Atmospheric Pressure Plasma Processing of an Optical Sinusoidal Grid

Abstract

1. Introduction

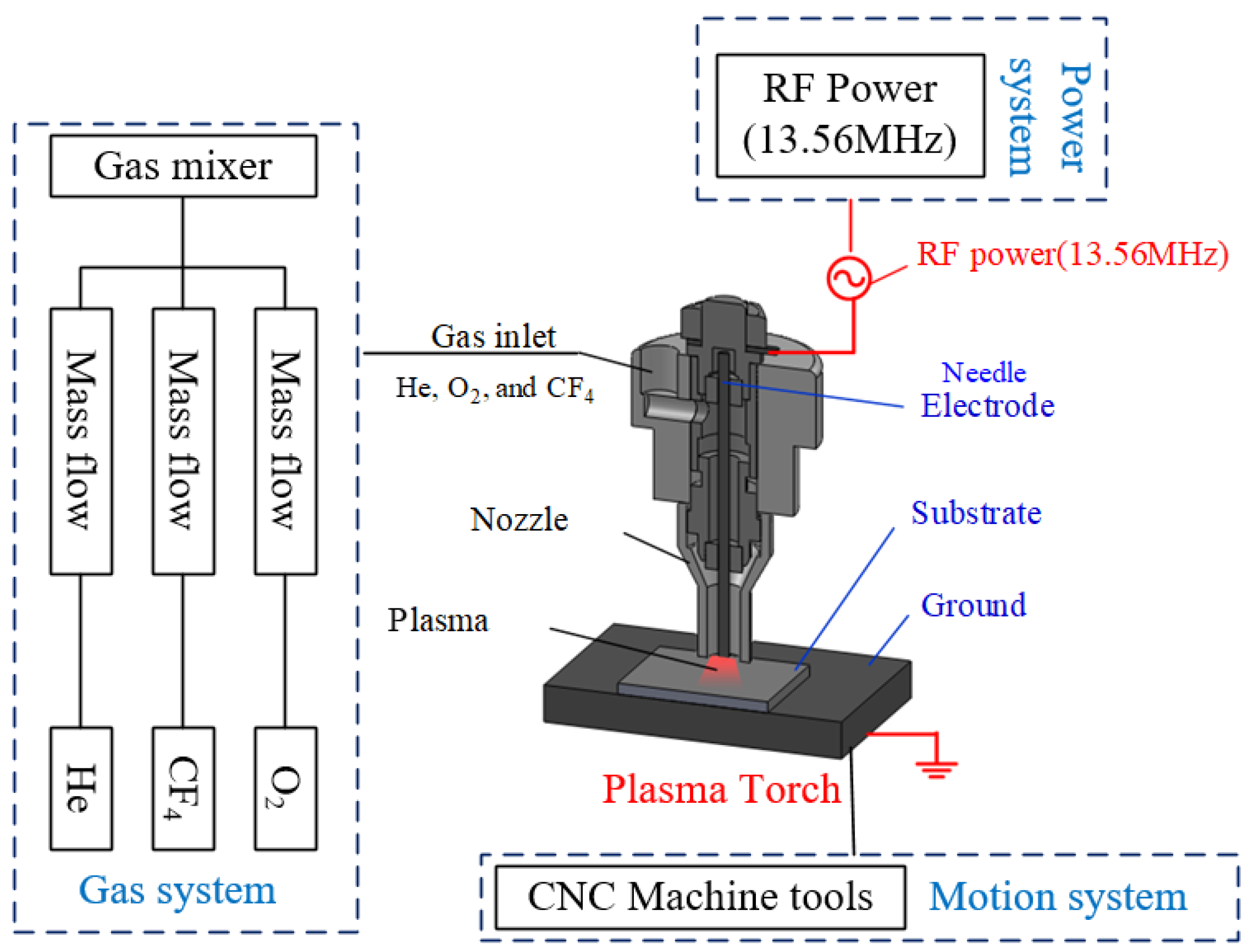

2. APPP Platform and Surface Generation Principle

