State-of-the-Art and Perspectives on Silicon Waveguide Crossings: A Review

Abstract

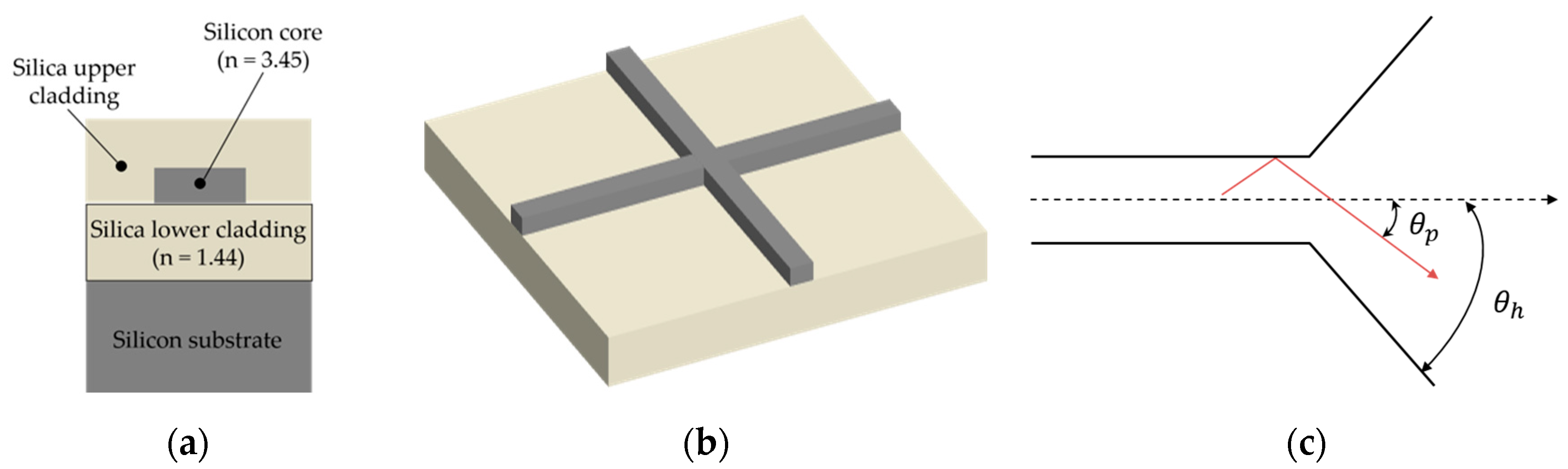

1. Introduction

2. The Key Technologies of Silicon Waveguide Crossing

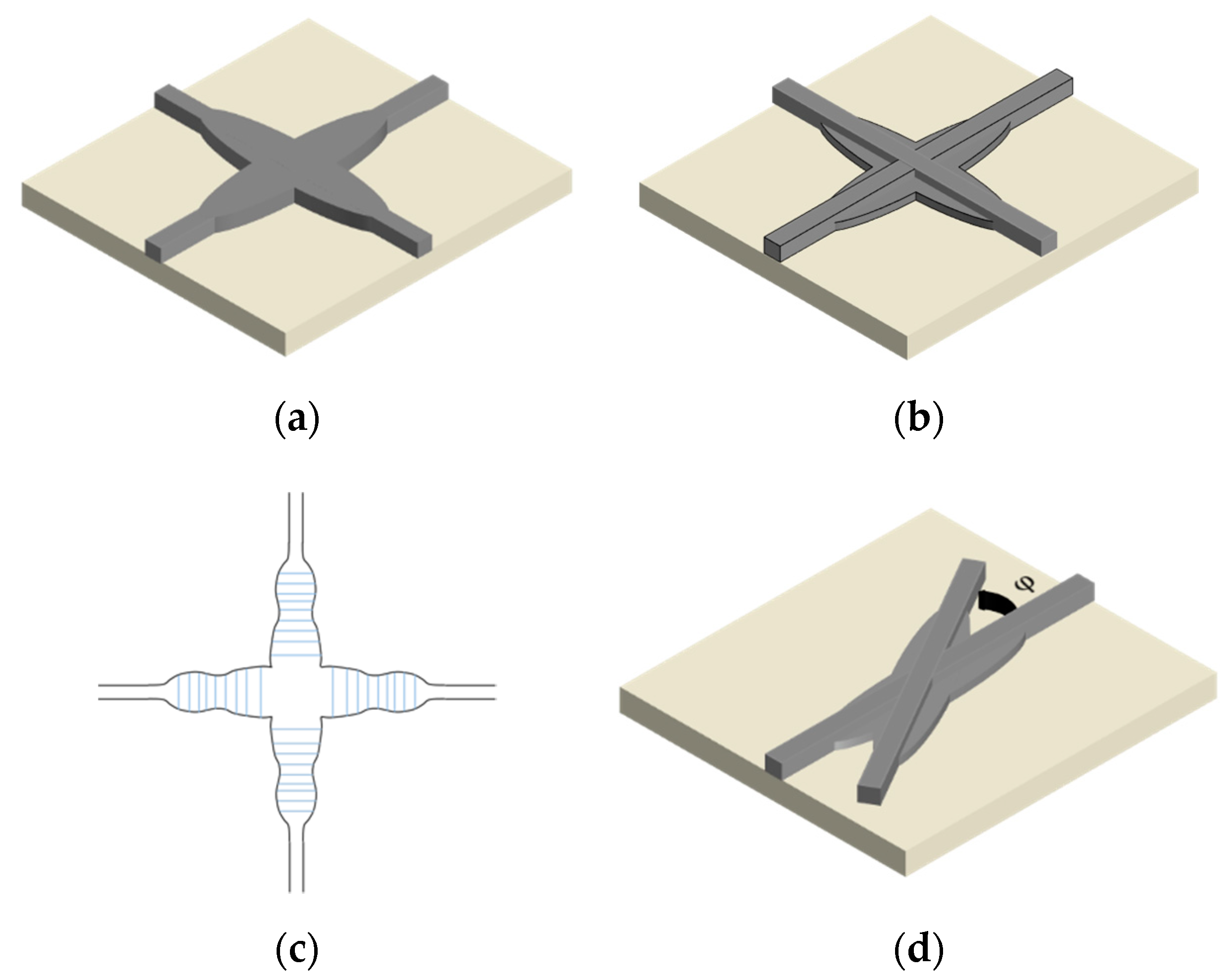

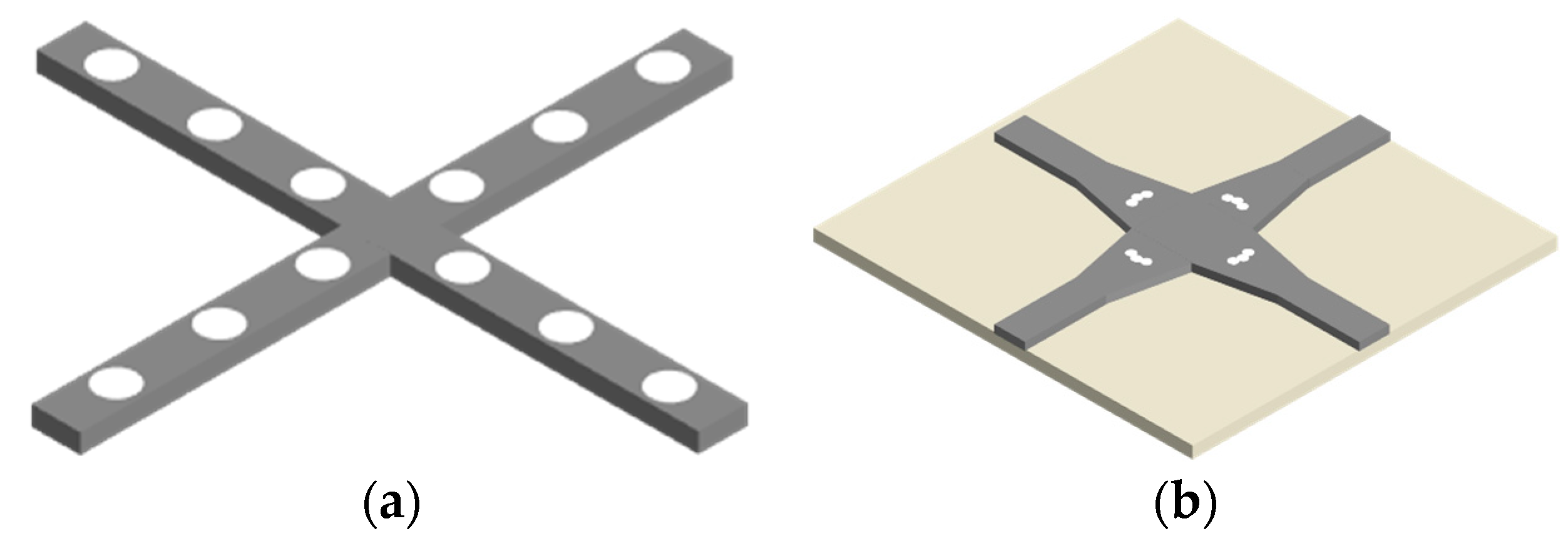

2.1. Shaped Taper Method

2.2. Multimode Interference Method

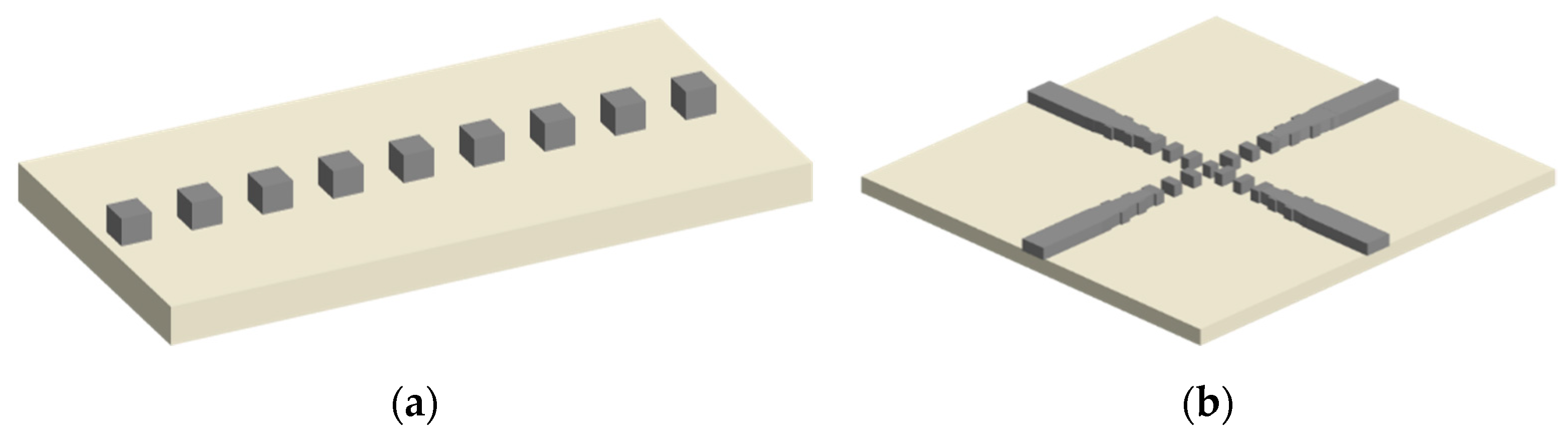

2.3. Sub-Wavelength Grating Method

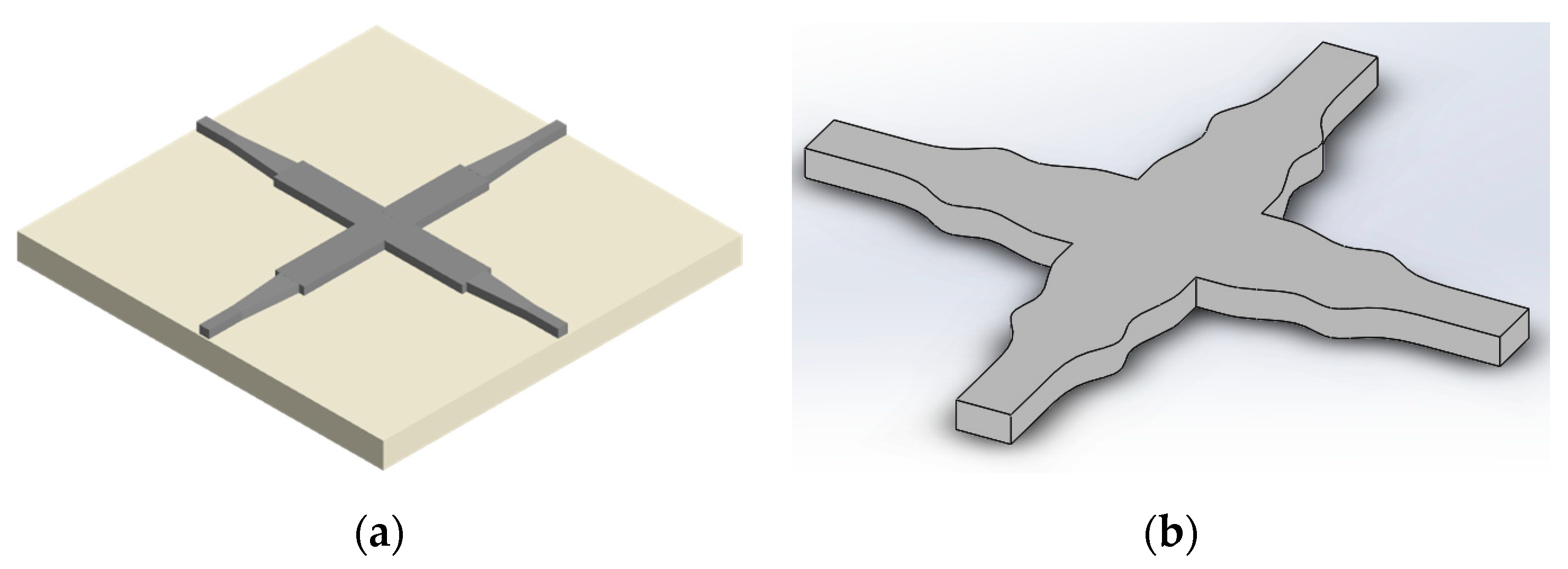

2.4. Holey Subwavelength Grating Method

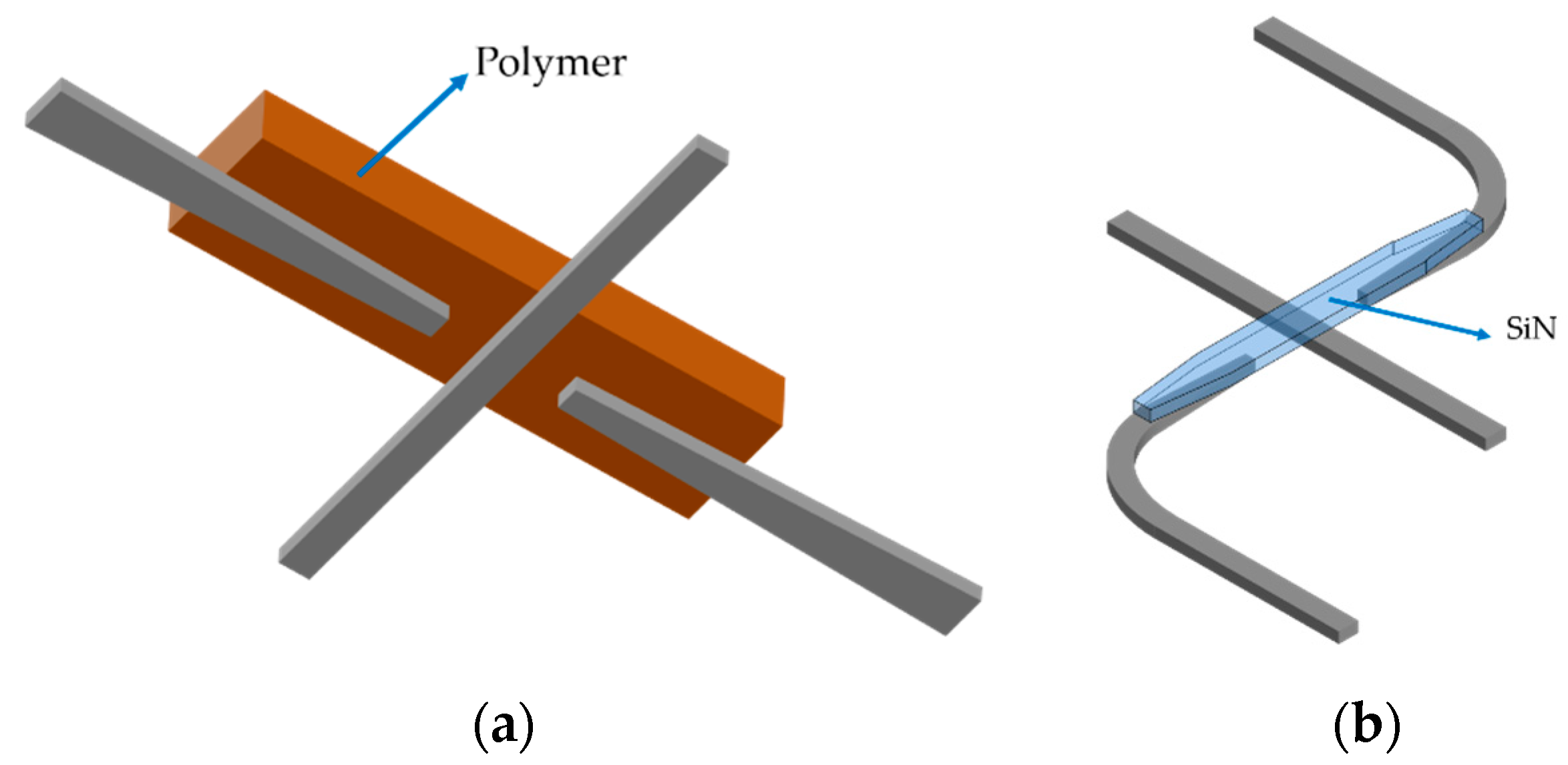

2.5. Vertical Directional Coupler Method

