Modification of Higher Alkanes by Nanoparticles to Control Light Propagation in Tapered Fibers

Abstract

:1. Introduction

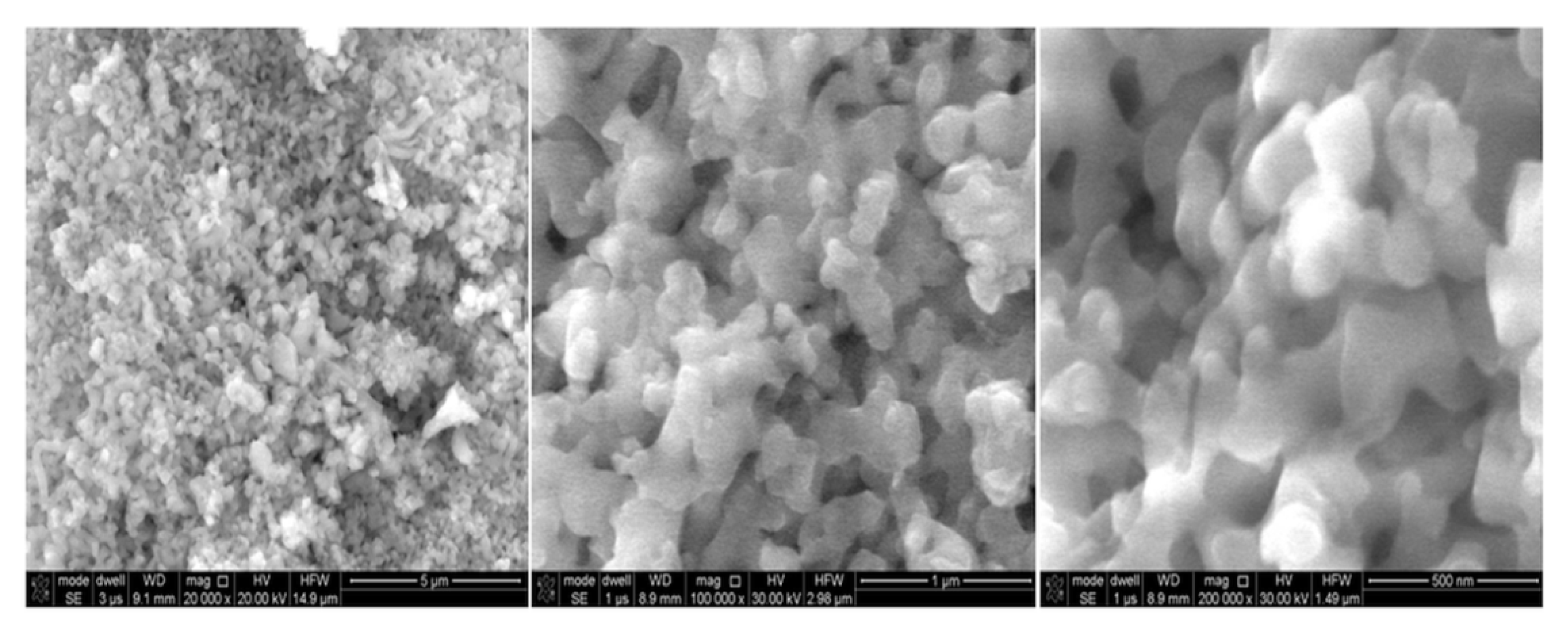

