Theoretical and Experimental Study on Hot-Embossing of Glass-Microprism Array without Online Cooling Process

Abstract

:1. Introduction

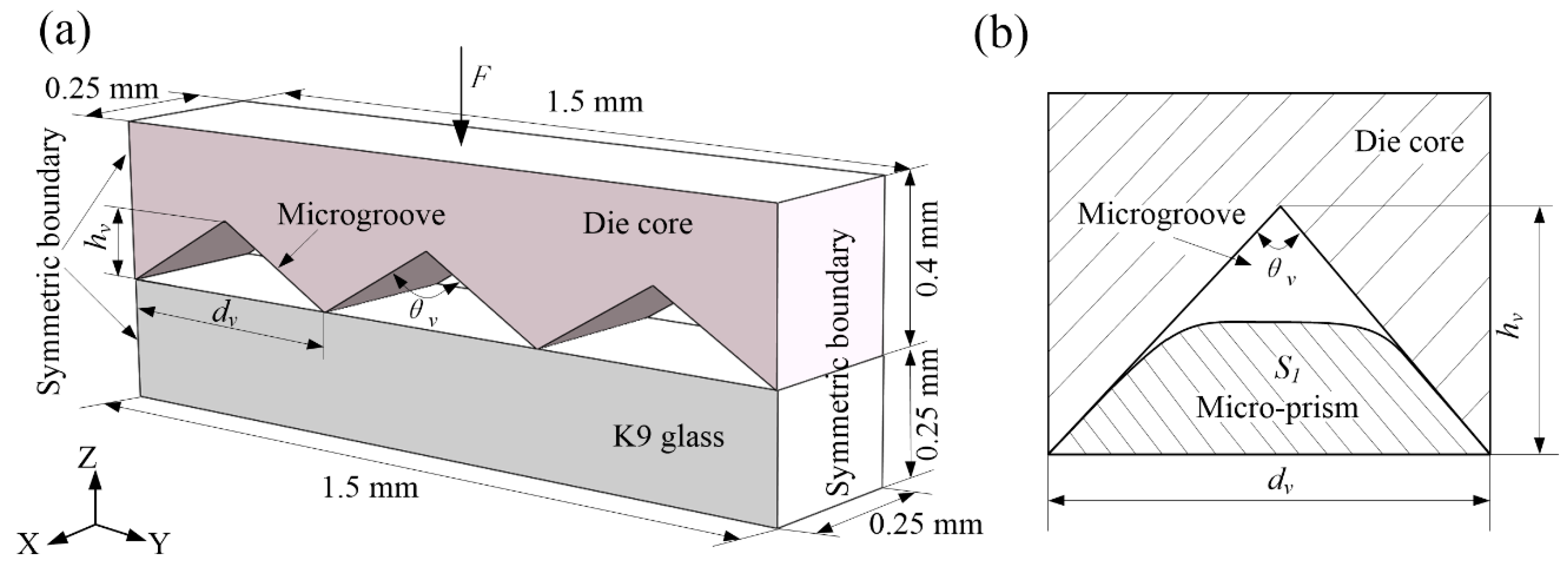

2. Numerical Simulation

