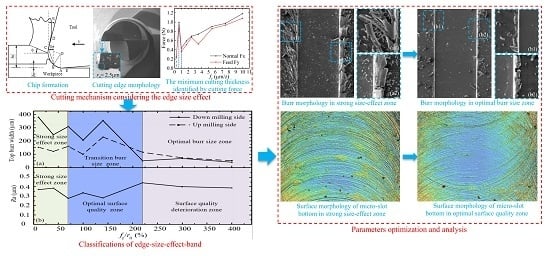

3.1. Classifications of Size-Effect Band in Micro-Milling

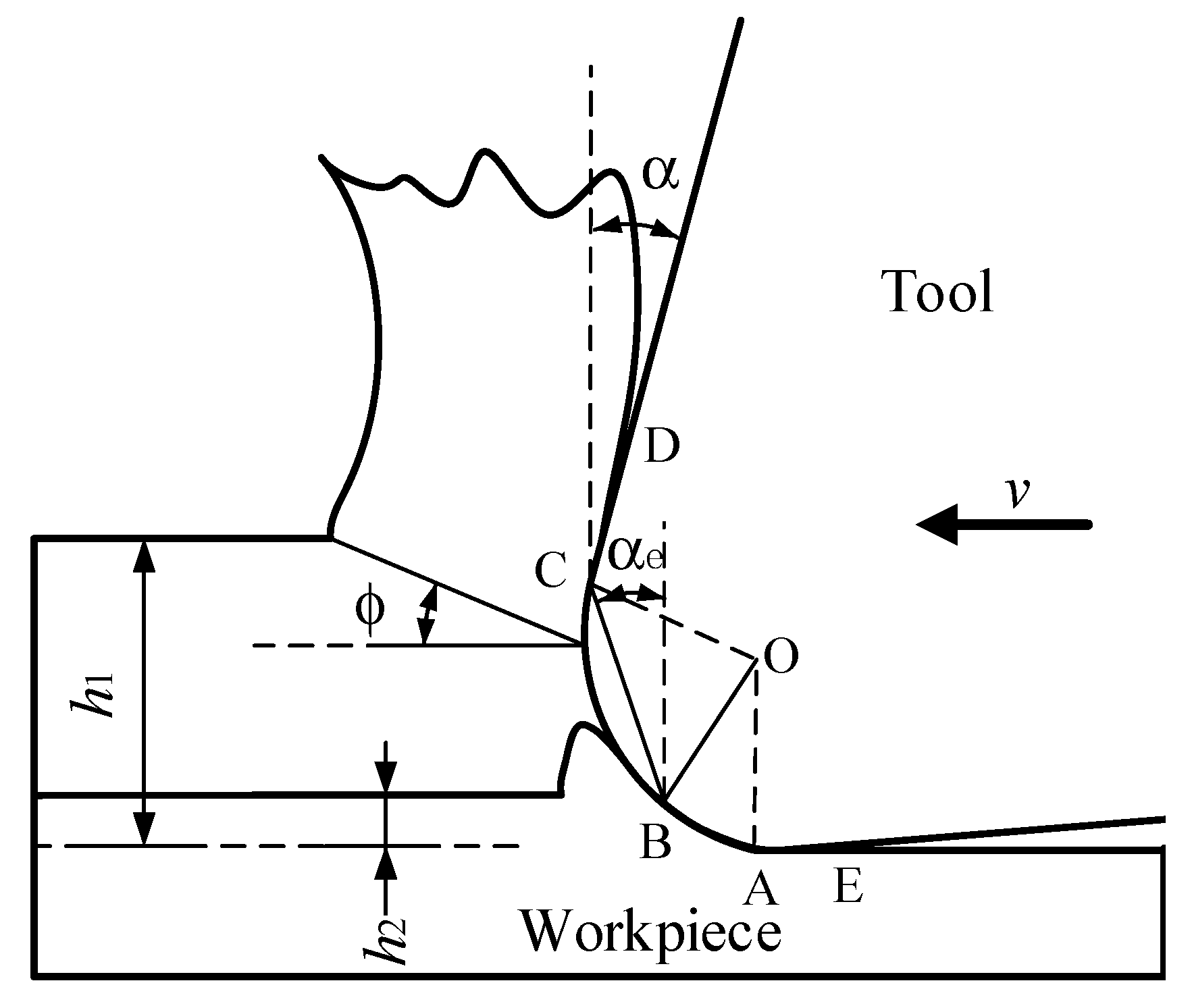

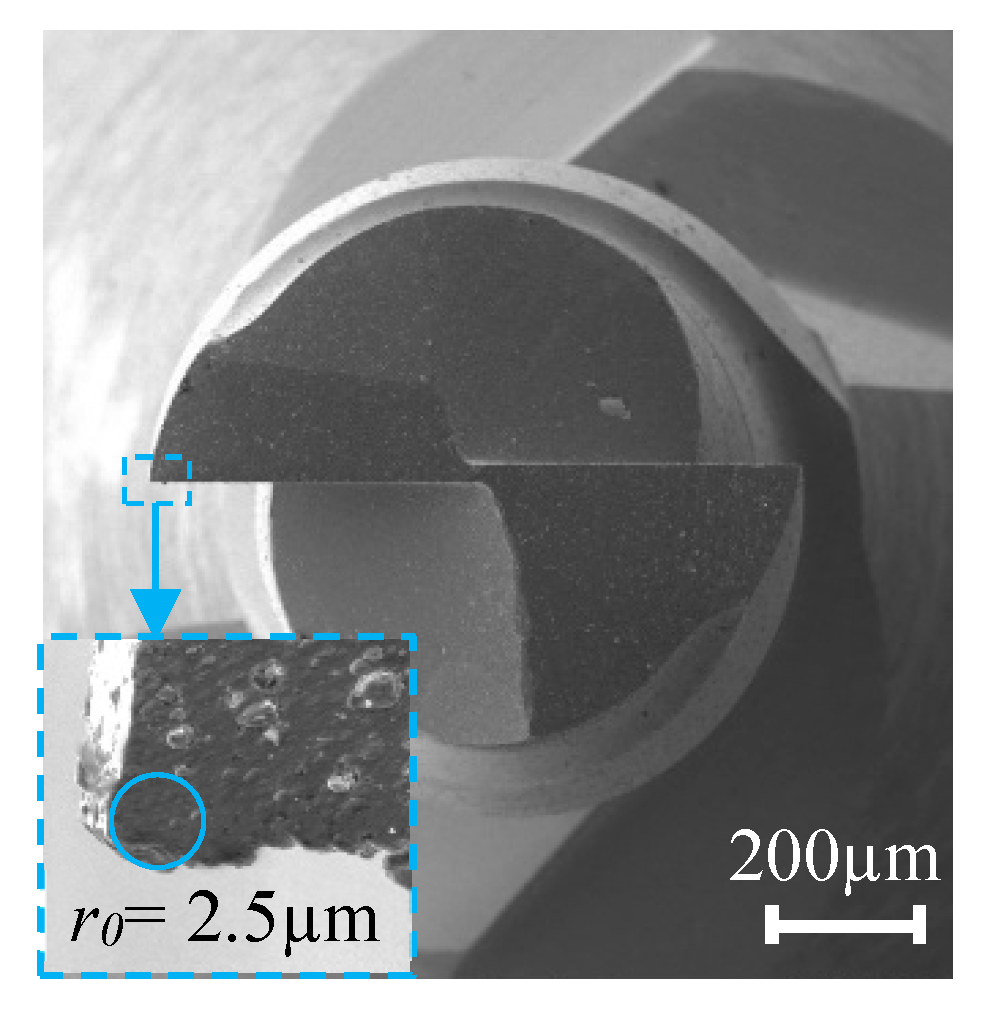

The size-effect band of micro-milling refers to the workpiece material Al7075 that is affected by the edge-size-effect of the micro tool in the micro-milling process, thereby the shape and size of micro-slot burr and the surface roughness of slot bottom change with fz/r0.

