Determination of Regulated and Emerging Mycotoxins in Organic and Conventional Gluten-Free Flours by LC-MS/MS

Abstract

1. Introduction

2. Results and Discussion

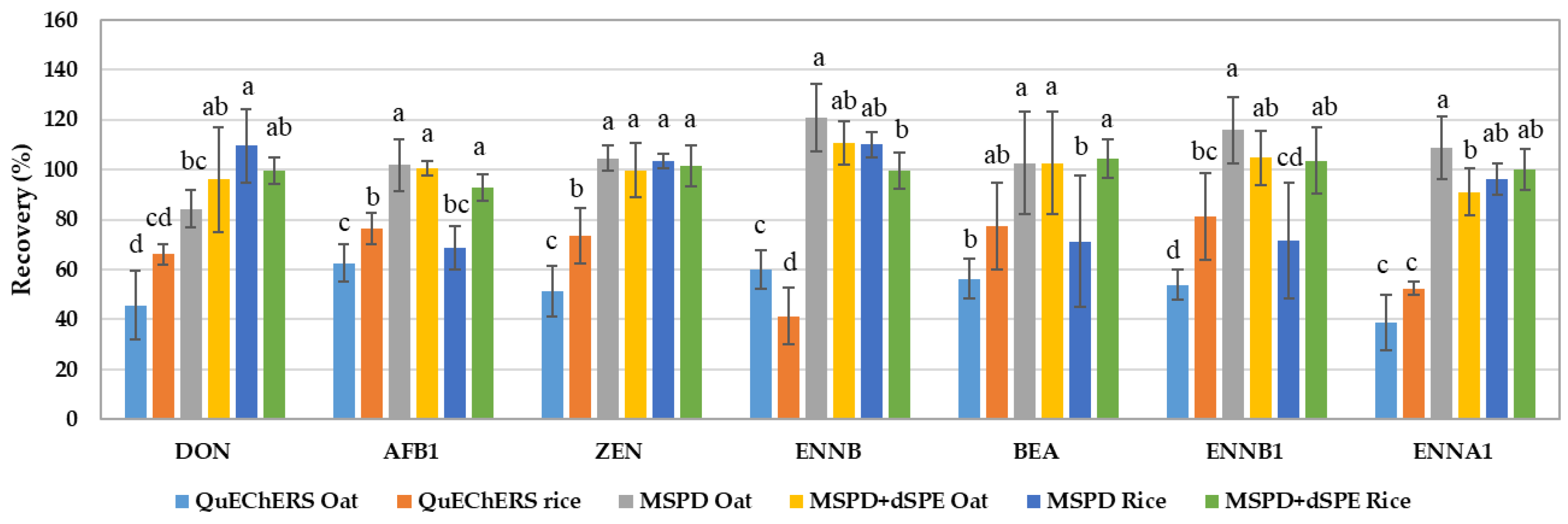

2.1. Extraction Procedures

2.2. Method Validation

2.3. Analysis of Mycotoxins in Flour Samples

3. Conclusions

4. Materials and Methods

4.1. Chemicals and Reagents

4.2. Sampling

4.3. Sample Preparation

4.3.1. QuEChERS

4.3.2. UA-MSPD with dSPE Cleanup

4.4. LC-MS/MS Analysis

4.5. Statistical Analysis

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Global Rice Flour Market By Product Type (Rice Flour, Brown Rice Flour, Glutinous Rice Flour, Others), Application (Rice Noodle And Rice Pasta, Sweets And Desserts, Snacks, Bakery And Bread Products, Thickening Agent, Animal Feed Including Pet Food, Non-Food Applications [biomaterials, Glue, Bio Plastics], Others), and Regional Analysis (North America, Europe, Asia Pacific, Latin America, and Middle East & Africa) and—Global Industry Analysis, Size, Share, Growth, Trends, and Forecast (2022–2027). Available online: http://www.marketdataforecast.com/market-reports/rice-flour-market (accessed on 12 December 2022).

- Global Oat Flour Market, By Type (Instant Food, Raw Oatmeal), Distribution Channel (Retail Stores, Department Store, Supermarket, Hypermarket, E-Commerce), Application (Health Care Food, Bakery Products, Functional Food, Fast Food, Others)—Industry Trends and Forecast to 2029. Available online: http://www.databridgemarketresearch.com/reports/global-oat-flour-market (accessed on 12 December 2022).

