Autonomous Microrobotic Manipulation Using Visual Servo Control

Abstract

1. Introduction

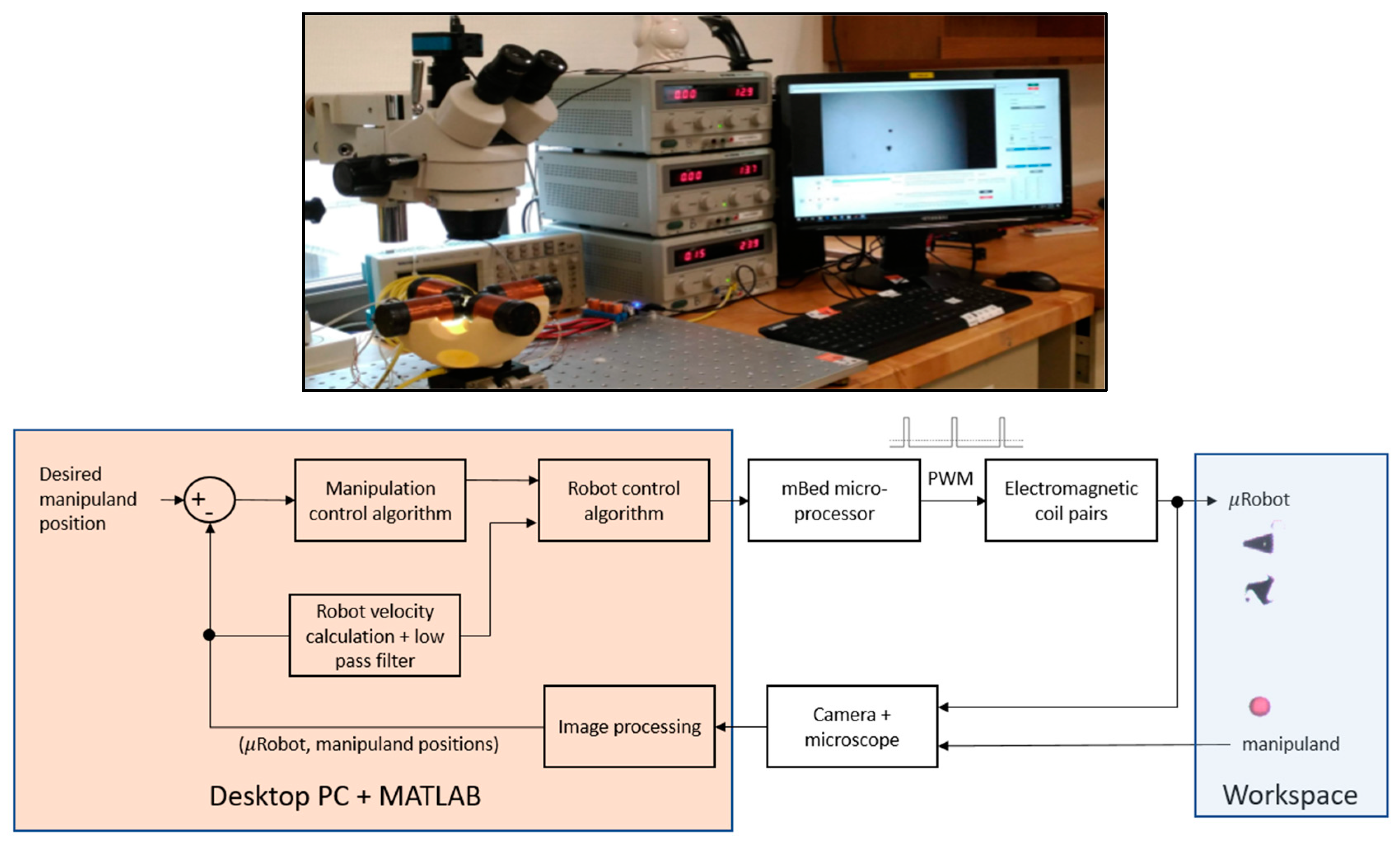

2. Experimental Setup

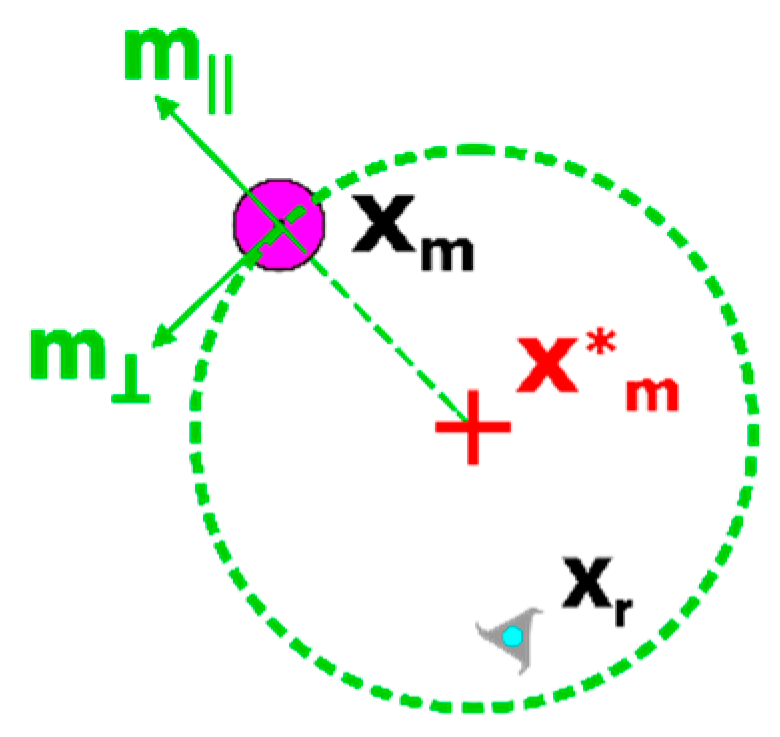

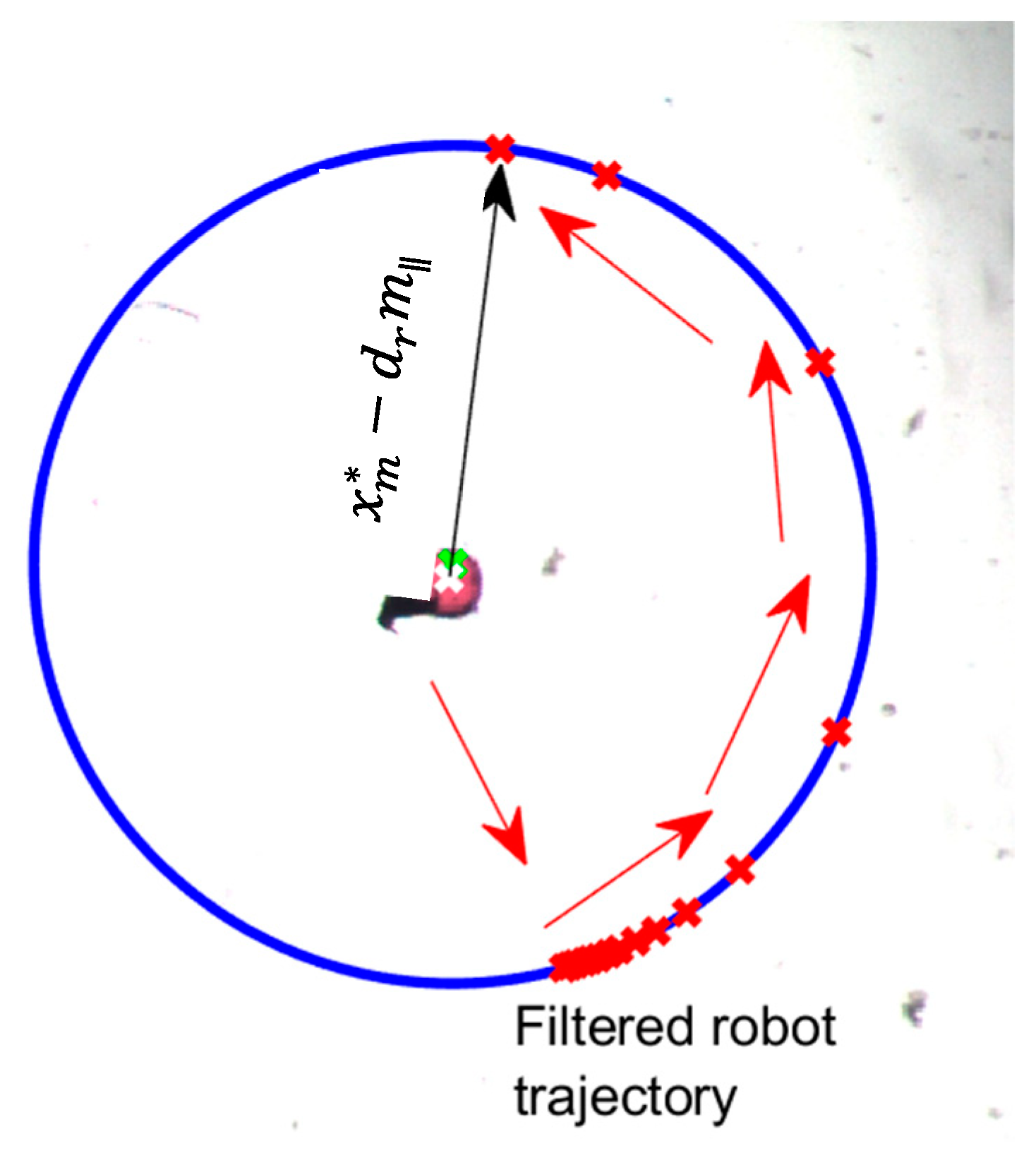

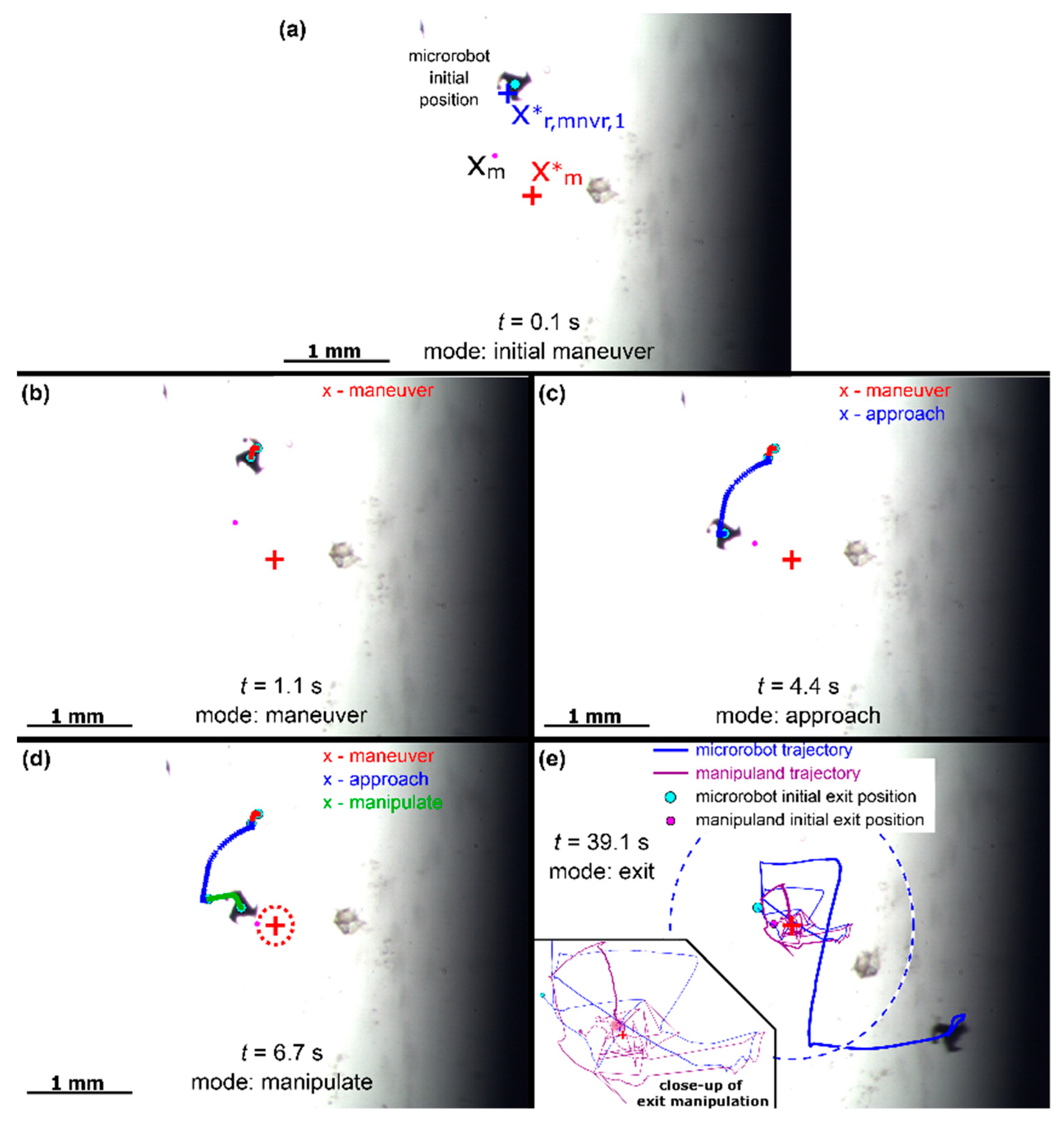

