Extended Applications of the Depth-Sensing Indentation Method

Abstract

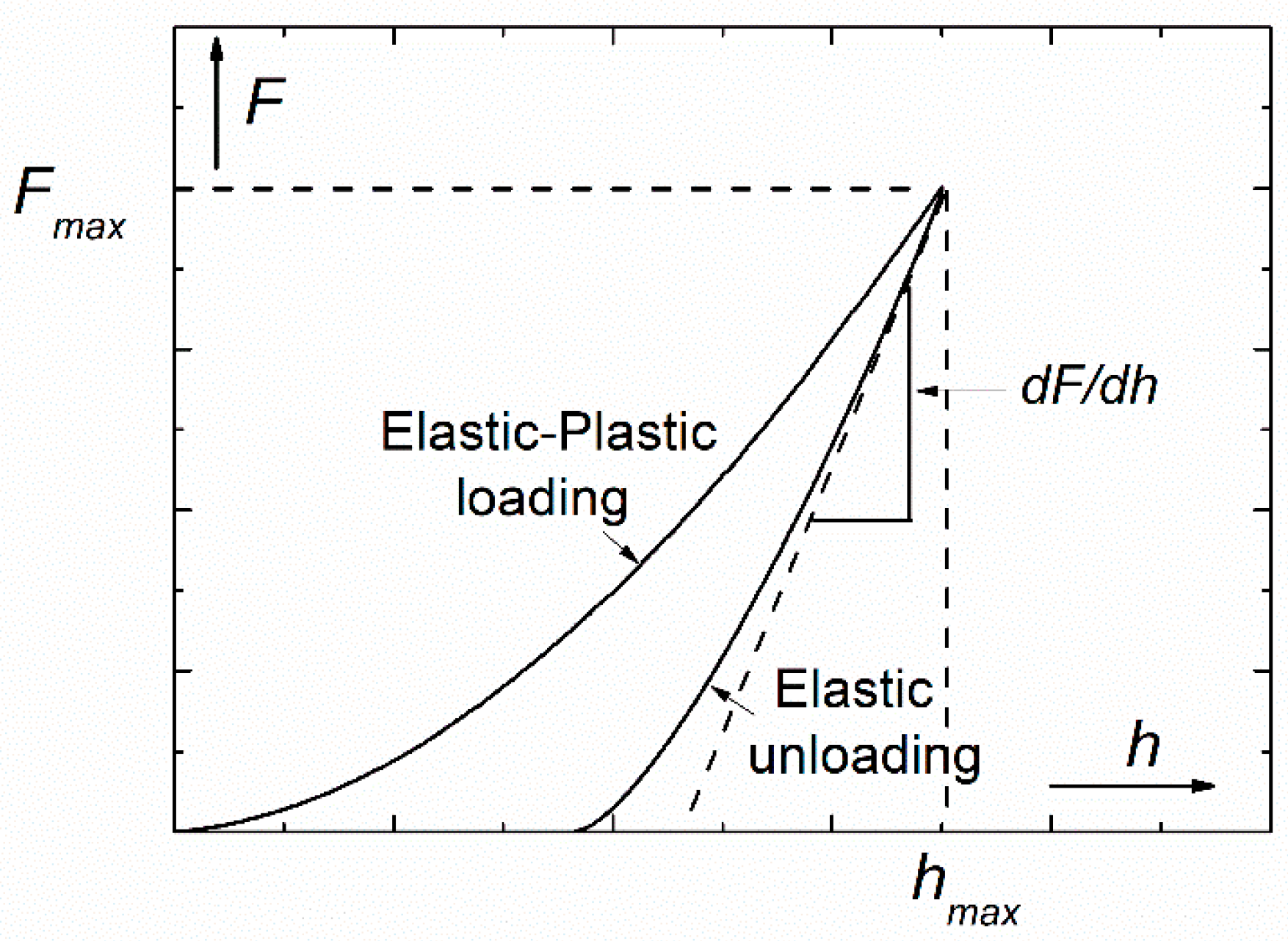

:1. Introduction

2. Extended Applications of the DSI Method

2.1. Phase Transformations during Indentation

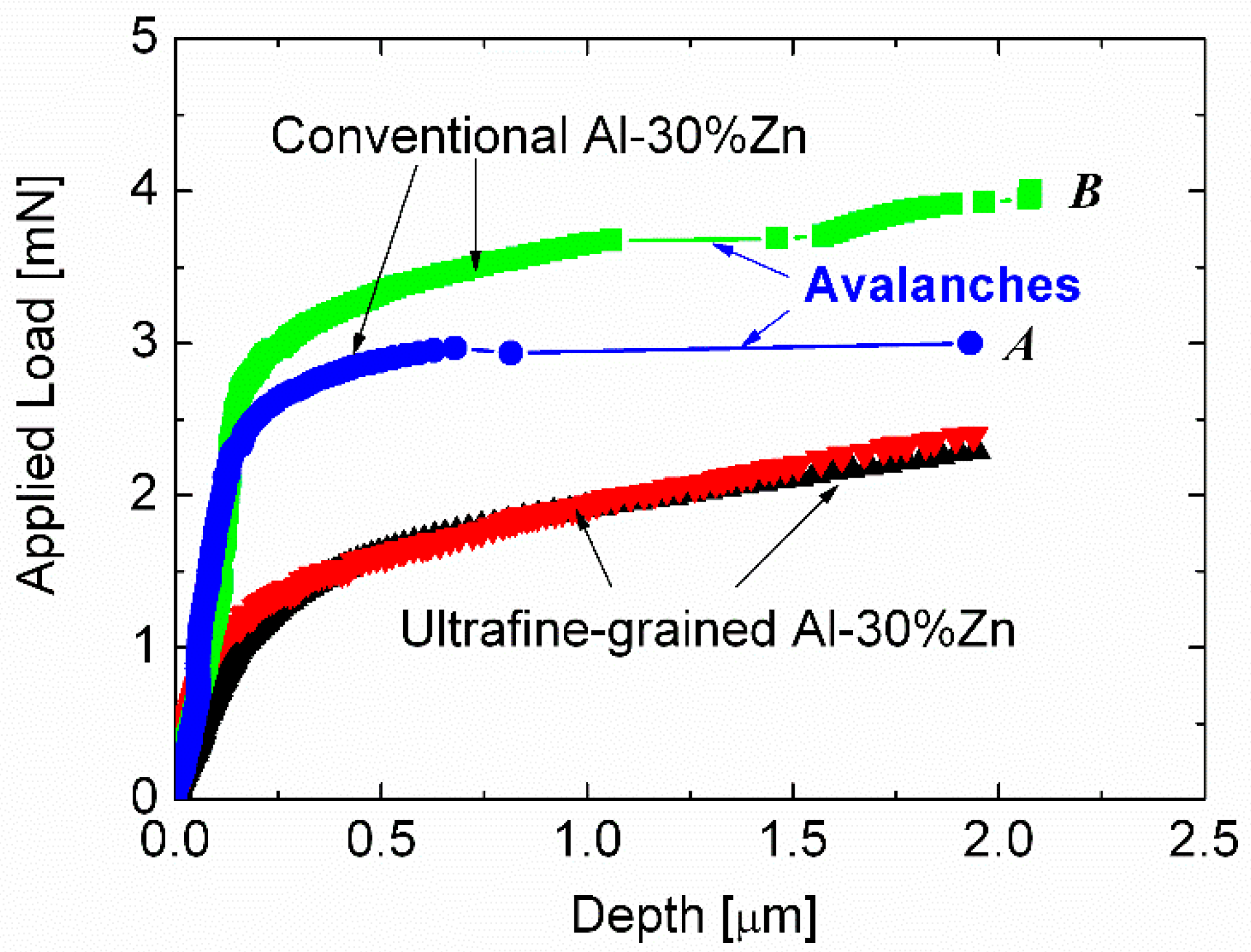

2.2. Studying Plastic Instabilities by Indentation

2.3. Investigation of Characteristics of Plastic Deformation by Indentation Tests

2.3.1. Determination of Strain Rate Sensitivity by Applying Different Loading Rates

2.3.2. Determination of Strain Rate Sensitivity from Indentation Creep

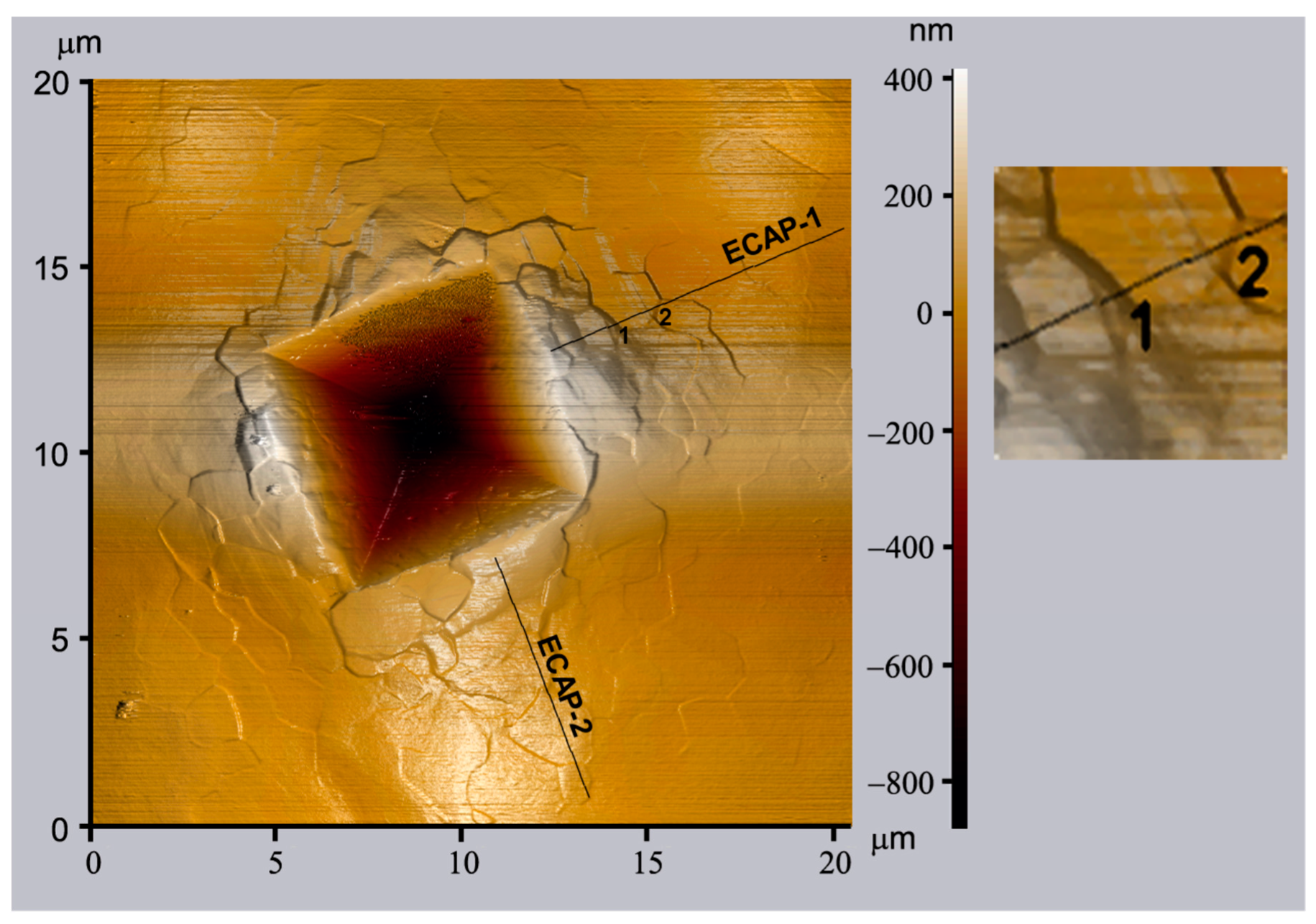

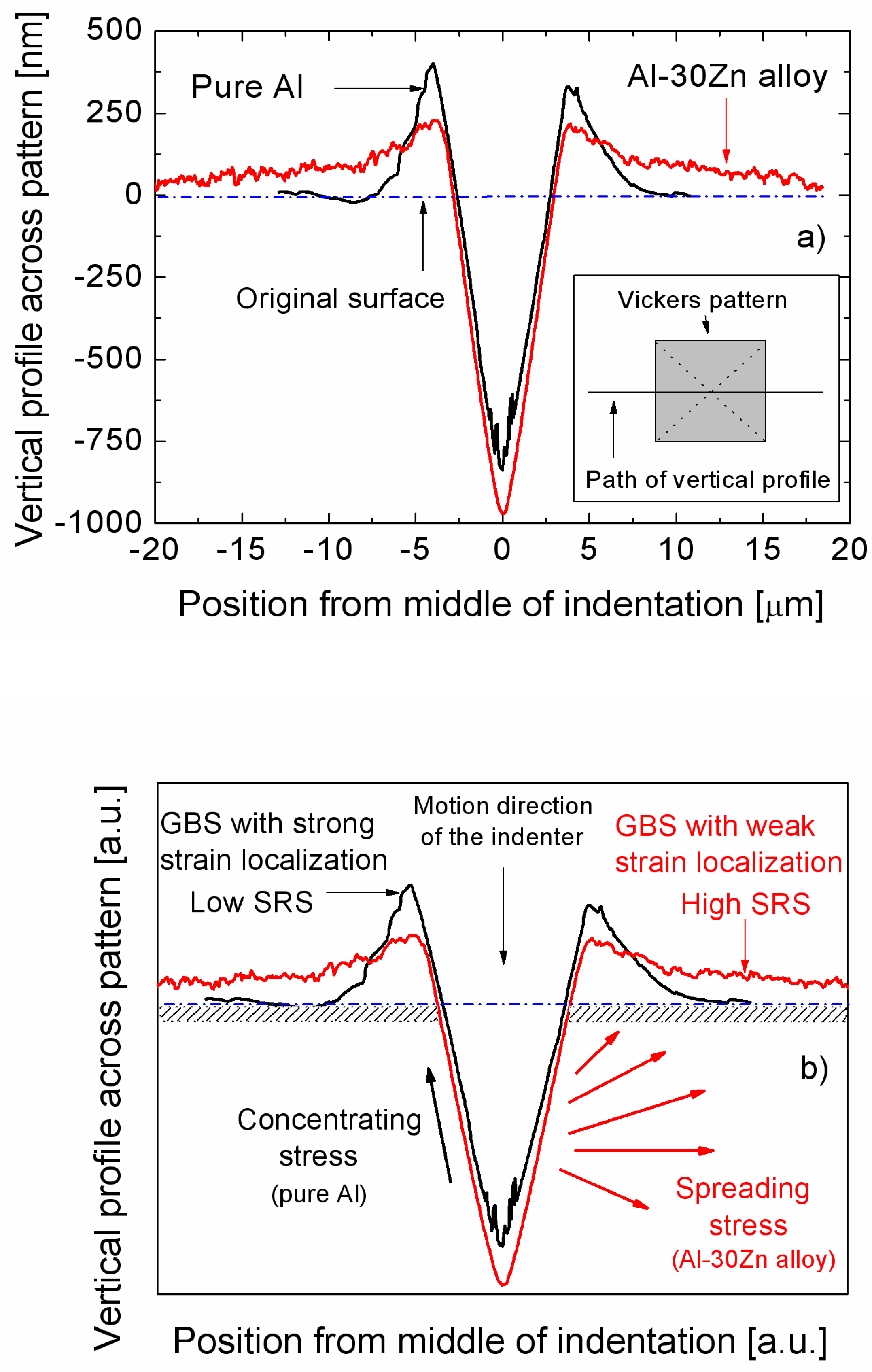

2.3.3. Demonstrating the Correlation between Strain Rate Sensitivity and Grain Boundary Sliding by Combining Indentation with Atomic Force Microscopy (AFM) Measurements

