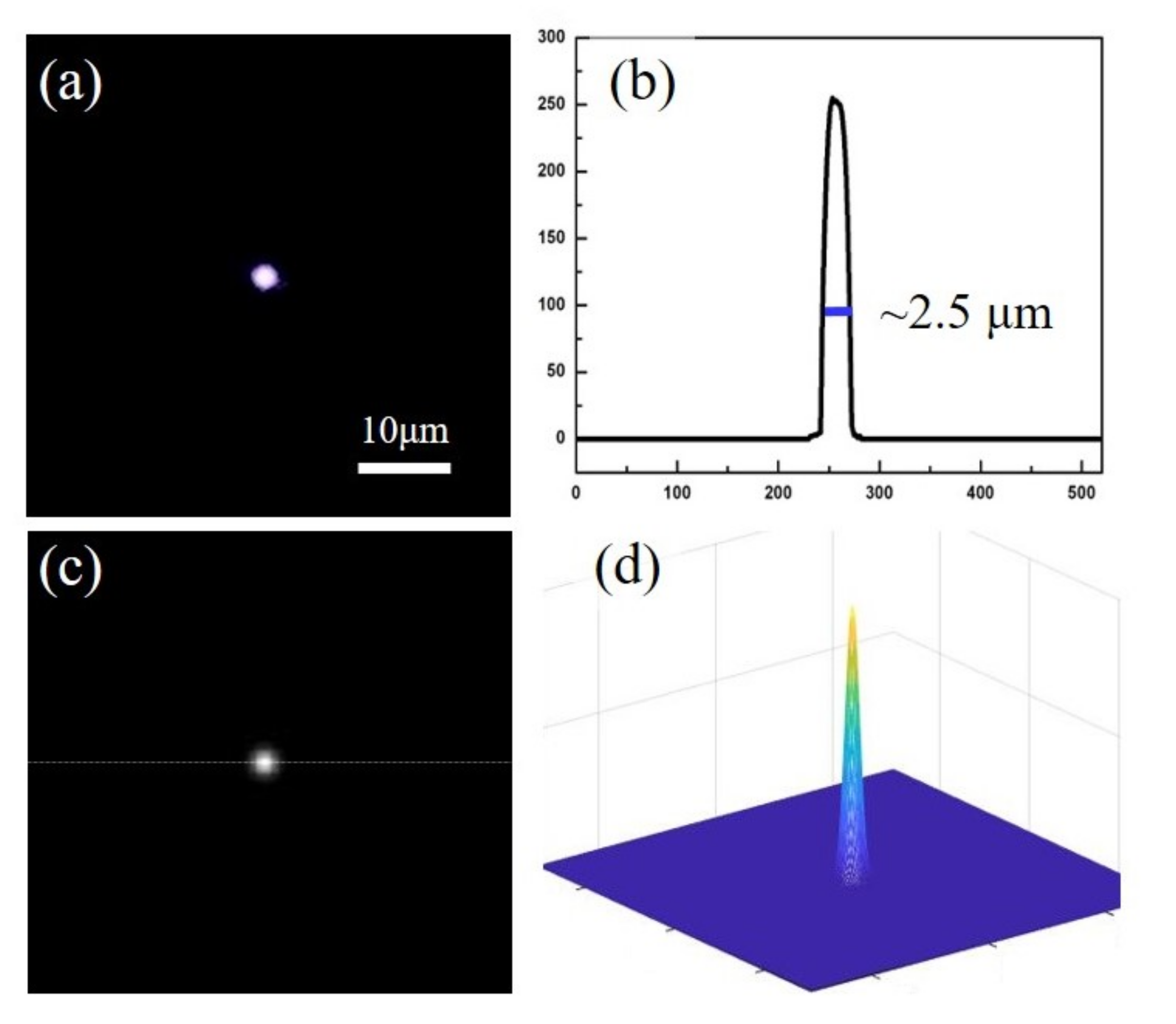

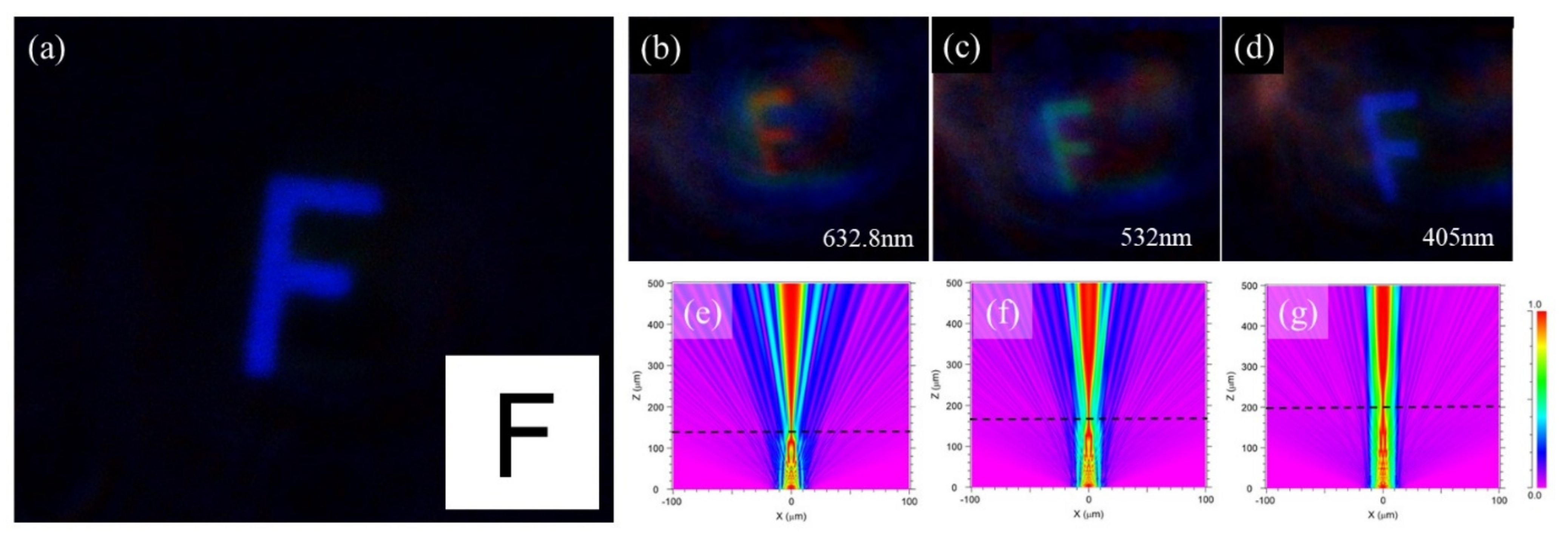

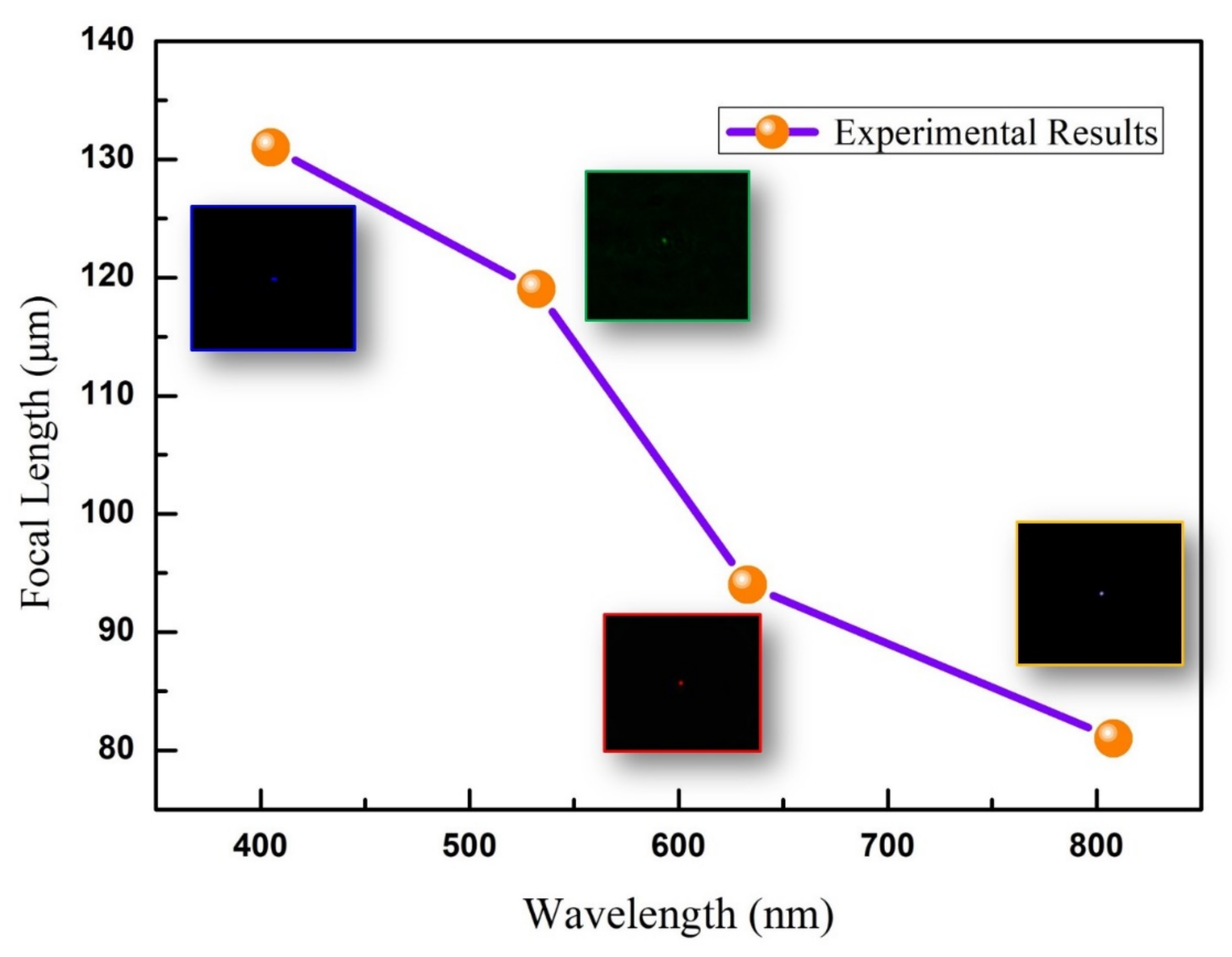

3. Results and Discussion

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- New, B.M. Design, Production and Performance of Circular Fresnel Zone Plates. Appl. Opt. 1971, 10, 498–503. [Google Scholar] [CrossRef]

- Hecht, E. Optics, Fourthed; Addison Wesley Longman Inc.: Boston, MA, USA, 1998. [Google Scholar]

- Keskinbora, K.; Grévent, C.; Bechtel, M.; Weigand, M.; Goering, E.; Nadzeyka, A.; Peto, L.; Rehbein, S.; Schneider, G.; Follath, R.; et al. Ion beam lithography for Fresnel zone plates in X-ray microscopy. Opt. Express 2013, 21, 11747–11756. [Google Scholar] [CrossRef] [Green Version]

- Yoon, G.; Jang, J.; Mun, J.; Nam, K.T.; Rho, J. Metasurface zone plate for light manipulation in vectorial regime. Commun. Phys. 2019, 2, 156. [Google Scholar] [CrossRef] [Green Version]