- Rosentrater, K.A.; Evers, A. Flour Treatments, Applications, Quality, Storage and Transport. In Kent’s Technology of Cereals, 5th ed.; Woodhead Publishing: Cambridge, UK, 2018; pp. 515–564. [Google Scholar]

- Paudel, D.; Dhungana, B.; Caffe, M.; Krishnan, P. A Review of Health-Beneficial Properties of Oats. Foods 2021, 10, 2591. [Google Scholar] [CrossRef] [PubMed]

- Popa, C.-N.; Tamba-Berehoiu, R.-M. Chapter 10—Oat Flour in Bread Manufacturing. In Trends in Wheat and Bread Making; Galanakis, C.M., Ed.; Academic Press: Cambridge, MA, USA, 2021; pp. 279–309. ISBN 9780128210482. [Google Scholar]

- Tamba-Berehoiu, R.M.; Cristea, S.; Negoiţă, M.; Popa, C.N.; Turtoi, M.O. Bread Making Potential Assessment of Wheat-Oat Composite Flours. Rom. Biotechnol. Lett. 2019, 24, 522–530. [Google Scholar] [CrossRef]

- Turner, N.W.; Subrahmanyam, S.; Piletsky, S.A. Analytical Methods for Determination of Mycotoxins: A Review. Anal. Chim. Acta 2009, 632, 168–180. [Google Scholar] [CrossRef] [PubMed]

- Forsythe, S.J. The Microbiology of Safe Food, 3rd ed.; John Wiley & Sons: Hoboken, NJ, USA, 2020; p. 462. ISBN 9781119405016. [Google Scholar]

- Smith, J.E.; Solomons, G.; Lewis, C.; Anderson, J.G. Role of Mycotoxins in Human and Animal Nutrition and Health. Nat. Toxins 1995, 3, 187–192. [Google Scholar] [CrossRef]

- Eskola, M.; Kos, G.; Elliott, C.T.; Hajšlová, J.; Mayar, S.; Krska, R. Worldwide Contamination of Food-Crops with Mycotoxins: Validity of the Widely Cited “FAO Estimate” of 25. Crit. Rev. Food Sci. Nutr. 2020, 60, 2773–2789. [Google Scholar] [CrossRef] [PubMed]

- Alshannaq, A.; Yu, J.-H. Occurrence, Toxicity, and Analysis of Major Mycotoxins in Food. Int. J. Environ. Res. Public Health 2017, 14, 632. [Google Scholar] [CrossRef]

- Awika, J.M. Major Cereal Grains Production and Use around the World. In Advances in Cereal Science: Implications to Food Processing and Health Promotion; ACS Symposium Series; American Chemical Society: Washington, DC, USA, 2011; Volume 1089, pp. 1–13. ISBN 9780841226364. [Google Scholar]

- European Commission. Commission Regulation (EC) No 1881/2006 of 19 December 2006 Setting Maximum Levels for Certain Contaminants in Foodstuffs. Available online: http://data.europa.eu/eli/reg/2006/1881/oj (accessed on 12 December 2022).

- Ekwomadu, T.I.; Akinola, S.A.; Mwanza, M. Fusarium Mycotoxins, Their Metabolites (Free, Emerging, and Masked), Food Safety Concerns, and Health Impacts. Int. J. Environ. Res. Public Health 2021, 18, 11741. [Google Scholar] [CrossRef] [PubMed]

- Jestoi, M. Emerging Fusarium-Mycotoxins Fusaproliferin, Beauvericin, Enniatins, and Moniliformin: A Review. Crit. Rev. Food Sci. Nutr. 2008, 48, 21–49. [Google Scholar] [CrossRef] [PubMed]

- Khodaei, D.; Javanmardi, F.; Khaneghah, A.M. The Global Overview of the Occurrence of Mycotoxins in Cereals: A Three-Year Survey. Curr. Opin. Food Sci. 2021, 39, 36–42. [Google Scholar] [CrossRef]

- Schöneberg, T.; Jenny, E.; Wettstein, F.E.; Bucheli, T.D.; Mascher, F.; Bertossa, M.; Musa, T.; Seifert, K.; Gräfenhan, T.; Keller, B.; et al. Occurrence of Fusarium Species and Mycotoxins in Swiss oats—Impact of Cropping Factors. Eur. J. Agron. 2018, 92, 123–132. [Google Scholar] [CrossRef]

- Rai, A.; Dixit, S.; Singh, S.P.; Gautam, N.K.; Das, M.; Tripathi, A. Presence of Zearalenone in Cereal Grains and Its Exposure Risk Assessment in Indian Population. J. Food Sci. 2018, 83, 3126–3133. [Google Scholar] [CrossRef] [PubMed]