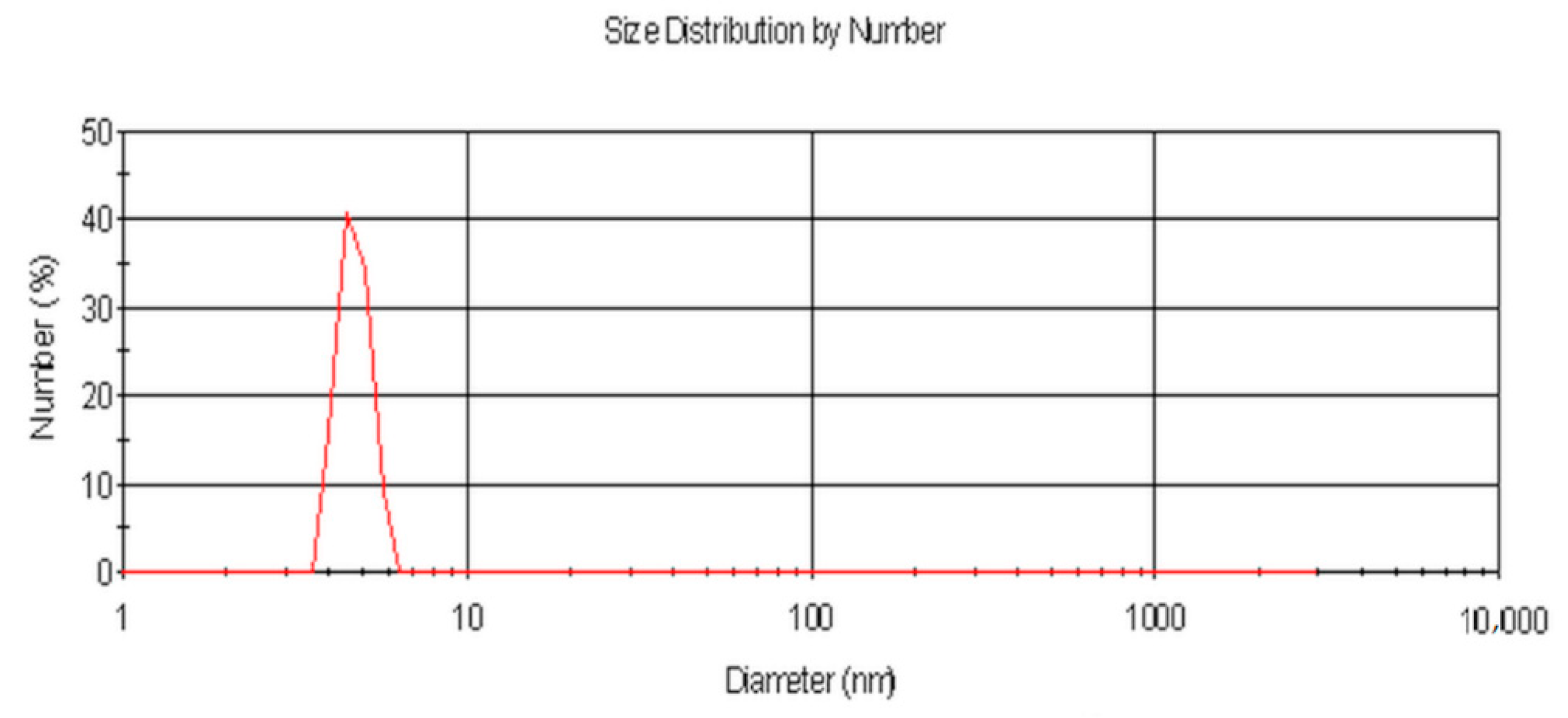

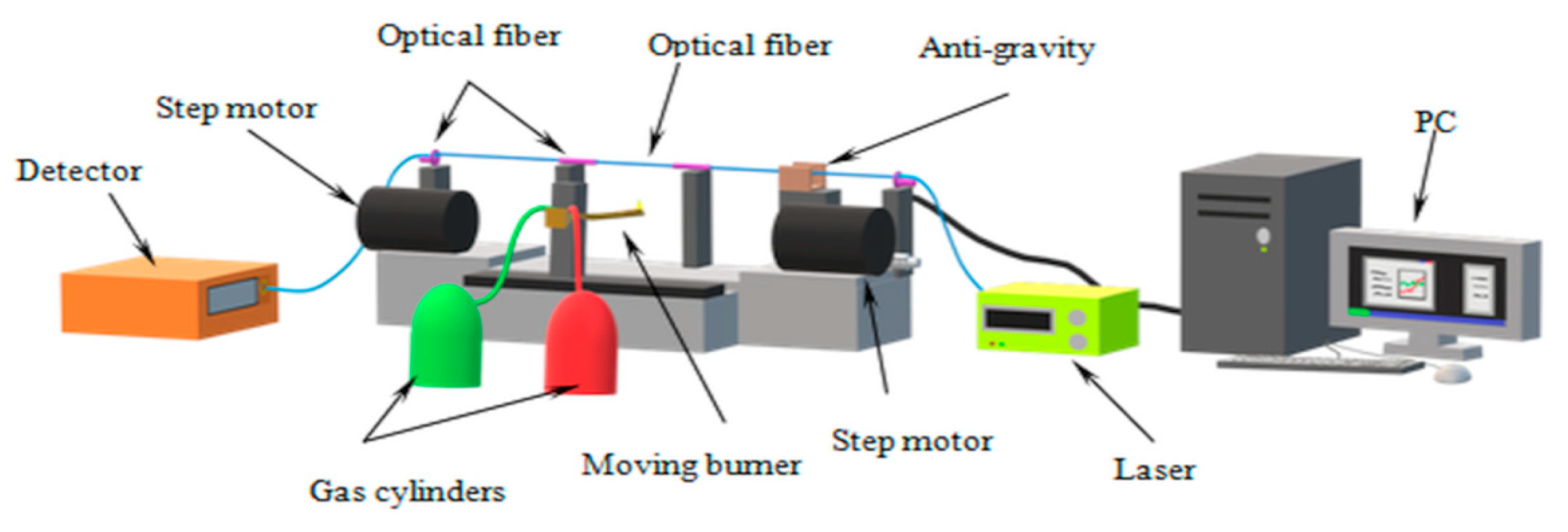

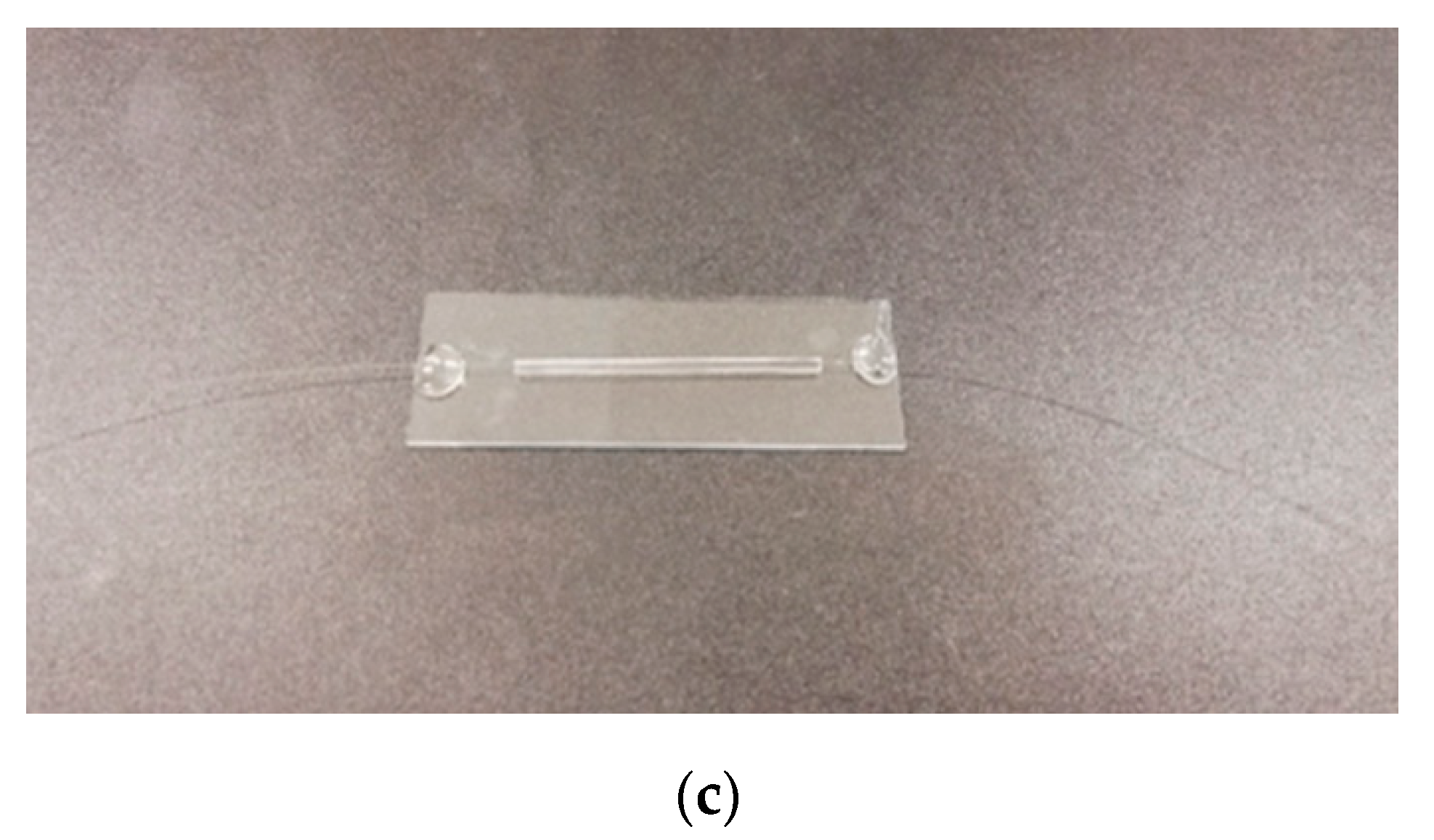