2.1. Simulation Model of Hot Embossing of Glass-Microprism Array

2.2. Material Properties

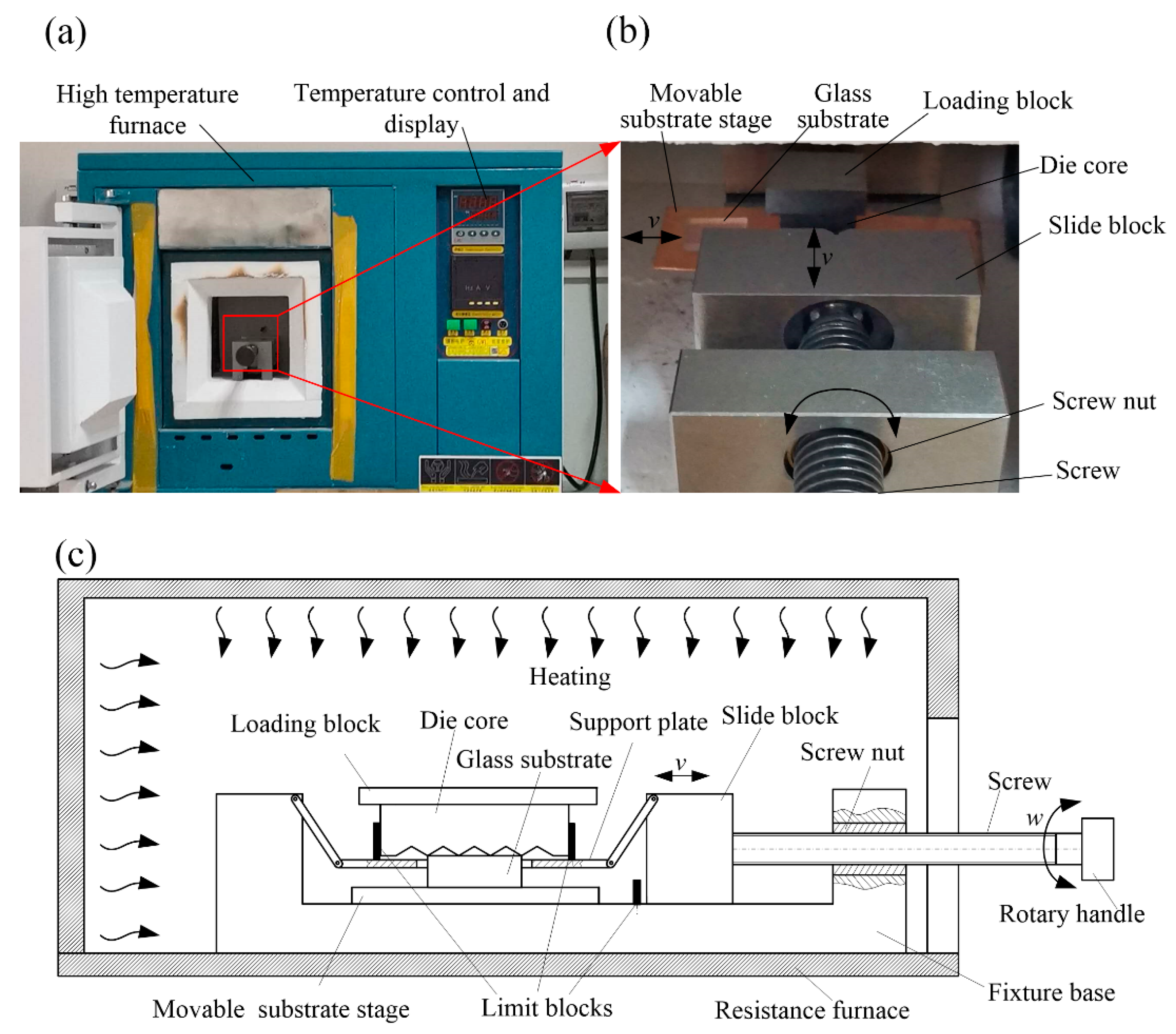

3. Experiment and Measurement

3.1. Microgrinding of Core Microgrooves

