Impact of Phytochemicals on Viability and Cereulide Toxin Synthesis in Bacillus cereus Revealed by a Novel High-Throughput Method, Coupling an AlamarBlue-Based Assay with UPLC-MS/MS

Abstract

:1. Introduction

2. Results and Discussion

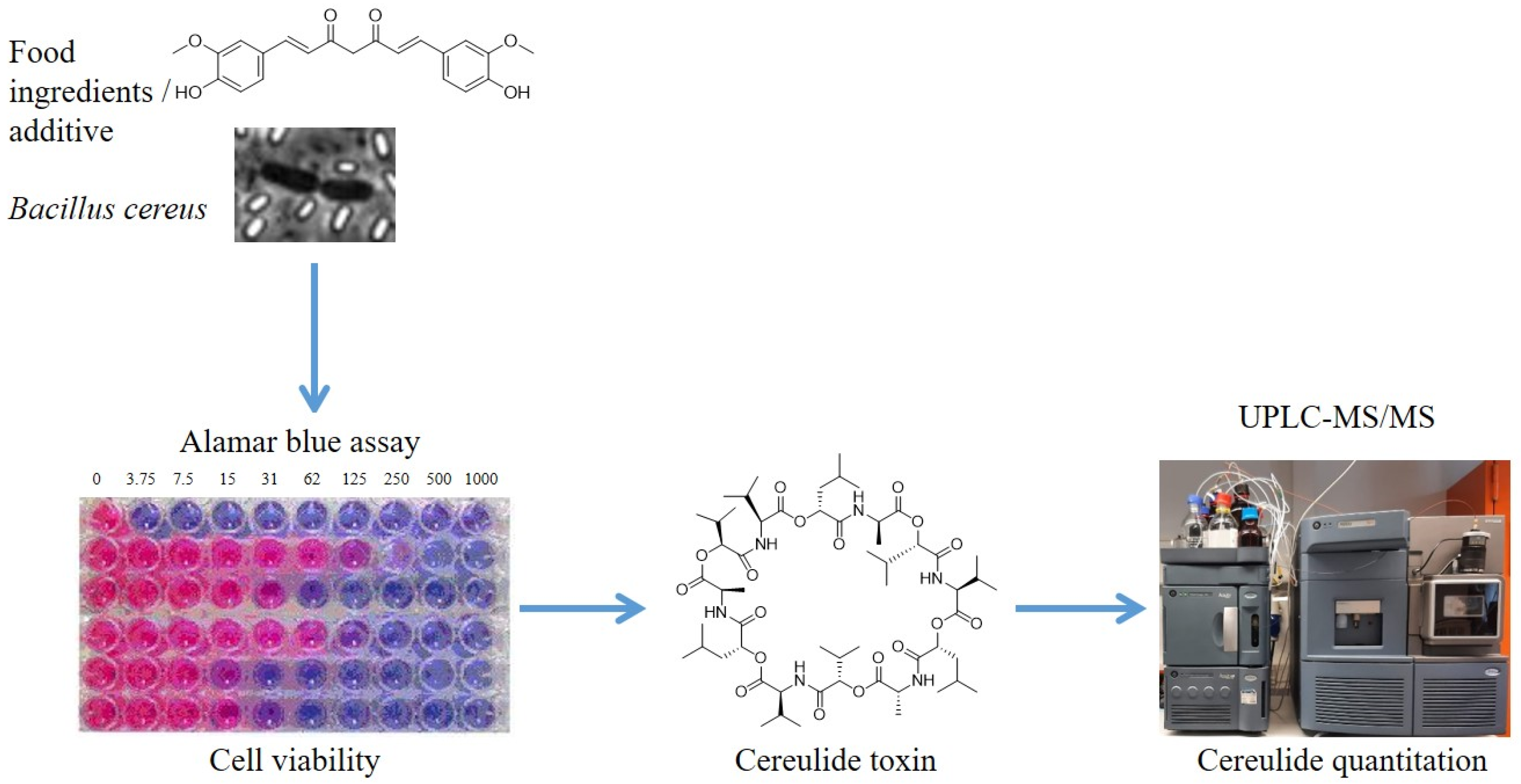

2.1. Development of a Micro-Scale Assay to Simultaneously Test the Effect of Food Ingredients on Growth and Cereulide Toxin Production in Emetic B. cereus

2.2. Selection of Phytochemicals to Be Tested in the Novel Combinatory Micro-Scale Assay

2.3. Screening of the Phytochemical Panel by Means of the Novel Micro-Scale Alamarblue & UPLC-MS/MS Assay for Inhibitory Substances