3. The Future Trends of Silicon Waveguide Crossing

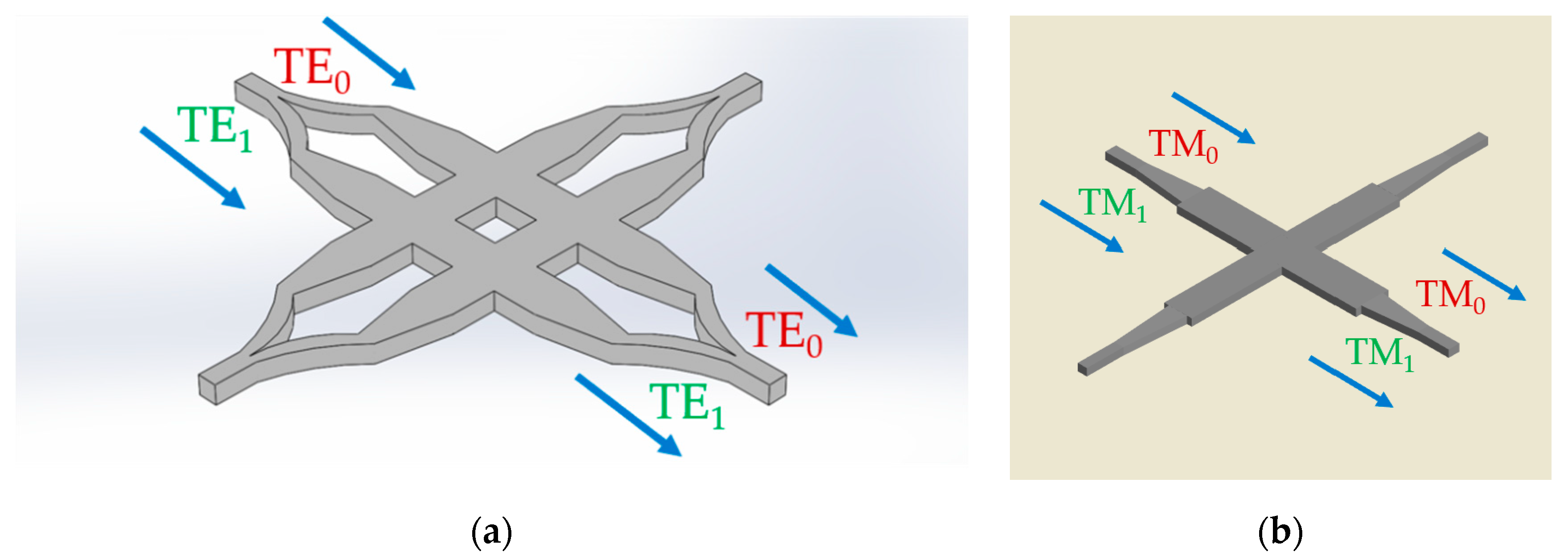

3.1. Mode-Division-Multiplexing Technology

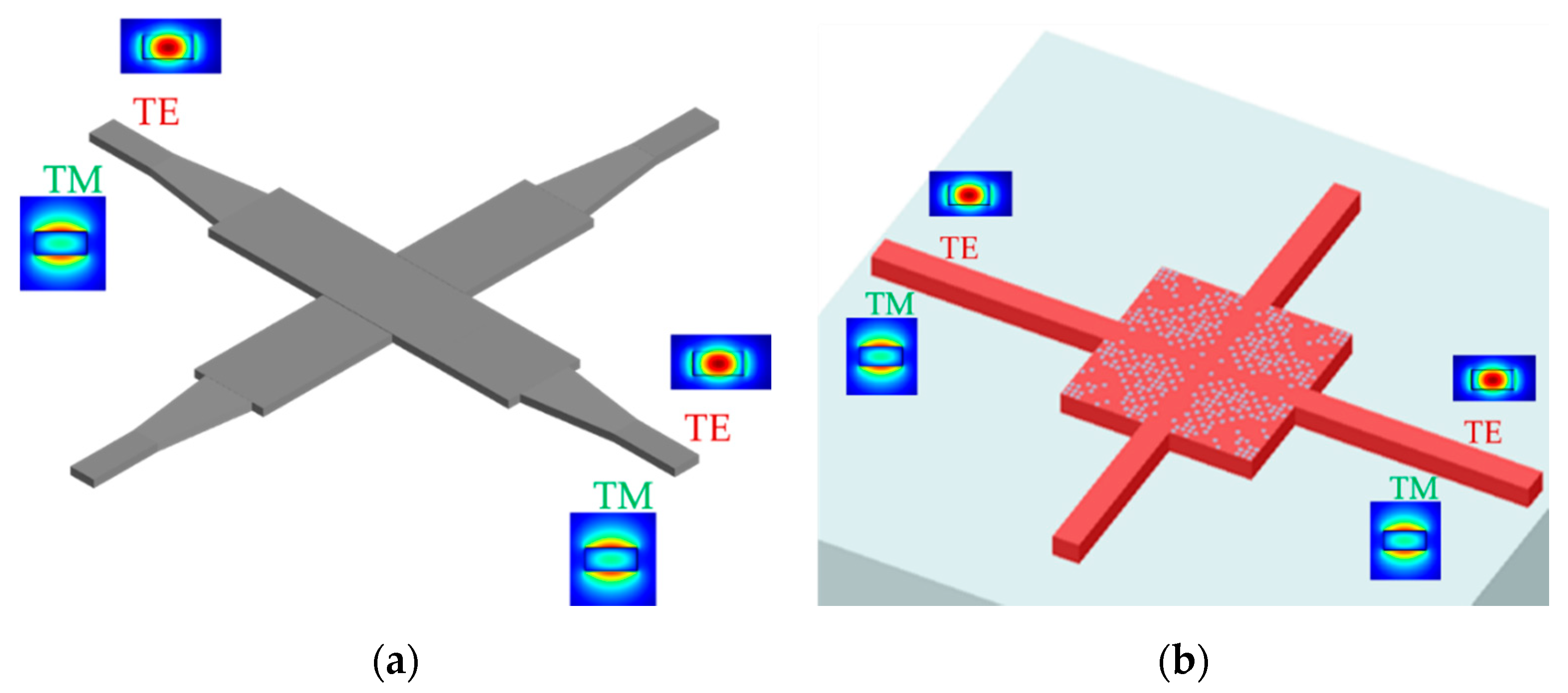

3.2. Polarization-Division-Multiplexing Technology

3.3. Summary

4. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Fang, Z.; Zhao, C.Z. Recent Progress in Silicon Photonics: A Review. ISRN Opt. 2012, 2012, 1–27. [Google Scholar] [CrossRef]

- Waldrop, M.M. More than moore. Nature 2016, 530, 144–148. [Google Scholar] [CrossRef]