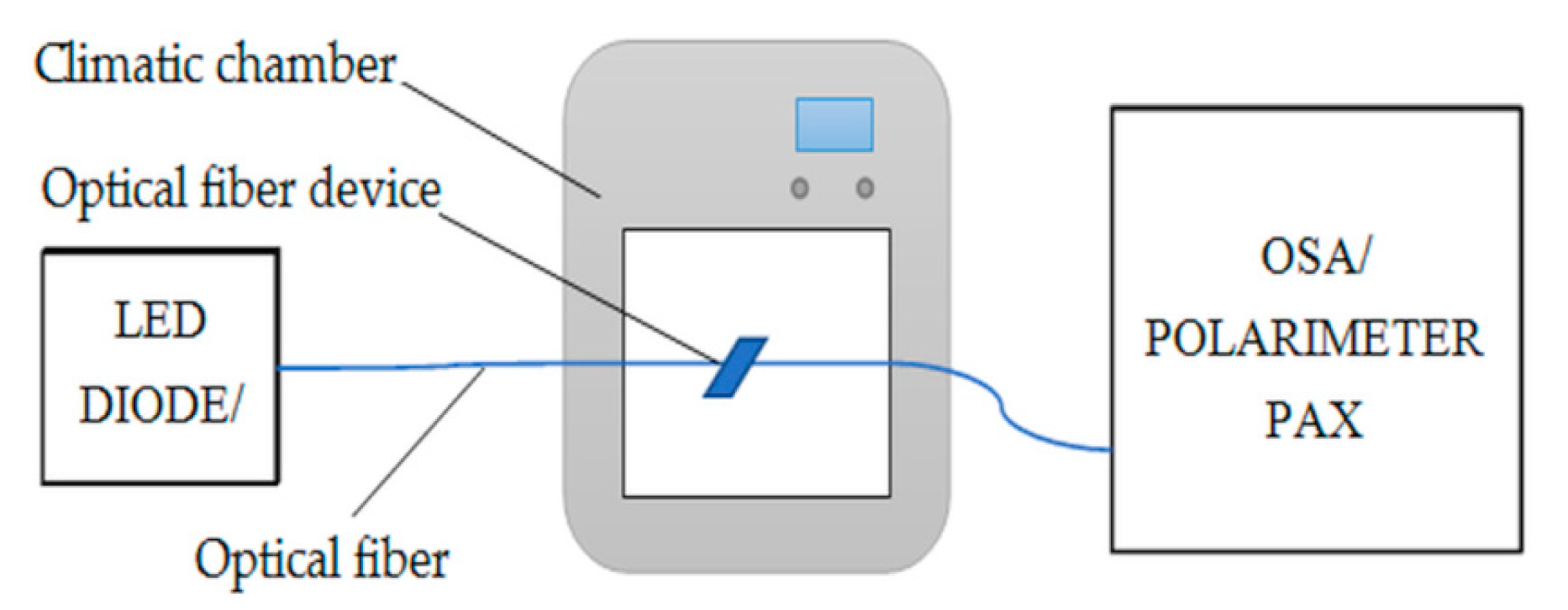

2. Materials and Methods

2.1. Materials

2.2. Technology

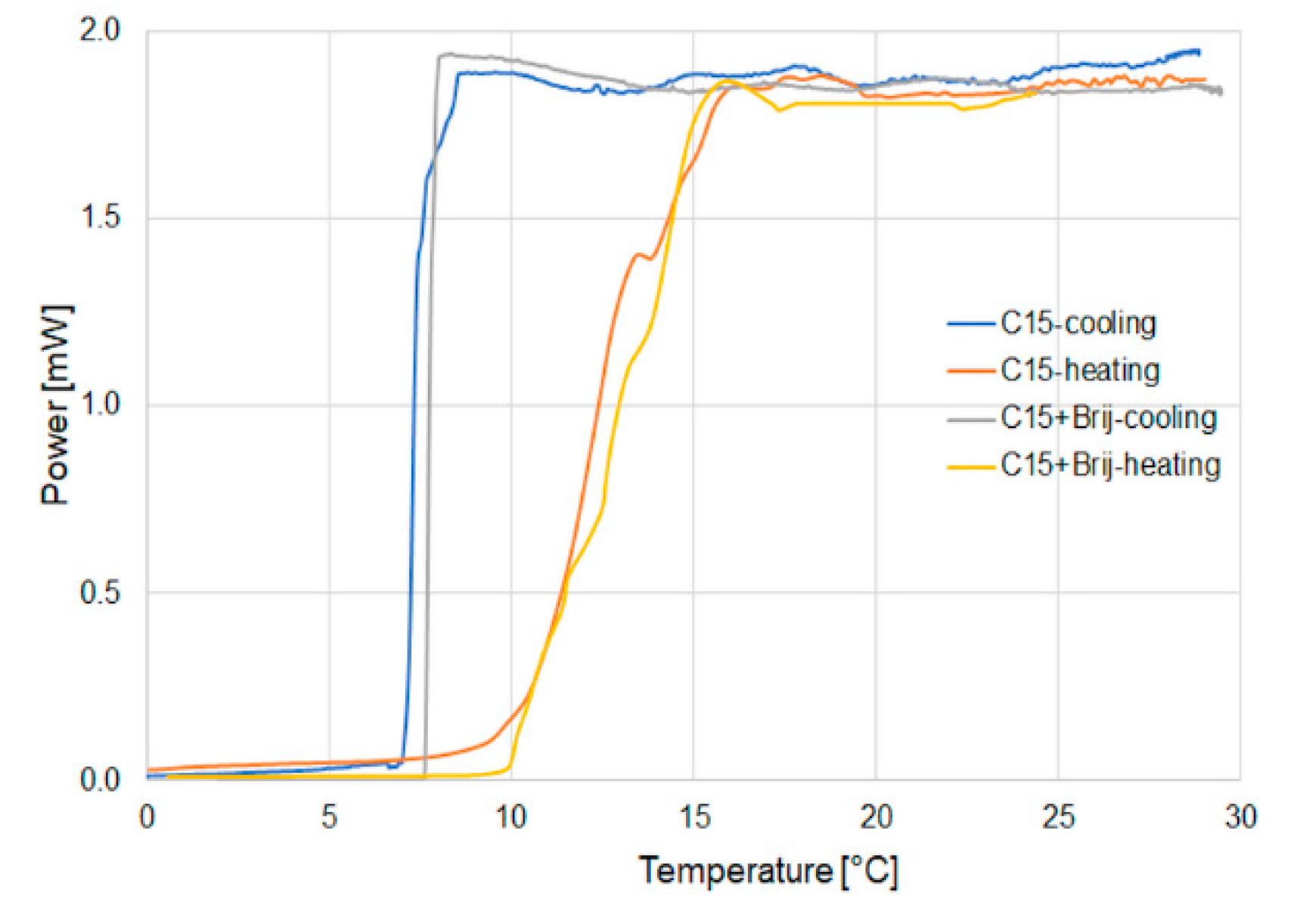

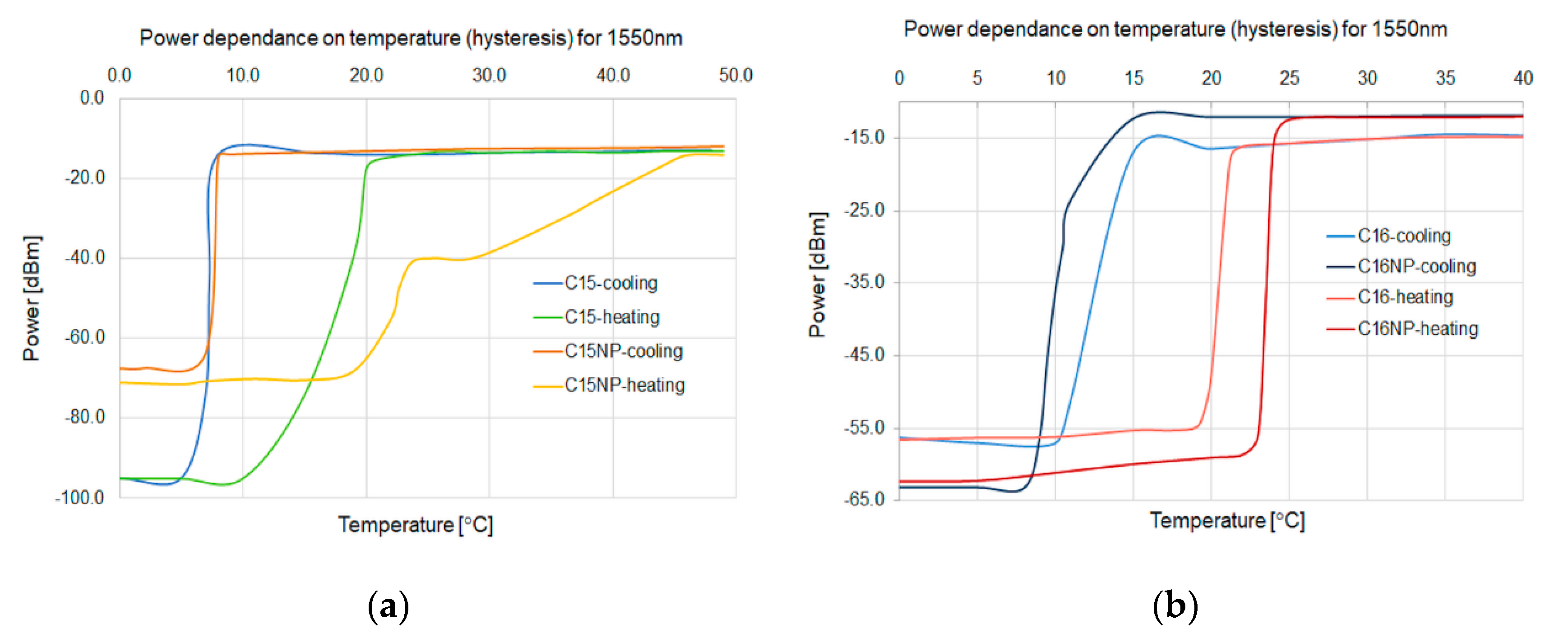