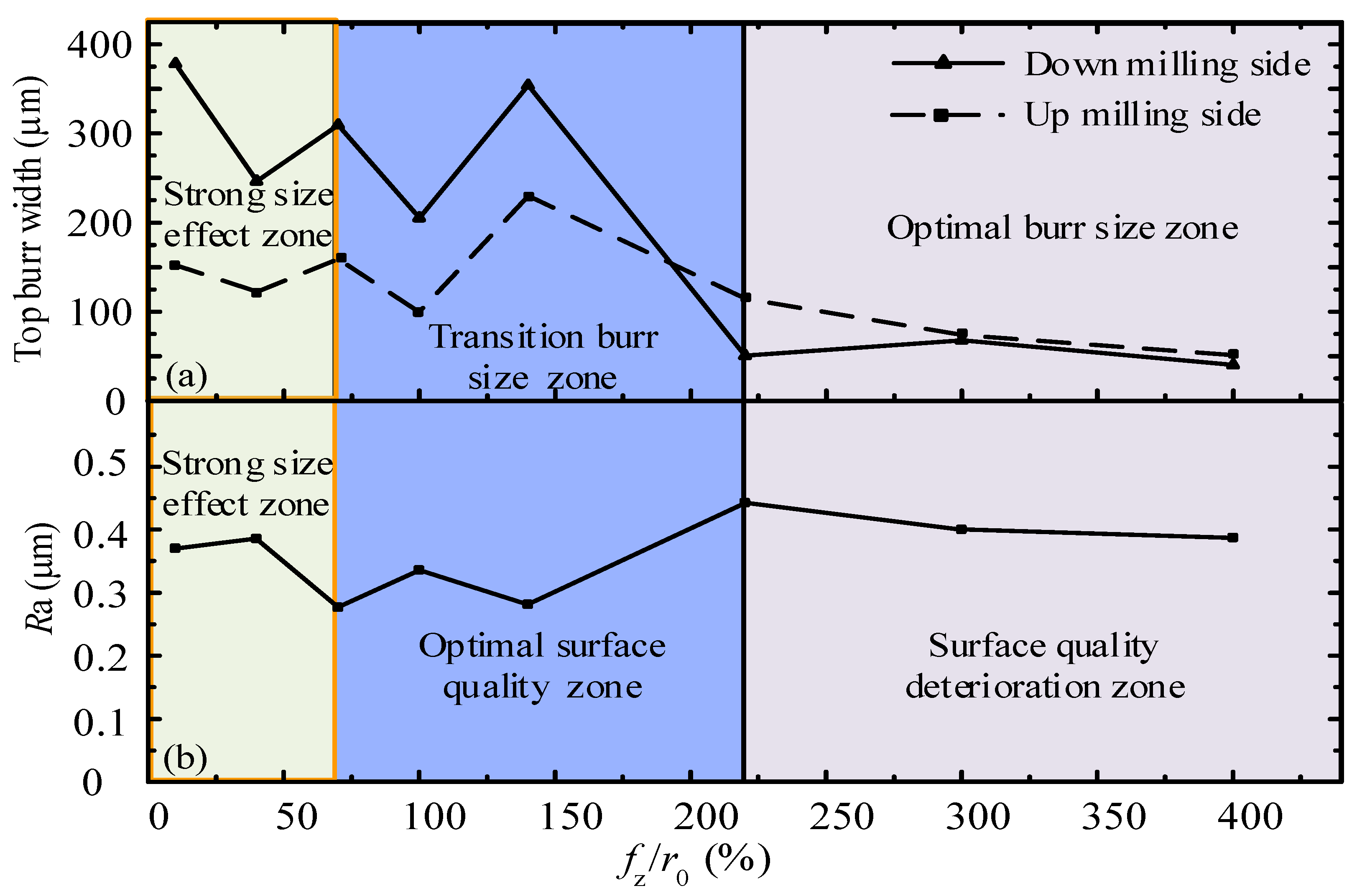

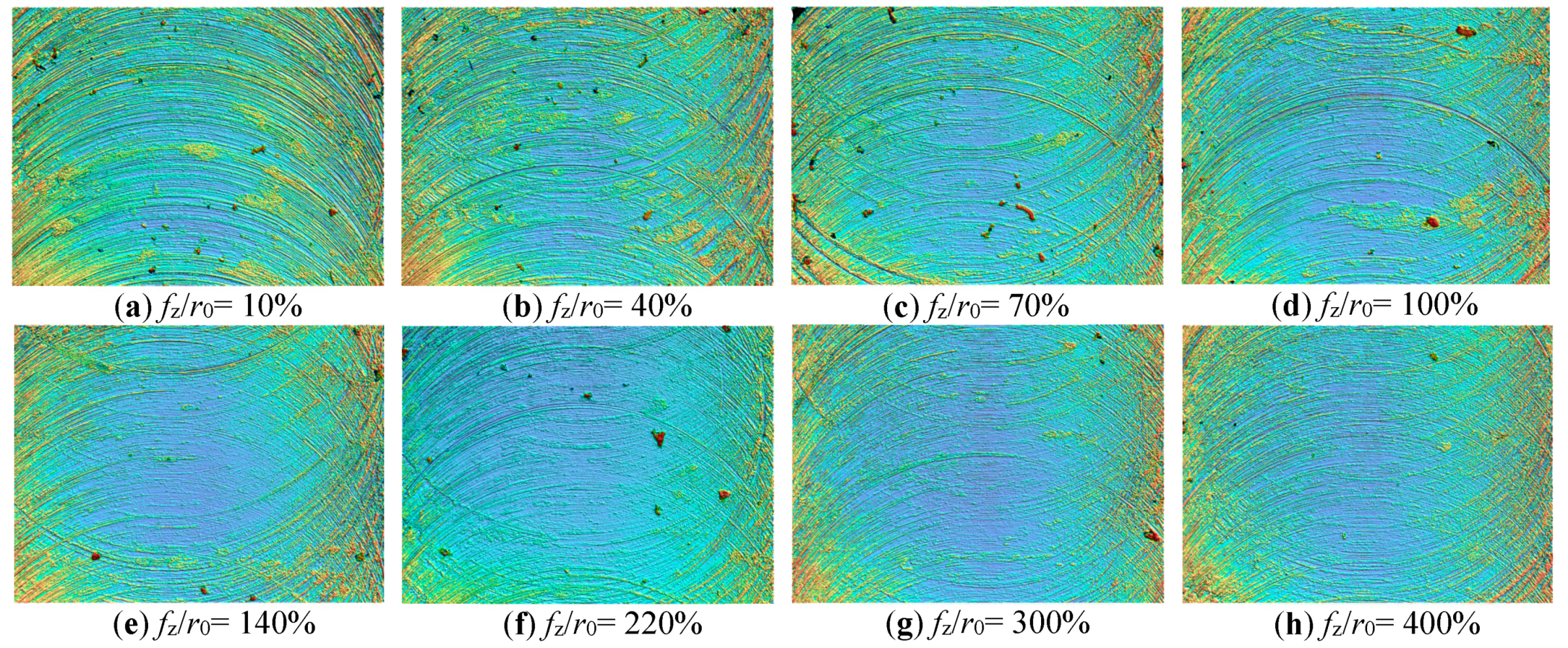

As observed from

Figure 7, when

fz/

r0 in the strong edge-size-effect zone is less than 70%, the width of the top burr is large, and the surface roughness of the micro-slot bottom is large. This is because, when

fz is close to

r0, the proportion of the cutting material in front of the cutting tool is small, and the size-effect of the cutting edge is significant. When

fz/

r0 in the transition size-effect zone is in the range of 70%–220%, the edge-size-effect has a significant effect on the top burr, and the width of the top burr has a great change, however, the surface quality of the micro-slot bottom is good, and

Ra value is relatively small. Therefore, an optimal surface quality zone is defined in this transition size-effect zone. When

fz/

r0 in the weak edge-size-effect zone is greater than 220%,

fz is far greater than

r0. The micro-milling is less affected by the edge-size-effect, similar to the traditional milling process, and the

Ra value of the slot bottom is larger. However, the burr is mainly in contact with the front face of the cutting tool, while the workpiece material is mainly plastic deformation, the burr is more easily pushed off, and the width of the burr at the top of the micro-slot becomes smaller. Therefore, the weak edge-size-effect zone can be defined as the optimal burr size zone. The large top burr width mainly occurs in the strong edge-size-effect zone and transition burr size zone (

Figure 7a), and the large

Ra of the micro-slot bottom mainly occurs in both the strong edge-size-effect zone and the surface quality deterioration zone (

Figure 7b).