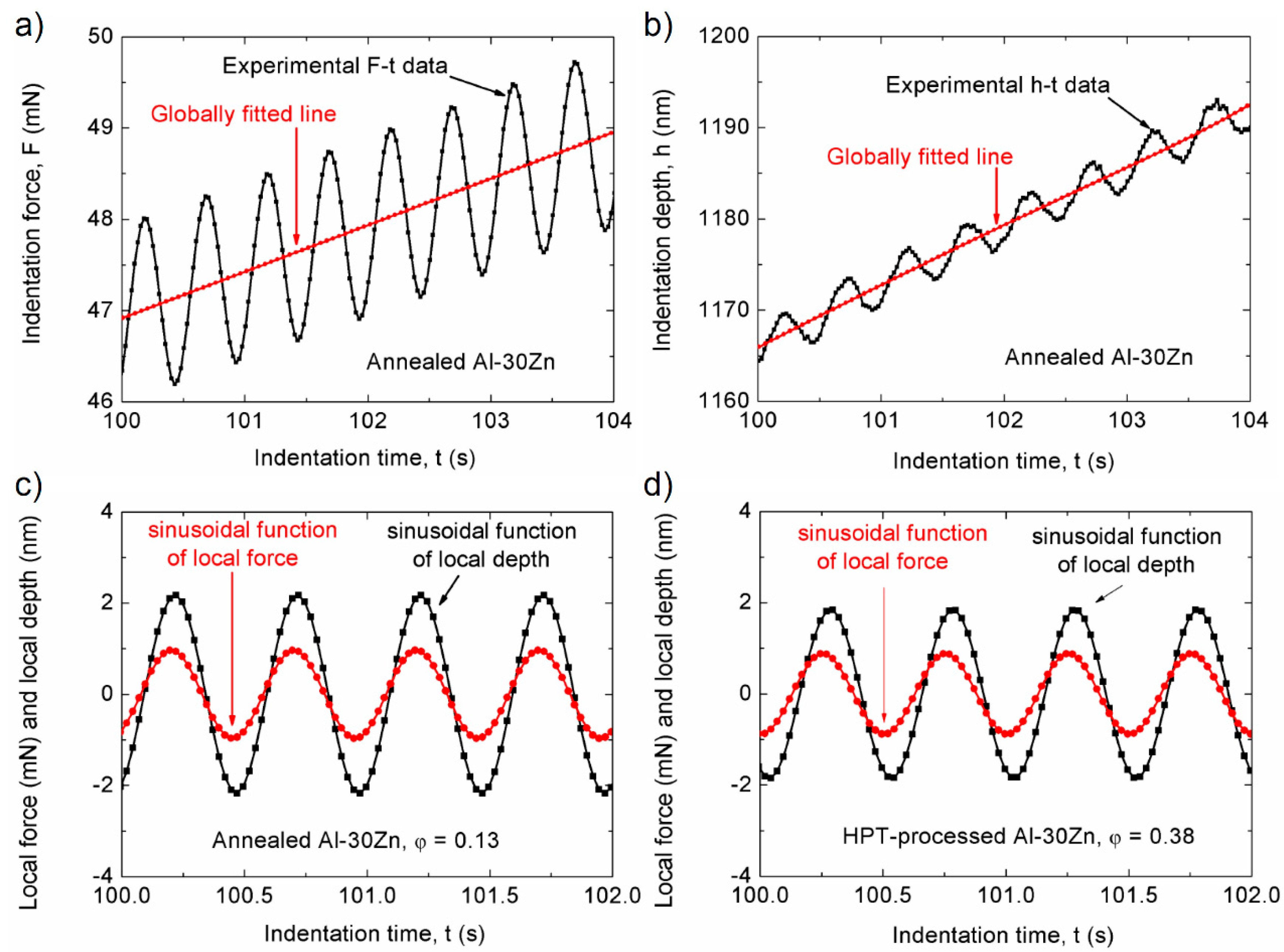

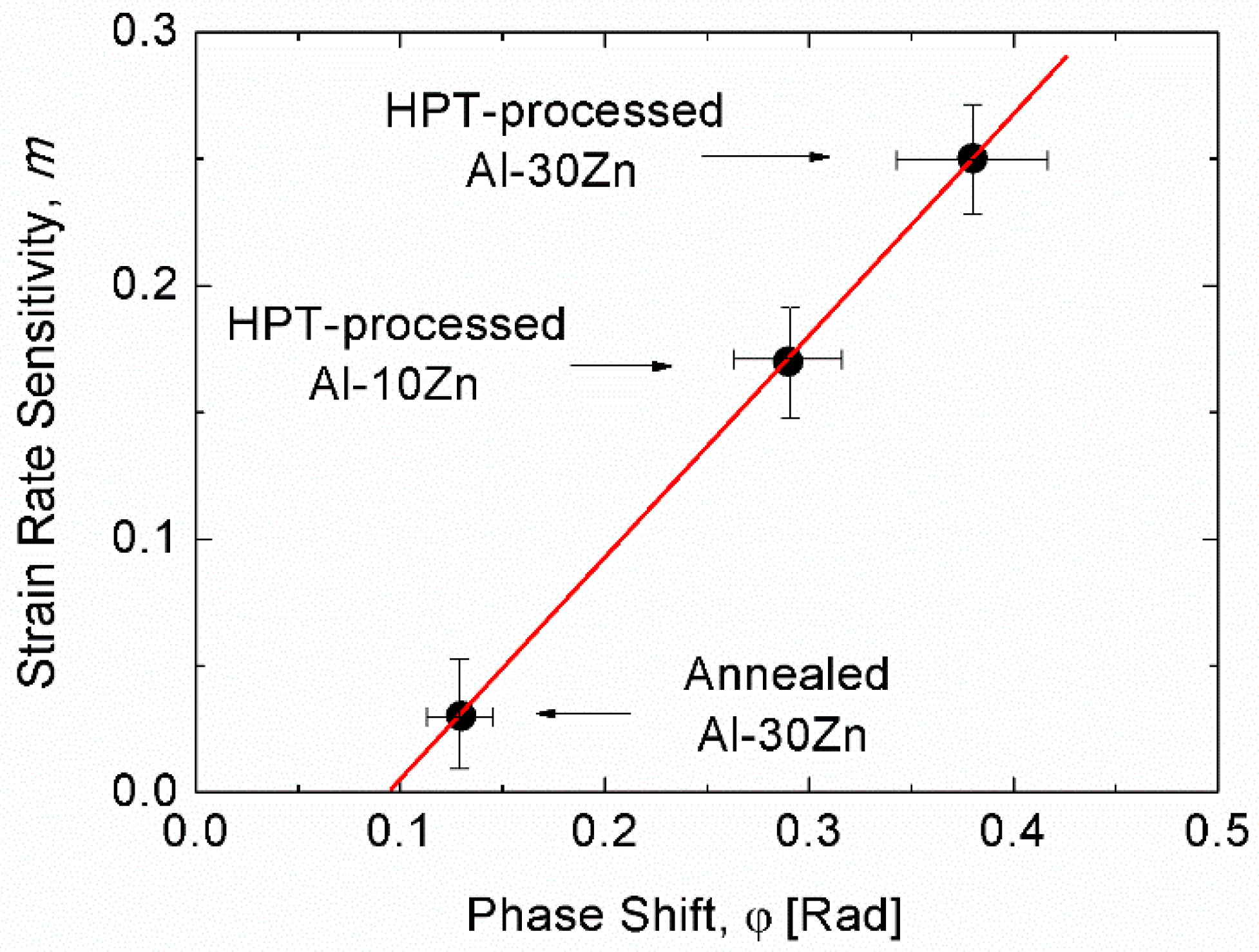

2.3.4. Application of Dynamic Indentation for Studying Plastic Behavior

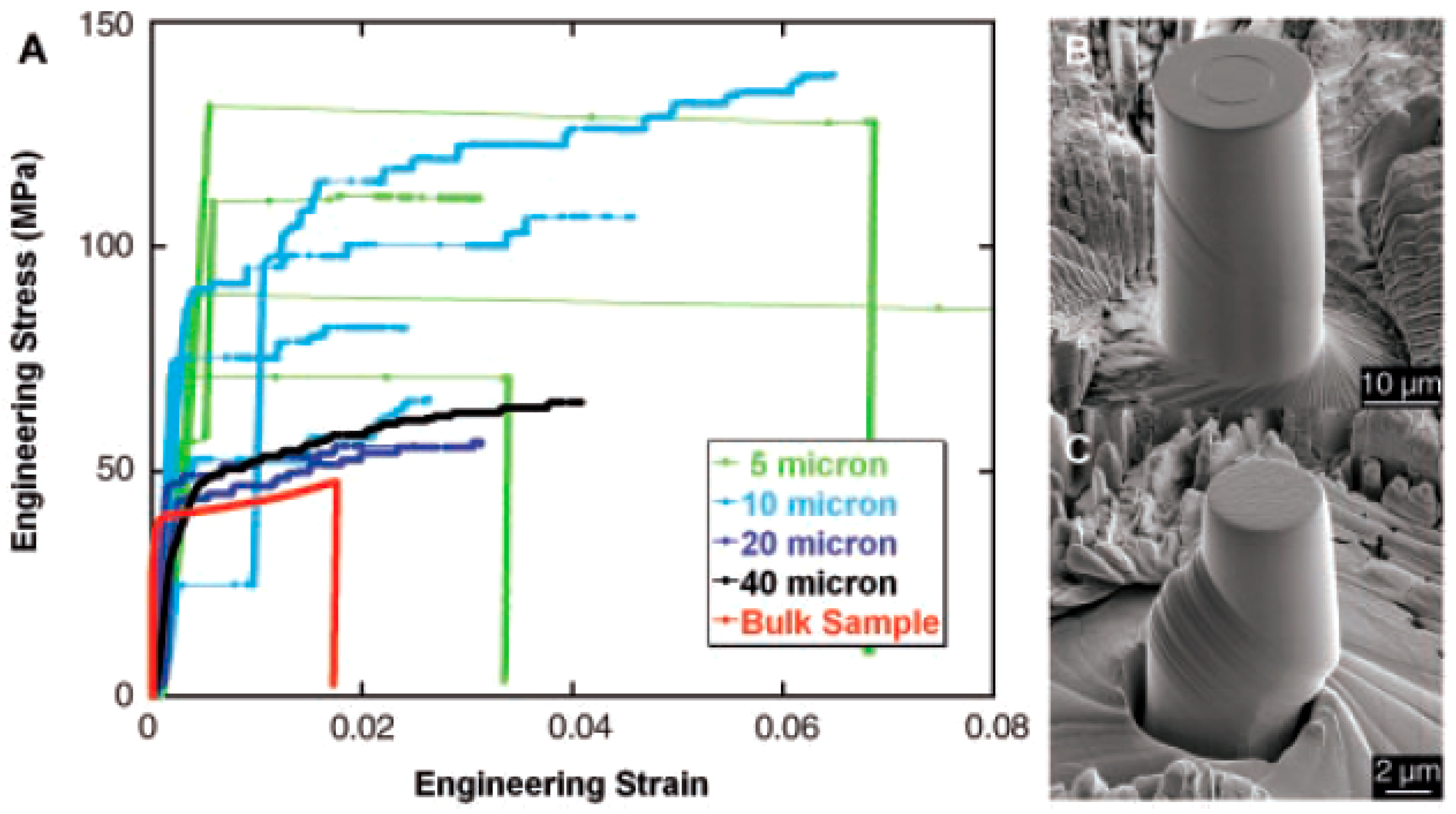

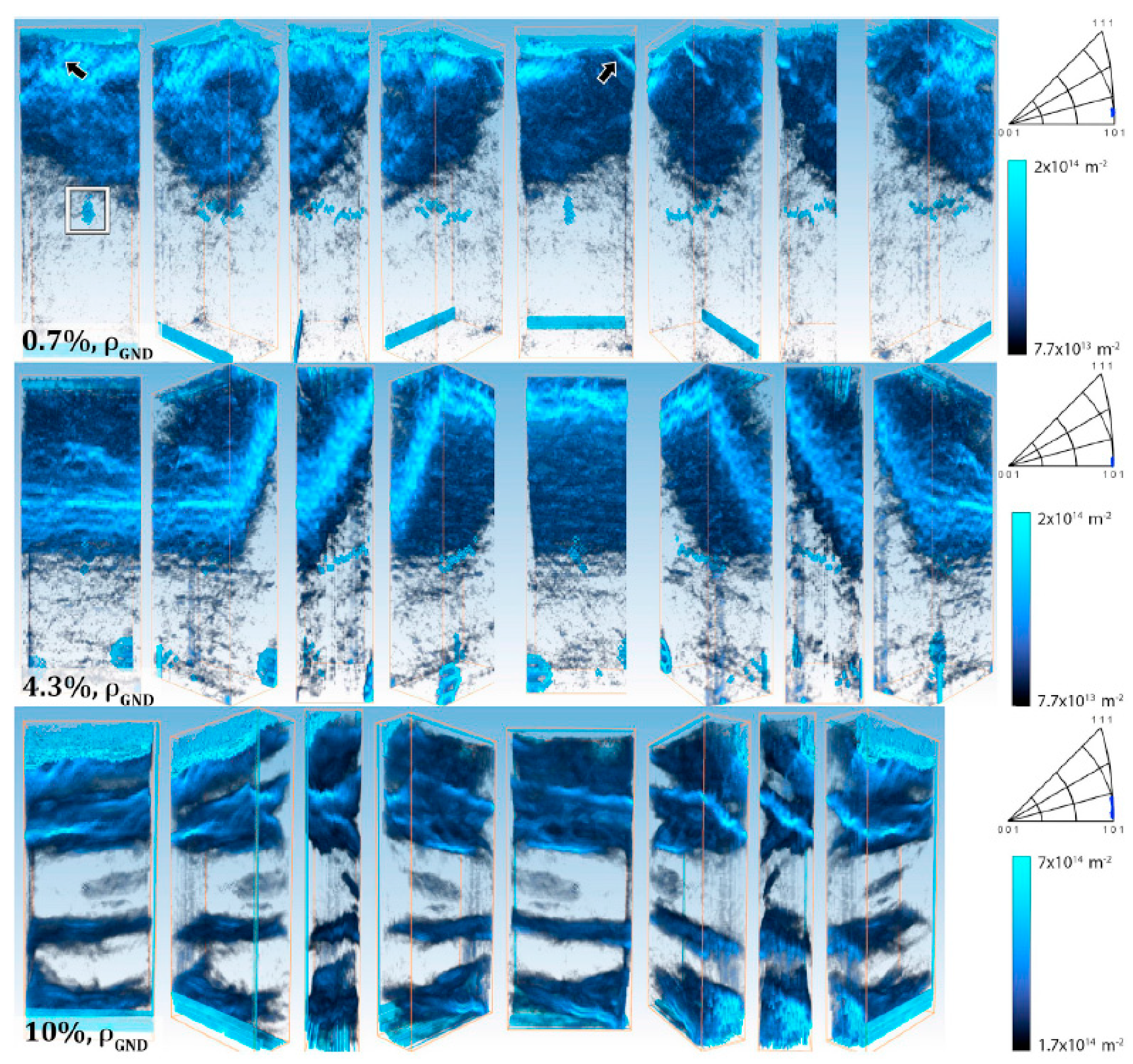