3.2. Experiment Setup of Hot-Embossing Glass-Microprism Array

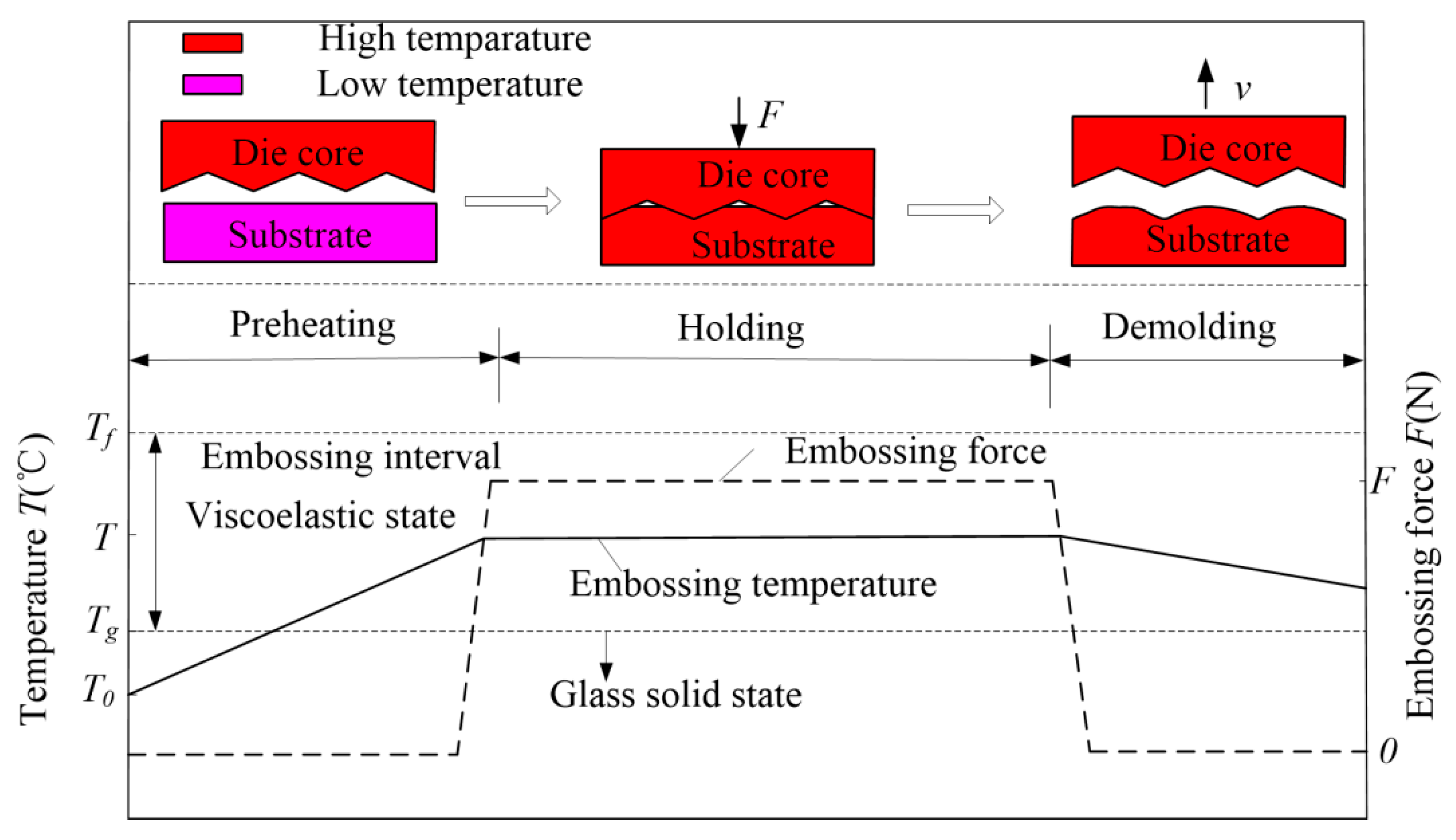

3.3. Processing of Hot-Embossing Glass-Microprism Array

4. Results and Discussion

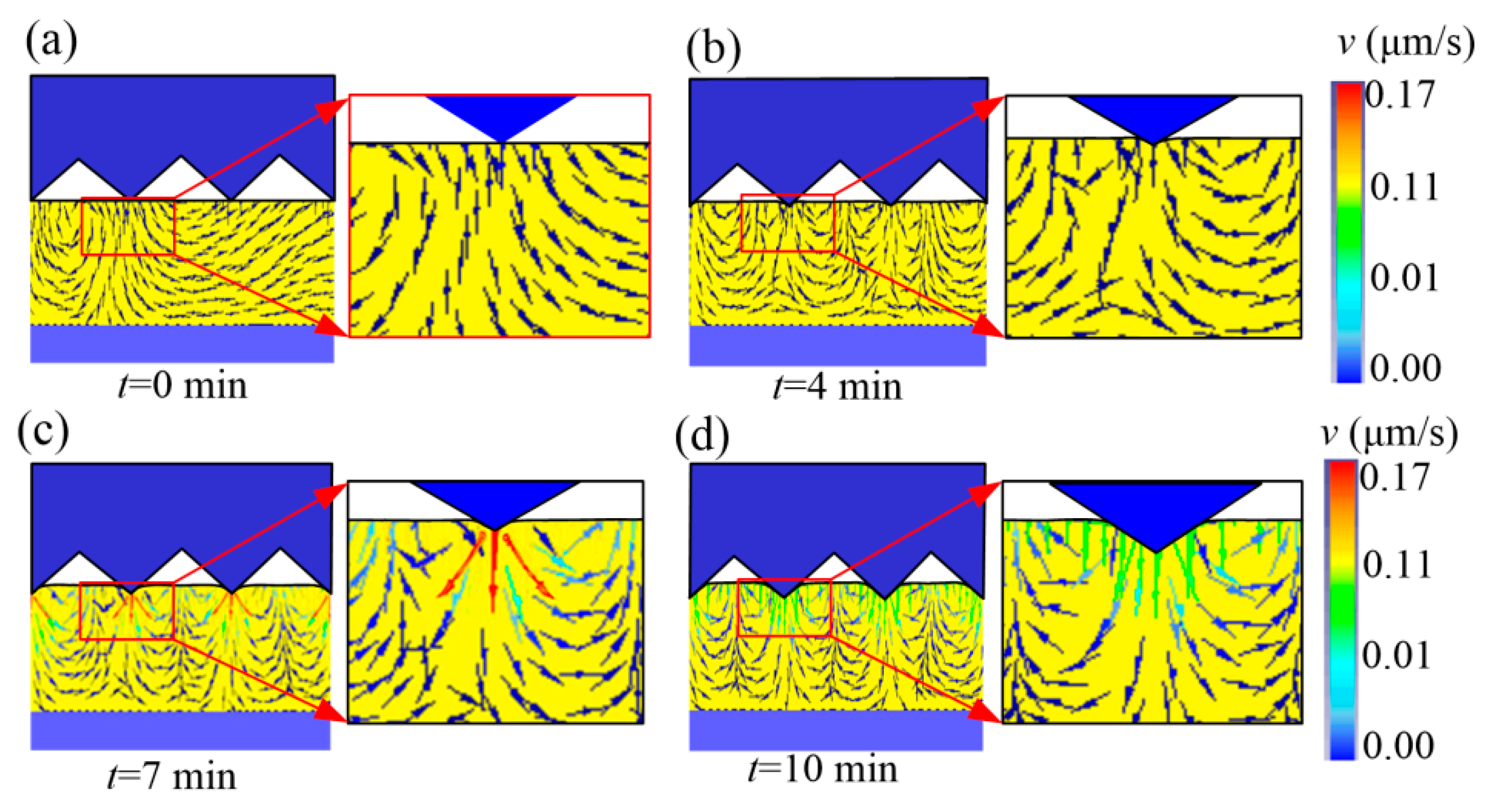

