Rapid Compaction Monitoring and Quality Control of Embankment Dam Construction Based on UAV Photogrammetry Technology: A Case Study

Abstract

1. Introduction

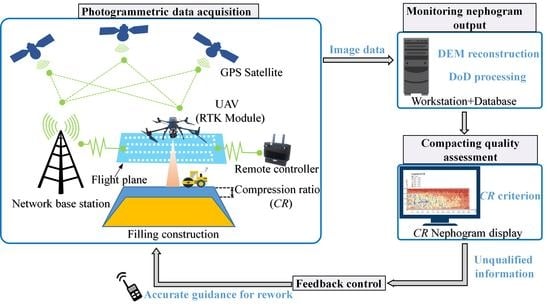

2. Methods

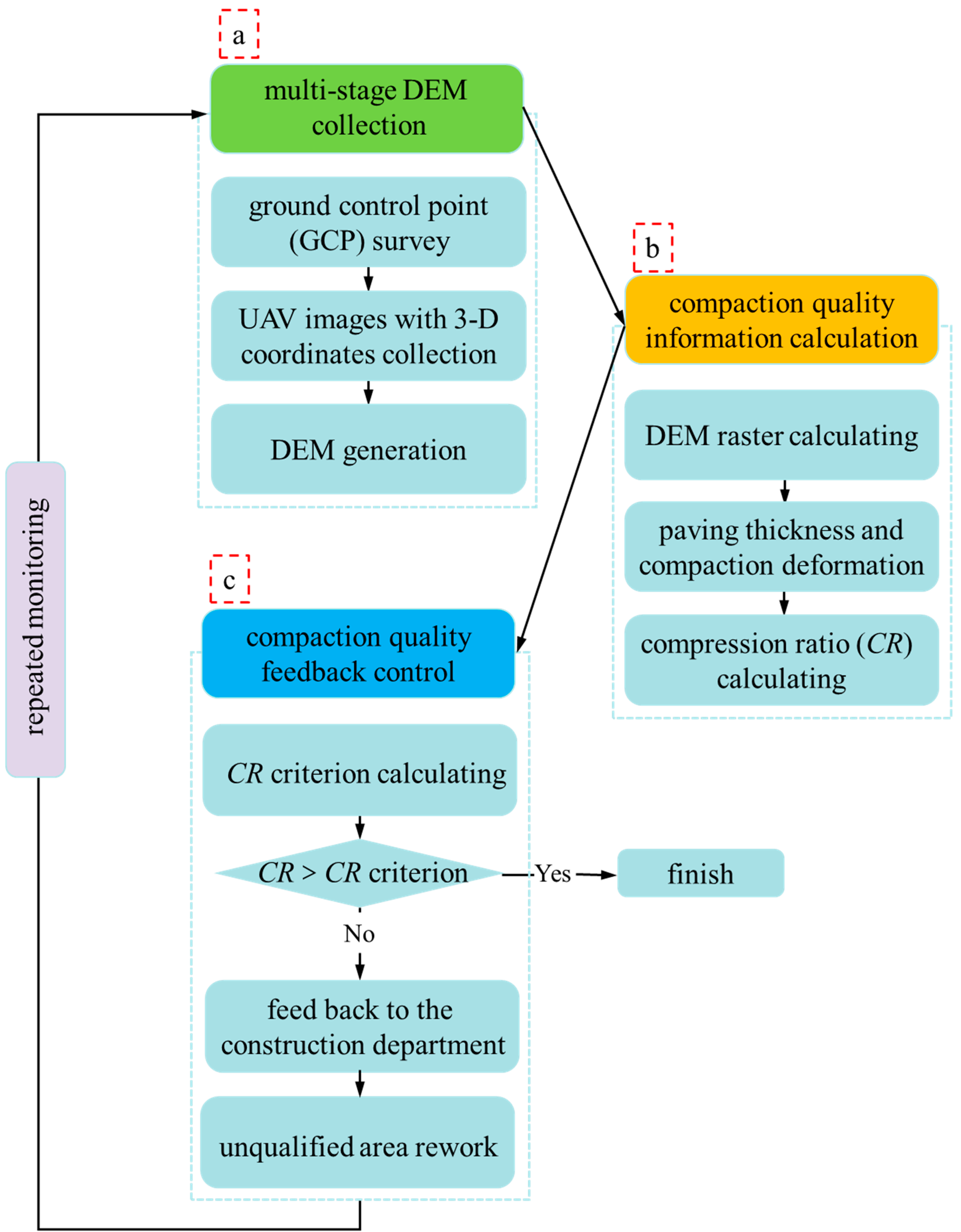

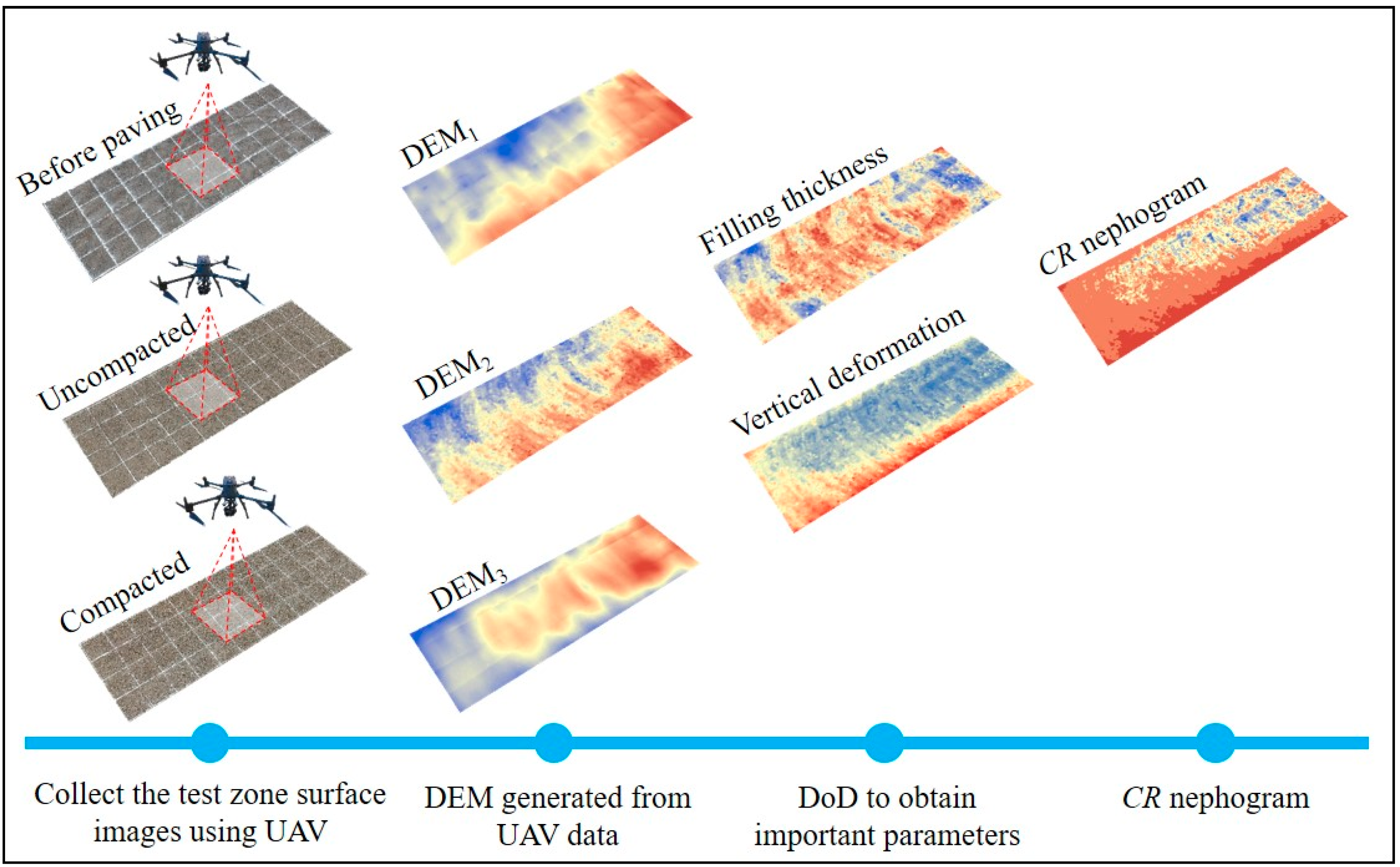

2.1. Multi-Stage DEM Collection

2.2. Compaction Quality Information

2.3. Compaction Quality Control

3. Case Study

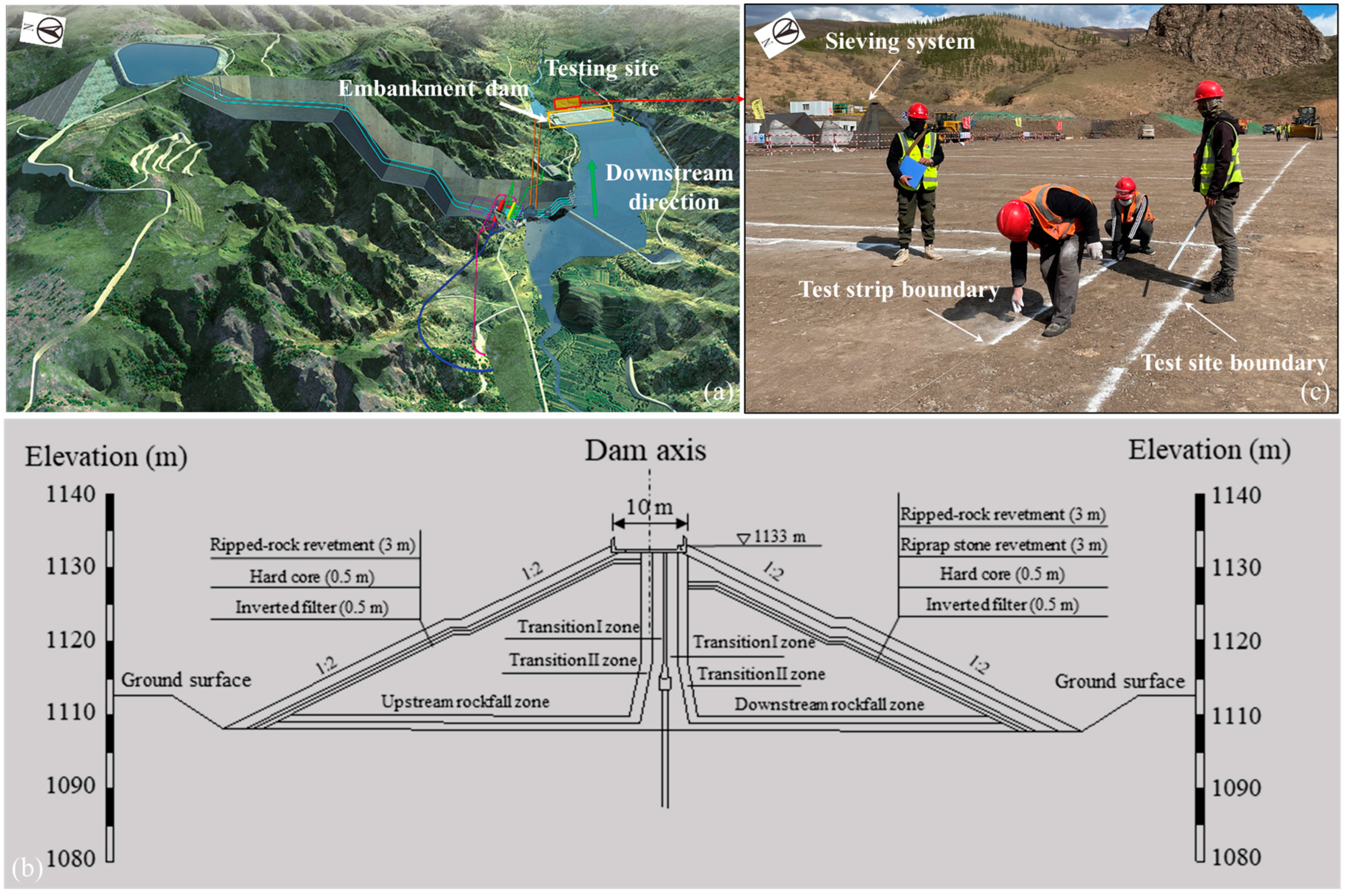

3.1. Study Area and Materials

3.2. Test Procedure

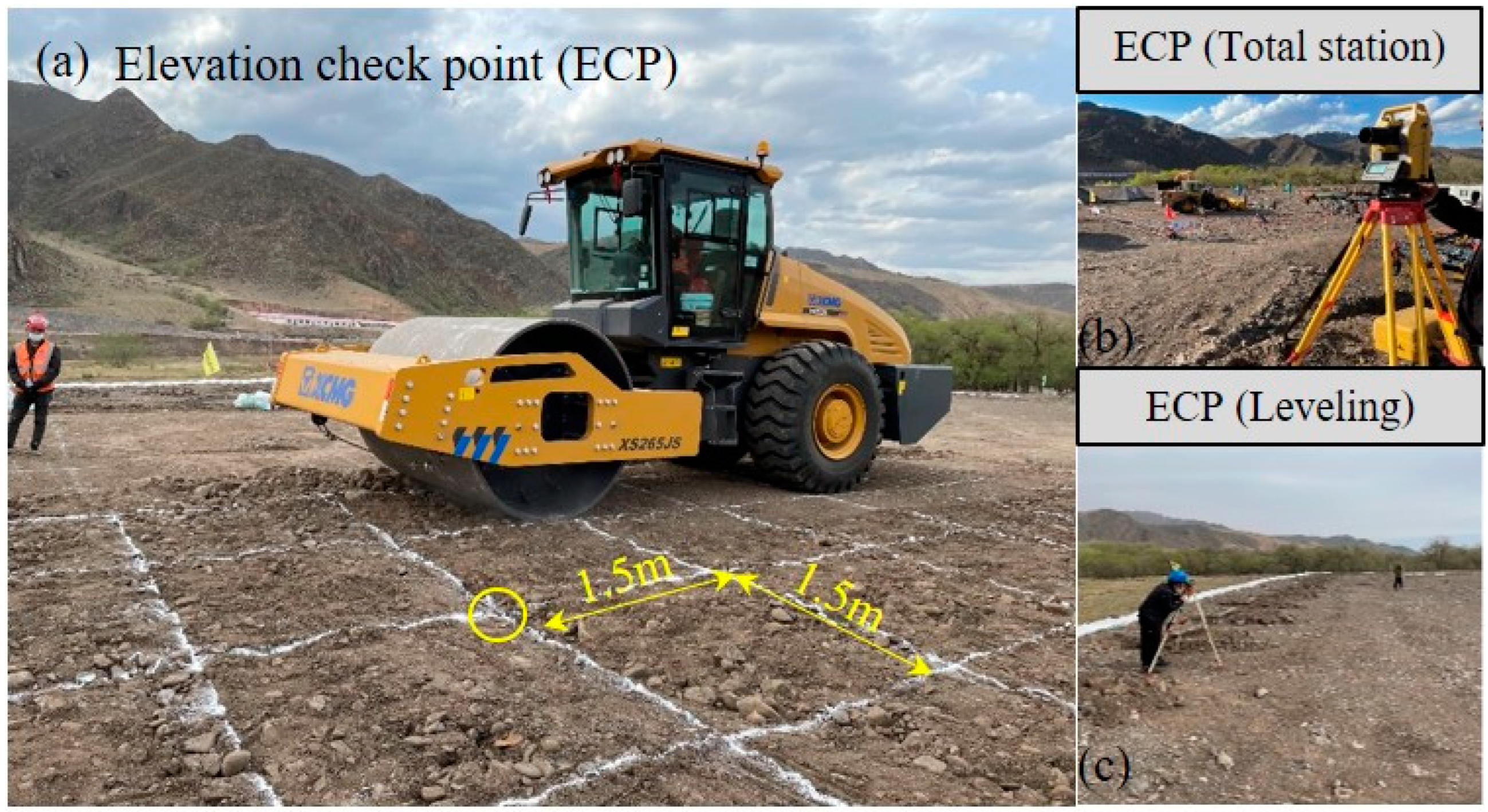

3.3. High-Precision Data Acquisition

3.3.1. UAV Photogrammetric Survey

3.3.2. Establishment of High-Precision Spatial Reference

3.4. Three-Dimensional DEM Modeling and Precision Evaluation

3.4.1. Three-Dimensional DEM Reconstruction

3.4.2. Precision Evaluation of DEM

4. Results

4.1. CR Nephogram and Compaction Quality Control

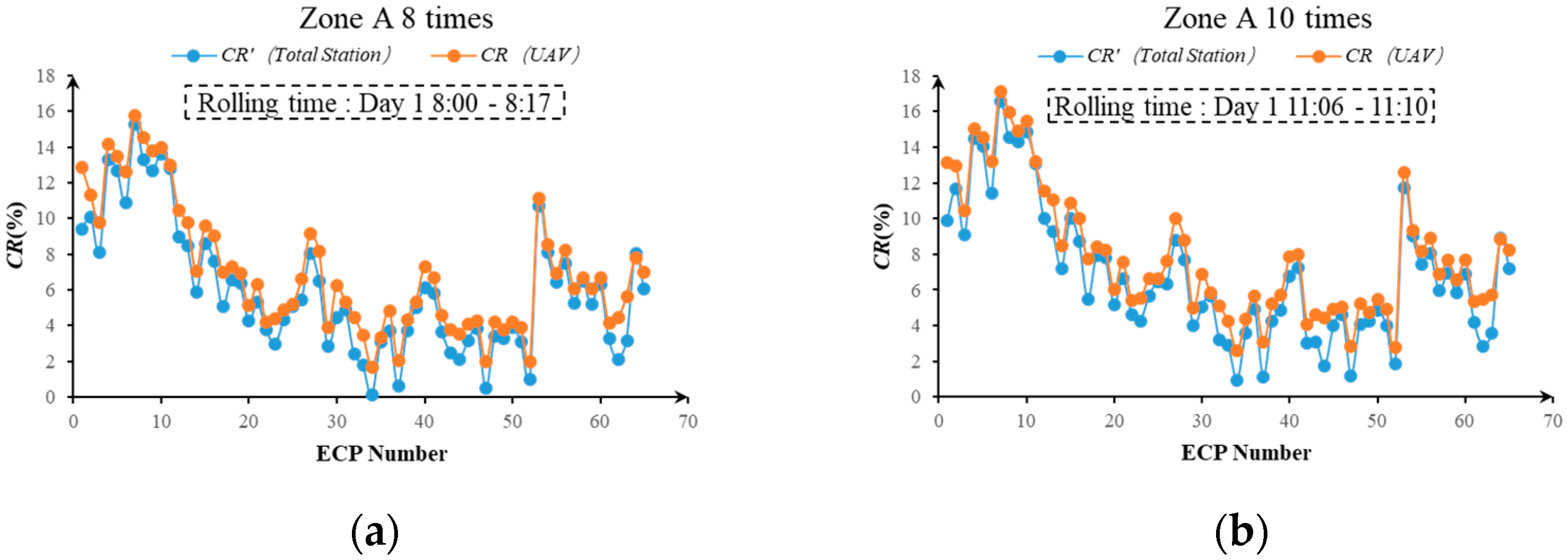

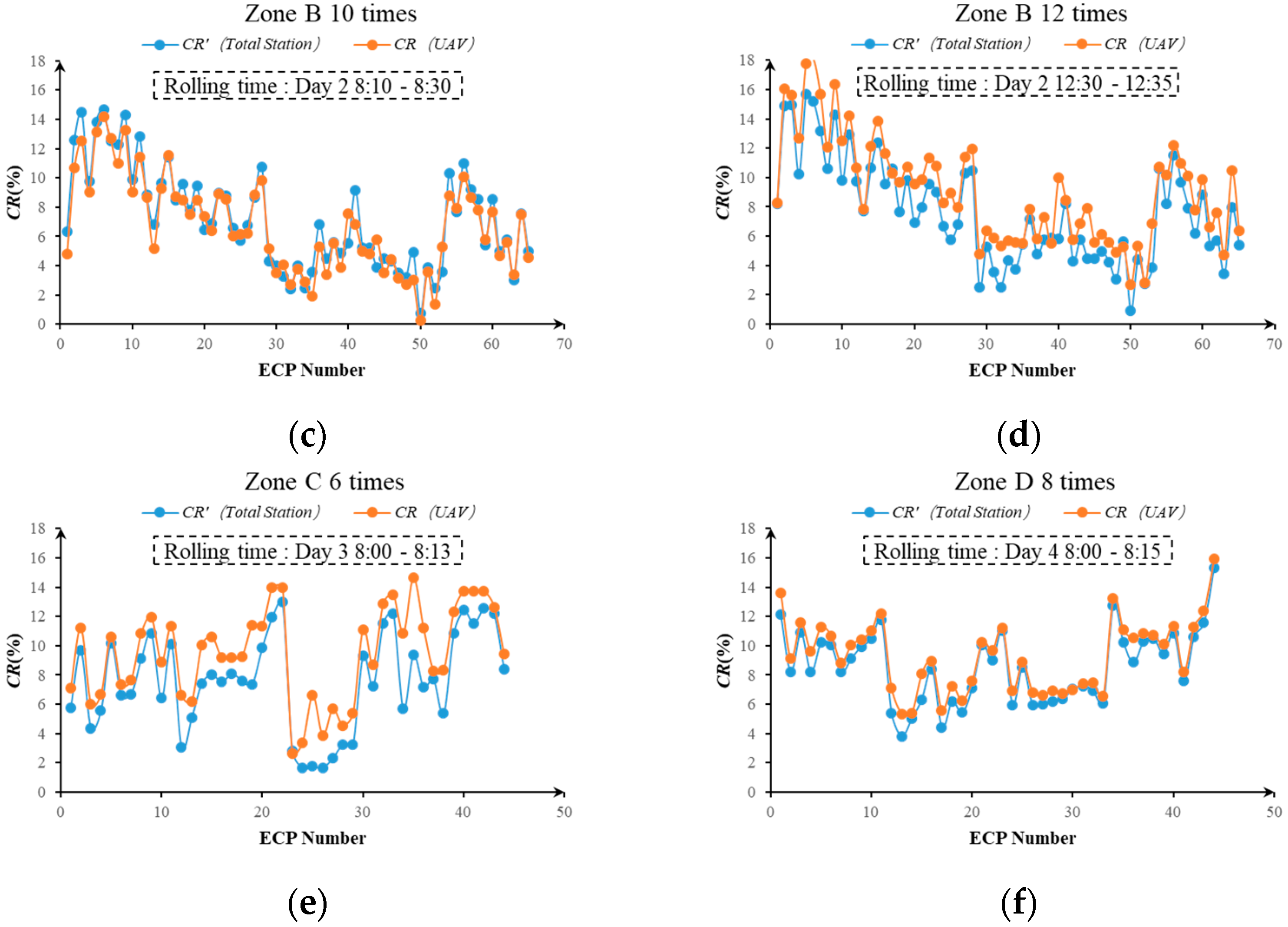

