1. Introduction

Anti-reflective (AR) functional nanostructures have been extensively researched for the suppression of the Fresnel reflection of cover glasses in solar panels and display devices [

1,

2]. The initial research on AR nanostructures was based on moth and butterfly eyes [

3], which exhibit gradual changes in the refractive index due to the subwavelength nanostructure. A polymer nanoimprinting technique has received significant research attention with respect to the fabrication of AR nanostructures on glass substrates, due to its high replication quality at the nanoscale level and high efficiency. Lim et al. [

4] fabricated a nanodome-shaped AR nanostructure on a glass substrate using ultra-violet (UV) nanoimprinting, and Chuang et al. [

5] fabricated an AR nanostructure on a glass substrate using thermal nanoimprinting with an anodic alumina oxide template. Although the polymer nanoimprinting is an alternative promising method for the fabrication of AR structures on glass substrates, there are several drawbacks with respect to durability and delamination. The ideal fabrication method of AR nanostructures on glass substrates is the direct patterning of nanostructures on glass. To directly pattern an AR nanostructure on a glass substrate, reactive ion etching (RIE) with a nanoscale barrier pattern is employed. Son et. al [

6] and Verma et. al [

7] successfully fabricated an AR nanostructure on a glass substrate using an annealed metallic nanodot array barrier, whereas Ji et al. [

8] and Yu et al. [

9] employed a colloidal nanosphere; both based on RIE. Although the ideal cone-shaped AR nanostructure can be obtained using RIE with a nanoscale barrier, the RIE of glass material is time-consuming and expensive due to the low etching ratio of glass material and the toxicity of glass etching gas.

This paper proposes a glass imprinting process as an alternative cost-effective fabrication technique for uniform glass AR nanostructures. In the glass imprinting process, the glass is pressed by a stamp at a temperature higher than the glass softening temperature, to replicate the pattern on the glass [

10]. Given that the glass imprinting process is conducted at high processing temperatures and pressures, a mold material with a high hardness under the processing conditions is essentially required. Among the various mold materials reported for glass nanoimprinting, vitreous carbon (VC) is regarded as the most suitable material, because it offers a high operating temperature (2500 °C in the non-oxidizing environment), chemical stability, and gas impermeability. Moreover, it provides superior releasing characteristic during the glass imprinting process [

11]. Several studies were reported on the fabrication of VC stamps with nanostructures using focused ion beam milling [

12], RIE with electron beam lithographed patterns, [

13,

14] and nanosphere lithographed patterns [

15]. However, these methods are expensive when large-area VC stamps or multiple VC stamps are required. Given that the VC material is obtained by the carbonization of a high carbon yield polymer, a fabrication method for VC micro stamps was proposed based on the carbonization of a micropatterned high carbon yield polymer [

16,

17].