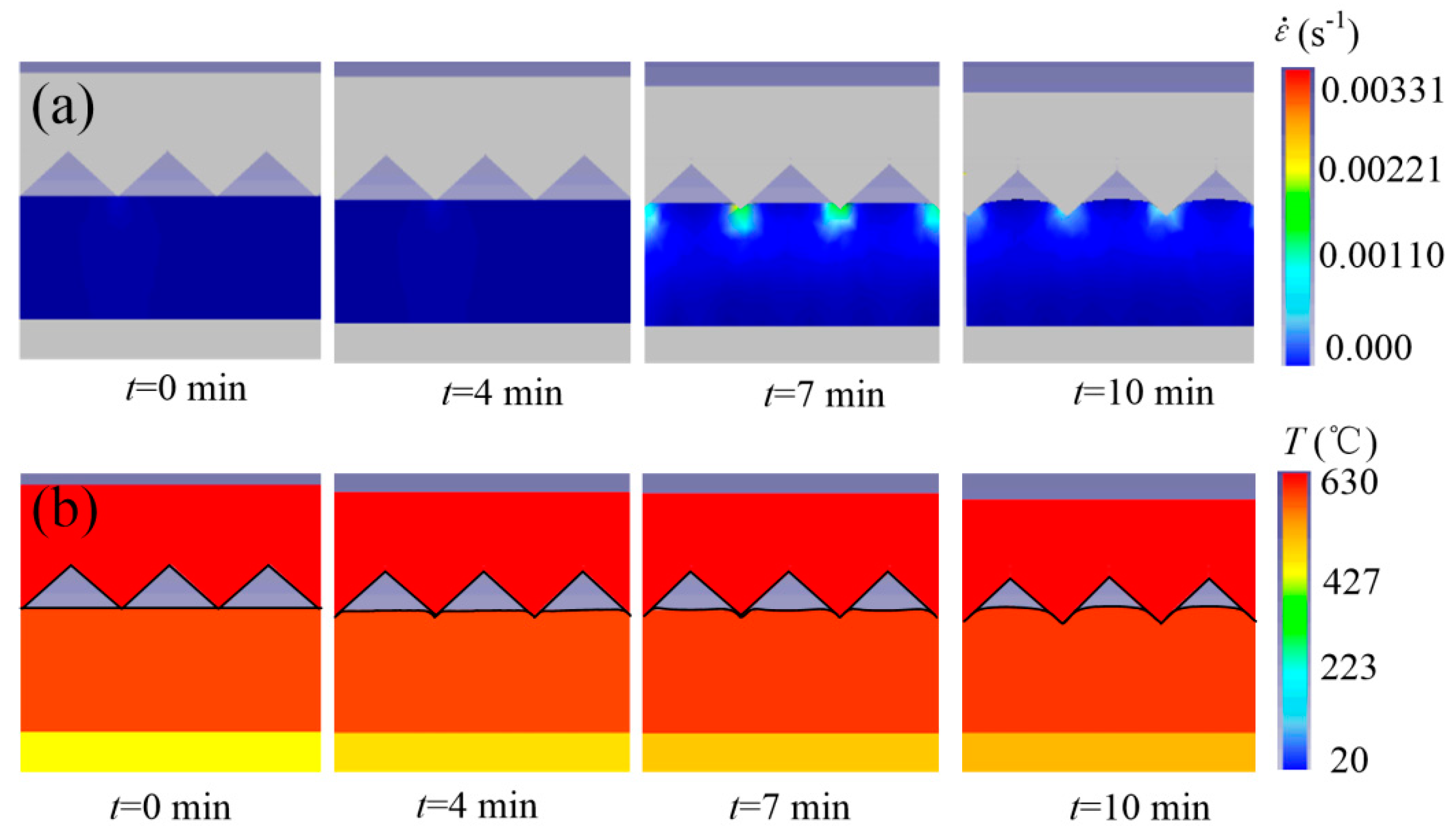

4.1. Theoretical Analysis of Microforming Glass-Microprism Array Process

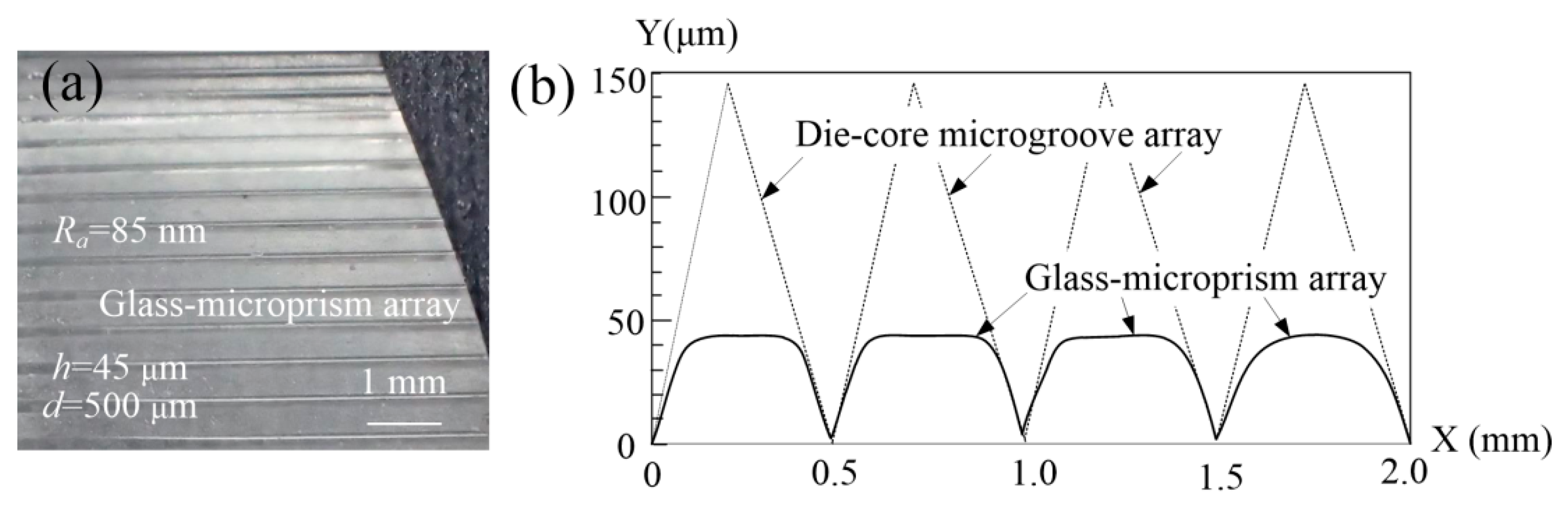

4.2. Microground Die Core

4.3. Photograph and Profile of Glass-Microprism Array