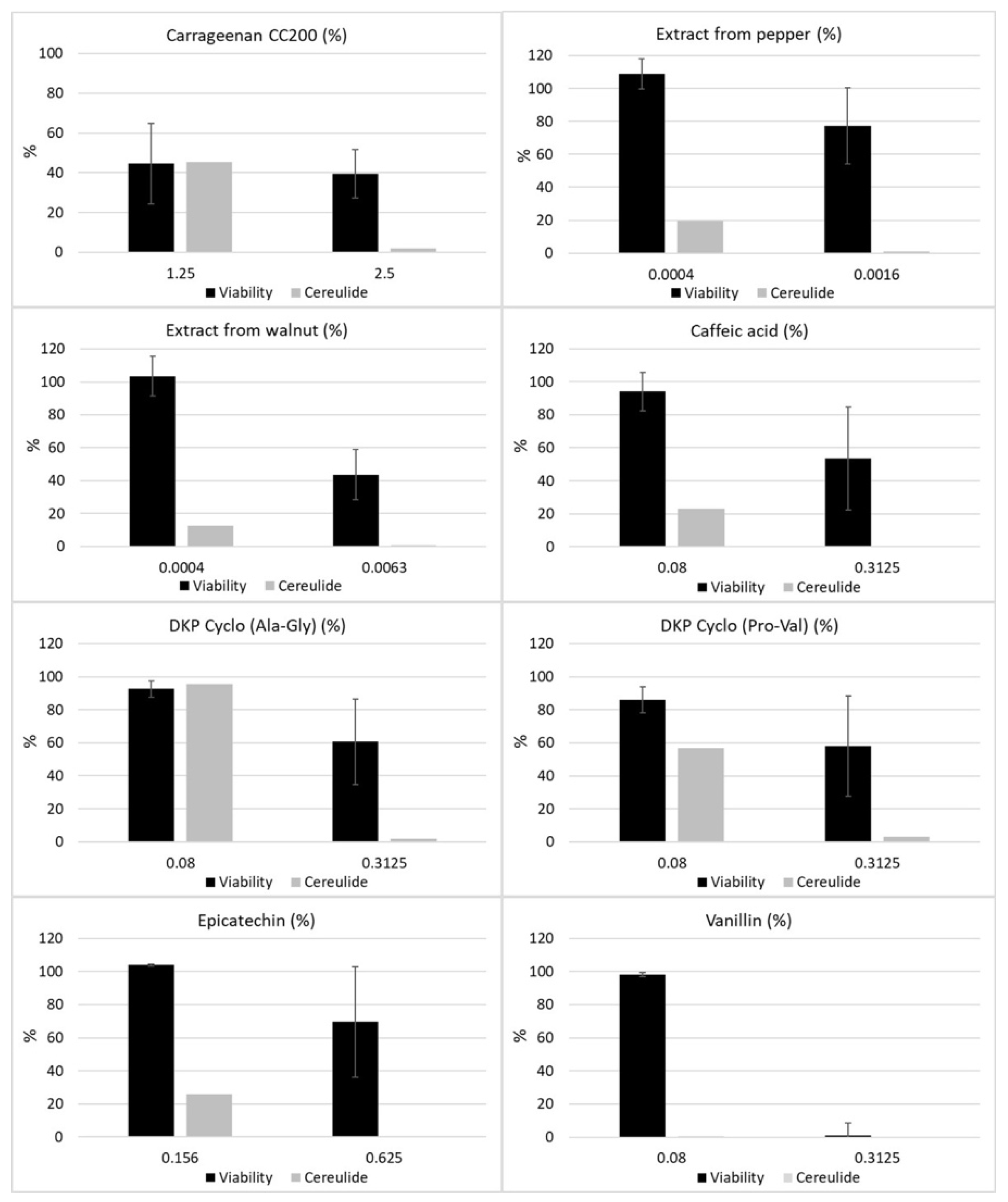

2.4. Identification of Phytochemicals with Inhibitory Potential against B. cereus Growth and Cereulide Biosynthesis

3. Conclusions

4. Materials and Methods

4.1. Bacterial Strains

4.2. Food Ingredients and Phytochemicals

4.3. Cell Viability Testing with Microscale AlamarBlue Assay

4.4. Cereulide Extraction and Quantification via UPLC-MS/MS Analysis

4.5. Ultraperformance Liquid Chromatography—Mass Spectrometry (UPLC-MS/MS)

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Ehling-Schulz, M.; Lereclus, D.; Koehler, T.M. The Bacillus Cereus Group: Bacillus Species with Pathogenic Potential. Microbiol. Spectr. 2019, 7. [Google Scholar] [CrossRef]

- European Food Safety Authority; Prevention European Centre for Disease Control. The European Union Summary Report on Trends and Sources of Zoonoses, Zoonotic Agents and Food-Borne Outbreaks in 2016. EFSA J. 2017, 15, e05077. [Google Scholar]