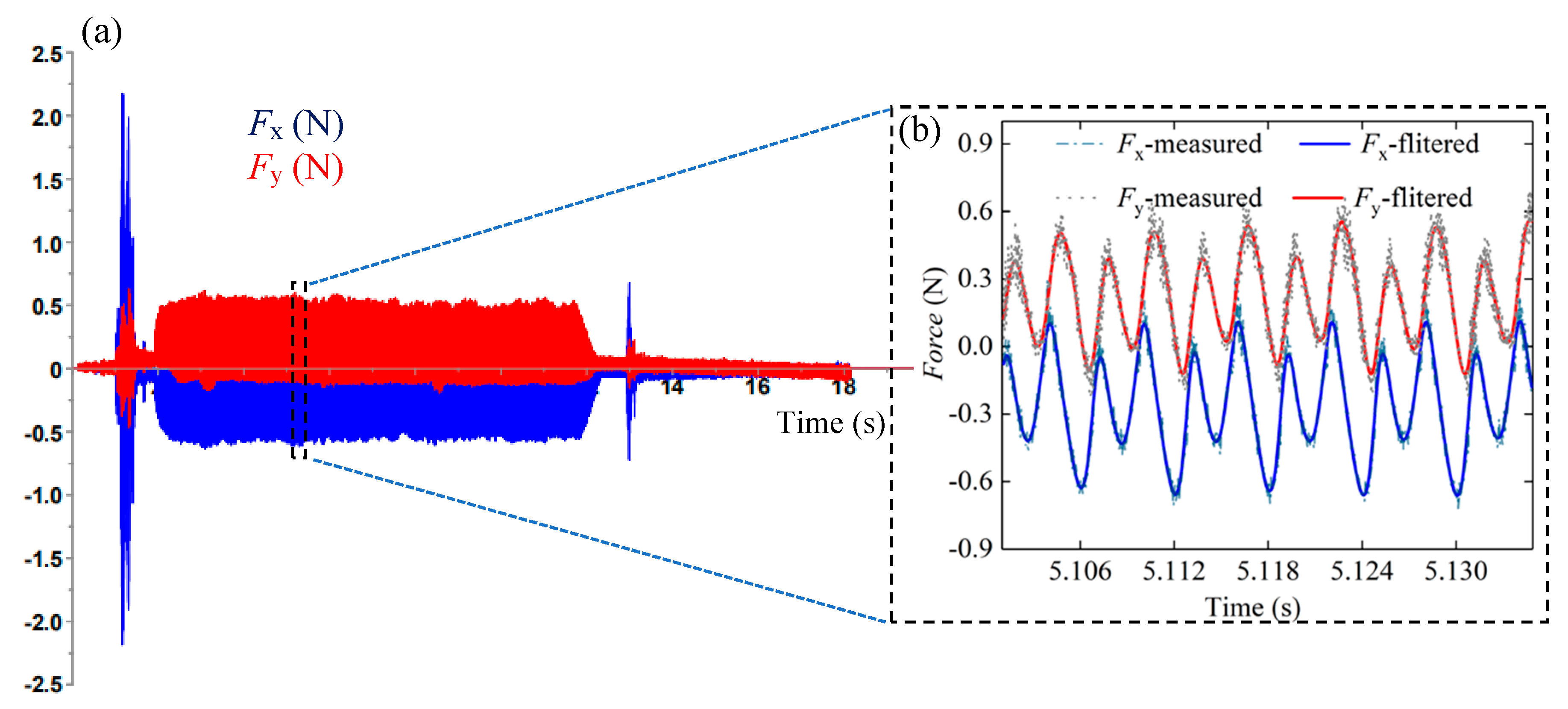

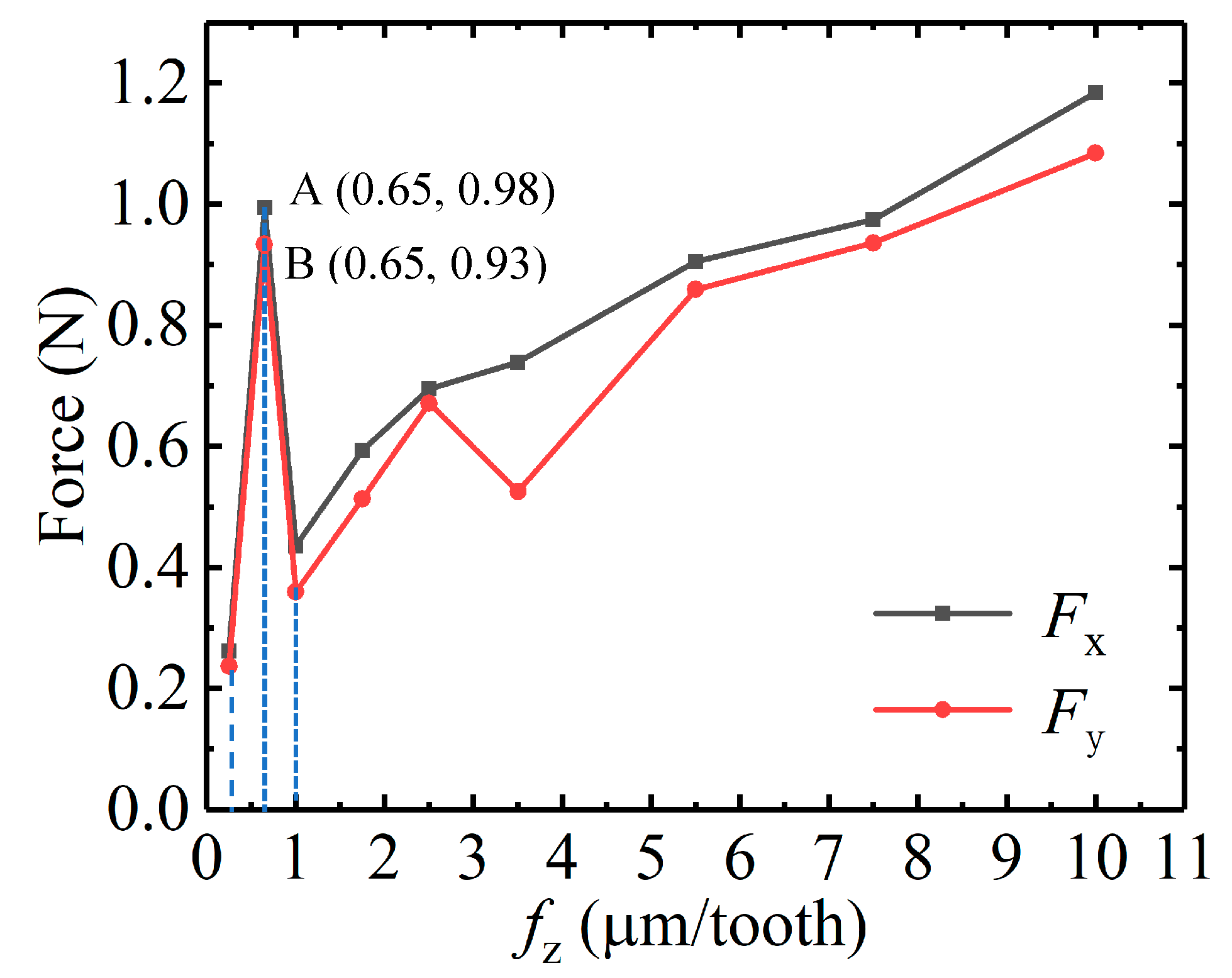

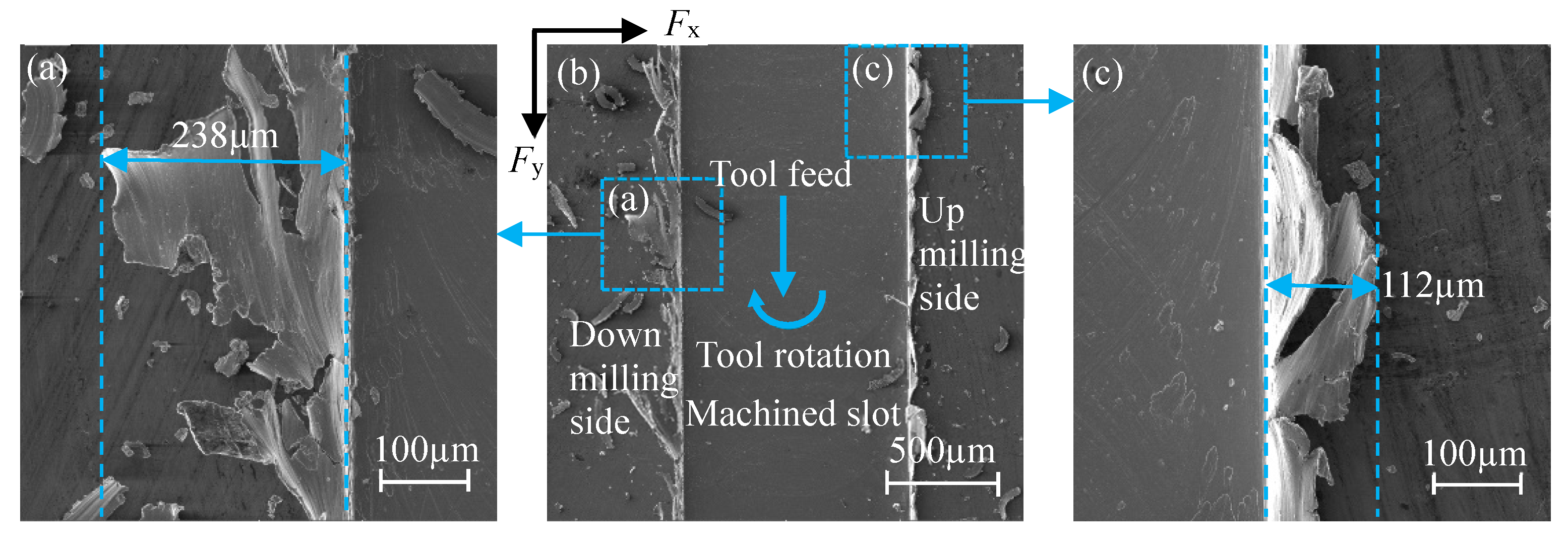

3.2. Optimization of Micro-Milling Parameters Based on Top Burr Morphology

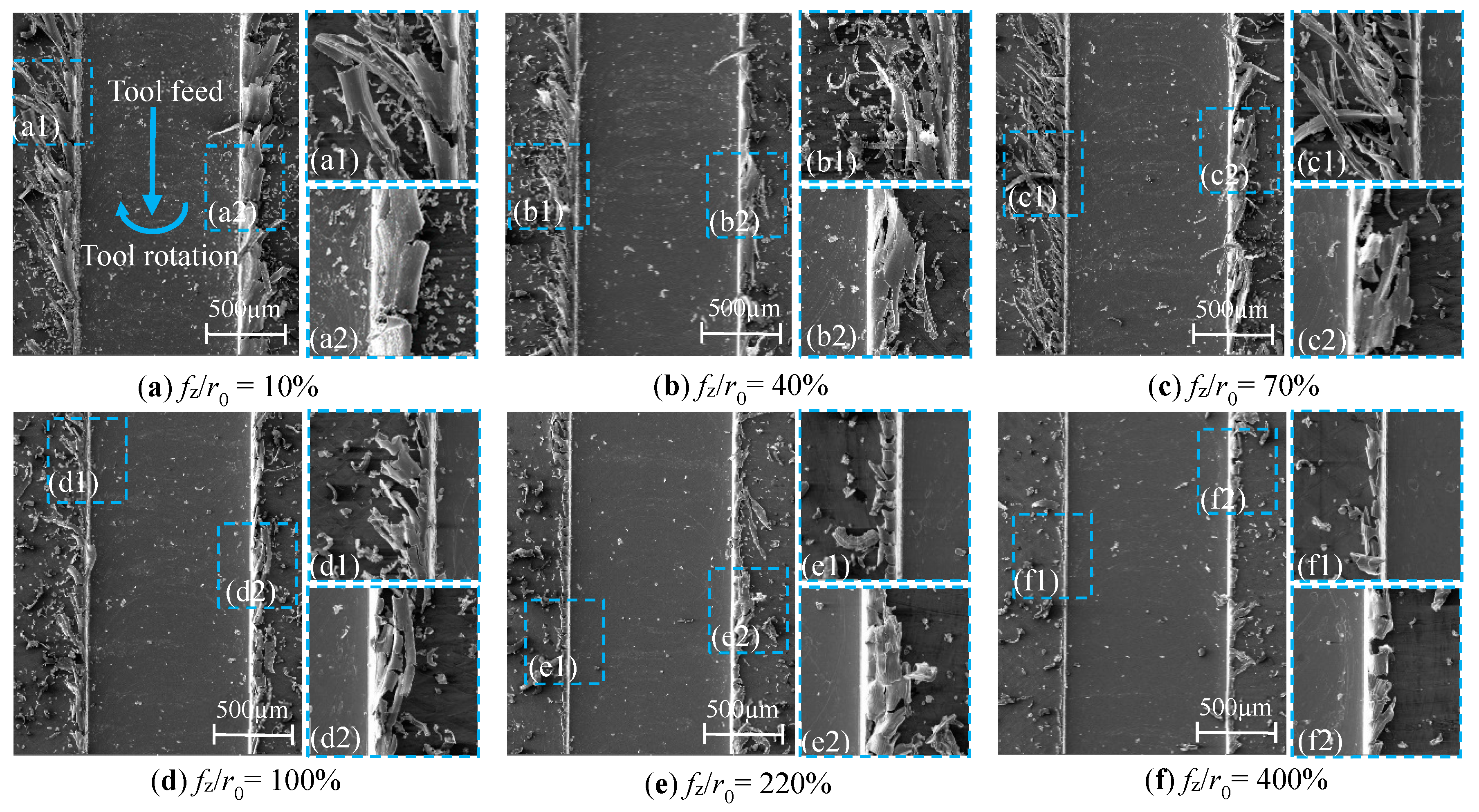

By observing the top burr morphology of the micro-slot, the influence of

fz on the burr morphology is studied; the micro-milling test is designed as N1–N8 in

Table 1. The micro-slot and burr morphology images captured by SEM are shown in

Figure 8.

When

fz/

r0 is less than 70%, the micro-milling process is in a strong size-effect zone. Along with the decrease of

fz/

r0, the top burrs’ width of both the down milling side and up milling side decreases first and then increases, as shown in

Figure 7a. The top burrs of the down milling side present a whisker-shaped morphology (

Figure 8a1–c1), while the top burrs of the up milling side present a block-shaped morphology (

Figure 8a2–c2). These phenomena show that the micro-milling cannot generate chips because of the influence of the strong edge-size-effect. However, the materials in contact with the tool are squeezed and scratched continuously along the micro-slot edge to form strip burr owing to the good plasticity and ductility of the aluminum alloy material.

When

fz/

r0 is larger than 70% and less than 220%, micro-milling is in the transition size-effect zone, and the top burr width in the down milling side and up milling side of the micro-slot is larger in size and deviations, as shown in

Figure 7a. This is because of the reduction of elastic recovery for the machined surface, the ploughing effect area reduces while the shear effect area increases, chips cannot be stably generated, chips reaching the edge of the micro-slot cannot be separated timely, and then the top burrs are formed. From