- Vijayakumar, A.; Bhattacharya, S. Design, fabrication, and evaluation of a multilevel spiral-phase Fresnel zone plate for optical trapping. Appl. Opt. 2012, 51, 6038–6044. [Google Scholar] [CrossRef] [PubMed]

- Cao, Q.; Jahns, J. Modified Fresnel zone plates that produce sharp Gaussian focal spots. J. Opt. Soc. Am. A 2013, 20, 1576–1581. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Jung, Y.J.; Park, D.; Koo, S.; Yu, S.; Park, N. Metal slit array Fresnel lens for wavelength-scale optical coupling to nanophotonic waveguides. Opt. Express 2009, 17, 18852–18857. [Google Scholar] [CrossRef] [PubMed]

- Pang, S.; Han, C.; Man Lee, L.; Yang, C. Fluorescence microscopy imaging with a Fresnel zone plate array based optofluidic microscope. Lab Chip 2011, 11, 3698–3702. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Yin, H.; Li, J.Q.; Liang, H.; Zhang, M.; Su, H.; Li, I.L. Full-transparent zone plates for THz focusing. Chin. Opt. Lett. 2018, 16, 082601. [Google Scholar] [CrossRef] [Green Version]

- Hoang Anh, N.N.; Rhee, H.G.; Ghim, Y.S. Design and lithographic fabrication of elliptical zone plate array with high fill factor. Curr. Opt. Photon. 2021, 5, 8–15. [Google Scholar]

- Fujita, T.; Nishihara, H.; Koyama, J. Blazed gratings and Fresnel lenses fabricated by electron-beam lithography. Opt. Lett. 1982, 7, 578–580. [Google Scholar] [CrossRef] [PubMed]

- Chen, Q.D.; Wu, D.; Niu, L.G.; Wang, J.; Lin, X.F.; Xia, H.; Sun, H.B. Phase lenses and mirrors created by laser micronanofabrication via two-photonphoto-polymerization. Appl. Phys. Lett. 2007, 91, 171105. [Google Scholar] [CrossRef] [Green Version]

