Microfabrication of Microlens by Timed-Development-and-Thermal-Reflow (TDTR) Process for Projection Lithography

Abstract

1. Introduction

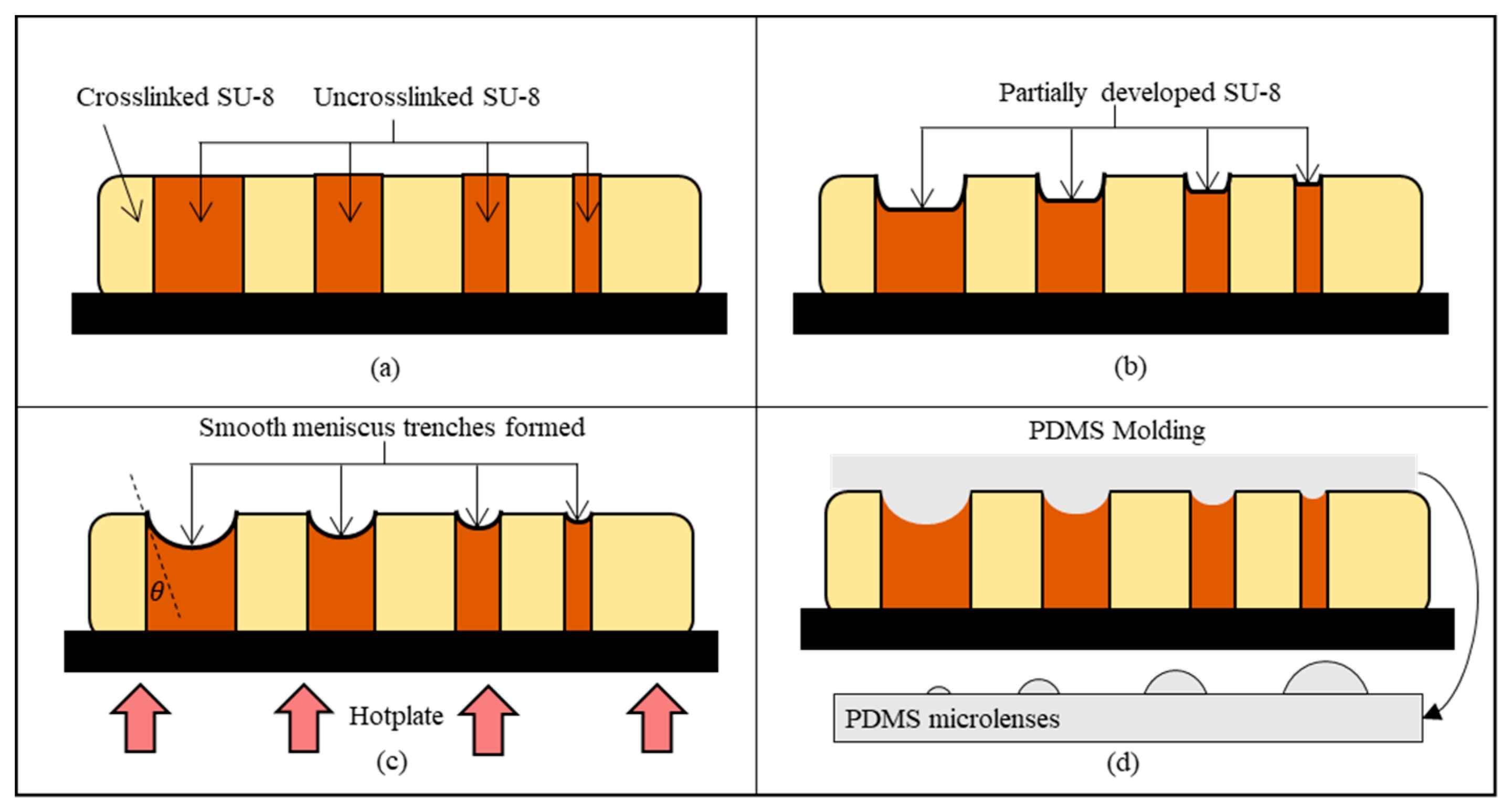

2. Timed-Development-and-Thermal-Reflow (TDTR) Process

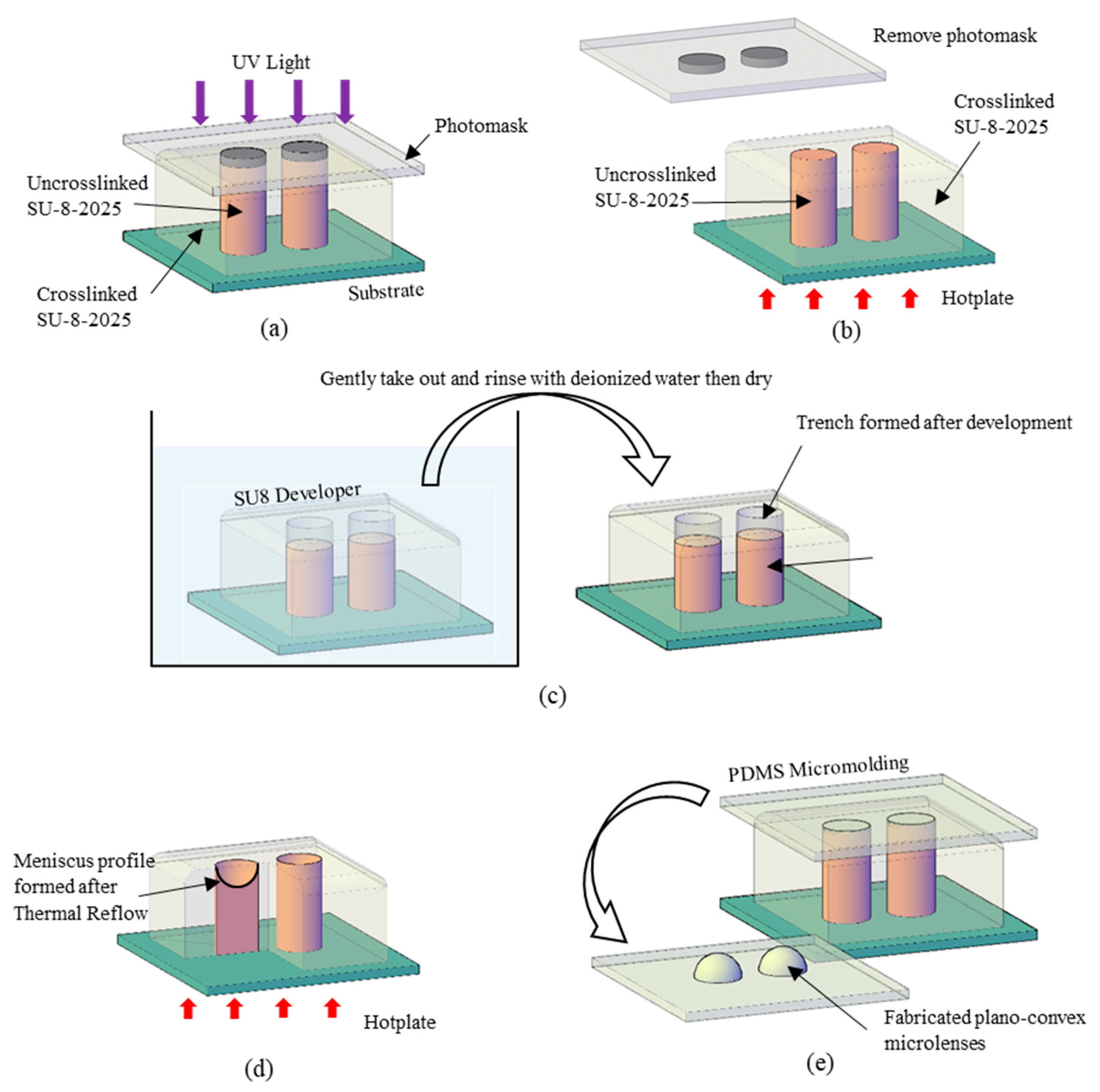

3. Modeling

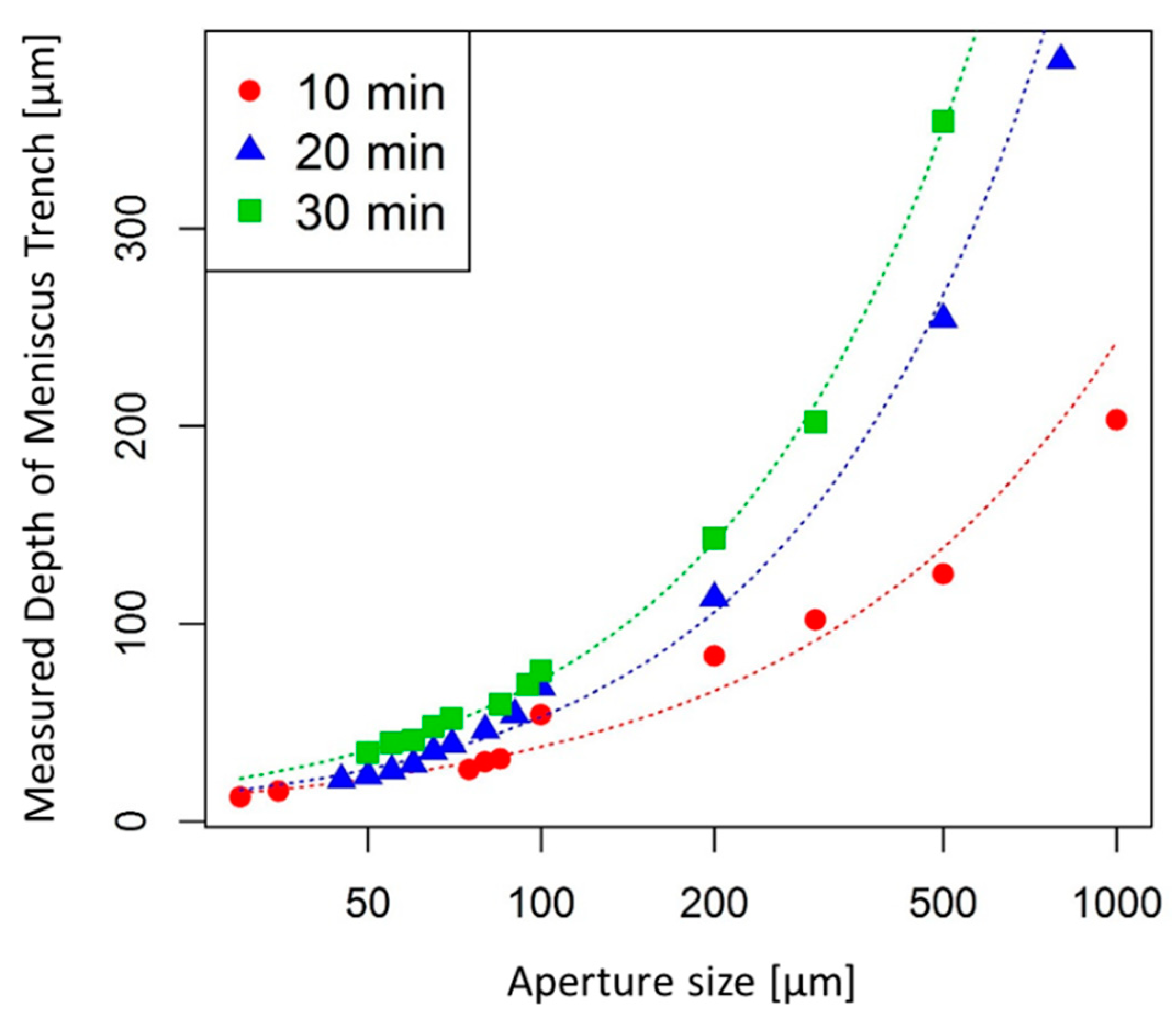

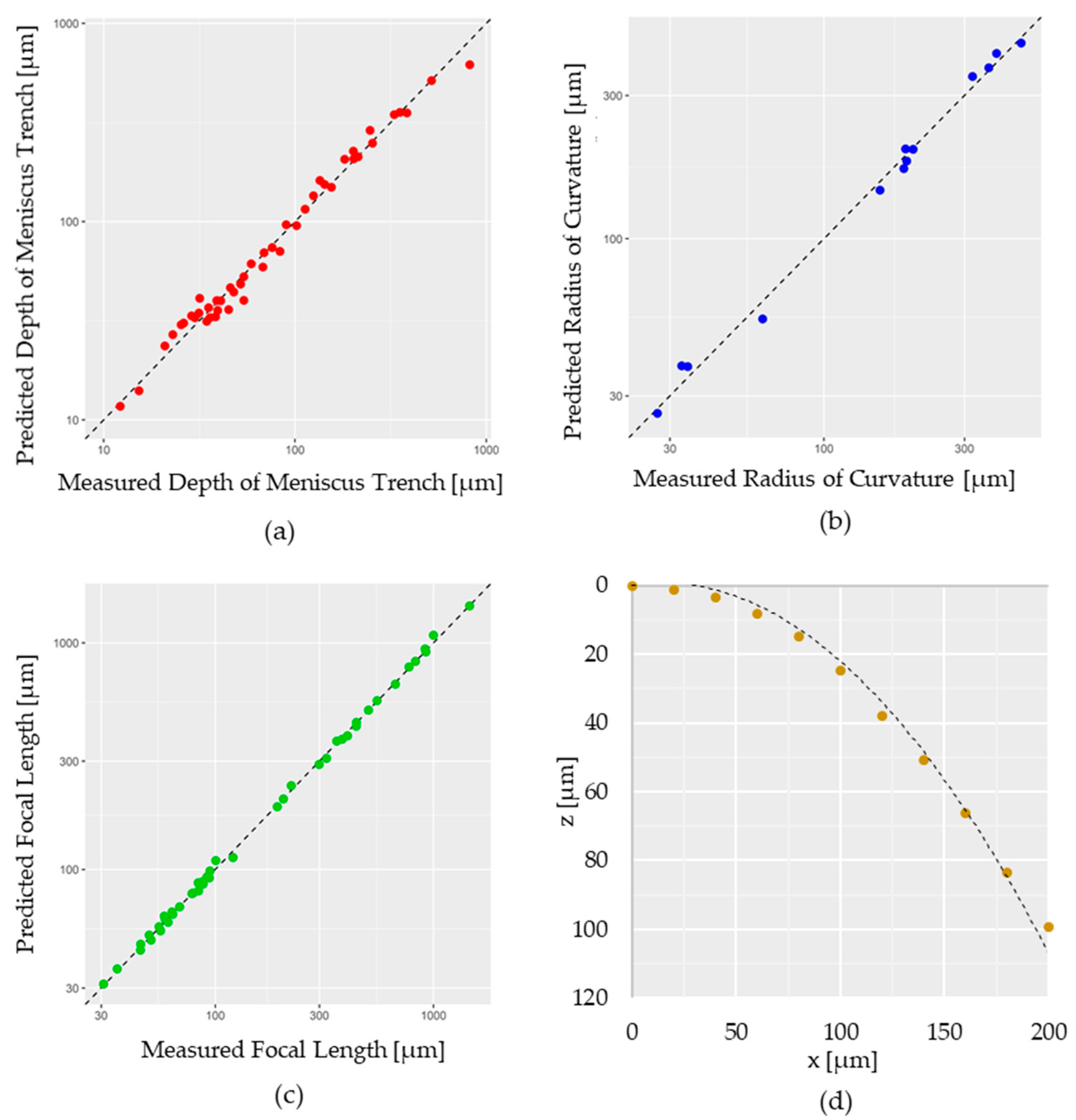

3.1. Depth of the Meniscus Trench

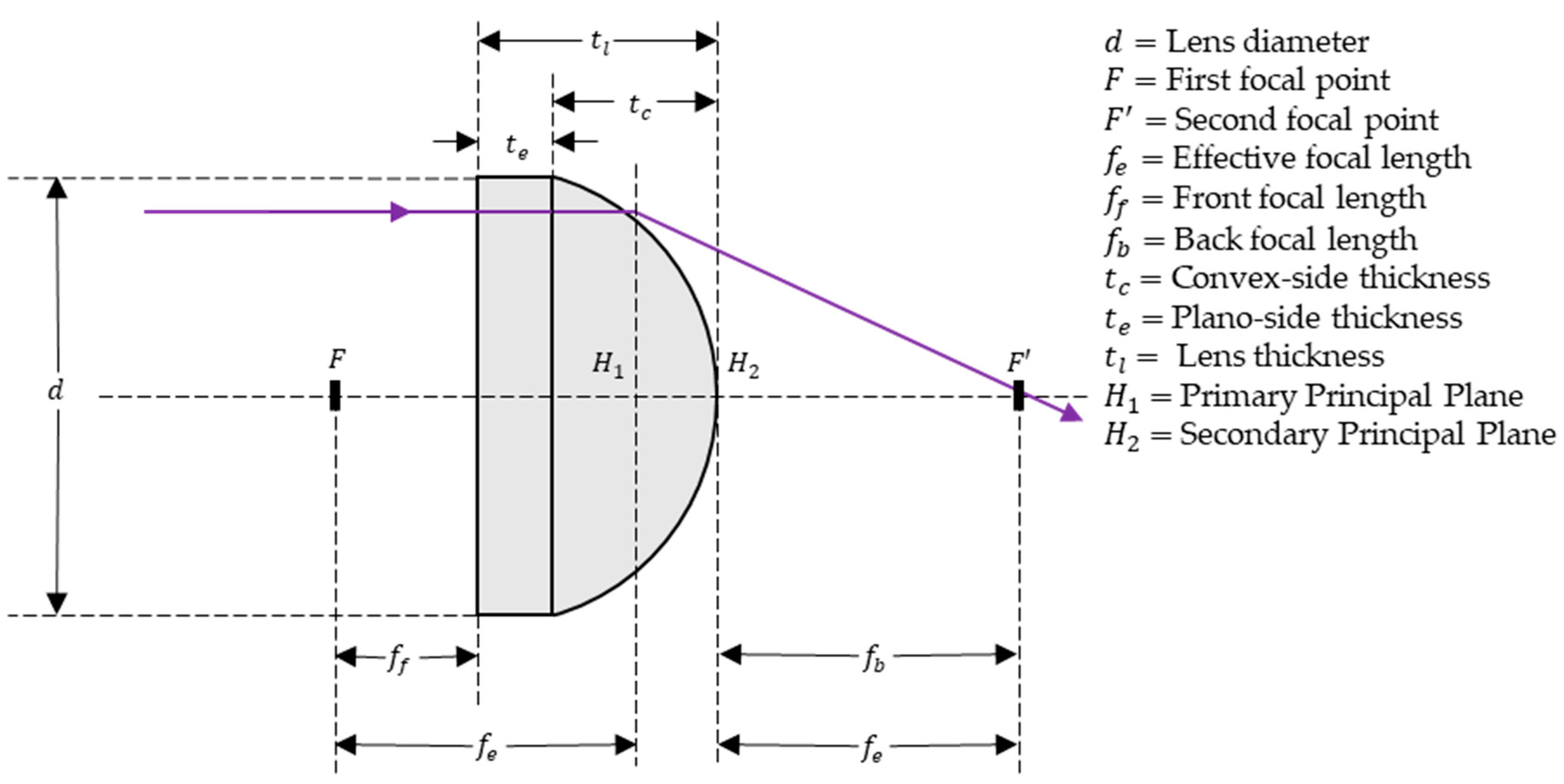

3.2. Effective Focal Length

3.3. Surface Profile

