Improvement and Optimization of Electromagnetic Integrated Scanning Micromirror

Abstract

:1. Introduction

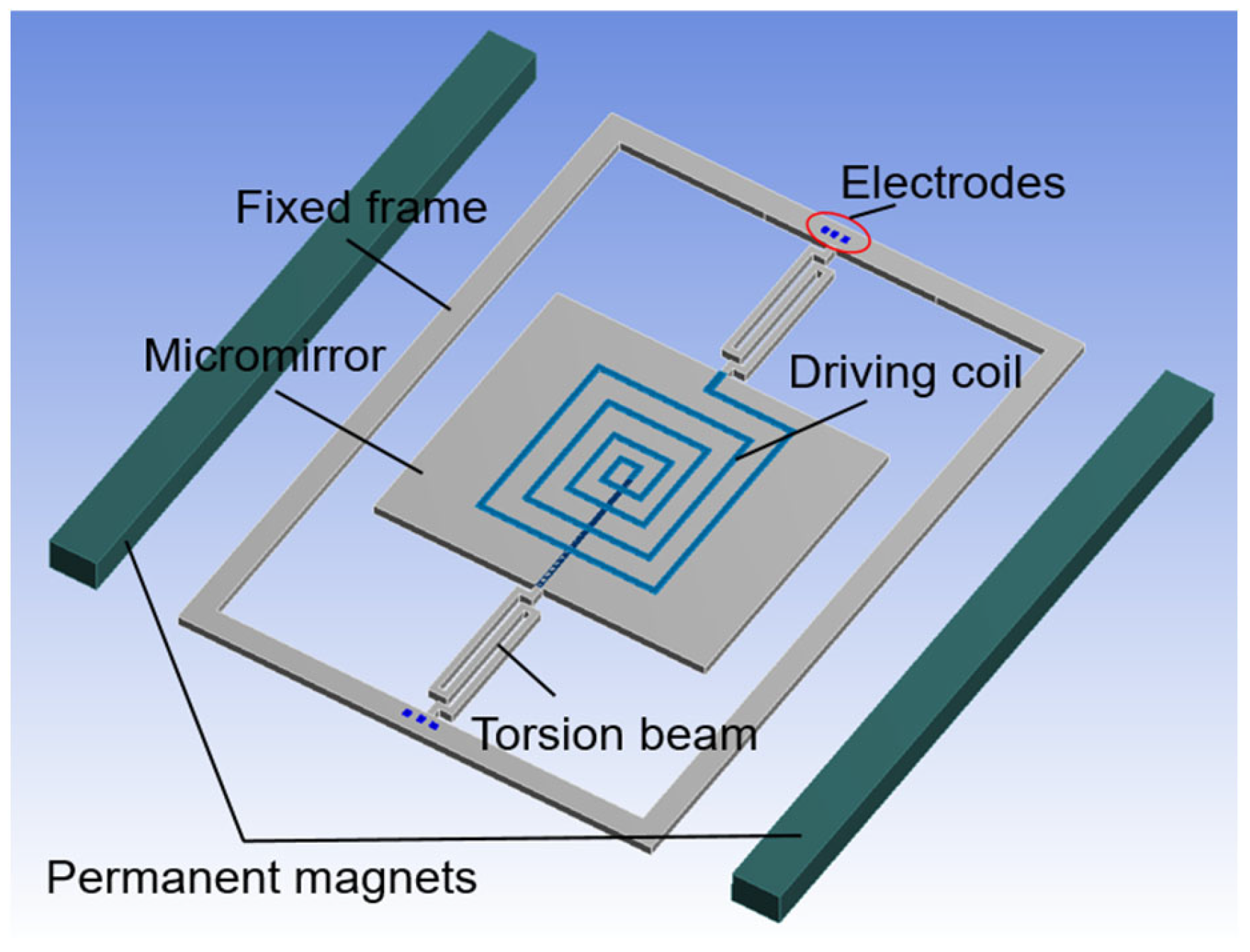

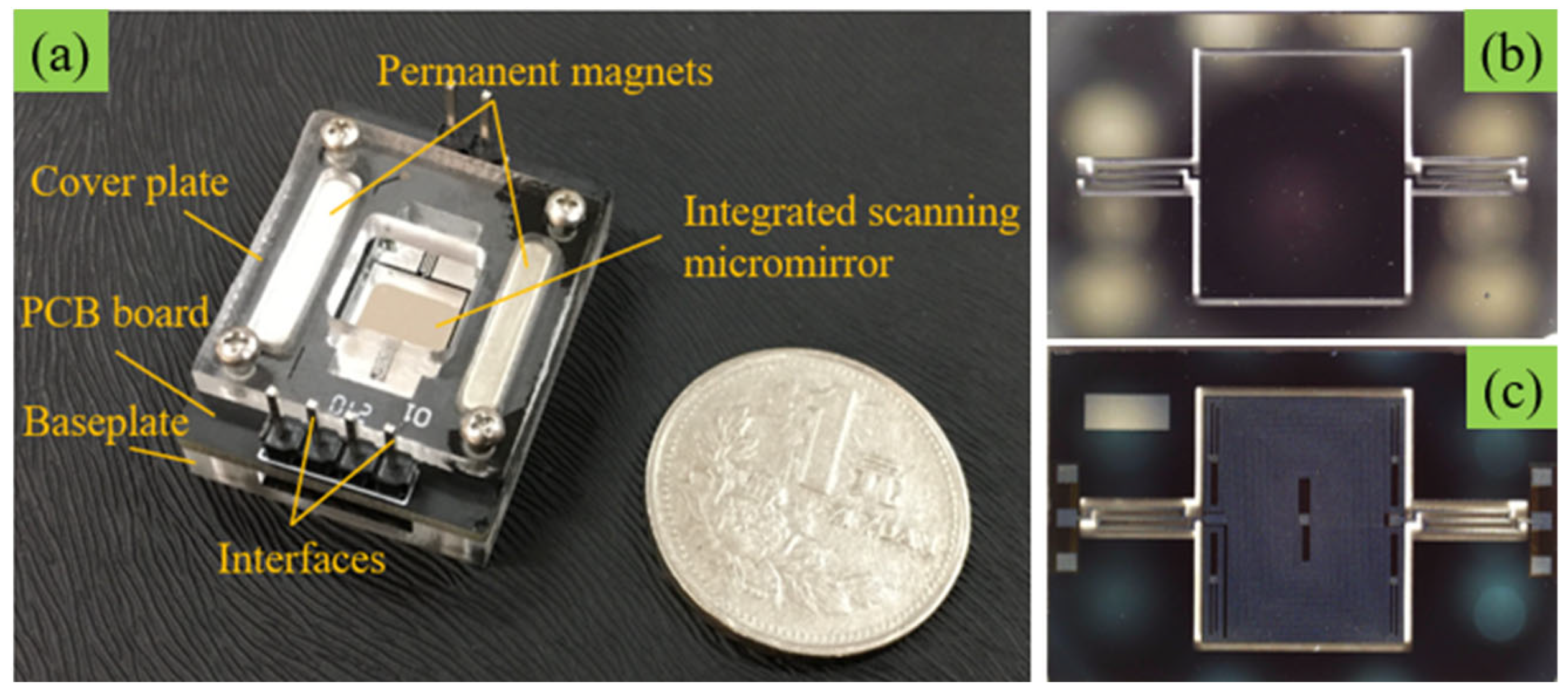

2. Structure and Working Principle

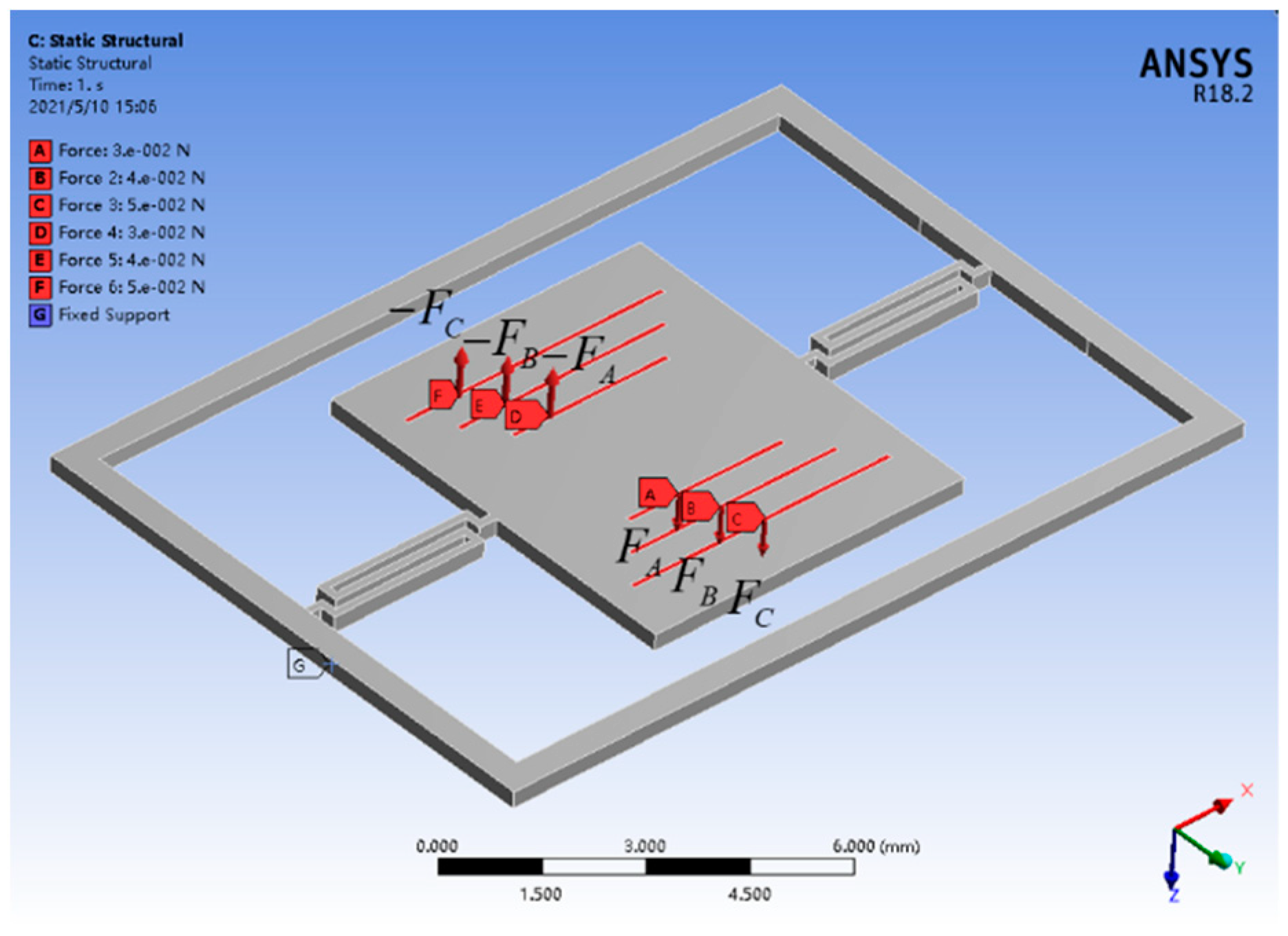

3. Simulation Analysis and Design

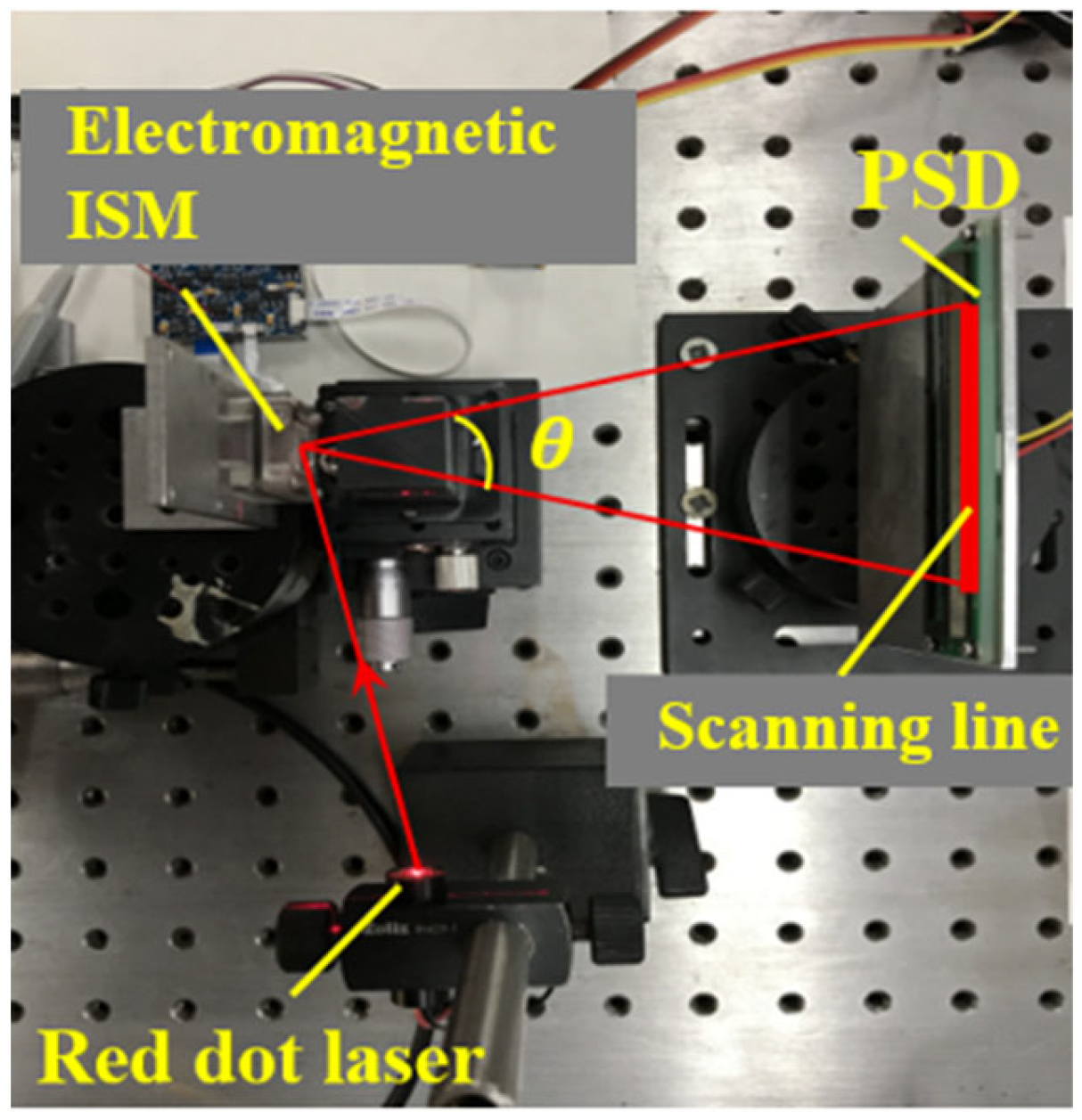

4. Test and Analysis