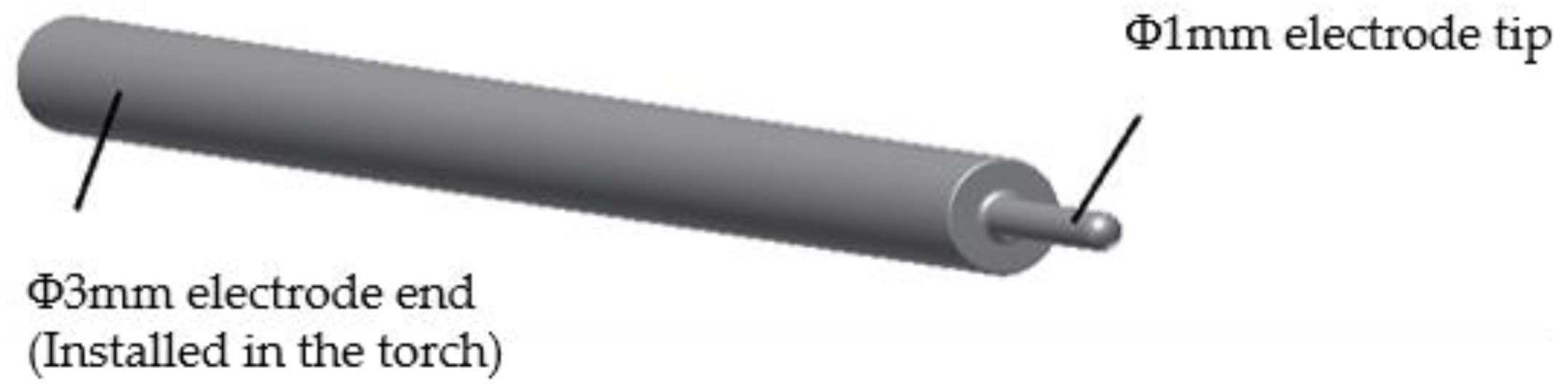

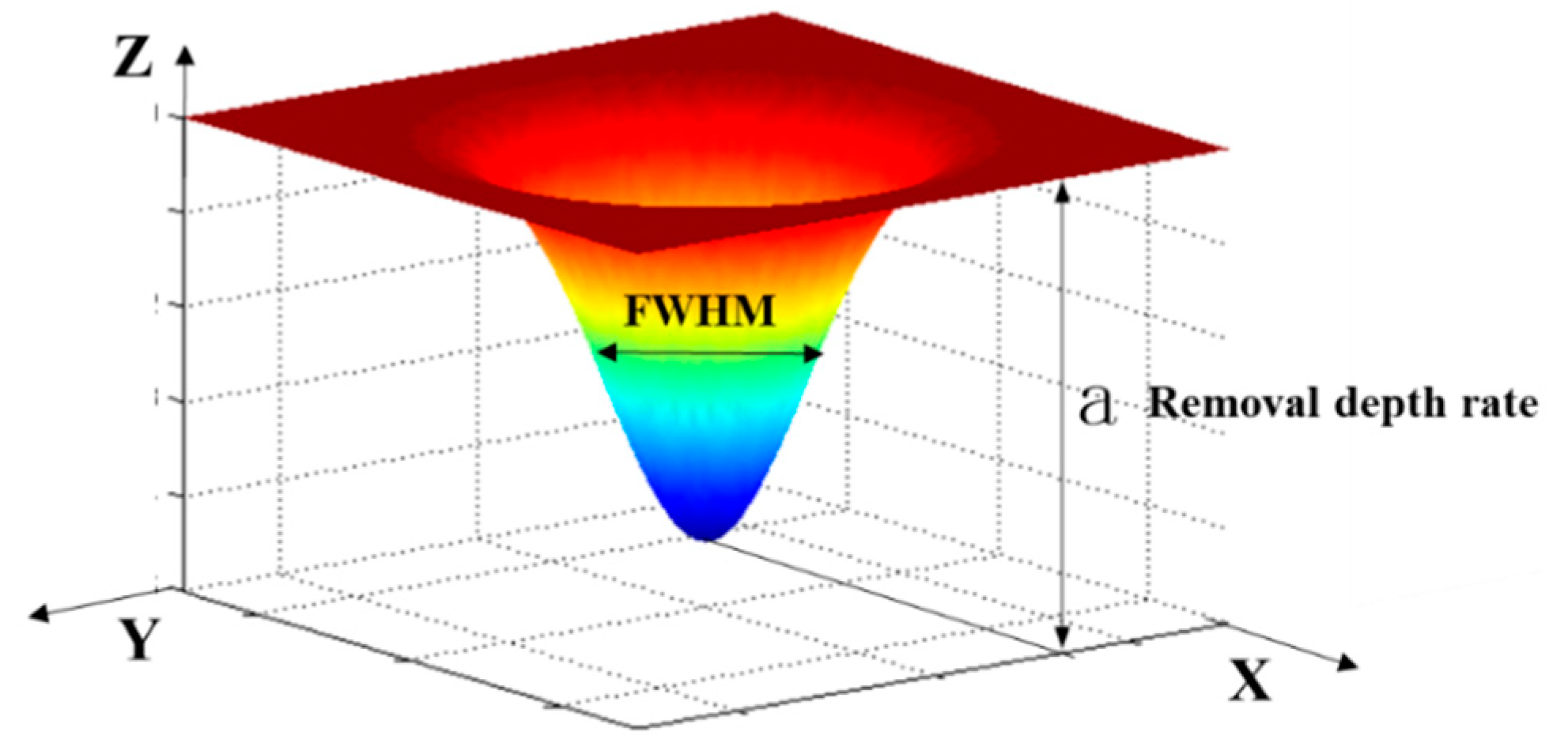

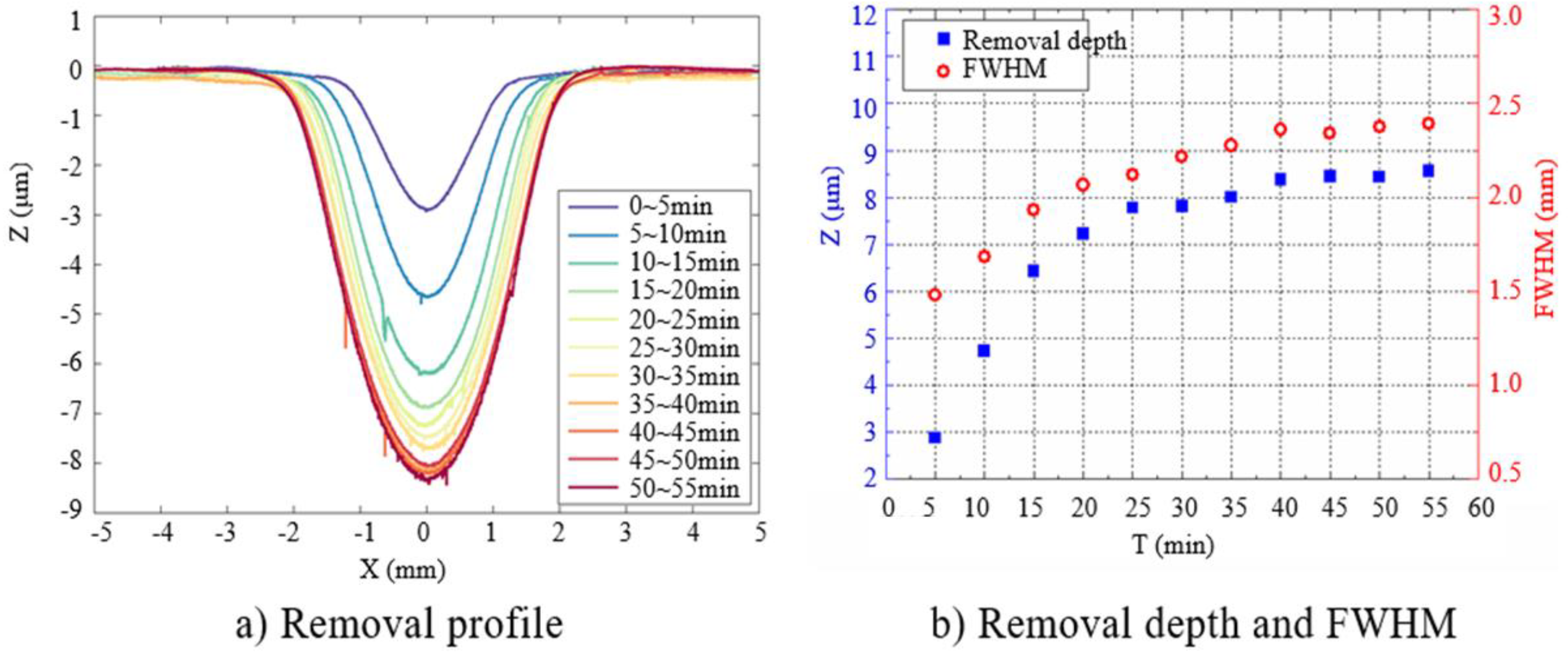