- Messelhäußer, U.; Ehling-Schulz, M. Bacillus Cereus—A Multifaceted Opportunistic Pathogen. Curr. Clin. Microbiol. Rep. 2018, 5, 120–125. [Google Scholar] [CrossRef] [Green Version]

- Dietrich, R.; Jessberger, N.; Ehling-Schulz, M.; Märtlbauer, E.; Granum, P.E. The Food Poisoning Toxins of Bacillus Cereus. Toxins 2021, 13, 98. [Google Scholar] [CrossRef] [PubMed]

- Ehling-Schulz, M.; Fricker, M.; Scherer, S. Bacillus Cereus, the Causative Agent of an Emetic Type of Food-Borne Illness. Mol. Nut.r Food Res. 2004, 48, 479–487. [Google Scholar] [CrossRef] [PubMed]

- European Food Safety Authority. Opinion of the Scientific Panel on Biological Hazards (Biohaz) on Bacillus Cereus and Other Bacillus Spp in Foodstuffs. EFSA J. 2005, 3, 175. [Google Scholar]

- Montone, A.M.I.; Capuano, F.; Mancusi, A.; di Maro, O.; Peruzy, M.F.; Proroga, Y.T.R.; Cristiano, D. Exposure to Bacillus Cereus in Water Buffalo Mozzarella Cheese. Foods 2020, 9, 1899. [Google Scholar] [CrossRef] [PubMed]

- Schmid, D.; Rademacher, C.; Kanitz, E.; Frenzel, E.; Simons, E.; Allerberger, F.; Ehling-Schulz, M. Elucidation of Enterotoxigenic Bacillus Cereus Outbreaks in Austria by Complementary Epidemiological and Microbiological Investigations, 2013. Int. J. Food Microbiol. 2016, 23, 280–286. [Google Scholar] [CrossRef]

- Jessberger, N.; Kranzler, M.; da Riol, C.; Schwenk, V.; Buchacher, T.; Dietrich, R.; Ehling-Schulz, M.; Martlbauer, E. Assessing the Toxic Potential of Enteropathogenic Bacillus Cereus. Food Microbiol. 2019, 84, 103276. [Google Scholar] [CrossRef] [PubMed]

- Agata, N.; Mori, M.; Ohta, M.; Suwan, S.; Ohtani, I.; Isobe, M. A Novel Dodecadepsipeptide, Cereulide, Isolated from Bacillus Cereus Causes Vacuole Formation in Hep-2 Cells. FEMS Microbiol. Lett. 1994, 121, 31–34. [Google Scholar]

- Ehling-Schulz, M.; Fricker, M.; Grallert, H.; Rieck, P.; Wagner, M.; Scherer, S. Cereulide Synthetase Gene Cluster from Emetic Bacillus Cereus: Structure and Location on a Mega Virulence Plasmid Related to Bacillus Anthracis Toxin Plasmid Pxo1. BMC Microbiol. 2006, 6, 20. [Google Scholar] [CrossRef] [Green Version]

- Ehling-Schulz, M.; Vukov, N.; Schulz, A.; Shaheen, R.; Andersson, M.; Märtlbauer, E.; Scherer, S. Identification and Partial Characterization of the Nonribosomal Peptide Synthetase Gene Responsible for Cereulide Production in Emetic Bacillus Cereus. Appl. Environ. Microbiol. 2005, 71, 105–113. [Google Scholar] [CrossRef] [Green Version]

- Dierick, K.; van Coillie, E.; Swiecicka, I.; Meyfroidt, G.; Devlieger, H.; Meulemans, A.; Hoedemaekers, G.; Fourie, L.; Heyndrickx, M.; Mahillon, J. Fatal Family Outbreak of ≪Em≫Bacillus Cereus≪/Em≫-Associated Food Poisoning. J. Clin. Microbiol. 2005, 43, 4277. [Google Scholar]

- Messelhausser, U.; Frenzel, E.; Blochinger, C.; Zucker, R.; Kampf, P.; Ehling-Schulz, M. Emetic Bacillus Cereus Are More Volatile Than Thought: Recent Foodborne Outbreaks and Prevalence Studies in Bavaria (2007–2013). Biomed. Res. Int. 2014, 2014, 465603. [Google Scholar] [CrossRef] [Green Version]

- Rouzeau-Szynalski, K.; Stollewerk, K.; Messelhausser, U.; Ehling-Schulz, M. Why Be Serious About Emetic Bacillus Cereus: Cereulide Production and Industrial Challenges. Food Microbiol. 2020, 85, 103279. [Google Scholar] [CrossRef]