Figure 8a–d, it is found that the top burr width in the down milling side is significantly larger than the top burr width in the up milling side, and the top burr width fluctuates with the decrease of

fz/

r0. When

fz/

r0 is 140%,

Figure 7a reports that the maximum value of the top burr width in the down milling side and the up milling side is 388 μm and 265 μm, respectively, which indicates that the shape and size of the formed chips are not consistent, thereby the formation of burrs owns uncertainty, and the top burr width has great changes. The top burrs in the down milling side are mainly in a tearing flag shape (

Figure 8d1), while the top burrs in the up milling side are in a continuous serration shape (

Figure 8d2).

When the

fz/

r0 value is greater than 220%,

Figure 7a shows that micro-milling is in the optimal burr size selection zone, where the edge-size-effect has the least effects. The top burrs on both sides of the down and up milling are small and few, and the top burrs’ width decreases with the increase of

fz/

r0, as shown in

Figure 8e–f. Further, the top burrs of the down milling side and up milling side mainly present a curly and wavy shape, as shown in

Figure 8f1–f2. When

fz/

r0 is 220%,

Figure 8e1–e2 show that the top burr width in the down milling side begins to be smaller than the top burr width in up milling side, which indicates that the top burr in the down milling side breaks away from the influence of the edge-size-effect zone before the top burr in the up milling side.