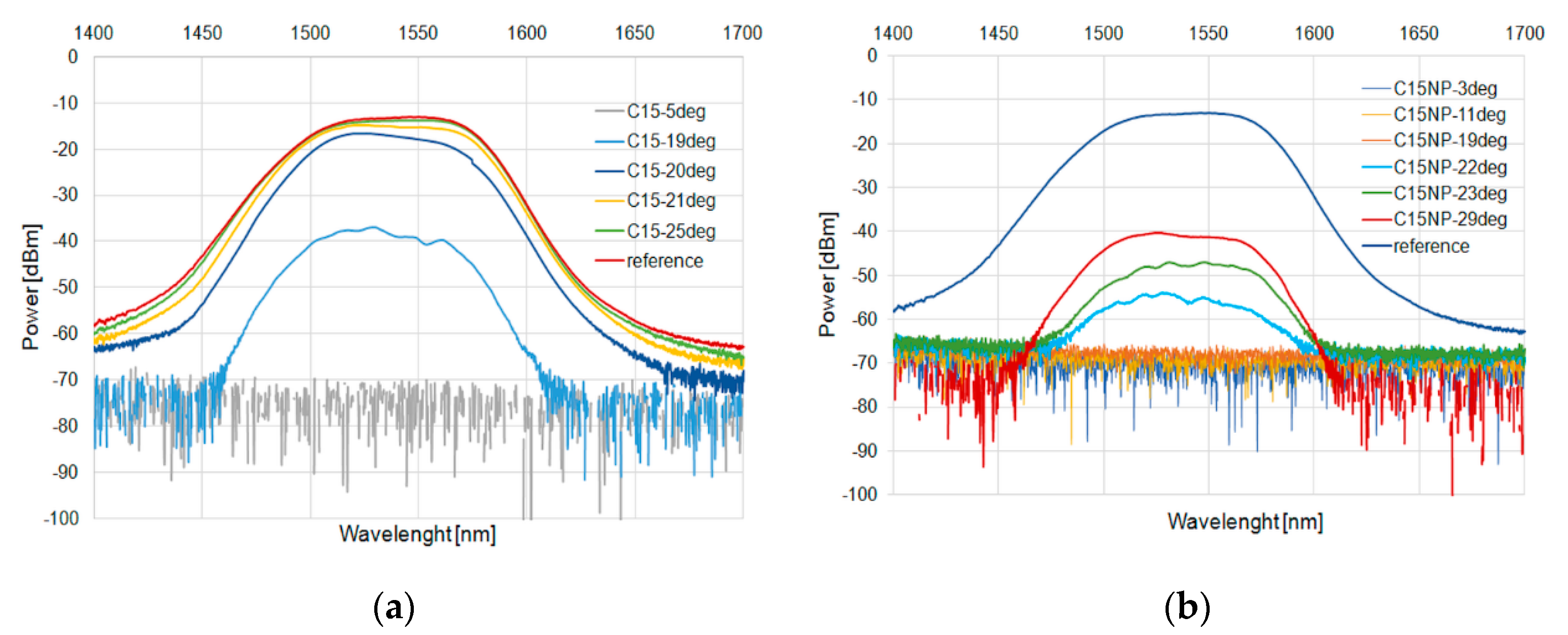

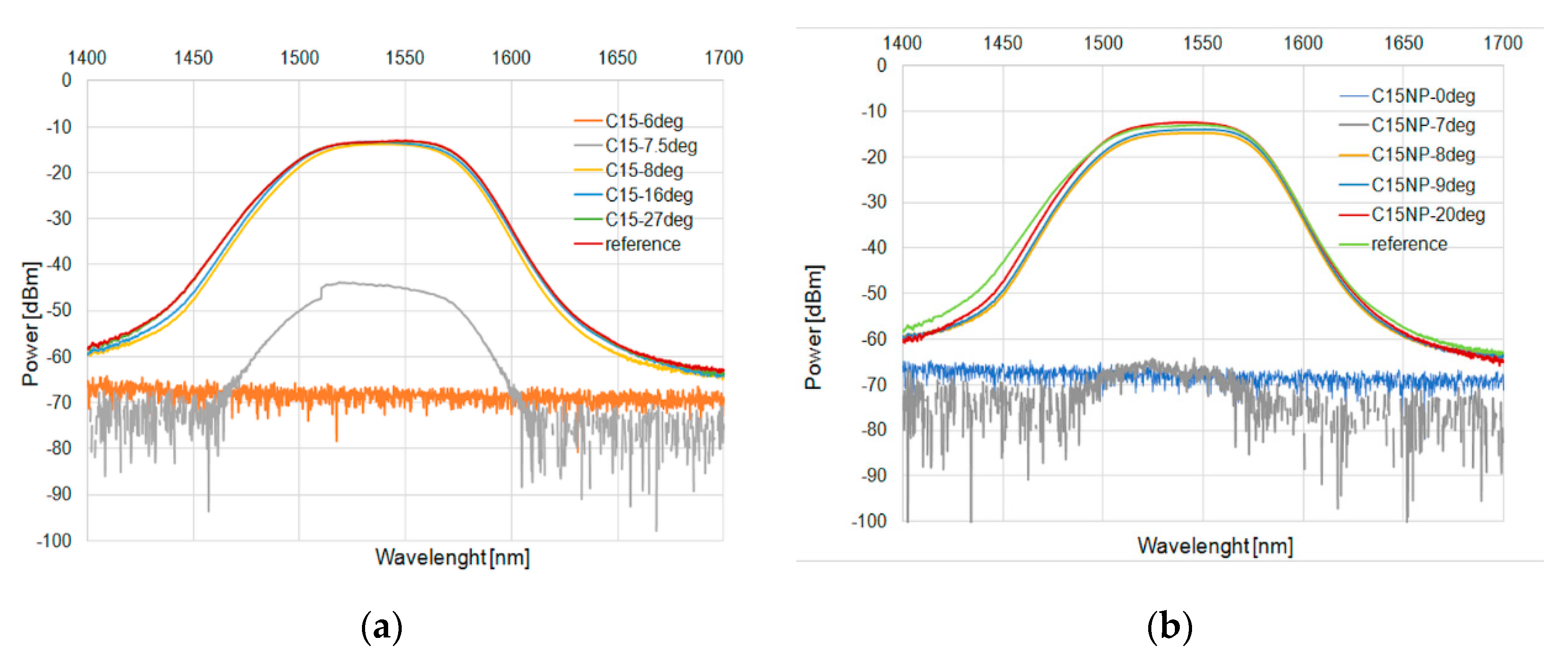

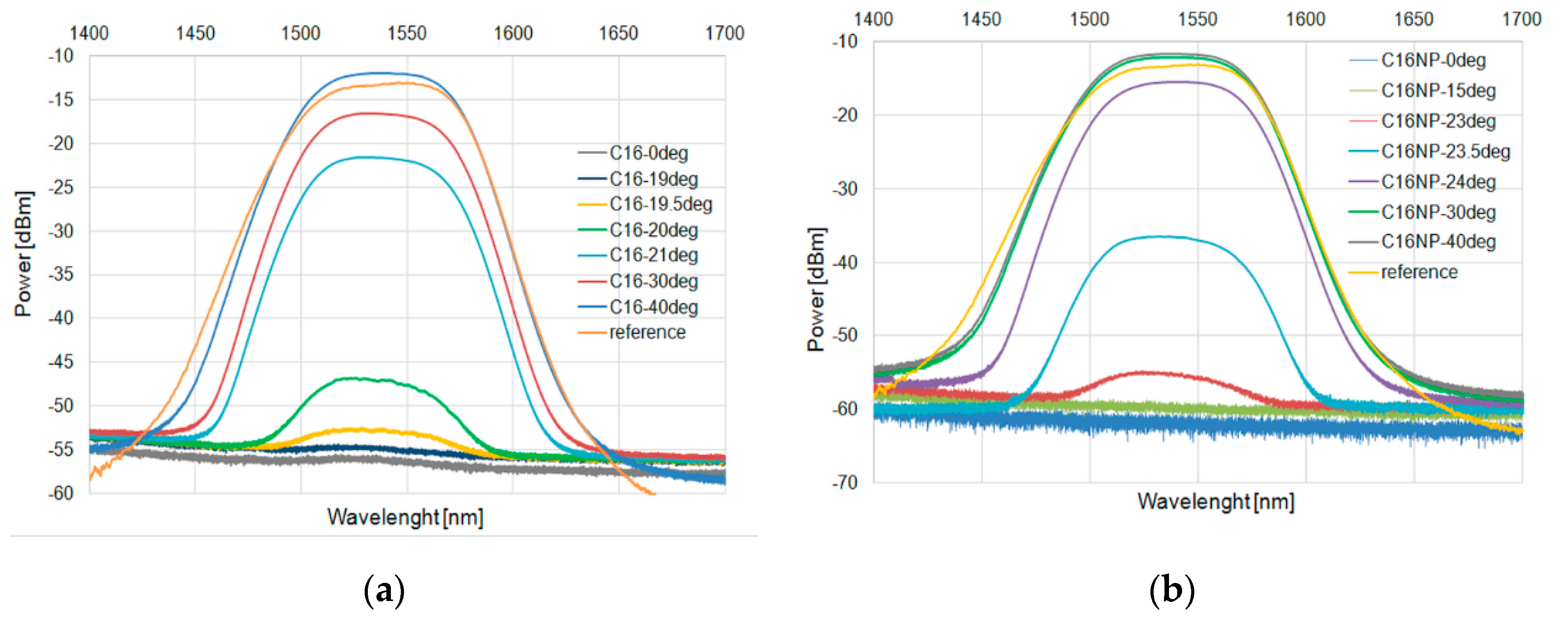

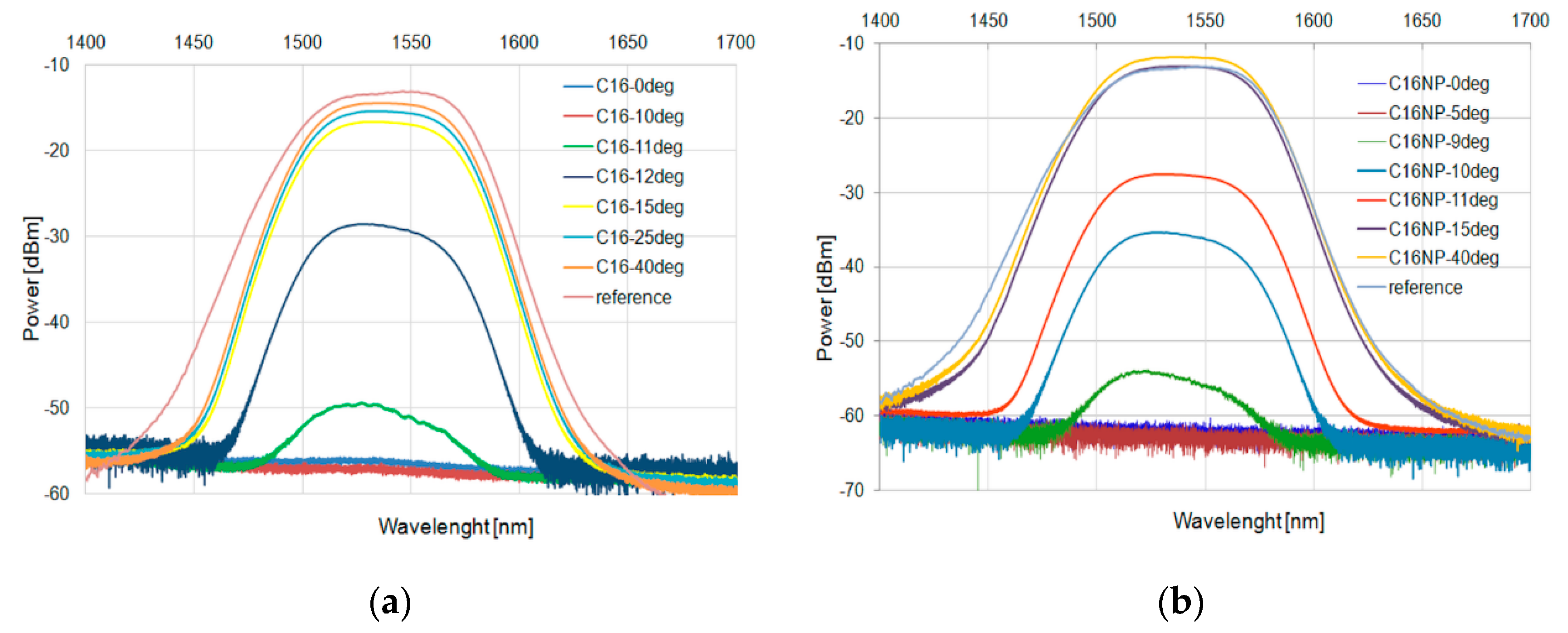