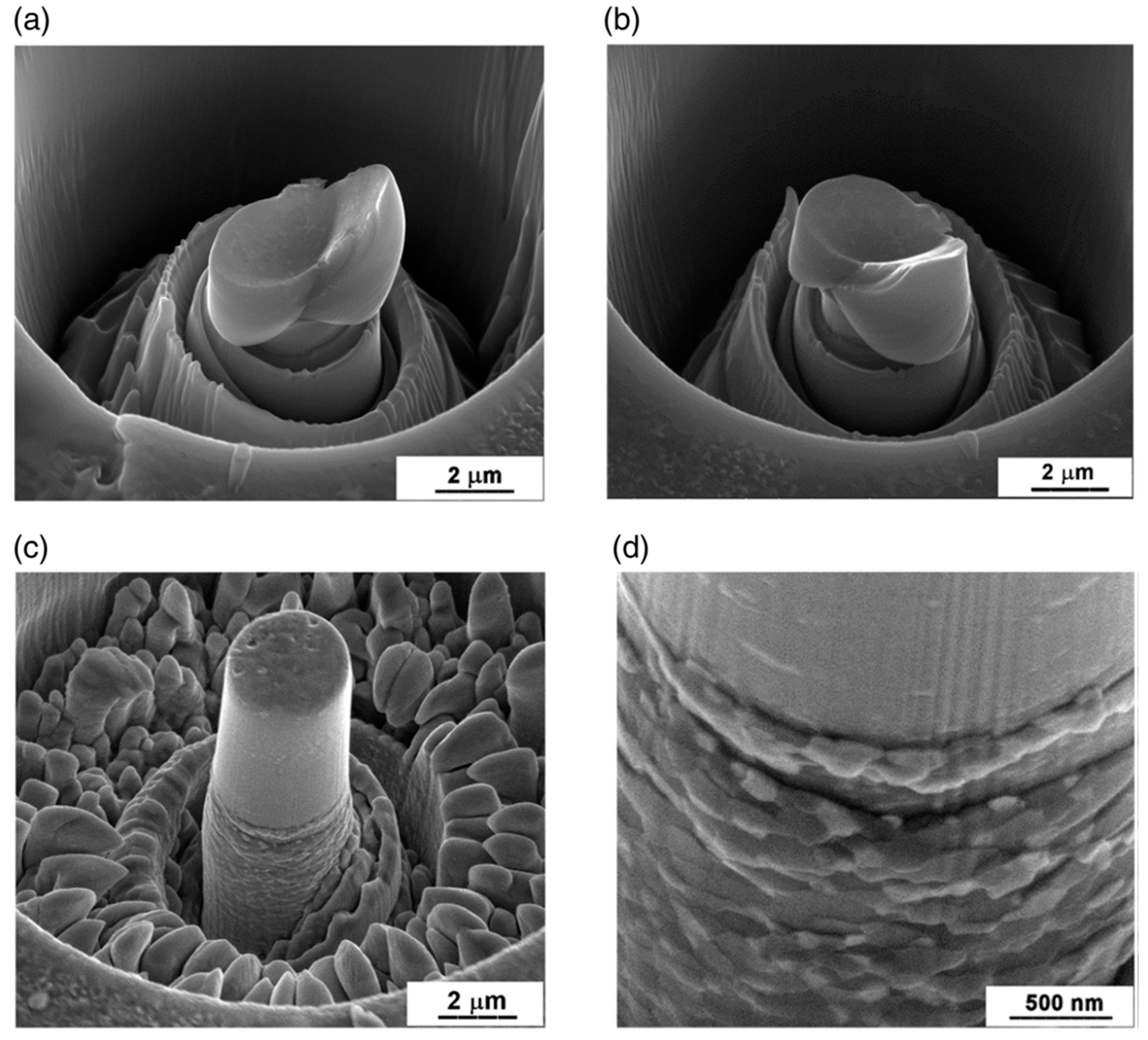

2.4. Indentation for Studying Micro-Plasticity: Compression of Micropillars

3. Summary

- (1)

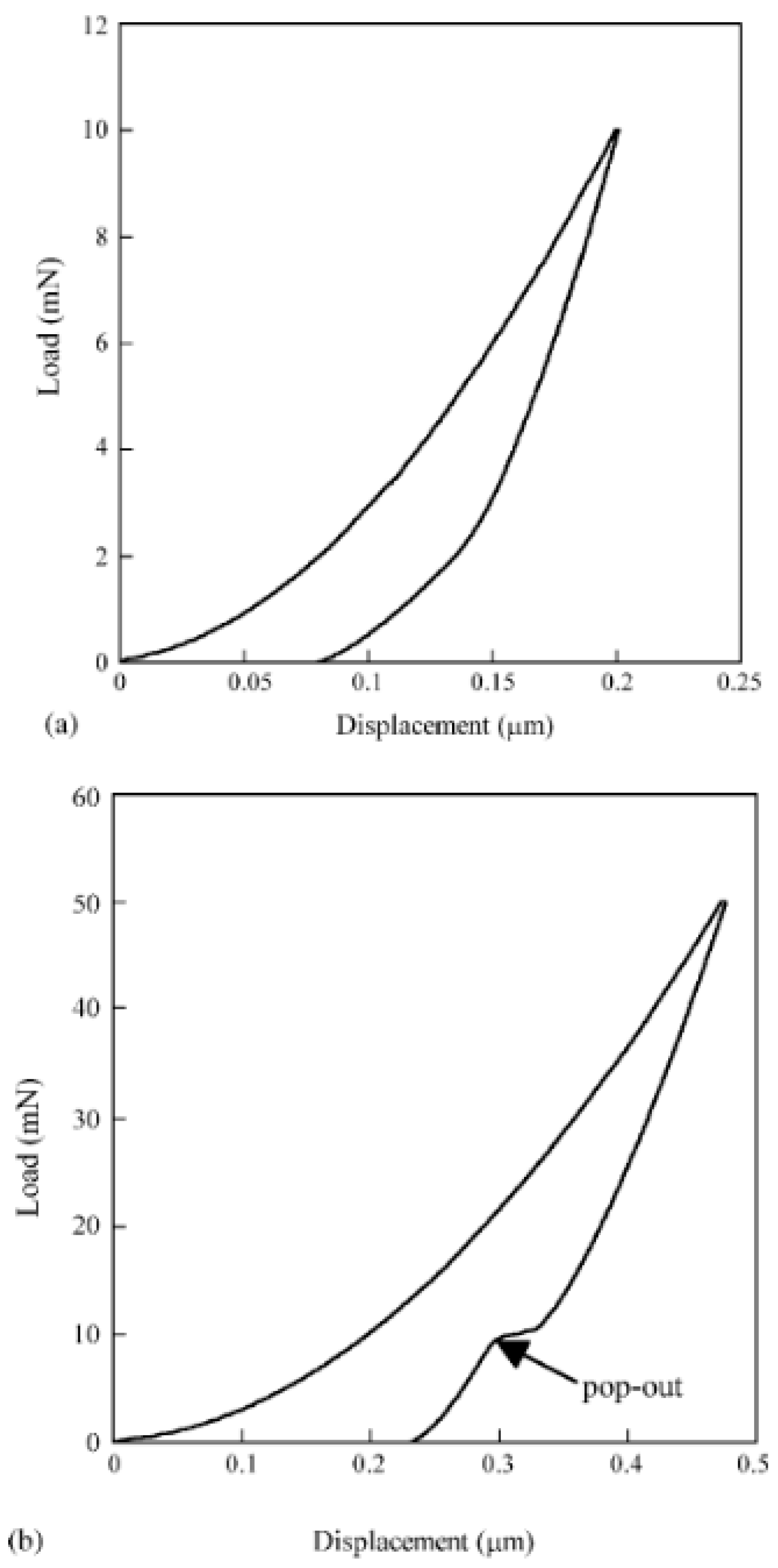

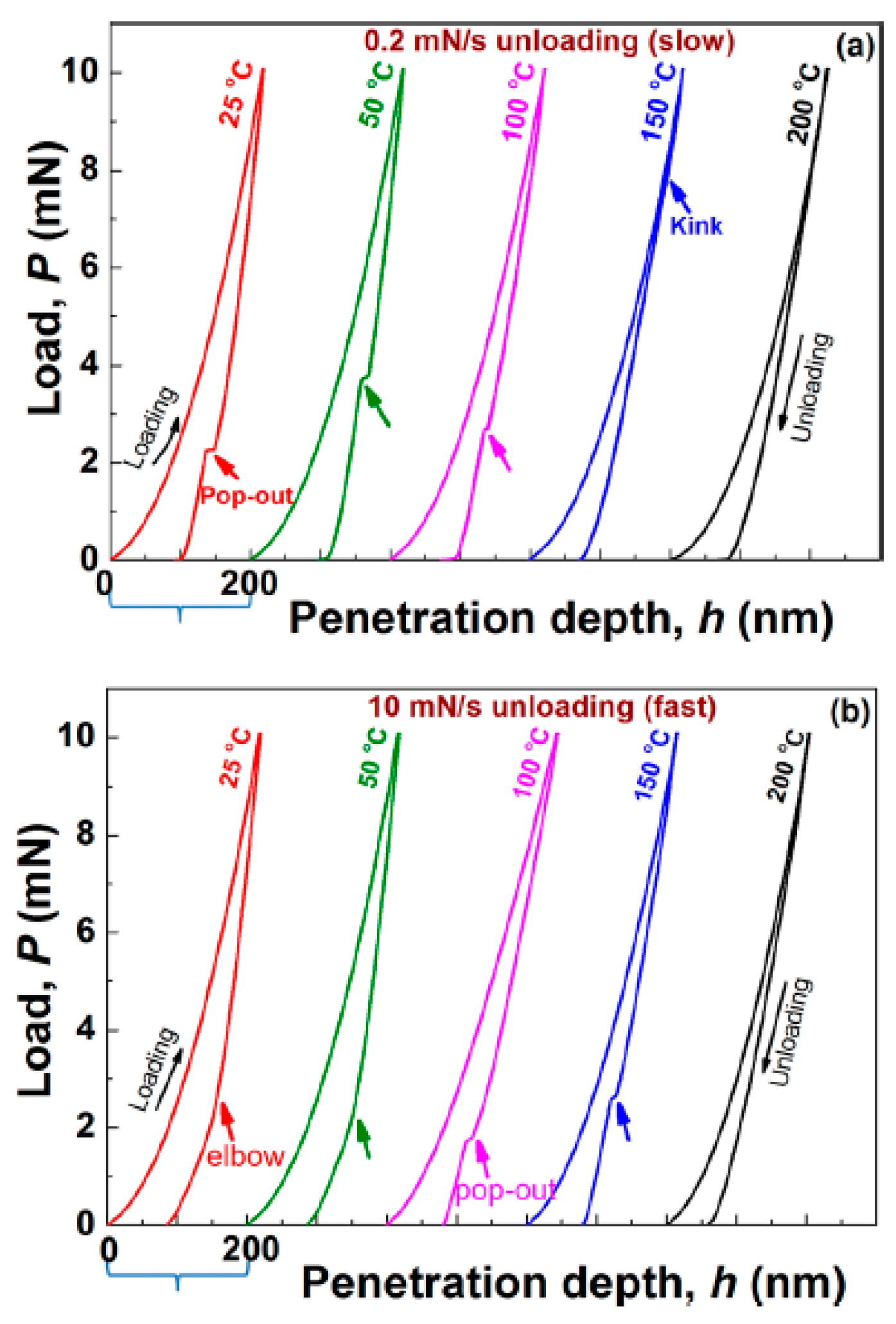

- During a nanoindentation measurement, the pressure under the tip of the indenter may be so high that it may induce structural phase transition in the investigated sample. This phenomenon may manifest itself as pop-out events or elbows appearing on the unloading stage of the indentation curve.