4.2. Verification of UAV-Based CR Method

5. Discussion

6. Conclusions

- (1)

- UAV photogrammetry technology can be used to monitor the quality of compaction. The verification results show that the mean absolute errors (MAE) of CR are close to 0.715% (compared with leveling survey), the corresponding settlement errors are millimeters, and the standard deviations (SD) of CR errors are 0.59 (compared with leveling survey). The accuracy of the new method is close to that of the manual method, and the dispersion degree is low, indicating that the proposed method is reasonable.

- (2)

- This method can monitor compaction quality visually and quickly without time-consuming, labor-intensive manual measurement. The verification results show that the efficiency of the new method can reach five times that of the traditional method as long as appropriate equipment is selected. Therefore, this method improves the efficiency of filling quality monitoring.

- (3)

- A quality control system combining UAV photogrammetry technology with computer graphic technology is proposed. The traditional rolling machine equipped with GNSS RTK can monitor only the elevation variation along the track line. While the proposed system can achieve full coverage and continuous evaluation of compaction quality. The visual compaction information is helpful to improve the compaction quality of embankment dam construction.

- (4)

- The successful application of this method has made a positive, beneficial exploration for the dam construction from automation to intelligence and low carbon. However, the CR criterion proposed in the present study may be not applicable to different materials, compaction quality standards, and construction environments. Therefore, extensive field experiments should be conducted to collect adequate data for evaluating the performance of the CR method in different projects.