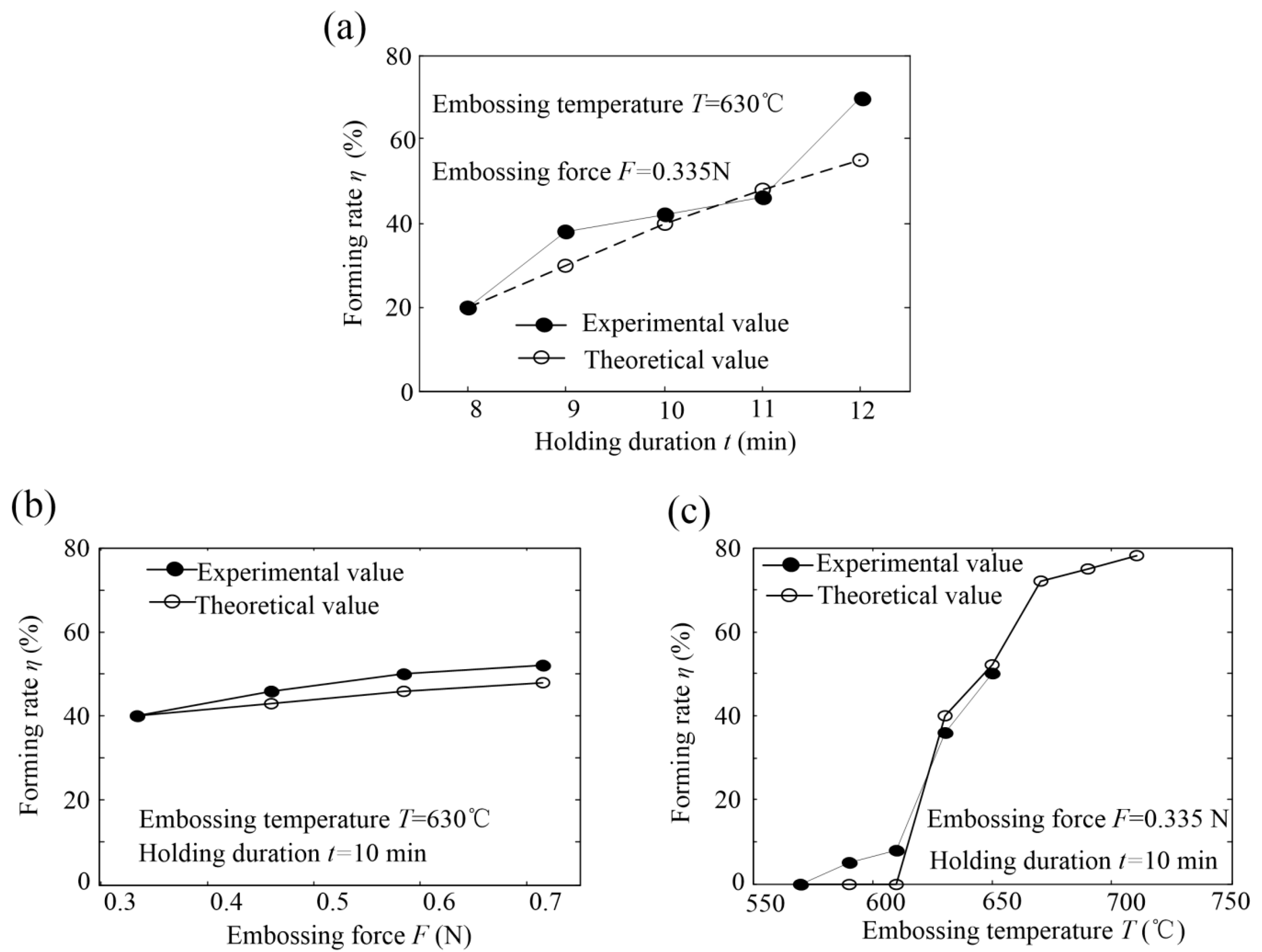

4.4. Theoretical and Experimental Forming Rates of Microprism Array

4.5. Forming Defects during Hot-Embossing Glass-Microprism Array Process

5. Conclusions

- (1)