- Photonic-Electronic Integrated Circuits. Available online: https://www.edmundoptics.com/resources/trending-in-optics/photonic-electronic-integrated-circuits/ (accessed on 8 February 2020).

- Doylend, J.K.; Knights, A.P. The evolution of silicon photonics as an enabling technology for optical interconnection. Laser Photonics Rev. 2012, 6, 504–525. [Google Scholar] [CrossRef]

- Smit, M.; van der Tol, J.; Hill, M. Moore’s law in photonics. Laser Photonics Rev. 2012, 6, 1–13. [Google Scholar] [CrossRef]

- Zou, Y.; Chakravarty, S.; Chung, C.J.; Xu, X.; Chen, R.T. Mid-infrared silicon photonic waveguides and devices. Photonics Res. 2018, 6, 254–276. [Google Scholar] [CrossRef]

- Hu, T.; Dong, B.; Luo, X.; Liow, T.Y.; Song, J.; Lee, C.; Lo, G.Q. Silicon photonic platforms for mid-infrared applications. Photonics Res. 2017, 1, 417–430. [Google Scholar] [CrossRef]

- Lin, H.; Luo, Z.; Gu, T.; Kimerling, L.C.; Wada, K.; Agarwal, A.; Hu, J. Mid-infrared integrated photonics on silicon: A perspective. Nanophotonics 2017, 7, 393–420. [Google Scholar] [CrossRef]

- Ram, R.J. CMOS Photonic Integrated Circuits. In Proceedings of the 2012 Optical Fiber Communication Conference, Los Angeles, CA, USA, 4–8 March 2012. [Google Scholar]