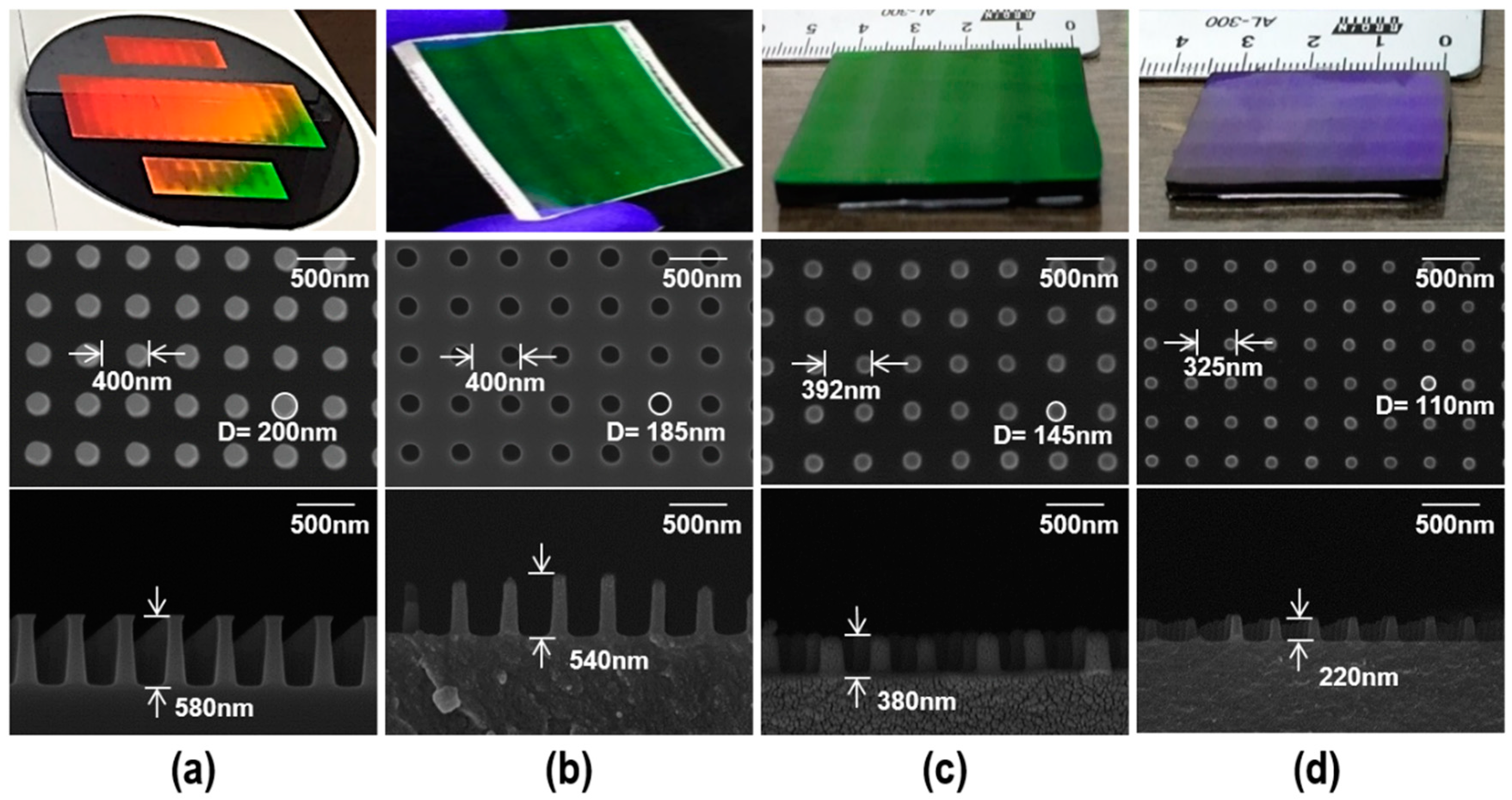

A high aspect ratio (HAR) cone-shape nanostructure is preferable for the realization of a gradually changing refractive index AR nanostructure [

18]. To pattern the HAR cone shape nanostructure on a glass substrate via the glass imprinting process, a stamp with an HAR negative cone shape nanostructure is required. However, it is relatively difficult to fill an HAR nanostructure via glass imprinting, as a high imprinting temperature and excessively high compression pressure are required. Hence, this paper proposes a method for the fabrication of a cross-sinusoidal nanostructure on a glass substrate via an incomplete filling technique using an HAR nanopin array (NPA) VC stamp, which is obtained by the carbonization of a replicated Furan precursor, as shown in

Figure 1.

An Si master with a HAR NPA was fabricated via photolithography and RIE, and a polydimethylsiloxane (PDMS) intermediate mold was replicated from the Si master (

Figure 1a). For the Furan imprinting process, a Furan substrate was obtained by bulk casting and back polishing processes (

Figure 1b,c, respectively) [

19]. For the fabrication of a Furan precursor with a HAR NPA, a thermal imprinting process was carried out on the Furan substrate using the PDMS intermediate mold (

Figure 1d). After the carbonization process, a VC stamp with a HAR NPA was obtained. During the glass imprinting process, the softened glass material gradually protruded into the space between the NPA due to the viscoelastic behavior (

Figure 1g). Hence, a cross-sinusoidal surface relief at a specific imprinting temperature and pressure was obtained, which can be considered as an AR nanostructure with a gradually changing refractive index. This paper presents an analysis of the effects of the glass imprinting conditions on the surface profile of the imprinted glass patterns, in addition to the optical transmittance characteristics of the fabricated cross-sinusoidal nanostructures, based on experimental and simulation methods.