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Kim, J.H.; Jeong, H.; Lee, S.K.; Ji, C.H.; Park, J.H. Electromagnetically actuated biaxial scanning micromirror fabricated with silicon on glass wafer. Microsyst. Technol. 2017, 23, 2075–2085. [Google Scholar] [CrossRef]

- Lei, H.; Wen, Q.; Yu, F.; Li, D.; Shang, Z.; Huang, J.; Wen, Z. AlN fifilm based piezoelectric large-aperture MEMS scanning micromirror integrated with angle sensors. J. Micromech. Microeng. 2018, 28, 115012. [Google Scholar] [CrossRef]

- Tan, V.J.; He, S.Y. Oscillation FPCB micromirror based triangulation laser rangefifinder. J. Micromech. Microeng. 2020, 30, 095008. [Google Scholar] [CrossRef]

- Aoyagi, I.; Shimaoka, K.; Kato, S.; Makishi, W.; Kawai, Y.; Tanaka, S.; Hane, K. 2-axis MEMS scanner for a laser range fifinder. In Proceedings of the 16th International Conference on Optical MEMS and Nanophotonics, Istanbul, Turkey, 8–11 August 2011. [Google Scholar]

- Balage, J.M.; Silva, S.D.L.; Gomide, C.A.; de Bonin, M.N.; Figueira, A.C. Predicting pork quality using Vis/NIR spectroscopy. Meat Sci. 2015, 108, 37–43. [Google Scholar] [CrossRef]

- Porep, J.U.; Kammerer, D.R.; Carle, R. On line application of near infrared (NIR) spectroscopy in food production. Trends Food Sci. Technol. 2015, 46, 211–230. [Google Scholar] [CrossRef]