- Soref, R. The Past, Present, and Future of Silicon Photonics. IEEE J. Sel. Top. Quantum Electron. 2006, 12, 1678–1687. [Google Scholar] [CrossRef]

- Stojanović, V.; Ram, R.J.; Popović, M.; Lin, S.; Moazeni, S.; Wade, M.; Sun, C.; Alloatti, L.; Atabaki, A.; Pavanello, F.; et al. Monolithic silicon-photonic platforms in state-of-the-art CMOS SOI processes [Invited]. Opt. Express 2018, 26, 13106–13121. [Google Scholar]

- Rickman, A. The commercialization of silicon photonics. Nat. Photonics 2014, 8, 579. [Google Scholar] [CrossRef]

- Soref, R.; Lorenzo, J. Single-crystal silicon: A new material for 1.3 and 1.6 μm integrated-optical components. Electron. Lett. 1985, 21, 953–954. [Google Scholar] [CrossRef]

- Thomson, D.; Zilkie, A.; Bowers, J.E.; Komljenovic, T.; Reed, G.T.; Vivien, L.; Marris-Morini, D.; Cassan, E.; Virot, L.; Fédéli, J.M.; et al. Roadmap on silicon photonics. J. Opt. 2016, 18, 73003. [Google Scholar] [CrossRef]

- Wen, K.; Rumley, S.; Samadi, P.; Chen, C.P.; Bergman, K. Silicon photonics in post Moore’s Law era: Technological and architectural implications. In Proceedings of the 2016 Conference on International Workshop on Post Moore’s Era Supercomputing, Salt Laker City, UT, USA, 11–14 November 2016; p. 12. [Google Scholar]

- Watari, T.; Murano, H. Packaging Technology for the NEC SX Supercomputer. IEEE Trans. Compon. Hybrids Manuf. Technol. 1985, 8, 462–467. [Google Scholar] [CrossRef]

- Bogaerts, W.; Fiers, M.; Dumon, P. Design challenges in silicon photonics. IEEE J. Sel. Top. Quantum Electron. 2013, 20, 1–8. [Google Scholar] [CrossRef]

- Fukazawa, T.; Hirano, T.; Ohno, F.; Baba, T. Low Loss Intersection of Si Photonic Wire Waveguides. Jpn. J. Appl. Phys. 2004, 43, 646–647. [Google Scholar] [CrossRef][Green Version]

- Sherwood-Droz, N.; Wang, H.; Chen, L.; Lee, B.G.; Biberman, A.; Bergman, K.; Lipson, M. Optical 4x4 hitless slicon router for optical networks-on-chip (NoC). Opt. Express 2008, 16, 15915–15922. [Google Scholar] [CrossRef]

- Hu, T.; Qiu, H.; Yu, P.; Qiu, C.; Wang, W.; Jiang, X.; Yang, M.; Yang, J. Wavelength-selective 4×4 nonblocking silicon optical router for networks-on-chip. Opt. Lett. 2011, 36, 4710–4712. [Google Scholar] [CrossRef]

- Sakai, A.; Hara, G.; Baba, T. Propagation characteristics of ultrahigh-Δ optical waveguide on silicon-on-insulator substrate. Jpn. J. Appl. Phys. 2001, 40, L383. [Google Scholar] [CrossRef]

- Qiu, C.; Sheng, Z.; Li, H.; Liu, W.; Li, L.; Pang, A.; Wu, A.; Wang, X.; Zou, S.; Gan, F. Fabrication, characterization and loss analysis of silicon nanowaveguides. J. Lightwave Technol. 2014, 32, 2303–2307. [Google Scholar] [CrossRef]

- Vlasov, Y.; McNab, S. Losses in single-mode silicon-on-insulator strip waveguides and bends. Opt. Express 2004, 12, 1622–1631. [Google Scholar] [CrossRef]

- Liu, H.; Tam, H.; Wai, P.K.A.; Pun, E. Low-loss waveguide crossing using a multimode interference structure. Opt. Commun. 2004, 241, 99–104. [Google Scholar] [CrossRef]

- Burns, W.K.; Milton, A.F.; Lee, A.B. Optical waveguide parabolic coupling horns. Appl. Phys. Lett. 1977, 30, 28–30. [Google Scholar] [CrossRef]

- Fu, Y.; Ye, T.; Tang, W.; Chu, T. Efficient adiabatic silicon-on-insulator waveguide taper. Photonics Res. 2014, 2, A41–A44. [Google Scholar] [CrossRef]

- Nelson, A.R. Coupling optical waveguides by tapers. Appl. Opt. 1975, 14, 3012–3015. [Google Scholar] [CrossRef]

- Bogaerts, W.; Dumon, P.; Van Thourhout, D.; Baets, R. Low-loss, low-cross-talk crossings for silicon-on-insulator nanophotonic waveguides. Opt. Lett. 2007, 32, 2801–2803. [Google Scholar] [CrossRef]

- Sanchis, P.; Villalba, P.; Cuesta, F.; Håkansson, A.; Griol, A.; Galán, J.V.; Brimont, A.; Martí, J. Highly efficient crossing structure for silicon-on-insulator waveguides. Opt. Lett. 2009, 34, 2760–2762. [Google Scholar] [CrossRef]

- Ma, Y.; Zhang, Y.; Yang, S.; Novack, A.; Ding, R.; Lim, A.E.J.; Lo, G.Q.; Baehr-Jones, T.; Hochberg, M. Ultralow loss single layer submicron silicon waveguide crossing for SOI optical interconnect. Opt. Express 2013, 21, 29374–29382. [Google Scholar] [CrossRef]

- Xie, Y.; Xu, J.; Zhang, J. Elimination of cross-talk in silicon-on-insulator waveguide crossings with optimized angle. Opt. Eng. 2011, 50, 064601. [Google Scholar]

- Tanaka, D.; Shoji, Y.; Kintaka, K.; Kawashima, H.; Ikuma, Y.; Tsuda, H. Low-crosstalk offset crossing waveguide fabricated on SOI substrates. In Proceedings of the 2010 OECC, Sapporo, Japan, 5–9 July 2010; pp. 870–871. [Google Scholar]

- Amin, S.; Aziz, K. Multimode interference (MMI) devices: A survey. In Proceedings of the 2010 the 8th International Conference on Frontiers of Information Technology, Islamabad, Pakistan, 21–23, December 2010; pp. 1–6. [Google Scholar]

- Soldano, L.B.; Pennings, E.C.M. Optical multi-mode interference devices based on self-imaging: Principles and applications. J. Lightwave Technol. 1995, 13, 615–627. [Google Scholar] [CrossRef]