- Dos Santos, I.D.; Pizzutti, I.R.; Dias, J.V.; Fontana, M.E.Z.; Souza, D.M.; Cardoso, C.D. Mycotoxins in Wheat Flour: Occurrence and Co-Occurrence Assessment in Samples from Southern Brazil. Food Addit. Contam. Part B 2021, 14, 151–161. [Google Scholar] [CrossRef] [PubMed]

- Škrbić, B.; Živančev, J.; Đurišić-Mladenović, N.; Godula, M. Principal Mycotoxins in Wheat Flour from the Serbian Market: Levels and Assessment of the Exposure by Wheat-Based Products. Food Control 2012, 25, 389–396. [Google Scholar] [CrossRef]

- Zhang, Y.; Pei, F.; Fang, Y.; Li, P.; Zhao, Y.; Shen, F.; Zou, Y.; Hu, Q. Comparison of Concentration and Health Risks of 9 Fusarium Mycotoxins in Commercial Whole Wheat Flour and Refined Wheat Flour by Multi-IAC-HPLC. Food Chem. 2019, 275, 763–769. [Google Scholar] [CrossRef]

- Oueslati, S.; Meca, G.; Mliki, A.; Ghorbel, A.; Mañes, J. Determination of Fusarium Mycotoxins Enniatins, Beauvericin and Fusaproliferin in Cereals and Derived Products from Tunisia. Food Control 2011, 22, 1373–1377. [Google Scholar] [CrossRef]

- Lairon, D. Nutritional Quality and Safety of Organic Food. A Review. Agron. Sustain. Dev. 2010, 30, 33–41. [Google Scholar] [CrossRef]

- da Luz, S.R.; Pazdiora, P.C.; Dallagnol, L.J.; Dors, G.C.; Chaves, F.C. Mycotoxin and Fungicide Residues in Wheat Grains from Fungicide-Treated Plants Measured by a Validated LC-MS Method. Food Chem. 2017, 220, 510–516. [Google Scholar] [CrossRef]

- Nugmanov, A.; Beishova, I.; Kokanov, S.; Lozowicka, B.; Kaczynski, P.; Konecki, R.; Snarska, K.; Wołejko, E.; Sarsembayeva, N.; Abdigaliyeva, T. Systems to Reduce Mycotoxin Contamination of Cereals in the Agricultural Region of Poland and Kazakhstan. Crop Prot. 2018, 106, 64–71. [Google Scholar] [CrossRef]

- Vrček, I.V.; Čepo, D.V.; Rašić, D.; Peraica, M.; Žuntar, I.; Bojić, M.; Mendaš, G.; Medić-Šarić, M. A Comparison of the Nutritional Value and Food Safety of Organically and Conventionally Produced Wheat Flours. Food Chem. 2014, 143, 522–529. [Google Scholar] [CrossRef]

- Armorini, S.; Altafini, A.; Zaghini, A.; Roncada, P. Occurrence of Aflatoxin B1 in Conventional and Organic Flour in Italy and the Role of Sampling. Food Control 2015, 50, 858–863. [Google Scholar] [CrossRef]

- Wang, J.; Hasanalieva, G.; Wood, L.; Markellou, E.; Iversen, P.O.; Bernhoft, A.; Seal, C.; Baranski, M.; Vigar, V.; Ernst, L.; et al. Effect of Wheat Species (Triticum aestivum vs. T. spelta), Farming System (organic vs. Conventional) and Flour Type (wholegrain vs. White) on Composition of Wheat Flour; Results of a Retail Survey in the UK and Germany—1. Mycotoxin Content. Food Chem. 2020, 327, 127011. [Google Scholar] [CrossRef] [PubMed]

- Sacco, C.; Donato, R.; Zanella, B.; Pini, G.; Pettini, L.; Marino, M.F.; Rookmin, A.D.; Marvasi, M. Mycotoxins and Flours: Effect of Type of Crop, Organic Production, Packaging Type on the Recovery of Fungal Genus and Mycotoxins. Int. J. Food Microbiol. 2020, 334, 108808. [Google Scholar] [CrossRef]

- Jadhav, M.R.; Oulkar, D.P.; Shabeer, T.P.A.; Banerjee, K. Quantitative Screening of Agrochemical Residues in Fruits and Vegetables by Buffered Ethyl Acetate Extraction and LC-MS/MS Analysis. J. Agric. Food Chem. 2015, 63, 4449–4456. [Google Scholar] [CrossRef] [PubMed]