3.4. Modeling Equation Summary

4. Fabrication Process

5. Results

5.1. Varying Development Time

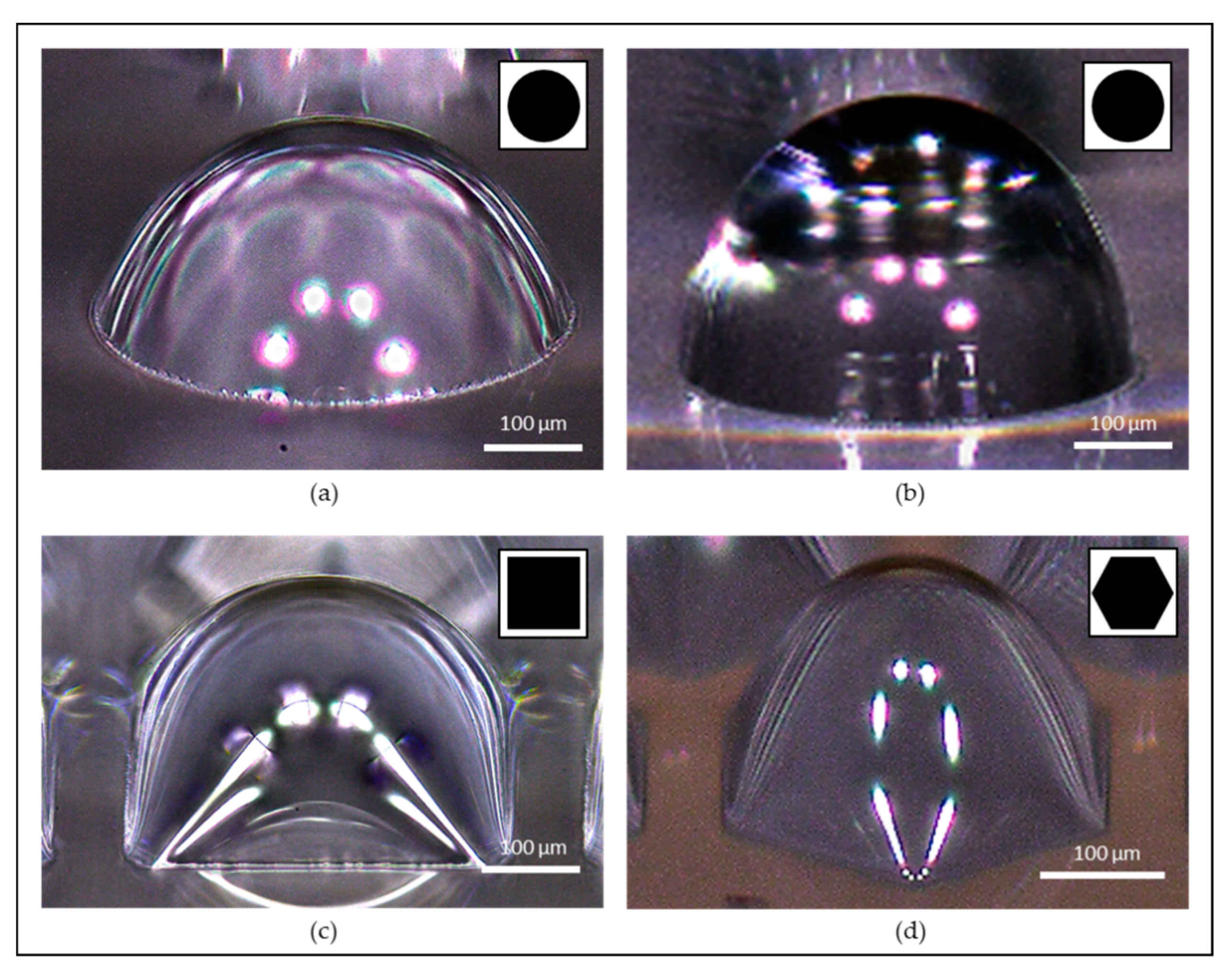

5.2. Varying Base Geometry

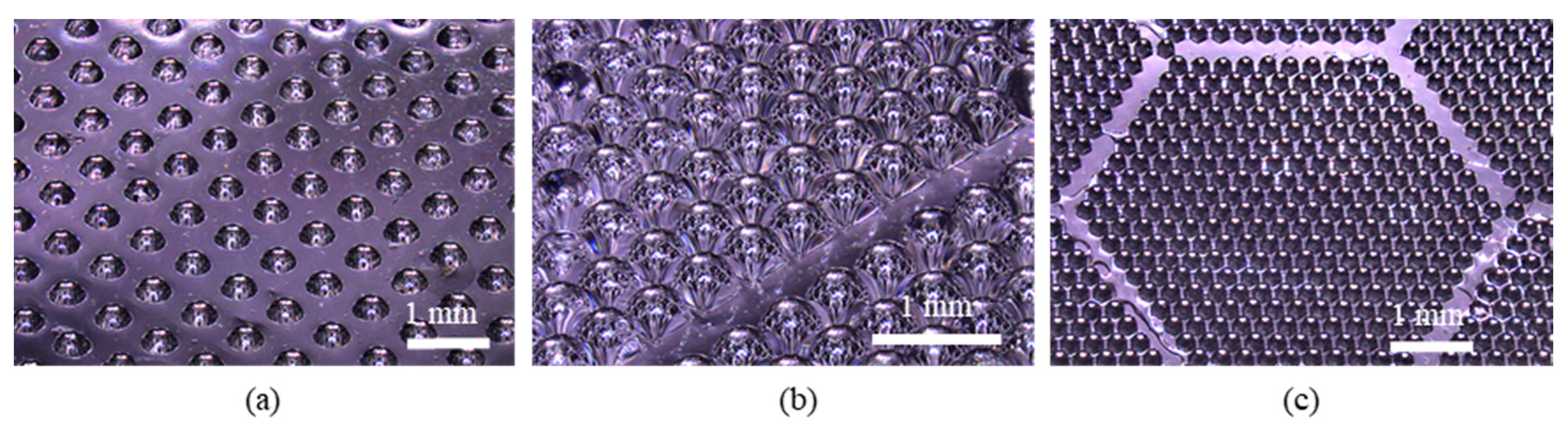

5.3. Lens Fill Factor

5.4. Uniformity Test

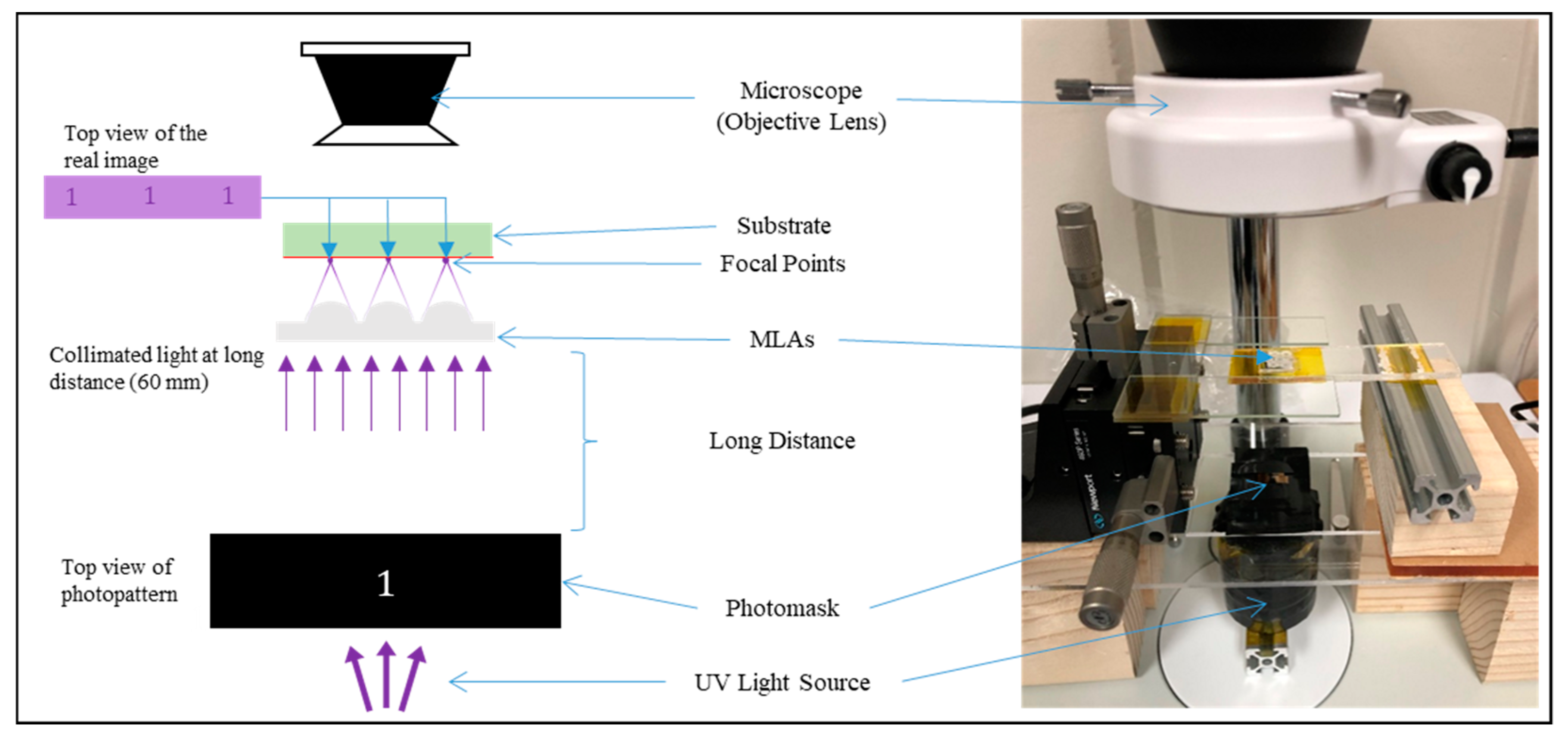

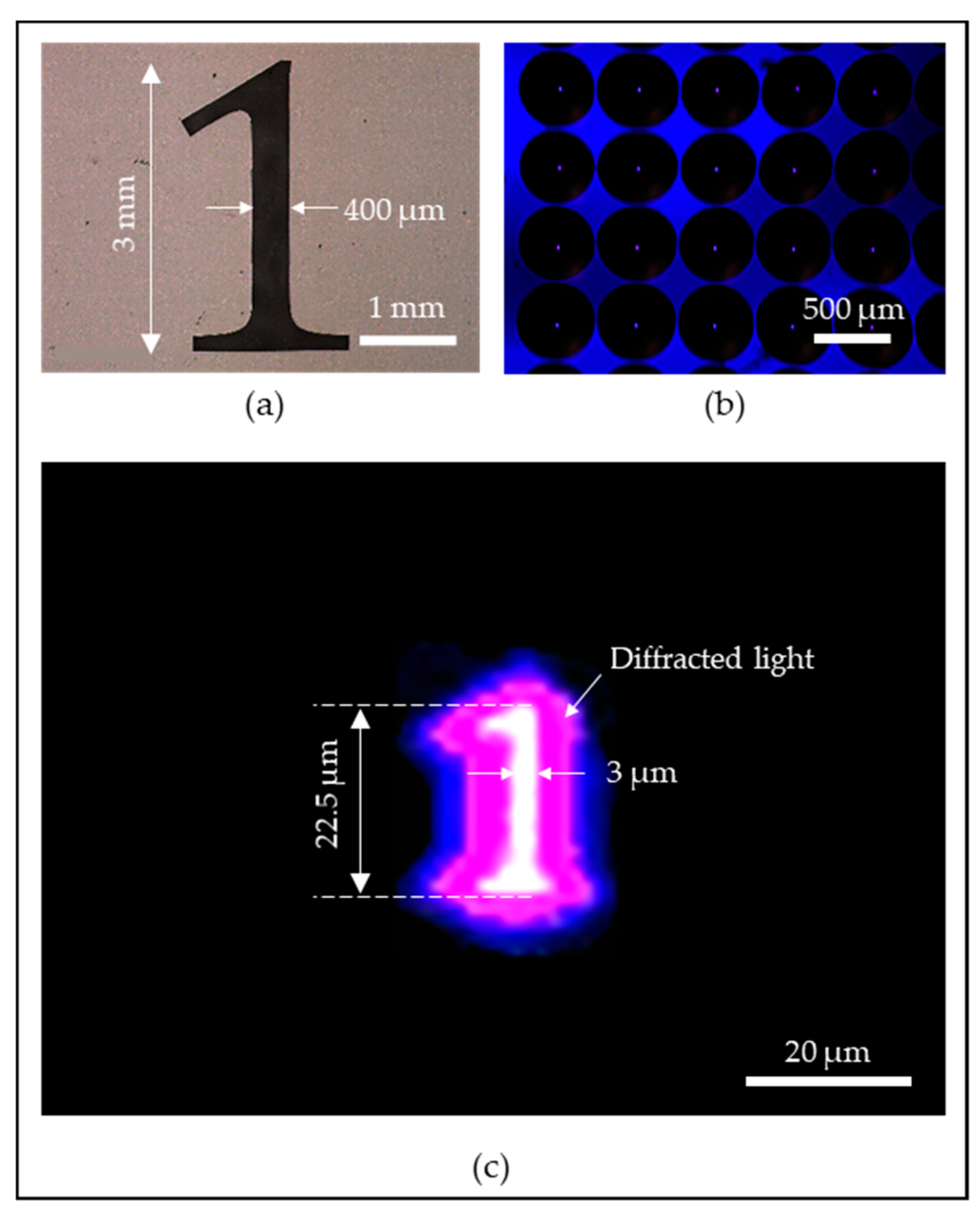

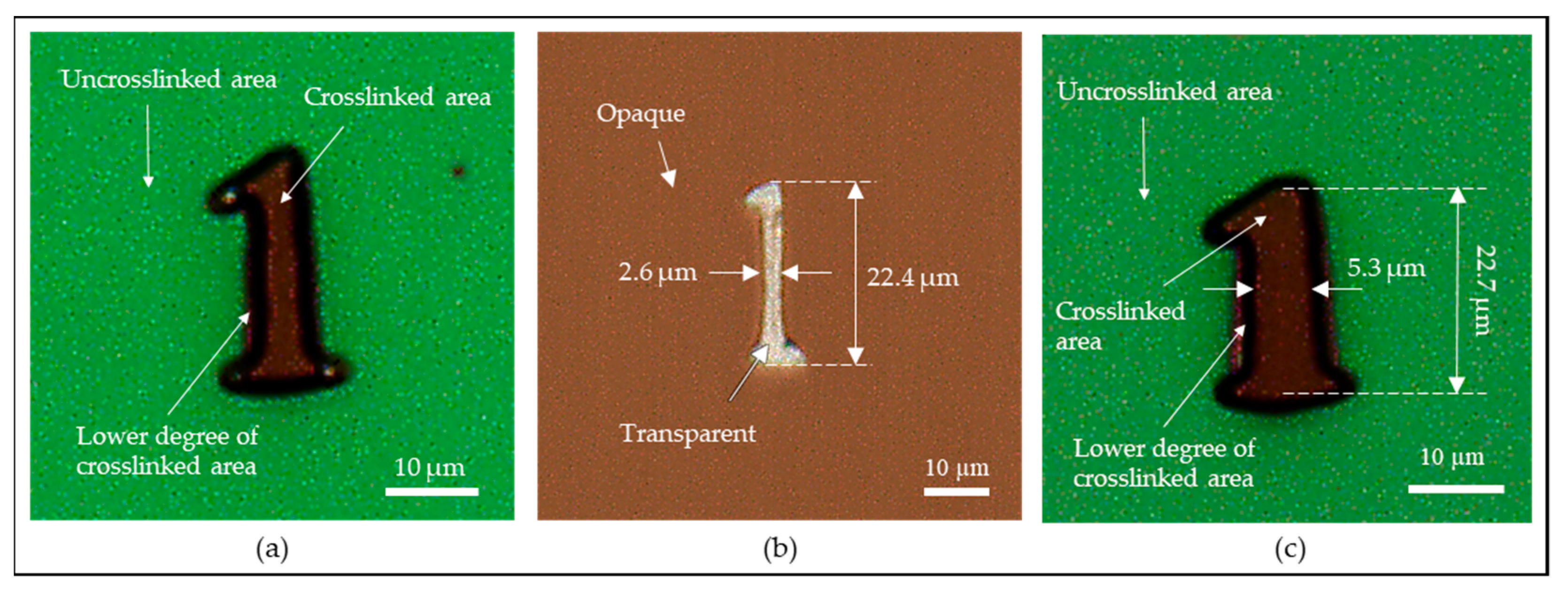

6. Application

7. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Yang, S.P.; Kim, J.B.; Jeong, K.H. Pattern