- Wu, D.; Niu, L.G.; Chen, Q.D.; Wang, R.; Sun, H.B. High efficiency multilevel phase-type fractal zone plates. Opt. Lett. 2008, 24, 2913–2915. [Google Scholar] [CrossRef] [PubMed]

- Srisungsitthisunti, P.; Ersoy, O.K.; Xu, X.F. Laser direct writing of volume modified Fresnel zone plates. J. Opt. Soc. Am. B 2007, 24, 2090–2096. [Google Scholar] [CrossRef]

- Yan, L.; Yang, D.; Gong, Q.H.; Li, Y. Rapid Fabrication of continuous surface Fresnel microlens array by femtosecond laser focal field engineering. Micromachines 2020, 11, 112. [Google Scholar] [CrossRef] [Green Version]

- Sanner, N.; Utéza, O.; Bussiere, B.; Coustillier, G.; Leray, A.; Itina, T.; Sentis, M. Measurement of femtosecond laser-induced damage and ablation thresholds in dielectrics. Appl. Phys. A 2009, 94, 889–897. [Google Scholar] [CrossRef]

- Uteza, O.; Bussiere, B.; Canova, F.; Chambaret, J.P.; Delaporte, P.; Itina, T.; Sentis, M. Laser-induced damage threshold of sapphire in nanosecond, picosecond and femtosecond regimes. Appl. Surf. Sci. 2007, 254, 799–803. [Google Scholar] [CrossRef]

- Vázquez, R.M.; Eaton, S.M.; Ramponi, R.; Cerullo, G.; Osellame, R. Fabrication of binary Fresnel lenses in PMMA by femtosecond laser surface ablation. Opt. Express 2011, 19, 11597–11604. [Google Scholar] [CrossRef]

- Lin, Z.Y.; Ji, L.F.; Hong, M.H. Enhancement of femtosecond laser-induced surface ablation via temporal overlapping double-pulse irradiation. Photon. Res. 2020, 8, 271–278. [Google Scholar] [CrossRef]

- Zhang, F.; Yang, Q.; Bian, H.; Hou, X.; Chen, F. Rapid fabrication of large-area concave microlens array on ZnSe. Micromachines 2021, 12, 458. [Google Scholar] [CrossRef]

- Rodrigues, V.R.M.; Thomas, J.; Santhosh, C.; Ramachandran, H.; Mathur, D. Microfabrication of Fresnel zone plates by laser induced solid ablation. J. Opt. 2016, 18, 075403. [Google Scholar] [CrossRef]

- Flamini, F.; Magrini, L.; Rab, A.S.; Spagnolo, N.; D’Ambrosio, V.; Mataloni, P.; Sciarrino, F.; Zandrini, T.; Crespi, A.; Ramponi, R.; et al. Thermally reconfigurable quantum photonic circuits at telecom wavelength by femtosecond laser micromachining. Light Sci. Appl. 2015, 4, e354. [Google Scholar] [CrossRef] [Green Version]

- Zhang, Q.; Li, M.; Xu, J.; Lin, Z.J.; Yu, H.F.; Wang, M.; Fang, Z.W.; Cheng, Y.; Gong, Q.H.; Li, Y. Reconfigurable directional coupler in lithium niobate crystal fabricated by three-dimensional femtosecond laser focal field engineering. Photon. Res. 2019, 7, 503–507. [Google Scholar] [CrossRef]

- Corrielli, G.; Atzeni, S.; Piacentini, S.; Pitsios, I.; Crespi, A.; Osellame, R. Symmetric polarization-insensitive directional couplers fabricated by femtosecond laser writing. Opt. Express 2018, 26, 15101–15109. [Google Scholar] [CrossRef] [Green Version]

- Li, Q.K.; Yu, Y.H.; Wang, L.; Cao, X.W.; Liu, X.Q.; Sun, Y.L.; Chen, Q.D.; Duan, H.A.; Sun, H.B. Sapphire-based Fresnel zone plate fabricated by femtosecond laser direct writing and wet etching. IEEE Photon. Technol. Lett. 2016, 28, 1290–1293. [Google Scholar] [CrossRef]

- Hopp, B.; Vass, C.; Smausz, T.; Bor, Z. Production of submicrometre fused silica gratings using laser-induced backside dry etching technique. J. Phys. D Appl. Phys. 2006, 39, 4843. [Google Scholar] [CrossRef]

- Hua, J.G.; Ren, H.; Jia, A.; Tian, Z.N.; Wang, L.; Juodkazis, S.; Chen, Q.D.; Sun, H.B. Convex silica microlens arrays via femtosecond laser writing. Opt. Lett. 2020, 45, 636–639. [Google Scholar] [CrossRef] [PubMed]