- Tschiedel, E.; Rath, P.-M.; Steinmann, J.; Becker, H.; Dietrich, R.; Paul, A.; Felderhoff-Müser, U.; Dohna-Schwake, C. Lifesaving Liver Transplantation for Multi-Organ Failure Caused by Bacillus Cereus Food Poisoning. Pediatric Transplant. 2015, 19, E11–E14. [Google Scholar] [CrossRef]

- Agata, N.; Ohta, M.; Yokoyama, K. Production of Bacillus Cereus Emetic Toxin (Cereulide) in Various Foods. Int. J. Food Microbiol. 2002, 73, 23–27. [Google Scholar] [CrossRef]

- Rajkovic, A.; Uyttendaele, M.; Vermeulen, A.; Andjelkovic, M.; Fitz-James, I.; In’t Veld, P.; Denon, Q.; Verhe, R.; Debevere, J. Heat Resistance of Bacillus Cereus Emetic Toxin, Cereulide. Lett. Appl. Microbiol. 2008, 46, 536–541. [Google Scholar] [CrossRef]

- Kranzler, M.; Stollewerk, K.; Rouzeau-Szynalski, K.; Blayo, L.; Sulyok, M.; Ehling-Schulz, M. Temperature Exerts Control of Bacillus Cereus Emetic Toxin Production on Post-Transcriptional Levels. Front. Microbiol. 2016, 7, 1640. [Google Scholar] [CrossRef] [Green Version]

- Collins, L.; Franzblau, S.G. Microplate Alamar Blue Assay Versus Bactec 460 System for High-Throughput Screening of Compounds against Mycobacterium Tuberculosis and Mycobacterium Avium. Antimicrob. Agents Chemother. 1997, 41, 1004–1009. [Google Scholar] [CrossRef] [Green Version]

- Bauer, T.; Stark, T.; Hofmann, T.; Ehling-Schulz, M. Development of a Stable Isotope Dilution Analysis for the Quantification of the Bacillus Cereus Toxin Cereulide in Foods. J. Agric. Food Chem. 2010, 58, 1420–1428. [Google Scholar] [CrossRef]

- Stark, T.; Marxen, S.; Rütschle, A.; Lücking, G.; Scherer, S.; Ehling-Schulz, M.; Hofmann, T. Mass Spectrometric Profiling of Bacillus Cereus Strains and Quantitation of the Emetic Toxin Cereulide by Means of Stable Isotope Dilution Analysis and Hep-2 Bioassay. Anal. Bioanal. Chem. 2013, 405, 191–201. [Google Scholar] [CrossRef] [PubMed]

- Frenzel, E.; Letzel, T.; Scherer, S.; Ehling-Schulz, M. Inhibition of Cereulide Toxin Synthesis by Emetic Bacillus Cereus Via Long-Chain Polyphosphates. Appl. Environ. Microbiol. 2011, 77, 1475–1482. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Adewunmi, Y.; Namjilsuren, S.; Walker, W.D.; Amato, D.N.; Amato, D.V.; Mavrodi, O.V.; Patton, D.L.; Mavrodi, D.V. Antimicrobial Activity of, and Cellular Pathways Targeted by, P-Anisaldehyde and Epigallocatechin Gallate in the Opportunistic Human Pathogen Pseudomonas Aeruginosa. Appl. Environ. Microbiol. 2020, 86, e02482-19. [Google Scholar] [CrossRef] [PubMed]

- Chen, H.; Zhong, Q. Antibacterial Activity of Acidified Sodium Benzoate against Escherichia Coli O157:H7, Salmonella Enterica, and Listeria Monocytogenes in Tryptic Soy Broth and on Cherry Tomatoes. Int. J. Food Microbiol. 2018, 274, 38–44. [Google Scholar] [CrossRef]

- Del Olmo, A.; Calzada, J.; Nunez, M. Benzoic Acid and Its Derivatives as Naturally Occurring Compounds in Foods and as Additives: Uses, Exposure, and Controversy. Crit. Rev. Food Sci. Nutr. 2017, 57, 3084–3103. [Google Scholar] [CrossRef]

- Fitzgerald, D.J.; Stratford, M.; Gasson, M.J.; Ueckert, J.; Bos, A.; Narbad, A. Mode of Antimicrobial Action of Vanillin against Escherichia Coli, Lactobacillus Plantarum and Listeria Innocua. J. Appl. Microbiol. 2004, 97, 104–113. [Google Scholar] [CrossRef]

- Kubo, I.; Fujita, K.; Nihei, K. Antimicrobial Activity of Anethole and Related Compounds from Aniseed. J. Sci. Food Agric. 2008, 88, 242–247. [Google Scholar] [CrossRef]