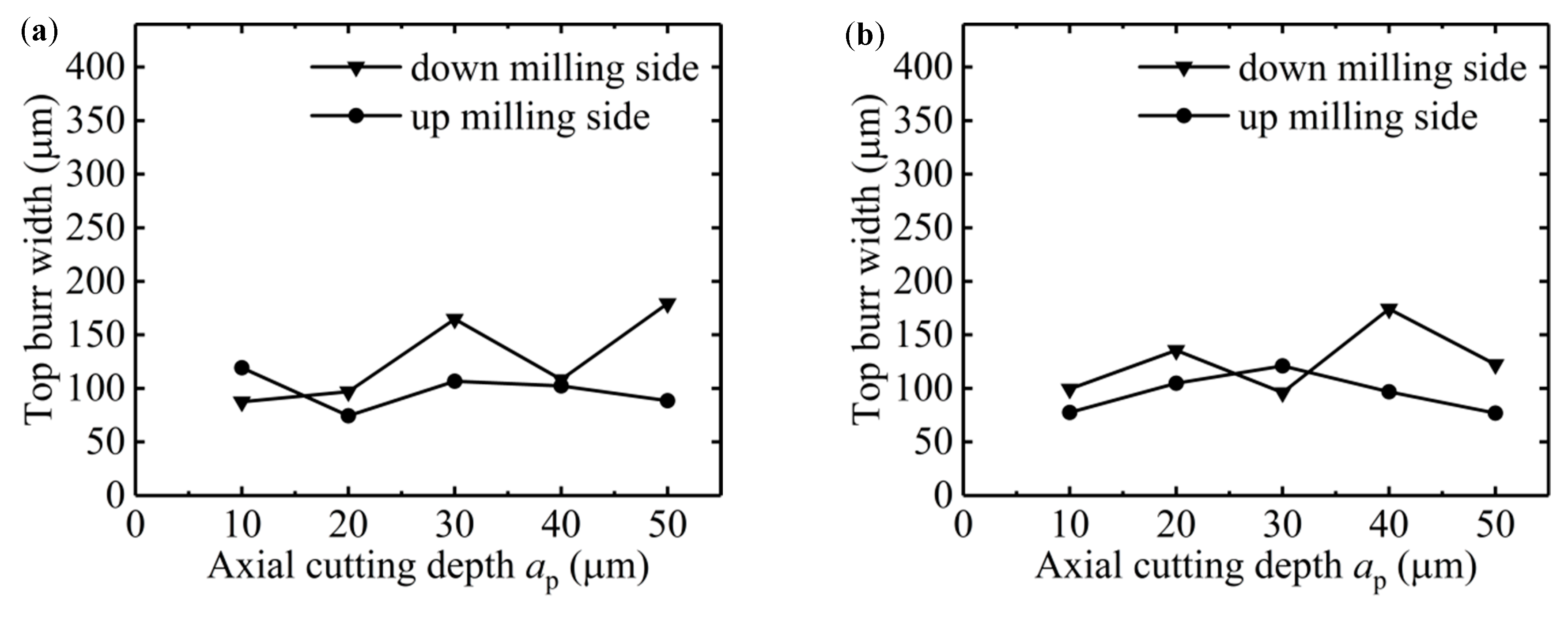

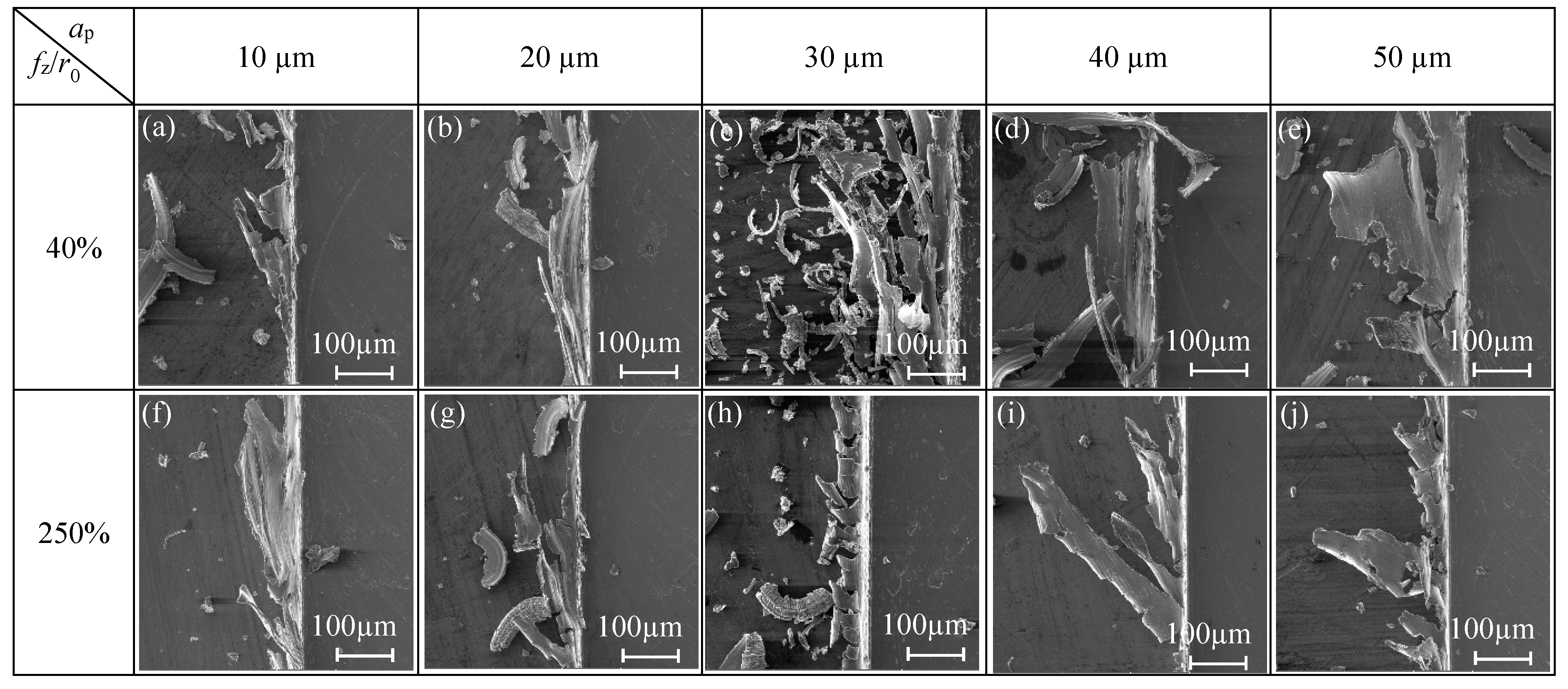

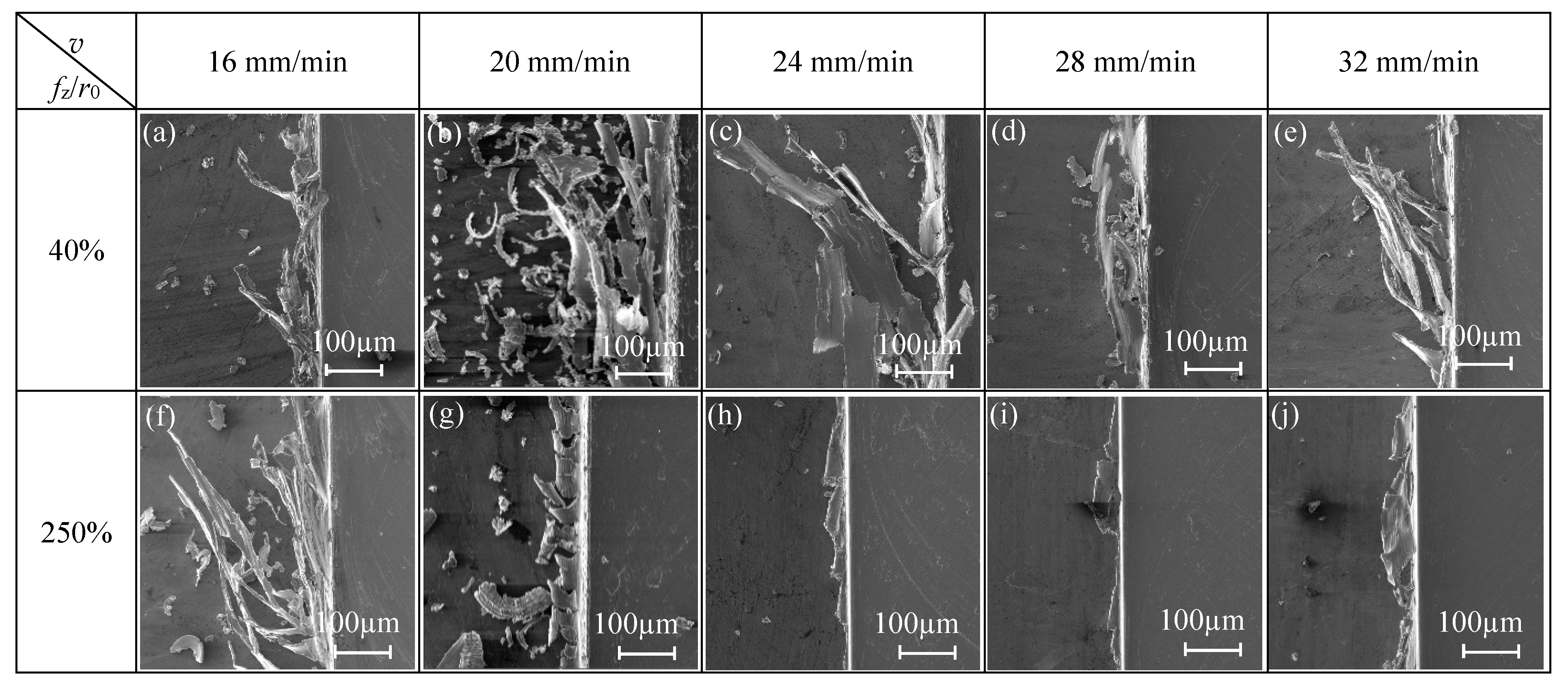

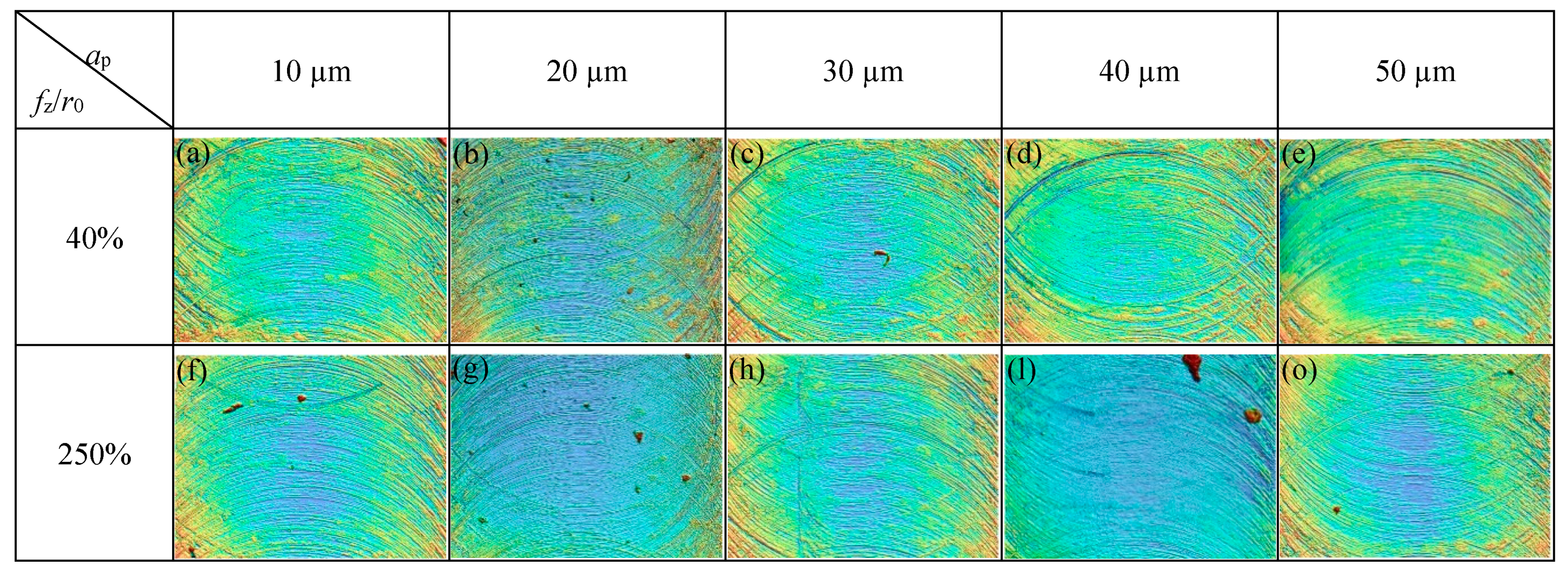

(1) Influence of Axial Cutting Depth on the Burr Size-Effect Band

The cutting parameters for the micro-milling straight slot test are shown in the N9–N16 groups in

Table 1. Under the two conditions of

fz/

r0 = 40% (strong size-effect zone) and

fz/

r0 = 250% (weak size-effect zone), observing the top burr morphology of the micro-slot when the axial cutting depth (

ap) was changes, the influence of

ap on the burr size-effect band is studied.