projector using superposition of double microlens arrays for hybrid 3D endoscope. In Proceedings of the IEEE International Conference on Micro Electro IEEE Mechanical Systems (MEMS), Belfast, UK, 21–25 January 2018; pp. 422–425. [Google Scholar]

- Yuan, W.; Li, L.H.; Lee, W.B.; Chan, C.Y. Fabrication of microlens array and its application: A review. Chin. J. Mech. Eng. 2018, 31. [Google Scholar] [CrossRef]

- Hou, T.; Zheng, C.; Bai, S.; Ma, Q.; Bridges, D.; Hu, A.; Duley, W.W. Fabrication, characterization, and applications of microlenses. Appl. Opt. 2015, 54, 7366. [Google Scholar] [CrossRef] [PubMed]

- Zaboub, M.; Guessoum, A.; Demagh, N.E.; Guermat, A. Fabrication of polymer microlenses on single mode optical fibers for light coupling. Opt. Commun. 2016, 366, 122–126. [Google Scholar] [CrossRef]

- Luo, Y.; Wang, L.; Ding, Y.; Wei, H.; Hao, X.; Wang, D.; Dai, Y.; Shi, Y. Direct fabrication of microlens arrays with high numerical aperture by ink-jetting on nanotextured surface. Appl. Surf. Sci. 2013, 279, 36–40. [Google Scholar] [CrossRef]

- Naessens, K.; Ottevaere, H.; van Daele, P.; Baets, R. Flexible fabrication of microlenses in polymer layers with excimer laser ablation. Appl. Surf. Sci. 2003, 208–209, 159–164. [Google Scholar] [CrossRef]

- Yong, J.; Chen, F.; Yang, Q.; Du, G.; Bian, H.; Zhang, D.; Si, J.; Yun, F.; Hou, X. Rapid fabrication of large-area concave microlens arrays on PDMS by a femtosecond laser. ACS Appl. Mater. Interfaces 2013, 5, 9382–9385. [Google Scholar] [CrossRef] [PubMed]

- Chiu, C.C.; Lee, Y.C. Fabricating of aspheric micro-lens array by excimer laser micromachining. Opt. Lasers Eng. 2011, 49, 1232–1237. [Google Scholar] [CrossRef]

- Zhong, K.; Gao, Y.; Li, F.; Zhang, Z.; Luo, N. Fabrication of PDMS microlens array by digital maskless grayscale lithography and replica molding technique. Optik 2014, 125, 2413–2416. [Google Scholar] [CrossRef]

- Lian, Z.J.; Hung, S.Y.; Shen, M.H.; Yang, H. Rapid fabrication of semiellipsoid microlens using thermal reflow with two different photoresists. Microelectron. Eng. 2014, 115, 46–50. [Google Scholar] [CrossRef]

- Kim, J.; Lee, K.; Jee, H.; Oh, K.W.; Yoon, Y.K. Fabrication of multiple height microstructures using UV lithography on timed-development-and-thermal-reflowed photoresist. In Proceedings of the IEEE International Conference on Micro Electro Mechanical Systems (MEMS), Hong Kong, China, 24–28 January 2010; pp. 376–379. [Google Scholar]