- Theoretical-simulation results showed that the vortexlike molten-glass material flowed into the core cavity to form a trapezoidal microprism array. Appropriate hot-embossing force and temperature led to small strain rate, which meant that thermal stress was low, and the online cooling process may not have been needed, reducing hot-embossing time.

- (2)

- A low-cost microforming control device was designed, and the SiC die-core microgroove array was microground by the grinding-wheel microtip. Moreover, the trapezoidal microprism array was successfully embossed without online cooling processing, and the highest experimental forming rate reached 66.56% with a holding duration of 12 min.

- (3)

- Theoretical and experimental values were in good agreement with standard deviation and difference of 7% and 12%, respectively. Theoretical and experimental results showed that the forming rate of the glass-microprism array increased with increasing holding duration, embossing force, and embossing temperature.

- (4)

- When embossing temperature and embossing force were high, the hot-melt glass material was stuck to the die-core microgroove surface, and the optical glass substrate cracked, which may have been caused by uneven thermal stress.

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Golozar, M.; Chu, W.K.; Casto, L.D.; McCauley, J.; Butterworth, A.L.; Mathies, R.A. Fabrication of high-quality glass microfluidic devices for bioanalytical and space flight applications. MethodsX 2020, 7, 101043. [Google Scholar] [CrossRef]

- Zhou, L.; Yu, X.M.; Feng, P.X.L.; Li, J.H.; Xie, H.K. A MEMS lens scanner based on serpentine electrothermal bimorph actuators for large axial tuning. Opt. Express 2020, 28, 23439–23453. [Google Scholar] [CrossRef]

- Hamam, H. A two-way optical interconnection network using a single mode fiber array. Opt. Commun. 1998, 150, 270–276. [Google Scholar] [CrossRef]

- Muraleedharan, M.; Singh, H.; Udayakumar, M.; Suresh, S. Modified active solar distillation system. Employing directly absorbing therminol 55-Al2O3 nano heat transfer fluid and Fresnel lens concentrator. Desalination 2019, 457, 32–38. [Google Scholar] [CrossRef]

- Li, L.; Yang, G.; Lee, W.B.; Ng, M.C.; Chan, K.L. Carbide-bonded graphene-based Joule heating for embossing fine microstructures on optical glass. Appl. Surf. Sci. 2019, 500, 144004. [Google Scholar] [CrossRef]

- Lee, S.K.; Jeong, H.-J.; Kim, Y.-C.; Jang, J.-H. Improvement in CIGS solar cell efficiency using a micro-prism array integrated with sub-wavelength structures. Sol. Energy Mater. Sol. Cells 2018, 186, 254–258. [Google Scholar] [CrossRef]

- Huang, X.P.; Wang, P.; Lin, E.; Jiao, J.; Wang, X.; Li, Y.; Hou, Y.M.; Zhao, Q. Fabrication of the glass microlens arrays and the collimating property on nanolaser. Appl. Phys. A-Mater. 2016, 122, 649. [Google Scholar] [CrossRef]

- Aishan, Y.; Yalikun, Y.; Amaya, S.; Shen, Y.; Tanaka, Y. Thin glass micro-dome structure based microlens fabricated by accurate thermal expansion of microcavities. Appl. Phys. Lett. 2019, 115, 263501. [Google Scholar] [CrossRef]

- Hu, M.F.; Xie, J.; Su, H.H.; Liu, J.N. Study on laser-assisted dry micro-ground surface of difficult-to-cut materials. Int. J. Adv. Manuf. Technol. 2017, 94, 2919–2928. [Google Scholar] [CrossRef]

- Akashi, T.; Yoshimura, Y. Deep reactive ion etching of borosilicate glass using an anodically bonded silicon wafer as an etching mask. J. Micromech. Microeng. 2006, 16, 1051–1056. [Google Scholar] [CrossRef]

- Luo, S.-W.; Chang, T.-L.; Tsai, H.-Y. Fabrication of glass micro-prisms using ultra-fast laser pulses with chemical etching process. Opt. Laser Eng. 2012, 50, 220–225. [Google Scholar] [CrossRef]

- Ku, X.Y.; Zhang, Z.W.; Liu, X.L.; Chen, L.; Li, G. Low-cost rapid prototyping of glass microfluidic devices using a micromilling technique. Microfluid. Nanofluid. 2018, 22, 82. [Google Scholar] [CrossRef]

- Li, K.S.; Xu, G.; Luo, H.X.; Liu, X.H.; Gong, F. Glass flow behaviors in micro-channels during hot embossing. Ceram. Int. 2020, 46, 21517–21526. [Google Scholar] [CrossRef]