3. Manipulation Control Algorithm

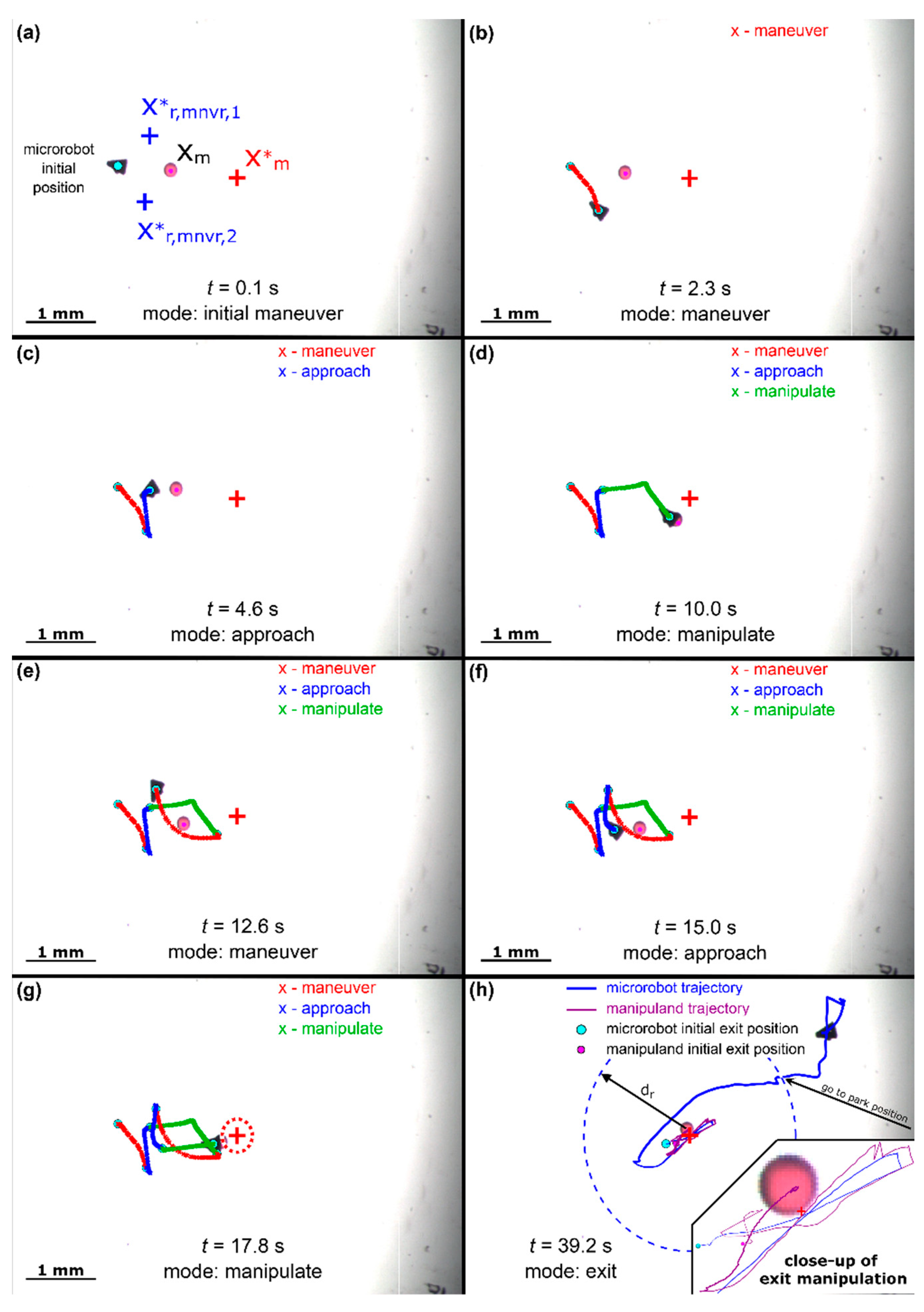

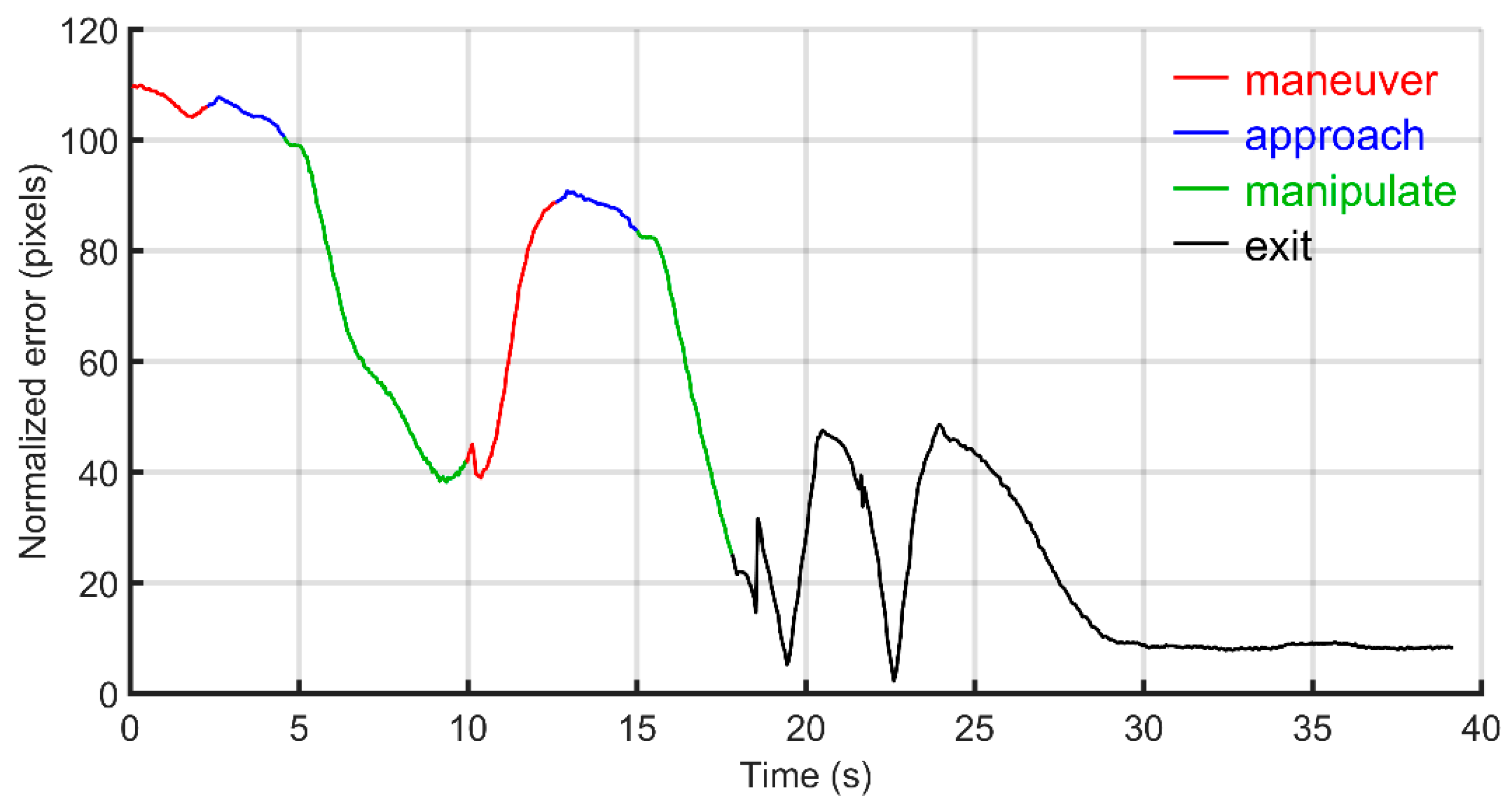

4. Robot Control Algorithm

5. Results and Discussion

6. Conclusions

Supplementary Materials

Author Contributions

Funding

Conflicts of Interest

References

- Sitti, M.; Ceylan, H.; Hu, W.; Giltinan, J.; Turan, M.; Yim, S.; Diller, E. Biomedical applications of untethered mobile Milli/Microrobots. Proc. IEEE 2015, 205–224. [Google Scholar] [CrossRef]

- Ceylan, H.; Giltinan, J.; Kozielski, K.; Sientti, M. Mobile microrobots for bioengineering applications. Lab on a Chip 2017, 17, 1705–1724. [Google Scholar] [CrossRef]

- Cappelleri, D.; Efthymiou, D.; Goswami, A.; Vitoroulis, N.; Zavlanos, M. Towards mobile microrobot swarms for additive micromanufacturing. Intl. J. Adv. Robot. Syst. 2014, 11, 1–14. [Google Scholar] [CrossRef]

- Steager, E.B.; Sakar, M.S.; Magee, C.; Kennedy, M.; Cowley, A.; Kumar, V. Automated manipulation of single cells using magnetic microrobots. Intl. J. Robotics Res. 2013, 23, 346–359. [Google Scholar] [CrossRef]