- Sohn, I.B.; Ahsan, M.S.; Noh, Y.C.; Choi, H.K.; Kim, J.T.; Ko, M.J. Fabrication of Fresnel zone plate lens in fused silica glass using femtosecond laser lithography technology. Opt. Eng. 2014, 53, 055107. [Google Scholar] [CrossRef]

- Li, Q.K.; Lu, T.M.; Hua, J.G.; Yu, Y.H.; Wang, L.; Chen, Q.D.; Juodkazis, S.; Sun, H.B. Multilevel phase-type diffractive lens embedded in sapphire. Opt. Lett. 2017, 42, 3832–3835. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Li, Q.S.; Yuan, X.Q.; Jiang, X.W.; Ju, Y.F.; Zhang, L. Femtosecond laser-induced damage characteristics of mid-infrared oxyfluorogallate glass. Opt. Laser Technol. 2019, 109, 659–665. [Google Scholar] [CrossRef]

- Peng, Y.P.; Wang, C.F.; Yuan, X.Q.; Zhang, L. Er3+-doped oxyfluorogallate glass for 2.7μm. J. Lumin. 2016, 172, 331–334. [Google Scholar] [CrossRef]

- Hagfeldt, A.; Gratzel, M. Light-induced redox reactions in nanocrystalline systems. Chem. Rev. 1995, 95, 49–68. [Google Scholar] [CrossRef]

- Zhu, B.; Liu, X.M.; Liu, H.G.; Liu, Y.A.; Yan, X.S.; Chen, Y.P.; Chen, X.F. Dual-wavelength focusing through Fresnel zone plate fabricated in lithium niobate crystal by femtosecond laser micromachining. Phys. Status Solidi RRL 2020, 14, 2000213. [Google Scholar] [CrossRef]

- Macisa-Monteo, M.; Dias, A.; Sotillo, B.; Moreno Zarate, P.; Ariza, R.; Fernandez, P.; Solis, J. Waveguide tapers fabrication by femtosecond laser induced element redistribution in glass. J. Light Technol. 2020, 38, 6578–6583. [Google Scholar] [CrossRef]

| Fabrication Methods | Materials | FWHM | Imaging | Reference |

|---|---|---|---|---|

| Femtosecond laser writing and chemical etching | Sapphire | 1.85 μm | Single wavelength | [25] |

| Laser-induced solid ablation | Metal-coated borosilicate glass | 5.95 μm | Multi-wavelength | [21] |

| Femtosecond laser focal field engineering | Polymer | None | White light | [15] |

| Femtosecond laser lithography and chemical etching | Fused silica glass | 2.02 μm | Single wavelength | [28] |

| Femtosecond-laser-induced refractive index change | Sapphire | 1.75 μm with four-level FZP | Multi-wavelength | [29] |

| Femtosecond-laser-induced refractive index change | Fluoroaluminate glass | 2.5 μm with second-level FZP | Multi-wavelength | This work |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Li, Q.; Dai, X.; Shi, H.; Liu, Y.; Zhang, L. Phase-Type Fresnel Zone Plate with Multi-Wavelength Imaging Embedded in Fluoroaluminate Glass Fabricated via Ultraviolet Femtosecond Laser Lithography. Micromachines 2021, 12, 1362. https://doi.org/10.3390/mi12111362

Li Q, Dai X, Shi H, Liu Y, Zhang L. Phase-Type Fresnel Zone Plate with Multi-Wavelength Imaging Embedded in Fluoroaluminate Glass Fabricated via Ultraviolet Femtosecond Laser Lithography. Micromachines. 2021; 12(11):1362. https://doi.org/10.3390/mi12111362

Chicago/Turabian StyleLi, Qisong, Xuran Dai, Haosong Shi, Yi Liu, and Long Zhang. 2021. "Phase-Type Fresnel Zone Plate with Multi-Wavelength Imaging Embedded in Fluoroaluminate Glass Fabricated via Ultraviolet Femtosecond Laser Lithography" Micromachines 12, no. 11: 1362. https://doi.org/10.3390/mi12111362

APA StyleLi, Q., Dai, X., Shi, H., Liu, Y., & Zhang, L. (2021). Phase-Type Fresnel Zone Plate with Multi-Wavelength Imaging Embedded in Fluoroaluminate Glass Fabricated via Ultraviolet Femtosecond Laser Lithography. Micromachines, 12(11), 1362. https://doi.org/10.3390/mi12111362