- Blasco, J.; Lorente, D.; Cortes, V.; Talens, P.; Cubero, S.; Munera, S.; Aleixos, N. Application of near infrared spectroscopy to the quality control of citrus fruits and mango. NIR News 2016, 27, 4–7. [Google Scholar] [CrossRef] [Green Version]

- Karande, A.D.; Heng, W.S.P.; Liew, C.V. In line quantifification of micronized drug and excipients in tablets by near infrared (NIR) spectroscopy: Real time monitoring of tabletting process. Int. J. Pharm. 2010, 396, 63–74. [Google Scholar] [CrossRef] [PubMed]

- Periyasamy, K.G.K.; Zuo, H.; He, S. Flexible printed circuit board magnetic micromirror for laser marking/engraving. J. Micromech. Microeng. 2019, 29, 085001. [Google Scholar] [CrossRef]

- Nagasawa, T.; Oguchi, Y.; Iwase, E. Operation of three-dimensional MEMS mirror by single superposed driving signal. Jpn. J. Appl. Phys. 2017, 56, 06GN12. [Google Scholar] [CrossRef] [Green Version]

- Yu, F.; Wen, Q.; Lei, H.; Huang, L.; Wen, Z. A compound control system for FR4-based electromagnetic scanning micrograting. Electronics 2019, 8, 770. [Google Scholar] [CrossRef] [Green Version]

- Chen, M.; Yu, H.; Guo, S.; Xu, R.; Shen, W. An electromagnetically-driven MEMS micromirror for laser projection. In Proceedings of the 10th IEEE International Conference on Nano/Micro Engineered and Molecular Systems, Xi’an, China, 7–11 April 2015. [Google Scholar]

- Naono, T.; Fujii, T.; Esashi, M.; Tanaka, S. A large-scan-angle piezoelectric MEMS optical scanner actuated by a Nb-doped PZT thin fifilm. J. Micromech. Microeng. 2014, 24, 5010. [Google Scholar] [CrossRef]

- Baran, U.; Brown, D.; Holmstrom, S.; Balma, D.; Davis, W.O.; Muralt, P.; Urey, H. Resonant PZT MEMS scanner for high-resolution displays. J. Microelectromech. Syst. 2012, 21, 1303–1310. [Google Scholar] [CrossRef] [Green Version]

- Nie, Q.Y.; Wen, Z.Y.; Huang, J. A high-performance scanning grating based on tilted (111) silicon wafer for near infrared micro spectrometer application. Microsyst. Technol. 2015, 21, 1749–1755. [Google Scholar] [CrossRef]

- Wen, Q.; Lei, H.; Huang, J.; Yu, F.; Huang, L.; Zhang, J.; Li, D.; Peng, Y.; Wen, Z. FR4-based electromagnetic scanning micro-grating integrated with an angle sensor for a low-cost NIR micro-spectrometer. Appl. Opt. 2019, 58, 4642–4646. [Google Scholar] [CrossRef] [PubMed]

- Suzuki, J.; Onishi, Y.; Terao, K.; Takao, H.; Shimokawa, F.; Oohira, F.; Miyagawa, H.; Namazu, T.; Suzuki, T. Development of a two-dimensional scanning micro-mirror utilizing magnetic polymer composite. Jpn. J. Appl. Phys. 2016, 55, 06GP01. [Google Scholar] [CrossRef]

- Ou, C.H.; Lin, Y.C.; Keikoin, Y.; Ono, T.; Esashi, M.; Tsai, Y.C. Two-dimensional MEMS Fe-based metallic glass micromirror driven by an electromagnetic actuator. Jpn. J. Appl. Phys. 2019, 58, SDDL01. [Google Scholar] [CrossRef]

- Zhou, Y.; Wen, Q.; Wen, Z.Y.; Huang, J.; Chang, F. An electromagnetic scanning mirror integrated with blazed grating and angle sensor for a near infrared micro spectrometer. J. Micromech. Microeng. 2017, 27, 125009. [Google Scholar] [CrossRef] [Green Version]

- Zhou, Y.; Wen, Q.; Wen, Z.; Yang, T. Modeling of MOEMS electromagnetic scanning grating mirror for NIR micro-spectrometer. AIP Adv. 2016, 6, 025025. [Google Scholar] [CrossRef] [Green Version]