2.1. Platform Configuration and Removal Function

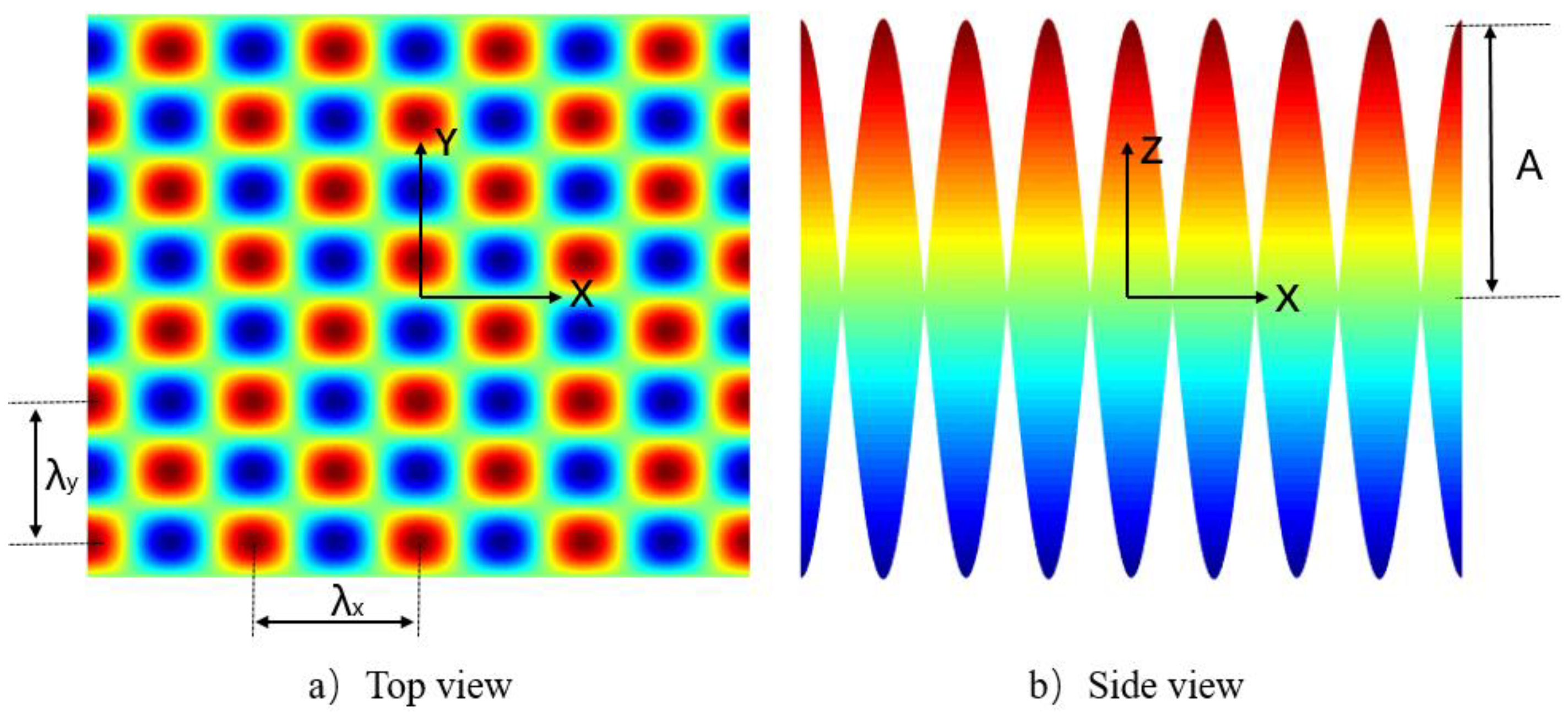

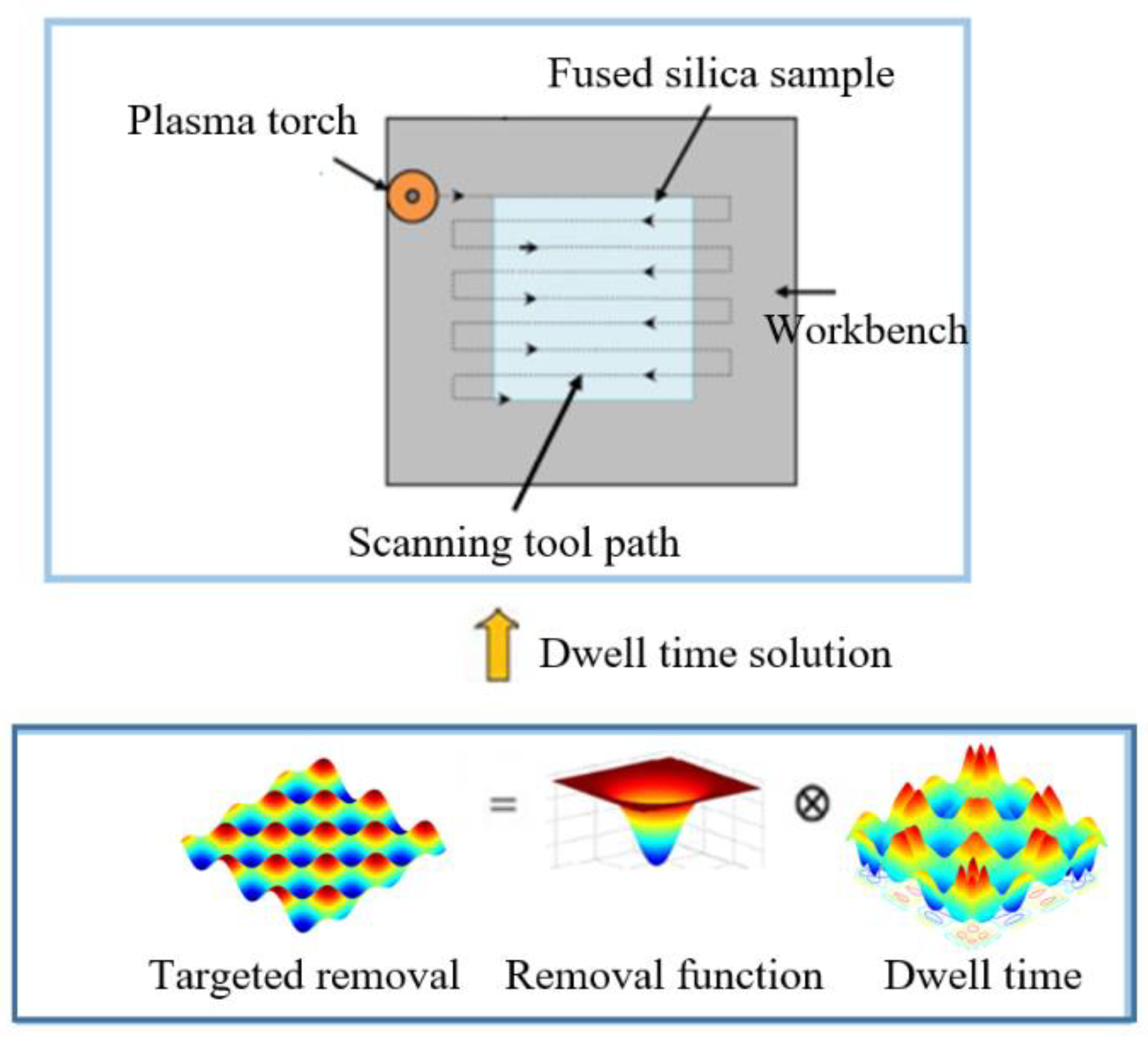

2.2. Surface Generation Principle for Sinusoidal Grid