- Pawashe, C.; Floyd, S.; Diller, E.; Sitti, M. Two-dimensional autonomous microparticle manipulation strategies for magnetic microrobots in fluidic environments. IEEE Trans. Robotics 2012, 28, 467–477. [Google Scholar] [CrossRef]

- Giltinan, J.; Diller, E.; Sitti, M. Programmable assembly of heterogeneous microparts by an untethered mobile capillary microgripper. Lab on a Chip 2016, 16, 4445–4457. [Google Scholar] [CrossRef]

- Ye, Z.; Edington, C.; Russell, A.J.; Sitti, M. Versatile non-contact micro-manipulation method using rotational flows locally induced by magnetic microrobots. In Proceedings of the IEEE/ASME International Conference on Advanced Intelligent Mechatronics (AIM), Besancon, France, 8–11 July 2014; pp. 26–31. [Google Scholar]

- Kwon, J.O.; Yang, J.S.; Chae, J.B.; Chung, S.K. Micro-object manipulation in a microfabricated channel using an electromagnetically driven microrobot with an acoustically oscillating bubble. Sens. Actuators A 2014, 215, 77–82. [Google Scholar] [CrossRef]

- Marino, H.; Bergeles, C.; Nelson, B.J. Robust electromagnetic control of microrobots under force and localization uncertainties. IEEE Trans. Autom. Sci. Eng. 2014, 11, 310–316. [Google Scholar] [CrossRef]

- Belharet, K.; Folio, D.; Ferreira, A. Control of a magnetic microrobot navigating in microfluidic arterial bifurcations through pulsatile and viscous flow. In Proceedings of the IEEE/RSJ International Conference on Intelligent Robots and Systems, Vilamoura, Portugal, 7–12 October 2012; pp. 2559–2564. [Google Scholar]

- Denasi, A.; Misra, S. A robust controller for micro-sized agents: The prescribed performance approach. In Proceedings of the International Conference on Manipulation, Automation and Robotics at Small Scales, MARSS, Paris, France, 18–22 July 2016. [Google Scholar]

- Arcese, L.; Fruchard, M.; Ferreira, A. Adaptive controller and observer for a magnetic microrobot. IEEE Trans. Robot. 2013, 29, 1060–1067. [Google Scholar] [CrossRef]

- Hosoda, K.; Asada, M. Versatile visual servoing without knowledge of true Jacobian. In Proceedings of the IEEE/RSJ International Conference on Intelligent Robots and Systems (IROS’94), Munich, Germany, 12–16 September 1994; pp. 186–193. [Google Scholar]

- Jagersand, M.; Fuentes, O.; Nelson, R. Experimental evaluation of uncalibrated visual servoing for precision manipulation. In Proceedings of the International Conference on Robotics and Automation, Albuquerque, NM, USA, 25–25 April 1997; pp. 2874–2880. [Google Scholar]

- Piepmeier, J.A.; McMurray, G.V.; Lipkin, H. Uncalibrated dynamic visual servoing. IEEE Trans. Robot. Autom. 2004, 20, 143–147. [Google Scholar] [CrossRef]

- Piepmeier, J.A.; Firebaugh, S.; Olsen, C.S. Uncalibrated visual servo control of magnetically actuated microrobots in a fluid environment. Micromachines 2014, 5, 797–813. [Google Scholar] [CrossRef]

- Cooke, J.F.; Piepmeier, J.A.; Elbidweihy, H.; Firebaugh, S.L. Uncalibrated three-dimensional microrobot control in a fluid environment. In Proceedings of the International Conference on Manipulation, Automation and Robotics at Small Scales (MARSS), Montreal, QC, Canada, 17–21 July 2017. [Google Scholar]

- Banerjee, A.G.; Gupta, S.K. Research in automated planning and control for micromanipulation. IEEE Trans. Automat. Sci. Eng. 2013, 10, 485–495. [Google Scholar] [CrossRef]

- Floyd, S.; Pawashe, C.; Sitti, M. Two-dimensional contact and noncontact micromanipulation in liquid using an untethered mobile magnetic microrobot. IEEE Trans. Robot. 2009, 25, 1332–1342. [Google Scholar] [CrossRef]

- Zhang, L.; Petit, T.; Peyer, K.E.; Kratochvil, B.E.; Zhang, J.; Lou, J.; Nelson, B.J. Noncontact and contact micromanipulation using a rotating nickel nanowire. In Proceedings of the IEEE International Conference on Nano/Molecular Medicine and Engineering, Hong Kong/Macau, China, 5–9 December 2010; pp. 38–43. [Google Scholar]

- Ye, Z.; Diller, E.; Sitti, M. Micro-manipulation using rotational fluid flows induced by remote magnetic micro-manipulators. J. Appl. Phys. 2012, 112, 064912. [Google Scholar] [CrossRef]