- Kim, M.; Oh, E.S.; Kwak, M.K. Shrinkage-considered mold design for improvement of micro/nano-structured optical element performance. Micromachines 2020, 11, 941. [Google Scholar] [CrossRef]

- Zhang, X.; Fang, G.; Jiang, T.J.; Zhao, N.; Li, J.F.; Dun, B.; Li, Q. Effects of cavity size and density on polymer micro hot embossing. Int. J. Precis. Eng. Manuf. 2015, 16, 2339–2346. [Google Scholar] [CrossRef]

- Zhang, N.; Liu, J.H.; Zhang, H.G.; Kent, N.J.; Diamond, D.; Gilchrist, M.D. 3D printing of metallic microstructured mould using selective laser melting for injection moulding of plastic microfluidic devices. Micromachines 2019, 10, 595. [Google Scholar] [CrossRef] [Green Version]

- Youn, S.W.; Takahashi, M.; Goto, H.; Maeda, R. Microstructuring of glassy carbon mold for glass embossing Comparison of focused ion beam, nano/femtosecond-pulsed laser and mechanical machining. Microelectron. Eng. 2006, 83, 2482–2492. [Google Scholar] [CrossRef]

- He, J.F.; Wu, M.; Zhang, R.L.; Liu, J.W.; Deng, Y.; Guo, Z.N. A one-step hot-embossing process for fabricating a channel with superhydrophobic inner walls. J. Manuf. Process. 2018, 36, 351–359. [Google Scholar] [CrossRef]

- Zou, W.; Sackmann, J.; Striegel, A.; Worgull, M.W.; Schomburg, K. Comparison of hot embossing micro structures with and without ultrasound. Microsyst. Technol. 2019, 25, 4185–4195. [Google Scholar] [CrossRef]

- Xie, J.; Lu, Y.X. Study on axial-feed mirror finish grinding of hard and brittle materials in relation to micron-scale grain protrusion parameters. Int. J. Mach. Tool Manuf. 2011, 51, 84–93. [Google Scholar] [CrossRef]

- Kim, Y.K.; Ju, J.H.; Kim, S.M. Replication of a glass microlens array using a vitreous carbon mold. Opt. Express 2018, 26, 14936–14944. [Google Scholar] [CrossRef]

- Kim, T.; Zawawi, M.Z.B.; Shin, R.; Kim, D.; Choi, W.; Park, C.; Kang, S. Replication of high refractive index glass microlens array by imprinting in conjunction with laser assisted rapid surface heating for high resolution confocal microscopy imaging. Opt. Express 2019, 27, 18869–18882. [Google Scholar] [CrossRef] [PubMed]

- Saotome, Y.; Imai, K.; Sawanobori, N. Microformability of optical glasses for precision molding. J. Mater. Process. Technol. 2003, 140, 379–384. [Google Scholar] [CrossRef]

- Huang, C.-Y.; Chen, C.-C.; Chou, H.-Y.; Chou, C.-P. Fabrication of Fresnel lens by glass molding technique. Opt. Rev. 2013, 20, 202–204. [Google Scholar] [CrossRef]

- Hung, Y.M.; Lu, Y.J.; Sung, C.K. Microstructure patterning on glass substrate by imprinting process. Microelectron. Eng. 2009, 86, 577–582. [Google Scholar] [CrossRef]

- Li, K.; Xu, G.; Huang, X.; Xie, Z.; Gong, F. Temperature effect on the deformation and optical quality of moulded glass lenses in precision glass moulding. Int. J. Appl. Glass Sci. 2019, 86, 577–582. [Google Scholar] [CrossRef]

- Kasztelanic, R.; Kujawa, I.; Ottevaere, H.; Pysz, D.; Stepien, R.; Thienpont, H.; Buczynski, R. Optical quality study of refractive lenses made out of oxide glass using hot embossing. Infrared Phys. Technol. 2015, 73, 212–218. [Google Scholar] [CrossRef]

- Zhang, F.; Yang, Q.; Bian, H.; Li, M.J.; Hou, X.; Chen, F. Fabrication of chalcogenide glass based hexagonal gapless microlens arrays via combining femtosecond laser assist chemical etching and precision glass molding processes. Materials 2020, 13, 3490. [Google Scholar] [CrossRef]

- Kujawa, I.; Kasztelanic, R.; Stępieńa, R.; Klimczak, M.; Cimek, J.; Waddie, A.J.; Taghizadeh, M.R.; Buczyński, R. Optimization of hot embossing method for development of soft glass microcomponents for infrared optics. Opt. Laser Technol. 2014, 55, 11–17. [Google Scholar] [CrossRef]

- Zhang, Z.; Ming, W.; Zhang, Y.; Yin, L.; Xue, T.; Yu, H.; Chen, Z.; Liao, D.; Zhang, G. Analyzing sustainable performance on high-precision molding process of 3D ultra-thin glass for smart phone. J. Clean. Prod. 2020, 255, 120196. [Google Scholar] [CrossRef]