3. Experiment and Results

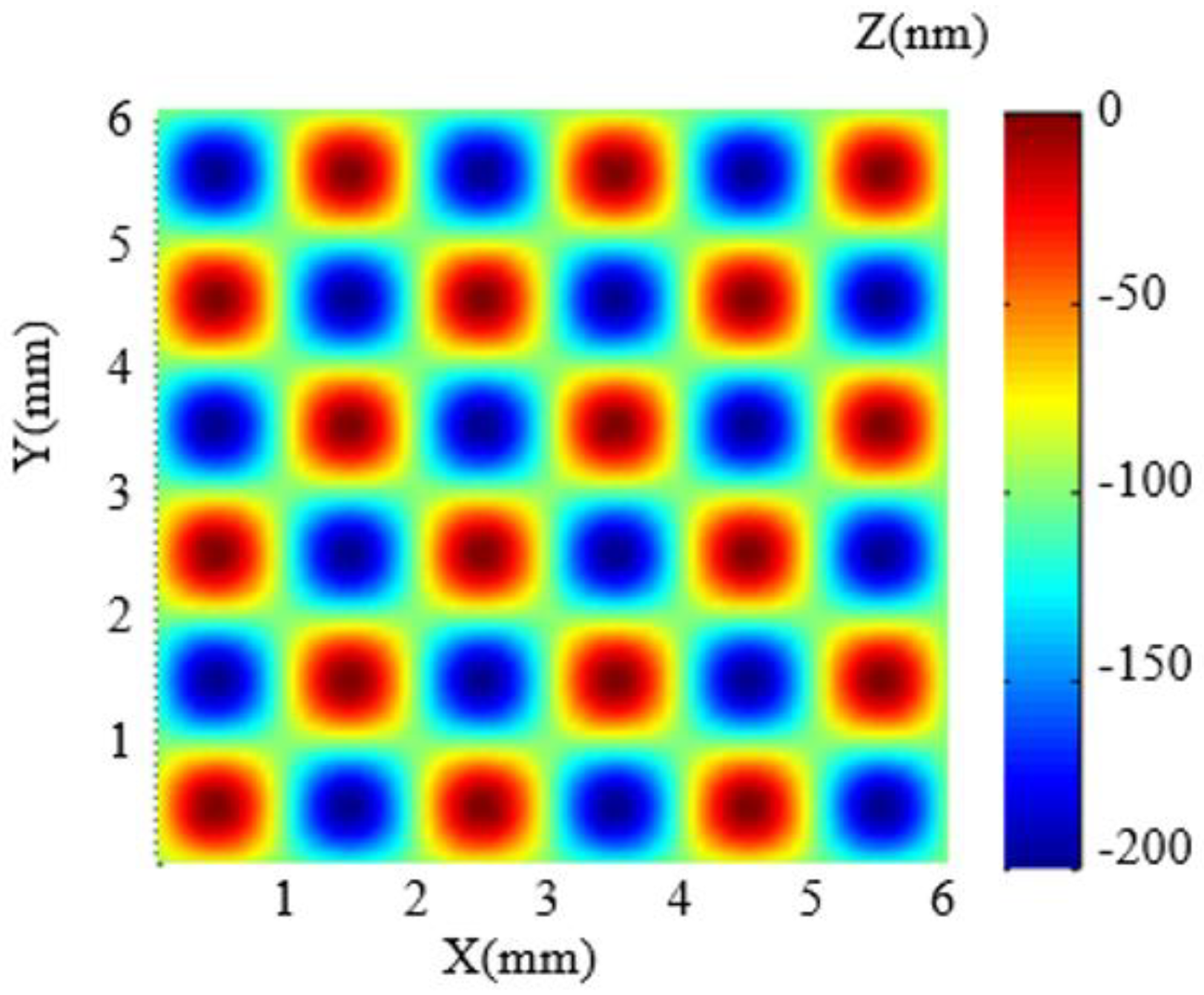

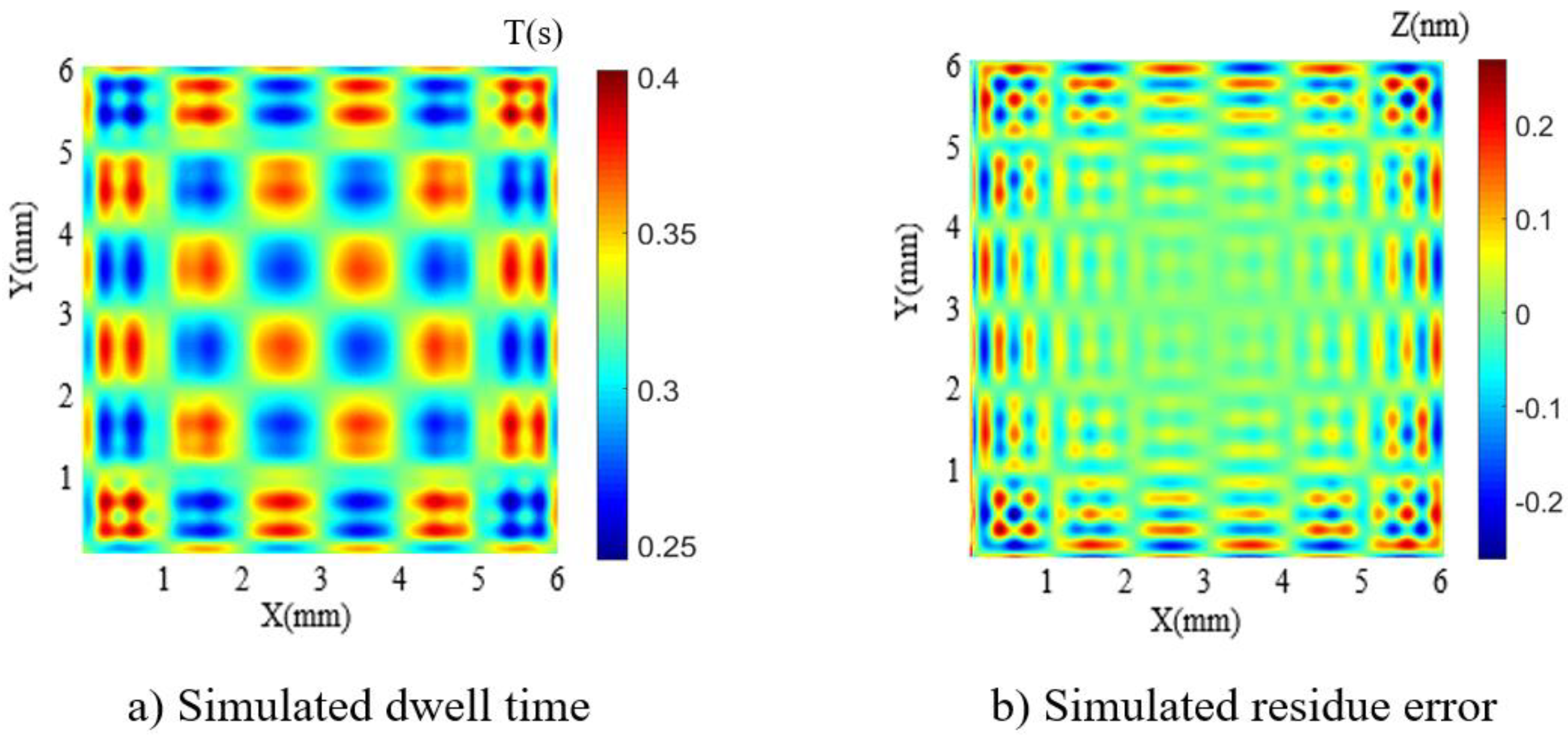

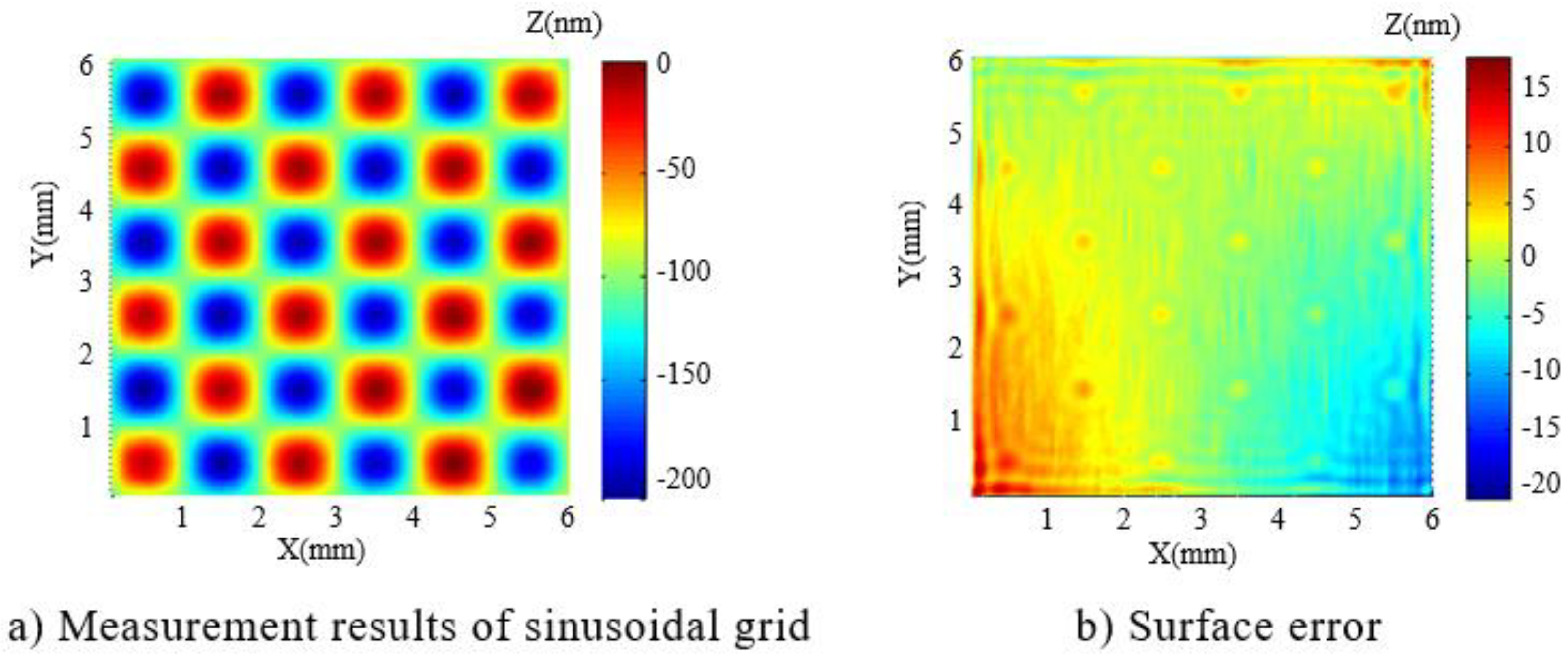