- Luo, X.J.; Peng, J.; Li, Y.J. Recent Advances in the Study on Capsaicinoids and Capsinoids. Eur. J. Pharmacol. 2011, 650, 1–7. [Google Scholar] [CrossRef]

- Marchiani, A.; Rozzo, C.; Fadda, A.; Delogu, G.; Ruzza, P. Curcumin and Curcumin-Like Molecules: From Spice to Drugs. Curr. Med. Chem. 2014, 21, 204–222. [Google Scholar] [CrossRef]

- Park, M.; Bae, J.; Lee, D.S. Antibacterial Activity of [10]-Gingerol and [12]-Gingerol Isolated from Ginger Rhizome against Periodontal Bacteria. Phytother. Res. 2008, 22, 1446–1449. [Google Scholar] [CrossRef]

- Srinivasan, K. Biological Activities of Red Pepper (Capsicum Annuum) and Its Pungent Principle Capsaicin: A Review. Crit. Rev. Food Sci. Nutr. 2016, 56, 1488–1500. [Google Scholar] [CrossRef]

- Bohlmann, J.; Keeling, C.I. Terpenoid Biomaterials. Plant. J. 2008, 54, 656–669. [Google Scholar] [CrossRef]

- Guimarães, A.C.; Meireles, L.M.; Lemos, M.F.; Guimarães, M.C.C.; Endringer, D.C.; Fronza, M.; Scherer, R. Antibacterial Activity of Terpenes and Terpenoids Present in Essential Oils. Molecules 2019, 24, 2471. [Google Scholar] [CrossRef] [Green Version]

- Trombetta, D.; Castelli, F.; Sarpietro, M.G.; Venuti, V.; Cristani, M.; Daniele, C.; Saija, A.; Mazzanti, G.; Bisignano, G. Mechanisms of Antibacterial Action of Three Monoterpenes. Antimicrob. Agents Chemother. 2005, 49, 2474–2478. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Morcia, C.; Malnati, M.; Terzi, V. In Vitro Antifungal Activity of Terpinen-4-Ol, Eugenol, Carvone, 1,8-Cineole (Eucalyptol) and Thymol against Mycotoxigenic Plant Pathogens. Food Addit. Contam. Part A Chem. Anal. Control Expo. Risk Assess. 2012, 29, 415–422. [Google Scholar]

- Wang, X.; Tian, L.; Fu, J.; Liao, S.; Yang, S.; Jia, X.; Gong, G. Evaluation of the Membrane Damage Mechanism of Thymol against Bacillus Cereus and Its Application in the Preservation of Skim Milk. Food Control 2022, 131, 108435. [Google Scholar] [CrossRef]

- Xu, J.; Zhou, F.; Ji, B.P.; Pei, R.S.; Xu, N. The Antibacterial Mechanism of Carvacrol and Thymol against Escherichia Coli. Lett. Appl. Microbiol. 2008, 47, 174–179. [Google Scholar] [CrossRef] [PubMed]

- Alam, M.A.; Subhan, N.; Hossain, H.; Hossain, M.; Reza, H.M.; Rahman, M.M.; Ullah, M.O. Hydroxycinnamic Acid Derivatives: A Potential Class of Natural Compounds for the Management of Lipid Metabolism and Obesity. Nutr. Metab. 2016, 13, 27. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- El-Seedi, H.R.; El-Said, A.M.; Khalifa, S.A.; Goransson, U.; Bohlin, L.; Borg-Karlson, A.K.; Verpoorte, R. Biosynthesis, Natural Sources, Dietary Intake, Pharmacokinetic Properties, and Biological Activities of Hydroxycinnamic Acids. J. Agric. Food Chem. 2012, 60, 10877–10895. [Google Scholar] [CrossRef]

- O’Byrne, S.M.; Blaner, W.S. Retinol and Retinyl Esters: Biochemistry and Physiology. J. Lipid Res. 2013, 54, 1731–1743. [Google Scholar] [CrossRef] [Green Version]

- Boonnoy, P.; Karttunen, M.; Wong-Ekkabut, J. Does Alpha-Tocopherol Flip-Flop Help to Protect Membranes against Oxidation? J. Phys. Chem. B 2018, 122, 10362–10370. [Google Scholar] [CrossRef]

- Chatron, N.; Hammed, A.; Benoit, E.; Lattard, V. Structural Insights into Phylloquinone (Vitamin K1), Menaquinone (Mk4, Mk7), and Menadione (Vitamin K3) Binding to Vkorc1. Nutrients 2019, 11, 67. [Google Scholar] [CrossRef] [Green Version]