- Stuart, H.R. Waveguide lenses with multimode interference for low-loss slab propagation. Opt. Lett. 2003, 28, 2141–2143. [Google Scholar] [CrossRef]

- Chen, H.; Poon, A.W. Low-Loss Multimode-Interference-Based Crossings for Silicon Wire Waveguides. IEEE Photonics Technol. Lett. 2006, 18, 2260–2262. [Google Scholar] [CrossRef]

- Chen, C.H.; Chiu, C.-H. Taper-integrated multimode-interference based waveguide crossing design. IEEE J. Quantum Electron. 2010, 46, 1656–1661. [Google Scholar] [CrossRef]

- Chen, C.H. Compact waveguide crossings with a cascaded multimode tapered structure. Appl. Opt. 2015, 54, 828–833. [Google Scholar] [CrossRef]

- Dumais, P.; Goodwill, D.J.; Celo, D.; Jiang, J.; Bernier, E. Three-mode synthesis of slab Gaussian beam in ultra-low-loss in-plane nanophotonic silicon waveguide crossing. In Proceedings of the 14th International Conference on Group IV Photonics, Berlin, Germany, 23–25 August 2017; pp. 97–98. [Google Scholar]

- Popović, M.A.; Ippen, E.P.; Kärtner, F.X. Low-loss bloch waves in open structures and highly compact, efficient Si waveguide-crossing arrays. In Proceedings of the 2007 Conference on Lasers and Electro-Optics Society Annual Meeting, Tallahassee, FL, USA, 21–25 October 2007; pp. 56–57. [Google Scholar]

- Xu, Y.; Wang, J.; Xiao, J.; Sun, X. Design of a compact silicon-based slot–waveguide crossing. Appl. Opt. 2013, 52, 3737–3744. [Google Scholar] [CrossRef]

- Kim, S.H.; Cong, G.; Kawashima, H.; Hasama, T.; Ishikawa, H. Low-crosstalk waveguide crossing based on 1 × 1 MMI structure of silicon-wire waveguide. In Proceedings of the 2013 Pacific Rim Conference on Lasers and Electro-Optics, Kyoto, Japan, 30 June–4 July 2013; pp. 1–2. [Google Scholar]

- García-Meca, C.; Lechago, S.; Brimont, A.; Griol, A.; Mas, S.; Sánchez, L.; Bellieres, L.; Losilla, N.S.; Martí, J. On-chip wireless silicon photonics: From reconfigurable interconnects to lab-on-chip devices. Light Sci. Appl. 2017, 6, e17053. [Google Scholar] [CrossRef]

- Xu, H.; Shi, Y. Metamaterial-Based Maxwell’s Fisheye Lens for Multimode Waveguide Crossing. Laser Photonics Rev. 2018, 12, 10. [Google Scholar] [CrossRef]

- Li, S.; Zhou, Y.; Dong, J.; Zhang, X.; Cassan, E.; Hou, J.; Yang, C.; Chen, S.; Gao, D.; Chen, H. Universal multimode waveguide crossing based on transformation optics. Optica 2018, 5, 1549–1556. [Google Scholar] [CrossRef]

- Chen, D.; Wang, L.; Zhang, Y.; Hu, X.; Xiao, X.; Yu, S. Ultralow crosstalk and loss CMOS compatible silicon waveguide star-crossings with arbitrary included angles. ACS Photonics 2018, 5, 4098–4103. [Google Scholar] [CrossRef]

- Tamm, I.E.; Ginzburg, V.L. Theory of electromagnetic processes in a layered core. Izv. Akad. Nauk SSSR Ser. Fiz. 1943, 7, 30–51. [Google Scholar]

- Rytov, S. Electromagnetic properties of a finely stratified medium. Sov. Phys. JEPT 1956, 2, 466–475. [Google Scholar]

- Taillaert, D.; Bienstman, P.; Baets, R. Compact efficient broadband grating coupler for silicon-on-insulator waveguides. Opt. Lett. 2004, 29, 2749–2751. [Google Scholar] [CrossRef]

- Shyh, W. Principles of distributed feedback and distributed Bragg-reflector lasers. IEEE J. Quantum Electron. 1974, 10, 413–427. [Google Scholar] [CrossRef]

- Halir, R.; Bock, P.J.; Cheben, P.; Ortega-Moñux, A.; Alonso-Ramos, C.; Schmid, J.H.; Lapointe, J.; Xu, D.X.; Wangüemert-Pérez, J.G.; Molina-Fernández, Í.; et al. Waveguide sub-wavelength structures: A review of principles and applications. Laser Photonics Rev. 2015, 9, 25–49. [Google Scholar] [CrossRef]

- Bock, P.J.; Cheben, P.; Schmid, J.H.; Lapointe, J.; Delâge, A.; Janz, S.; Aers, G.C.; Xu, D.X.; Densmore, A.; Hall, T.J. Subwavelength grating periodic structures in silicon-on-insulator: A new type of microphotonic waveguide. Opt. Express 2010, 18, 20251–20262. [Google Scholar] [CrossRef] [PubMed]

- Chen, L.R.; Wang, J.; Naghdi, B.; Glesk, I. Subwavelength Grating Waveguide Devices for Telecommunications Applications. IEEE J. Sel. Top. Quantum Electron. 2018, 25, 1–11. [Google Scholar] [CrossRef]

- Bock, P.J.; Cheben, P.; Schmid, J.H.; Lapointe, J.; Delâge, A.; Xu, D.X.; Janz, S.; Densmore, A.; Hall, T.J. Subwavelength grating crossings for silicon wire waveguides. Opt. Express 2010, 18, 16146–16155. [Google Scholar] [CrossRef]

- Schmid, J.H.; Cheben, P.; Janz, S.; Lapointe, J.; Post, E.; Delâge, A.; Densmore, A.; Lamontagne, B.; Waldron, P.; Xu, D.X. Subwavelength Grating Structures in Silicon-on-Insulator Waveguides. Adv. Opt. Technol. 2008, 2008, 685489. [Google Scholar] [CrossRef]

- Zhang, Y.; Hosseini, A.; Xu, X.; Kwong, D.; Chen, R.T. Ultralow-loss silicon waveguide crossing using Bloch modes in index-engineered cascaded multimode-interference couplers. Opt. Lett. 2013, 38, 3608–3611. [Google Scholar] [CrossRef]

- Shen, B.; Wang, P.; Polson, R.; Menon, R. An integrated-nanophotonics polarization beamsplitter with 2.4 × 2.4 μm2 footprint. Nat. Photonics 2015, 9, 378–382. [Google Scholar] [CrossRef]