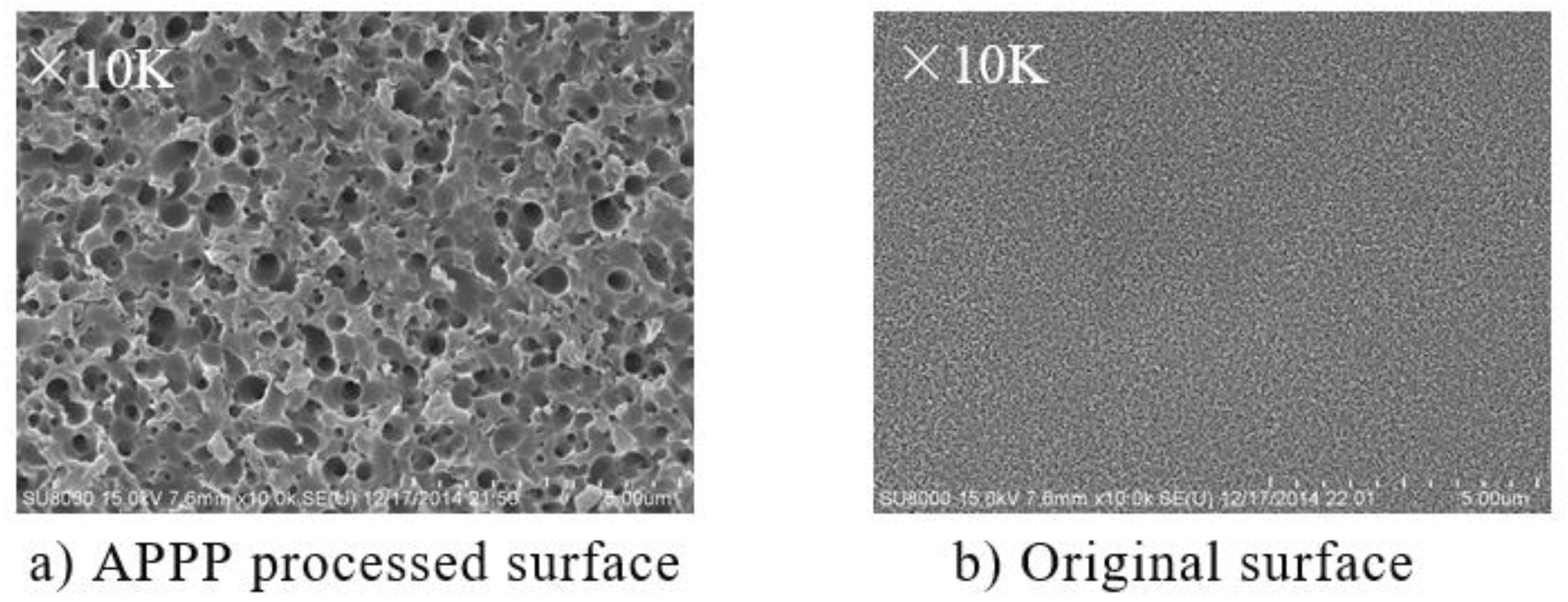

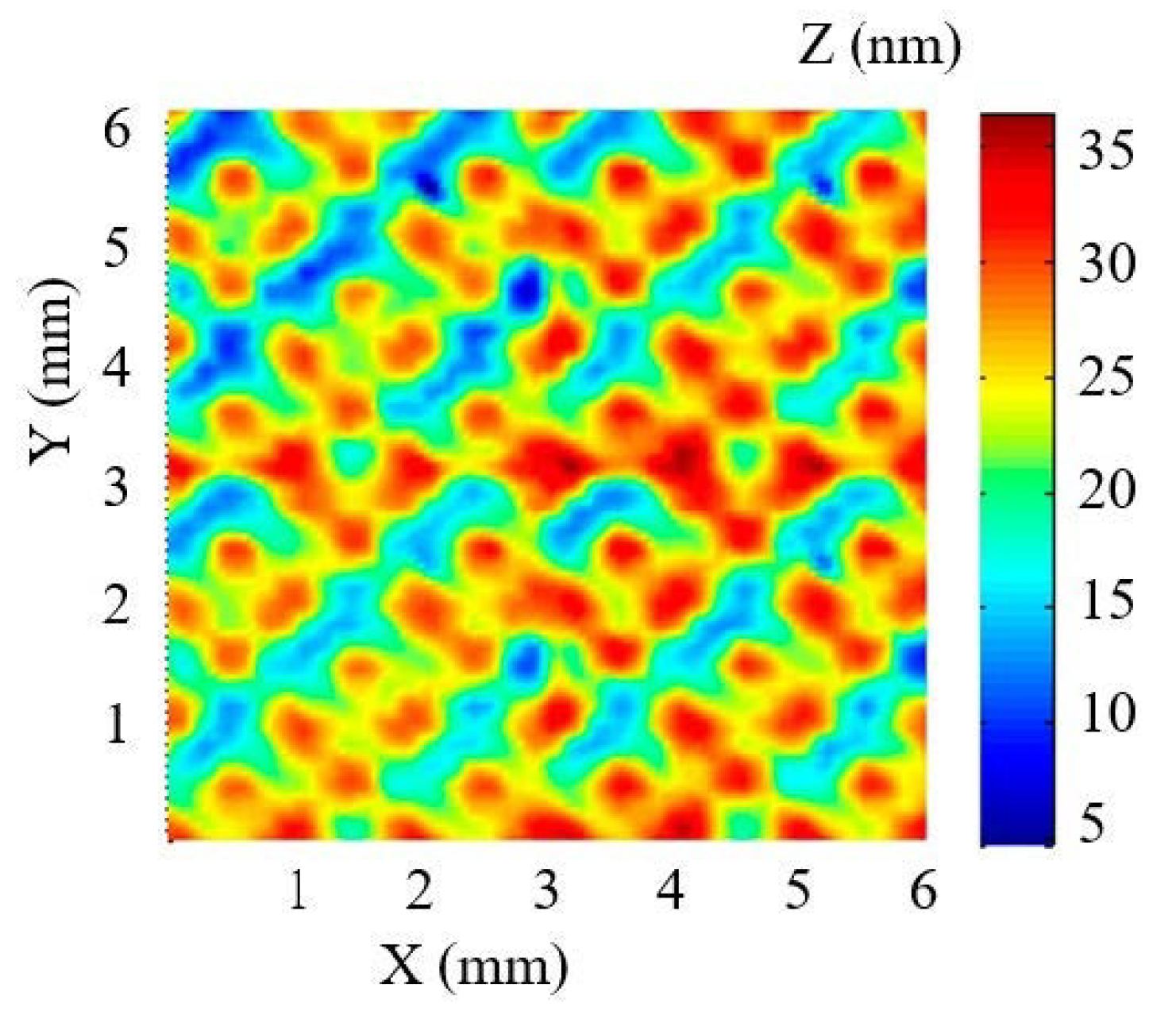

3.1. APPP of Sinusoidal Grid

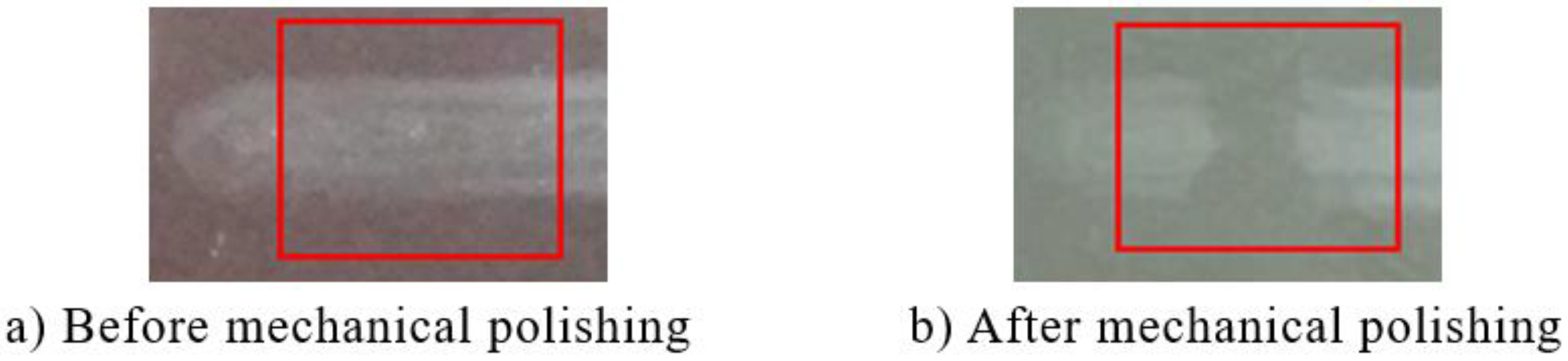