- (2)

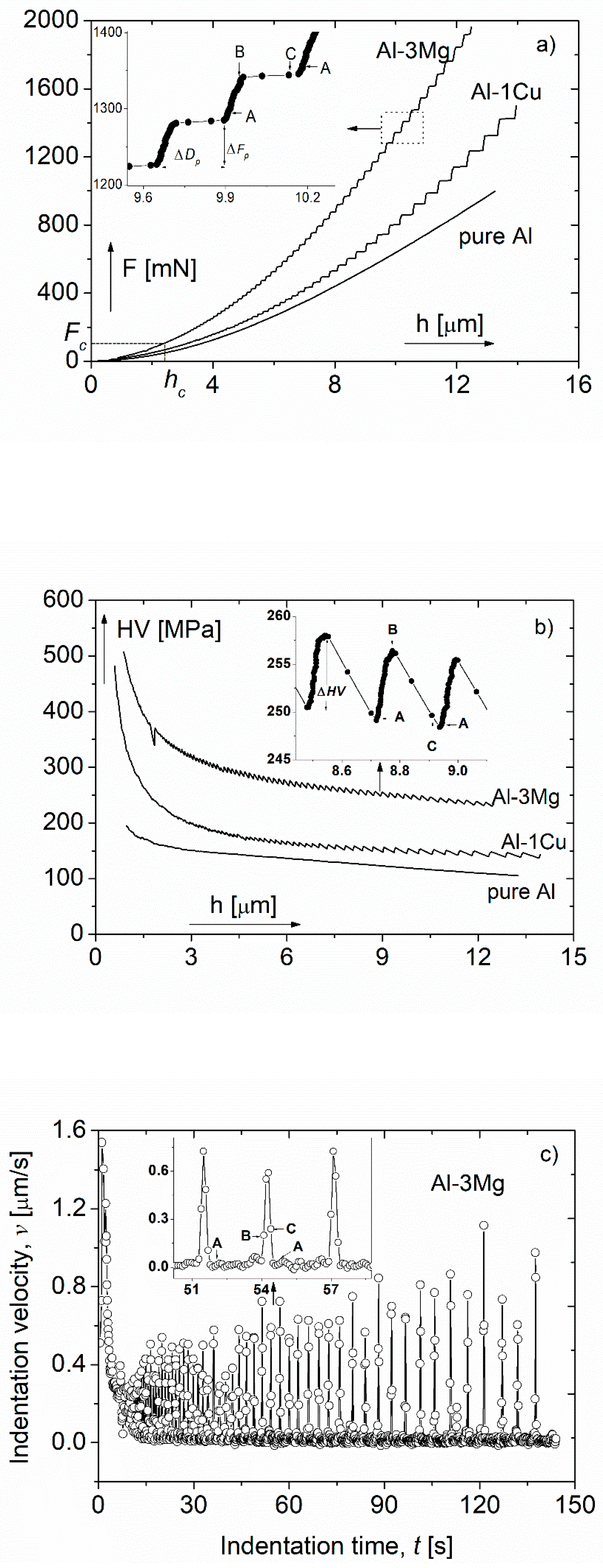

- The Portevin-Le Chatelier type plastic instabilities, as the phenomenon of discontinuous yielding during plastic deformation, can be studied by using indentation method. During indentation, the phenomenon of plastic instability manifests itself as step-like indentation depth–load curves, indicating discontinuous indentation process. The occurrence and the development of the instability-steps depends strongly on both the loading rate and the composition of the investigated materials.

- (3)

- Beside the investigation of plastic instabilities, other dynamic characteristics, such as strain rate sensitivity or viscoelastic behavior can also be studied by using indentation. Furthermore, deformation mechanisms, such as slipping in individual atomic planes, or grain boundary sliding can be observed and investigated by combining indentation with atomic force microscope and/or with scanning electron microscopy.

- (4)

- It has also been shown that indentation can be applied for studying micro-plasticity. As today’s devices are getting smaller and smaller, there is an urgent need to understand the deformation processes of small-size samples, where most of the conventional methods are very hard to apply. Typical examples have been shown to demonstrate the advantages of investigating micro-plasticity by compression of micro-pillars using nanoindentation.

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Herrmann, K. Hardness Testing: Principles and Applications; ASM International: Cleveland, OH, USA, 2011. [Google Scholar]

- Hertz, H. On the contact of elastic solids. J. Reine Angew. Math. 1881, 92, 156–171. [Google Scholar]

- Stilwell, N.A.; Tabor, D. Elastic Recovery of Conical Indentations. Proc. Phys. Soc. 1961, 78, 169–179. [Google Scholar] [CrossRef]

- Oliver, W.; Pharr, G. An improved technique for determining hardness and elastic modulus using load and displacement sensing indentation experiments. J. Mater. Res. 1992, 7, 1564–1583. [Google Scholar] [CrossRef]

- Pharr, G.; Oliver, W.; Brotzen, F. On the generality of the relationship among contact stiffness, contact area, and elastic modulus during indentation. J. Mater. Res. 1992, 7, 613–617. [Google Scholar] [CrossRef]

- Doerner, M.F.; Nix, W.D. A method for interpreting the data from depth-sensing indentation instruments. J. Mater. Res. 1986, 1, 601–609. [Google Scholar] [CrossRef]

- Pharr, G.M. The Anomalous Behavior of Silicon During Nanoindentation. MRS Proc. 1992, 239, 301–312. [Google Scholar] [CrossRef]

- Yan, J.; Takahashi, H.; Gai, X.; Harada, H.; Tamaki, J.; Kuriyagawa, T. Load effects on the phase transformation of single-crystal silicon during nanoindentation tests. Mater. Sci. Eng. A 2006, 423, 19–23. [Google Scholar] [CrossRef]

- Rao, R.; Bradby, J.; Williams, J.-S. Nanoindentation-Induced Phase Transformation in Silicon. In Proceedings of the 2006 International Microsystems, Package, Assembly Conference, Taipei, Taiwan, 18–20 October 2006; pp. 46–49. [Google Scholar]

- Lee, W.-S.; Chen, T.-H.; Lin, C.-F.; Chang, S.-L. Load Effects on Nanoindentation Behaviour and Microstructural Evolution of Single-Crystal Silicon. Mater. Trans. 2010, 51, 1173–1177. [Google Scholar] [CrossRef] [Green Version]

- Schuh, C.A. Nanoindentation studies of materials. Mater. Today 2006, 9, 32–40. [Google Scholar] [CrossRef]

- Huang, H.; Yan, J. On the mechanism of secondary pop-out in cyclic nanoindentation of single-crystal silicon. J. Mater. Res. 2015, 30, 1861–1868. [Google Scholar] [CrossRef]

- Jang, J.-I.; Lance, M.; Wen, S.; Tsui, T.Y.; Pharr, G. Indentation-induced phase transformations in silicon: Influences of load, rate and indenter angle on the transformation behavior. Acta Mater. 2005, 53, 1759–1770. [Google Scholar] [CrossRef]

- Jian, S.-R.; Chen, G.-J.; Juang, J.-Y. Nanoindentation-induced phase transformation in (110)-oriented Si single-crystals. Curr. Opin. Solid State Mater. Sci. 2010, 14, 69–74. [Google Scholar] [CrossRef]

- Kiran, M.S.R.N.; Tran, T.T.; Smillie, L.A.; Haberl, B.; Subianto, D.; Williams, J.S.; Bradby, J. Temperature-dependent mechanical deformation of silicon at the nanoscale: Phase transformation versus defect propagation. J. Appl. Phys. 2015, 117, 205901. [Google Scholar]

- Nagy, P.M.; Horvath, P.; Pető, G.; Kálmán, E. Nanoindentation of Silicon. Mater. Sci. Forum 2008, 604–615, 29–36. [Google Scholar]

- Patriarche, G.; Le Bourhis, E.; Khayyat, M.M.O.; Chaudhri, M. Indentation-induced crystallization and phase transformation of amorphous germanium. J. Appl. Phys. 2004, 96, 1464–1468. [Google Scholar]

- Oliver, D.J.; Bradby, J.; Williams, J.S.; Swain, M.V.; Munroe, P. Rate-dependent phase transformations in nanoindented germanium. J. Appl. Phys. 2009, 105, 126101. [Google Scholar] [CrossRef] [Green Version]

- Domnich, V.; Gogotsi, Y. Phase Transformations in Silicon under Contact Loading. Rev. Adv. Mater. Sci. 2002, 3, 1–36. [Google Scholar]

- Ctvrtlik, R.; Tomastik, J.; Ranc, V. Nanoindentation-Induced Phase Transformation in Silicon Thin Films. Key Eng. Mater. 2014, 586, 112–115. [Google Scholar] [CrossRef]

- Bérces, G.; Chinh, N.Q.; Juhász, A.; Lendvai, J. Kinetic analysis of plastic instabilities occurring in microhardness tests. Acta Metall. 1998, 46, 2029–2037. [Google Scholar]

- Bérces, G.; Chinh, N.Q.; Juhász, A.; Lendvai, J. Occurrence of plastic instabilities in dynamic micro-hardness testing. J. Mater. Res. 1998, 13, 1411–1413. [Google Scholar]

- Chinh, N.Q.; Csikor, F.; Bérces, G.; Lendvai, J. Plastic instabilities in Al-Cu, Al-Mg and Al-Si alloys investigated by Dynamic Ultra Micro-hardness Testing. Alum. Alloys 1998, 2, 979–984. [Google Scholar]

- Portevin, A.; Le Chatelier, F. Sur un phénomène observé lors de l’essai de traction d’alliages en cours de transformation. C. R. Acad. Sci. Paris 1923, 176, 507–512. [Google Scholar]

- Neuhäuser, H.; Schwink, C. Materials Science and Technology. Mughrabi, H., Ed.; VCH: Weinheim, Germany, 1993; Volume 6, p. 191. [Google Scholar]

- McCormick, P. The portevin-le chatelier effect in an Al-Mg-Si alloy loaded in torsion. Acta Met. 1982, 30, 2079–2083. [Google Scholar] [CrossRef]

- Penning, P. Mathematics of the portevin-le chatelier effect. Acta Met. 1972, 20, 1169–1175. [Google Scholar] [CrossRef]

- Brechet, Y.; Estrin, Y. On the influence of precipitation on the Portevin-Le Chatelier effect. Acta Met. Mater. 1995, 43, 955–963. [Google Scholar] [CrossRef]

- Chinh, N.Q.; Horváth, G.; Kovács, Z.; Lendvai, J. Characterization of plastic instability depth-load steps occurring in depth sensing indentation tests. Mater. Sci. Eng. A 2002, 324, 219–224. [Google Scholar]

- Chinh, N.Q.; Gubicza, J.; Kovács, Z.; Lendvai, J. Depth-sensing indentation tests in studying plastic instabilities. J. Mater. Res. 2004, 19, 31–45. [Google Scholar]