- Shao, J.; Li, Q.; Feng, C.; Li, W.; Yu, H.B. AlN based piezoelectric micromirror. Opt. Lett. 2018, 43, 987–990. [Google Scholar] [CrossRef] [PubMed]

- Zuo, H.; He, S. FPCB ring-square electrode sandwiched micromirror-based laser pattern pointer. IEEE Trans. Ind. Electron. 2017, 64, 6319–6329. [Google Scholar] [CrossRef]

- Chen, H.; Pallapa, M.; Sun, W.J.; Sun, Z.D.; Yeow, J.T.W. Nonlinear control of an electromagnetic polymer MEMS hard-magnetic micromirror and its imaging application. J. Micromech. Microeng. 2014, 24, 045004. [Google Scholar] [CrossRef]

- Watanabe, Y.; Takahashi, Y.; Abe, Y.; Iwamatsu, S.; Yahagi, T.; Kobayashi, S.; Konno, S.; Sato, T. Electromagnetically Dual-Axis Driven MEMS Grating and Its Application to 3D Profiling with Near-Infrared Low-Coherence Interferometry. Electron. Commun. Jpn. 2013, 96, 31–36. [Google Scholar] [CrossRef]

| Number | Type | Fore [FA, FB, FC] (N) | Ratio of Maximum Stress to Maximum Displacement |

|---|---|---|---|

| 1 | Bilateral force | 0.010, 0.012, 0.014 | 683.77 |

| 2 | 0.020, 0.024, 0.028 | 683.81 | |

| 3 | 0.024, 0.028, 0.032 | 683.81 | |

| 4 | 0.032, 0.034, 0.036 | 683.81 | |

| 5 | Unilateral force | 0.010, 0.012, 0.014 | 708.39 |

| 6 | 0.020, 0.024, 0.028 | 710.15 | |

| 7 | 0.024, 0.028, 0.032 | 708.75 | |

| 8 | 0.032, 0.034, 0.036 | 709.88 |

| Mark | Remanence (T) | Coercive Force (KA/m) | Size (mm3) | Spacing (mm) |

|---|---|---|---|---|

| N35 | 1.22 | 890 | 15 × 3 × 5 | 22 |

| N38 | 1.25 | 910 | 15 × 3 × 6 | 12 |

| N52 | 1.39 | 915 | 20 × 3 × 10 | 10.6 |

| Mark | ISM Chip | Driving Coil Resistance | Driving Voltage | Maximum Deflection Angle |

|---|---|---|---|---|

| N35 | A1 | 56.05 Ω | 5.12 Vpp | 2.11° |

| A2 | 59.58 Ω | 7.50 Vpp | 2.24° | |

| N38 | A3 | 69.49 Ω | 2.72 Vpp | 4.89° |

| A4 | 66.10 Ω | 2.84 Vpp | 4.81° |

| Mark | ISM Chip | Driving Coil Resistance | Resonant Frequency | Driving Voltage | Maximum Deflection Angle |

|---|---|---|---|---|---|

| N38 | B1 | 90.13 Ω | 520.0 Hz | 1.51 Vpp | 5.85° |

| B2 | 113.13 Ω | 604.5 Hz | 2.57 Vpp | 6.03° | |

| N52 | B1 | 90.13 Ω | 523.8 Hz | 1.41 Vpp | 7.03° |

| B2 | 113.13 Ω | 604.4 Hz | 2.35 Vpp | 7.08° |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Chen, L.; Gu, W. Improvement and Optimization of Electromagnetic Integrated Scanning Micromirror. Micromachines 2021, 12, 1213. https://doi.org/10.3390/mi12101213

Chen L, Gu W. Improvement and Optimization of Electromagnetic Integrated Scanning Micromirror. Micromachines. 2021; 12(10):1213. https://doi.org/10.3390/mi12101213

Chicago/Turabian StyleChen, Liang, and Wenwen Gu. 2021. "Improvement and Optimization of Electromagnetic Integrated Scanning Micromirror" Micromachines 12, no. 10: 1213. https://doi.org/10.3390/mi12101213

APA StyleChen, L., & Gu, W. (2021). Improvement and Optimization of Electromagnetic Integrated Scanning Micromirror. Micromachines, 12(10), 1213. https://doi.org/10.3390/mi12101213