Robust Tracking of a Cost-Effective Micro-Stereolithography System Based on a Compliant Nanomanipulator †

Abstract

:1. Introduction

- The proposed RBF-based robust tracking control strategy is capable of dealing with unknown and complex nonlinear dynamics, and repetitive control (RC) is innovatively integrated with RBF to improve the tracking performance of closed patterns for a compliant manipulator.

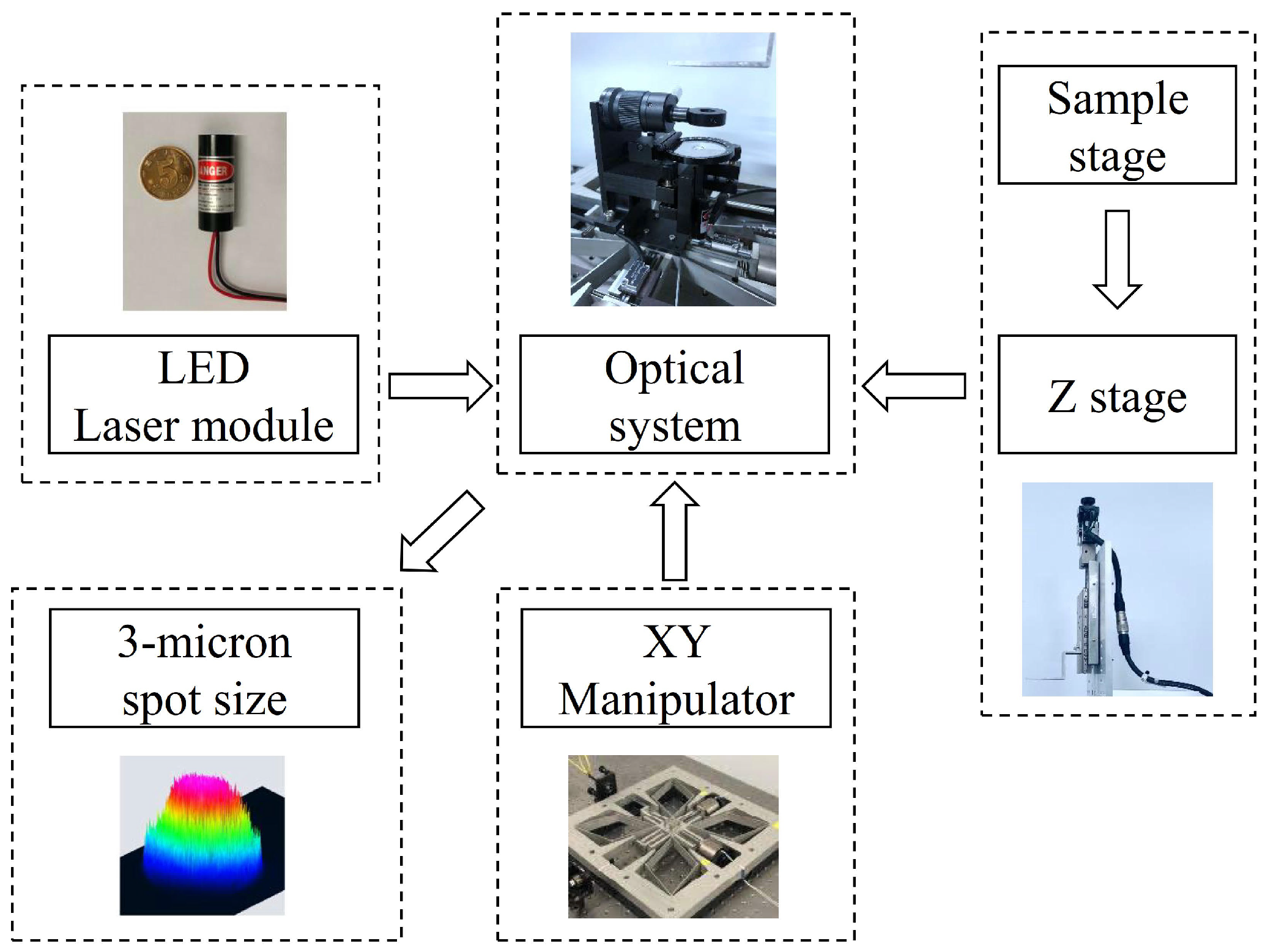

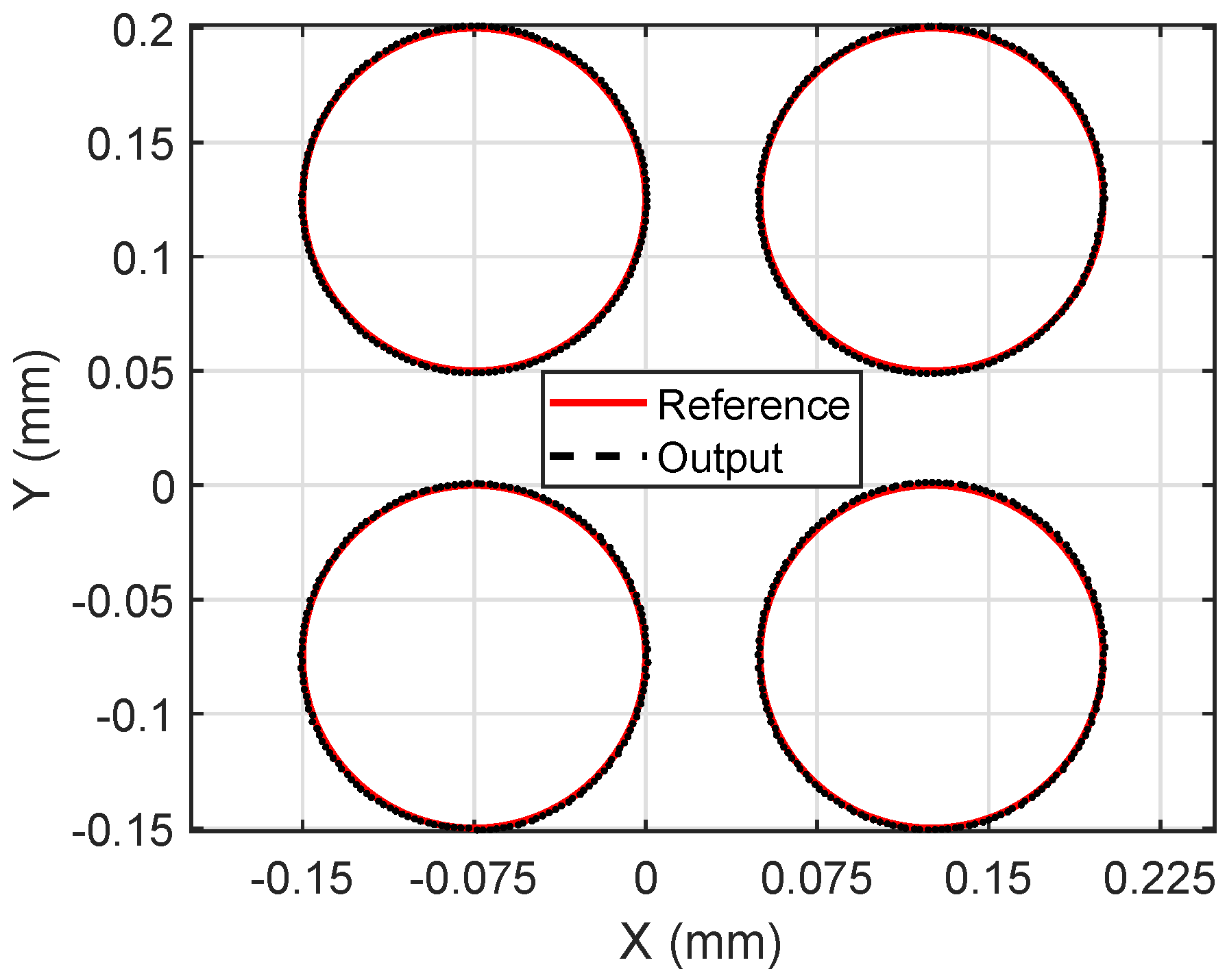

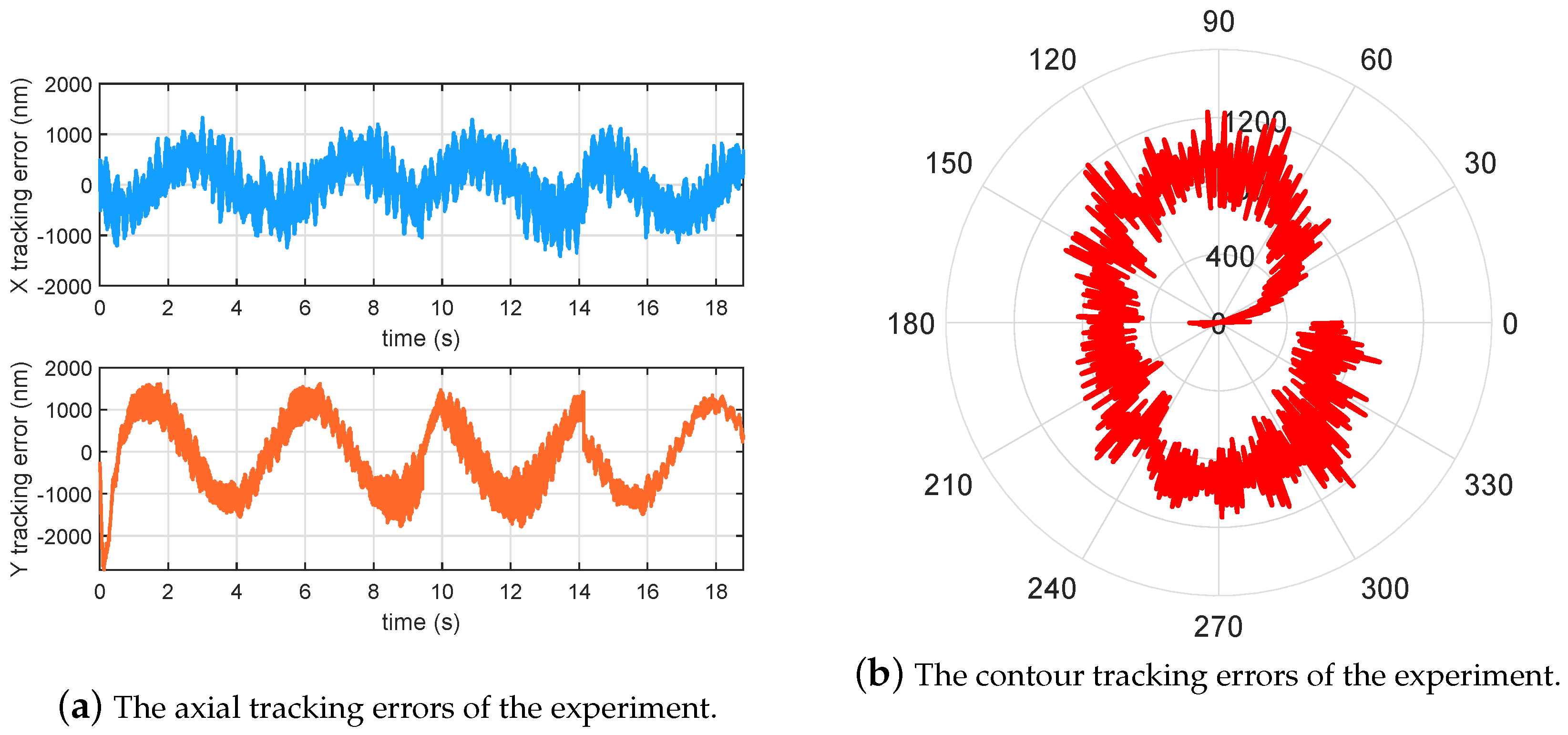

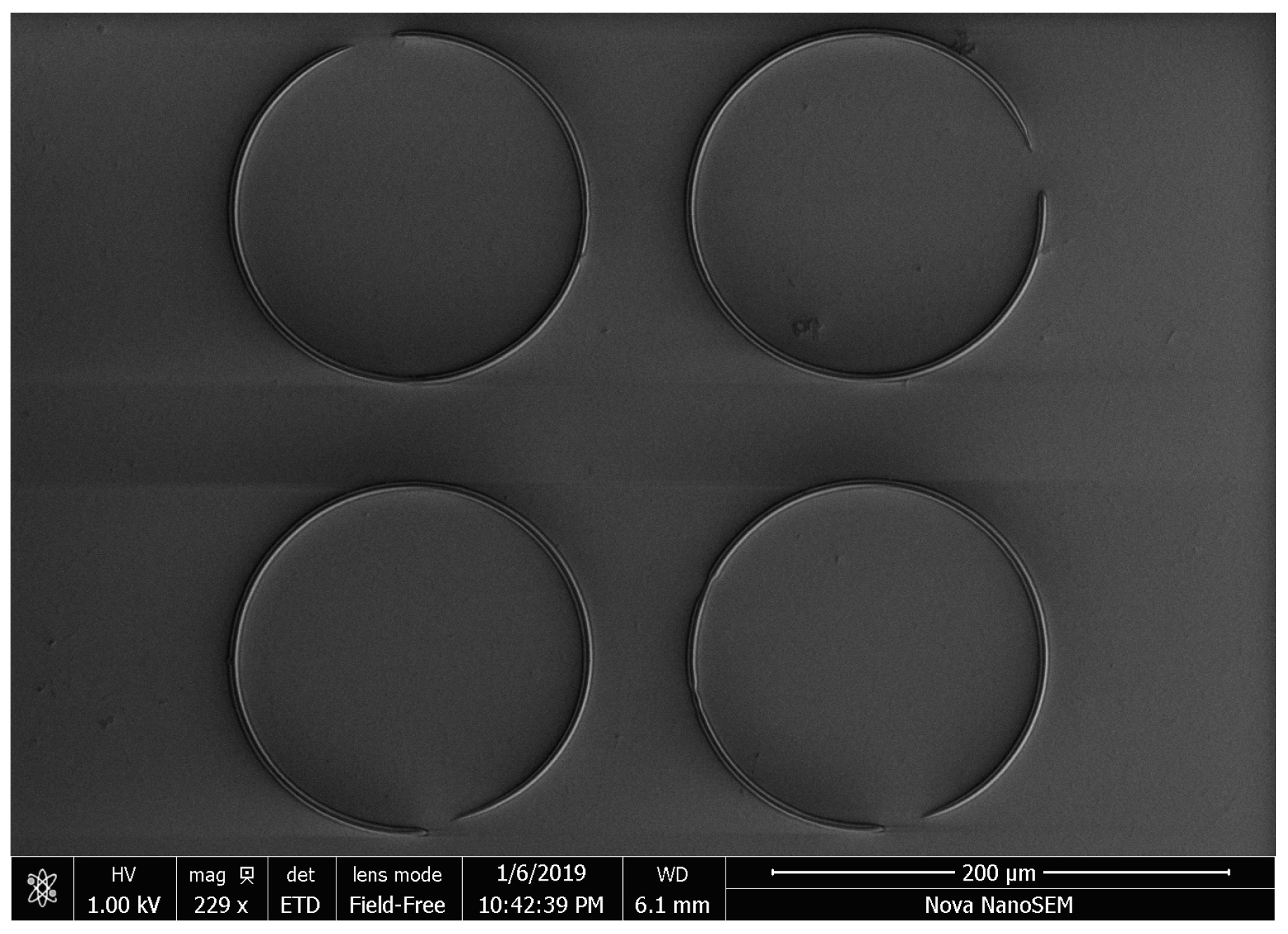

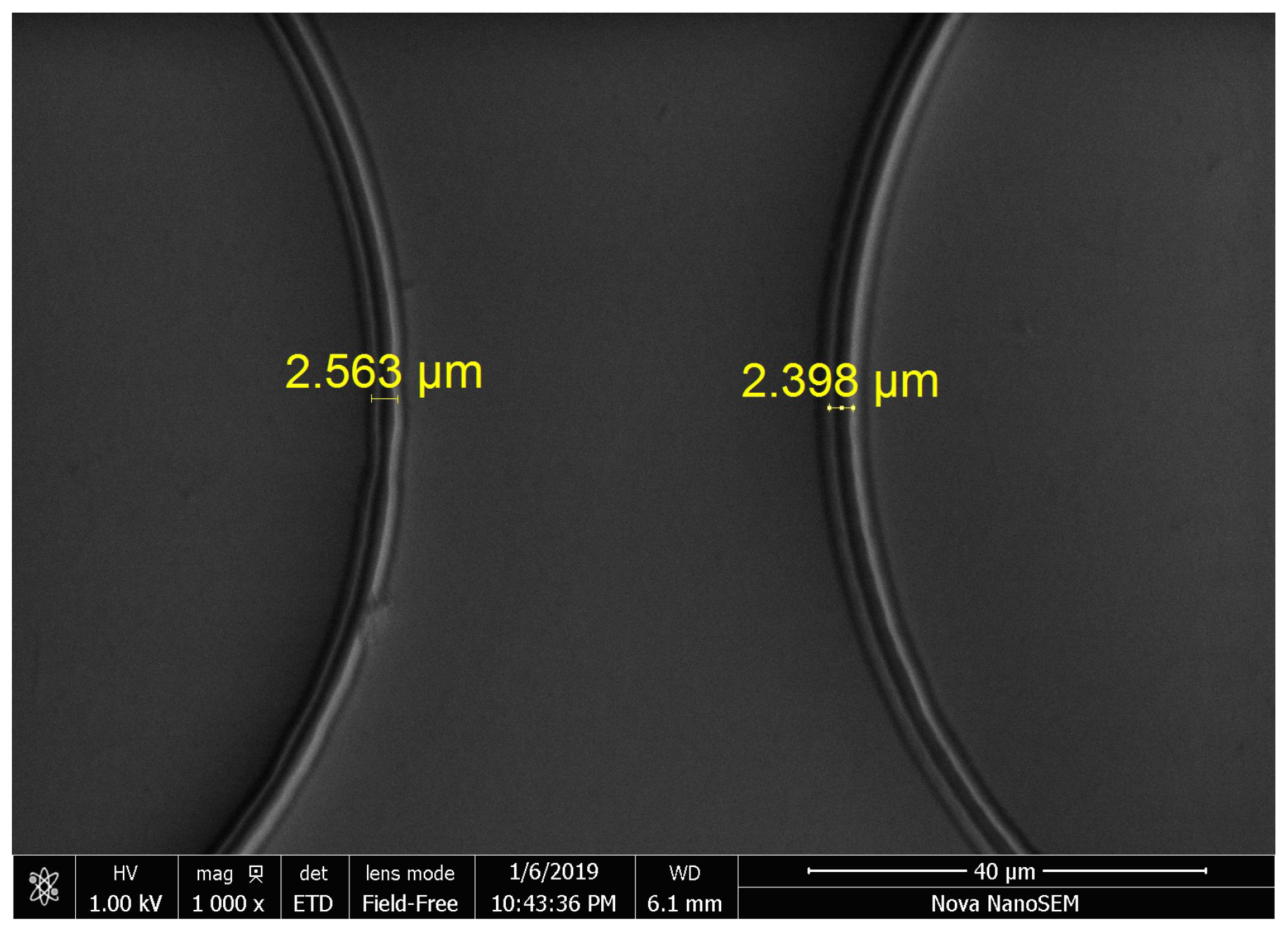

- With the proposed control applied on a self-developed cost-effective MSL system, the fabrication of a closed pattern will not be started (by switching on the laser source) until the tracking error reaches to submicrons. The fabrication results demonstrate that the cost-effective MSL system is capable of fabricating 2.5 µm feature size in a 0.5 mm working range.