- Zengin, H.; Baysal, A.H. Antibacterial and Antioxidant Activity of Essential Oil Terpenes against Pathogenic and Spoilage-Forming Bacteria and Cell Structure-Activity Relationships Evaluated by Sem Microscopy. Molecules 2014, 19, 17773–17798. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Schlievert, P.M.; Merriman, J.A.; Salgado-Pabon, W.; Mueller, E.A.; Spaulding, A.R.; Vu, B.G.; Chuang-Smith, O.N.; Kohler, P.L.; Kirby, J.R. Menaquinone Analogs Inhibit Growth of Bacterial Pathogens. Antimicrob. Agents Chemother. 2013, 57, 5432–5437. [Google Scholar] [CrossRef] [Green Version]

- Andrade, J.C.; Braga, M.F.B.M.; Guedes, G.M.M.; Tintino, S.R.; Freitas, M.A.; Quintans, L.J., Jr.; Menezes, I.R.A.; Coutinho, H.D.M. Menadione (Vitamin K) Enhances the Antibiotic Activity of Drugs by Cell Membrane Permeabilization Mechanism. Saudi J. Biol. Sci. 2017, 24, 59–64. [Google Scholar] [CrossRef] [Green Version]

- EFSA Panel on Additives and Products or Substances used in Animal Feed (FEEDAP). Scientific Opinion on the Safety and Efficacy of Vitamin K3 (Menadione Sodium Bisulphite and Menadione Nicotinamide Bisulphite) as a Feed Additive for All Animal Species. EFSA J. 2014, 12, 3532. [Google Scholar]

- Marsh, S.K.; Myers, D.J.; Stahr, H.M. Effects of Phosphate Solutions on Aflatoxin Production in a Synthetic Medium and in Frankfurters†. J. Food Prot. 1996, 59, 626–630. [Google Scholar] [CrossRef]

- Wagner, M.K.; Busta, F.F. Inhibition of Clostridium Botulinum 52a Toxicity and Protease Activity by Sodium Acid Pyrophosphate in Media Systems. Appl. Environ. Microbiol. 1985, 50, 16–20. [Google Scholar] [CrossRef] [Green Version]

- Cermak, P.; Olsovska, J.; Mikyska, A.; Dusek, M.; Kadleckova, Z.; Vanicek, J.; Nyc, O.; Sigler, K.; Bostikova, V.; Bostik, P. Strong Antimicrobial Activity of Xanthohumol and Other Derivatives from Hops (Humulus Lupulus L.) on Gut Anaerobic Bacteria. Apmis 2017, 125, 1033–1038. [Google Scholar] [CrossRef]

- Hiserodt, R.D.; Franzblau, S.G.; Rosen, R.T. Isolation of 6-, 8-, and 10-Gingerol from Ginger Rhizome by Hplc and Preliminary Evaluation of Inhibition of Mycobacterium Avium and Mycobacterium Tuberculosis. J. Agric. Food Chem. 1998, 46, 2504–2508. [Google Scholar] [CrossRef]

- Xia, K.; Zhang, G.; Li, S.; Gong, D. Groove Binding of Vanillin and Ethyl Vanillin to Calf Thymus DNA. J. Fluoresc. 2017, 27, 1815–1828. [Google Scholar] [CrossRef] [PubMed]

- Marini, E.; Magi, G.; Mingoia, M.; Pugnaloni, A.; Facinelli, B. Antimicrobial and Anti-Virulence Activity of Capsaicin against Erythromycin-Resistant, Cell-Invasive Group a Streptococci. Front. Microbiol. 2015, 6, 1281. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Tyagi, P.; Singh, M.; Kumari, H.; Kumari, A.; Mukhopadhyay, K. Bactericidal Activity of Curcumin I Is Associated with Damaging of Bacterial Membrane. PLoS ONE 2015, 10, e0121313. [Google Scholar] [CrossRef] [Green Version]

- Asher, G.N.; Spelman, K. Clinical Utility of Curcumin Extract. Altern. Ther. Health Med. 2013, 19, 20–22. [Google Scholar]

- Gallucci, M.N.; Oliva, M.; Casero, C.; Dambolena, J.; Luna, A.; Zygadlo, J.; Demo, M. Antimicrobial Combined Action of Terpenes against the Food-Borne Microorganisms Escherichia Coli, Staphylococcus Aureus and Bacillus Cereus. Flavour Fragr. J. 2009, 24, 348–354. [Google Scholar] [CrossRef]

- Shi, C.; Song, K.; Zhang, X.; Sun, Y.; Sui, Y.; Chen, Y.; Jia, Z.; Sun, H.; Sun, Z.; Xia, X. Antimicrobial Activity and Possible Mechanism of Action of Citral against Cronobacter Sakazakii. PLoS ONE 2016, 11, e0159006. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Sarwar, T.; Ishqi, H.M.; Rehman, S.U.; Husain, M.A.; Rahman, Y.; Tabish, M. Caffeic Acid Binds to the Minor Groove of Calf Thymus DNA: A Multi-Spectroscopic, Thermodynamics and Molecular Modelling Study. Int. J. Biol. Macromol. 2017, 98, 319–328. [Google Scholar] [CrossRef]