- Chinh, N.Q.; Horváth, G.; Kovács, Z.; Juhász, A.; Bérces, G.; Lendvai, J.; Horváth, G.; Kovács, Z. Kinematic and dynamic characterization of plastic instabilities occurring in nano- and microindentation tests. Mater. Sci. Eng. A 2005, 409, 100–107. [Google Scholar]

- Pink, E.; Grinberg, A. Stress drops in serrated flow curves of Al5Mg. Acta Metall. 1982, 30, 2153–2160. [Google Scholar]

- Kubin, L.; Chihab, K.; Estrin, Y. The rate dependence of the portevin-Le chatelier effect. Acta Met. 1988, 36, 2707–2718. [Google Scholar] [CrossRef]

- McCormick, P.; Venkadesan, S.; Ling, C. Propagative instabilities: An experimental view. Scr. Met. Mater. 1993, 29, 1159–1164. [Google Scholar] [CrossRef]

- Horváth, G.; Chinh, N.Q.; Gubicza, J.; Lendvai, J. Plastic instabilities and dislocation densities during plastic deformation in Al–Mg alloys. Mater. Sci. Eng. A 2007, 445–446, 186–192. [Google Scholar]

- Chinh, N.Q.; Csikor, F.; Kovács, Z.; Lendvai, J. Critical concentration of Mg addition for plastic instabilities in Al–Mg alloys. J. Mater. Res. 2000, 15, 1037–1040. [Google Scholar] [CrossRef]

- Bérces, G.; Lendvai, J.; Juhász, A.; Chinh, N. Dynamic characterization of Portevin–Le Chatelier instabilities occurring in depth-sensing microhardness tests. J. Mater. Res. 2003, 18, 2874–2881. [Google Scholar] [CrossRef]

- Schuh, C.; Nieh, T. A nanoindentation study of serrated flow in bulk metallic glasses. Acta Mater. 2003, 51, 87–99. [Google Scholar] [CrossRef]

- Kim, J.-J.; Choi, Y.; Suresh, S.; Argon, A.S. Nanocrystallization during nanoindentation of a bulk amorphous metal alloy at room temperature. Science 2002, 295, 654–657. [Google Scholar]

- Golovin, Y.; Ivolgin, V.; Khonik, V.; Kitagawa, K.; Tyurin, A. Serrated plastic flow during nanoindentation of a bulk metallic glass. Scr. Mater. 2001, 45, 947–952. [Google Scholar] [CrossRef]

- Schuh, C.; Nieh, T.G.; Kawamura, Y. Rate Dependence of Serrated Flow During Nanoindentation of a Bulk Metallic Glass. J. Mater. Res. 2002, 17, 1651–1654. [Google Scholar] [CrossRef]

- Jiang, W.H.; Atzmon, M. Rate dependence of serrated flow in a metallic glass. J. Mater. Res. 2003, 18, 755–757. [Google Scholar] [CrossRef] [Green Version]

- Chinh, N.Q.; Győri, T.; Gubicza, J.; Lendvai, J.; Langdon, T.G. Possible self-organized criticality in the Portevin–Le Chatelier effect during decomposition of solid solution alloys. MRS Commun. 2012, 2, 1–4. [Google Scholar] [CrossRef]

- Cottrell, A. LXXXVI. A note on the Portevin-Le Chatelier effect. Lond. Edinb. Dublin Philos. Mag. J. Sci. 1953, 44, 829–832. [Google Scholar] [CrossRef]

- Van den Beukel, A. Theory of the effect of dynamic strain aging on mechanical properties. Phys. Status Solidi 1975, 30, 197–206. [Google Scholar]

- Robinson, J.M. Serrated flow in aluminium base alloys. Int. Mater. Rev. 1994, 39, 217–227. [Google Scholar]

- Woodford, D.A. Strain-rate sensitivity as a measure of ductility. Trans. ASM 1969, 62, 291–293. [Google Scholar]

- Chinh, N.Q.; Rácz, G.; Gubicza, J.; Valiev, R.Z.; Langdon, T.G. A possible stabilizing effect of work hardening on the tensile performance of superplastic materials. Mater. Sci. Eng. A 2019, 759, 448–454. [Google Scholar] [CrossRef]

- Adabbo, H.E.; González-Doncel, G.; Ruano, O.A.; Belzunce, J.M.; Sherby, O.D. Strain hardening during superplastic deformation of Al-7475 alloy. J. Mater. Res. 1989, 4, 587–594. [Google Scholar]

- Wang, Y.; Ma, E. Three strategies to achieve uniform tensile deformation in a nanostructured metal. Acta Mater. 2004, 52, 1699–1709. [Google Scholar] [CrossRef]

- Kabirian, F.; Khan, H.; Pandey, A. Negative to positive strain rate sensitivity in 5xxx series aluminum alloys: Experiment and constitutive modeling. Int. J. Plast. 2014, 55, 232–246. [Google Scholar] [CrossRef]

- Alabort, E.; Putman, D.; Reed, R.C. Superplasticity in Ti-6Al-4V: Characterisation, modelling and applications. Acta Mater. 2015, 95, 428–442. [Google Scholar]

- Chinh, N.Q.; Illy, J.; Juhász, A.; Lendvai, J. Mehanical Properties and Superplasticity of AlZnMg Alloys with Copper and Zirconium Additions. Phys. Stat. Sol. 1995, 149, 583–599. [Google Scholar]

- Chinh, N.Q.; Tasnádi, P.; Juhasz, A.; Kovacs, I.; Kovács-Csetényi, E. Evaluation of the true activation enthalpy of superplastic flow including a threshold stress. J. Mater. Sci. 1994, 29, 2341–2344. [Google Scholar] [CrossRef]

- Li, J.C. Impression creep and other localized tests. Mater. Sci. Eng. A 2002, 322, 23–42. [Google Scholar] [CrossRef]

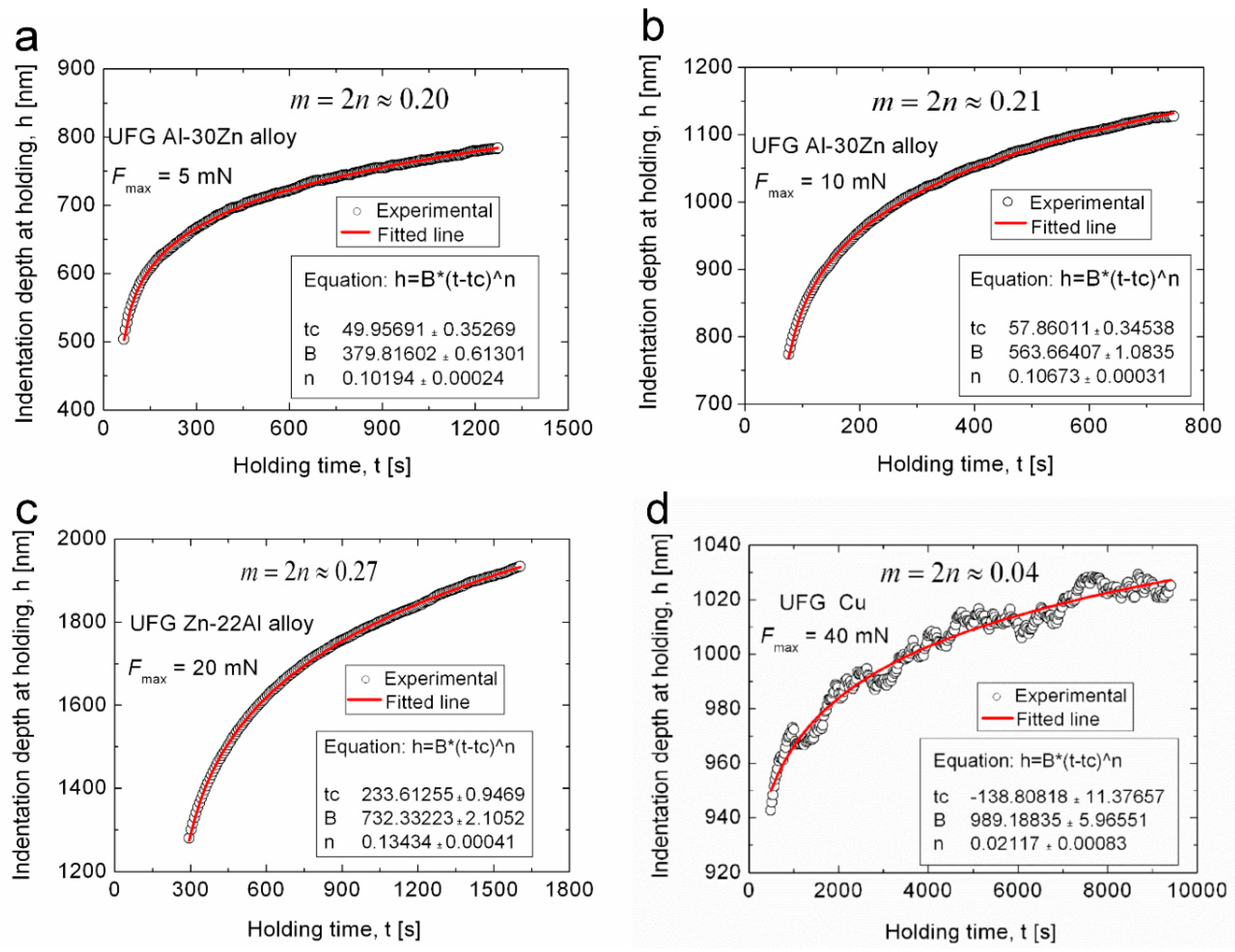

- Choi, I.-C.; Kim, Y.-J.; Ahn, B.; Kawasaki, M.; Langdon, T.G.; Jang, J.-I. Evolution of plasticity, strain-rate sensitivity and the underlying deformation mechanism in Zn–22% Al during high-pressure torsion. Scr. Mater. 2014, 75, 102–105. [Google Scholar] [CrossRef]

- Cao, Z.; Wang, L.; Hu, K.; Huang, Y.; Meng, X. Microstructural evolution and its influence on creep and stress relaxation in nanocrystalline Ni. Acta Mater. 2012, 60, 6742–6754. [Google Scholar] [CrossRef]

- Chinh, N.Q.; Szommer, P. Mathematical description of indentation creep and its application for the determination of strain rate sensitivity. Mater. Sci. Eng. A 2014, 611, 333–336. [Google Scholar] [CrossRef]

- Kawasaki, M.; Jang, J.-I. Micro-Mechanical Response of an Al-Mg Hybrid System Synthesized by High-Pressure Torsion. Materials 2017, 10, 596–610. [Google Scholar]

- Maier-Kiener, V.; Durst, K. Advanced Nanoindentation Testing for Studying Strain-Rate Sensitivity and Activation Volume. JOM 2017, 69, 2246–2255. [Google Scholar] [CrossRef] [Green Version]