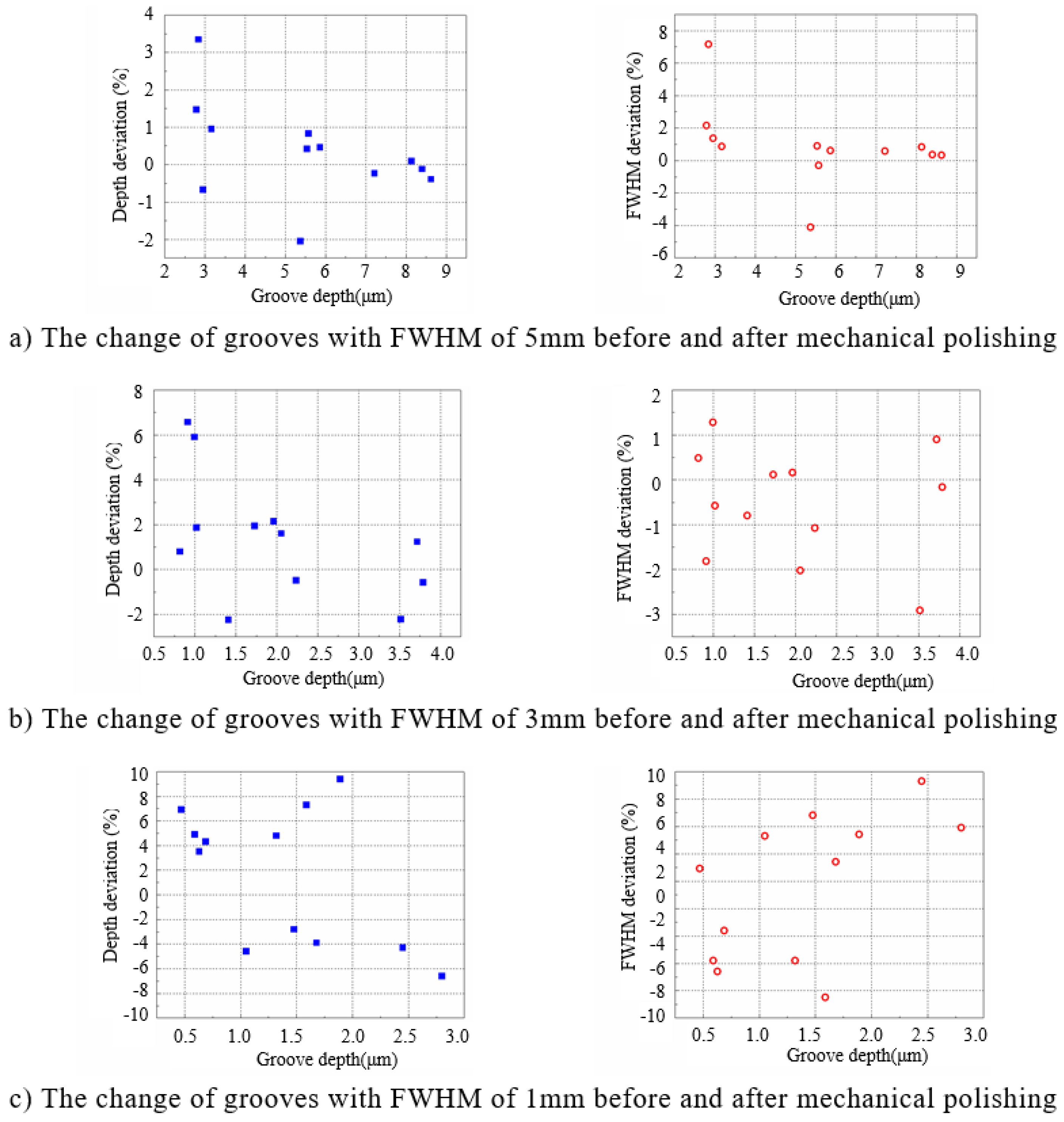

3.2. Post-Processing by Mechanical Polishing

4. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Kiyono, S.; Cai, P.; Gao, W. An angle-based position detection method for precision machines. JSME Int. J. Ser. C Mech. Syst. Mach. Elem. Manuf. 1999, 42, 44–48. [Google Scholar] [CrossRef][Green Version]