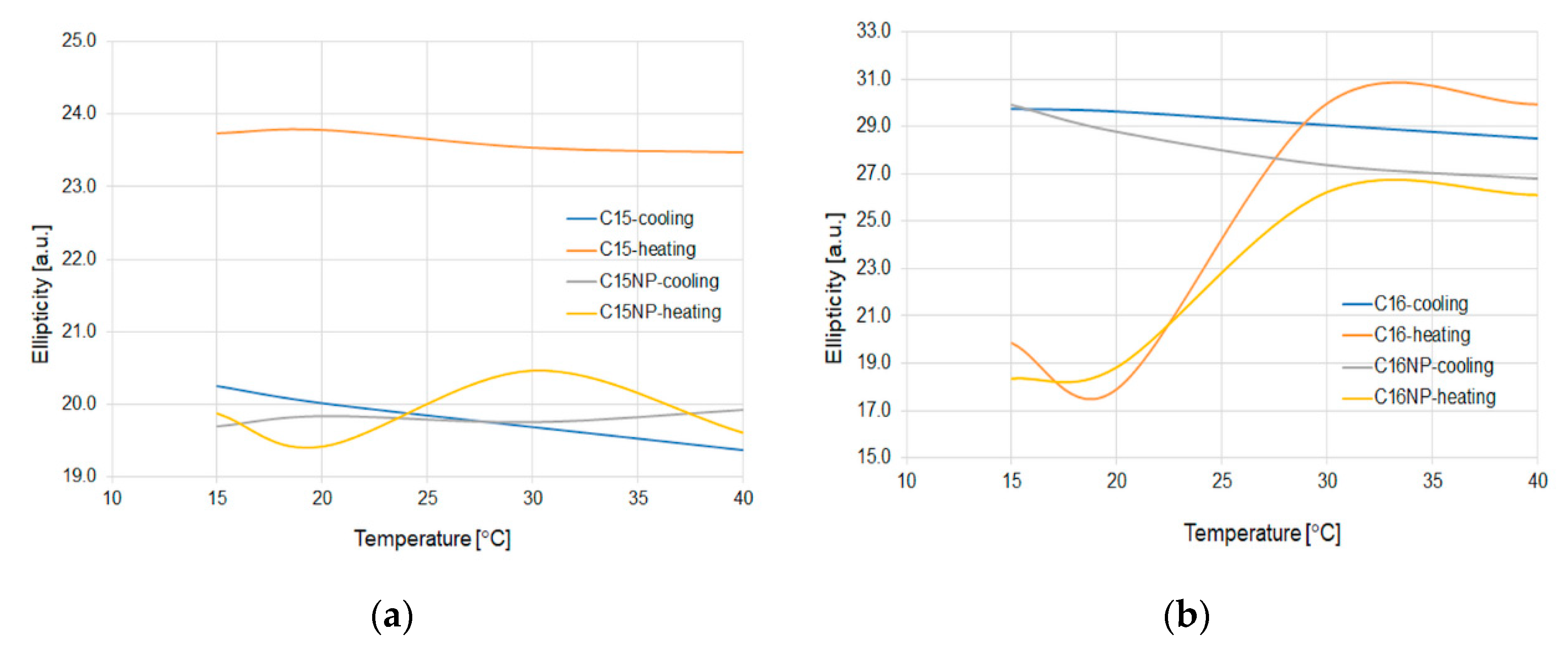

3. Results and Discussion

4. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Katsunari, O. Wave Theory of Optical Waveguides. In Fundamentals of Optical Waveguides, 2nd ed.; Academic Press: London, UK, 2006; Volume 3, pp. 32–47. [Google Scholar]