The change of

ap in different size-effect zones has different effects on the burr morphology in the two sides of the micro-slot. As shown in

Figure 9a,b, the top burr width in the down milling side changed from 90 µm to 179 µm, while the top burr width in the up milling side remained around 100 µm, which shows that the change of

ap has a more significant effect on the top burr size of the down milling side. This is because the tool cutting depth in the down milling side changes from the maximum to the minimum, and the direction of the chip flow-out is the same as the moving direction of the workpiece, thus it is easier to slit the top burr and generate long chips.

fz/

r0 = 40%, which means the micro-milling is in the strong size-effect zone (

Figure 7), when the cutting depth is less than 20 μm, the top burr width in down milling side is close to 100 μm. When the axial cutting depth continues to increase to 50 μm, the top burr width in the down milling side increases to 179 μm and with obvious fluctuation, while the top burr width in the up milling side of the micro-slot decreases slightly, as shown in

Figure 9a. The top burrs in both the down milling side and up milling side mainly present lager patches or a striped shape, as shown in

Figure 10a–e and

Figure 11a–e, respectively.

fz/

r0 = 250%, which means the micro-milling is in the weak edge-size-effect zone, and the change of axial cutting depth has little effect on the top burr size. The change range of the top burr width of the micro-slot is small and does not exceed 30 μm in both the down milling side or up milling side, and the top burr in the up milling side increases first and then decreases with the increase of the axial cutting depth (

Figure 9b). Therefore, the separation of micro-milling from the strong size-effect zone could be realized by increasing the axial cutting depth to reduce the top burr or selecting a smaller

fz/

r0 value, in order to reduce the optional range of cutting parameters. The top burr morphology in the down milling side and up milling side mainly presents as discontinuous serration or wavy (

Figure 10f–j and

Figure 11f–j, respectively).

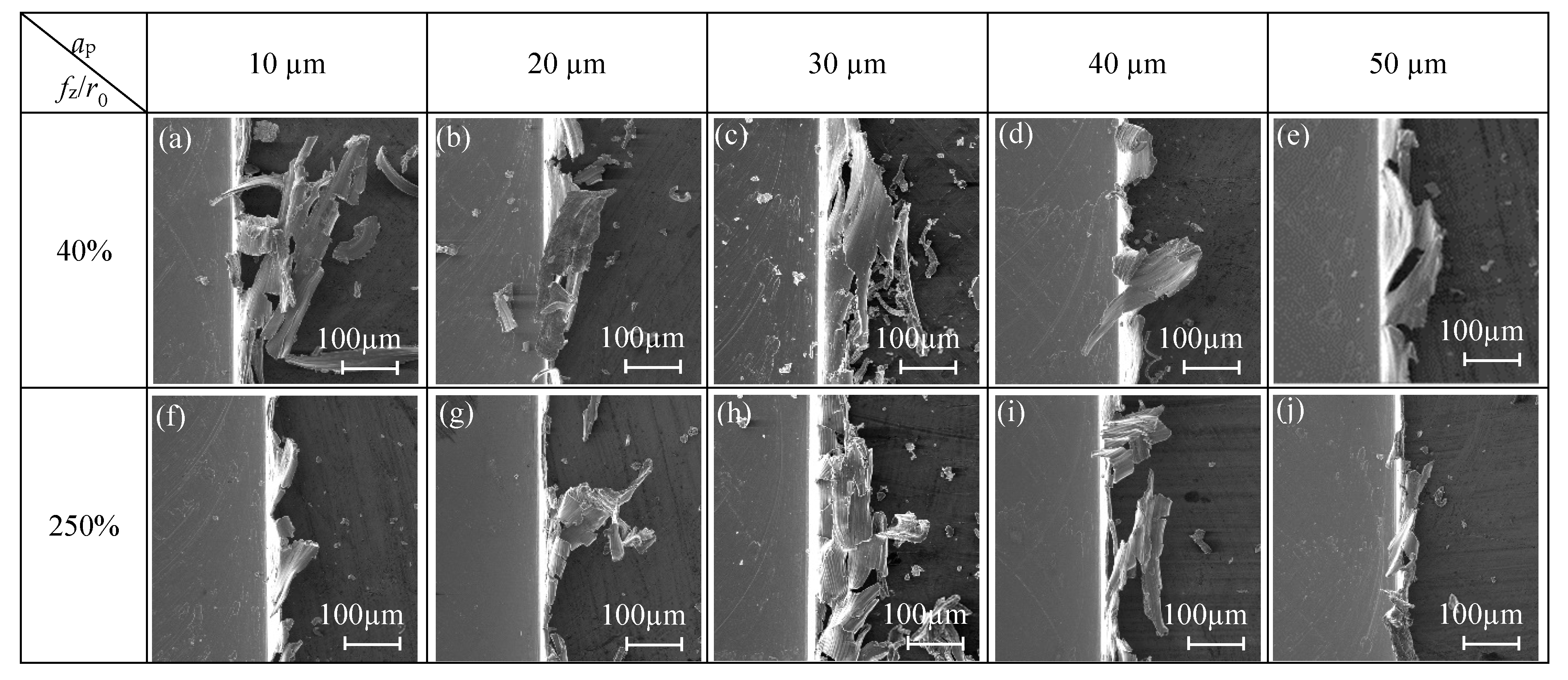

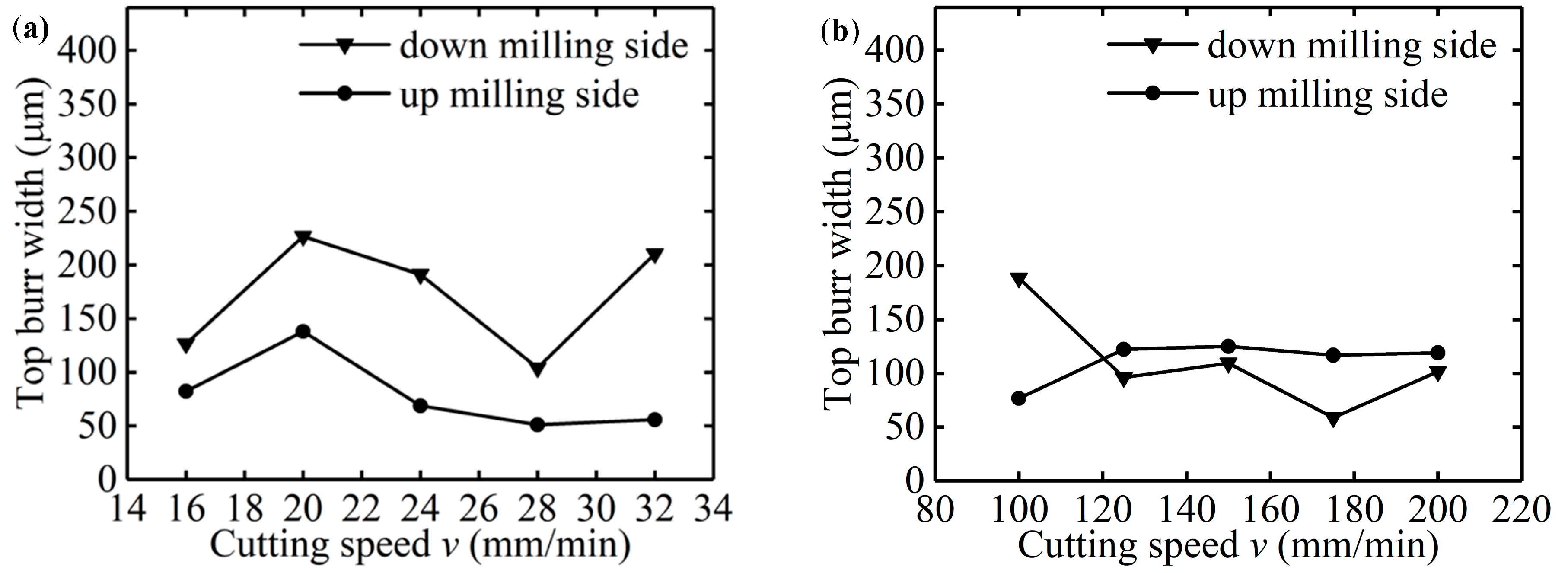

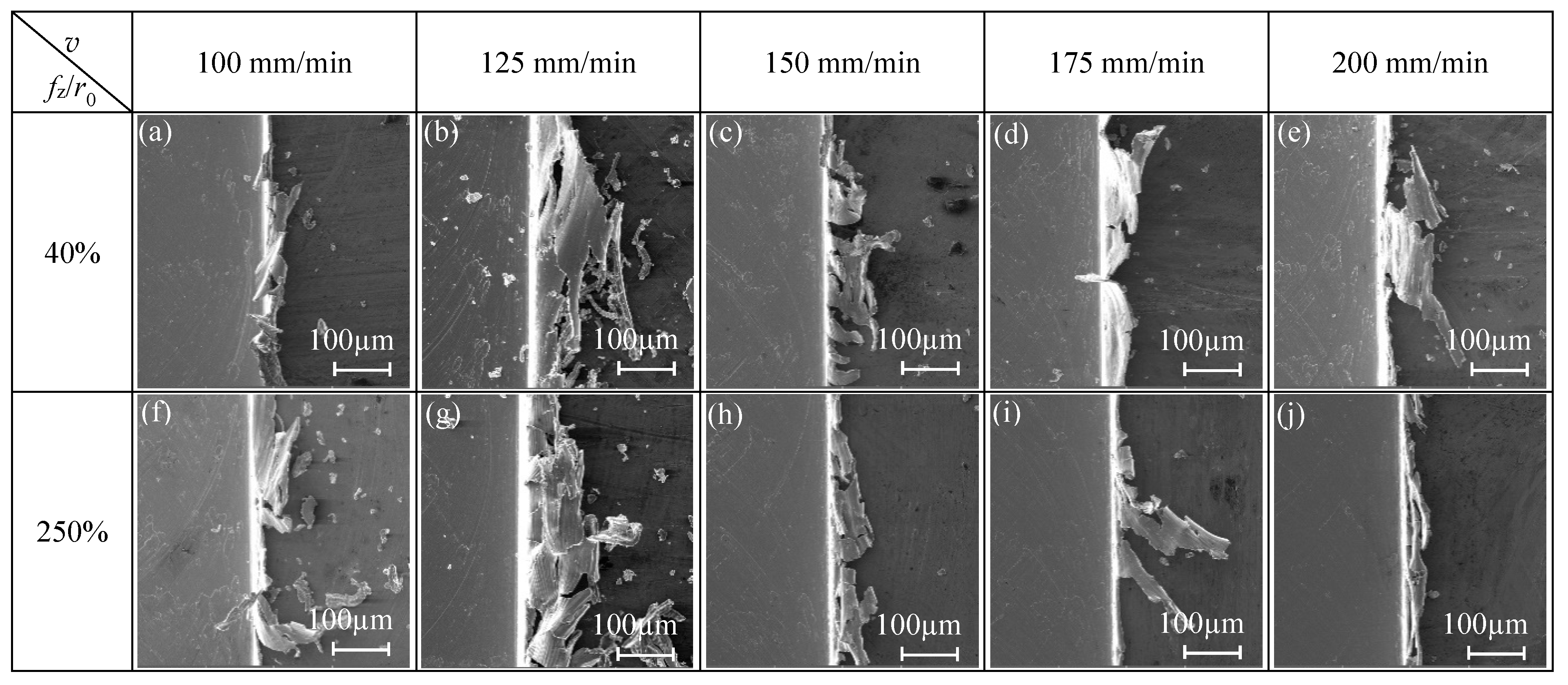

(2) Influence of Cutting Speed on Burr Size-Effect Band

The cutting parameters for the micro-milling straight slot test are shown in the N17–N24 group in