- Malachová, A.; Stránská, M.; Václavíková, M.; Elliott, C.T.; Black, C.; Meneely, J.; Hajšlová, J.; Ezekiel, C.N.; Schuhmacher, R.; Krska, R. Advanced LC–MS-Based Methods to Study the Co-Occurrence and Metabolization of Multiple Mycotoxins in Cereals and Cereal-Based Food. Anal. Bioanal. Chem. 2018, 410, 801–825. [Google Scholar] [CrossRef] [PubMed]

- Amirahmadi, M.; Shoeibi, S.; Rastegar, H.; Elmi, M.; Mousavi Khaneghah, A. Simultaneous Analysis of Mycotoxins in Corn Flour Using LC/MS-MS Combined with a Modified QuEChERS Procedure. Toxin Rev. 2018, 37, 187–195. [Google Scholar] [CrossRef]

- Stanciu, O.; Juan, C.; Miere, D.; Loghin, F.; Mañes, J. Analysis of Enniatins and Beauvericin by LC-MS/MS in Wheat-Based Products. CyTA-J Food 2017, 15, 433–440. [Google Scholar] [CrossRef]

- Ji, X.; Xiao, Y.; Wang, W.; Lyu, W.; Wang, X.; Li, Y.; Deng, T.; Yang, H. Mycotoxins in Cereal-Based Infant Foods Marketed in China: Occurrence and Risk Assessment. Food Control 2022, 138, 108998. [Google Scholar] [CrossRef]

- Noroozi, R.; Kobarfard, F.; Rezaei, M.; Ayatollahi, S.A.; Paimard, G.; Eslamizad, S.; Razmjoo, F.; Sadeghi, E. Occurrence and Exposure Assessment of Aflatoxin B1 in Iranian Breads and Wheat-Based Products Considering Effects of Traditional Processing. Food Control 2022, 138, 108985. [Google Scholar] [CrossRef]

- Iqbal, S.Z.; Asi, M.R.; Hanif, U.; Zuber, M.; Jinap, S. The Presence of Aflatoxins and Ochratoxin A in Rice and Rice Products; and Evaluation of Dietary Intake. Food Chem. 2016, 210, 135–140. [Google Scholar] [CrossRef]

- Liu, X.; Liu, X.; Huang, P.; Wei, F.; Ying, G.; Zhang, S.; Lu, J.; Zhou, L.; Kong, W. Regeneration and Reuse of Immunoaffinity Column for Highly Efficient Clean-Up and Economic Detection of Ochratoxin A in Malt and Ginger. Toxins 2018, 10, 462. [Google Scholar] [CrossRef]

- Gab-Allah, M.A.; Tahoun, I.F.; Yamani, R.N.; Rend, E.A.; Shehata, A.B. Natural Occurrence of Deoxynivalenol, Nivalenol and Deoxynivalenol-3-Glucoside in Cereal-Derived Products from Egypt. Food Control 2022, 137, 108974. [Google Scholar] [CrossRef]

- Torović, L. Aflatoxins and Ochratoxin A in Flour: A Survey of the Serbian Retail Market. Food Addit. Contam. Part B 2018, 11, 26–32. [Google Scholar] [CrossRef] [PubMed]

- Rubert, J.; Soler, C.; Mañes, J. Evaluation of Matrix Solid-Phase Dispersion (MSPD) Extraction for Multi-Mycotoxin Determination in Different Flours Using LC–MS/MS. Talanta 2011, 85, 206–215. [Google Scholar] [CrossRef] [PubMed]

- Meca, G.; Zinedine, A.; Blesa, J.; Font, G.; Mañes, J. Further Data on the Presence of Fusarium Emerging Mycotoxins Enniatins, Fusaproliferin and Beauvericin in Cereals Available on the Spanish Markets. Food Chem. Toxicol. 2010, 48, 1412–1416. [Google Scholar] [CrossRef]

- Bouafifssa, Y.; Manyes, L.; Rahouti, M.; Mañes, J.; Berrada, H.; Zinedine, A.; Fernández-Franzón, M. Multi-Occurrence of Twenty Mycotoxins in Pasta and a Risk Assessment in the Moroccan Population. Toxins 2018, 10, 432. [Google Scholar] [CrossRef]