- Sun, J.Y.; Wu, D.M.; Liu, Y.; Dai, L.; Jiang, C. Numerical simulation and experimental study of filling process of micro prism by isothermal hot embossing in solid-like state. Polym. Adv. Technol. 2017, 37, 1581–1591. [Google Scholar] [CrossRef]

- Liu, C.; Li, J.M.; Liu, J.S.; Wang, L.D. Deformation behavior of solid polymer during hot embossing process. Microelectron. Eng. 2010, 87, 200–207. [Google Scholar] [CrossRef]

- Lan, S.H.; Lee, H.-J.; Lee, S.-H.; Ni, J.; Lai, X.M.; Lee, H.-W.; Song, J.-H.; Lee, M.G. Experimental and numerical study on the viscoelastic property of polycarbonate near glass transition temperature for micro thermal imprint process. Mater. Des. 2009, 30, 3879–3884. [Google Scholar] [CrossRef]

- Gomez, J.A.; Lek, D.; Song, I.-H.; You, B.H. Study on stress evolution in the cooling process of micro hot embossing. Int. J. Mech. Mater. Des. 2014, 9, 1–6. [Google Scholar] [CrossRef] [Green Version]

- Vu, A.T.; Vu, A.N.; Grunwald, T.; Bergs, T. Modeling of thermo-viscoelastic material behavior of glass over a wide temperature range in glass compression molding. J. Am. Ceram. Soc. 2020, 103, 2791–2807. [Google Scholar] [CrossRef] [Green Version]

- Zhang, T.; He, Y.; Fu, J.Z. Finite element modeling of polymer flow during hot embossing with different mold structures and embossing conditions. Adv. Mater. 2011, 305, 144–148. [Google Scholar] [CrossRef]

- Yao, D.; Virupaksha, V.L.; Kim, B. Study on squeezing flow during nonisothermal embossing of polymer microstructures. Polym. Eng. Sci. 2005, 45, 652–660. [Google Scholar] [CrossRef]

- CDGM GLASS Company Home Page. Available online: http://www.cdgmgd.com//go.htm?k=wu_se_guang_xue_bo_li&url=goods (accessed on 29 October 2020).

- Li, L.H.; Chan, M.-K.; Lee, W.-B.; Ng, M.-C.; Chan, K.-L. Modeling and experimental performance analysis of a novel heating system and its application to glass hot embossing technology. Opt. Lett. 2019, 44, 3454–3457. [Google Scholar] [CrossRef] [PubMed]

- He, W.B.; Chen, Z.J.; Ming, W.Y.; Du, J.G.; Cao, Y.; Ma, J.; Wei, A.Y. Multi-objective optimization of glass multi-station bending machining for smartphone curved screen. J. Braz. Soc. Mech. Sci. 2019, 41, 476. [Google Scholar] [CrossRef]

- Xie, J.; Jiang, Y.N.; Liu, J.N.; Man, T.R. A rapid and precision hot embossing of LGP micro-arch lens array inside core microgrooves: Simulation and experiment. Int. J. Adv. Manuf. Technol. 2018, 95, 171–180. [Google Scholar] [CrossRef]

- Li, K.; Xu, G.; Liu, X.; Gong, F. Deformation behavior of glass nanostructures in hot embossing. ACS Appl. Mater. Int. 2020, 12, 36311–36319. [Google Scholar] [CrossRef] [PubMed]

| Material | Density (kg/m3) | Thermal Conductivity (W/(m·K)) | Specific Heat (J/(kg·K)) | Young’s Modulus (GPa) | Poisson’s Ratio |

|---|---|---|---|---|---|

| SiC die core | 3.02 × 103 | 77.5 | 670 | 192 | 0.142 |

| K9 optical glass | 2.41 × 103 | 5 | 2100 | 79.2 | 0.211 |

| 503 °C | 603 °C | 703 °C | 803 °C | |

|---|---|---|---|---|

| 0.0001 | 967 | 100 | 1.42 × 10−5 | 2.98 × 10−7 |

| 0.01 | 96,760 | 10,000 | 1.42 × 10−3 | 2.98 × 10−5 |

| 1 | 9,676,000 | 1,000,000 | 0.142 | 2.98 × 10−3 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Hu, M.; Xie, J.; Li, W.; Niu, Y. Theoretical and Experimental Study on Hot-Embossing of Glass-Microprism Array without Online Cooling Process. Micromachines 2020, 11, 984. https://doi.org/10.3390/mi11110984

Hu M, Xie J, Li W, Niu Y. Theoretical and Experimental Study on Hot-Embossing of Glass-Microprism Array without Online Cooling Process. Micromachines. 2020; 11(11):984. https://doi.org/10.3390/mi11110984

Chicago/Turabian StyleHu, Manfeng, Jin Xie, Wei Li, and Yuanhang Niu. 2020. "Theoretical and Experimental Study on Hot-Embossing of Glass-Microprism Array without Online Cooling Process" Micromachines 11, no. 11: 984. https://doi.org/10.3390/mi11110984

APA StyleHu, M., Xie, J., Li, W., & Niu, Y. (2020). Theoretical and Experimental Study on Hot-Embossing of Glass-Microprism Array without Online Cooling Process. Micromachines, 11(11), 984. https://doi.org/10.3390/mi11110984