Table 1. Under the two conditions of

fz/

r0 = 40% (strong edge-size-effect zone) and

fz/

r0 = 250% (weak edge-size-effect zone), observing the top burr morphology of the micro-slot when cutting speed(

v) changes, the influence of

v on the burr size-effect band is studied.

When

fz/

r0 = 40%, cutting speed has an obvious effect on the top burr width in the down milling side. As shown in

Figure 12a, the top burr width in the up milling side increases first and then decreases gradually when

v increases from 16 mm/min to 32 mm/min, and the top burr width in the down millling side is larger than that in the up milling side. As shown in

Figure 13a–e, the top burr morphology in the down milling side is mainly shown as a long strip block shape, and the top burr morphology in the up milling side mainly presents as a tearing block shape.

When

fz/

r0 = 250%,

Figure 12b shows that cutting speed has little effect on the top burr width in the micro-milling slot; the change of the top burr width in the up milling side is less than 30 μm when

v increases from 100 mm/min to 200 mm/min. However, the top burr width in the down milling side is less than that in the up milling side when

v increases from 12 mm/min. The top burr morphology in the down milling side changes from a long and thin strip burr to a small serrated burr (

Figure 13f–j), and the top burr morphology in the up milling side changes from a large serrated burr to a small wavy burr (

Figure 14f–j).

3.3. Optimization of Micro-Milling Parameters Based on Surface Roughness

There is an ideal

fz/

r0 cutting parameter range to make the surface roughness of the micro-slot bottom the micro-milling minimum. As shown in

Figure 7b, when

fz/

r0 is less than 70%, the surface quality of the micro-slot bottom is poor, and the surface roughness of the micro-slot bottom increases rapidly with the decrease of

fz/

r0. This is because the micro-milling is in a strong size-effect zone, when

fz is less than

hmin, the material being machined mainly has elastic recovery, and the smaller the value of

fz/

r0, the stronger the squeezing and friction between the rake face of the micro-milling tool and the machined surface of the workpiece, thereby the changes in ploughing force are more significant. In addition, it is difficult to generate chips during the ploughing, and the workpiece material is slowly squeezed out after feeding multiple teeth, thus increasing the surface roughness, as shown in

Figure 15a–c.

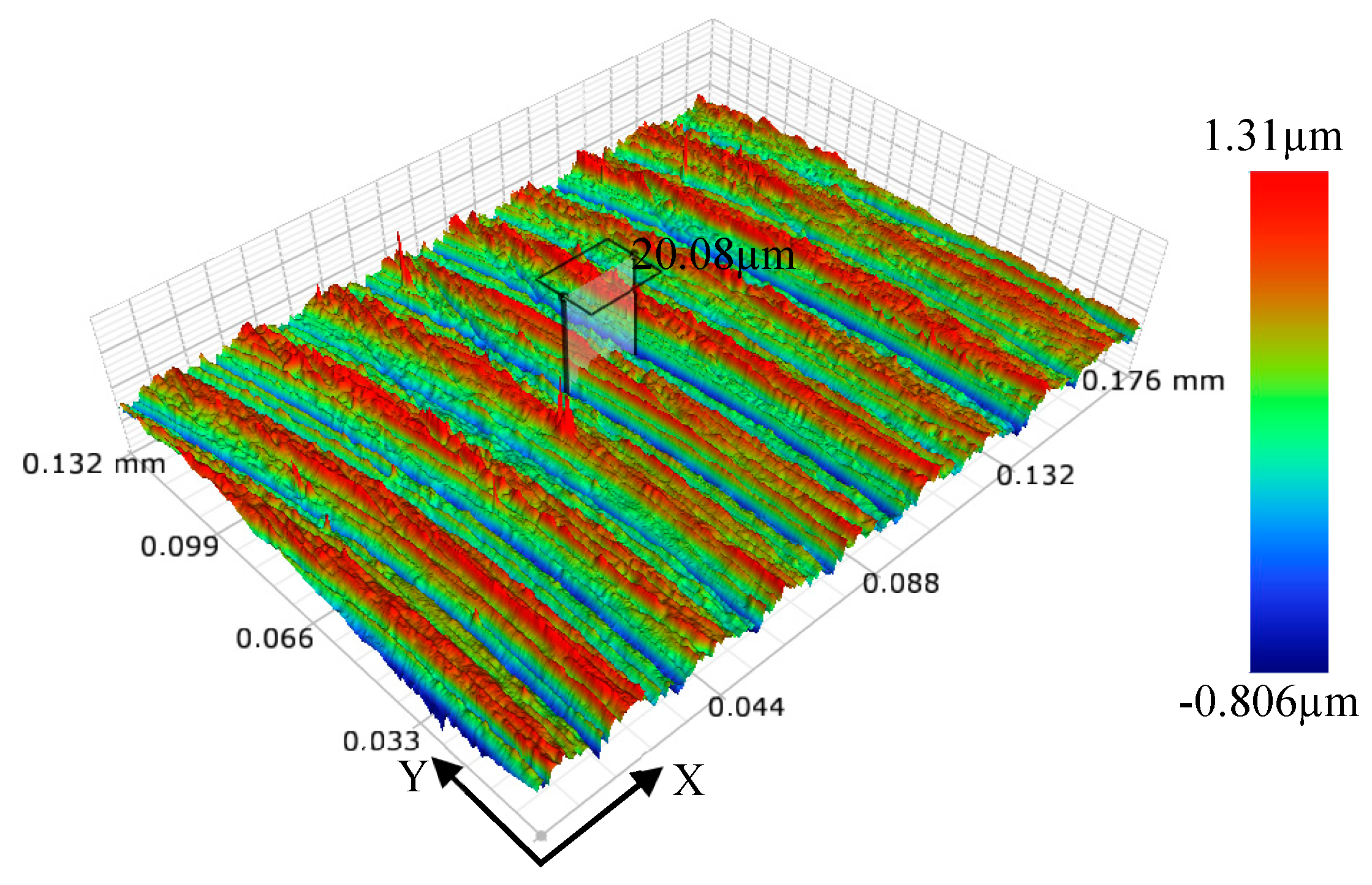

When

fz/

r0 is larger than 220%, micro-milling is in a weak size-effect zone (as shown in

Figure 7b). Shear force dominates the whole micro-milling process; the edge-size-effect of the tool is weakened; and surface roughness increases with the increase of

fz/

r0 value, but basically remains stable. As shown in

Figure 16, when

fz/

r0 is 400%,

fz is far greater than

r0 and

hmin; obvious regular tool marks were found on the machined surface. The distance between adjacent tool marks in the feed direction is 20.08 μm, which is close to the feed value (20 μm) of two neighboring teeth in a tool rotation circle. Consistent with the macro milling mechanism, this means there is an imprint of micro profile copying of micro-milling tool, resulting in a large

Ra of the micro-slot bottom.

When

fz/

r0 is larger than 70% and less than 220%, micro-milling is in the transition zone of the edge-size-effect (

Figure 7b), which means that micro-milling is in a process of ploughing transfer to shear. At this time,

fz is close to

hmin which can just generate chips, with less adhesion of the chips on tools, thereby the machined surface is smooth with few defects and lower surface roughness at the slot bottom, as shown in

Figure 15d–f. Therefore, the cutting parameters should be selected in the optimal roughness zone where

fz/

r0 is within 70%–220%, where the surface roughness can come down to 0.331 μm–0.44 μm, and an optimal

fz/

r0 value exists to minimize the surface roughness of the micro-slot bottom. The best

fz/

r0 value obtained from the N1–N8 group test in

Table 1 is 140%, the surface topography is shown in

Figure 15e.