- Tolosa, J.; Barba, F.J.; Font, G.; Ferrer, E. Mycotoxin Incidence in Some Fish Products: QuEChERS Methodology and Liquid Chromatography Linear Ion Trap Tandem Mass Spectrometry Approach. Molecules 2019, 24, 527. [Google Scholar] [CrossRef]

- Albero, B.; Fernández-Cruz, M.L.; Pérez, R.A. Simultaneous Determination of 15 Mycotoxins in Aquaculture Feed by Liquid Chromatography-Tandem Mass Spectrometry. Toxins 2022, 14, 316. [Google Scholar] [CrossRef]

| Wholegrain Oat Flour | Rice Flour | LOQ (μg/kg) | |||||||

|---|---|---|---|---|---|---|---|---|---|

| Recovery | Recovery | Inter-Day RSD% * | Recovery | Recovery | Inter-Day RSD% * | ||||

| 1–100 μg/kg | 20–2000 μg/kg | 1–100 μg/kg | 20–2000 μg/kg | ||||||

| DON | 105.4 ± 11.5 | 110.1 ± 8.0 | 11.7 | 102.9 ± 5.0 | 99.6 ± 5.5 | 6.9 | 100.0 | ||

| AFB1 | 98.5 ± 9.6 | 110.3 ± 3.7 | 12.1 | 84.8 ± 7.8 | 92.9 ± 5.2 | 8.4 | 1.0 | ||

| ZEN | 99.4 ± 6.7 | 113.5 ± 7.8 | 13.3 | 100.4 ± 7.8 | 101.7 ±8.2 | 11.8 | 10.0 | ||

| ENNB | 108.3 ± 9.0 | 94.5 ± 8.2 | 11.6 | 97.7 ± 5.4 | 99.8 ± 7.2 | 6.0 | 1.0 | ||

| BEA | 121.7 ± 11.5 | 96.5 ± 7.3 | 9.4 | 121.6 ± 7.6 | 104.4 ± 7.7 | 8.7 | 1.0 | ||

| ENNB1 | 87.4 ± 6.9 | 99.0 ± 2.6 | 11.4 | 107.7 ± 8.6 | 103.6 ± 6.6 | 5.7 | 1.0 | ||

| ENNA1 | 98.9 ± 6.2 | 90.6 ± 8.9 | 11.5 | 89.8 ± 5.0 | 100.3 ± 8.2 | 7.5 | 1.0 | ||

| Flour Type(s) | Analytes (Common with This Study) | Method | Recoveries in Flours % | LOQs | Mean Levels, μg/kg (Positive/Total Samples) | Ref. |

|---|---|---|---|---|---|---|

| Wheat | 20 mycotoxins (AFB1, DON, ZEN, ENNB, ENNA1) | SLE shaking | 73–100 | 0.1–3 | ENNB; 0.6 (2/54); ENNB1 9.5 (2/54); DON 79 (49/54) | [34] |

| Wheat | 1 mycotoxin (AFB1) | SLE + IAC | 96–99 | 0.15 | AFB1 0.5–3.4 (5/5) | [35] |

| Corn and wheat | 3 mycotoxins (DON) | SLE shaking + IAC | 86–102 | 43–47 | DON < LOQ–853 (73/104) | [38] |

| Wheat | 12 mycotoxins (AFB1, DON, ZEN) | QuEChERS | 75–116 | 1–50 | DON 53–2905 (200/200); ZEN < LOQ (102/200) | [19] |

| Wheat | 9 mycotoxins (DON, ZEN) | SLE shaking + IAC | 82–99 | 5–60 | DON < LOD–924.6 (66/85); ZEN < LOD–17 (6/85) | [21] |

| Wheat, buckwheat, rye, oat, barley, rice, millet, and corn | 5 mycotoxins (AFB1) | SLE shaking + IAC | 53–85 | 0.1 | AFB1 0.53–4.76 (28/66) | [39] |

| Wheat | 5 mycotoxins (ENNA1, ENNB, ENNB1, BEA) | SLE shaking | 61–127 | 1–4 | ENNB 9.8 (1/4); ENNB1 2.3 (1/4) | [33] |

| Corn | 6 mycotoxins (AFB1, DON, ZEN) | QuEChERS | 97–116 | 2–75 | AFB1 < LOQ–1060 (25/40) ZEN < LOQ–3170 (14/40) | [32] |

| Wheat and corn flours | 1 mycotoxin (AFB1) | UAE | 78–100 | 0.50 | 0.2–3.7 (9/42) | [27] |