3. Imperfect Glass Imprinting Process for Cross-Sinusoidal Anti-Reflective Glass Nanostructure

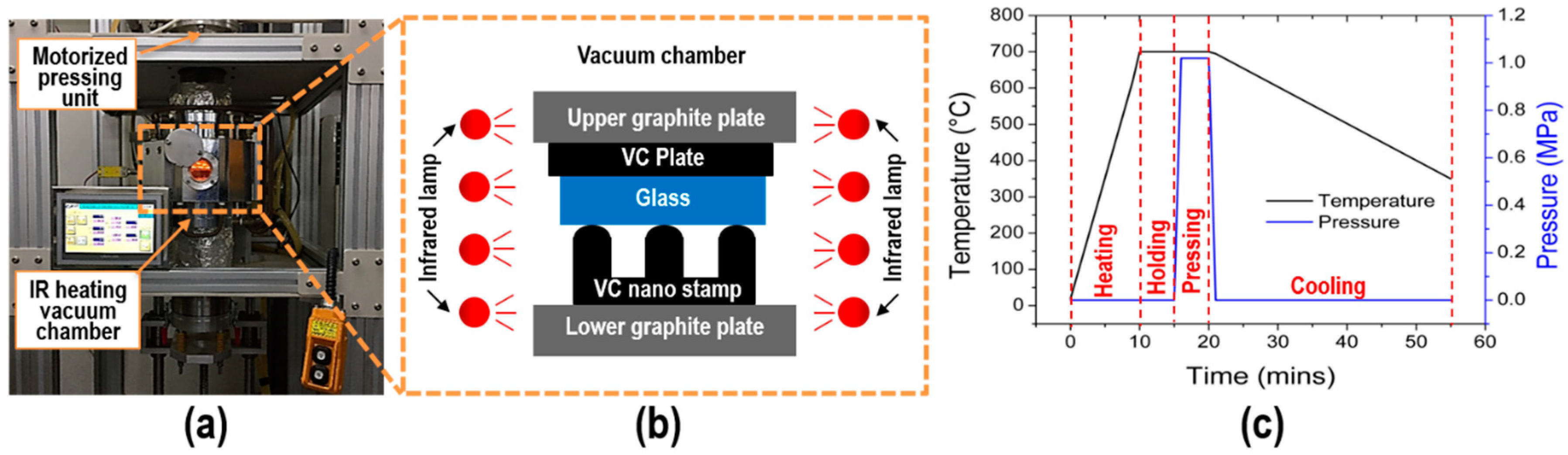

The glass imprinting system consists of a vacuum facilitated infrared (IR) heating chamber for a maximum operating temperature of 1,050 °C, with a temperature increase rate of 70 °C/min. In addition, a motorized pressing unit with a maximum applied force of 120 kgf was designed and constructed, as shown in

Figure 3a. A low iron soda-lime glass (White Clear Glass; JMC Glass Inc., Seoul, Republic of Korea) with a glass transition temperature of 564 °C and dimensions of 20 mm × 20 mm × 3.1 mm was used as an imprinting material.

Figure 3b presents the schematics of the experimental set-up for glass imprinting. The fabricated HAR NPA VC stamp was placed on the lower graphite plate, and the glass plate was located on it. An optically polished VC substrate was also placed on the glass plate to prevent damages to the backside of the glass plate due to the porous graphite plate.

Figure 4c presents the typical temperature and pressure history of the glass imprinting process. When the stack of the VC stamps and glass was located on the graphite plate, an evacuation process was carried out to prevent oxidation during the glass imprinting process. Thereafter, the chamber temperature was increased to 700 °C for 10 min, and then maintained for 5 min to provide uniform temperature distribution. After the holding time, a compression pressure was applied to the stack of the VC stamp and glass substrate for 5 min. In the cooling stage, the compression pressure was released, and natural cooling was applied. After the cooling process, the glass imprinted sample was extracted to check the replication quality.

During the glass imprinting process with the HAR NPA VC stamp, the softened glass material gradually protruded into the spaces between the nanoposts due to the viscoelastic behavior of glass material, and a cross-sinusoidal nanostructure was formed on the surface of the glass when the glass did not completely fill the nanocavity of the VC stamp. Given that the height of the cross-sinusoidal nanostructure (protrusion depth) is dependent on the imprinting temperature and pressure, and the HAR cross-sinusoidal nanostructure can provide a better AR performance; the imprinting temperature and pressure should be optimized to maximize the height of the pattern and prevent complete filling.