- Johnson, S.G.; Manolatou, C.; Fan, S.; Villeneuve, P.R.; Joannopoulos, J.D.; Haus, H.A. Elimination of cross talk in waveguide intersections. Opt. Lett. 1998, 23, 1855–1857. [Google Scholar] [CrossRef]

- Manolatou, C.; Steven, G.; Johnson, S.F.; Pierre, R.; Villeneuve, H.A.; Haus, J.D. High-Density Integrated Optics. J. Lightwave Technol. 1999, 17, 1682–1692. [Google Scholar] [CrossRef]

- Han, H.L.; Li, H.; Zhang, X.P.; Liu, A.; Lin, T.Y.; Chen, Z.; Lv, H.B.; Lu, M.H.; Liu, X.P.; Chen, Y.F. High performance ultra-compact SOI waveguide crossing. Opt. Express 2018, 26, 25602–25610. [Google Scholar] [CrossRef] [PubMed]

- Xu, P.; Zhang, Y.; Shao, Z.; Yang, C.; Liu, L.; Chen, Y.; Yu, S. 5 × 5 μm2 compact waveguide crossing optimized by genetic algorithm. In Proceedings of the 2017 Conference on Asia Communications and Photonics Conference, Guangzhou, China, 10–13 November 2017; pp. 1–3. [Google Scholar]

- Lu, L.; Zhang, M.; Zhou, F.; Chang, W.; Tang, J.; Li, D.; Ren, X.; Pan, Z.; Cheng, M.; Liu, D. Inverse-designed ultra-compact star-crossings based on PhC-like subwavelength structures for optical intercross connect. Opt. Express 2017, 25, 18355–18364. [Google Scholar] [CrossRef] [PubMed]

- Wakayama, Y.; Kita, T.; Yamada, H. Optical crossing and integration using hybrid si-wire/silica waveguides. Jpn. J. Appl. Phys. 2011, 50, 4–20. [Google Scholar] [CrossRef]

- Sun, R.; Beals, M.; Pomerene, A.; Cheng, J.; Hong, C.Y.; Kimerling, L.; Michel, J. Impedance matching vertical optical waveguide couplers for dense high index contrast circuits. Opt. Express 2008, 16, 11682–11690. [Google Scholar] [CrossRef]

- Tsarev, A.V. Efficient silicon wire waveguide crossing with negligible loss and crosstalk. Opt. Express 2011, 19, 13732–13737. [Google Scholar] [CrossRef]

- Jones, A.M.; DeRose, C.T.; Lentine, A.L.; Trotter, D.C.; Starbuck, A.L.; Norwood, R.A. Ultra-low crosstalk, CMOS compatible waveguide crossings for densely integrated photonic interconnection networks. Opt. Express 2018, 21, 12002–12013. [Google Scholar] [CrossRef]

- Li, Z.; Shubin, I.; Zhou, X. Optical interconnects: Recent advances and future challenges. Opt. Express 2015, 23, 3717–3720. [Google Scholar] [CrossRef]

- Vahdat, A.; Liu, H.; Zhao, X.; Johnson, C. The emerging optical data center. In Proceedings of the 2011 Conference on Optical Fiber Communication Conference, Los Angeles, CA, USA, 6–10 March 2011. [Google Scholar]

- Li, C.; Wu, H.; Tan, Y.; Wang, S.; Dai, D. Silicon-based on-chip hybrid (de)multiplexers. Sci. China Inf. Sci. 2018, 61, 080407. [Google Scholar] [CrossRef]

- Winzer, P.J. Making spatial multiplexing a reality. Nat. Photonics 2014, 8, 345–348. [Google Scholar] [CrossRef]

- Dai, D.; Bowers, J.E. Silicon-based on-chip multiplexing technologies and devices for Peta-bit optical interconnects. Nanophotonics 2014, 3, 283–311. [Google Scholar] [CrossRef]

- Sun, C.; Yu, Y.; Zhang, X. Ultra-compact waveguide crossing for a mode-division multiplexing optical network. Opt. Lett. 2017, 42, 4913–4916. [Google Scholar] [CrossRef] [PubMed]

- Wu, B.; Yu, Y.; Zhang, X. Ultralow Loss Waveguide Crossing with Low Imbalance for Two Transverse Electric Modes. In Proceedings of the 2018 Conference on Asia Communications and Photonics, Hangzhou, China, 26–29 October 2018; pp. 1–3. [Google Scholar]

- Xu, H.; Shi, Y. Dual-mode waveguide crossing utilizing taper-assisted multimode-interference couplers. Opt. Lett. 2016, 41, 5381–5384. [Google Scholar] [CrossRef] [PubMed]

- Chen, J.; Shi, Y. Polarization-insensitive silicon waveguide crossing based on multimode interference couplers. Opt. Lett. 2018, 43, 5961–5964. [Google Scholar] [CrossRef] [PubMed]

- Yu, Z.; Feng, A.; Xi, X.; Sun, X. Inverse-designed low-loss and wideband polarization-insensitive silicon waveguide crossing. Opt. Lett. 2019, 44, 77–80. [Google Scholar] [CrossRef]

- Wu, S.; Mu, X.; Cheng, L.; Tu, X.; Fu, H.Y. Inverse-designed Compact and Polarization-insensitive Waveguide Crossing. In Proceedings of the 2019 Conference on Asia Communications and Photonics, Chengdu, China, 2–5 November 2019; p. M4A-280. [Google Scholar]

- Li, C.; Liu, D.; Dai, D. Multimode silicon photonics. Nanophotonics 2019, 8, 227–247. [Google Scholar] [CrossRef]

- Wang, J.; Chen, S.; Dai, D. Silicon hybrid demultiplexer with 64 channels for wavelength/mode-division multiplexed on-chip optical interconnects. Opt. Lett. 2014, 39, 6993–6996. [Google Scholar] [CrossRef]

- Koonen, A.M.J.; Chen, H.; van den Boom, H.P.; Raz, O. Silicon Photonic Integrated Mode Multiplexer and Demultiplexer. IEEE Photonics Technol. Lett. 2012, 24, 1961–1964. [Google Scholar] [CrossRef]

- Stern, B.; Zhu, X.; Chen, C.P.; Tzuang, L.D.; Cardenas, J.; Bergman, K.; Lipson, M. On-chip mode-division multiplexing switch. Optica 2015, 2, 530–535. [Google Scholar] [CrossRef]

- Chang, W.; Lu, L.; Ren, X.; Li, D.; Pan, Z.; Cheng, M.; Liu, D.; Zhang, M. Ultra-compact mode (de) multiplexer based on subwavelength asymmetric Y-junction. Opt. Express 2018, 26, 8162–8170. [Google Scholar] [CrossRef]