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Vaughan, P.R.; Kluth, D.J.; Leonard, M.W.; Pradoura, H.H.M. Cracking and erosion of the rolled clay core of Balderhead Dam and the remedial works adopted for its repair. In Selected Papers on Geotechnical Engineering; Thomas Telford Publishing: London, UK, 2009. [Google Scholar]

- Uddin, N. Lessons Learned: Failure of a Hydroelectric Power Project Dam. J. Perform. Constr. Facil. 2005, 19, 69–77. [Google Scholar] [CrossRef]

- Chen, H.; Liu, D.; Qi, L. Spatial Estimation of Material Parameters and Refined Finite-Element Analysis of Rockfill Dam Based on Construction Digitization. Int. J. Géoméch. 2018, 18, 04018119. [Google Scholar] [CrossRef]

- U.S. Army Corps of Engineers (USACE). Engineering and Design of Roller-Compacted Concrete; Engineer Manual (EM) 1110-2-2006; U.S. Army Corps of Engineers (USACE): Washington, DC, USA, 2000. [Google Scholar]

- Liu, D.H.; Yang, J.Q.; Dong, B. Discrete element analysis of the influence of compaction quality on mechanical properties of rockfill materials. Comput. Geotech. 2022, 151, 104958. [Google Scholar] [CrossRef]

- Meehan, C.L.; Khosravi, M.; Cacciola, D. Monitoring Field Lift Thickness Using Compaction Equipment Instrumented with Global Positioning System (GPS) Technology. Geotech. Test. J. 2013, 36, 755–767. [Google Scholar] [CrossRef]

- Cacciola, D.V.; Khosravi, M.; Meehan, C.L. Using Compaction Equipment Instrumented with Global Positioning System (GPS) Technology to Monitor Field Lift Thickness. Geo-Congr. Tech. Pap. 2014, 2630–2639. [Google Scholar] [CrossRef]

- Kumar, S.A.; Aldouri, R.; Nazarian, S.; Si, J. Accelerated assessment of quality of compacted geomaterials with intelligent compaction technology. Constr. Build. Mater. 2016, 113, 824–834. [Google Scholar] [CrossRef]

- Zhong, D.; Liu, D.; Cui, B. Real-time compaction quality monitoring of high core rockfill dam. Sci. China Technol. Sci. 2011, 54, 1906–1913. [Google Scholar] [CrossRef]