- Born, M.; Wolf, E. Principles of Optics; Cambridge University Press: Cambridge, UK, 2003. [Google Scholar]

- Tsao, C. Optical Fiber Waveguide Analysis; Oxford University Press: London, UK, 1992. [Google Scholar]

- Russell, P.J. Photonic crystal fibers. Science 2003, 299, 358–362. [Google Scholar] [CrossRef] [PubMed]

- Paschotta, R. Field Guide to Optical Fiber Technology; SPIE Press: Bellingham, WA, USA, 2010. [Google Scholar]

- Rajan, G. Optical Fiber Sensors: Advanced Techniques and Applications. In Optical Fiber Sensors: Advanced Techniques and Applications; CRC Press: London, UK, 2015; pp. 413–425. [Google Scholar]

- Tian, Y.; Wang, W.; Wu, N.; Zou, X.; Wang, X. Tapered Optical Fiber Sensor for Label-Free Detection of Biomolecules. Sensors 2011, 11, 3780–3790. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Villatoro, J.; Monzon-Hernandez, D.; Mejıa, E. Fabrication and modeling of uniform-waist single-mode tapered optical fiber sensors. Appl. Opt. 2003, 42, 2278–2283. [Google Scholar] [CrossRef] [PubMed]

- Paul, P.H.; Kychakoff, G. Fiber-optic evanescent field absorption sensor. Appl. Phys. Lett. 1987, 51, 12–14. [Google Scholar] [CrossRef]

- Moar, P.N. Fabrication, modeling, and direct evanescent field measurement of tapered optical fiber sensors. J. Appl. Phys. 1999, 85, 3395–3398. [Google Scholar] [CrossRef]

- Stasiewicz, K.; Moś, J. Influence of a thin metal layer on a beam propagation in a biconical optical fibre taper. Opto-Electron. Rev. 2016, 24, 196–208. [Google Scholar] [CrossRef] [Green Version]

- Kaminow, I. Optical Fiber Telecommunication; Academic Press: Cambridge, MA, USA, 2008. [Google Scholar]

- Lee, B.H.; Kim, J.H.; Park, K.S.; Eom, J.B.; Kim, M.J.; Rho, B.S.; Choi, H.Y. Interferometric Fiber Optic Sensor. Sensors 2012, 12, 2467–2480. [Google Scholar] [CrossRef] [Green Version]

- Fang, Z. Fundamentals of Optical Fiber Sensors; Wiley: Hoboken, NJ, USA, 2012. [Google Scholar]

- Talapin, D.V.; Lee, J.S.; Kovalenko, M.V.; Shevchenko, E.V. Prospects of Colloidal Nanocrystals for Electronic and Optoelectronic Applications. Chem. Rev. 2010, 110, 389–458. [Google Scholar] [CrossRef]

- Matras-Postolek, K.; Bogdal, D. Polymer Nanocomposites for Electro-Optics: Perspectives on Processing Technologies, Material Characterization, and Future Application. Adv. Polym. Sci. 2010, 230, 221–282. [Google Scholar]

- Matras-Postolek, K.; Sovinska, S.; Żaba, A.; Yang, P. Microwave-assisted heating versus conventional heating in solvothermal and non-solvothermal synthesis of photocatalytic active ZnSe·0.5N2H4 and ZnSe:Mn·0.5N2H4 anisotropic colloidal quasi-two-dimensional hybrid nanoplates. Chem. Eng. Process. 2017, 122, 346–356. [Google Scholar] [CrossRef]

- Matras-Postołek, K.; Sovinska, S.; Węgrzynowicz, A. Synthesis and characterization of ZnSe and ZnSe:Mn nanosheets and microflowers with high photoactive properties by microwave-assisted method. Chem. Eng. Process. 2019, 135, 204–216. [Google Scholar] [CrossRef]

- Liu, Y.; Yang, P.; Li, J.; Matras-Postolek, K.; Yue, Y.; Huang, B. Formation of SiO2@SnO2 core–shell nanofibers and their gas sensing properties. RSC Adv. 2016, 6, 13371–13376. [Google Scholar] [CrossRef]

- Bredola, M.; Matras, K.; Szatkowski, A.; Sanetra, J.; Prodi-Schwab, A. P3HT/ZnS: A new hybrid bulk heterojunction photovoltaic system with very high open circuit voltage. Sol. Energy Mater. Sol. Cells 2009, 93, 662–666. [Google Scholar] [CrossRef]

- Matras-Postołek, K.; Żaba, A.; Nowak, E.M.; Dąbczyński, P.; Rysz, J.; Sanetra, J. Formation and characterization of one-dimensional ZnS nanowires for ZnS/P3HT hybrid polymer solar cells with improved efficiency. Appl. Surf. Sci. 2018, 451, 180–190. [Google Scholar] [CrossRef]

- Matras, K.; Bredol, M.; Sakhnov, O.; Stumpe, J.; Bogdal, D.; Szatkowski, A. Composites from luminescent nanosized ZnS and optical polimer. Mol. Cryst. Liq. Cryst. 2008, 485, 776–779. [Google Scholar] [CrossRef]

- Martínez-Castañóna, G.A.; Martínez-Mendoza, J.R.; Ruiz, F.; González-Hernández, J. Synthesis and optical characterization of ZnS, ZnS:Mn and (ZnS:Mn)_CdS core-shell nanoparticles. Inorg. Chem. Commun. 2007, 5, 531–534. [Google Scholar]

- Sharma, R.; Bisen, D.P. Thermoluminescence of mercaptoethanol-capped ZnS:Mn nanoparticles. Luminescence 2015, 30, 175–181. [Google Scholar] [CrossRef]

- Tong, L.; Sumetsky, M.I. Subwavelength and Nanometer Diameter Optical Fibers; Springer: Berlin, Germany, 2011; pp. 1–22. [Google Scholar]

- Moayyed, H.; Teixeira Leite, I.; Coelho, L.; Santos, J.; Viegas, D. Analysis of Phase Interrogated SPR Fiber Optic Sensors with Biometallic Layers. IEEE Sens. J. 2014, 14, 3662–3668. [Google Scholar] [CrossRef]