- Kępa, M.; Miklasińska-Majdanik, M.; Wojtyczka, R.D.; Idzik, D.; Korzeniowski, K.; Smoleń-Dzirba, J.; Wąsik, T.J. Antimicrobial Potential of Caffeic Acid against Staphylococcus Aureus Clinical Strains. BioMed Res. Int. 2018, 2018, 7413504. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Turnbull, P.C.; Kramer, J.M.; Jørgensen, K.; Gilbert, R.J.; Melling, J. Properties and Production Characteristics of Vomiting, Diarrheal, and Necrotizing Toxins of Bacillus Cereus. Am. J. Clin. Nutr. 1979, 32, 219–228. [Google Scholar] [CrossRef]

- Marxen, S.; Stark, T.D.; Rütschle, A.; Lücking, G.; Frenzel, E.; Scherer, S.; Ehling-Schulz, M.; Hofmann, T. Multiparametric Quantitation of the Bacillus cereus Toxins Cereulide and Isocereulides A-G in Foods. J. Agric. Food Chem. 2015, 63, 8307–8313. [Google Scholar] [CrossRef] [PubMed]

| Benzene Derivatives | Stock Solution | Monoterpenes | Stock Solution | Hydroxycinnamic Acids | Stock Solution |

|---|---|---|---|---|---|

| Anisaldehyde | ≥97.5% * | Camphor | 100% (1 g/mL) | Caffeic acid | 5% (50 mg/mL) |

| Carvacrol | 99% * | Chlorogenic acid | 25% (0.25 g/mL) | ||

| p-Anisic acid | 1.7% (0.01 g/mL) | (R)-Carvone | 98% * | Cinnamic acid | 50% (0.5 g/mL) |

| Anisole | ≥99% * | (S)-Carvone | 96% * | p-Coumaric acid | 10% (0.1 g/mL) |

| Benzaldehyde | ≥99.5% * | Citral | 95% * | Coumarin | 50% (0.5 g/mL) |

| Benzoic acid | 50% (0.5 g/mL) | Cuminaldehyde | 98% * | Ferulic acid | 10% (0.1 g/mL) |

| Capsaicin | 1% (0.01 g/mL) | Eucalyptol | 99% * | Rosmarinic acid | 12.5% (0.125 g/mL) |

| Curcumin | 0.3% (0.003 g/mL) | Geraniol | 98% * | Sinapinic acid | 5% (0.05 g/mL) |

| [8]-Gingerol | 0.1% (0.001 g/mL) | Menthol | 99% * | Vitamins | Stock solution |

| Juglone | 1% (0.01 g/mL) | Myrcene | 100% * | Menadione | 5% (0.05 g/mL) |

| Salicylic acid | 10% (0.1 g/mL) | Nerol | 100% * | Retinol | 25% (0.25 g/mL) |

| Sodium benzoate ** | 10% (0.1 g/mL) | α-Phellandrene | ≥85% * | Menaquinone | 25% (0.25 g/mL) |

| Vanillin | 50% (0.5 g/mL) | Sabinene | 75% * | Phylloquinone | ≥97% * |

| Xanthohumol | 0.1% (0.01 g/mL) | Thymol | 50% (0.5 g/mL) | α-Tocopherol | ≥96% * |