- Zhang, Q.L.; An, Z.Z.; Huangfu, Z.H.; Li, Q.B. A Review on Roller Compaction Quality Control and Assurance Methods for Earthwork in Five Application Scenarios. Materials 2022, 15, 2610. [Google Scholar] [CrossRef]

- Zhang, Q.; Liu, T.; Zhang, Z.; Huangfu, Z.; Li, Q.; An, Z. Unmanned rolling compaction system for rockfill materials. Autom. Constr. 2019, 100, 103–117. [Google Scholar] [CrossRef]

- Chen, C.; Hu, Y.; Jia, F.; Wang, X. Intelligent compaction quality evaluation based on multi-domain analysis and artificial neural network. Constr. Build. Mater. 2022, 341, 127583. [Google Scholar] [CrossRef]

- Liu, D.; Lin, M.; Li, S. Real-Time Quality Monitoring and Control of Highway Compaction. Autom. Constr. 2016, 62, 114–123. [Google Scholar] [CrossRef]

- Wang, N.; Ma, T.; Chen, F.; Ma, Y. Compaction quality assessment of cement stabilized gravel using intelligent compaction technology—A case study. Constr. Build. Mater. 2022, 345, 128100. [Google Scholar] [CrossRef]

- Dawei, Z.; Lizhuang, Q.; Demin, Z.; Baohui, Z.; Lianglin, G. Unmanned Aerial Vehicle (UAV) Photogrammetry Technology for Dynamic Mining Subsidence Monitoring and Parameter Inversion: A Case Study in China. IEEE Access 2020, 8, 16372–16386. [Google Scholar] [CrossRef]

- Krishnamurthy, B.K.; Tserng, H.-P.; Schmitt, R.L.; Russell, J.S.; Bahia, H.U.; Hanna, A.S. AutoPave: Towards an automated paving system for asphalt pavement compaction operations. Autom. Constr. 1998, 8, 165–180. [Google Scholar] [CrossRef]

- Liu, D.; Li, Z.; Liu, J. Experimental study on real-time control of roller compacted concrete dam compaction quality using unit compaction energy indices. Constr. Build. Mater. 2015, 96, 567–575. [Google Scholar] [CrossRef]

- Xu, P.; Zhu, X.; Qiao, S.; Wang, G.; Yu, P. Field Study of Compaction Quality Control Parameters and Compaction Mechanism of Large Particle Size Stone-filled Embankment. Rock Mech. Rock Eng. 2022, 55, 3687–3702. [Google Scholar] [CrossRef]

- Weng, C.C.; Wu, H.; Liu, X.D.; Du, Z.Y.; Shi, L.; Feng, Y.Q.; Yang, J.; Yuan, L.Y. A Novel Integration of GNSS and GIS Approach to Foundation Roller Compaction in Civil Engineering. Adv. Mater. Res. 2012, 468–471, 186–189. [Google Scholar] [CrossRef]

- Pampagnin, L.H.; Peyret, F.; Garcia, G. Architecture of a GPS-based guiding system for road compaction. In Proceedings of the 1988 IEEE International Conference on Robotics & Automation, Leuven, Belgium, 20 May 1998; pp. 2422–2427. [Google Scholar]

- Oloufa, A.A.; Do, W.S.; Thomas, H.R. An automated system for quality control of compaction operations: Receiver tests & algorithms. In Proceedings of the 16th International Symposium on Automation and Robotics in Construction, Madrid, Spain, 22–24 September 1999; pp. 67–71. [Google Scholar]

- Oloufa, A. Quality control of asphalt compaction using GPS-based system architecture. IEEE Robot. Autom. Mag. 2002, 9, 29–35. [Google Scholar] [CrossRef]

- Huang, S.X.; Liu, J.N.; Wu, X.M. GPS real-time supervisory system and its preliminary application in the construction of face rockfill dam. Geomat. Inf. Sci. Wuhan Univ. 2005, 30, 813–816. [Google Scholar]

- Zhang, J.; Chen, X.L.; Zhong, C.; Wu, H.; Duan, S.H. Application of geo-spatial information technology in the engineering manage of roller compaction construction. In Proceedings of the Geoscience and Remote Sensing Symposium, 2008 IEEE International-IGARSS, Boston, MA, USA, 7–11 July 2008. [Google Scholar]

- Huang, S.; Zhang, W. A fast calculation method of rolling times in the GNSS real-time compaction quality supervisory system. Adv. Eng. Softw. 2018, 128, 20–33. [Google Scholar] [CrossRef]

- Huang, S.; Zhang, W.; Wu, G. Research on Real-Time Supervisory System for Compaction Quality in Face Rockfill Dam Engineering. J. Sens. 2018, 2018, 6487405. [Google Scholar] [CrossRef]

- Liu, D.; Li, Z.; Lian, Z. Compaction quality assessment of earth-rock dam materials using roller-integrated compaction monitoring technology. Autom. Constr. 2014, 44, 234–246. [Google Scholar] [CrossRef]

- Li, Z.L.; Liu, L.; Sun, Y.C.; Ma, R.X.; Ge, G.S. Research and application of real-time control system for construction quality of digital dynamic compaction. In Proceedings of the 2018 IEEE 4th Information Technology and Mechatronics Engineering Conference (ITOEC), Chongqing, China, 14–16 December 2018. [Google Scholar]

- Zhang, Q.; An, Z.; Liu, T.; Zhang, Z.; Huangfu, Z.; Li, Q.; Yang, Q.; Liu, J. Intelligent rolling compaction system for earth-rock dams. Autom. Constr. 2020, 116, 103246. [Google Scholar] [CrossRef]