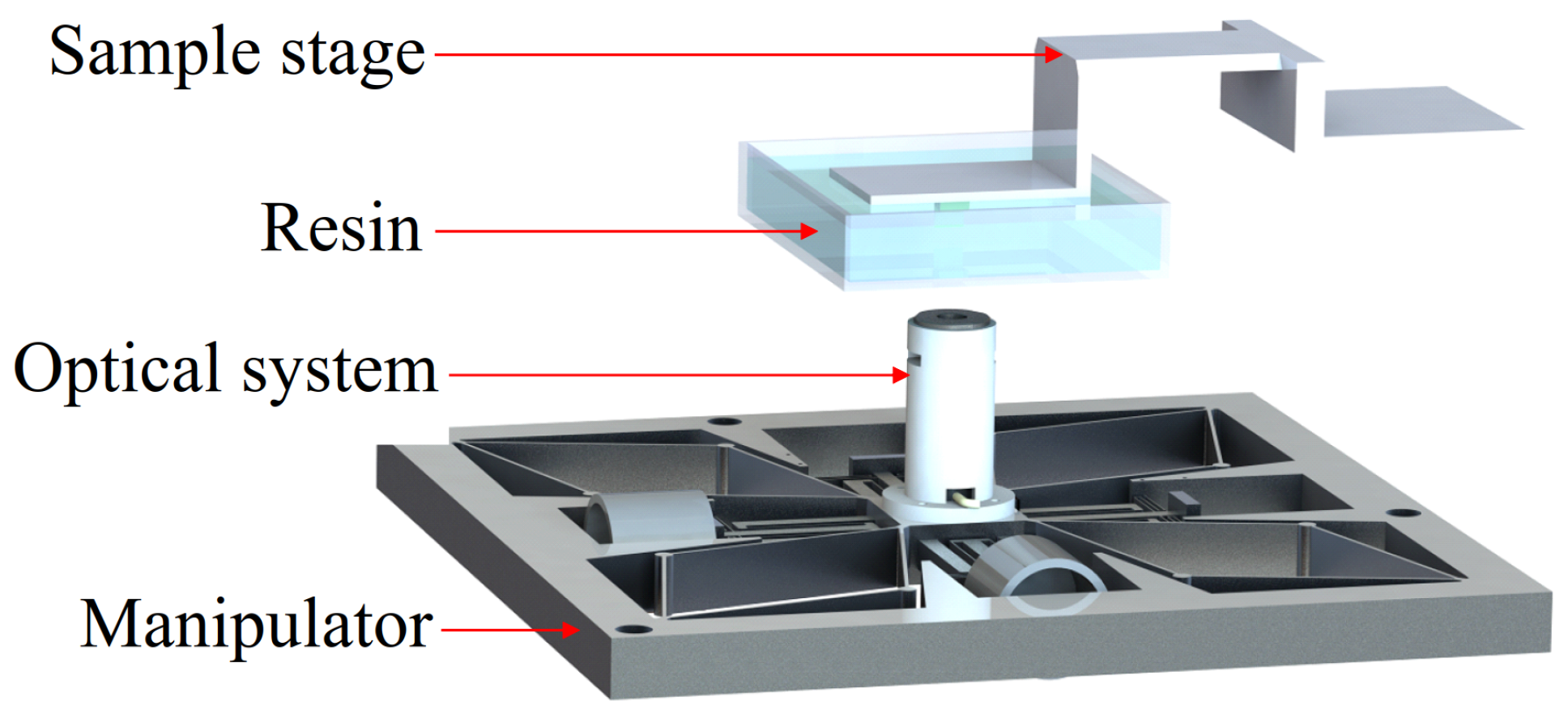

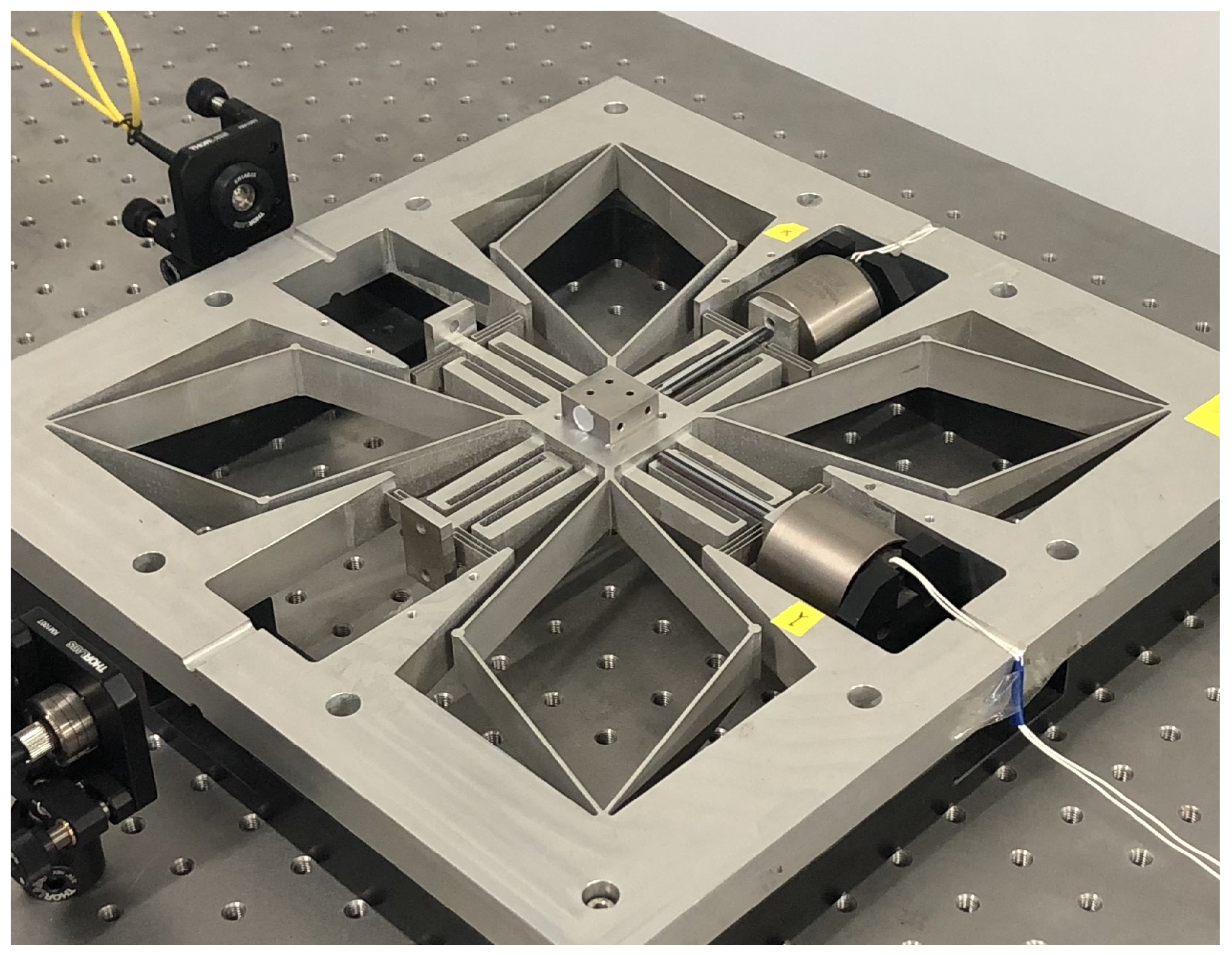

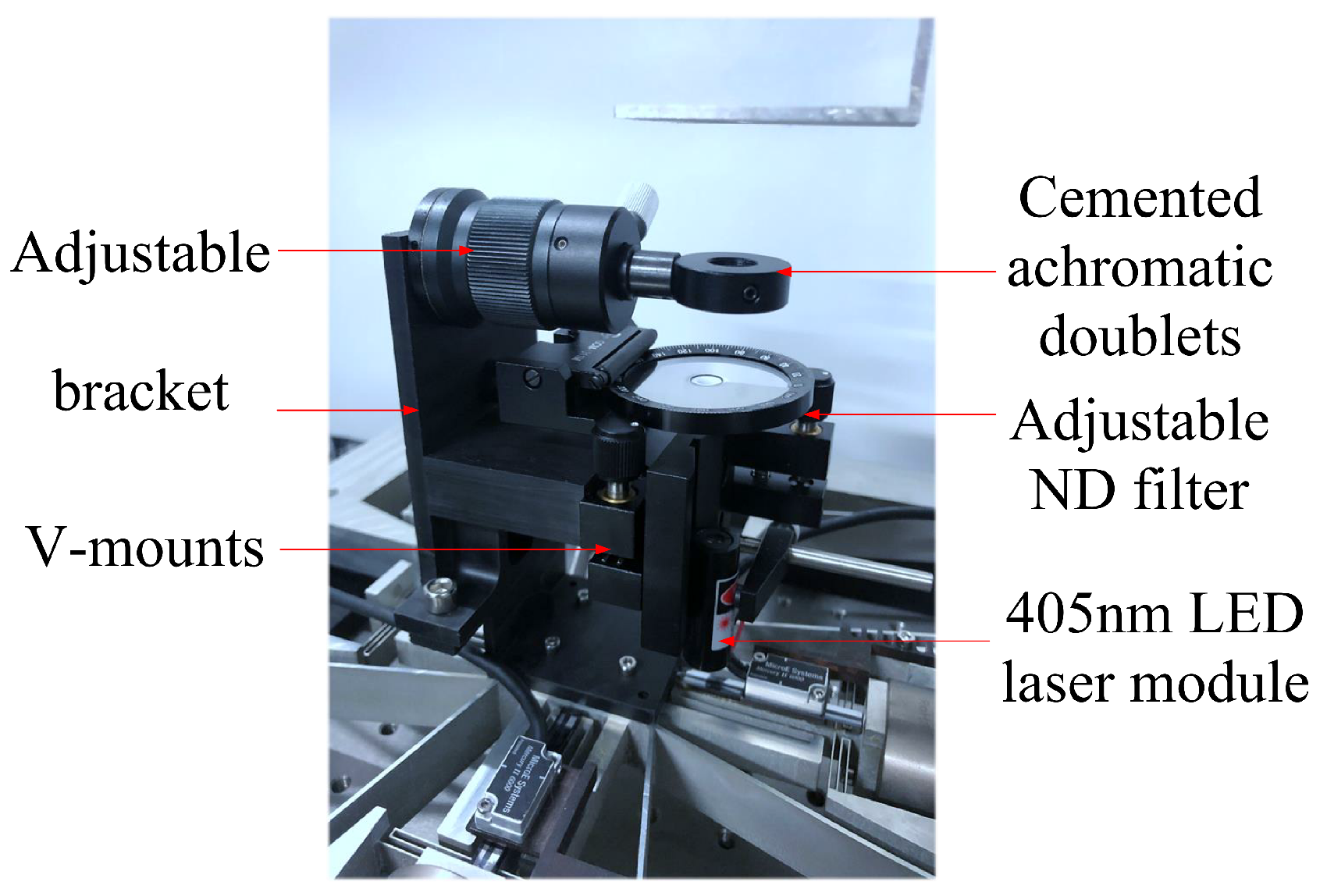

2. System Description of a Cost-Effective MSL Apparatus

3. Robust Control Design

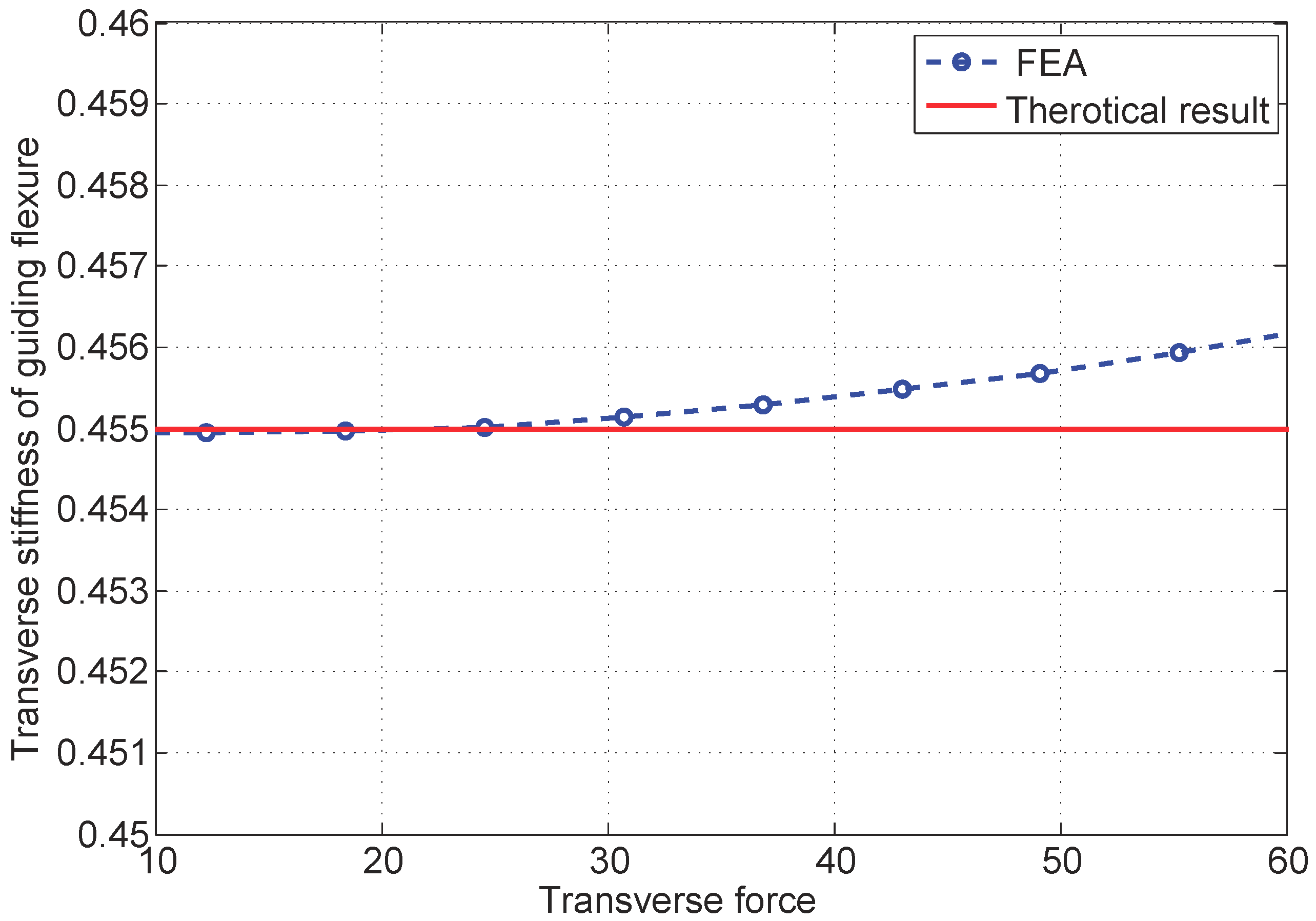