- Valiev, R.; Murashkin, M.Y.; Kilmametov, A.; Straumal, B.B.; Chinh, N.Q.; Langdon, T.G. Unusual super-ductility at room temperature in an ultrafine-grained aluminum alloy. J. Mater. Sci. 2010, 45, 4718–4724. [Google Scholar] [CrossRef]

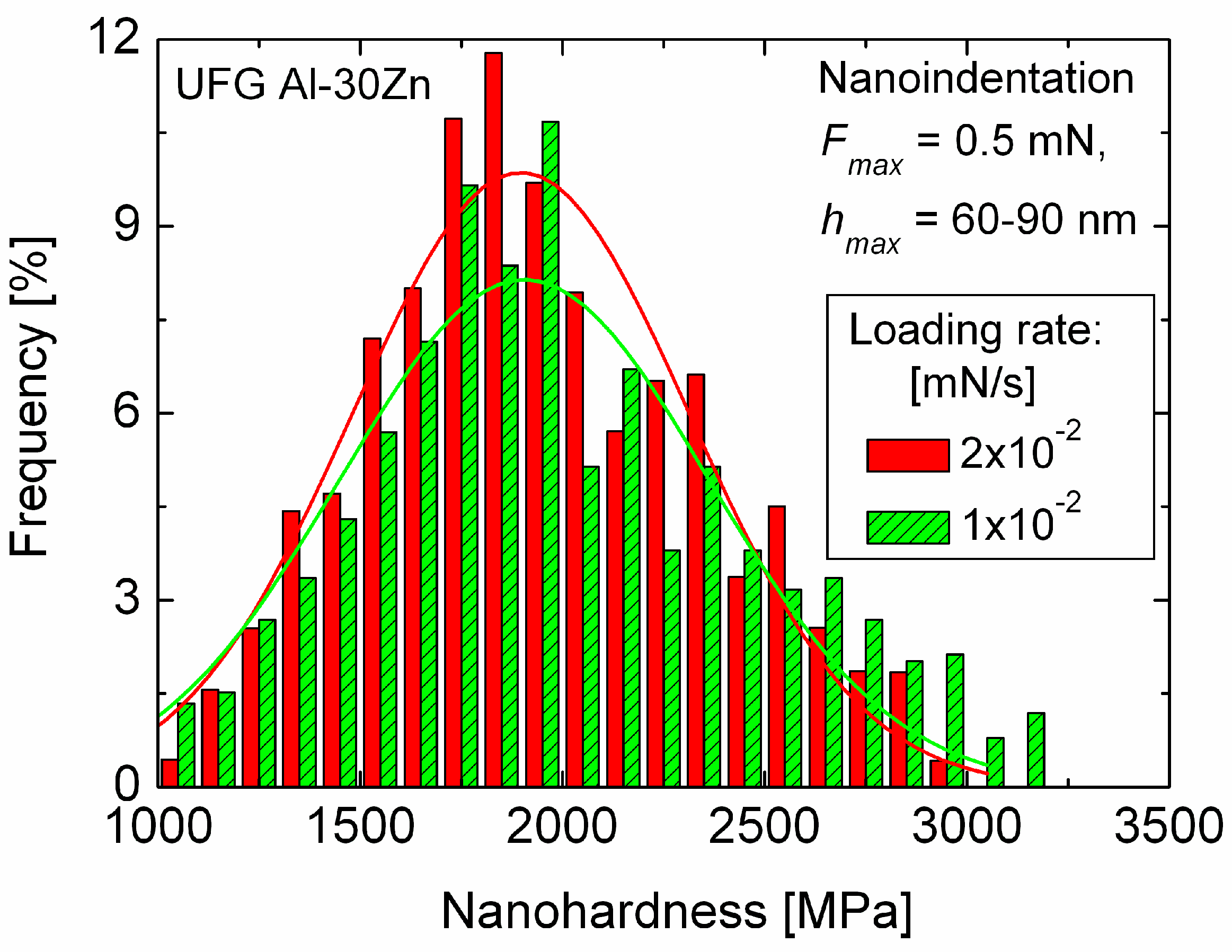

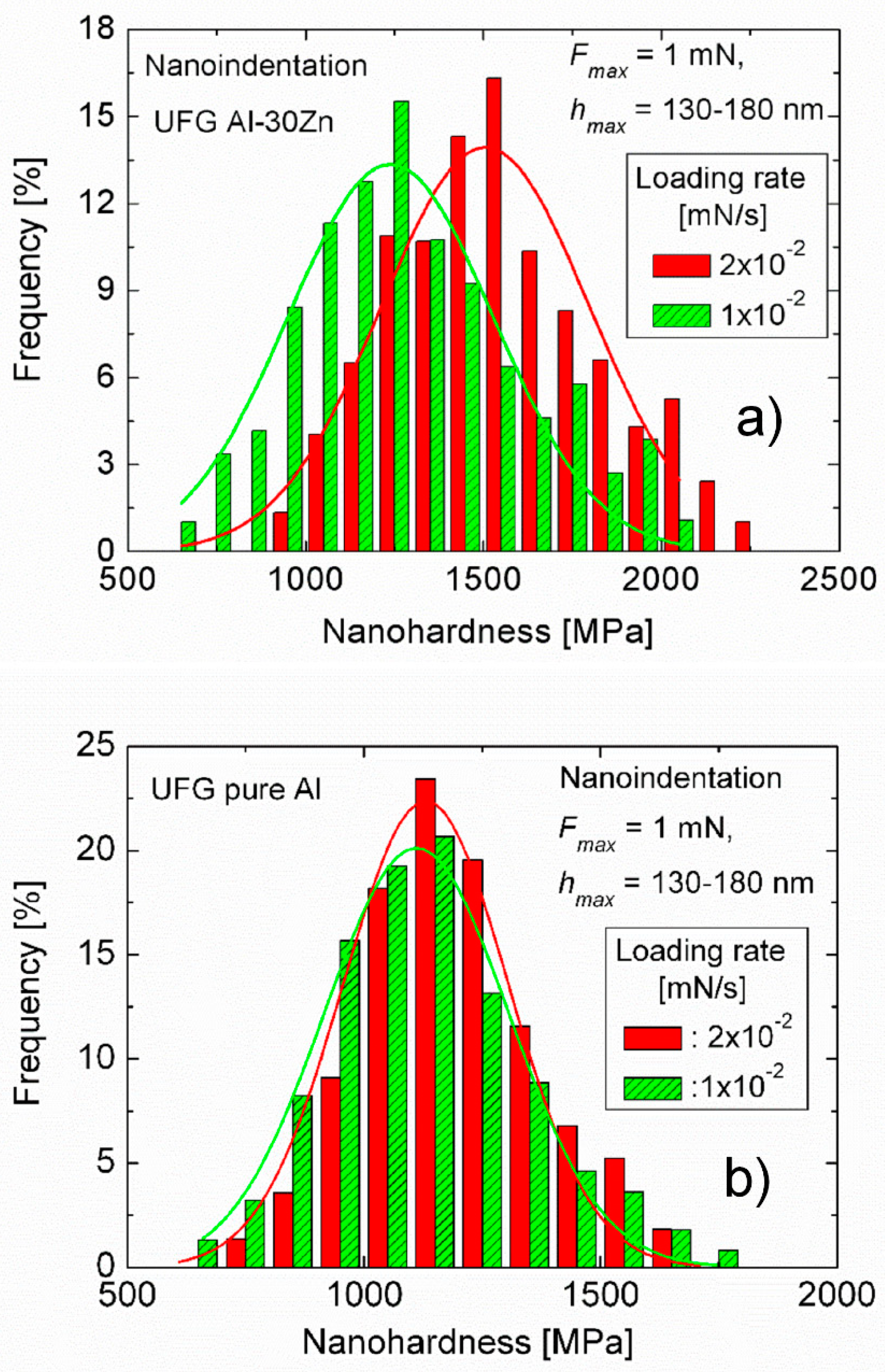

- Chinh, N.Q.; Csanádi, T.; Győri, T.; Valiev, R.Z.; Straumal, B.B.; Kawasaki, M.; Langdon, T.G. Strain rate sensitivity studies in an ultrafine-grained Al–30wt.% Zn alloy using micro- and nanoindentation. Mater. Sci. Eng. A 2012, 543, 117–120. [Google Scholar] [CrossRef]

- Langdon, T.G. Twenty-five years of ultrafine-grained materials: Achieving exceptional properties through grain refinement. Acta Mater. 2013, 61, 7035–7059. [Google Scholar] [CrossRef]

- Zhilyaev, A.P.; Langdon, T. Using high-pressure torsion for metal processing: Fundamentals and applications. Prog. Mater. Sci. 2008, 53, 893–979. [Google Scholar] [CrossRef]

- Chinh, N.Q.; Jenei, P.; Gubicza, J.; Bobruk, E.V.; Valiev, R.Z.; Langdon, T.G. Influence of Zn content on the microstructure and mechanical performance of ultrafine-grained Al-Zn alloys processed by high-pressure torsion. Mater. Lett. 2017, 186, 334–337. [Google Scholar]