In this study, the influence of the imprinting temperature on the height of the glass imprinted cross-sinusoidal AR nanostructure was examined at a fixed imprinting pressure of 1 MPa. It should be noted that the HAR NPA on the VC stamp can be easily damaged during the glass imprinting process due to the low structural strength of the HAR NPA. After the preliminary glass imprinting experiments with the HAR NPA VC stamp, the imprinting pressure of this study was fixed at 1 MPa, which is the maximum allowable pressure for the prevention of damages to the HAR NPA on the VC stamp.

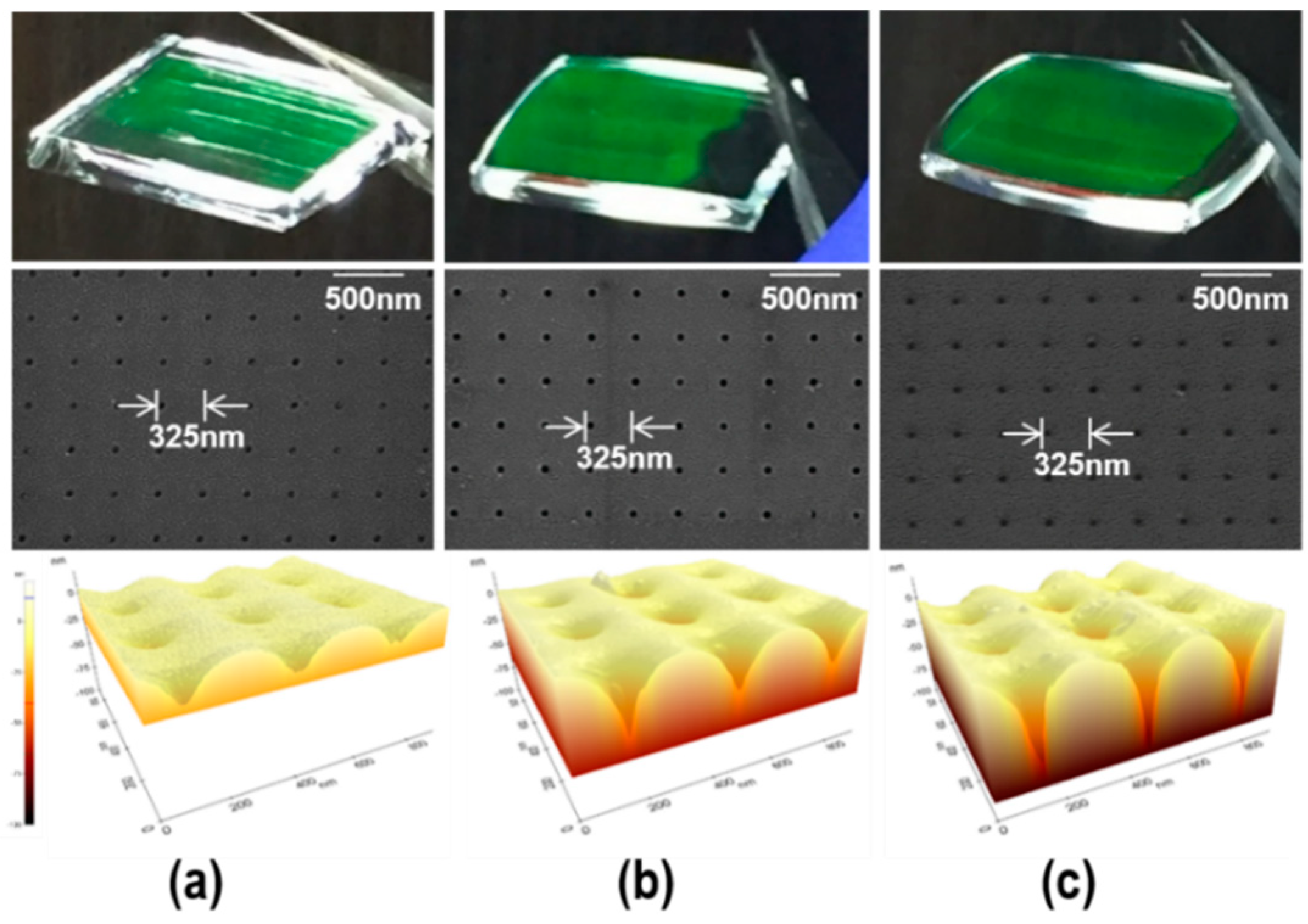

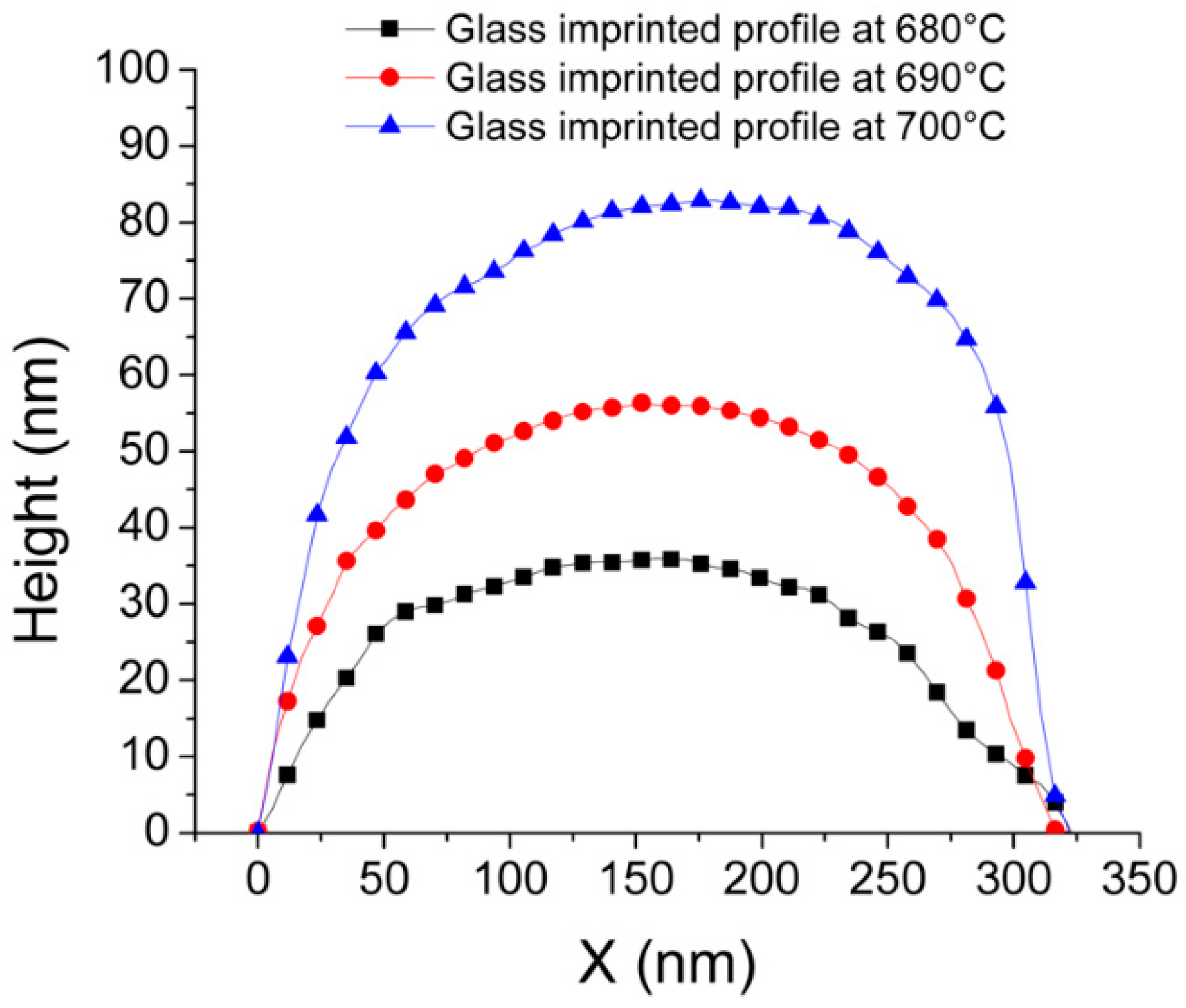

Figure 4 presents the images (top), top-view SEM images (middle), and three-dimensional (3D) surface profiles obtained by atomic force microscope (AFM) measurements (bottom) of the cross-sinusoidal nanostructured glass substrates, which were glass imprinted at temperatures of (a) 680 °C, (b) 690 °C, and (c) 700 °C; with a fixed pressure of 1 MPa. The uniform diffraction color of the samples in the images clearly indicate that the uniform nanostructures were entirely fabricated on a glass substrate without defects. In the top-view SEM images, the uniform-stamped patterns with a pitch of 325 nm were observed. The 3D surface profiles obtained by the AFM measurements indicated that the cross-sinusoidal structures were fabricated via the imperfect glass imprinting technique. To qualitatively examine the influence of the imprinting temperature on the height of the cross-sinusoidal structures, the cross-sectional surface profiles of the cross-sinusoidal structures were compared, as shown in