| Wheat | 11 mycotoxins (AFB1, DON, ZEN) | SLE shaking | 72–115 | 1.0–2.3 | DON 17.5–976 (13/15); ZEN 1.9–21.1 (5/15) | [20] |

| Wheat, corn, rice, soy, oat, and multi-cereal | 14 mycotoxins (AFB1, DON, ZEN, BEA) | MSPD | 73–89 | 1–31 | DON 45–367 (6/40); ZEN 39–70 (2/40); BEA 150–720 (9/40) | [40] |

| Rice | 5 mycotoxins (AFB1) | SLE and IAC | 88–90 | 0.20 | LOD-9.8 (11/37) | [36] |

| Wholegrain oat and rice | 7 mycotoxins (AFB1, DON, ZEN, ENNB, ENNB1, ENNA1, BEA) | MSPD and dSPE | 85–122 | 1–100 | AFB1 < LOQ (1/28); ZEN 83 (1/28); ENNA1 < LOQ-7.1 (12/28); ENNB < LOQ-56 (15/28); ENNB1 < LOQ-21 (13/28); BEA < LOQ-10 (13/28) | Present work |

| Type and Number (% Frequency) | Levels in µg/kg (Frequency of Detection) | |||||

|---|---|---|---|---|---|---|

| AFB1 | ZEN | ENNB | BEA | ENNB1 | ENNA1 | |

| Conventional wholegrain oat | - | - | 3–56 | <LOQ-10 | 2–21 | <LOQ-2 |

| n = 7 (100%) | (0%) | (0%) | (100%) | (100%) | (100%) | (100%) |

| Organic wholegrain oat | - | - | <LOQ-6.7 | <LOQ-1.1 | 1.4–10 | <LOQ-7.1 |

| n = 7 (71%) | (0%) | (0%) | (71)% | (57%) | (57%) | (57%) |

| Conventional | <LOQ | 83.2 | <LOQ | 2.2 | <LOQ | - |

| rice n = 7 (29%) | (14%) | (14%) | (14%) | (14%) | (14%) | (0%) |

| Organic rice | - | - | <LOQ | <LOQ | <LOQ | <LOQ |

| n = 7 (29%) | (0%) | (0%) | (29%) | (14%) | (14%) | (14%) |

| Compound | MRM 1 | CE (eV) | Fragmentor (V) | MRM 2 | CE (eV) | Fragmentor (V) | Polarity |

|---|---|---|---|---|---|---|---|

| AFB1 | 313 > 128.1 | 70 | 165 | 313 > 285.2 | 20 | 100 | Positive |

| DON | 297.1 > 249.1 | 10 | 100 | 297.1 > 77 | 80 | 100 | Positive |

| ZEN | 317 > 175 | 20 | 195 | 317 > 131 | 28 | 195 | Negative |

| BEA | 801.5 > 262 | 32 | 180 | 801.5 > 244 | 36 | 180 | Positive |

| ENNA1 | 685 > 228 | 32 | 150 | 685 > 210 | 32 | 150 | Positive |

| ENNB1 | 672 > 196 | 32 | 170 | 671.4 > 214 | 60 | 170 | Positive |

| ENNB | 657 > 196 | 32 | 160 | 657 > 214 | 32 | 160 | Positive |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Giannioti, Z.; Albero, B.; Hernando, M.D.; Bontempo, L.; Pérez, R.A. Determination of Regulated and Emerging Mycotoxins in Organic and Conventional Gluten-Free Flours by LC-MS/MS. Toxins 2023, 15, 155. https://doi.org/10.3390/toxins15020155

Giannioti Z, Albero B, Hernando MD, Bontempo L, Pérez RA. Determination of Regulated and Emerging Mycotoxins in Organic and Conventional Gluten-Free Flours by LC-MS/MS. Toxins. 2023; 15(2):155. https://doi.org/10.3390/toxins15020155

Chicago/Turabian StyleGiannioti, Zoe, Beatriz Albero, María Dolores Hernando, Luana Bontempo, and Rosa Ana Pérez. 2023. "Determination of Regulated and Emerging Mycotoxins in Organic and Conventional Gluten-Free Flours by LC-MS/MS" Toxins 15, no. 2: 155. https://doi.org/10.3390/toxins15020155

APA StyleGiannioti, Z., Albero, B., Hernando, M. D., Bontempo, L., & Pérez, R. A. (2023). Determination of Regulated and Emerging Mycotoxins in Organic and Conventional Gluten-Free Flours by LC-MS/MS. Toxins, 15(2), 155. https://doi.org/10.3390/toxins15020155