3.1. Dynamic Model of the Compliant Nanomanipulator

3.2. Robust Adaptive Control Based on Radial Basis Function (RBF) Neural Network

3.3. An Add-On Structure of Plug-In RC

4. Simulation and Experimental Results

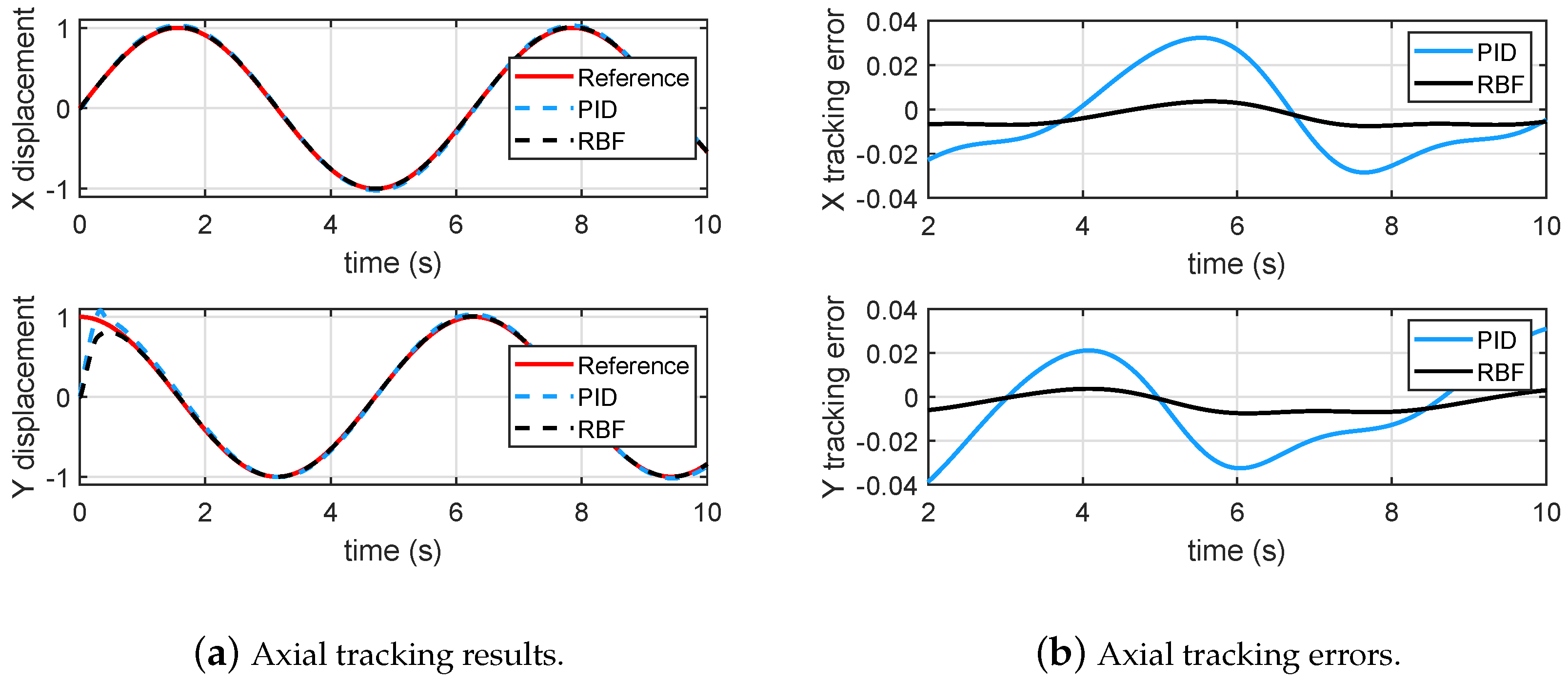

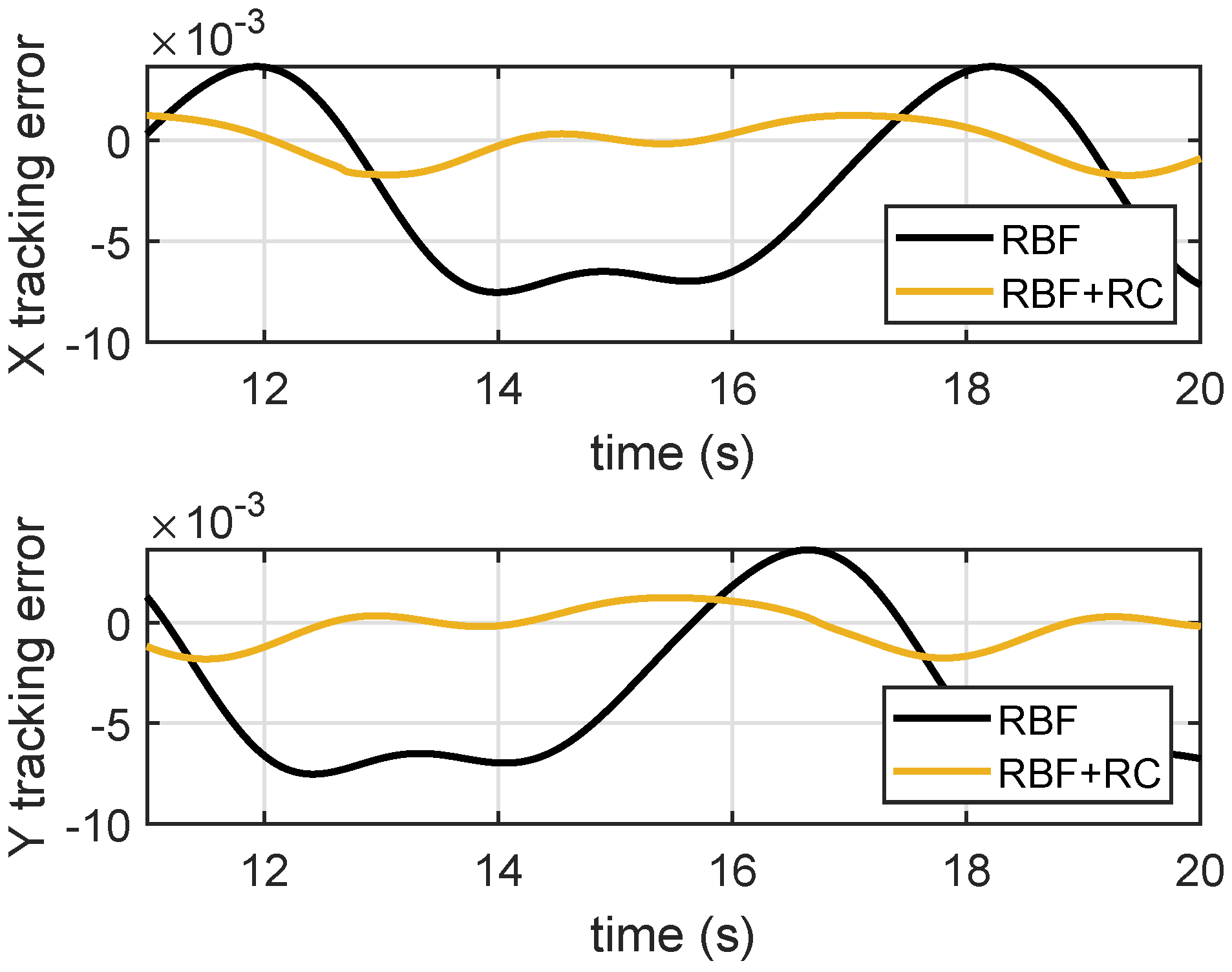

4.1. Simulation Results

4.2. Experimental Results

5. Conclusions

Author Contributions

Funding

Conflicts of Interest

Appendix A

References

- Ikuta, K.; Hirowatari, K. Real three dimensional micro fabrication using stereolithography and metal molding. In Proceedings of the IEEE Micro Electro Mechanical Systems, Fort Lauderdale, FL, USA, 10 February 1993; pp. 42–47. [Google Scholar]

- Takagi, T.; Nakajima, N. Photoforming applied to fine forming. JSME Int. J. Ser. C Dyn. Control Robot. Des. Manuf. 1995, 38, 811–817. [Google Scholar] [CrossRef]