Figure 5. The measured heights of the cross-sinusoidal nanostructures were 35 nm, 55 nm, and 80 nm for the imprinting temperatures of 680 °C, 690 °C, and 700 °C, respectively. The heights of the glass imprinted cross-sinusoidal nanopatterns were gradually increased in accordance with an increase in temperature. Although samples with greater heights could be obtained at imprinting temperatures higher than 700 °C and pressures higher than 1 MPa, several defects were observed on the glass imprinted samples due to the broken NPA on the VC stamp during the releasing process. Therefore, the optimized imprinting condition was selected as the imprinting temperature of 700 °C and pressure of 1 MPa to fabricate the highest cross-sinusoidal nanostructure on the glass substrate without any releasing problem.

4. AR Characteristics of the Fabricated Glass Cross-Sinusoidal Nanostructure

To examine the AR characteristics of the fabricated glass cross-sinusoidal nanostructures, the ultraviolet–visible (UV-Vis) (wavelength range of 400–800 nm) transmission spectra were measured using a spectrophotometer (V-670 UV-Vis, Jasco Inc., Easton, MD, USA) and compared with the simulated transmission spectra.

For the simulation of transmission spectra of the glass cross-sinusoidal nanostructure with different heights, a rigorous coupled wave analysis (RCWA) was conducted using commercial software (DiffractMOD, Rsoft, Synopsys, Inc., Mountain View, CA, USA). Based on the measured data of the glass imprinted cross-sinusoidal nanostructure, the 3D simulation models were constructed as shown in

Figure 6.

Figure 6a presents the top-view image of the 3D simulation model of the cross-sinusoidal structure, as generated using the Rsoft computer-aided design (CAD) tool. In particular, it was a combination of a positive cone structure (red), which represents glass (

n = 1.5); and a negative cone structure (cyan), which represents air (

n = 1), on a glass substrate (

n = 1.5). The environmental material was set as air (

n =1). Given that the pitch of the square-arrayed sinusoidal structure was 325 nm, and the diagonal distance between peaks was 460 nm; the x- and y-direction peak-to-valley distances (center of the positive cone and center of the negative cone) were set as 230 nm. The heights of the positive cone and depth of the negative cone were set as half of the measured heights of the cross-sinusoidal nanostructures (35 nm, 55 nm, and 80 nm). The dimensions of the simulation area were set as 460 nm × 460 nm, with repeated boundary conditions.

Figure 6b−d present the A-A and B-B cross-sectional refractive index contour maps for the simulation models with total heights of (b) 35 nm, (c) 55 nm, and (d) 80 nm, respectively.