- Zhong, D.; Li, X.; Cui, B.; Wu, B.; Liu, Y. Technology and application of real-time compaction quality monitoring for earth-rockfill dam construction in deep narrow valley. Autom. Constr. 2018, 90, 23–38. [Google Scholar] [CrossRef]

- Zhang, Q.; Liu, T.; Zhang, Z.; Huangfu, Z.; Li, Q.; An, Z. Compaction quality assessment of rockfill materials using roller-integrated acoustic wave detection technique. Autom. Constr. 2019, 97, 110–121. [Google Scholar] [CrossRef]

- Zhang, Q.; Liu, T.; Li, Q. Roller-Integrated Acoustic Wave Detection Technique for Rockfill Materials. Appl. Sci. 2017, 7, 1118. [Google Scholar] [CrossRef]

- Yang, W.; Kong, Q.; Ho, S.C.M.; Mo, Y.-L.; Song, G. Real-Time Monitoring of Soil Compaction Using Piezoceramic-Based Embeddable Transducers and Wavelet Packet Analysis. IEEE Access 2018, 6, 5208–5214. [Google Scholar] [CrossRef]

- Wang, Z.M. Design and Implementation of Dynamic Compaction Quality Control System. Master’s thesis, Jilin University, Changchun, China, 2016. (In Chinese). [Google Scholar]

- Karray, M.; Lefebvre, G.; Ethier, Y.; Bigras, A. Assessment of deep compaction of the Péribonka dam foundation using “modal analysis of surface waves” (MASW). Can. Geotech. J. 2010, 47, 312–326. [Google Scholar] [CrossRef]

- Shi, M.N.; Wang, J.J.; Li, Q.H.; Cui, B.; Guan, S.W.; Zeng, T.C. Accelerated Earth-Rockfill Dam Compaction by Collaborative Operation of Unmanned Roller Fleet. J. Constr. Eng. Manag. 2022, 148, 04022046. [Google Scholar] [CrossRef]

- Cândido, B.M.; Quinton, J.N.; James, M.R.; Silva, M.L.N.; de Carvalho, T.S.; de Lima, W.; Beniaich, A.; Eltner, A. High-resolution monitoring of diffuse (sheet or interrill) erosion using structure-from-motion. Geoderma 2020, 375, 114477. [Google Scholar] [CrossRef]

- Yang, Y.; Shi, Y.Z.; Liang, X.Z.; Huang, T.T.; Fu, S.H.; Liu, B.Y. Evaluation of structure from motion (SfM) photogrammetry on the measurement of rill and interrill erosion in a typical loess. Geomorphology 2021, 385, 107734. [Google Scholar] [CrossRef]

- Daliakopoulos, I.N.; Tsanis, I.K. A SIFT-Based DEM Extraction Approach Using GEOEYE-1 Satellite Stereo Pairs. Sensors 2019, 19, 1123. [Google Scholar] [CrossRef]

- Yang, Z.; Sun, P.C.; Xie, Q.; Zhang, W.J.; Ye, K. The experiment of making DEM by GF3 Satellite Images. Sci. Surv. Mapp. 2020, 45, 53–60. (In Chinese) [Google Scholar]

- Nappo, N.; Mavrouli, O.; Nex, F.; van Westen, C.; Gambillara, R.; Michetti, A.M. Use of UAV-based photogrammetry products for semi-automatic detection and classification of asphalt road damage in landslide-affected areas. Eng. Geol. 2021, 294, 106363. [Google Scholar] [CrossRef]

- Menegoni, N.; Giordan, D.; Perotti, C.; Tannant, D.D. Detection and geometric characterization of rock mass discontinuities using a 3D high-resolution digital outcrop model generated from RPAS imagery—Ormea rock slope, Italy. Eng. Geol. 2019, 252, 145–163. [Google Scholar] [CrossRef]

- Cucchiaro, S.; Cazorzi, F.; Marchi, L.; Crema, S.; Beinat, A.; Cavalli, M. Multi-temporal analysis of the role of check dams in a debris-flow channel: Linking structural and functional connectivity. Geomorphology 2019, 345, 106844. [Google Scholar] [CrossRef]

- Cucchiaro, S.; Cavalli, M.; Vericat, D.; Crema, S.; Llena, M.; Beinat, A.; Marchi, L.; Cazorzi, F. Geomorphic effectiveness of check dams in a debris-flow catchment using multi-temporal topographic surveys. Catena 2019, 174, 73–83. [Google Scholar] [CrossRef]

- Ajibola, I.I.; Mansor, S.; Pradhan, B.; Shafri, H.Z.M. Fusion of UAV-based DEMs for vertical component accuracy improvement. Measurement 2019, 147, 106795. [Google Scholar] [CrossRef]

- Jidesh, P.; Febin, I.P. A Perceptually Inspired Variational Model for Enhancing and Restoring Remote Sensing Images. IEEE Geosci. Remote Sens. Lett. 2020, 18, 251–255. [Google Scholar] [CrossRef]

- Li, S.; Wang, H. Adaptive dodging method based on variational mask for remote sensing images. J. Remote Sens. 2018, 22, 450–457. [Google Scholar] [CrossRef]

- Wang, W. The Research on Dodging Technique of UAV Image. Master’s Thesis, Changsha University of Science & Technology, Changsha, China, 2017. (In Chinese). [Google Scholar]