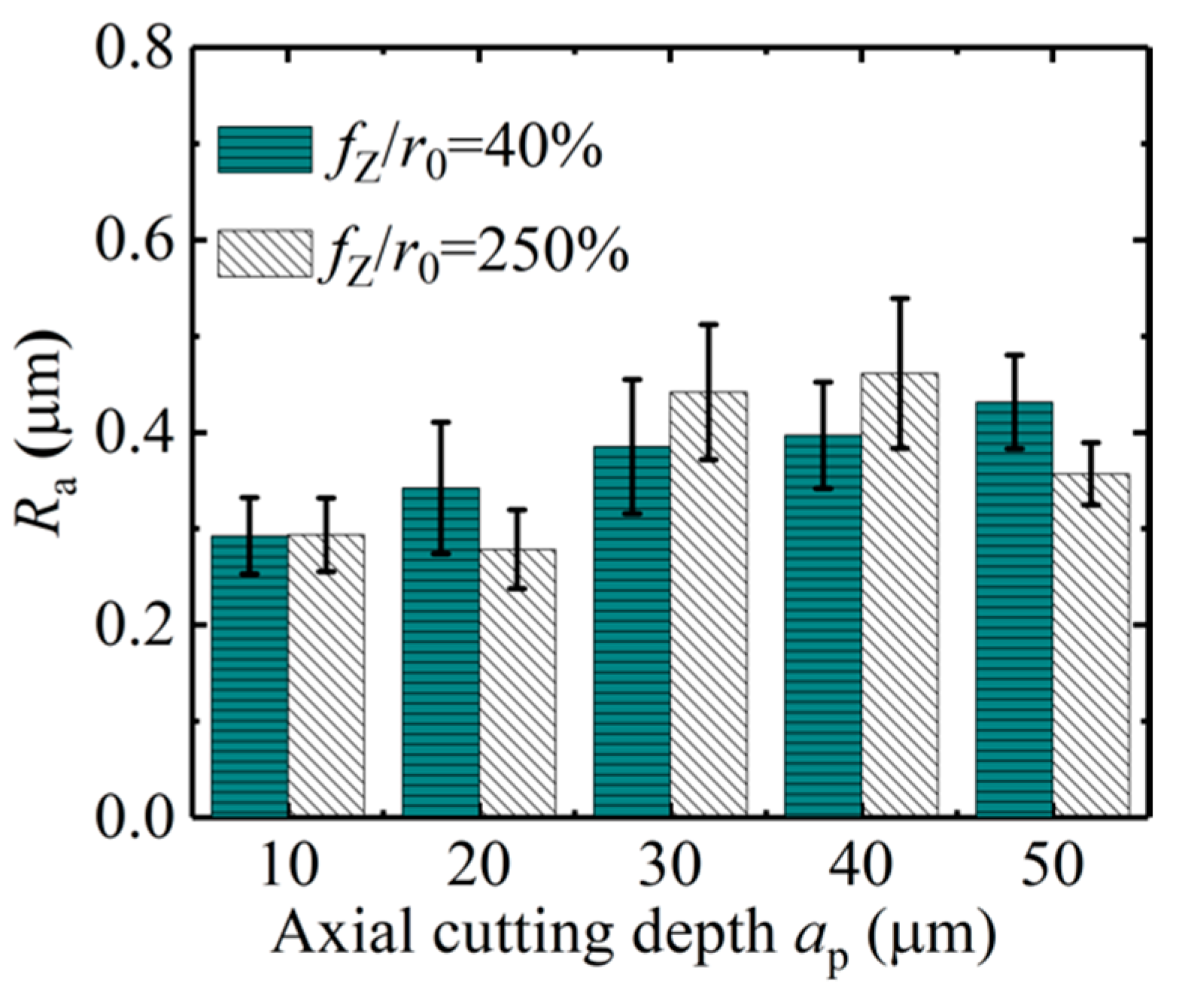

(1) Influence of Axial Cutting Depth on the Roughness of Micro-Slot Bottom

The influence of the axial cutting depth on the surface roughness of the micro-slot bottom is shown in

Figure 17; the cutting parameters used in the micro-milling test are listed in N9–N16 in

Table 1. When

fz/r0 is 40% and the axial cutting depth increases from 10 μm to 50 μm, the surface roughness of the micro-slot bottom gradually increases. This is because the micro-milling is in a strong size-effect zone and the edge-size-effect is significant, and notably squeeze and scratch exists between the tool and workpiece material, which causes the flank wear of the micro tool. Moreover, the increase of the axial cutting depth leads to the increase of the contact squeeze area, the volume of the squeezed workpiece material increases correspondingly, and the ploughing resistance increases. Although it is hard to form chips, many tool marks are formed on the surface of the micro-slot bottom, as shown in

Figure 18a–e.

When

fz/r0 is 250%, micro-milling is in the weak size zone.

Figure 17 shows that, when the axial cutting depth increases from 10 μm to 40 μm, the

Ra value of the micro-slot bottom increases from 0.28 μm to 0.42 μm correspondingly. This indicates that, although the tool is in contact with the workpiece material to generate stable chips under the main shear force, the resistance to plastic deformation of the workpiece material and the friction between the chips and the tool increase, and a small amount of chips left at the bottom of the micro-slot (

Figure 18f–l), thus some of the chips are extruded twice by the tool flank (

Figure 18)). When the axial cutting depth increases to 50 μm, the surface roughness decreases slightly. It is likely that the cutting edge of the milling tool is worn after the previous groups of experiments, which causes the larger cutting edge arc radius of the milling tool and, correspondingly, the

fz/r0 value is reduced; the chip is easy to generate and to fall off at the edge of the micro-slot; and the regular and consistent tool imprints are formed at the bottom of the micro-slot, as shown in

Figure 18o.

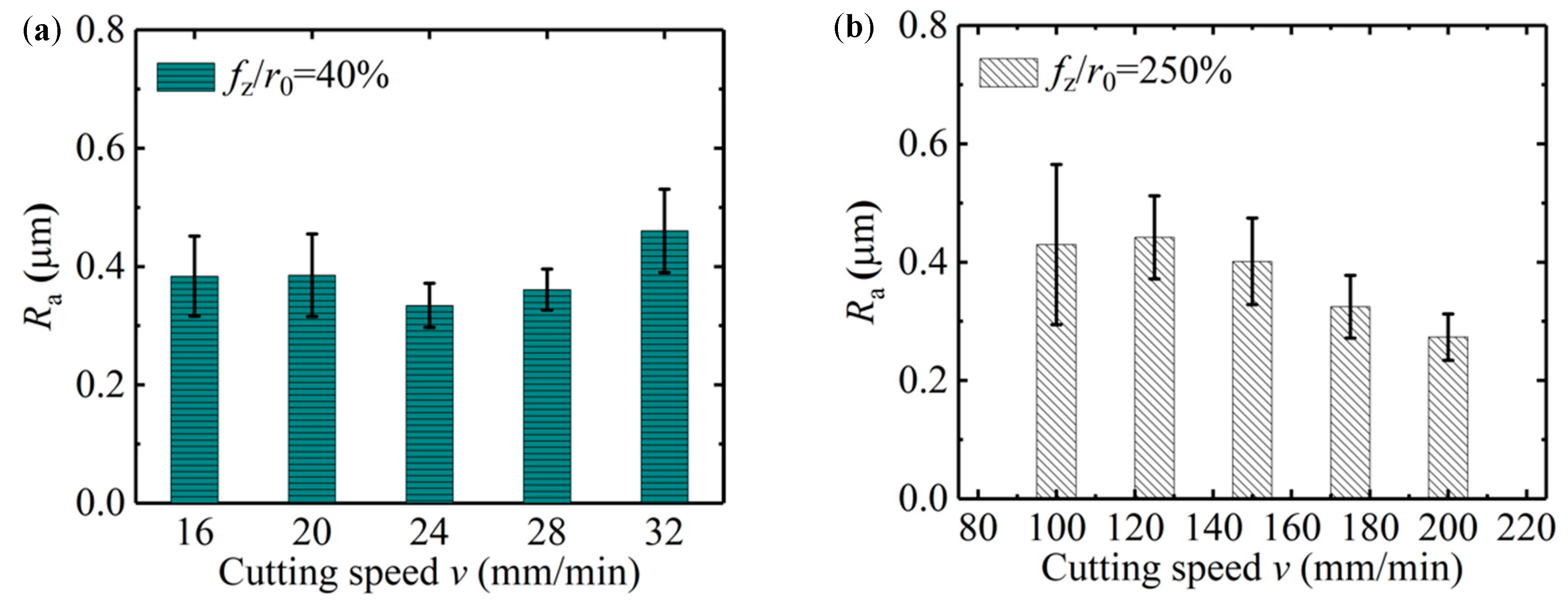

(2) Influence of Cutting Speed on the Surface Roughness

The effect of cutting speed on the surface roughness is shown in

Figure 19a; the cutting parameters of the micro-milling test are shown in

Table 1 as N17–N24. When

fz/r0 is 40%,

v increases gradually from 16 mm/min to 32 mm/min, and the surface roughness value of the micro-slot bottom is small and slightly decreased. This shows that the micro-milling process is in a strong size-effect zone and no chips are formed, but with the increase of

v, the contact time between the micro-milling tool and the workpiece material becomes shorter, and the material elastic deformation between the tool flank face and machined surface is small, the squeeze and friction effects reduce, and the plough cutting force has little deviations. When

v increases to 200 mm/min, the tool may appear obviously runout, causing the sudden increase in the surface roughness value of the micro-slot bottom.

When

fz/r0 is 250%, the surface roughness value of the micro-slot bottom gradually decreases with the increase of

v, as shown in

Figure 19b. This is because micro-milling is in the weak-edge-effect zone, the workpiece material forms stable chips under the effects of shear force, and regular tool marks are formed on the micro-slot bottom surface. In addition, the contact time between the tool and the chip becomes shorter when

v is increased, the chips adhere less to the tool and separate more easily from the micro-slot bottom, leading to less residual chip on the micro-slot bottom.