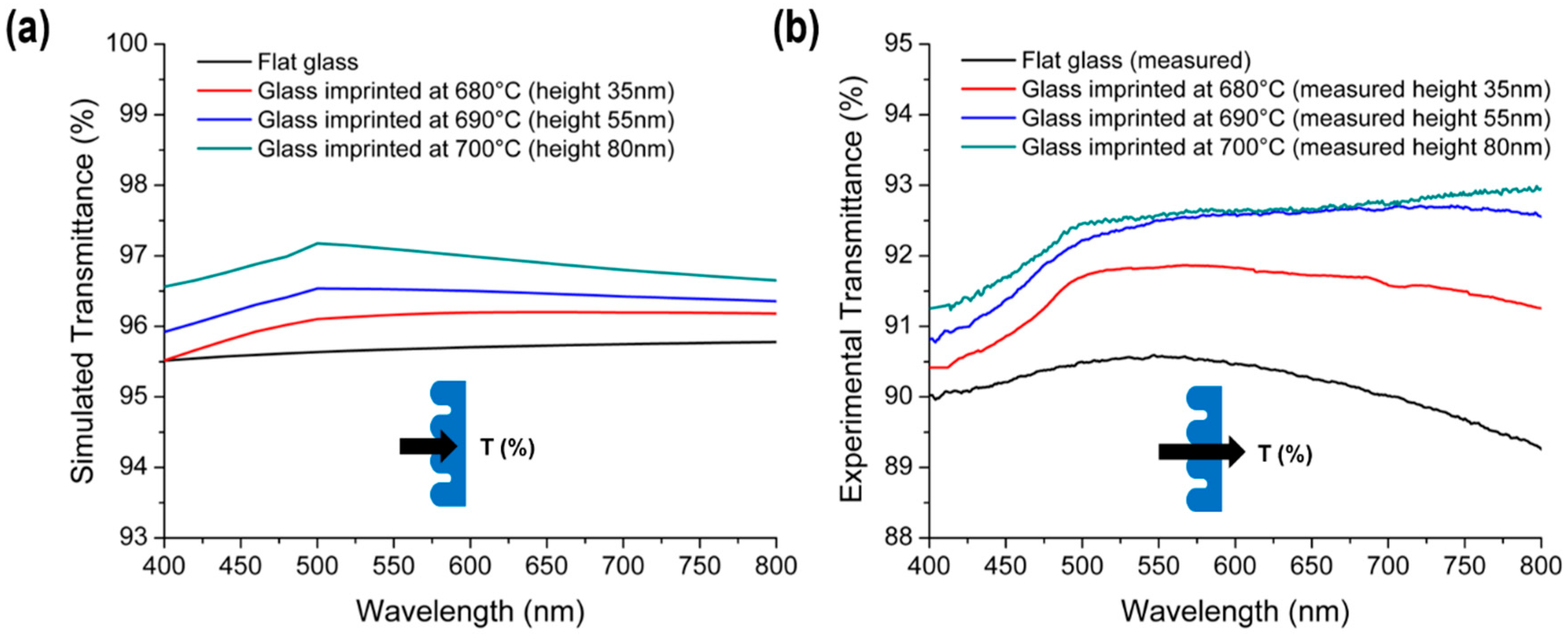

Figure 7 presents the effect of the imprinting temperature (height of cross-sinusoidal nanostructure) on the (a) simulated and (b) measured transmission spectra. In the simulation, the reflectance at the backside of the glass sample was not considered. The trends of the measured transmission results were found to be in good agreement with the simulation results. With an increase in the cross-sinusoidal nanostructure heights, the average transmittances increased in the case of the flat glass over the entire spectral range. By increasing the sinusoidal structure height from 55 nm to 80 nm, several differences were observed between the experimental transmission and simulation result, because the fabricated cross-sinusoidal structure with a height of 80 nm (

Figure 4c) was not an ideal cone-shaped structure. However, both the experimental and simulation results revealed that a transmittance enhancement of ~2% in the visible wavelength was achieved from the glass imprinted cross-sinusoidal structure at a height of 80 nm, when compared with the flat glass.

5. Conclusions

In this study, a cross-sinusoidal structure was fabricated on a glass substrate via an imperfect glass imprinting method with a HAR NPA VC stamp. The VC stamp was obtained by the carbonization of a replicated Furan precursor, which was obtained by Furan imprinting on a Furan plate with a-PDMS replicated mold from an Si master. The Si master with an NPA having an aspect ratio of ~3 was fabricated via photolithography and RIE processes. After the PDMS replication, Furan imprinting, and the carbonization process; the VC stamp with an NPA having an aspect ratio of ~2 was obtained due to the non-filling of the highly viscous PDMS and Furan materials, in addition the shrinkages during the Furan curing and carbonization. However, the VC NPA with an aspect ratio of 2 was sufficient for the fabrication of the designed cross-sinusoidal structure via the imperfect glass imprinting process. To optimize the glass imprinting process conditions, the effects of the imprinting temperature on the height of the imprinted cross-sinusoidal structure were analyzed, in addition to the measured and simulated transmission spectra. At the imprinting temperature of 700 °C and pressure of 1 MPa, a glass imprinted cross-sinusoidal nanostructure with a pitch of 325 nm and a height of 80 nm was obtained. The transmittance of the glass imprinted cross-sinusoidal structure with a height of 80 nm was increased by ~2% over the entire visible-light range when compared with that of the flat glass substrate. This clearly indicates that the proposed imperfect glass imprinting with HAR NPA VC stamp can be employed as an alternative method for the direct fabrication of an AR nanostructure on a glass substrate. Furthermore, the fabrication of a large-area AR cross-sinusoidal nanostructured glass substrate via a roll type glass imprinting process with roll type VC mold with HAR NPA is the objective of future research.