- Liu, Y.; Xu, K.; Wang, S.; Shen, W.; Xie, H.; Wang, Y.; Xiao, S.; Yao, Y.; Du, J.; He, Z.; et al. Arbitrarily routed mode-division multiplexed photonic circuits for dense integration. Nat. Commun. 2019, 10, 1–7. [Google Scholar] [CrossRef] [PubMed]

- Chang, W.; Lu, L.; Ren, X.; Lu, L.; Cheng, M.; Liu, D.; Zhang, M. An Ultracompact Multimode Waveguide Crossing Based on Subwavelength Asymmetric Y-Junction. IEEE Photonics J. 2018, 10, 1–8. [Google Scholar] [CrossRef]

- Chang, W.; Lu, L.; Ren, X.; Li, D.; Pan, Z.; Cheng, M.; Liu, D.; Zhang, M. Ultracompact dual-mode waveguide crossing based on subwavelength multimode-interference couplers. Photonics Res. 2018, 6, 660–665. [Google Scholar] [CrossRef]

- Yamada, K. Silicon photonic wire waveguides: Fundamentals and applications. In Silicon Photonics II; Springer: Berlin/Heidelberg, Germany, 2011; pp. 1–29. [Google Scholar]

- Ding, Y.; Liu, L.; Peucheret, C.; Ou, H. Fabrication tolerant polarization splitter and rotator based on a tapered directional coupler. Opt. Express 2012, 20, 20021–20027. [Google Scholar] [CrossRef] [PubMed]

- Vermeulen, D.; Selvaraja, S.; Verheyen, P.; Absil, P.; Bogaerts, W.; Van Thourhout, D.; Roelkens, G. Silicon-on-Insulator Polarization Rotator Based on a Symmetry Breaking Silicon Overlay. IEEE Photonics Technol. Lett. 2012, 24, 482–484. [Google Scholar] [CrossRef]

- Liu, L.; Ding, Y.; Yvind, K.; Hvam, J.M. Silicon-on-insulator polarization splitting and rotating device for polarization diversity circuits. Opt. Express 2011, 19, 12646–12651. [Google Scholar] [CrossRef]

- Dai, D.; Bauters, J.; Bowers, J.E. Passive technologies for future large-scale photonic integrated circuits on silicon: Polarization handling, light non-reciprocity and loss reduction. Light Sci. Appl. 2012, 1, e1. [Google Scholar] [CrossRef]

- Wu, S.; Mu, X.; Cheng, L.; Tu, X.; Fu, H.Y. Polarization-insensitive Waveguide Crossings Based on SWGs-assisted MMI. In Proceedings of the 2019 Conference on 18th Optical Communications and Networks, Huangshan, China, 5–8 August 2019; pp. 1–3. [Google Scholar]

- Molesky, S.; Lin, Z.; Piggott, A.Y.; Jin, W.; Vucković, J.; Rodriguez, A.W. Inverse design in nanophotonics. Nat. Photonics 2018, 12, 659–670. [Google Scholar] [CrossRef]

- Sajedian, I.; Badloe, T.; Rho, J. Finding the best design parameters for optical nanostructures using reinforcement learning. arXiv 2018, arXiv:1810.10964. Available online: https://arxiv.org/abs/1810.10964 (accessed on 20 March 2020).

| Type | Institute | Insertion loss (dB) | Crosstalk (dB) | Footprint (μm2) | Thick (nm) | Fabrication Cost | Ref. |

|---|---|---|---|---|---|---|---|

| Shaped taper | YNU1 | <0.1 | <−30 | 7.21.5 | 320 | Low | [18] |

| Shaped taper | Ghent Uni. | 0.16 | −40 | 220 | Low | [28] | |

| Shaped taper | UPV2 | <0.2 | <−40 | 250 | Medium | [29] | |

| Shaped taper | Univ. of Delaware | ~0.028 | <−37 | 220 | Medium | [30] | |

| MMI | HKUST3 | ~0.4 | −30 | 340 | Low | [36] | |

| MMI | NCTU4 | 0.13 | −43.5 | 4.1 | 220 | Low | [38] |

| MMI | Huawei | ~0.007 | < −40 | 220 | Low | [39] | |

| MMI | Southeast Uni. | 0.086 | −35.58 | ~1616 | 250 | Low | [41] |

| SWG | NRC5 | 0.023 | <−40 | ~1010 | 260 | Medium | [54] |

| SWG | UT Austin6 | ~0.02 | <−40 | ~3 | 250 | Medium | [56] |

| Holey SWG | SYSU Uni. | 0.1~0.3 | <−35 | ~5 | 220 | High | [61] |

| Holey SWG | HUST7 | 0.75 | <−20 | -- | 220 | High | [62] |

| Vertical DC | ISP SB RAS8 | 0.08 | −70 | -- | -- | High | [65] |

| Vertical DC | SNL9 | 0.16 | −49 | -- | -- | High | [66] |

| Type | Institute | Insertion Loss (dB) | Crosstalk (dB) | Footprint (μm2) | Thick (nm) | Ref. |

|---|---|---|---|---|---|---|

| MDM | HUST1 | TE0: ~1.82 TE1: ~0.46 | <−18 | 21 | 220 | [72] |

| MDM | HUST | TE0: 0.87 TE1: 0.54 | <−50 | 220 | [73] | |

| MDM | Zhejiang Uni. | TM0: 0.56 TM1: 0.84 | <−20 | ~ | 340 | [74] |

| PDM | Zhejiang Uni. | TE0: 1.2 TM0: 1.5 | <−25 | 23 | 220 | [75] |

| PDM | CUHK2 | TE0: 0.2 TM0: 0.5 | <−28 | 250 | [76] | |

| PDM | TBSI3 | TE0: 0.67 TM0: 0.69 | <−20 | 340 | [77] |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wu, S.; Mu, X.; Cheng, L.; Mao, S.; Fu, H.Y. State-of-the-Art and Perspectives on Silicon Waveguide Crossings: A Review. Micromachines 2020, 11, 326. https://doi.org/10.3390/mi11030326

Wu S, Mu X, Cheng L, Mao S, Fu HY. State-of-the-Art and Perspectives on Silicon Waveguide Crossings: A Review. Micromachines. 2020; 11(3):326. https://doi.org/10.3390/mi11030326

Chicago/Turabian StyleWu, Sailong, Xin Mu, Lirong Cheng, Simei Mao, and H.Y. Fu. 2020. "State-of-the-Art and Perspectives on Silicon Waveguide Crossings: A Review" Micromachines 11, no. 3: 326. https://doi.org/10.3390/mi11030326

APA StyleWu, S., Mu, X., Cheng, L., Mao, S., & Fu, H. Y. (2020). State-of-the-Art and Perspectives on Silicon Waveguide Crossings: A Review. Micromachines, 11(3), 326. https://doi.org/10.3390/mi11030326