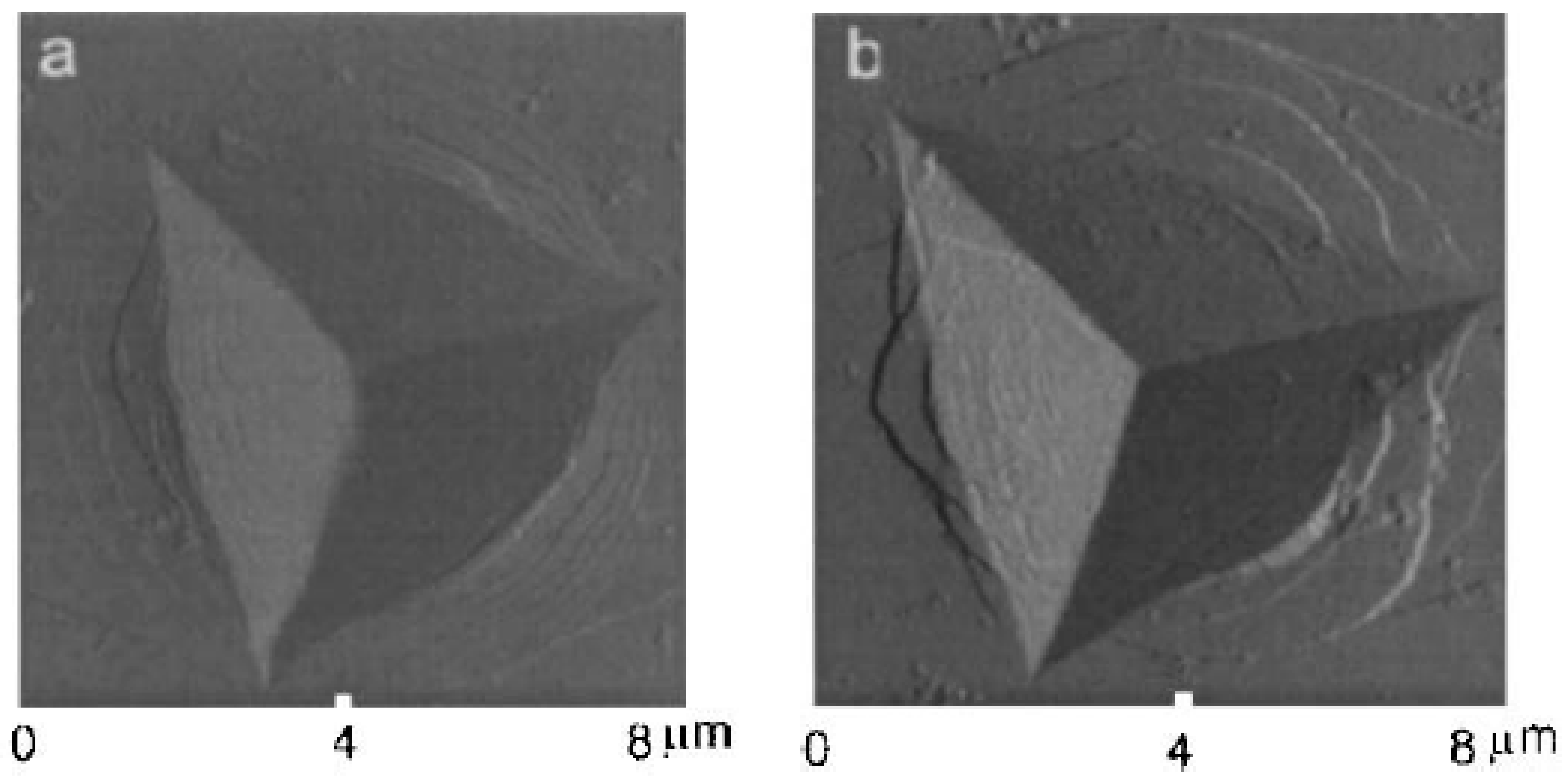

- Chinh, N.Q.; Szommer, P.; Horita, Z.; Langdon, T.G. Experimental Evidence for Grain-Boundary Sliding in Ultrafine-Grained Aluminum Processed by Severe Plastic Deformation. Adv. Mater. 2006, 18, 34–39. [Google Scholar] [CrossRef]

- Chinh, N.Q.; Szommer, P.; Csanádi, T.; Langdon, T.G. Flow processes at low temperatures in ultrafine-grained aluminum. Mater. Sci. Eng. A 2006, 434, 326–334. [Google Scholar]

- Chinh, N.Q.; Valiev, R.Z.; Sauvage, X.; Varga, G.; Havancsák, K.; Kawasaki, M.; Straumal, B.B.; Langdon, T.G. Grain Boundary Phenomena in an Ultrafine-Grained Al-Zn Alloy with Improved Mechanical Behavior for Micro-Devices. Adv. Eng. Mater. 2014, 16, 1000–1009. [Google Scholar] [CrossRef]

- Straumal, B.B.; Sauvage, X.; Baretzky, B.; Mazilkin, A.; Valiev, R. Grain boundary films in Al–Zn alloys after high pressure torsion. Scr. Mater. 2014, 70, 59–62. [Google Scholar] [CrossRef]

- Chinh, N.Q.; Szommer, P.; Gubicza, J.; El-Tahawy, M.; Bobruk, E.V.; Murashkin, M.Y.; Valiev, R.Z. Characterizing Microstructural and Mechanical Properties of Al–Zn Alloys Processed by High-Pressure Torsion. Adv. Eng. Mater. 2020, 22, 1900672. [Google Scholar]

- Chinh, N.Q.; Csanádi, T.; Gubicza, J.; Valiev, R.Z.; Straumal, B.B.; Langdon, T.G. The Effect of Grain Boundary Sliding and Strain Rate Sensitivity on the Ductility of Ultrafine-Grained Materials. Mater. Sci. Forum 2011, 667–669, 677–682. [Google Scholar] [CrossRef]

- Hay, J.; Agee, P.; Herbert, E. CONTINUOUS STIFFNESS MEASUREMENT DURING INSTRUMENTED INDENTATION TESTING. Exp. Tech. 2010, 34, 86–94. [Google Scholar] [CrossRef]

- A.C. Fischer-Crips HandBook, “IBIS Uncovered”; Fischer-Crips Laboratories Pty Ltd.: Forestville, Australia, 2011.

- Herbert, E.G.; Oliver, W.C.; Pharr, G.M. Nanoindentation and the dynamic characterization of viscoelastic solids. J. Phys. D Appl. Phys. 2008, 41, 074021. [Google Scholar] [CrossRef]

- Chinh, N.Q.; Csanádi, T.; Gubicza, J.; Valiev, R.Z. Correlation between strain-rate sensitivity and viscous properties derived from dynamic nanoindentation of ultrafine-grained Al–Zn alloys. MRS Commun. 2019, 9, 310–314. [Google Scholar] [CrossRef]

- Leitner, A.; Maier-Kiener, V.; Kiener, D. Dynamic nanoindentation testing: Is there an influence on a material’s hardness? Mater. Res. Lett. 2017, 5, 486–493. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Zhou, G.; Guo, J.; Zhao, J.; Tang, Q.; Hu, Z. Nanoindentation Properties of 18CrNiMo7-6 Steel after Carburizing and Quenching Determined by Continuous Stiffness Measurement Method. Metals 2020, 10, 125–135. [Google Scholar]

- Siu, K.; Ngan, A.H.W. The continuous stiffness measurement technique in nanoindentation intrinsically modifies the strength of the sample. Philos. Mag. 2013, 93, 449–467. [Google Scholar] [CrossRef]

- Merle, B.; Maier-Kiener, V.; Pharr, G.M. Influence of modulus-to-hardness ratio and harmonic parameters on continuous stiffness measurement during nanoindentation. Acta Mater. 2017, 134, 167–176. [Google Scholar] [CrossRef]

- Uchic, M.D.; Dimiduk, D.; Florando, J.N.; Nix, W.D. Exploring specimen size effects in plastic deformation of Ni3(Al, Ta). MRS Proc. 2003, 753, BB1.4.1–BB1.4.6. [Google Scholar]

- Uchic, M.; Dimiduk, D.M.; Florando, J.N.; Nix, W.D. Sample Dimensions Influence Strength and Crystal Plasticity. Science 2004, 305, 986–989. [Google Scholar] [CrossRef]

- Uchic, M.D.; Shade, P.A.; Dimiduk, D.M. Plasticity of Micrometer-Scale Single Crystals in Compression. Annu. Rev. Mater. Res. 2009, 39, 361–386. [Google Scholar] [CrossRef] [Green Version]

- Ispánovity, P.D.; Hegyi, Á.; Groma, I.; Györgyi, G.; Ratter, K.; Weygand, D. Average yielding and weakest link statistics in micron-scale plasticity. Acta Mater. 2013, 61, 6234–6245. [Google Scholar] [CrossRef] [Green Version]

- Dimiduk, D.; Woodward, C.; Lesar, R.; Uchic, M.D. Scale-Free Intermittent Flow in Crystal Plasticity. Science 2006, 312, 1188–1190. [Google Scholar] [CrossRef] [Green Version]

- Zhao, Y.; Guo, Y.; Wei, Q.; Dangelewicz, A.; Xu, C.; Zhu, Y.; Langdon, T.; Zhou, Y.; Lavernia, E. Influence of specimen dimensions on the tensile behavior of ultrafine-grained Cu. Scr. Mater. 2008, 59, 627–630. [Google Scholar] [CrossRef]

- Zhao, Y.; Guo, Y.; Wei, Q.; Topping, T.; Dangelewicz, A.; Zhu, Y.; Langdon, T.; Lavernia, E. Influence of specimen dimensions and strain measurement methods on tensile stress–strain curves. Mater. Sci. Eng. A 2009, 525, 68–77. [Google Scholar] [CrossRef]

- Chinh, N.Q.; Győri, T.; Valiev, R.Z.; Szommer, P.; Varga, G.; Havancsák, K.; Langdon, T.G. Observations of unique plastic behavior in micro-pillars of an ultrafine-grained alloy. MRS Commun. 2012, 2, 75–78. [Google Scholar] [CrossRef]

- Csanádi, T.; Bľanda, M.; Duszová, A.; Chinh, N.Q.; Szommer, P.; Dusza, J. Deformation characteristics of WC micropillars. J. Eur. Ceram. Soc. 2014, 34, 4099–4103. [Google Scholar] [CrossRef]

- Tarragó, J.; Roa, J.; Jimenez-Pique, E.; Keown, E.; Fair, J.; Llanes, L. Mechanical deformation of WC–Co composite micropillars under uniaxial compression. Int. J. Refract. Met. Hard Mater. 2016, 54, 70–74. [Google Scholar] [CrossRef] [Green Version]

- Csanádi, T.; Szommer, P.; Chinh, N.Q.; Grasso, S.; Dusza, J.; Reece, M. Plasticity in ZrB 2 micropillars induced by anomalous slip activation. J. Eur. Ceram. Soc. 2016, 36, 389–394. [Google Scholar] [CrossRef]

- Csanádi, T.; Bl’anda, M.; Chinh, N.Q.; Hvizdoš, P.; Dusza, J. Orientation-dependent hardness and nanoindentation-induced deformation mechanismm of WC crystals. Acta Mater. 2015, 83, 397–407. [Google Scholar]

- Kalácska, S.; Dankházi, Z.; Zilahi, G.; Maeder, X.; Michler, J.; Ispánovity, P.D.; Groma, I. Investigation of geometrically necessary dislocation structures in compressed Cu micropillars by 3-dimensional HR-EBSD. Mater. Sci. Eng. A 2020, 770, 138499. [Google Scholar] [CrossRef] [Green Version]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Olasz, D.; Lendvai, J.; Szállás, A.; Gulyás, G.; Chinh, N.Q. Extended Applications of the Depth-Sensing Indentation Method. Micromachines 2020, 11, 1023. https://doi.org/10.3390/mi11111023

Olasz D, Lendvai J, Szállás A, Gulyás G, Chinh NQ. Extended Applications of the Depth-Sensing Indentation Method. Micromachines. 2020; 11(11):1023. https://doi.org/10.3390/mi11111023

Chicago/Turabian StyleOlasz, Dániel, János Lendvai, Attila Szállás, Gábor Gulyás, and Nguyen Q. Chinh. 2020. "Extended Applications of the Depth-Sensing Indentation Method" Micromachines 11, no. 11: 1023. https://doi.org/10.3390/mi11111023

APA StyleOlasz, D., Lendvai, J., Szállás, A., Gulyás, G., & Chinh, N. Q. (2020). Extended Applications of the Depth-Sensing Indentation Method. Micromachines, 11(11), 1023. https://doi.org/10.3390/mi11111023