- Prodi-Schwab, A.; Adam, D.; Lüthge, T.; Bredol, M.; Matras, K.; Szatkowski, A. Lumineszente nanoskalige Partikel mit hydrophober Oberflächenausstattung, Verfahren zu ihrer Herstellung sowie ihre Verwendung. Germany Patent No. WO2009133138A1, 5 November 2009. [Google Scholar]

- Bumb, A.; Sarkar, S.K.; Neuman, K.C.; Brechbiel, M. Method of Preparing Silica-Coated Nanodiamonds. U.S. Patent No. US 2015/0190843 A1, 9 July 2015. [Google Scholar]

- Sabri, N.; Aljunid, S.A.; Salim, M.S.; Ahmad, R.B.; Kamaruddin, R. Toward Optical Sensors: Review and Applications. J. Phys. Conf. Ser. 2013, 423, 2064–2072. [Google Scholar] [CrossRef]

- Chen, L.; Chan, C.; Ni, K.; Hu, P.; Li, K.; Wong, W.; Leong, K. Label-free fiber-optic interferometric immunosensors based on waist-enlarged fusion taper. Sensor Actuat. B-Chem. 2013, 178, 176–184. [Google Scholar] [CrossRef]

- Arregui, F.J.; Matías, I.R.; López-Amo, M. Optical fiber strain gauge based on a tapered single-mode fiber. Sensor Actuat. A 2000, 79, 90–96. [Google Scholar] [CrossRef]

- Kieu, K.Q.; Mansuripur, M. Biconical fiber taper sensors. IEEE Photonics Technol. Lett. 2006, 18, 2239–2241. [Google Scholar] [CrossRef]

- Latifi, H.; Zibaii, M.I.; Hosseini, S.M.; Jorge, P. Nonadiabatic tapered optical fiber for biosensor applications. Photonic Sens. 2012, 2, 340–356. [Google Scholar] [CrossRef]

- Stasiewicz, K.A.; Musiał, J.E. Threshold temperature optical fibre sensors. Opt. Fiber Technol. 2016, 32, 111–118. [Google Scholar] [CrossRef]

- Vélez, C.; de Zárate, J.M.O.; Khayet, M. Thermal properties of n-pentadecane, n-heptadecane and n-nonadecane in the solid/liquid phase change region. Int. J. Therm. Sci. 2015, 94, 139–146. [Google Scholar] [CrossRef]

- Vélez, C.; Khayet, M.; de Zárate, J.M.O. Temperature-dependent thermal properties of solid/liquid phase change even-numbered n-alkanes: N-Hexadecane, n-octadecane and n-eicosane. Appl. Energ. 2015, 143, 383–394. [Google Scholar] [CrossRef]

- Oćwieja, M.; Matras-Postołek, K.; Maciejewska-Prończuka, J.; Morga, M.; Adamczyk, Z.; Sovinska, S.; Żaba, A.; Gajewska, M.; Król, T.; Cupiał, K.; et al. Formation and stability of manganese-doped ZnS quantum dot monolayers determined by QCM-D and streaming potential measurements. J. Colloid Interf. Sci. 2017, 503, 186–197. [Google Scholar] [CrossRef]

- Murugadoss, G.; Rajamannan, B.; Ramasamy, V. Synthesis, characterization and optical properties of water-soluble ZnS:Mn2+ nanoparticles. J. Lumin. 2010, 130, 2032–2039. [Google Scholar] [CrossRef]

- Ma, X.; Song, J.; Yu, Z. The light emission properties of ZnS:Mn nanoparticles. Thin Solid Films 2011, 519, 5043–5045. [Google Scholar] [CrossRef]

- Popovetskiy, P.S. Synthesis and Characterization of Silver Nanoparticles in Reverse Micelles of Nonionic Surfactants and in Their Mixed Micelles with AOT. Colloid J. 2020, 82, 144–151. [Google Scholar] [CrossRef]

- Marc, P.; Przybysz, N.; Molska, A.; Jaroszewicz, L.R. Photonic Crystal Fiber Transducers for an Optical Fiber Multilevel Temperature Threshold Sensor. J. Lightwave Technol. 2017, 36, 898–903. [Google Scholar] [CrossRef]

- Freund, M.; Csikos, R.; Keszthelyi, S.; Mozes, G.Y. Paraffin Products: Properties Technologies, Applications; Elsevier Scientific Publishing Company: New York, NY, USA, 1982; pp. 90–123. [Google Scholar]

| Parameter [Units] | Core | Cladding | Mode Field |

|---|---|---|---|

| Diameter [µm] | 8.2 | 125 | 10.98 |

| Refractive index [a.u.] | 1.4548 | 1.443 | -- |

| Alkane | Formula | Molecular Mass | Melting Point | Boiling Point | Flash Point | Density | Refractive Index | Refractive Index at 20.4 °C |

|---|---|---|---|---|---|---|---|---|

| n-Pentadecane | CH3(CH2)13CH3 | 212.42 | 9–10 °C | 269–270 °C | 132 °C (269 °F) | 0.769 | 1.4320 | 1.4317 |

| n-Hexadecane | CH3(CH2)14CH3 | 226.45 | 18 °C | 287 °C | 135 °C (275 °F) | 0.773 | 1.4345 | 1.4344 |

| Formula | Molecular Mass | Melting Point | Solubility |

|---|---|---|---|

| C58H118O24 | 1199.57 | ~56–60 °C | At 20 °C in methanol, chloroform and ethanol |

| C15 | C15 with Brij | C15 with Brij and Nanoparticles | C16 | C16 with Brij | C16 with Brij and Nanoparticles |

|---|---|---|---|---|---|

| 1.4317 | 1.4319 | 1.4319 | 1.4344 | 1.4346 | 1.4346 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Stasiewicz, K.A.; Jakubowska, I.; Korec, J.; Matras-Postołek, K. Modification of Higher Alkanes by Nanoparticles to Control Light Propagation in Tapered Fibers. Micromachines 2020, 11, 1006. https://doi.org/10.3390/mi11111006

Stasiewicz KA, Jakubowska I, Korec J, Matras-Postołek K. Modification of Higher Alkanes by Nanoparticles to Control Light Propagation in Tapered Fibers. Micromachines. 2020; 11(11):1006. https://doi.org/10.3390/mi11111006

Chicago/Turabian StyleStasiewicz, Karol A., Iwona Jakubowska, Joanna Korec, and Katarzyna Matras-Postołek. 2020. "Modification of Higher Alkanes by Nanoparticles to Control Light Propagation in Tapered Fibers" Micromachines 11, no. 11: 1006. https://doi.org/10.3390/mi11111006