- Koyama, K.; Takakura, M.; Furukawa, T.; Maruo, S. 3D shape reconstruction of 3D printed transparent microscopic objects from multiple photographic images using ultraviolet illumination. Micromachines 2018, 9, 261. [Google Scholar] [CrossRef] [PubMed]

- Lin, H.; Zhang, D.; Alexander, P.G.; Yang, G.; Tan, J.; Cheng, A.W.; Tuan, R.S. Application of visible light-based projection stereolithography for live cell-scaffold fabrication with designed architecture. Biomaterials 2013, 34, 331–339. [Google Scholar] [CrossRef] [PubMed]

- Miri, A.K.; Nieto, D.; Iglesias, L.; Hosseinabadi, G.; Maharjan, S.; Ruiz-Esparza, G.U.; Khoshakhlagh, P.; Manbachi, A.; Dokmeci, M.R.; Chen, S.; et al. Microfluidics-enabled multimaterial maskless stereolithographic bioprinting. Adv. Mater. 2018, 30, 1800242. [Google Scholar] [CrossRef] [PubMed]

- Fuad, N.M.; Carve, M.; Kaslin, J.; Wlodkowic, D. Characterization of 3D-printed moulds for soft lithography of millifluidic devices. Micromachines 2018, 9, 116. [Google Scholar] [CrossRef] [PubMed]

- Wester, B.A.; Rajaraman, S.; Ross, J.D.; LaPlaca, M.C.; Allen, M.G. Development and characterization of a packaged mechanically actuated microtweezer system. Sens. Actuators A Phys. 2011, 167, 502–511. [Google Scholar] [CrossRef]

- Petersen, C.L.; Lin, R.; Petersen, D.H.; Nielsen, P.F. Micro-scale sheet resistance measurements on ultra shallow junctions. In Proceedings of the IEEE International Conference on Advanced Thermal Processing of Semiconductors, Kyoto, Japan, 10–13 October 2006; pp. 153–158. [Google Scholar]

- Maruo, S.; Kawata, S. Two-photon-absorbed near-infrared photopolymerization for three-dimensional microfabrication. J. Microelectromech. Syst. 1998, 7, 411–415. [Google Scholar] [CrossRef]

- Kawata, S.; Sun, H.B.; Tanaka, T.; Takada, K. Finer features for functional microdevices. Nature 2001, 412, 697. [Google Scholar] [CrossRef] [PubMed]

- Maruo, S.; Ikuta, K. Three-dimensional microfabrication by use of single-photon-absorbed polymerization. Appl. Phys. Lett. 2000, 76, 2656–2658. [Google Scholar] [CrossRef]

- Thiel, M.; Fischer, J.; Von Freymann, G.; Wegener, M. Direct laser writing of three-dimensional submicron structures using a continuous-wave laser at 532 nm. Appl. Phys. Lett. 2010, 97, 221102. [Google Scholar] [CrossRef]

- Kang, H.W.; Jeong, Y.S.; Lee, S.J.; Kim, K.S.; Yun, W.S. Development of a compact micro-stereolithography (MSTL) system using a Blu-ray optical pickup unit. J. Micromech. Microeng. 2012, 22, 115021. [Google Scholar] [CrossRef]

- Kim, J.H.; Lee, J.W.; Yun, W.S. Fabrication and tissue engineering application of a 3D PPF/DEF scaffold using Blu-ray based 3D printing system. J. Mech. Sci. Technol. 2017, 31, 2581–2587. [Google Scholar] [CrossRef]

- Zhang, Y.; Yan, P.; Zhang, Z. Robust adaptive backstepping control for piezoelectric nano-manipulating systems. Mech. Syst. Signal Process. 2017, 83, 130–148. [Google Scholar] [CrossRef]

- Zhang, Y.; Yan, P. An adaptive integral sliding mode control approach for piezoelectric nano-manipulation with optimal transient performance. Mechatronics 2018, 52, 119–126. [Google Scholar] [CrossRef]

- Ge, S.S.; Hang, C.C.; Lee, T.H.; Zhang, T. Stable Adaptive Neural Network Control; Springer Science & Business Media: New York, NY, USA, 2013. [Google Scholar]

- Esfandiari, K.; Abdollahi, F.; Talebi, H.A. Adaptive control of uncertain nonaffine nonlinear systems with input saturation using neural networks. IEEE Trans. Neural Netw. Learn. Syst. 2015, 26, 2311–2322. [Google Scholar] [CrossRef] [PubMed]

- Park, J.; Sandberg, I.W. Universal approximation using radial-basis-function networks. Neural Comput. 1991, 3, 246–257. [Google Scholar] [CrossRef] [PubMed]

- Zhang, Z.; Yan, P.; Hao, G. A large range flexure-based servo system supporting precision additive manufacturing. Engineering 2017, 3, 708–715. [Google Scholar] [CrossRef]

- Cosner, C.; Anwar, G.; Tomizuka, M. Plug in repetitive control for industrial robotic manipulators. In Proceedings of the IEEE International Conference on Robotics and Automation, Cincinnati, OH, USA, 13–18 May 1990; pp. 1970–1975. [Google Scholar]

- Krstić, M.; Kanellakopoulos, I.; Kokotović, P.V. Nonlinear and Adaptive Control Design; John Wiley & Sons: Hoboken, NJ, USA, 1995. [Google Scholar]

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Cao, Y.; Zhang, Z. Robust Tracking of a Cost-Effective Micro-Stereolithography System Based on a Compliant Nanomanipulator. Micromachines 2019, 10, 785. https://doi.org/10.3390/mi10110785

Cao Y, Zhang Z. Robust Tracking of a Cost-Effective Micro-Stereolithography System Based on a Compliant Nanomanipulator. Micromachines. 2019; 10(11):785. https://doi.org/10.3390/mi10110785

Chicago/Turabian StyleCao, Yue, and Zhen Zhang. 2019. "Robust Tracking of a Cost-Effective Micro-Stereolithography System Based on a Compliant Nanomanipulator" Micromachines 10, no. 11: 785. https://doi.org/10.3390/mi10110785

APA StyleCao, Y., & Zhang, Z. (2019). Robust Tracking of a Cost-Effective Micro-Stereolithography System Based on a Compliant Nanomanipulator. Micromachines, 10(11), 785. https://doi.org/10.3390/mi10110785