- Kim, J.K.; Ahn, H.; Cheng, X.; Kim, K.T.; Kim, G.H.; Yoon, Y.K. Fabrication of multiple height microprobes using UV lithograhy on timed-development-and-thermal-reflowed photoresist. In Proceedings of the Technical Digest—Solid-State Sensors, Actuators, and Microsystems Workshop, Hilton Head Island, SC, USA, 6–10 June 2010; pp. 202–205. [Google Scholar]

- Kim, J.K.; Lee, K.; Oh, K.W.; Yoon, Y.K. Microfabrication of rounded channel and waveguide integrated microlens using timed development and thermal reflow process. In Proceedings of the Conference, MicroTAS 2009—The 13th International Conference on Miniaturized Systems for Chemistry and Life Sciences, Jeju Island, Korea, 1–5 November 2009; pp. 1365–1367. [Google Scholar]

- Goh, G.; Tan, J.Y.; Lee, K.K.S.; Kim, Y.; Kim, J.J.K. Modeling and fabrication of timed-development-and-thermal-reflow (TDTR) process for microlens. In Proceedings of the NEMS 2018—13th Annual IEEE International Conference on Nano/Micro Engineered and Molecular Systems, Singapore, 22–26 April 2018; pp. 578–581. [Google Scholar]

- Luo, Z.; Yin, K.; Dong, X.; Duan, J. Fabrication of parabolic cylindrical microlens array by shaped femtosecond laser. Opt. Mater. 2018, 78, 465–470. [Google Scholar] [CrossRef]

- Li, Y.; Wu, S.-T. Polarization independent adaptive microlens with a blue-phase liquid crystal. Opt. Express 2011, 19, 8045. [Google Scholar] [CrossRef] [PubMed]

- Adamson, A.W.; Petry, A.G. Physical Chemistry of Surfaces, 6th ed.; Wiley-Interscience: Hoboken, NJ, USA, 1997. [Google Scholar]

- Kim, J.; Allen, M.G.; Yoon, Y.K. Automated dynamic mode multidirectional UV lithography for complex 3-D microstructures. In Proceedings of the IEEE International Conference on Micro Electro. Mechanical Systems (MEMS), Wuhan, China, 13–17 January 2008; pp. 399–402. [Google Scholar]

- Seber, G.A.F.; Wild, C.J. Nonlinear Regression; John Wiley & Sons, Inc.: Hoboken, NJ, USA, 1989. [Google Scholar]

- Schneider, F.; Draheim, J.; Kamberger, R.; Wallrabe, U. Process and material properties of polydimethylsiloxane (PDMS) for optical MEMS. Sens. Actuators A Phys. 2009, 151, 95–99. [Google Scholar] [CrossRef]

- Surdo, S.; Diaspro, A.; Duocastella, M. Microlens fabrication by replica molding of frozen laser-printed droplets. Appl. Surf. Sci. 2017, 418, 554–558. [Google Scholar] [CrossRef]

- Wang, L.; Jiang, W.; Liu, H. Fabrication of bifocal microlens arrays based on controlled electrohydrodynamic reflowing of pre-patterned polymer related content adjusting light distribution for generating microlens arrays with a controllable profile and fill factor. J. Micromec. Microeng. 2014, 24, 095027. [Google Scholar] [CrossRef]

- Waldbaur, A.; Waterkotte, B.; Schmitz, K.; Rapp, B.E. Maskless projection lithography for the fast and flexible generation of grayscale protein patterns. Small 2012, 8, 1570–1578. [Google Scholar] [CrossRef] [PubMed]

- Lee, D.; Hiroshima, H.; Zhang, Y.; Itoh, T.; Maeda, R. Cylindrical projection lithography for microcoil structures. Microelectron. Eng. 2011, 88, 2625–2628. [Google Scholar] [CrossRef]

| Coefficient | Estimate | Standard Error | p-Value |

|---|---|---|---|

| 1.574077 | 0.07574 | <0.0001 | |

| −1.089105 | 0.05139 | <0.0001 | |

| 1.078329 | 0.04032 | <0.0001 |

| Coefficient | Estimate | Standard Error | p-Value |

|---|---|---|---|

| −1.17852 | 0.16926 | <0.0001 | |

| 1.31930 | 0.08206 | <0.0001 | |

| −0.27266 | 0.07436 | <0.0001 |

| Coefficient | Estimate |

|---|---|

| a0 | 3.79583504 |

| a1 | 0.742831171 |

| a2 | 2.153050191 |

| a3 | 2.407866931 |

| Aperture Geometry | Lens Thickness Mean | Variance | Standard Deviation | Uniformity (%) |

|---|---|---|---|---|

| Circular | 139.25 | 24.58 | 4.96 | 96.44% |

| Square | 137.07 | 11.20 | 3.35 | 97.56% |

| Hexagonal | 98.38 | 65.88 | 8.12 | 91.75% |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Tan, J.Y.; Goh, G.; Kim, J. Microfabrication of Microlens by Timed-Development-and-Thermal-Reflow (TDTR) Process for Projection Lithography. Micromachines 2020, 11, 277. https://doi.org/10.3390/mi11030277

Tan JY, Goh G, Kim J. Microfabrication of Microlens by Timed-Development-and-Thermal-Reflow (TDTR) Process for Projection Lithography. Micromachines. 2020; 11(3):277. https://doi.org/10.3390/mi11030277

Chicago/Turabian StyleTan, Jun Ying, Gyuhyeong Goh, and Jungkwun Kim. 2020. "Microfabrication of Microlens by Timed-Development-and-Thermal-Reflow (TDTR) Process for Projection Lithography" Micromachines 11, no. 3: 277. https://doi.org/10.3390/mi11030277

APA StyleTan, J. Y., Goh, G., & Kim, J. (2020). Microfabrication of Microlens by Timed-Development-and-Thermal-Reflow (TDTR) Process for Projection Lithography. Micromachines, 11(3), 277. https://doi.org/10.3390/mi11030277