- Li, W.; Sun, K.; Li, D.; Bai, T. Algorithm for automatic image dodging of unmanned aerial vehicle images using two-dimensional radiometric spatial attributes. J. Appl. Remote Sens. 2016, 10, 36023. [Google Scholar] [CrossRef]

- Zhang, Q. An improved Mask dodging method for areial images. Surv. Sci. 2015, 40, 122–124, 143. (In Chinese) [Google Scholar]

| Material | Design Indicators | |

|---|---|---|

| Rockfill material | Maximum size | 400 mm |

| Proportion <5 mm | 25%~41% | |

| Proportion <0.075 mm | ≤5% | |

| Non-uniformity coefficient | >10 | |

| Relative density | ≥72% | |

| Maximum density | 2.2 g/cm3 | |

| Minimum density | 1.9 g/cm3 | |

| Transitional material | Maximum size | 200 mm |

| Proportion <5 mm | 25%~39% | |

| Proportion <0.075 mm | ≤5% | |

| Non-uniformity coefficient | >15 | |

| Relative density | ≥75% | |

| Maximum density | 2.3 g/cm3 | |

| Minimum density | 2.0 g/cm3 | |

| Material | Zone | Passes | Velocity (km/h) | Thickness (m) | Material Volume (m3) | Density Test | Total Station Survey | Leveling Survey |

|---|---|---|---|---|---|---|---|---|

| Rockfill material | A | 8 | 2.5 ± 0.5 km/h | 0.8 | 160 | 2 | 1 | 1 |

| A | 10 | 0.8 | 2 | 1 | 1 | |||

| B | 10 | 1.0 | 200 | 2 | 1 | 1 | ||

| B | 12 | 1.0 | 2 | 1 | 1 | |||

| Transitional material | C | 6 | 0.6 | 100 | 2 | 1 | 1 | |

| D | 8 | 1.0 | 145 | 2 | 1 | 1 |

| Number | Dx (mm) | Dy (mm) | Dz (mm) |

|---|---|---|---|

| DEMA1 | 0.35 | 0.41 | 0.06 |

| DEMA2 | 0.27 | 0.30 | 0.04 |

| DEMA3 | 0.26 | 0.34 | 0.05 |

| DEMB1 | 0.26 | 0.34 | 0.05 |

| DEMB2 | 0.31 | 0.40 | 0.03 |

| DEMB3 | 0.23 | 0.25 | 0.03 |

| DEMC1 | 0.24 | 0.25 | 0.04 |

| DEMC2 | 0.22 | 0.23 | 0.03 |

| DEMD1 | 0.24 | 0.25 | 0.04 |

| DEMD2 | 0.22 | 0.23 | 0.03 |

| Material | Nephograms | /% | g/cm3 | g/cm3 | CRk/% | /% |

|---|---|---|---|---|---|---|

| Rockfill material | Zone A 8 times | 75 | 2.20 | 1.95 | 8.52 | 20.79 |

| Zone A 10 times | 42.56 | |||||

| Zone B 10 times | 20.98 | |||||

| Zone B 12 times | 28.67 | |||||

| Transitional material | Zone C 6 times | 75 | 2.30 | 2.00 | 9.78 | 45.53 |

| Zone D 8 times | 38.29 |

| CR/% | CRL | CR’ | CR | MAE (CR’) | MAE (CR) |

|---|---|---|---|---|---|

| Zone A 8 times | 6.58 | 7.20 | 6.77 | 0.76 | 0.80 |

| Zone A 10 times | 8.91 | 7.63 | 9.13 | 1.32 | 0.61 |

| Zone B 10 times | 6.57 | 5.98 | 7.00 | 0.59 | 0.58 |

| Zone B 12 times | 7.26 | 6.85 | 7.95 | 0.43 | 0.72 |

| Zone C 6 times | 8.53 | 7.60 | 9.51 | 0.96 | 0.99 |

| Zone D 8 times | 8.69 | 8.54 | 9.27 | 0.23 | 0.57 |

| MAE (CR’)/% | MAE (CR)/% | SD (CR’)/% | SD (CR)/% |

|---|---|---|---|

| 0.72 | 0.71 | 0.68 | 0.59 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Yin, H.; Tan, C.; Zhang, W.; Cao, C.; Xu, X.; Wang, J.; Chen, J. Rapid Compaction Monitoring and Quality Control of Embankment Dam Construction Based on UAV Photogrammetry Technology: A Case Study. Remote Sens. 2023, 15, 1083. https://doi.org/10.3390/rs15041083

Yin H, Tan C, Zhang W, Cao C, Xu X, Wang J, Chen J. Rapid Compaction Monitoring and Quality Control of Embankment Dam Construction Based on UAV Photogrammetry Technology: A Case Study. Remote Sensing. 2023; 15(4):1083. https://doi.org/10.3390/rs15041083

Chicago/Turabian StyleYin, Han, Chun Tan, Wen Zhang, Chen Cao, Xinchuan Xu, Jia Wang, and Junqi Chen. 2023. "Rapid Compaction Monitoring and Quality Control of Embankment Dam Construction Based on UAV Photogrammetry Technology: A Case Study" Remote Sensing 15, no. 4: 1083. https://doi.org/10.3390/rs15041083

APA StyleYin, H., Tan, C., Zhang, W., Cao, C., Xu, X., Wang, J., & Chen, J. (2023). Rapid Compaction Monitoring and Quality Control of Embankment Dam Construction Based on UAV Photogrammetry Technology: A Case Study. Remote Sensing, 15(4), 1083. https://doi.org/10.3390/rs15041083