- El-Gazzar, A.G.; Al-Khouly, L.E.; Klingner, A.; Misra, S.; Khalil, I.S.M. Non-Contact manipulation of microbeads via pushing and pulling using magnetically controlled clusters of paramagnetic microparticles. In Proceedings of the IEEE/RSJ International Conference on Intelligent Robots and Systems (IROS), Hamburg, Germany, 28 September–2 October 2015; pp. 778–783. [Google Scholar]

- Wong, D.; Liu, I.B.; Steager, E.B.; Stebe, K.J.; Kumar, V. Directed micro assembly of passive particles at fluid interfaces using magnetic robots. In Proceedings of the International Conference on Manipulation, Automation and Robotics at Small Scales (MARSS), Paris, France, 18–22 July 2016. [Google Scholar]

- Muñoz, E.M.; Quispe, J.E.; Régnier, S.; Vela, E. Laser-induced thermocapillary flow manipulation of microparticles with obstacle avoidance in a non-patterned fluidic environment. In Proceedings of the International Conference on Manipulation, Automation and Robotics at Small Scales (MARSS), Montreal, QC, Canada, 17–21 July 2017. [Google Scholar]

- Rahman, M.A.; Takahashi, N.; Siliga, K.F.; Ng, N.K.; Wang, Z.; Ohta, A.T. Vision-assisted micromanipulation using closed-loop actuation of multiple microrobots. Robot. Biomim. 2017, 4, 7. [Google Scholar] [CrossRef] [PubMed]

- El-Etriby, A.E.; Klingner, A.; Tabak, A.F.; Khalil, I.S.M. Manipulation of non-magnetic microbeads using soft microrobotic sperm. In Proceedings of the International Conference on Manipulation, Automation and Robotics at Small Scales (MARSS), Nagoya, Japan, 4–8 July 2018. [Google Scholar]

- Brooks, R. Intelligence without representation. Artif. Intell. 1991, 47, 139–159. [Google Scholar] [CrossRef]

- Zeydan, B.; Petruska, A.J.; Somm, L.; Pieters, R.; Fang, Y.; Sargent, D.F.; Nelson, B.J. Automated particle collection for protein crystal harvesting. IEEE Robot. Automat. Letters 2017, 2, 1391–1396. [Google Scholar] [CrossRef][Green Version]

- Thakur, A.; Chowdhury, S.; Svec, P.; Wang, C.; Losert, W.; Gupta, S.K. Indirect pushing based automated micromanipulation of biological cells using optical tweezers. Intl. J. Robot Res. 2014, 33, 1098–1111. [Google Scholar] [CrossRef]

- Donald, B.; Levey, C.; Paprotny, I.; Rus, D. Planning and control for microassembly of structures composed of stress-engineered MEMS microrobots. Intl. J. Robot. Res. 2013, 32, 218–246. [Google Scholar] [CrossRef]

- Ruz, M.; Garrido, J.; Vazquez, F.; Morilla, F. Interactive tuning tool of proportional-integral controllers for first order plus time delay processes. Symmetry 2018, 10, 569. [Google Scholar] [CrossRef]

- Khatib, O. Real-time obstacle avoidance for manipulators and mobile robots. Intl. J. Robot. Res. 1986, 5, 90–98. [Google Scholar] [CrossRef]

| Ref. | Actuation Method | Path Planning | Control Type | Release Strategy | Positioning Accuracy (%manip. size) |

|---|---|---|---|---|---|

| Floyd [19] | Contact and non-contact pushing by magnetic microrobot | Not discussed | Open loop | Not discussed | Not discussed |

| Zhang [20] | Non-contact pulling and pushing with rotating nanowire | Not discussed | Not discussed | Passive | ~30% |

| Ye [21] | Non-contact entrapment by rotating 360 um spherical microrobot | Not discussed | Not discussed | Active (cease rotation) | Not discussed |

| El-Gazzar [22] | Non-contact pulling and pushing by a magnetic cluster | Not discussed | Teleoperation | Active (increase speed) | 30–60% |

| Wong [23] | Capillary action at fluid interface | Not discussed | Closed loop | Not discussed | Not discussed |

| Munoz [24] | Laser-induced thermocapillary flow | Artificial potential fields | Closed loop | Not required | Discussed but not quantified |

| Rahman [25] | Microrobot bubbles actuated by laser-induced thermocapillary flow | Grasping, rotation, and translation modes | Open loop and hybrid closed loop | Active | 5–10% |

| El-Etriby [26] | Flagellar microswimmer contact pushing | Not discussed | Teleoperation | Active (increase flagellation frequency) | 55% |