- Gao, W.; Dejima, S.; Shimizu, Y.; Kiyono, S.; Yoshikawa, H. Precision measurement of two-axis positions and tilt motions using a surface encoder. Cirp. Ann. Manuf. Technol. 2003, 52, 435–438. [Google Scholar] [CrossRef]

- Gao, W.; Dejima, S.; Yanai, H.; Katakura, K.; Kiyono, S.; Tomita, Y. A surface motor-driven planar motion stage integrated with an XYθZ surface encoder for precision positioning. Precis. Eng. 2004, 28, 329–337. [Google Scholar] [CrossRef]

- Gao, W.; Araki, T.; Kiyono, S.; Okazaki, Y.; Yamanaka, M. Precision nano-fabrication and evaluation of a large area sinusoidal grid surface for a surface encoder. Precis. Eng. 2003, 27, 289–298. [Google Scholar] [CrossRef]

- Zhang, X.; Fang, F.; Wang, H.; Wei, G.; Hu, X. Ultra-precision machining of sinusoidal surfaces using the cylindrical coordinate method. J. Micromech. Microeng. 2009, 19, 054004. [Google Scholar] [CrossRef]

- Li, D.; Jiang, X.; Tong, Z.; Blunt, L. Kinematics Error Compensation for a Surface Measurement Probe on an Ultra-Precision Turning Machine. Micromachines 2018, 9, 334. [Google Scholar] [CrossRef] [PubMed]

- Paul, E.; Evans, C.J.; Mangamelli, A.; McGlauflin, M.L.; Polvani, R.S. Chemical aspects of tool wear in single point diamond turning. Precis. Eng. 1996, 18, 4–19. [Google Scholar] [CrossRef]

- Takino, H.; Yamamura, K.; Sano, Y.; Mori, Y. Removal characteristics of plasma chemical vaporization machining with a pipe electrode for optical fabrication. Appl. Opt. 2010, 49, 4434–4440. [Google Scholar] [CrossRef] [PubMed]

- Arnold, T.; Boehm, G.; Paetzelt, H. New freeform Manufacturing Chain Based on Atmospheric Plasma Jet Machining. In Proceedings of the Freeform Optics 2015, Arlington, VA, USA, 7–11 June 2015; p. FTh1B-3. [Google Scholar]

- Meister, J.; Arnold, T. New process simulation procedure for high-rate plasma jet machining. Plasma Chem. Plasma Process. 2011, 31, 91–107. [Google Scholar] [CrossRef]

- Li, D.; Li, N.; Su, X.; Liu, K.; Ji, P.; Wang, B. Modelling of removal characteristics and surface morphology formation in capacitively coupled atmospheric pressure plasma processing of fused silica optics. Opt. Mater. Express 2019, 9, 1893–1906. [Google Scholar] [CrossRef]

- Li, D.; Li, N.; Su, X.; Liu, K.; Ji, P.; Wang, B. Characterization of fused silica surface topography in capacitively coupled atmospheric pressure plasma processing. Appl. Surf. Sci. 2019, 489, 648–657. [Google Scholar] [CrossRef]

- Jourdain, R.; Castelli, M.; Shore, P.; Sommer, P.; Proscia, D. Reactive atom plasma (RAP) figuring machine for meter class optical surfaces. Prod. Eng. 2013, 7, 665–673. [Google Scholar] [CrossRef][Green Version]

- Li, D.; Li, N.; Su, X.; Liu, K.; Ji, P.; Wang, B. Continuous Phase Plate Structuring by Multi-Aperture Atmospheric Pressure Plasma Processing. Micromachines 2019, 10, 260. [Google Scholar] [CrossRef] [PubMed]

- Carnal, C.L.; Egert, C.M.; Hylton, K.W. Advanced matrix-based algorithm for ion-beam milling of optical components. In Current Developments in Optical Design and Optical Engineering II. Int. Soc. Opt. Photonics 1992, 1572, 54–62. [Google Scholar]

- Wu, J.F.; Lu, Z.W.; Zhang, H.X.; Wang, T.S. Dwell time algorithm in ion beam figuring. Appl. Opt. 2009, 48, 3930–3937. [Google Scholar] [CrossRef] [PubMed]

- Chen, D.; Plemmons, R.J. Nonnegativity Constraints in Numerical Analysis. In The Birth of Numerical Analysis; World Scientific: Singapore, 2010; pp. 109–139. [Google Scholar]

| He Flow (sccm) | CF4 Flow (sccm) | O2 Flow (sccm) | Distance (mm) | Power (W) |

|---|---|---|---|---|

| 539 | 48 | 5 | 3 | 47 |

| FWHM (mm) | Depth (μm) |

|---|---|

| 5 | 2.8–8.6 |

| 3 | 0.8–3.8 |

| 1 | 0.5–2.8 |

| FWHM (mm) | Depth Deviation (%) | Depth Deviation Mean (%) | FWHM Deviation (%) | FWHM Deviation Mean (%) |

|---|---|---|---|---|

| 5 | −3–4 | 0.92 | −5–8 | 1.62 |

| 3 | −3–7 | 2.29 | −3–2 | 1.02 |

| 1 | −7–10 | 5.28 | −8–10 | 4.94 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Li, D.; Li, N.; Su, X.; Ji, P.; Wang, B. Atmospheric Pressure Plasma Processing of an Optical Sinusoidal Grid. Micromachines 2019, 10, 828. https://doi.org/10.3390/mi10120828

Li D, Li N, Su X, Ji P, Wang B. Atmospheric Pressure Plasma Processing of an Optical Sinusoidal Grid. Micromachines. 2019; 10(12):828. https://doi.org/10.3390/mi10120828

Chicago/Turabian StyleLi, Duo, Na Li, Xing Su, Peng Ji, and Bo Wang. 2019. "Atmospheric Pressure Plasma Processing of an Optical Sinusoidal Grid" Micromachines 10, no. 12: 828. https://doi.org/10.3390/mi10120828

APA StyleLi, D., Li, N., Su, X., Ji, P., & Wang, B. (2019). Atmospheric Pressure Plasma Processing of an Optical Sinusoidal Grid. Micromachines, 10(12), 828. https://doi.org/10.3390/mi10120828