| Substances leading to growth inhibition (Viability < 5%) | |||

|---|---|---|---|

| Substance | MIC (mg/mL) | Cereulide (%) | Viability (%) |

| Benzene derivatives | |||

| Anisaldehyde | 5.0 | - | - |

| p-Anisic acid | 1.7 | ||

| Benzaldehyde | 5.0 | ||

| Benzoic acid | 2.5 | ||

| Capsaicin * | 0.1 | ||

| Curcumin * | 0.07 | ||

| [8]-Gingerol * | 0.01 | ||

| Juglone * | 0.1 | ||

| Salicylic acid | 1.0 | - | - |

| Sodium benzoate | 10.0 | 1.3 ± 1.1 | |

| Vanillin | 2.5 | - | |

| Xanthohumol * | 6 × 10−3 | 0.8 | |

| Monoterpenes | |||

| Camphor | 10.0 | - | 0.4 ± 0.1 |

| Carvacrol | 0.2 | - | |

| (R)-Carvone | 20.0 | - | |

| (S)-Carvone | 20.0 | 0.6 ± 0.4 | |

| Citral | 0.4 | 1.9 ± 1.0 | |

| Cuminaldehyde | 2.5 | - | |

| Eucalyptol | 40.0 | 0.2 ± 0.0 | |

| Geraniol | 0.4 | - | |

| Menthol | 1.0 | ||

| Nerol | 1.0 | ||

| α-phellandrene | 40.0 | 0.5 ± 0.2 | |

| Thymol | 0.2 | - | |

| Hydroxycinnamic acid derivatives | |||

| Chlorogenic acid | 5.0 | - | 2.1 ± 1.8 |

| Cinnamic acid | 2.5 | - | |

| p-Coumaric acid | 1.0 | ||

| Coumarin | 10.0 | ||

| Ferulic acid | 1.0 | ||

| Rosmarinic acid | 2.5 | ||

| Vitamins | |||

| Menadione | 0.02 * | - | - |

| Retinol | 0.05 * | - | |

| Substances no/moderate growth inhibitory effect (viability > 85%) but leading to decreased cereulide production (<15%) | |||

| Substance | MIC (mg/mL) | Cereulide (%) | Viability (%) |

| Benzene derivatives | |||

| Anisole | 40.0 | - | 131.6 ± 22.9 |

| Curcumin * | 0.03 | 0.1 | 92.3 ± 28.6 |

| [8]-Gingerol * | 5 × 10−3 | 12.6 | 88.6 ± 4.3 |

| Juglone * | 0.05 | - | 109.0 ± 4.7 |

| Sodium benzoate | 5.0 | - | 117.2 ± 6.3 |

| Vanillin | 0.8 | - | 98.2 ± 1.3 |

| Monoterpenes | |||

| Citral | 0.2 | - | 133.5 ± 27.2 |

| 0.1 | 0.2 | 155.7 ± 31.4 | |

| Myrcene | 10.0 | - | 149.5 ± 3.0 |

| 5.0 | - | 119.8 ± 7.9 | |

| Nerol | 0.5 | - | 173.0 ± 24.3 |

| 0.25 | - | 127.5 ± 22.2 | |

| Hydroxycinnamic acid derivatives | |||

| Caffeic acid | 0.25 | 7.8 | 89.5 ± 9.4 |

| Cinnamic acid | 0.5 | 0.2 | 94.7 ± 12.0 |

| Ferulic acid | 0.5 | 1.6 | 89.6 ± 1.3 |

| Rosmarinic acid | 0.625 | - | 83.4 ± 9.1 |

| Sinapinic acid | 1.0 | 9.6 | 113.1 ± 8.6 |

| Vitamins | |||

| Menadione * | 2 × 10−3 | - | 87.5 ± 13.3 |

| 2 × 10−4 | 8.1 | 101.4 ± 33.5 | |

| Phylloquinone | 10.0 | 12.8 | 89.9 ± 12.7 |

| 5.0 | 12.3 | 110.0 ± 4.4 | |

| Retinol | 5 × 10−4 | 11.2 | 108.8 ± 16.0 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kranzler, M.; Frenzel, E.; Walser, V.; Hofmann, T.F.; Stark, T.D.; Ehling-Schulz, M. Impact of Phytochemicals on Viability and Cereulide Toxin Synthesis in Bacillus cereus Revealed by a Novel High-Throughput Method, Coupling an AlamarBlue-Based Assay with UPLC-MS/MS. Toxins 2021, 13, 672. https://doi.org/10.3390/toxins13090672

Kranzler M, Frenzel E, Walser V, Hofmann TF, Stark TD, Ehling-Schulz M. Impact of Phytochemicals on Viability and Cereulide Toxin Synthesis in Bacillus cereus Revealed by a Novel High-Throughput Method, Coupling an AlamarBlue-Based Assay with UPLC-MS/MS. Toxins. 2021; 13(9):672. https://doi.org/10.3390/toxins13090672

Chicago/Turabian StyleKranzler, Markus, Elrike Frenzel, Veronika Walser, Thomas F. Hofmann, Timo D. Stark, and Monika Ehling-Schulz. 2021. "Impact of Phytochemicals on Viability and Cereulide Toxin Synthesis in Bacillus cereus Revealed by a Novel High-Throughput Method, Coupling an AlamarBlue-Based Assay with UPLC-MS/MS" Toxins 13, no. 9: 672. https://doi.org/10.3390/toxins13090672

APA StyleKranzler, M., Frenzel, E., Walser, V., Hofmann, T. F., Stark, T. D., & Ehling-Schulz, M. (2021). Impact of Phytochemicals on Viability and Cereulide Toxin Synthesis in Bacillus cereus Revealed by a Novel High-Throughput Method, Coupling an AlamarBlue-Based Assay with UPLC-MS/MS. Toxins, 13(9), 672. https://doi.org/10.3390/toxins13090672