| This work | Magnetic microrobot using contact pushing and non-contact pushing and pulling | Behavior based | Closed loop | Active (feedback driven escape vector) | 33% |

| Mode | Commanded robot position |

|---|---|

| Maneuver | |

| Approach | |

| Manipulate | |

| Exit |

| Symbol | Description | Equation | |

|---|---|---|---|

| Manipuland target position | Given | ||

| Radial unit vector | ( | (1) | |

| Tangential unit vector | (( | (2) | |

| Maneuver targets | (3) | ||

| Approach target | (4) | ||

| Manipulate target | (5) | ||

| Robot exit/separation position | (6) | ||

| Parameter | Description | Value |

|---|---|---|

| Set point arrival tolerance | 10 (pixels) | |

| Radial offset from manipuland for maneuver point | 35 (pixels) | |

| Tangential offset from manipuland for maneuver point | 70 (pixels) | |

| Radial offset from manipuland for approach mode | 35 (pixels) | |

| Radial offset from manipuland for manipulate mode | −5 (pixels) | |

| Radius from for robot to exit mode to park position | 175 (pixels) | |

| Filter time constant for separation/exit mode | 1 | |

| Velocity gain per pixel error | 2 (s−1) | |

| Proportional velocity gain | 10−3 | |

| Integral velocity gain | 10−2 |

| Trial | Initial Manipuland Error (pixels) | Initial Robot/Manipuland Separation (pixels) | Time to Exit Mode (s) | Time in Exit Mode (s) | Final Manipuland Error (pixels) | Robot/Manipuland Type |

|---|---|---|---|---|---|---|

| 1 | 33.10 | 299.50 | 17.70 | 47.88 | 4.41 | Wedge, 200-µm |

| 2 | 28.00 | 275.11 | 8.17 | 72.75 | 3.49 | Wedge, 200-µm |

| 3 | 16.74 | 140.39 | 8.66 | 21.82 | 7.89 | Wedge, 200-µm |

| 4 | 171.38 | 81.63 | 9.34 | 39.50 | 12.26 | Wedge, 200-µm |

| 5 | 27.86 | 13.17 | 7.71 | 33.62 | 7.43 | Wedge, 200-µm |

| 6 | 5.85 | 100.48 | 16.91 | 9.83 | 9.42 | Wedge, 200-µm |

| 7 | 8.88 | 262.05 | 11.88 | 18.87 | 4.91 | Wedge, 200-µm |

| 8 | 109.71 | 87.85 | 17.86 | 21.29 | 8.31 | Wedge, 200-µm |

| 9 | 37.79 | 204.80 | 6.66 | 29.78 | 6.33 | Wedge, 200-µm |

| 10 | 102.45 | 134.01 | 8.88 | 14.07 | 8.38 | Wedge, 200-µm |

| 11 | 202.97 | 110.30 | 14.07 | 17.70 | 9.37 | Star, 200-µm |

| 12 | 150.17 | 226.13 | 25.17 | 40.72 | 26.26 | Star, 200-µm |

| 13 | 213.66 | 234.12 | 32.1 | 41.25 | 1.52 | Star, 200-µm |

| 14 | 74.77 | 62.67 | 6.72 | 32.38 | 6.70 | Star, 50-µm |

| Avg: | 84.52 | 159.44 | 13.70 | 31.53 | 8.33 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Feemster, M.; Piepmeier, J.A.; Biggs, H.; Yee, S.; ElBidweihy, H.; Firebaugh, S.L. Autonomous Microrobotic Manipulation Using Visual Servo Control. Micromachines 2020, 11, 132. https://doi.org/10.3390/mi11020132

Feemster M, Piepmeier JA, Biggs H, Yee S, ElBidweihy H, Firebaugh SL. Autonomous Microrobotic Manipulation Using Visual Servo Control. Micromachines. 2020; 11(2):132. https://doi.org/10.3390/mi11020132

Chicago/Turabian StyleFeemster, Matthew, Jenelle A. Piepmeier, Harrison Biggs, Steven Yee, Hatem ElBidweihy, and Samara L. Firebaugh. 2020. "Autonomous Microrobotic Manipulation Using Visual Servo Control" Micromachines 11, no. 2: 132. https://doi.org/10.3390/mi11020132

APA StyleFeemster, M., Piepmeier, J. A., Biggs, H., Yee, S., ElBidweihy, H., & Firebaugh, S. L. (2020). Autonomous Microrobotic Manipulation Using Visual Servo Control. Micromachines, 11(2), 132. https://doi.org/10.3390/mi11020132